Ajay Punnapadam: the serial entrepreneur, pg. 14

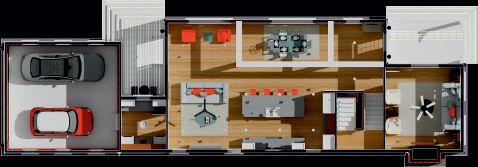

Creative Eye: My House/Build/Team, pg. 16

Leading Edge: the great housing reckoning, pg. 20

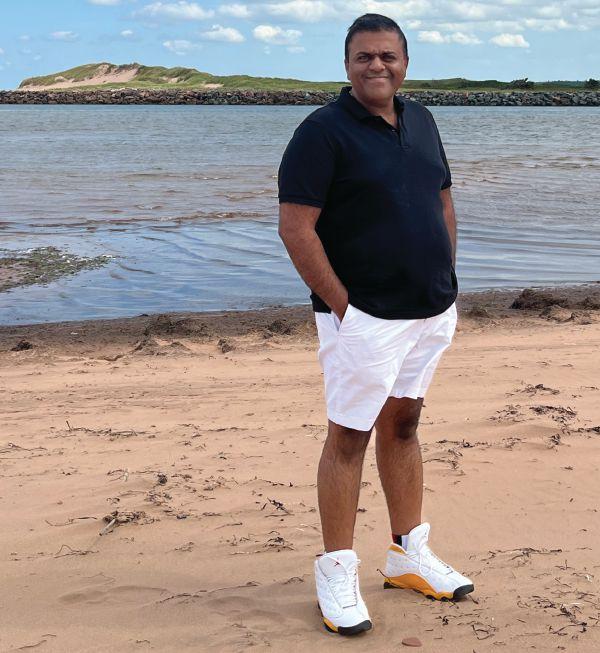

Ajay Punnapadam: the serial entrepreneur, pg. 14

Creative Eye: My House/Build/Team, pg. 16

Leading Edge: the great housing reckoning, pg. 20

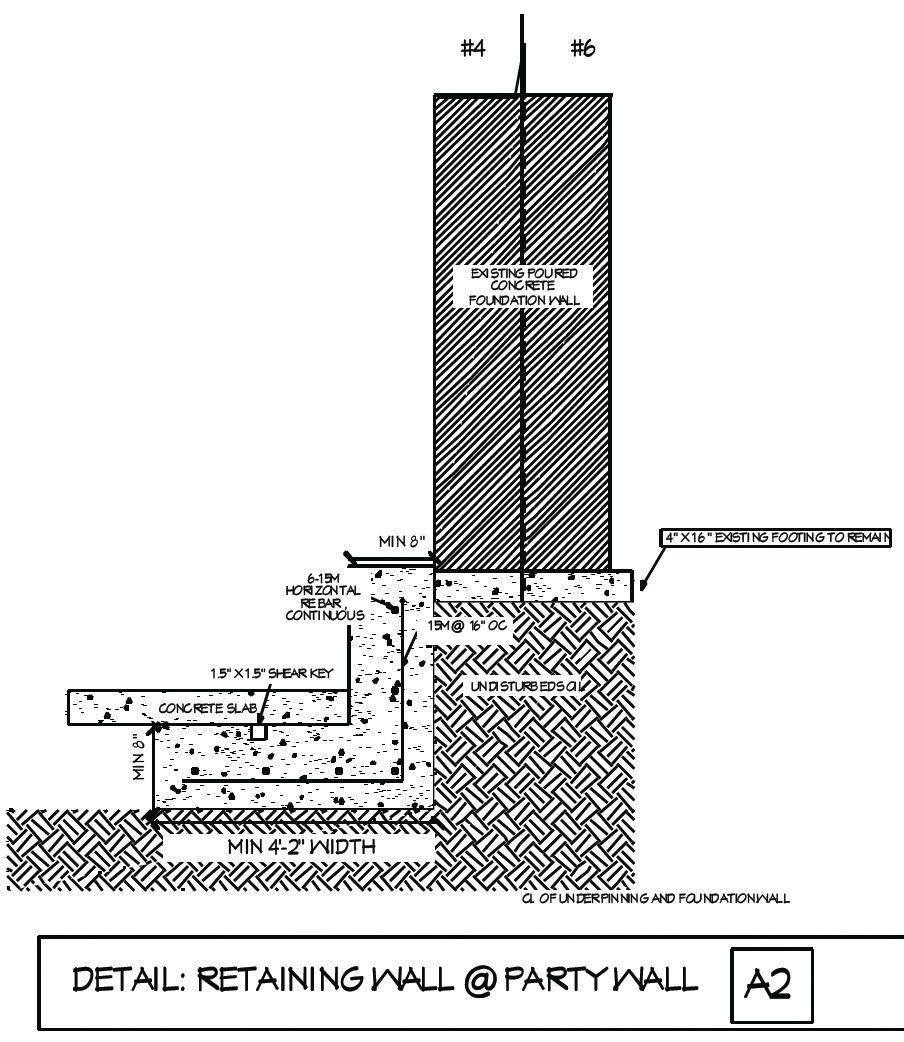

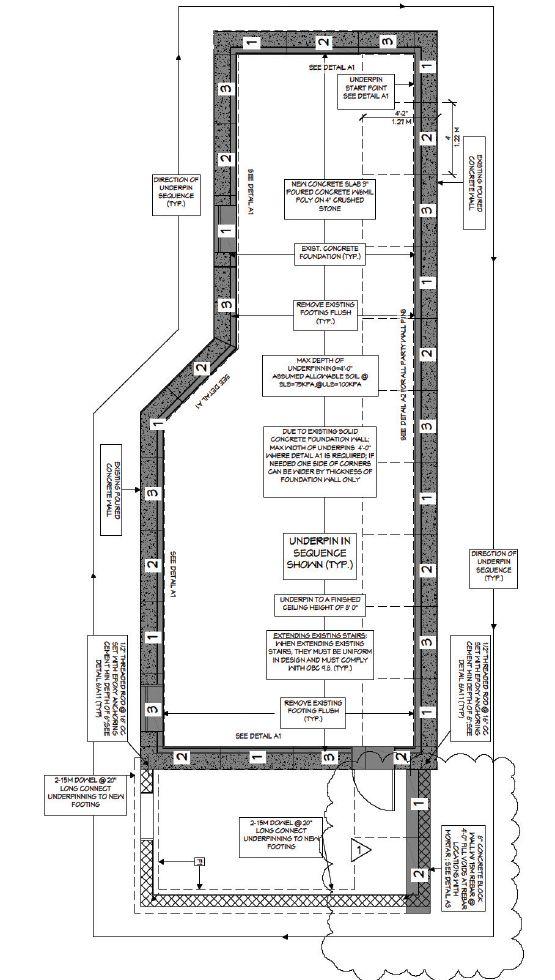

The deal with maintaining party walls and obtaining consent

Page 10

ENHANCED SECURITY

MULTIPLE OPERATING STYLES AND CUSTOMIZATION OPTIONS

DURABLE AND LOW-MAINTENANCE STEEL CONSTRUCTION

DUAL-PANE AND TRI-PANE LOW-E GLASS OPTIONS

Show your customers the benefits of upgrading their home with JELD-WEN ® of Canada’s steel French or garden patio doors.

Steel doors offer a classic and sophisticated look while providing increased safety and security with its strong outer shell, making it resistant to forced entry. The excellent insulation properties of steel allow for increased efficiency to help homeowners maintain a comfortable temperature in their home year round.

