Energy advisors

Get them involved

Pg. 14

Creative Eye Contemporary Calgary Pg. 22

Hot stuff

Hot water flow facts

Pg. 26

Energy advisors

Get them involved

Pg. 14

Creative Eye Contemporary Calgary Pg. 22

Hot stuff

Hot water flow facts

Pg. 26

After building a successful business, Richard Speare is educating the next generation of contractors

Page 10

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the digital edition archives at canadiancontractor.ca.

One third of opioid overdose deaths in Ontario last year were construction industry workers. Jan Chappel of the Canadian Centre for Occupational Health and Safety joins The Hammer to help us understand how to identify substance use disorders and how to react as an employer.

Jacqui Collier of Tamarack Homes in Kingston describes what it’s like to build a career in construction in a slick video from the Eastern Ontario College Consortium.

Oooo...pretty pictures. Follow canadiancontractor on Instagram for photos we don’t have room for in the magazine. Plus links to other stuff we like.

Brand Sales Manager Nav Matharu (226) 931-5095 nmatharu@annexbusinessmedia.com

Account Coordinator Barb Comer bcomer@annexbusinessmedia.com

Media Designer Lisa Zambri

1498-8941 (Print)

Patrick Flannery pflannery@annexbusinessmedia.com Associate Editor Daniel Reale-Chin dreale-chin@annexbusinessmedia.com

Group Publisher Danielle Labrie (226) 931-0375 dlabrie@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

By Patrick Flannery Editor

” ” We’re understanding that the conditions we build for today will not be the ones our buildings face tomorrow.

It’s funny how certain words float up to prominence in our discourse around an issue, linger for a while on the tips of everyone’s tongues, then fade away to be replaced by other words. “Pollution” is probably the first word I remember from the environmentally conscious green movement, back when concern for the environment was primarily attached to images of industrial waste pouring out of pipes into open ditches and the Detroit River on fire. “Acid rain” had it’s day, as did “smog” and later the “ozone layer.” Then came the Big Kahuna –“global warming” – soon tweaked to “climate change.” With it, the terms for how companies should position themselves took on more esoteric and sophisticated meanings. “Recycling” was everything for a long time, until it started to become evident that we were never going to be able to reuse enough of what we consume to meet our climate objectives. That was broadened into a need to be “green” or “environmentally friendly,” taking in energy conservation as well as avoiding waste and not obtaining materials from non-green sources. “Green” also carried some cultural overtones, aligned as it was with the names of environmental political parties around the world...some of whom were not, shall we say, business-friendly. At some point, the environmental movement realized that a complete cessation of making things was probably not in the cards, so a new word came along that incorporated some allowance for the need for industry to exist: “sustainability.” Go ahead and manufacture and consume and build if you must, but at least try to do it in a way that ensures you will be able to continue to do so tomorrow. And while you’re at it, don’t forget to include “embodied carbon” in your calculations.

At the recent Spring Training Camp conference hosted by Building Knowledge and McLeod Associates, I saw a new word poking its head up: “resilient.” Aside from a being the first opportunity I’ve had since I became editor of this magazine to actually rub shoulders in person with my readers, the conference was a really excellent education in the most recent building science. There were some very knowledgeable and highly placed industry experts there, including contractors with long track records in sustainable building, engineers from Natural Resources Canada, energy advisors from the Canadian Association of Consulting Energy Advisors and Gord Cooke, Andy Oding and Tex McLeod themselves. All seemed quite interested in this “resilient” term and a couple of the presentations were built around it.

Resiliency obviously means building better: to a higher quality standard and for more longevity. That makes sense. There’s no better way to reduce the carbon impact of construction than to not have to renovate, repair or rebuild in the first place. But “resilient” is not exactly the same as “durable.” It also suggests the ability to roll with the punches; to adapt and be repaired or upgraded as time and changing conditions do their damage. The relevance of this today is obvious - it’s called climate change. We’re understanding that the conditions we build for today will not be the ones our buildings face tomorrow. That adds another level of complexity to the challenge. Finally, resiliency is also about resisting a higher level of punishment from the more frequent extreme weather we are already seeing. So the term carries with it a sad realization that some of the damage is already done and our jobs as builders will be to make homes that mitigate the permanent impact of climate change on our clients. cc

There was a lot of talk about housing in the federal budget Ottawa brought down April 7, but surprisingly little of it is very relevant to Canadian Contractor readers. Most of the measures to address housing supply and to make housing more affordable will primarily impact larger, newbuild developers rather than renovation and custom home contractors. We’ve picked out some highlights of specific interest to you.

There’s a vague plan to incentivize municipalities to approve more housing projects, especially affordable projects. From the federal website:

“Budget 2022 proposes to provide $4 billion over five years, starting in 2022-23, to the Canada Mortgage and Housing Corporation to launch a new Housing Accelerator Fund. The fund will be designed to be flexible to the needs and realities of cities and communities, and could include support such as an annual per-door incentive for municipalities, or up-front funding for investments in municipal housing planning and delivery processes that will speed up housing development. Its focus will be on increasing supply, but government supports will be targeted to ensure a balanced supply that includes a needed increase to the supply of affordable housing.”

The mayor of Mississauga, Ont., was on television following the budget speech delivering a line that we will no doubt hear from many municpal leaders: there is lots of land approved for housing but developers are not taking advantage of it. That aside, if these funds do anything to reduce red tape and speed up the permit process at the municipal level, it will be welcome.

This might be the biggest announcement in the budget for Canadian Contractor readers!

“To support these families, Budget 2022 proposes to introduce a Multigenerational Home Renovation Tax Credit, which would provide up to $7,500 in support for constructing a secondary suite for a senior or an adult with a disability.”

Renovating houses up to modern energy-efficiency standards is going to be big business for the foreseeable future because of programs like this.

“Budget 2022 proposes to provide $200 million over five years, starting in 2022-23, to Natural Resources Canada to create the Deep Retrofit Accelerator Initiative, which will provide support for retrofit audits and project management for large projects to accelerate the pace of deep retrofits in Canada, including a focus on low-income affordable housing.”

Word is the 2025 National Energy Building Code update will include regulation of the energy performance of home renovations, which no doubt dovetails with this initative. Canadian Contractor is seeking more information.

A lot of the affordable housing initiatives will only be of interest to developers. But here’s one that throws some money at repairs to existing units, which could drive some business in our sector.

“Budget 2022 proposes to advance $2.9 billion in funding, on a cash basis, under the National Housing Co-Investment Fund, so that all remaining funds will be spent by 2025-26. This will accelerate the creation of up to 4,300 new units and the repair of up to 17,800 units for the Canadians who need them most.”

Energiwhowhatsis?

Interesting.

“The Energiesprong model, adopted by Netherlands, the United Kingdom, France, Germany, and the United States, accelerates the pace and scale of retrofits by aggregating homes and buildings in an entire neighbourhood and retrofitting them all at the same time. This support for community-level home retrofits aligns with the Net-Zero Advisory Body’s recommendation to seek out opportunities to decarbonize multiple buildings at once.”

You could hand out flyers in a neighbourhood and invite people to join the local Energiesprong.

“Budget 2022 proposes to provide $33.2 million over five years, starting 2022-23, to Natural Resources Canada, including $6 million from the Green Infrastructure – Energy Efficient Buildings Program to implement a Greener Neighbourhoods Pilot Program in up to six community housing neighbourhoods to pilot the “Energiesprong” model in Canada.”

Despite the name, it would seem the problem here is rental laws that allow landlords to force people out of their homes, not the renovations themselves.

