Keeping track

Equipment tracking Pg. 16

Creative Eye Building with hempcrete Pg. 22

FOCUS

Energy efficiency Pg. 26

Keeping track

Equipment tracking Pg. 16

Creative Eye Building with hempcrete Pg. 22

FOCUS

Energy efficiency Pg. 26

Prestige Custom Homes’ owners combine their expertise to create unique experiences.

Page 12

THERE’S MORE WAYS TO HELP YOU GET MORE DONE. Tool, Truck and Large Equipment Rentals. Pro Xtra Loyalty Rewards. Grow your business as a Local Pro with Pro Xtra. Shop Online with a Pro Business Account. Express or Scheduled Jobsite Delivery. Download our Mobile App for on-the-go convenience.

See all the ways at homedepot.ca/wepowerpros

The passion, partnership and vision of Prestige Custom Homes’ owners Karl and Katherine Bach add up to more than the sum of their parts.

2021

22, Number 4

COVER STORY Partners in success 12 Prestige Custom Homes is completely involved in projects and are ready to take on lesser numbers for better service.

Creative Eye: Efficient alternatives 22 Hempcrete Natural Building is creating efficient lightweight houses with an unusual material.

Edge 11 Hey government, can you spare a little change?

track 16 Tool and equipment tracking open up a whole new world of data collection and security.

Dilemma 30 Allison’s construction crew catcalled a woman. What action should she take?

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Canadian Contractor is proud to offer our new job search site dedicated to careers in Canada’s construction trades. Post a job or find a job at canadianjobsite.ca or by clicking Job Board on the Contractor home page.

Call her a contracting broker. In the latest episode of The Hammer, Michelle Kaplan of Better Than New explains her model for connecting contractors and homeowners –and removing headaches for both.

Join Canadian Contractor associate editor, Sukanya Ray Ghosh, for this inspiring series of video interviews with amazing women from the trades.

Follow @CanConMag or look us up on Facebook to add Canadian Contractor to your daily diet of online interaction. New! Check us out on Instagram at canadiancontractor.

After a lot of talk, Ottawa has launched its Greener Homes Grant program. It’s worth about $4 billion over five years and gives homeowners up to $5,000 towards home renovations that meet standards for energy efficiency. Windows, insulation and HVAC systems are the main targets. The feds say up to 700,000 projects will be funded.

The bottom line is the homeowner has to commission an EnerGuide evaluation of their home and the work and the products have to be signed off on by the auditor. Windows and HVAC have to be Energy Starcertified. Normally I’d predict the need for the evaluation and the cost and aggravation of arranging it would kill the program, but the amounts on offer are significant enough to make it worthwhile and the Grant reimburses the homeowner for the evaluation cost once the work is done.

So the question becomes, is providing energy-efficient solutions the kind of thing we should be aligning our businesses toward, or is this a pipe dream that’s going to fizzle in the face of market resistance, as previous energy-efficiency drives have?

The question is more pressing in light of the fact that the Greener Homes Grant can only be viewed as a small gesture towards the scale of the work needed to meet the government’s stated objectives. When Ontario implemented its short-lived GreenON program in 2017, it looked set to burn through its budget of $377 million in less than a year. The Pembina Institute estimates the actual investment needed to bring Canadian homes up to the net-zero-ready standard is more like 13 times the amount budgeted for the program – $26 billion per year. What it means is the whole plan is resting on us selling energy efficiency to our clients, and their willingness to buy it.

In a recent episode of The Hammer, I had a great conversation with Gord Cooke of Building Knowledge about this issue. His insight was that we’ve tried to sell energy efficiency the wrong way for the last 50 years. Most salesmen have traditionally tried to upsell more efficient designs by showing the ROI over time in saved energy costs. This is a tough move to pull off. You’re essentially saying, “Pay me today and I promise you money back tomorrow.” A lot of people have too many trust issues to go for that one. Also, in the past, it was often hard to make those numbers come out attractively with Canada’s relatively low energy prices.

Instead, Cooke recommends a quality, longevity and comfort message. In most cases, building for energy efficiency simply means building to a higher quality standard. Airtightness of the building envelope is the single biggest contributor to a home’s overall efficiency. Aside from being resistant to thermal transmission, energyefficient windows, doors and walls tend to use more durable materials with longer warranties. As for comfort, Cooke relates the story of his grandparents’ home that had a big single-pane picture window in the dining room looking out on a beautiful view...to the west. You needed a bathing suit and sunscreen to sit there on a sunny day. Installing low-E glass in that window returned 200 square feet of living space to the home.