The durability and low maintenance of steel patio doors make them a long-term investment that can last many years without significant maintenance, repairs or replacements. Multiple customization options are available, including configuration, design and hardware options, to add a touch of elegance to any space.

Help homeowners increase overall value of their home with the combination of enhanced security, energy efficiency, durability and aesthetic appeal.

EXPERIENCE THE VIEW OF A LIFETIME WITH TOP-PERFORMING DOORS AT

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the digital edition archives at canadiancontractor.ca.

Bonny Kaobel of Access Rebates discusses Enbridge’s Home Energy Rebate program, energy audits, the Greener Home Loan program, and how knowledge about these funding programs can help contractors and homeowners alike.

Making sure windows and doors meet fire codes is critical for any builder. An expert team from Jeld-Wen shows us how in this sponsored video.

Oooo...pretty pictures. Follow canadiancontractor on Instagram for photos we don’t have room for in the magazine. Plus links to other stuff we like.

1498-8941 (Print)

or changes,

contact Angelita Potal Tel: (416) 510-5113 Fax: (416) 510-6875 Email: apotal@annexbusinessmedia.com Mail: 111 Gordon Baker Rd.,

Editor Kaitlin Secord ksecord@annexbusinessmedia.com

Brand Sales Manager

Matharu (226) 931-5095 nmatharu@annexbusinessmedia.com

Audience Development Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com

Media Designer Lisa Zambri

Group Publisher Danielle Labrie (226) 931-0375 dlabrie@annexbusinessmedia.com

President/COO Scott Jamieson sjamieson@annexbusinessmedia.com

TO OUR GENEROUS SPONSORS FOR THEIR SUPPORT OF

IN CONSTRUCTION THANK YOU TO THIS YEAR’S KEYNOTE SPEAKER, MODERATORS AND PANELISTS SPECIAL THANK YOU TO ALL OF YOU WHO ATTENDED. ALL SESSION RECORDINGS ARE NOW LIVE ON THE WOMEN IN CONSTRUCTION WEBSITE

Iam so honoured to bring you the June 2023 edition of Canadian Contractor as its new editor. Before we can begin this new chapter, I’d like to thank Patrick Flannery, Adam Freill and Mark Stephens for their help in navigating this new role and market. You can still find them as editors of Fenestration Review, Glass Canada, Canadian Rental Service, On-Site and Canadian Plastics respectively. Another thanks goes to Anthony Capkun, editor of Electrical Business Magazine, for his guidance and support throughout my first couple of months. This group of steadfast editors have reminded me just how important teamwork is!

Before we get into our June edition, I’d like to share a bit about myself. I stepped into this editorial role mid-March and have quickly learned the basic in-and-outs of the contractor world. Before taking on this new role, I was associate editor for Fire Fighting in Canada and Canadian Firefighter, two publications I hold near and dear to my heart. As I move up the editorial ladder, I can’t think of a more perfect fit for myself than an industry full of welcoming and interesting individuals. To everyone who has reached out to me over the past few months, your open arms and wealth of knowledge have been invaluable to my start in your industry.

Outside of my job as an editor, I have a keen interest in midcentury modern design, rollerskating and attending every concert I can get tickets to.

” To everyone who has reached out to me over the past few months, your open arms and wealth of knowledge have been invaluable to my start in your industry.

By Kaitlin Secord Editor ”

With my introduction out of the way, I’m excited to share with you this month’s edition of Canadian Contractor, which includes columns and features from a variety of industry experts.

Gordon Wornoff profiles CHBA award-winners, My House Design/ Build/Team, on their process of tackling net-zero renovations in Vancouver.

New contributor Christopher Smith of Woodsmith Construction Inc. touches on the process of dealing with party walls and gaining consent in our focus feature for this edition.

Casey Edge covers the great housing reckoning throughout the country and Steve Ryan asks, “what is the real housing shortage?” in the Ryan Report.

In this month’s profile, Jack Kazmierski spoke with Ajay Punnapadam, an entrepreneur turned P.E.I.-based contractor on his journey to building in Canada.

We’re also introducing a new segment, CON the move, which gives you an inside look at Canadian Contractor’s experience at events. In this edition, I had the opportunity to attend Building Knowledge Canada’s Spring Training in conjunction with CHBA’s net-zero summit.

As I begin this new journey with Canadian Contractor, I invite you to pitch me your ideas, send me your latest news and accomplishments, or connect with me just to have a conversation. You can reach me at ksecord@annexbusinessmedia.com.

I am looking forward to meeting more of you in the coming months at industry events, including our first-ever golf tournament happening on June 1.

Until next time, happy reading! cc

BuildForce Canada has launched their Construction Career Pathways, which aims to connect job seekers and employers across Canada’s construction sector. The program facilitates 16-week, paid, entry-level work placements on construction sites across the country. No prior industry experience is needed for workers, and employers can take advantage of financial incentives to help offset onboarding costs. The program was designed to provide opportunities to a wide diversity of workers, including women, members of

Black, Indigenous, and racialized communities, persons with disabilities, newcomers to Canada, and those who identify as LGBTQ2+; people from equity-deserving groups who want to work in construction; young people seeking work experience; and individuals looking for employment or looking to change careers. For employers, a wage subsidy of up to $2,400 per employee is available to businesses that complete their 16-week work placements, with funding provided by the Government of Canada. cc

Budget 2023, titled the Made-In-Canada Plan: Affordable Energy, Good Jobs, and a Growing Clean Economy, includes labour investments and apprenticeship opportunities for clean electricity and clean technology projects. The Clean Electricity Investment Tax Credit will ensure the wages paid are at the prevailing level and that apprenticeship training opportunities are being created in order to receive the full 15 per cent tax credit. The credit would be available as of the day of Budget 2024 for projects that did not begin construction before the day of Budget 2023. To ensure that Canada has the skilled workforce required to build Canada’s clean economy and double the number of new homes that will be built in Canada by 2030, Budget 2023 proposes to double the maximum employment deduction for tradespeople’s tool expenses from $500 to $1,000. Reducing barriers to interprovincial and territorial trade and improving labour mobility would create more opportunities for Canadian businesses to grow, make it easier for Canadians to get help from medical professionals, and bring down costs for Canadians through increased competition and consumer choice. Budget 2023 proposes to provide $197.7 million in 2024-25 to the Student Work Placement Program to continue creating quality work-integrated learning opportunities for students through partnerships between employers and postsecondary education institutions. cc

23_002275_CN_Contractor_JUN_CN Mod: April 14, 2023 11:48 AM Print: 04/28/23 3:30:45 PM page 1 v7

JLL released their 2023 Canada construction outlook. The report looks at how raw material price hikes, labour shortages and rising capital costs will impact construction momentum across the country. Key trends identified by the report in Canadian construction were as follows; demand for residential construction due to Canada’s housing shortage and increased immigration and labour shortage across many trades groups due to a spike in retirements.

Labour shortages are putting upward pressure on construction wages. Statistics Canada estimates job vacancies sit at 4.2 per cent across the economy, but 4.99 per cent across construction trades. This is well above the 10-year average of 4.1 per cent for construction. These unfilled positions peaked in early 2022. The report states that construction industry advocates predict a potential shortage of 100,000 trades people by 2029 if no interventions are made. The Canadian government has responded by promoting trades education with scholarships and specialized programs as well as investing in other means of gaining skilled tradespeople. As a result of the employment shortage, many builders are offering higher wages and other incentives to new-hires, “who are often less experienced.” This ultimately leads to slower construction at a higher cost. Full-time salaries are up 5.4 per cent from over a year ago, compared to the average increase of 4.9 per cent across all goods-producing industries and four per cent across serviceproviding industries.