“However, in recent years, the significant increase in housing prices has led to large investors acquiring a larger portfolio of residential housing. There is a concern that this concentration of ownership in residential housing can drive up rents and house prices, and undercut the important role that small, independent landlords play. Many believe that this trend has also led to a rise in “renovictions”, when a landlord pressures and persuades their tenants to leave, or is formally permitted to evict them to make extensive renovations in order to raise rents.”

This one is unfortunate for us, as people often renovate the home they are planning to flip.

“Budget 2022 proposes to introduce new rules to ensure profits from flipping properties are taxed fully and fairly. Specifically, any person who sells a property they have held for less than 12 months would be considered to be flipping properties and would be subject to full taxation on their profits as business income. Exemptions would apply for Canadians who sell their home due to certain life circumstances, such as a death, disability, the birth of a child, a new job, or a divorce. Exemptions will be set in forthcoming rules and Canadians will be consulted on the draft legislative proposals.”

This is a great idea that could help alleviate our problems with finding skilled labour to hire.

Budget 2022 proposes to introduce a Labour Mobility Deduction, which would provide tax recognition on up to

$4,000 per year in eligible travel and temporary relocation expenses to eligible tradespersons and apprentices. This measure would apply to the 2022 and subsequent taxation years.

Anything that incentivizes more people entering the trades is a good thing.

Budget 2022 proposes to provide $84.2 million over four years to double funding for the Union Training and Innovation Program, which would each year help 3,500 apprentices from underrepresented groups – including women, newcomers, persons with disabilities, Indigenous peoples and Black and racialized Canadians – begin and succeed in careers in the skilled trades through mentorship, career services and job-matching.

Canadian businesses have tended to remain small and not aggressively pursue growth in part because of an archaic $15 million capital threshold. Taking a six-percent tax hit the minute you go over this arbitrary line is a huge blow. The longer phase-in is welcome.

“Small businesses currently benefit from a reduced federal tax rate of nine per cent on their first $500,000 of taxable income, compared to a general federal corporate tax rate of 15 per cent. A business no longer has access to this lower rate once its level of capital employed in Canada reaches $15 million. However, phasing out access to the lower tax rate too quickly – and then requiring a small business to pay more in tax – can discourage some businesses from continuing to grow and create jobs. Budget 2022 proposes to phase out access to the small business tax rate more gradually, with access to be fully phased out when taxable capital reaches $50 million, rather than at $15 million. This measure would apply to taxation years that begin on or after April 7, 2022.” cc

The the 2020 National Model Codes have been released after a two-year delay. Highlights from the new codes include:

• Strengthened protections for openable windows in residential occupancies to minimize the risk of falling;

• Safety glazing in windows and doors for schools, and similar buildings, to reduce the hazards of wired glass;

• Updates to evaporative equipment and drain pans to minimize the growth and transmission of legionella and

other bacteria;

• Adjustments to the minimum dimensions of building elements to accommodate people using a wider variety of mobility devices, and requirements for tactile signage and for more pedestrian entrances and floor levels to be accessible;

• A tiered energy performance compliance path which incrementally improves energy efficiency at each successive tier;

• The introduction of whole-

building airtightness testing as an option for complying with air leakage requirements; and

• The introduction of encapsulated mass timber construction to allow for the construction of wood buildings up to 12 storeys tall

The 2020 codes are available through the National Research Council of Canada (NRC)’s publications archive in a free electronic format for download. To purchase the publications in print format, an order can be placed online through the NRC’s virtual store. cc

Members of Liuna Local 183 in Ontario went on strike following expiration of their collective bargaining agreement on April 30. Below is a statement from the Residential Construction Council of Ontario and LiUNA.

From RESCON:

The Residential Construction Council of Ontario is advising that all collective bargaining agreements for residential construction in the Greater Toronto Area expired April 30. We are pleased that a large number of collective agreements have been settled, a tentative agreement has been reached, or the parties are waiting for an arbitration award. However, RESCON has been notified by LiUNA Local 183 that its members in the high-rise forming, house framing, self-levelling flooring sectors, as well as railing, tile, carpet and hardwood installers have rejected settlements and are now on strike in the GTA, central Ontario and parts of southern, eastern and southwestern Ontario. The Ontario Labour Relations Act allows residential construction strikes

in the GTA to last about six weeks before mandating a return to work and handing over any outstanding disputes to binding arbitration. Approximately 30 collective agreements exist in the residential construction sector. For direct employees, the parties went to arbitration April 21. The award (final decision) settled all outstanding issues in dispute, including wages. Taking into account other settlements in the residential and broader construction sector, the arbitrator awarded a $6.40 increase on the total hourly package over a three-year period. This represents an increase of approximately $12,500 to annual compensation. This settlement is in line with the established pattern set in the construction industry as an arbitrator is required to determine what the parties would have reached in bargaining.

From LIUNA:

Members of LiUNA Local 183 that work in various sectors of the residential construction industry were forced to go on strike in support of fair

When Gary Jans of Ray-Jans Construction in Cornwall, Ont., says he’s going to do something, he does it. Last summer, Gary won our Dilemma contest with his answer to our question about how a young contractor should face hard times. When we notified him that he’d won our prize of a DeWalt pressure washer, he said he’d like to donate it to a deserving young person entering the trade. When we couldn’t come up with anyone, Gary took matters into his own hands. Here’s the rest of the story in his words:

“We were able to coordinate with Mark MacDonell of the St.Lawrence College Cornwall Campus for a photo opportunity on a nice day. Mark is the head of the carpentry/construction division of the school and teaches it

compensation and workers’ rights. The job action, by over 15,000 skilled construction labourers, could impact both ground-related and high-rise multi-family residential builds across the GTA. Local 183 requested fair compensation for its members given the ongoing increases to the cost of living that is being experienced across Ontario. These are mature collective agreements, some of which have existed for more than 30 years. These workers build high rise and low-rise housing throughout the GTA.

LiUNA Local 183 is calling on the contractors’ associations to return to the bargaining table with employment terms that address the costs of inflation and demands on the sector over the coming years. Employers in other construction sectors, and in other parts of the residential sector, offered employment terms and conditions that better reflect the current cost of living and anticipated increases in inflationary pressures over the life of the collective agreement. cc

as well. Through a bit of a process, we finally decided to award the prize to an individual in the apprenticeship program that showed serious dedication to his education as well as a rounded out lifestyle including ambitious carpentry projects of his own and discipline to work on his off hours. Johnathan Lang met those expectations while earning a 3.66 GPA in his first term of the program. Johnathan Lang is now employed by Ray-Jans Construction and will see Johnathan through the progressive stages of his apprenticeship program. Coincidentally, Mark and Gary attended high school together but that’s many, many moons ago.”

Thanks, Gary, for your sincere interest in helping the next generation of skilled tradespeople. cc

Not only is Richard Speare a successful contractor, he’s also eager to share his knowledge and expertise with the next generation of carpenters.

By Jack Kazmierski

Richard Speare, president of Barrie, Ont.,-based Speare Construction and Contracting, got into the construction business by accident, but he’s glad he made the jump.

After finishing high school in 1978, Speare started working for Ontario Hydro as an electrical operator. His career path took him into management positions where he learned how to oversee projects and manage people — skills that he would put to good use years later when running his own company.

His career in the utility sector ended in 1993 when Speare decided that sitting behind a desk was not what he wanted to do for the rest of his life. He took the severance package he was offered, and soon after accepted his brother’s invitation to help build a house in the Muskokas (cottage country for many who live in the Greater Toronto Area).