Cooke’s killer close is to point out that we don’t think about ROI when buying TVs or furniture, so why is that the pitch for energyefficient home upgrades? It’s time to shift toward a conversation about the benefits homeowners will experience right away. cc

By Patrick Flannery Editor

” It’s time to change the conversation around energy-efficient renovations.

The Canadian Home Builders’ Association announced the winners of the 2021 CHBA National Awards for Housing Excellence, a competition that recognizes excellence in new homes, renovations, community development, and residential marketing. Over 700 entries were submitted into 53 categories this year. Finalists and winners were selected by a group of nearly 200 judges made up of industry professionals from all over Canada. Frame Custom Homes from Kelowna, BC was the winner of the Design Excellence award for their cumulative results in the new home and new home spaces categories. The Renovation Excellence award for best overall performance in the home renovation categories was awarded to Twin Lions Contracting from North Vancouver, B.C. Following are some of the individual awards won. Best Kitchen Renovation – under $70,000 went to Ultimate Renovations for “Marda Loop Kitchen Transformation.” Best Kitchen Renovation – $70,000 to $100,000 went to Twin Lions Contracting, for its “80’s Makeover” with TLG Millwerks. Best Kitchen Renovation – Over $100,000 was won by Vision Pacific Contracting for “White Gold Revival.” The Best Bathroom Renovation went to Reborn Renovations for “Modern Makeover.” Best Exterior Renovation was awarded to Ultimate Renovations for “The

Roxanne.” Best Renovated Space was won by Ultimate Renovations for “Fast Cars, Whiskey, and Rock and Roll Basement.” Best Renovated Detail award went to Twin Lions Contracting, for “Embracing Change – EV Carport.” Best Whole Home Renovation – under $200,000 was won by Enzo Design Build for “The Aquarius.” Worton Homes won Best Whole Home Renovation –$200,000 to $400,000 for “Clean Slate” with Barber Glass, Ceramic Decor Centre, Patene Building Supplies, Core Electric, CentreStaged, Rona, Cooper Admin and Consulting and Emco. Best Whole Home Renovation – $400,001 to $600,000 award went to Creek Stone Fine Homes for “Mercier Residence.” Best Whole Home Renovation –$600,001 to $800,000 award went to Amsted Design-Build for “Muskoka

Makeover” with Stylehaus Interiors. Twin Lions Contracting won the Best Whole Home Renovation – over $800,000 award for “Making New Memories” with TLG Millwerks. Best Detached Custom Home under 2,000 square feet went to Maric Homes for “Urban Contemporary.” Best Detached Custom Home 2,000 to 3,000 square feet was won by Reid Developments for “Monarch” with Peter Rose Architecture and Interiors. Best Detached Custom Home 3,001 to 4,000 square feet was won by Barrett Group Custom Builders for “All Decked Out.” Best Detached Custom Home 4,001 to 5,000 square feet went to Frame Custom Homes for “The Overlook.” Best Detached Custom Home Over 5,000 square feet went to Frame Custom Homes for “Lakeside Haven.” cc

The Ontario government has passed Bill 288, which replaces the Ontario College of Trades with a new Crown agency called Skilled Trades Ontario. The new agency is designed to consolidate training and certification of apprentices and certified tradespeople under one organization while leaving enforcement of compulsory trades to the Ministry of Labour, Training and Skills Development. The Ministry press release stated:

Under the proposed legislation, Skilled Trades Ontario would become the province’s industry-informed training authority to lead the promotion, research and development of the latest apprenticeship training and curriculum standards. It will also provide a seamless one window experience for clientfacing services including apprentice registration, issuance of certificates and renewals, and conduct equivalency assessments all in one place with many services offered digitally. As recommended by the Skilled Trades Panel’s first report, Ontario will streamline and simplify the apprenticeship system by establishing a new Crown agency. The Ministry will provide system oversight and be responsible for regulatory decisions, financial supports and take on responsibility for compliance and enforcement of the skilled trades, building on existing expertise, best practices and a robust inspector network that is already in place across the province. cc