Despite these high-than-normal wage increases, “the 6.8 per cent annual increase in inflation was higher than wage growth.” cc

By Jessica Nelson, Local Journalism Initiative Reporter

Net-zero can’t be achieved unless carbon dioxide removal technologies are used, according to a report released last week.

On April 13, the Pembina Institute released a report on the need for Canada to use carbon dioxide removal (CDR) along with emission reduction to hit netzero target by 2050.

Carbon Upcycling, a company from Calgary, is exploring the CDR potential in concrete by using waste material to reduce the amount of cement in concrete and combining it with flue gas CO2 to make the end product more durable. But what is CDR and why is it needed?

The Pembina Institute report said CDR can be an “indirect solution for hard-to-reduce emissions,” and “can extract some of the legacy carbon that humanity has released into the

atmosphere over the last few centuries.”

According to the report CDR is a method to extract CO2 from the atmosphere and store it so “it does not re-enter the atmosphere.” The process must remove more C02 than it emits, and it is an additional measure to “anything that is already happening.”

There are two types of CDR engineered and biological. Biological CDR solutions include afforestation, reforestation, soil sequestration.

Engineered non-biological CDR solutions are newer technologies that, according to the report, could play a larger role in the future, “but need additional attention getting there.”

These newer technologies include direct air capture, ocean alkalinity enhancements, carbon mineralization,

geological storage, and carbon use “which takes carbon dioxide and turns it into products” which includes concrete.

According to the Government of Canada, concrete is the most used building material on the planet. In Canada, cement accounts for 1.5 per cent of CO2 emissions while globally cement accounts for seven per cent of C02 emissions. In February, the government of Alberta announced $58 million for circular economy projects through Emissions Reduction Alberta (ERA). Carbon Upcycling received $4.4 million for a project that will “support the first commercial-scale deployment of two carbon capture and cementitious material production facilities in the Albertan construction sector.” cc

Dealers share and participate equally without the influence of any external shareholders. Harness our massive buying power, comprehensive distribution, national brand recognition and marketing support.

deal with maintaining party walls and obtaining consent

By Christopher Smith

With the growing density requirements of today’s home construction, attached and semidetached homes are becoming a significant part of the market. Toronto already has a large stockpile of these homes, but surprisingly we don’t have the proper framework to renovate them.

I have worked on many semidetached homes over the years, and it baffles me why we don’t have some sort of policy to deal with party-wall construction. Our current system relies upon consent in the form of a party wall agreement from the adjoining neighbours to do any permitted work on the party wall itself.

A party-wall agreement is a document intended to stipulate terms of construction and remediation if any damages occur. The problem is that

now it is being weaponized to hold up construction or stop projects altogether, as there is no legal recourse if the adjoining neighbours refuses to sign one.

The result is a huge mess, as one would expect because when playing by the rules can be thwarted by the simple refusal to sign, there’s a problem. We, as contractors, need better policies that help secure the development of these types of properties without relying on the consent of the neighbouring parties. We need a new framework similar to the ones used in other countries like the UK, where conjoined housing is also popular. Prioritizing the maintenance of party-walls in any new developments while also protecting the rights of both sides would aid in future development of party wall homes.

To give a bit of background on where all of this is coming from, I would be remiss if I didn’t share my own story. I work a lot in the east end of Toronto, which is a place with a tremendous number of semidetached homes.

Until COVID, I had never experienced anything like this as all of my projects that dealt with party-walls always had party wall agreements and, in most cases, it was the neighbouring property that insisted upon it.

Today it seems to be a different world, however, in that there is a level of hostility towards the development of any home, especially semidetached ones, that I have never seen before.

Whatever the root causes, the result is a level of irrational behaviour that is baffling to me to say the least. The two projects I have been involved with both wanted third floors to expand their homes to fit their growing family. In both cases, the adjoining neighbours

was completely opposed.

So, we went to C of A with an opposition for what would be considered a small addition in any other situation. We won in both cases, which would have been the end of things in the past, but not so much today. When it came time to sign a party wall agreement, we learned the horrible truth, you have no legal recourse to compel adjoining neighbours to consent to fully permitted work on the shared party wall. This seemed crazy, but it was confirmed repeatedly after my discussions with various lawyers.

This meant that the disapproval of neighbours forced the issue in a direction that benefits neither party. In these instances, it meant revising the proposal to build the third-floor additions at the property line, which is often done in cases where an impasse on party walls can’t be overcome.

The problem with it, though, is that it has huge implications down the line for

Building in Canada has its own challenges. What you need for downtown is different from what you need out-of-town. It’s why our equipment is cold weather tested. It’s also why we offer compact sizes for flexibility, versatile attachments for multitasking, and comfort for long days on the job. Best of all, with a range of financing and extended warranty options, you can get started and keep working from dawn until deadline.

both sides especially when it comes to a third-floor structure. This would be completely unnecessary if with just had some sort of laws in place to make sure party-walls stay party walls and work on them doesn’t require the consent of anyone other than the city itself, just like any other permitted work.

Limitations of building to the property line

So, what’s the big deal with maintaining party-walls or obtaining consent when you can simply build to the property line?

At first glance, it appears to be a practical alternative to bypassing the complexities of party-wall disputes. However, the issue with this approach is that it only works effectively once and can create significant challenges in the long run for both property owners.

Building to the property line may initially seem like a

viable solution for one side, but it becomes problematic when the neighbouring property owner also wants to build to the property line. This approach leads to a host of limitations and constraints on future development possibilities for both properties. When both parties attempt to build up to the property line, they inadvertently create a new party-wall, albeit one that exists only in theory.

This theoretical party-wall cannot function as a traditional party-wall because each structure relies on its own foundations, resulting in a lack of structural interdependence. Furthermore, building to the property line can lead to potential issues with building codes and zoning regulations, as well as increased costs associated with constructing separate walls and additional insulation for sound and thermal protection.

The separate walls might also result in a less visually appealing streetscape due to the lack of uniformity and continuity. Additionally, the lack of a shared party-wall can hinder future maintenance, repair, and renovation efforts for both property owners. Without a shared wall, it becomes more challenging to access and address any structural or cosmetic issues that may arise over time. This can result in increased costs and complications for both parties, ultimately defeating the purpose of building to the property line in the first place.

While building to the property line might seem like a practical alternative to dealing with party-wall disputes, it is a shortsighted practice that can lead to numerous challenges and limitations for both neighbouring property owners in the long run. Instead of resorting to this approach, adopting a comprehensive legal framework for managing party-wall disputes would be a more effective and sustainable solution for all parties involved.

Several countries have implemented legal frameworks to address party-wall disputes. For instance, in the UK, the Party Wall Act 1996 provides a clear legal framework for resolving disputes between neighbours over party-walls, boundary walls, and excavations near neighbouring buildings.

The Act establishes a process that enables both parties to agree on the work to be carried out or appoint a surveyor to resolve disputes. This approach helps to maintain partywalls and protect the rights of both parties without requiring explicit consent.