Transition into the trades

That build with his brother turned out to be one of many to come. The siblings built several custom homes together until Speare started his own company in 1995.

“I think my transition to ownership was natural,” he says, “since I like meeting people and finding solutions to people’s perceived needs. My previous jobs helped with the planning aspects of construction, and although I really enjoy working with my hands, I think I am better at the management side of things.”

Speare is thankful for the many years he spent working for a major utility, prior to starting his own construction business. That experience helped him hone the business and management skills that have allowed him to succeed where others have failed.

“I think someone might consider themselves a builder, but if they don’t follow good business practices, they won’t be successful,” he explains. The need to balance business skills with carpentry skills is good advice for those already in the trade, but even better advice for the next generation of carpenters and contractors. It’s the kind of advice Speare

In business since 1995, Speare credits his breadth of experience with helping his career. His time in the utilities field and now as a college instructor give him extra knowledge.

is happy to share with students at his part-time teaching job.

In fact, when he’s not on the job, Speare is in a classroom at Georgian College in Bracebridge, Ont., teaching the trade to tomorrow’s carpenters. His penchant for business and his love of carpentry has him juggling two careers: running a business full-time, and teaching carpentry parttime.

“I’ve been teaching since 2011,” he explains, “and I enjoy it very much. I’ve even hired a few of my students. The college program is a great well for good employees.”

Juggling two careers isn’t easy and Speare says that the only reason he can do so successfully is because of his very supportive team, which includes his brother and his sister, who handle much of the administrative responsibilities that keep the company humming along smoothly, even when Speare is at the college with his students.

He enjoys teaching so much, in fact, that Speare says he can see himself retiring from his business in the future, while continuing to teach carpentry and shaping the skills

and minds of future contractors.

“I plan to transition ownership of this company in a number of years,” Speare adds, “and then probably continue working on maybe a consulting basis. But the teaching — that I could conceivably continue doing as long as they want me.”

Having taught now for more than a decade, Speare says he’s seen a few interesting trends. “For one,” he says, “we’re seeing more women interested in carpentry. They’re still a minority, but they fit in very well and they’re very capable.”

The other trend is students who are increasingly techsavvy, which Speare says is a good trend for the trades. “I think we’re seeing more technology in carpentry and construction,” he adds, “and it will help them to do well in this business.”

The shortage of skilled labour, and of individuals willing to give the trades a chance, is well known here in Canada. It’s a problem that has continued to worsen in recent decades. As older individuals reach retirement age and hang up their hammers in order to enjoy more time with their grandchildren, the question for our industry is, who will take over and where will tomorrow’s trade professionals come from?

Speare, however, says he is seeing a change in attitudes that gives him hope for the future. “While there’s still a bit of a stigma when it comes to the trades,” he admits, “I’m seeing a growing number of students who already took college or university courses and then had a summer job in construction where they ended up loving it enough to completely change their career path.”

Another encouraging trend is the way high schools view the trades. Speare says he’s seeing teachers and counsellors promoting the trades as a serious career possibility; painting the trades in a more positive light than they used to in the past when the trades were promoted to those who weren’t “book smart.” This is a refreshing new direction that offers us more reasons for hope that new talent is in the pipeline for the future.

22_0086_Canadian_Contractor_JUN_CN Mod: April 14, 2022 9:56 AM Print: 04/19/22 page 1 v7

Speare’s focus on health and special-needs projects has created a strong bond between him and his clients. Helping clients renovate their homes for better access while still looking good puts a smile on their faces and the faces of his team.

When he’s not teaching, Speare is out in the real world running his business and caring for his customers’ needs. His attention to details and his genuine interest in others has earned him a “preferred contractor” status with the agencies that hire his company to care for a variety of projects, including those in the health-care sector, as well as people with special needs. “We’re always getting high praise for the professionalism and the quality of the work my guys do,” he adds.

The foray into healthcare and special-needs projects has seen Speare and his team work with organizations like the March of Dimes and the Salvation Army to help those with accessibility challenges, and to undertake construction projects with clinics and hospitals.

Speare has managed to carve out a niche for his company as the go-to contractor when homeowners have accessibility issues, and when they need walk-in tubs or zero-threshold showers or ramps that allow someone with limited ability to avoid a flight of stairs. He’s even worked on projects where elevators were needed. “We didn’t install the elevator,” he explains, “but we did all the carpentry work associated with it.”

house so that they could access the basement,” Speare recalls. “We also built a beautiful big bathroom in the basement with a roll-in shower. That was one our more memorable projects.”

Speare’s genuine concern for his customers and his attention to detail have earned him a loyal following. His customers keep calling him back, sometimes years later, because they want him to take on other projects. One of these customers was a couple who contracted Speare to renovate their cottage in 2013. After working with the architect and starting some of the preliminary work, Speare soon realized that he couldn’t proceed with the project as planned. The cottage would have to be demolished.

“I’ve been teaching since 2011,” he explains, “and I enjoy it very much. I’ve even hired a few of my students. The college program is a great well for good employees.”

“We got partway into the project and realized that the cottage was not salvageable,” Speare recalls. “We had to knock it down, and that really seemed to dash the hopes and dreams of that couple. I remember them being in tears when they heard the news.”

But Speare and his team managed to put a smile on the couple’s faces after replacing the old cottage with a new high-efficiency home. What appeared to be a shattered dream, turned out to be the couple’s dream home.

He says that his customers want to avoid an institutional look when converting their existing bathrooms to something that’s more accessible. Speare is proud of the way he and his team can cater to that need by renovating the space to be fully accessible, as well as completely eye-pleasing.

“One of our customers had an elevator installed in their

“They were thrilled with the work,” Speare says. “They were so glad that they had to replace the cottage after all. In fact, they recently called us back to build them a sunroom. The whole project shows really nicely and I think this is one of the builds that we’re most proud of. It’s our pride and joy.”

Glass half full

When asked about how he feels about the future of carpentry and of our industry in general, Speare is optimistic. “I would like to see the introduction to trades re-introduced into the public school system. I don’t think that exists presently and

Join a completely Dealer-Owned company today.

Dealers share and participate equally without the influence of any external shareholders. Harness our massive buying power, comprehensive distribution, national brand recognition and marketing support.

I know it used to. I am encouraged by the attention the high school systems are giving to the trades and the technical courses they offer. I think there’s a bright future ahead for our industry.” cc

Energy advisors are critical to access the new retrofit rebates. Here’s who they are and what they do.

By Leon Wasser

Energy efficiency has become one of the key determinants of what the market now considers a high-quality home. The energy design of a home may be invisible to the naked eye, but leading Canadian home builders and renovators now recognize the business opportunities arising in green building. While there is no question that how a home looks from the outside is still important, industry leaders increasingly recognize the growing importance of optimized energy design in their projects. They now know that when it comes to energy it’s what’s inside the home that counts.

The field of efficient energy design is something complex, incorporating multiple building materials and systems. Energy analysis requires a systems approach because how a building performs from an energy perspective is dependent on the interaction of many building components and every building element is important to determining the overall energy performance of the structure.