The total value of building permits remained at historically high levels in April 2021, edging down 0.5 percent to $11.1 billion, following the record set in March. The slight pullback was mainly due to declines in the residential sector in British Columbia and Quebec, which outweighed national gains in the non-residential sector. On a constant dollar basis (2012=100), building permits were largely unchanged. In the residential sector, the value of building permits fell 6.7 percent to $7.7 billion in April. Despite the decrease, this was the second highest value on record. British Columbia (down 23.7 percent) and Quebec (down 14.9 percent) accounted for most of this decline. The value of building permits for multi-family dwellings dropped 6.5 percent to $4.1 billion. Gains in Ontario and Alberta were not enough to offset decreases in British Columbia and Quebec, where several large permits had been issued (in both provinces) during the previous month. Eight provinces reported a decline in the value of permits issued for single-family dwellings, with the national total down seven percent to $3.6 billion, mainly as a result of fewer new projects in Ontario and Quebec. cc

It’s so nice, we’re doing it twice. The Canadian Rental Mart returns to your screens July 20 with a fresh roundup of great conversations, expert education and a chance to browse the latest tech and talk to representatives. This is where home renovation and custom home contractors can touch base with the equipment rental industry and see the latest technology that will be on offer for them in the months and years ahead. During the keynote, platinum sponsor Point of Rental will go over the growing importance of digital technology in the rental world today. In the “Ask the Mechanic” panel, grizzled veterans of the back shops will join Canadian Contractor editor Patrick Flannery to share their tips and tricks – and take your questions – on the most pressing equipment maintenance and repair issues of today. During the “Women in Rental” panel, Canadian Contractor associate editor Sukanya Ray Ghosh will convene an all-star group of successful women to talk about their experiences in the rental industry. At the Equipment Expo, the Rental Mart will be joined by top suppliers of rental-ready equipment for the Canadian market with virtual displays and a chance to interact with live representatives. cc

21_1167_CN_Contractor_JUL_AUG_CN Mod: May 26, 2021 11:15 AM Print: 06/16/21 9:59:25 AM page 1 v7

Natural Resources Canada has launched its portal allowing Canadian homeowners to apply for the Canada Greener Homes Grant, a subsidy of up to $5,000 for qualifying energyefficiency upgrades on residences. An EnerGuide evaluation must be conducted in advance. The program will reimburse the cost of the EnerGuide evaluation if the homeowner completes the full retrofit process. Residents of Quebec need to apply through the RenoClimat programs and residents of Nova Scotia through the Home Energy Assessment program. All others use the NRCan portal. The program is backdated to qualifying retrofits occurring after Dec. 1, 2020. The retrofits must have been recommended by the EnerGuide evaluator. The grant may stack with other grants from the homeowner’s provincial and regional governments. For windows and doors, the homeowner can receive up to $125 per hole for Energy Star windows or sliding glass doors, $250 per hole for Energy Star Most Efficient windows or sliding glass doors and $125 per hole for Energy Star hinged doors. Windows and doors must be purchased in Canada. Insulating an attic to an R-50

rating can attract a rebate of up to $1,800 depending on the former rating. Flat roofs or cathedral ceilings get rebates for insulating to R-28, or increasing the rating by R-20. Exterior walls qualify for up to $5,000 in grants if insulated to an R-20 value or above. All insulation grants are pro-rated for the percentage of the home’s total area being upgraded. Air sealing the home can get grants anywhere from $550 for work that meets the recommendations in the evaluation to $1,000 for renovations that exceed them by 20 percent or more. Replacing manual thermostats with programmable models gets a $50 grant. Heat pump grants range from $5,000 for a full geothermal system down to $2,500 for an Energy Starcertified air source pump. Upgrading to an Energy Star hot water heater pays $3,000. Installing solar panels on a singlefamily home gets a grant of $1,000 per kilowatt generating capacity. There are also grants for installing battery power storage, roofing membrane, foundation waterproofing and moisture-proofing crawlspaces, walls and basement headers. cc