In other countries like France, Spain, and Germany, legal frameworks or civil codes deal with shared walls, property boundaries, and construction, offering mechanisms for resolving disputes without relying on one party’s consent. These frameworks typically involve negotiation, mediation, or arbitration before resorting to litigation. Such mechanisms can be less time-consuming, less expensive, and less adversarial than going to court, which is currently not an option.

Toronto and Canada, more broadly, could benefit from adopting a similar legal framework to manage party-

wall disputes. This would involve creating legislation or regulations specifically addressing these disputes and providing clear guidelines for resolving such conflicts. A well-designed legal framework would balance the rights and interests of both parties and establish a fair process for resolving disputes without relying solely on the consent of one party. By looking at what has worked as successful

legal frameworks in other countries, Canada could develop a more effective and efficient system for managing party wall disputes, thus ensuring that future development of party-wall homes can proceed based on the merits of approval by the governing bodies in charge of giving such approval.

Ultimately, addressing the issue of party-wall disputes in Toronto would help to fostering a constructive environment for development and ensuring that the city continues to grow and thrive. cc

Christopher Smith is the owner and founder of Woodsmith Construction Inc, a design and build renovation company that has specialized in working with older homes in the east end of Toronto since 2001. His passion for everything to do with older homes was rooted in his early childhood experiences working on Victorian homes in Cabbagetown with his architect/builder father. He is a Red Seal Carpenter and a BCIN registered designer. Woodsmith Construction has completed a wide range of projects, including full-home renovations, additions, and restorations.

P.E.I. contractor, Ajay Punnapadam, is committed to quality, and to making a difference.

By Jack Kazmierski

For as long as he can remember, Ajay Punnapadam has been an entrepreneur. Even as a young boy, living in India, he was always coming up with innovative ways to make money.

“When I was eight years old, my uncle ran a store that rented out VHS video cassettes,” Punnapadam recalls. “The cassettes were imported from Singapore, and they came with stickers that nobody wanted. Each sticker was an individual letter of the alphabet or a number between zero and nine. When my uncle threw them in the garbage, I would pick them out and sell them to my classmates. That’s how I made my very first few rupees.”

Bigger & better opportunities

His entrepreneurial spirit never died, and Punnapadam continued to seek out bigger and better opportunities. “I went from selling stickers to selling shoes,” he recalls. “Then I moved into selling motorbikes, then cars, and eventually I started in construction.”

A serial entrepreneur, Punnapadam started and ran a number of successful companies along the way. “Soon after completing my Bachelor of Commerce degree, I started my first venture, which was called Painting Solutions,” he recalls. “The pride of ownership of this company is still fresh in my mind. Our business grew, and we soon became one of southern India’s largest paint applicators.”

Punnapadam was only 20 years old when he started his painting company. Not only was he painting houses, but he grew his business to the point where he eventually took on contracts to paint factories and other large facilities, including universities.

Creator India, another one of his ventures, took advantage of the construction and real estate boom in India and focused on high-value real estate.

He also owned Creator Homes, which was a company that developed and leased properties. Finally, Global Telecom Solutions was started by Punnapadam in order to bring down the cost of international phone calls. “This was one of the first VOIP calling companies at the time,” he adds.

Punnapadam credits his work ethic as a painter for eventually getting him into the construction business. “I was, and still am, a really hard worker,” he says. “I would be on the job site at 5:30 and I would work through to 11 or 12 at night. We used to work out of a small office, and the landlord of this building was very impressed with our commitment and attention to detail, as well as our honesty and our integrity. He came up with a proposal to build an extension to his existing building.”

With limited construction experience, Punnapadam did not want to take on the project, but his landlord insisted. “He gave me an architect and a structural engineer to assist me in the venture,” he adds. “This was our first construction project and we made history by completing the project way ahead of schedule.”

In June 2019 he, his wife and their three children moved to Canada. They settled in Stratford, Prince Edward Island, and a month later Punnapadam set up his current business, Confederation Construction And Interiors (CCI) Inc.

CCI now has a dynamic team of sub-trades, suppliers, engineers and architects. “Our maiden project was two sixunit builds that were successfully completed and handed over in record time in P.E.I.,” he says. “In 2022, our company showcased our prowess in the custom home segment by building two stunning humongous homes in Stratford, P.E.I.

“We are extremely proud to have created 14 dwelling units between 2020 and 2022 that people in P.E.I. very proudly call their homes. It gives us immense pride to be a part of the solution to a huge housing crisis. We have exceeded our initial projection by 233 per cent.”

Punnapadam says that everything he builds is above code,

It’s this attention to detail that defines the way Punnapadam does business. “I believe that small things make perfection, but perfection is not a small thing,” he explains. “Every small thing adds to the cost of the building, but I can guarantee that the home buyer will be more than satisfied with what they get from us. Our products are built to last, to be environmentally-friendly and pocket-friendly, as far as energy costs are concerned.”

Despite his success in Canada, Punnapadam had to overcome a number of challenges in order to get things off the ground. The first hurdle was the collapse of a deal to build multiple units, which initially looked promising after he arrived in P.E.I., but then eventually fell through.

Next, Punnapadam had to wrap his mind around how things are done here in Canada. “In India,” he explains, “as soon as I got a piece of land, I would decide what I was going to build there. After everything was done, I would go to get the paperwork done, and there was never a problem.”

In Canada, on the other hand, Punnapadam discovered that he couldn’t simply buy land and build whatever his heart desired, only to get approvals later. “I realized that it’s a whole new ballgame over here,” he says. “You’ve got land re-zoning, you need a building permit, a development permit, the water, the pollution control, and more.”

Paperwork wasn’t his only challenge. After getting his permits for his first project in Canada, COVID struck. Despite the pandemic, however, Punnapadam managed to line up the sub-trades he needed, only to find himself struggling with the inflated prices of lumber and other building supplies. Nonetheless, he and his team persevered, and he says they completed the project to accolades from customers.

He also had to wrap his mind around how homes are built here in Canada. Since India is so hot, he says, they do things a bit differently. Home insulation, for example, is something Punnapadam discovered only after coming to Canada. Another novelty was a hot water tank. “If you live in the southern part of India, you don’t need a water heater because we’re used to temperatures over 40 degrees.”

Today, Punnapadam continues to build homes in P.E.I., and says that he has no desire to move anywhere else… at least not for now. In fact, it could be said that he and his family have fallen in love with P.E.I.

“We’re very happy with the very limited amount of traffic that we

Punnapadam is looking beyond the obvious as he seeks solutions to today’s housing needs. Punnapadam says that everything he builds is above code.

have here,” he says. “There’s no pollution, there’s no garbage, and we have everything that we really want. We’re enjoying this quieter kind of lifestyle, rather than the hustle and bustle of the city.”

Although his business is doing well, and Punnapadam has a growing number of happy customers, he’s planning to expand his company into other areas, including energyefficient homes and net-zero construction.

Punnapadam’s commitment to P.E.I. is only surpassed by his commitment to quality craftsmanship and customer satisfaction. “We primarily focus on new residential construction, which is a mix of single-family homes, duplexes, and multiplexes,” he explains. “In a very short period of time in Canada, we have built a reputation for being reliable, trustworthy and dependable.”

His vision is to continue to develop projects, “that are architecturally distinguished, with a focus on attention-todetail, and delivered with the highest commercial quality. We strive to create architectural marvels every single time, and to better ourselves with what we do best.”