The Canada Greener Homes Grant program

In the summer of 2021, the federal government announced a major new

program to help Canada meet its greenhouse gas (GHG) reduction obligations under the Paris Accord. Canadian housing generates about 40 percent of our GHG emissions. The government recognized that there was a great opportunity to meet our international climate change obligations and to meet other policy goals such as promoting the business sector and reducing energy costs for Canadian homeowners. The goal of this program is to improve the energy performance of Canada’s huge inventory of existing homes by subsidizing numerous types of energy retrofits for individual homes. Overall, this massive federal program was provided a budget of $2.7 billion to fund energy retrofits for to up to 700,000 existing homes over the seven-year span of the program, which will run to 2028. More specifically, the program offers homeowners up to $5,000 for approved energy retrofit projects as well as up to $600 for a mandatory energy audit.

The list of qualifying energy retrofits is extensive starting with energy conservation measures such as improving the home’s building envelope through upgraded windows

and doors as well as applying increased insulation to attics, walls and basements. A second area of potential improvement is through a select range of HVAC system upgrades. A third focus for energy performance improvement is through the installation of renewable energy systems including geothermal, heat pump and solar photovoltaics systems.

Tapping into the program and its funding is a multistage process. First, individual homeowners need to register individually for the CGHGP through a link on the Natural Resources Canada website

Once approved by NRCan, the homeowner needs to engage a registered energy advisor from an extensive list of candidates listed on the NRCan program website. Registered energy advisors are specially trained and NRCan-approved professionals. Prospective energy advisors must undertake intensive training and complete two NRCan-administered exams to qualify to offer their services. There are only a limited number of training institutions that offer this instruction. Because of high demand for their services, it is important for homeowners to engage an energy

advisor as early as possible. The energy advisor will visit their home, conduct a mandatory comprehensive energy audit of the home’s current condition and recommend a detailed plan for potential improvements. The energy advisor then submits their energy audit electronically to NRCan for review and approval.

Once approved, the homeowner can scope the market for contractors who can perform the desired home energy improvements. The homeowner then needs to get quotations for any of the recommended measures they want to proceed with. Smart home renovators can market their ability to perform the types of home improvements typically recommended, such as envelope improvements, HVAC upgrades and renewable energy systems. Currently there is limited government guidance on the marketing of these services.

A skilled contractor can facilitate the energy retrofit process by developing a detailed knowledge of this program. They can help homeowners decide which measures to proceed with from the list recommended by the registered energy advisor based on which project may offer a better payback period, which are easiest to undertake, and

Energy advisors and energy modellers have to be experts on many aspects of home construction, as well as understanding the latest energy-efficient building concepts.

which provide the best long-term value. The renovator then implements the project and provides the homeowner with their invoice. As a final step the homeowner invites their registered energy advisor back to verify that the work performed was a measure which they recommended, and that the contractor or supplier invoice is valid. Once this is done, they complete the process by submitting their approval to NRCan. NRCan will then release the funds for the both energy upgrade up to $5,000 and for the energy audit up to $600.

In some provinces there are similar incentives through other levels of government or through utilities. In Ontario, Enbridge offers a Home Energy Retrofit grant of $5,000 which operates is a very similar fashion to the Canada Green Home Grant and uses an analogous process involving registered energy advisors.

The Canada Greener Homes program is generating substantial interest in green retrofits for existing homes. There is also growing demand for greener new homes.

Homebuilders in Ontario are aware of SB12, the sustainable building energy performance requirements for Part 9 of the Ontario Building Code, which governs the design and construction of new homes. Some savvy home builders have recognized the growing demand for high energy performance homes, such as those that are designed to meet the Passive House, net zero or Energy Star for New Homes standards. These high-performance homes consume less energy, are generally more comfortable and command a price premium from home buyers. Whichever high-performance standard is adopted for the home, the process begins with a comprehensive energy model. This brings to mind to the famous adage, measure twice, cut once. Green building homes need to be planned effectively before construction starts.

This process begins with visualizing the energy performance of the proposed home with energy modelling software. In Canada, we generally use the HOT2000 software or the H2K energy modelling program. This software was developed by NRCan. In some cases, the project architect designing the home can also run the Hot2000 energy modelling for the project. There are also consultants who specialize in HOT2000 modelling.

Energy modelling considers many building elements including overall geometry, building materials, orientation and window location. Building envelope materials like insulation, window construction and sizing and HVAC equipment are also reflected in HOT2000 captures. HOT2000 also incorporates renewable energy systems for the home such as geothermal, air-source heat pump, solar photovoltaic or solar hot water systems.

The model may have to be run several times to optimize the building design. Once the digital twin of the house is finalized it is submitted to the municipality’s building department as part of the building permit review process program, when and where required. Skilled municipal building officials can view, understand and approve the HOT2000 model.

In some jurisdictions and for certain projects, in addition to HOT2000 energy modelling, registered energy advisors are required to review the new construction projects at key points during the project’s construction to verify that the project complies with the applicable green building standard and HOT200 energy model.

High energy performance homes require deep expertise. Both becoming an energy advisor or a HOT2000 energy modeller requires a significant amount of professional training. It is clear, however, that due to both the strategic direction of government policy regarding GHG emission reduction

in many jurisdictions, and the everincreasing market demand for greener homes, there is a rapidly increasing demand for these energy experts.

HOT2000 energy modelling training involves developing a deep understanding of house construction and how each element of the structure contributes to how structures use energy. Energy modellers need aptitude with both mathematics, especially complex geometry, as well as some comfort with computer programing.

Energy advisor training is far more challenging and involved. Energy advisors must first develop a very deep understanding of home construction if they do not come from the home building sector. In addition, prospective energy advisors need to understand the full range of energy performance characteristics of the wide variety of homes. They must be able to quickly identify energy optimization opportunities. For existing home retrofits, this requires a combination of a sharp eye and a profound understanding of home energy construction. They must also have an extensive understanding of the performance of the numerous energy measures available on the market.

In all cases, home-energy professionals need expert training to comprehend and assimilate the vast amount of background knowledge needed to operate credibly in this sector. Most importantly, individuals motivated to become professionals in this growing area need to be willing and able to devote the time and resources to truly become home energy experts. The rewards for this dedication can substantial. Both energy modellers and registered energy advisors will make a positive contribution to the future of the planet, and benefit from the solid foundation from a career in growing segments of the building sector. cc

Leon Wasser, MBA, P.Eng., is the director of the School of Energy of the Resilient World Institute and is the vice-chair on the Ontario Sustainable Energy Association.

by James Hong

In January, the Ontario government announced $45 million in funding to cut red tape and speed up applications for new home construction. Ontario premier, Doug Ford, said, “Streamlining will assist Ontario’s 39 largest municipalities to modernize and accelerate the home-building process. Updating old outdated systems with online systems will make it easier for applicants seeking to build homes to navigate the development approvals process, manage their applications and get timely updates on the status of those applications.” They also plan to develop a uniform data standard for planning and development applications to help speed up approval

“With provincial government investments to connect 900 new immigrants across the province in construction jobs, the rapid influx of new construction workers is eagerly expected”

times. This is good news for the residential homebuilding industry, but raises a concern with me about how a rush of building, probably using workers who are new to Canada, might

impact jobsite safety.

The cut-red-tape strategy will undoubtedly generate many more millions in residential project construction. A robust workforce active in a busy construction industry will and does require safety practices and protocol implementation. No matter how big or small the company or the project, all employers are responsible for the safety of their workers.

In any type of building construction the same steps apply. Scope the project, including the safety requirements, implement preconstruction necessities, schedule the job and workers and communicate the conditions and demands of the job. I stress the step of communication at all levels is critical to safety. And although we expect that seasoned workers have the tools and knowledge to carry out the job successfully, there are always junior workers entering the construction workforce who need the company’s guidance to maintain a safe working environment as well as safety for themselves.