During its meeting with Transport Canada, the Western Retail Lumber Association presented the freight issues being experienced with containers and exorbitant costs that need to be paid in order for containers to be shipped. Container costs have increased 300-500 percent since last year and if vendors aren’t able to pay these increased costs, their containers are sitting in ports full of product. While no solutions were provided during this meeting, the issue is being looked into and WRLA will provide an update as soon as they are able. Resins and petrochemical plants are not 100 percent back online. WRLA anticipates that by July 1, plants will be functioning at 90 percent, which means that inventory levels won’t return to normal until August or September. Lumber in some areas is starting to be more readily available. Engineered wood products are the number one constraint in the Canadian market and new construction will consume all the available EWP this year. Oriented strand board is on short supply, and WRLA cautions about the use of offshore material that has made its way into the market. It is important to check with building offices if product substitutions plan to be used. Treated lumber such as fence boards, decking and timbers are in very tight supply. Severe supply constraints continue and price increases need to be expected. The shortages will add further pressure to exterior sheathing in the summer months. Price increases expect to continue in all lines of insulation. Demand for mineral wool, blowing wool and batts continues to outstrip supply for a majority of 2021 and lead times will remain fairly consistent. With steel studs, demand outstrips mill capacity, which has led to

major shortages. The roofing situation varies with suppliers, some supply is on allocation while other manufacturers are in a good position. Granules have become an issue for some manufacturers, which could increase lead times as supply is picked up. Expect price increases on roofing products as well as accessories since the plastic components are impacted by resin availability and challenges. Pricing of interior doors is expected to climb, and product allocations have been imposed by some manufacturers while others have been able to increase their capacity to supply the market. The demand for interior doors has almost doubled over the past year, as such some manufacturers have been investing heavily into capacity. Pricing for mouldings expects to remain volatile with more inventory allocations to be expected. Expect some increased prices on some windows and exterior door product lines. Resin availability has created some disruptions. Some suppliers have product more readily available than others. Steel doors have become an issue due to lack of material, however substitutions are readily available. Price increases and long lead times have been experienced for vinyl siding and aluminum. Steel prices continue to escalate and lead times will vary based on supplier availability of product. Some colours are low or out of stock. For paints and adhesives, there continues to be shortages and issues related to resin as well as spray cans, so products are on allocation and price increases have been experienced. Concrete products such as retaining walls, paving stones and slabs have a limited offering and demand has been outstripping supply. cc

By Casey Edge

Occasionally, I hear from government officials and consultants complaining about how builders are unwilling to change. The complaint often arises when builders express concern about jumping into new regulations lacking research diligence such as fast-tracking net zero housing in B.C.’s Step Code.

B.C. Step Code is actually a Leap Code, where several Vancouver region municipalities plan to launch into Net Zero Step 5 this year – about 11 years earlier than the government’s target of 2032.

In light of past energy-efficiency debacles such as leaky condo, asbestos insulation and urea formaldehyde, it’s understandable that responsible builders want to prioritize health and safety first and minimize any unintended consequences.

Municipalities leaping into Step 5 open the door to issues such as higher radon levels, especially where there is often no requirement for radon rough-in mitigation. High radon levels are site-specific. Relying on B.C.’s radon map is a recipe for disaster.

The Canadian Association of Radon Scientists and Technicians (CARST) offered presentations at their recent conference, offering the following observations. Canada has the third highest radon levels in the world. Radon is Canada’s second-highest cause of lung cancer. Increasing airtightness can elevate radon by 56.6 percent. Tests in the Vancouver region reveal over 600 bq, Canada’s maximum is 200 bq. First-time homebuyers (that is, between ages 24 and 44) have limited financial resources that preclude buying or renting in more established neighbourhoods with less energy-efficient homes. They tend to buy in more affordable areas with modern home designs that are also energy efficient. Younger Canadians are being disproportionately exposed to higher radon and projections paint an alarming picture of rising exposure, along with younger ages of radoninduced lung cancer.Clearly, caution is warranted, which is why the National Building Code is reviewing radon and other potential unintended consequences of very energyefficient homes.

The B.C. government circumvented this review, enabling municipalities to leap into any level of energy efficiency several years ago. In doing so, the B.C. government also ignored their agreement to harmonize the B.C. Building Code with the National Building Code, abandoning this health and safety diligence fundamentally important to building codes. The point is not to oppose energy efficiency, but to ensure any change to the building code is done responsibly with the primary goal of health and safety and consumer protection.