This commitment to quality is part of Punnapadam’s DNA, and it defines what he views as his company’s business mission. “We strive to create great products that are of great value aesthetically and functionally to the home/property owner,” he says. “Our passion has, is, and will be to be ecofriendly and to build homes that are of the highest standards. In fact, we ensure that every square inch is inspected before handover. All of this is met through our core values of integrity, honesty, and commitment to what we are best known for: construction.”

Keenly aware of the growing need for affordable housing, Punnapadam continues to innovate as he envisions the future of the province he and his family now call home.

Just like that eight-year-old who managed to turn his uncle’s waste into profit, Punnapadam is looking beyond the obvious as he seeks solutions to today’s housing needs. “CCI has adopted creativity as its culture,” he concludes. “We are currently exploring the possibilities of creating new subdivisions to accommodate the ever-increasing need for housing on the island. I look forward to being a part of the solution.” cc

By Gordon Wornoff

According to the Canadian Home Builder’s Association, the country’s most impressive net zero home is a renovated 1967 bungalow in the Oakridge area of Vancouver. My House Design/Build/Team was nominated for seven awards at the CHBA’s annual spring National Awards for Housing Excellence, and they walked away with “Best Single Room Renovation” for a project in Surrey, as well as “Best Custom or Renovated Net Zero Home” for their finespun net zero “Modern Cottage.”

The company founder, Graeme Huguet, says it’s the first net zero renovation in all Greater Vancouver and it’s certified Platinum by “Built Green,” a third-party certification body that

considers energy consumption, occupant health, and conservation of building resources.

What are some key details of this project? How did it come about?

This bungalow was owned by a senior couple in the area looking to create a living-in-place environment that would be their last major residence. They wanted a healthy, family-friendly home for their kids and grandchildren. They also wanted it to be high-performance, in terms of both energy efficiency and operating costs. They wanted to pursue the idea of net zero with renewable energy as well, so we used solar.

Tell us more about getting to net zero.

If we’re talking about west coast building, we’re talking about the BC Energy Step Code. It’s basically mandated by the province that by the year 2032 all new construction will need to meet net zero ready or Passive Certification. Many of the municipalities already have the step process in place for high-efficiency, energy efficient certifications on homes. Net zero and passive certifications have always been a priority to us as a company and they’re becoming a higher priority across the entire province.

Municipalities like Vancouver City are using this opportunity in the Step Code to put forward their agenda, which is to make sure that projects are high performance. Vancouver is dictating carbon neutral projects – so no gas appliances or furnaces – only electrical.

“Modern Cottage” falls in that category – it’s in Vancouver and we rebuilt this existing home to these new construction standards. High performance has been the standard of our construction for the last 20 years. I’ve been building this way for 30 years.

What were the challenges of getting modern high-performance standards out of a 60-year-old house?

To someone who does high performance building on a regular basis, it doesn’t

matter if it’s a renovation or a new home for us. We build and rebuild so many homes to these high-performance standards and have numerous awards from national, provincial, and local levels for best high-performance. It just means you must take a holistic approach to any renovation. You can’t take an existing house and make it a highperformance house. You must holistically rebuild the house.

The first thing on any project or renovation or new home is you need a good energy advisor.

In this case, there were no additions to the home. So, we gutted it back to the studs to get our air barrier and vapor barrier and proper insulation and built out from there. The homeowner realized is this house didn’t end up in the landfill. This house was taken apart and then rebuilt in a high-efficiency manner.

What were some key pieces of technology in this project?

Building in a high-performance way means you are very deliberate with everything outside the building envelope. It’s all the things you don’t see, like what’s in the wall, how the wall is assembled. There are many different methods, many different types of insulation, whether it’s batt, it’s rigid, spray, interior, exterior, and so on. The building assembly is what allows you to accomplish what you’re looking for. That’s number one. The mechanical system is also very important. However, there are no regulations really, or building inspection on mechanical systems themselves.

We use a third-party mechanical engineering firm for design and quality control because it’s not just about how the gas or electricity was hooked up. It’s about duct sizing, it’s about the balancing of air. In this case, the homeowner has asthma, so air quality was the most important thing. Whether it was heated or cooled air, they wanted to make sure the filtration was maximized. We put in an electronic air filter, as well as ultraviolet – which does not just filter the air – it purifies the air because it kills off bacteria and mold to 0.3

microns which is smaller than pollen. So, if the windows and doors are closed, it provides an atmosphere equal to or better than most hospitals.

Once we finished insulating, we use Aerobarrier to air seal the house. It combines pressurizing the house and releasing aerosols that fill in any gaps in the building envelope. This allows us to get down to less than one air exchange per hour, creating an extremely tight envelope.

Does focusing on your client’s long-term health -- in this case treating asthma -- does it give you an advantage over other builders?

Absolutely. I think what it draws attention to the most is that we’re designers. We’re a design and build firm. Most designers don’t talk about these issues in the design phase and that’s exactly where it needs to be talked about. It’s too late once you’ve got a finished set of plans and a permit to talk about these types of goals.

Most designers and architects are mainly focused on what the client asks for rather than educating and communicating what options and better building practices are available to the client. Most builders are looking for speed and cost savings. We also look to be on time and on budget. But there’s a difference between speed and building towards a cost rather than an end result.

The downfall of a good build is when builders cut corners in areas that are unseen. It’s behind the drywall and the homeowner doesn’t know the difference because they haven’t been educated on what those differences are.

We do weekly webinars on different subjects for our clients. We cover healthy and energy-efficient homes. When I got involved in the construction industry, I made building science the foundation of my understanding, and it should be for anyone understanding what highperformance building even means.

How big is your company? How many projects a year do you complete?

We do 25 to 50 projects a year. My wife

and I are often asked what we do for a living, and we say we provide 50 families full time employment. We have full-time staff; we have full-time trades. We also supply two to 300 other part-time jobs to people in our community through sub trades, local manufacturers, and suppliers. That’s no exaggeration. We have longstanding partnerships with local companies that align with our values.

Our team is the biggest thing we have going for us. We’ve got 15 people

that have been together for more than 20 years. We’ve got another 15 that have been here for 10. Having good people is one thing, but having good people for a long period of time is essential to build and adapt processes that are 100 per cent consistent. Each team member, no matter what project, can deliver a consistent product to our clients whether that’s a small, medium, large renovation — or a whole house.

Our niche is high quality renovations and custom homes. In our marketplace — in Greater Vancouver — I don’t like using the term high-end or luxury, or anything like that because that’s really based on loose visual perceptions. Imagine someone walks into a home and says, “oh this is really high end,” and they have no idea how the house was built, how energy efficient it is, what the actual quality is. So, I say high-quality, healthy homes.

Where is your company headed?

We have several other projects that stem from My House Design/Build/Team. One is a dedicated design-only company that’s just a design studio. We’re also producing our own millwork, so we have a dedicated kitchen and bath subsidiary. We are looking forward to doing more high-performance building – not just in single family residential but in smaller commercial projects and other specialty projects.

But it’s not my name on the company. This is all possible because of a great team. That’s why the company is called My House Design/Build/Team. That is the actual incorporated name and I put it that way because I’ve always found that there was no one person that made any project happen – it was a team effort. And that includes everyone on the build and behind the scenes. cc

Introducing Rust-Oleum®’s latest innovation, Tremclad Rust Paint featuring the patented Turbo Spray System™ - the perfect solution for contractors who need to tackle big projects quickly and efficiently. RustOleum® has been a trusted brand for small project paints, woodcare, automotive, and high-performance coatings since 1921, and the Tremclad Rust Paint with the Turbo Spray System™ is no exception.