With provincial government investments to connect 900 new immigrants across the province in construction jobs, as well as the Ontario Skilled Trades Alliance’s call to increase the cap on temporary foreign workers from 10 to 20 per cent of the workforce building public infrastructure projects and housing, the rapid and numerous influx of new construction workers is eagerly expected. Even so the industry continues to have demand exceeding

the supply, which means the workers will likely be overwhelmed with work. Safety training for immigrant construction workers is as essential, as it is for all workers. Let’s acknowledge that many other countries do not emphasize safety or even have safety protocols for construction workers. Safety may very well be an entirely new concept for some immigrant workers. That coupled with any possible language barriers requires a whole new level of safety training and relies greatly on team work, which I have written about extensively. Not to mention that it’s never a bad idea to remind all workers of the safety requirements for any job. The safety specifications for a job are best communicated by both written and verbal methods and should be accompanied by testing the information taught. Whether working in industrial or residential construction, safety training methods and requirements are not new concepts. We sometimes forget that demolition work for one room poses many of the same risks as building a house. Working at heights, moving objects, slips, trips and falls, noise, material handling, collapse and asbestos are universal risks no matter the job size or category.

Complete the pre-work inspection phase. Determine the risks and preventive measures needed. Wear your basic safety gear. If you don’t have any ask your employer to provide it to you. If you need special safety gear, make sure you have it before the start of the job that requires it. If you don’t understand the instructions or safety requirements for the job, ask your supervisor and your teammates. These are all steps we sometimes forget because we’re so busy getting on with the hard work. All construction comes with time constraints which can cause intense pressure when setbacks occur. Another reason to focus on safety and not succumb to the occasional urge to skip a step or two.

Be safe. Be well. cc

James Hong is an OHS consultant, writer and journalist.

Spring Training Camp combines high-level education with fun networking.

Energy efficiency, resiliency and embodied carbon were the keywords at the Spring Training Camp, held April 25 and 26 at Hockley Valley Resort in Mono, Ont. The event welcomed about 150 paying guests for two very full days of building science discussion and education, with ample opportunities for mingling and networking around meals and after-hours social gatherings. Building Knowledge principals Gord Cooke and Andy Oding did a great job hosting with lots of energy, breezy comedy and a sharp eye on the clock. Tex McLeod of The McLeod Associates joined remotely from B.C. The audience was mostly custom home contractors with a large contingent of energy advisors and public servants from various relevant government agencies. A smaller group of manufacturers and engineers rounded out the group. Rachel Oding greeted guests, dealt with venue staff, wrangled swag and generally made the whole thing run smoothly. The Camp is a joint venture of The McLeod Associates and Building Knowledge, with support from Enbridge and the Canadian Wood Council.

Highlights from the presentations

There was too much in the content-filled days to cover comprehensively here, so we’ll just focus on some key takeaways.

Jim Moore and Joe Starr of Beazer Homes, the 17th largest

builder in the U.S., described their ongoing journey as a company to arrive at a place where they are only building net zero homes. They plan to get there by 2025 with such features as R60 insulation in attics, 24-inch R21 in walls, window U-factors of 0.28, 1.5 air changes per hour, 75 percent sensible heat recovery, ducts in conditioned space and a raft of other energy-efficient upgrades, all leading to homes that consume only 32 MMBtu per year, a 55 percent reduction from today. Moore in particular was a quote machine.

On building to a higher performance standard than required by code: “There’s value in being a leader, but you never want to get too far ahead. If you get too far ahead, you just don’t see the value for it.”

On why Beazer decided to build high-performance homes: “We’re going to have to do it anyway. Why not get ahead of it?”

On why they move in three phased steps: “If we started

talking about Phase Three now it’s like telling customers to wait three years and we’ll build you a better house.”

On selling indoor air quality: “You know who is the most interested in indoor air quality? The customers. You know who is the least interested? The mechanical people.”

On how to sell better HVAC to people who don’t understand the certification labels: “I’ve found that when people are comfortable, people are happy, and beyond that I don’t care what form you give them.”

On marketing: “Fifty percent of the money spent on marketing is wasted. The hard part is telling which 50 percent.”

On keeping managers on board with the plan: “Every time we get a new division president he says, ‘Why are we using all this expensive material?’”

Jeff Baker of WestLab joined the conference remotely to explain high-performance window technology, focusing mostly on explaining solar heat gain, how it is and is not related to energy efficiency and how glass coatings act to control it. Coatings can reduce solar heat gain by a factor of three versus clear glass. He expressed doubt that we will see further major advances in glass insulating value through improvements to coatings – in his view, we have gone close to as far as we can with this technology. People are often concerned that low-emmissivity coatings will darken the glass or change it’s colour; Baker pointed out that research has shown people’s brains automatically colourcorrect what they see to what colour they expect it to be, and therefore glass can be tinted to a surprising degree before people will notice. Baker also explained insulating glass and how it works, mentioning that a shortage of krypton due to Elon Musk buying it for satellites and the war in Ukraine is making it too expensive to produce the most efficient window designs. He also advised against using the HOT2000 code editor to produce energy efficiency values for windows as it has old values in it that don’t reflect the performance of today’s materials.

future where manufacture of panelized components could be highly automated. So far, robots have only been found to economical when doing the repetitive tasks required to make high volumes of the same thing, such as in automotive manufacturing. Attar thinks technology has advanced to the point where processes could be flexible enough to address the semi-custom nature of panelized home construction –and could be feasible even for small builders with one-off designs. Promise Robotics is seeking builders who want to work with them to develop these processes.

John Straube of RDH Building Science brought a high level of energy and humour to his discussion of one of the big overarching topics of the conference: resiliency. With embodied carbon entering awareness as the next focus of environmentally friendly construction practices, forward thinkers are starting to call for designs and materials that last longer without the need for replacement or repair. In addition, more frequent extreme weather caused by climate change is forcing builders to consider upgrading their designs to be more resistant to such threats as floods, power outages, high heat and wildfires. Straube called for intelligent design for projects built in floodplains; backup power for sumps; better crawlspaces; power grid upgrades; less solar heat gain in windows; and exterior shading as measures to address these concerns. When it comes to wildfires, the key message was, “Don’t build in a forest.”

“I’ve found that when people are comfortable, people are happy, and beyond that I don’t care what form you give them.”

Possibly the most prosaic presentation came remotely from Gary Klein of Gary Klein Associates, who explained how to deliver hot water more efficiently and at desired pressures. Key takeaway: get that tank closer to where the water will be used. He threw cold water on recirculating pumps and insulating pumps and cautioned that heat pump water heaters need significant air space around them to work effectively without the coils freezing.