Which brings us to the original complaint of builders allegedly unwilling to change. Ironically, it is the government that has a history of unwillingness to change. Governments are always fast and ready to impose new regulations on builders and change their business model. But when it comes to their own organizations, governments refuse to make changes that would significantly boost housing affordability and create more skilled trades – both alleged goals. For example, provincial governments have the power to require municipalities to re-zone for higher density and make development approvals more efficient. Provinces have the power to refuse triple-digit increases to municipal development cost charges. They have the power to rein in permit fees, often charged erroneously on the cost of construction rather than a fee for service. Rising prices for materials and labour enable some municipalities to accumulate big surpluses for inspections while their new housing starts actually decline. Yet, provincial governments usually decline to take municipalities to task citing the importance of municipal self-determination. In other words, they are unwilling to change a failed governance structure driving up housing prices.

The CD Howe Institute’s most recent study, called “Gimme shelter: How high municipal housing charges and taxes decrease housing supply,” says “Vancouver’s housing regulation costs are by far the largest in Canada, resulting in an extra cost of $644,000 for the average new house. Elsewhere in Canada – Vancouver, Abbotsford, Victoria, Kelowna, Regina, Calgary, Toronto and Ottawa-Gatineau – homebuyers paid an average $230,000 extra on a new house because of limits on supply.”

Change is also lacking in the government-funded, education system which continues to operate in silos. To address the extreme shortage of skilled trades, provinces could instruct universities to accept skilled trades, such as carpentry, as electives for degrees in arts and sciences. These electives would offer a more well-rounded education and provide employable skills during the summer and immediately after graduation. Some students might even choose to pursue construction as a career, after their initial introduction to skills training.

Yet that would again change the existing dysfunctional governance model. So, before government regulators and their supporters jump on their favourite hobby horse of criticizing builders for reluctance to change, they should first look in the mirror. cc

Casey Edge is executive director of the Victoria Residential Builders Association.

The owners of Prestige Custom Homes combine their expertise to give life to dream homes.

Sukanya Ray Ghosh

Located in Mississauga, Ont., Prestige Custom Homes has been creating dream homes for its clients since 1995. Karl Bach, owner of the company, is a second-generation builder and contractor. The company’s roots go back to where Jan Bach, the company’s founder, first ventured into the home renovation and construction industry more than 30 years ago. In 2004, Karl joined his father. Now together, they have over 40 years of combined building experience.

“I was doing a little bit of framing, I was helping with electrical and many other things initially. As time went on, I started managing all the projects more and more. We continued working together, all the way up until two years ago,” says Karl.

While Jan has phased out of the business, Prestige Custom Homes now has a new family member. Karl’s wife Katherine entered the picture a few years back and is now an integral part of the business.

While doing extensive home renovations is still part of their business, building custom homes will always be the primary focus of the company.

“We’ve recently transitioned more into custom homes. But over the years, we’ve done some large-scale renovation projects and additions. We’ve taken older larger homes, gutted them to the bone and overhauled them completely,” says Karl.

Involved throughout

Being in this niche business, Karl has never brought in other foremen or other staff to oversee his projects and the

Karl and Katherine Bach’s complementary skills are instrumental in creating boutique-style services for their clients.

Katherine finds the vision, Karl gets it done.

“We are offering our clients a boutique-style experience.”

business operations. Prestige Custom Homes has always been involved in all aspects of its projects. The company likes to have control. This is why they never take on too many projects at once. And this, says Karl, has helped immensely with the management of his trades. Most importantly, the clients deal directly with them and there are no misunderstandings.

“Our projects run smoothly and this method keeps our customers happy. People like this working style as we are always there and completely focussed on their project,” explains Karl.

Some may think this might be a drawback for the growth of their business because they cannot take on too many projects. However, Karl says that they have always stuck to this system so that they can remain in control and keep their reputation intact. Typically, the company takes on three to four major projects in a year. They are primarily large-scale

projects, such as custom homes between 4,000 and 8,000 square feet or complete remodels. The company also takes smaller projects for existing clients.

Karl notes that although Prestige Custom Homes has not faced a single major challenging project, there have been some projects with very strict timelines. Prestige’s team completed these projects in their entirety on time, leaving the clients pleasantly surprised and happy. Karl adds that even with the rush, quality was never compromised. He attributes the success of these projects to the people who work with him on them.

“Over the years, working together with all of our trades, we have become a tight knit community. They work very well as a team and are able to do quality work quickly and efficiently,” he says.