The innovative Turbo Spray System™ offers 3X more paint per second than traditional spray paints, making large projects a breeze. The super tall fan tip coats surfaces faster and provides pro spray equipment results with no messy clean up required. Plus, the mega-sized 680g of paint is perfect for covering big surfaces, such as tables and chairs, entry and garage doors, fences, sheds, and more!

Tremclad Turbo Rust Paint is ideal for contractors who need a durable, long-lasting paint that can withstand harsh weather conditions. Whether you’re working on a residential or commercial project, this product is perfect for restoring and beautifying all of your projects.

Tremclad Rust Paint has been the go-to product for rust protection and prevention for over 60 years, and now with the Turbo Spray System™,

it’s easier and faster to apply than ever before.

Contractors can rest easy knowing that they are using a product that is tried and true. Its advanced formula provides superior adhesion, durability, and corrosion resistance, making it the perfect choice for projects.

In addition to its durability, Tremclad Turbo is also incredibly easy to use. The Turbo Spray System™ ensures that the paint goes on smoothly and evenly, leaving no drips or runs. The large size of the canister also means that you can cover more surface area with fewer passes, saving you time and effort.

At Rust-Oleum®, we are committed to providing our customers with the best products on the market. That’s why we’ve paired our trusted Tremclad Rust Paint with the Turbo Spray System™. This innovative product is ideal for contractors who need to get the job done quickly and efficiently without sacrificing quality.

So, whether you’re restoring an old metal fence, repainting a garage door, or tackling any other large project, the Tremclad Turbo Rust Paint is the perfect solution. Try it today and experience the Rust-Oleum® difference for yourself!

Link: https://www.rustoleum.ca/productcatalog/consumer-brands/tremclad/rustpaint/tremclad-turbo

By Casey Edge

Foryears, builders have been very vocal about Canada’s lack of housing supply causing high prices.

Several years ago, pre-pandemic, I wrote an article in Canadian Contractor called, “Recipe for a Housing Crisis? Just Add Government”. I wrote: “governments can’t choke housing with taxes, regulations, greenbelts, and abominably slow processes without creating housing shortages and sending prices spiraling upwards. Add huge numbers of millennials and downsizing boomers, and you have a recipe for a housing crisis. Just add government.”

In another article called, “Fast-Growing Canada Needs Housing; Public Policy Needs To Keep Pace,” I continued with “to understand rising home prices, it’s important to appreciate that Canada is undergoing some of the fastest population growth in our history, due largely to permanent and temporary immigration (Statistics Canada). This growth is also part of the reason for our strong economy –people bringing their skills and expertise to the country. In welcoming these new Canadians, we have an obligation to ensure there is sufficient housing. A big part of the issue is local municipalities out of sync with national policies. Canada is growing significantly yet many municipalities’ zoning policies don’t recognize this.”

At the time, governments at all levels continued to be in denial about short supply. They claimed it was purely a demand issue to be solved by more taxes on housing like foreign buyers tax, speculation tax, land (school) tax. Even major national media bought into the solution of

more taxes, some advocating a tax on principal homes.

Of course, housing prices continued rising and it became clear taxes were not the solution. The emperor (government) had no clothes. Average home prices topped over one million dollars in B.C. and Ontario. Thus began the great housing reckoning. Government lost credibility and a fed-up public demanded more supply.

Senior levels of government had to shift to what builders have been saying for years – housing supply must increase. This government shift to advocating supply was most noticeable by politicians during the federal election in 2021. However, housing approvals are the domain of municipalities, presenting an embarrassing conundrum.

The federal government has no direct authority over municipalities. Provincial governments, such as B.C., have spent decades proudly supporting municipal councils’ right to self-determination, including zoning.

Many municipal councils obstruct rezonings due to the influence of small community associations. Studies show this obstruction results in astronomically high prices.

A C.D. Howe Institute study revealed zoning regulations, development charges, etc. added $168,000 to the price of single-family homes in Greater Toronto, and $644,000 to prices in Vancouver. Prices in Victoria increased by $264,000, Calgary was up $152,000, and Ottawa-Gatineau by $112,000.

It’s not just a Canadian phenomenon. An Australian report says, “Zoning regulations provide benefits, but they also restrict housing supply and hence raise prices.” Zoning

regulations raised prices by 73 per cent in Sydney, 69 per cent in Melbourne and 42 per cent in Brisbane.

Add B.C.’s costly Property Transfer Tax and myriad of municipal fees, and it only gets worse for new homebuyers.

Ottawa is equally embarrassed by the great housing reckoning. Deputy Prime Minister Chrystia Freeland recently said, “one of the things that I am most concerned about as someone who — it shocks me to say this — is 53 years old, is the intergenerational injustice. We had a better shot at buying a home and starting a family than young people today, and we cannot have a Canada where the rising generation is shut out of the dream of home ownership.”

Freeland had “a better shot at buying a home” thirty years ago because three levels of government, including her own, had yet to discover homebuyers’ mortgages as a big source of revenue.

GST was launched in 1991 and today adds about $50,000 to the cost of an average new home in B.C. Freeland could help reduce this cost but has declined to index the GST New Home Rebate to inflation and today’s prices, as promised when it was introduced.

Freeland and other governments collect billions of dollars from housing, driving up prices, and now scramble in search of supply.

Now to expedite rezonings, Ontario and B.C. are announcing measures to override municipal authority, when necessary. Of course, obstructive councils will focus on the least they can do to both appease their NIMBY’s and avoid being in the provinces’ crosshairs.

Ottawa, as usual, promises thousands of new homes without identifying any practical way to achieve it. They continue to have an eye on taxing the sale of homeowners’ principal residences if the opportunity arises. That’s why the property declaration is in Canadians’ tax forms.

At the end of the day, builders can take some satisfaction in being right about supply, proving again that people building and selling homes are better at housing policy than politicians and academics.

As usual, many politicians have jumped to the front of the parade and now act as if the supply solution was their idea all along.

Which is what emperors with no clothes are wont to do.

Next will be a Royal Commission into the high cost of housing. cc

Casey Edge is executive director of the Victoria Residential Builders Association.

Now part of Tremco Construction Products Group (CPG), Nudura® ICFs gives you the most user friendly system on the market with a single point of contact for a leak-free wall assembly. One source for ICF forms, bracing, waterproofing, sealants, flashings and window/door bucks. Allowing you to achieve a full ICF wall system, backed by the best warranty in the industry. Plus, with Nudura you get fast, local technical support that can assist and advise you on the job site, while also providing the largest Authorized Distributor network in North America.

One Wall. One Solution.

Let me begin this column with a disclaimer. This is not an attempt to make a statement or imply authoritative opinion. It is an admission that I am puzzled and would like to know the answer.

So, let’s get to the question: Why is there a housing shortage in Canada when the rate of home completions over the past 10 years is roughly in balance with the rate of new household formations? Canada’s principal keeper of housing statistics, the Canada Mortgage and Housing Corporation (CMHC) tells us that from 2013 to 2021 the number of households in the country grew by 1.7 million. On the face of it, CMHC suggests that this is a reasonable indicator of the need for new housing. The same source tells us slightly more homes were completed in that time 1.75 million. Not my idea of a wild surplus, but nor is it my definition of desperate undersupply.