Ramtin Attar of Promise Robotics showed builders a

Mike Memme of Mountainview Building Group had the whole crowd laughing along as he presented the 10 things that keep him up at night with Andy Oding acting as Ed McMahon. The guy should really have his own late-night construction-themed talk show. But don’t get us wrong, there was a lot of substance there, too. Why doesn’t everyone do kickout flashing? How can we prevent truss uplift? Memme got serious talking about treating even nightmare customers as people who go through their day wondering why every interaction they have is a nightmare. He also had some strong political opinions, slamming city development departments for creating bizarre zoning requirements then leaving builders to clean up the mess when the department director leaves. Finally, Memme bemoaned consolidation in the industry, saying housing is becoming an oligopoly with everything being built by a few big companies, leaving small builders with no way into the market and customers with fewer choices and fewer ways to find unique designs. “More and more homes are being built by accountants and lawyers instead of the trades,” Memme said. Hockley Valley was an excellent venue with great amenities and food, set in the picturesque hills just west of Toronto. Next year’s Spring Training Camp should be on everyone’s radar who wants to brush up their building science knowledge and meet some of the brightest minds in Canada’s construction industry. cc

By CONEXPO-CON/AGG

have become a very fashionable topic in the construction industry. A number of employee-monitoring systems have been introduced to the construction industry with the aim of making employees safer. Dash cams are being installed into truck cabs – not to record traffic but to record the activities of the driver. Truck companies want to make sure drivers are checking their mirrors and especially aren’t using their phones when behind the wheel. Fall alert and emergency evacuation systems can monitor employees’ movements to alert safety personnel if the device changes elevation quickly, indicating a fall. And it alerts workers of a emergency evacuation. Radio frequency identification (RFID) tags monitor employees’ locations and alert equipment operators of employees who are located behind a mobile machine. Some smart watches detect vibration. That technology is used to monitor the impact on the body from using power equipment for a long time. Alerts tell the end-user when power tool use exceeds what the body can safely perform, and this is to prevent handarm vibration syndrome. Smart helmets monitor several health elements, such as fatigue, heart rate and stress, so workers and management can modify workers’ activities in ways that promote employee health and jobsite safety and productivity.

A lot of times, this monitoring can lead to policy changes and coaching opportunities.

“One customer who uses our RFID technology reported to me the following story,” says Jonathan Fava, president of Scan-Link Technologies. “‘We were looking at the number of times equipment operators were alerted to the presence of a nearby worker, and we noticed one person was causing a lot of alerts, so we pulled that individual aside and asked him why. He explained that he’s the flagger so, when operators load the machine onto a float, he gets up on the float to aid the operator to place the machine. We advised him that this behavior is unsafe; he could get struck by the machine or fall off the float. So, we told him a safer way to perform his job and wrote down new safety protocols into our guidelines and training.”

Using historical data to learn how things happen is the first step to promoting safety on the jobsite. “It’s not enough just to learn how accidents have happened,” says Fava. “The next step is to analyze data in order to prevent accidents from happening.”

With all of the employee detections picked up by the RFID system, managers can identify “hot spots”— spots where machines detect people the most frequently.

“Using this data, customers can identify areas where a struck-by incident is most likely to occur. Then, customers can make decisions that will decrease the risk of an accident from happening by moving the location of materials so workers don’t have to walk in a machine’s workspace. Or they can by put up signage warning employees of high-risk areas,” says Fava.

Applications for wearable augmented reality technology include mapping drawings onto actual jobsites, leaving messages for different shifts and trades and collecting activity data.

Assisted reality connects two physical worlds

Wearables are also instrumental in merging realities, which is bringing connectivity, productivity and accuracy to job sites. “Assisted reality” devices are designed to extend or enhance the capabilities of the user. Exoskeleton and assisted-reality headset manufacturers are releasing updated versions of their assisted-reality headsets. The new headsets are sleeker, lighter and more ergonomic than previous models for all-day comfort, yet are rugged and durable for use on construction sites and in industrial settings. These construction-focused headsets feature a modular design, a 48-megapixel camera sensor with enhanced zoom capability, incredible low light performance and are compatible with a wide variety of optimized apps. Hot-swappable batteries allow for continuous use the whole day.

“With our Navigator 500, we wanted to provide scale enterprise solutions as part of the digital transformation movement. Today, we see the acceleration of digital transformation on the future of work, especially since the pandemic,” says Andrew Chrostowski,

chairman and CEO of RealWear Technologies. “Our device is handsfree and keeps you present. You don’t want your head stuck in the metaverse when you’re working around heavy equipment.”

Chrostowski’s device allows the user to take photo and video at six different zoom levels, as well as call someone. The device takes audio commands for all features: you say the words “take a picture” or “zoom” or “call Harold” and it does it, so you can keep your hands on what you’re doing. With it, users can aid in remote inspections and diagnostics. By equipping someone at the job site with an assisted-reality headset, a worker can act as the eyes for inspectors and technicians, so inspections and troubleshooting equipment can be done remotely, saving time and travel costs.

Augmented reality expands by becoming handheld Augmented reality devices bring a

different kind of connectivity and reality. The technology connects virtual reality to physical reality to provide mixed reality. Using special goggles users can see both the physical world and the virtual world; the digital image is overlaid onto the physical world. This technology is especially handy to trades. Now, they no longer need to look at paper designs for what they are installing and then try to map out where that is in the physical world by establishing a frame of reference and taking out the measuring tape. They can simply see, for example, virtual pipes and their detailed measurements and install the pipes with high accuracy. They can also see what is being installed nearby, so they can identify potential complications. Some augmented reality suppliers have recently expanded the potential for BIM (business information modeling) users to deploy augmented reality on the jobsite by introducing apps that connect the AR device to a phone or tablet. The

app provides the augmented reality experience by pushing BIM data to their phone and overlaying it onto images of the real world on the device’s screen.

“This eliminates what can be a costly financial barrier to some customers,” says Martin Holmgren, general manager of building field solutions at Trimble, an AR provider. “And users can interact with AR users in the digital space. For example, I can leave a message in the digital space with my Trimble XR10 and someone with the Trimble Connect AR app on their phone can detect the message even weeks later as they walk by the location where it was left and read it. This greatly enhances communications and streamlines workflows.” Trimble expects people who don’t need to be fully hands-free, such as supervisors, managers, inspectors and building owners will use it to perform tasks, such as quality assurance, updating punch lists and measuring construction progress. cc

Powerful and economical with a compact quiet design which makes it perfect for any gray

Pre-assembled system with low inlets. Will discharge up to 14 Ft vertically

By Gordon Wornoff

Calgary’s Reborn Renovations recently earned a stampede of recognition from the Canadian Home Builders’ Association for their exquisite kitchens and bathrooms. At the 2021 CHBA National Awards for Housing Excellence, Reborn Renovations was awarded the country’s Best Bathroom Renovation for its project “Modern Makeover.” Reborn Renovations was also a country-wide finalist for the best kitchen under $70, 000, on a different project.

Canadian Contractor spoke to Reborn Renovations owner, Danielle Matthews.

This build is an incredible transformation of a typical suburban bungalow into a stunning modern design, inside and out. Please tell us about this award-winning bathroom, Modern Makeover, that secured the win at the 2021 CHBA National Awards for Housing Excellence.

We were very lucky. The clients had an extensive Pinterest board and lots of ideas about what they wanted to do. My coordinator, my assistants and I fleshed out the design. It took about a month and a half, meeting with the client once a week.

We had to absorb a spare bedroom to make room for this bathroom, which was okay because they still had a guest bedroom downstairs.

I was really excited about the moodiness of this project, as we do a lot of white here in Calgary. Every surface of this bathroom is covered and draped in different types of tiles. There are big charcoal tiles surrounding the bathroom, jewel slabs behind the mirrors, corrugated matte black tile behind the tub, and a mixed-pebble mosaic in the floor of the shower.

The under-vanity strip lighting has become quite popular. It’s a nice clean white light, you don’t have to change any bulbs and these ones are on motion sensors – so when the client enters the bathroom in the

middle of the night, they just turn on automatically.

Is it challenging to be cohesive in your whole-house design when the client brings many different ideas to you?

You’ve got to keep the size of the home in mind. A lot of inspirational photos from clients are from large homes and mansions. We are trying to translate that into something suburban – something with nine-foot ceilings versus 10- or 12-foot ceilings in the photos. That translation can get lost sometimes.