Please note that this not the same as saying the rate of home completions is keeping up with demand. Clearly there is a housing shortage in this country. But based on the raw numbers and if we could magically assign each newly completed home to someone who needs to live in it, then enough homes have been built in Canada to provide for those who need a place to live.

Obviously, that is a naive statement. Not all homes are principal residences. Not all new homes are occupied. Some of the existing housing stock gets torn down or re-purposed. So yes, the measure of new household formations will understate the precise number of new residences the market is calling for. Should we work harder to quantify the impact of these other factors though? Because public policy seems to be driven by a mindset that all segments of the housing market respond to one single metric and that is supply. This seems to lead to a strategy that the only possible path forward is a vast upswing in that supply.

Now, of course, supply is critical, but if we don’t temper that policy response with a better understanding of demand, then we might be chasing our tails. CMHC says that we must build 5.8 million new homes in Canada between 2022 and 2030. Yet in the Housing Observer’s “Canada’s Housing Supply Shortage: Restoring affordability by 2030 report”, they

forecast the number of new household formations in that time to be 2.3 million. Do we really need an excess of 3.5 million homes to catch up our current deficit?

So, the question remains: What’s going on? Because we might be better served by fixing some of the distortions than by blindly throwing up more buildings. It seems that CMHC sees something other than the growth in number of households driving demand for new homes. It would be wise for all of us to understand what those other drivers are.

There is nothing vague or discretionary about the need for a place to live. Affordability changes but the underlying need for homes does not. We can reliably understand that much of future demand. However, those other factors that seem to drive the market respond to conditions that can be much more variable and demand from those directions can change abruptly.

If CMHC’s guidance is affected so significantly by something beyond the number of households then they should be more forthcoming about how fickle those other sources of demand might be. Public policy that promotes new home construction at twice the rate of growth of the core market may be provoking builders to simply bludgeon the problem away.

Let’s hope that public policy makes it easier for builders to get things done, but I suggest caution in substituting that policy for your own market research. In 1982, a four-plane formation from the US Airforce demonstration team all flew into the ground performing one of their aerobatics. Tragically all four pilots died. For a split second, that lead pilot may have known what was about to happen but the other three had just been following their training and stuck with the leader. As an industry we have all been flying in formation for a long time. You can’t ignore the advice of experts, but don’t lose your ability to lift your head and check the horizon from time to time. cc

Steve Ryan is the founder of MMI Professional Services. MMI is committed to the success of contractors by helping them develop the business and management skills they need. For information on way to run a better building business, contact the writer at steveryan@mmiproservices.com

The three-day advance building science and practical application event was a tactical and educational experience for attendees.

Building Knowledge Canada held their annual Spring Training from April 16 to 19 in Stratford, Ont. This year’s camp saw CHBA join in, putting on their Net Zero Summit.

This year’s camp saw a number of speakers touch on topics like understanding and expanding net zero, exergy, air source heat pumps, climate resiliency, understanding carbon emissions and more.

Day one kicked off with a welcome message from Building Knowledge Canada’s Gord Cooke and Andy Oding, CHBA’s Sonja Winkelmann and Tex McLeod of The McLeod Associates. The group explained the purpose behind this year’s joint event was to collaborate to tackle the ultimate building science challenges – resiliency, carbon, energy, affordability, and health.

The first session of the day was on exergy, by Robert Bean, ASHRAE Fellow. Bean touched on the difference between energy efficiency and exergy efficiency, acknowledging that conservation is flawed when it comes to exergy.

Next up, John Siegenthaler of Appropriate Designs spoke to attendees about air-to-water heat pumps, noting that trends support an emerging market for these pumps.

Attendees heard from Brad Carr, CEO of Mattamy Homes Canada next, about the road to high performance homes and the lessons Mattamy has learned along the way.

Through lunch, Doug Tarry of Doug Tarry Homes took the stage to talk about his book, From Bleeding Edge to Leading Edge

Bringing us back to heat pumps, Gary Proskiw of Proskiw Engineering Ltd., Dr. Nima Alibabaei of BKR Energy Company and Maxime Savard from NRCan took part in a panel presentation on testing and in-field performance of air-source heat pumps. Proskiw touched on the results of these pumps as observed using HOT2000. Trevor Trainor, president of Bawating Building Science’s presentation followed, touching on deep energy retrofitting of old or historic masonry. Trainor noted that new construction accounts for 40 per cent of embodied carbon in carbon emissions, and that revamping and making these older homes more comfortable reduces this carbon footprint.

Gord Cooke & Nigel Watts of RHEIA wrapped up day one with a conversation on advance air distribution systems for low-load homes.

Day two started off with another greeting from Gord Cooke, Winkelmann, and Andy Oding. Winkelmann reminded attendees that “we all have to climb the mountain so let’s do it together and make sure no one gets left behind.”

Dr. John Straube of RDH Building Science Labs covered the topic of carbon reduction and resiliency as it relates to building science. He noted a new focus on carbon emissions from embodied carbon. Straube was joined by Clarice Kramer of NRCan’s LEEP team, where she shared information on their new wall construction training videos and new collaboration program with CHBA to bring LEEP sessions to builders through HBAs.

Straube, Gord Cooke and the Building Knowledge team presented their variety of wall mock-ups, discussing stipulations of high-performance walls and enclosures.

Wrapping up the morning was Frank Lohmann of CHBA, Dr. Marzieh Riahinezhad of the National Research Council Canada, Dan Sandink of ICLR and Chirs Chopik. This group of speakers touched on integrating resiliency, explaining that adaptations and resilience go hand-in-hand; adapt for future, be resilient to recover faster and in turn, increase survivability. There is the question of ‘what to prioritize? Who will prioritize it? And do we know where its needed?’ Lunch saw a presentation from Matt Cable from Enbridge Gas on new technologies for low carbon community development.

He discussed the company’s development pilots of hybrid heating and smart controls.

After lunch, attendees were met with a presentation by Carl Pawlowski from Minto Group, Stefanie Coleman of Doug Tarry Homes, Phillip Santana from Mattamy and Alex Ferguson of CanmetENERGY (NRC). This panel, hosted by Andy Oding of Building Knowledge, covered carbon reduction strategies for home builders.

Next up was Home Builder Night in Canada with Mike Memme of Mountainview Building Group and Andy Oding. Memme went over the top 10 things that keep him up at night. They are: flashing, air tightness, framing mis-steps, new product types, swimming upstream, safety, fire, people, making the same mistakes and government.

Day two wrapped up with a group affirmation/ hopes for what to accomplish for Spring Training 2024. Topics included heat pumps, net-zero and green retrofitting, air-to-water pumps and load management, reframing post-secondary trades programs, pushing beyond the envelope for shading, in-home energy conservation and exergy.

The third and final day of Spring Training started off with an energy and carbon codes update with Frank Lohmann from CHBA.

Lohmann spoke on the harmonization of codes and the switch to government officials and decision makers and industry and stakeholder as guidance/ advisors.

Coleman, chief sustainability officer for Doug Tarry Homes touched on ESG (environmental, social, and governance) and what it means for business owners. Coleman went on to explore disruptions and innovations in home construction, including building information modelling, offsite manufacturing like modular homes, 3D printed homes and robotic-assisted building.

The first half of the day wrapped up with a presentation from Leigh St. Hilaire and Aidan Brookson of Volta Research, Patric Langevin, Lucas Coletta and Ferguson from NRCan, Andy Oding and Scott Schrier from Building Knowledge Canada, and Dan Sinclair of Sinclair Homes. The presentation touch on Volta’s SNAP tool and its expansion to the current HOT2000 application.

After lunch, attendees who did not head out on the morning’s CHBA net zero and net zero ready homes tour chose between two concurrent interactive workshops. One on energy, cost, and carbon optimization tools and another on adaptation, resilience, climate risk disclosure and ESG.

This year marked another successful Spring Training and first-ever collaboration with CHBA’s Net Zero Summit.

For information on future CHBA events, visit chba.ca or drop them a line at chba@chba.ca

For a more in-depth review of this event, visit our website. cc

What caught our interest

JELD-WEN NORTHERN TRI-PANE COLLECTION

jeld-wen.ca

JELD-WEN’s Northern Tri-Pane collection are ENERY STAR certified and are designed to be energy-efficient and durable. The triplepane glass aims to deliver soundproofing, and the Low-E coatings are designed to help regulate interior temperatures. The Canadian-made windows provide two ½ inch air spaces, which is designed to act as a second layer of insulation. The Tri-Pane collection is available in a variety of styles.

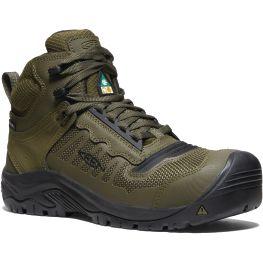

KEEN UTILITY CSA RENO

keenfootware.com

KEEN Utilitiy’s CSA Reno book features KEEN.BELLOWS FLEX technology, an ergonomically engineered system, designed to offer multidirectional flex to make bending, squatting, kneeling and knee-down work easier. These boots feature KEEN.ReGEN midsole, a KEEN.KonnectFit heel capture system and an ankle-height engineered mesh upper and KEEN. DRY membrane. The boots also offer asymmetrical carbon-fibre toes and an EH_rated oil-and-slip prevention outsole. They are available in both men and women sizing.

BENJAMIN MOORE ELEMENT GUARD EXTERIOR PAINT

ROOFRUNNER AIR

certainteed.com

Introduced to the Canadian market in November 2022, RoofRunner AIR is a breathable synthetic roof underlayment with a multilayer coated structure that promotes rapid roof deck drying. The product is made for use on roof decks as a water-resistant layer beneath asphalt roofing shingles, helping to maintain a dry and healthy roof deck.

benjaminmoore.com

Benjamin Moore’s Element Guard paint is formulated with the aim of tackling high moisture areas. Designed to withstand wind-driven rain, excessive humidity, and other harsh weather conditions, Element Guard exterior paint can be used on various exterior substrates such as vinyl and cedar siding, wood, brick, and more. The paint can resist rain as soon as 60 minutes after application and be applied in temperatures as low as two degrees. The Element Guard formula can be tinted in more than 3,500 Benjamin Moore colours, including curated Colours for Vinyl palette, which is formulated to reduce sun-induced warping. It is available in flat, low lustre, and soft gloss finishes.

This toolbelt apparatus includes two belt loops and a reinforced rear loop for secure carry on the belt, three main accessory sleeves to carry items such as multitools, flashlights, pocket knives, pens, etc., and an attached key ring for keys or carabiners. It comes in three colours – black chestnut and burgundy – and is made using full-grain leather.

LEROS AND LEROS-S WALL, CEILING, AND DRYWALL SANDER mirka.com

The LEROS series of wall, ceiling and drywall sanders are designed to be ergonomic and lightweight. The nine-inch sanding head has 180 degrees of flexibility and a fivemillimeter random orbital movement. The sanders can also be connected to an extension shaft. The LEROS-S (LEROS Short) features the same features as the LEROS but is a compact length wall sander with two grip points.

FESTOOL CORDLESS MITRE SAW

festoolcanada.com

Festool Canada’s KAPEX KSC 60 Cordless Sliding Compound Mitre Saw was designed to aid users to produce cross-cuts in a range of applications. It has a dual-battery 36-volt system combined with the brushless EC-TEC motor. Other features include mitre angles of up to 60 degrees on each side and bevel angles of up to 47 degrees, ergonomic handles, and a transport locking device.

The KSC 60 is available in two options, including the KSC 60 EB-Basic for $1,299 and the KSC 60 EB 5.0 I-Plus for $1,699.

owenscorning.com

Owens Corning’s FOAMULAR NGX extruded polystyrene insulation line is a XPS insulation that contains a proprietary blowing agent that is designed to eliminate HFC 134a. It delivers a 90 per cent reduction in blowing agent GWP compared to legacy FOAMULAR insulation. It is optimized to demonstrate a greater than 80 per cent reduction in embodied carbon. FOAMULAR NGX is manufactured with patent Hydrovac technology and was designed to be used in a variety of applications, such as; load-bearing vegetative roofs, foundational supports, and wall assemblies. The product is available in C-200 and CodeBord, C-300, 350 and 350 CVI and, 400, 600 and 1000 high density.

Henry decided to grow his family business and bring in new employees to help handle expanding projects. He has noticed that one of his new employees, Jess, has started showing up to work late, taking long breaks and, is quiet and reserved. When she was hired, Jess was ambitious, excited, and always up for a challenge. She is the only woman working on a male-dominant worksites. Henry speaks with Jess about her change in behaviour and Jess explains she has been feeling underestimated and isolated by the “boys club” of the family business, so has not felt comfortable coming and being at work. Jess says she knows the way she went about her discomfort was wrong but didn’t want to be seen as a complainer or ungrateful for the job. She is thinking of resigning. When he hired Jess, Henry was eligible for wage subsidy, as she is a minority in the construction business. He does not want to lose her as an employee and is afraid this will affect his business’ reputation. What should Henry do?

Jim’s business has been impacted by the pandemic, leaving him in thousands of dollars in debt. He asked his clients about increasing material costs and they’ve threatened him with legal action if the job isn’t done as contracted

By degrees, many contractors and developers have been faced with similar situations due to unprecedented market conditions. I know of a builder/ developer that went back to his clients and said, we can’t build for the price contracted. If you pay an additional amount now, you are still well below the cost to get the project repriced now. They also offered the clients the option of cancelling their contract with all deposits returned. Most clients accepted the price adjustment. For his clients to threaten a lawsuit, may be a toothless tiger as many individuals have won in court only to find that the company that they are suing has no funds left and they get nothing.

It may be very beneficial to have a solicitor write up the agreement for the revised contract as he would know how to make it more acceptable to the clients. Any lawyer will tell you that there is no such thing as an ironclad case in the courts. Don’t let a threatened lawsuit intimidate you.

Not many informed people would argue against the fact that we have been faced with unprecedented market conditions in the past two years. For the clients that threatened lawsuits, I would try my best to get out of the contracts.

1. Fire Jess. This clearly isn’t the right fit for her.

2. Offer Jess an alternate job in the business, somewhere she will feel more comfortable.

3. Talk to his male crew members about their behaviour and attitude towards Jess. Remind them she is equally as capable.

4. Hold an equity, diversity and inclusion training course to refresh employees and management on the impacts of their behaviours.

5. Something else?

If you have a solution to Henry’s dilemma, email your entry to ksecord@annexbusinessmedia.com and put “Henry dilemma” in the subject line. Include your email information in your response. Please don’t post your response in the comments section on our website.

Entries close June 10, 2023. The winner will be announced in the August issue.