To effectively design with such a sleek and modern look, we layer many textures to create interest without a lot of profile.

For example, in this house, we have a lot of flat surfaces – tile, countertops, drawer fronts, boxes, paint, no casings around the windows for the most part – very little detail – all flat. But, there are a lot of layers and textures in this job when you really dissect it. We’ve introduced mixed metals throughout: from the appliances, to the sink, to the plumbing fixtures, to the lighting.

The mixed kitchen cabinetry is highlighted against the bright quartz

slab countertops and backsplash. We used a mixture of lacquered MDF and a product called Uniboard to achieve a grain-matched look throughout the kitchen. I love the juxtaposed contrast of the warm, vertical grain-matched wood against black charcoal cabinetry. I think it’s outstanding. It gives it some life and some punch.

We added some dark wall paneling

behind the master bed for that wow factor but also to carry some moodiness from the bathroom into the bedroom while still maintaining an overall bright space in there.

We make what we call a “selection form” which identifies every material – where it’s going, what it’s doing, all the information, the grout colour. At the time, this renovation had the longest

selection form we’d ever had on a job, due to all the materials. Since then, we’ve had even longer ones.

How do you keep up with kitchen and bathroom design trends?

I think design is something you either have in you, or you don’t. After years of doing this, I realize it’s just like dressing yourself. Nobody teaches

you what’s current or what’s not. You just see people doing it or you read magazines and literature and you start to understand what’s new and what’s coming.

I’ve been through multiple trends. I’ve been through maple cabinets, then espresso cabinets, well into white cabinets. Now we’re into flat-slab blacks and colours. Keeping on-trend means looking for what’s next, being able to dissect it, understand it, and recreate it.

How big is your company and what are you working on now?

We started out as Reborn Kitchens in 2008. Back in the day that’s all we did –kitchens. A lot of successful renovators do that...start with one thing and get really good at it before you take on another thing (basements, additions, etc). That’s how you get good growth. Most builders or renovators that try to take it all on from the get-go end up

crashing and burning. I have watched tons of renovators come and go, and that’s usually the reason.

We got good at kitchens and then we started expanding to the next thing. We move slow and we make sure we’re masters of what we’re doing before we take something on. We didn’t even start with additions and expansions until six years ago.

Here we are, 13 years in and we’re doing our first development.

Our design centre is currently attached to our wood finishing shop, which keeps the quality controlled. Reborn Renovations has the longest warranty in the city of Calgary at five years, so quality is overly important to us.

Our company is pretty large. If you’re counting our trades and subcontractors, we employ well over 200 people. In management, we’re a couple dozen.

In this company, no one is more important than the next person because every job depends on so many key individuals. Each job goes from estimating, to design, to project management, and then it can go to warranty if there is a deficiency. A lot of hands touch these jobs, and we’re only as good as any team member. Good trades are so hard to come by these days. When we get a good tradesperson, we are good to them. We make sure they’re paid on time, have upfront money for materials, and are always provided proper information through our software – addresses, contact information, customer requirements, drawings and material selection forms. All of this makes for a very loyal relationship.

I’m really lucky. I’m one of the few women in this industry. I feel like all of the men I work with are always very respectful – which I can’t say is always the case across the board.

Did you always intend on this career path?

I wanted to be an architect when I was young. My dad was a project manager for commercial high-rises. I loved his blueprints, and I loved that idea. And then as I got older and became a teenager, instead I thought, “How do I make the most amount of money in the quickest amount of time?”

That is what led me into pipeline design in oil and gas. At that time, that sector was booming so that’s where I went. You were allowed to fast track school for those things during the boom, so I did that.

But I hated it. I hated every minute of it. I’m a social butterfly. I like people, I like my clients. I like working with people, I like my work. Every job is like Christmas to me when we get the transformation photos. Sometimes we get small gifts, or a thank you card, or hug for all the blood sweat and tears. I love that because I know the client is truly happy.

What are some challenges you face?

Hours. I work a lot. I’m never off the clock. I’m in my truck right now. That’s what I do. I’m either at the design centre with clients or I’m at job sites.

I’m a mom with a five-year-old son with autism at home. That mom guilt is real.

We went out and assisted with the rebuilds in Fort MacMurray (after the fire). My son was a few months old as I was traveling back and forth doing that.

We didn’t get to where we are without a lot of hard work. I’m hoping within the next couple of years I’ll be able to sit back and enjoy – I keep saying that – but I’m too much of a control freak to not be involved in all the jobs.

What’s next for Reborn Renovations?

We are doing our first ground-up development right now, on the outskirts of Calgary in De Winton. We do a lot of additions and expansions, but this is our first development. It’s great because there’s no unforeseen structural challenges. Its refreshing to build everything new.

We’re really crushing the timeline on it. We’re very very proud of ourselves to be able to keep things moving in light of everything that’s happening with the pandemic and materials shortages.

I’m not sure where it will take us. We already have a busy workload. We do what we’re good at and when someone trusts us to do something else, we do that. It’s been a fun, refreshing adventure: always something different, something new. cc

Plumbing guru Gary Klein explains some basic facts about hot water supply.

By Gary Klein

It’sno mystery what your clients want out of their hot water tap: clean water at the right temperature...and fast. Industry standards call for a 10 second wait for hot water, but few of us get it that quick. Gary Klein of Gary Klein Associates, a California-based plumbing engineer, can explain where the wait comes from and how to calculate what a given piping configuration will deliver.

Spoiler: it’s mostly about the distance from the water heater to the fixture in question.

To see why, take Klein’s typical example of a 2,400-squarefoot two-storey house (approximately 30- by 40-foot footprint) above a basement, with the water heater in the basement and the master bathroom on the second floor diagonally opposite the water heater location.

“I think architects lose their licences if they put the water heater close to the fixtures,” Klein comments.

The distance the piping needs to traverse will be approximately the length plus the width of the house plus the height from water heater to the fixture. Copper pipe rarely runs diagonally, Klein notes, as plumbers are trained to install it rectilinearly with as few fittings as possible. In our example, the line will need to cover 30 feet plus 40 feet plus about 20 feet up (assuming the height of the water heater approximately cancels out the height of the shower fixture on the upper floor). Assuming a 3/4-inch trunk line, every 2.5 feet of pipe contains eight ounces of water. Ninety feet of pipe therefore holds 288 ounces – which equates to 2.25 gallons of roomtemperature water sitting in the hot water pipe at any time. This is the water that has to be flushed out before the person turning the tap on will start to feel warmer water.

hot water and are waiting for it to warm up, it warms slowly rather than suddenly becoming hot. Because of this effect, Klein’s research shows you need to flush closer to 1.5 to 2.5 times the initial volume of cold water before you get water hot enough to shower. So a median multiplier for the volume would be twice the volume in the pipe, which effectively doubles the wait time at the same flow rate.

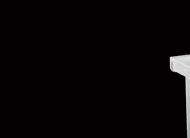

But wait, it gets worse. Maximum allowable water pressure into houses in most North American jurisdictions is 80 pounds per square inch. A 20-foot rise from the basement water heater to the fixture creates a pressure drop of nine psi. Twenty psi is lost in the piping. And the anti-scald valves that most modern shower fixtures have drops the pressure another 11 psi, for a grand total of 40 psi lost. The pressure our homeowner will likely get at the shower fixture is about half of what is coming into the house from the street.

“Looking at the advertised flow rate for shower heads, you’d think it would be a little over a minute before the user would get hot water. But the truth turns out to be more complicated.”

Shower head flow rates are stated as if the shower is being fed at 80 psi. At 40 psi, the flow rate on a twogallon-per-minute shower head drops to 1.4 gpm. (A pressure-compensating shower head can almost fix this.) Now you have to clear out that 4.5 gallons of water at 1.4 gpm instead of two or 2.5. Your wait time for hot water has just crept closer to three minutes. And note that many jurisdictions commonly set household water pressure lower. Toronto, for instance, recommends 50 to 70 psi water pressure in homes.

But wait! What about renovations?

Looking at the advertised flow rate for shower heads of two gallons per minute, you’d think it would be something a little over a minute before the user would get hot water. But the truth turns out to be more complicated. The hot water loses heat to the cold pipe when it initially starts flowing. The pipe has to warm up before the water coming out of the fixture is at full temperature. This is why when you turn on

The above is fine when pipes are exposed or their layout is otherwise known. Klein has developed a protocol that will allow a homeowner or contractor to determine the key information needed to determine where to install a recirculating pump, which can be used to improve water flow in an existing home.

The purpose of the protocol is to understand the layout of the trunks, branches and twigs (sometimes called fixture branches) within the hot water distribution system. This information can be used to determine the applicability of

the installation of one or more demand-activated pumping systems and, if so, where to locate the pump(s).

Klein’s protocol was developed so that the evaluation can be done even whether or not pipes are exposed and visible. While the protocol is written assuming the evaluation will be conducted in a home, it can be used in almost any occupancy.

Measure the full-on flow rate of the hot water outlets. One way to do this is to measure the volume of water that comes out of the outlet within given period of time. (The volume is a function of flow rate multiplied by time.) This can be done one outlet after the other, with the focus on sinks and showers. A simple way to measure flow rate is to turn the tap on full and capture the water for 15 seconds. Pour this water into a measuring container and determine the volume. Convert the result to gallons. Multiply the result times four to get gallons per minute. There are 16 cups in one gallon. Pick any easy multiple of 60 (5, 6, 10, 12, 15, 20 or 30 seconds) to determine how long you want to capture the water. Longer is better than shorter but volume and weight become an issue (10, 12 or 15 seconds are good compromises). Be sure to use the correct multiplier to get gallons per minute. When the flow rates of the hot water outlets are significantly different or they are unknown, it is necessary to measure the volume. When the flow rates can be assumed to be very similar (the water coming out of all the sinks looks and feels about the same), time may be used as a proxy for flow rate.

2 Step 2

Measure the time-to-tap of hot water at each hot water outlet. This test can take several days (or at least long enough between tests for the temperature of the water in the pipes to cool down – it can take several hours). It may be best to ask the occupants to conduct this portion of the test. First thing in the morning, at one sink, turn the hot tap on full and measure the time it takes for hot water to arrive. Write down the time. Do this on successive mornings for the remaining sinks and showers. If there is a tub/shower combination valve, measure the time using the shower. Now multiply the time–to–tap values by the flow rate to get the volume–to–hot.

After completing these timed tests on all the sinks and showers, on the next morning go back to the sink with the largest volume–to–hot and turn the hot water on full hot and measure the time again. It should be similar to when you measured it the first time, but it may not be identical. This is normal. Immediately after you have hot water at this sink, go back to each previously measured hot water outlet, turn the hot water on full hot, measure the time again and write it down. Do this for the showers too, even if you haven’t measured them

before. Compare the measured time (or volume) from the first morning (cold start) and the last morning (hot start for all but the furthest sink). If there is a 50 percent or more decrease in the time from first morning (cold start) to the last morning then the hot water outlet is on the same trunk line as the furthest sink. The higher the percentage reduction, the closer the plumbing fixture is to the trunk line.

You may find that the volume and time did not change much from the cold starts to the day with the hot start at one or more plumbing fixtures. If so, you could repeat Step 3 the next day and see if there is another trunk line (or main branch).

A demand-activated pumping system makes sense to install if the wait and waste is large in a given hot water location (kitchen, bathroom, laundry), and if that location is regularly used, say a kitchen or master bathroom. If there are two or more hot water locations on the trunk line, an activation mechanism can be installed in each location that tells the pump to turn on when hot water is desired. Wired and wireless buttons are the most common mechanisms used to activate the pump when these systems are installed in retrofit applications. If Step 3 indicates there are two or more main branches and these are used regularly, it would then be effective to install a demand-activated pumping system at the end of each main branch. Each main branch gets its own set of activation mechanisms. The pump is generally placed on each branch under the sink furthest from the water heater on the trunk line or at the end of each main branch. Activating the pump shortly before hot water is needed can significantly reduce the time-totap at each commonly used hot water plumbing fixture. cc

Gary Klein is president of Gary Klein and Associates. He has been intimately involved with energy efficiency and renewable energy since 1973. After more than 20 years fixing hot water problems in sustainable building designs, he now spends his days teaching architects, builders and contractors. For more information visit garykleinassociates.com.

What caught our interest

wetwall.com

Wetwall is helping homeowners reimagine their bathrooms with the introduction of two new Wetwall waterproof wall panel system pro designs, Larisis Marble and Augusta Calacatta. These modern yet warm designs are the latest additions to the nature-inspired collection that offers homeowners and designers an easy and affordable way to create a spa-like oasis at home. Larisis Marble features cooltinged greys and wispy streaks throughout an ultra-modern marble pattern to intricately add a graceful, tiled look, without the upkeep, for a clean and casual space. Augusta Calacatta delivers a glamorous look boasting bold, largescale grey veining with warm shadows that offset a milky white background. Ideal for shower walls, bath surrounds, accent walls and cladding, Wetwall eliminates the need for disruptive demolitions, giving installers and DIYers an easy solution to transform new or existing bathrooms. With its simple tongue-and-groove installation system, Wetwall panels can be installed in as little as two and a half hours and don’t require any special tooling. The system is also grout-free, making it simple to maintain and clean. Created with a patented, waterproof core and antimicrobial

The Sanicompact toilet from Saniflo installs quickly and easily anywhere in the home, with no venting required. In addition to handling toilet waste, the toilet can also pump water away from a nearby sink. This fixture saves space through a sleek design that measures 14.5 inches wide and 21.5 inches deep and combines a macerating pump and a tankless toilet bowl into a single fixture. Operating with only one to 1.28 gallons of water per flush, the self-contained toilet uses approximately 38 percent less water than a standard 1.6 gpf toilet.

protection that inhibits the growth of stain- and odorcausing mold and mildew, Wetwall panels are engineered to withstand everyday use with little maintenance required. The system additionally features Aeon enhanced scratch and scruff-resistant performance technology, giving it superior durability and ease. Manufactured in Temple, Texas, Wetwall is Greenguard Gold Certified to meet low chemical emission limits for better indoor air quality. Wetwall is made for residential and commercial settings and is available nationally online.

caesarstone.ca

Celebrating its 35th anniversary in 2022, luxury quartz brand Caesarstone has introduced new, nature-inspired surfaces. The Pebbles Collection is a series of sustainable surfaces in a dynamic palette of warm, grey monochromes laced with softer hues. Like all Caesarstone surfaces, these designs are aimed at effective resilience and timeless benefits: nonporous, durable, hygienic, heat and scratch resistant with low maintenance supporting their commitment to a healthier environment and better use of material resources. The five colours of the Pebbles Collection are:

• 1001 Riverlet: A gentle off-white touched by honied amber capillaries that flow softly across the surface, with a honed finish for a tinge of freshness that reflects more light in the kitchen.