The success of Prestige Custom Homes has been driven by the strong partnerships between the people at the helm of the affairs. It started with Jan and Karl and today it has moved on to Karl and Katherine.

Karl says that growing up in this industry has given him an advantage. “I had an advantage because it is difficult to start a business from scratch. I always had my dad guiding me at the beginning.”

However, it was not all smooth sailing for them as they clashed a lot on differences of opinion. “We got through it.

Prestige only does three to four large-scale custom homes or renovations in a year. Quality over quantity is the maxim.

And then he got older and I got older and wiser. So, that evened things out.

Jan still shows up at the sites even though he is not actively involved any more. He’s proud of Karl and he still likes to stay connected with his projects. Over the past few years, Katherine has become a part of the operations more and more. This partnership has worked well from the get go.

“Katherine handles the selection processes. She deals with clients, answers their questions, tells them where to buy things and what questions to ask,” explains Karl.

Interestingly, Katherine designs all of the cabinetry for Prestige’s projects. People, says Karl, love the aspect of the husband-wife team working together. There is less chance of error and communication gaps.

Katherine Bach is a trained teacher; she does not have a formal background in construction or a degree in a related subject. She developed a passion for interior design when she met Karl about 19 years ago. Since then, she experimented with designs and realised that she loved it. When Karl and his father worked together, Katherine would come in with ideas and inputs, help with the overall design of the homes and she also helped stage the homes.

Over the last few years, Katherine has become interested specifically in cabinetry design. She decided to pursue her interest further by taking courses and learning more about

how to design kitchen millwork for custom homes.

“Over the past two years, I have been working closely together with our clients. I design their kitchens and other millwork in the home. What started out as a passion has now turned into Karl and I becoming business partners. We are offering our clients a boutique-style experience where we provide in-house design services. People do not have to bring in their own designer. Karl and I work together to bring their vision to life,” explains Katherine.

Initially, there were some hard parts to this business partnership. Since Karl and Katherine are married, it was difficult to set boundaries about when to discuss business and when not to. That hurdle has now been overcome; both have found their groove and know when and how to work.

“I work separately from Karl, but also together. Both of us collaborate with our clients on different things. Things are a lot smoother now. We bring in our ideas, opinions and inputs,” says Katherine.

They now have a vision of how they want to see their business prosper in the future. In the meantime, Katherine has learnt a lot from Karl and his experience in the industry.

The most memorable project that Karl and Katherine have worked on was creating their own home. It was an interesting collaboration for them. They complement each other at work and they were able to bring in their ideas for their shared home. It was a learning opportunity. And it was also the real solid beginning of their work partnership.

Karl has a special interest in energy efficiency. When building their home, he was able to experiment with energy efficiency, learn from mistakes and pass the experience on to his customers.

Karl says that over the years he has experimented a lot with energy efficiency, including with materials and technologies. “I’ve taken many workshops, and always try to improve the efficiency of homes, understanding the whole building science. I believe that’s how you become an expert in your field, if you know the whole science behind how the house works.”

He is able to advise and educate his clients on energy efficiency by guiding them on their choice of windows and insulation. He educated clients on how these choices impact energy bills even though they cost a bit more initially. Karl wishes to build a Passive Home someday. He diligently keeps track of all the developments in this area.

Just as Karl educates clients on energy efficiency, Katherine is able to guide them on making the right millwork choices and selecting the most suitable designs for their home. For example, being a mother has given her an insight into certain designs and materials that might not work best when there are little children in the house. The idea is to ensure that clients love their home and find it practical as well.

The path ahead

Coming into the industry with no background knowledge was challenging for Katherine. She was afraid to ask the wrong question and look inexperienced. So, Karl was the one who had the conversations with the trades. Now, she feels empowered. Karl’s main focus remains dealing with the trades team. He supervises them and gets them on board for project execution. Katherine works strictly with clients and also enjoys a strong relationship with the kitchen company they work with.

Despite being successful at what they do, both Karl and Katherine have thoughts about the future of Prestige Custom Homes that keep them up at night. Karl is constantly thinking about the work they do and about what lies in store for the next day or the week after. There are things that could go wrong, so he likes to think ahead to prevent problems before they happen.

Katherine’s thoughts, on the other hand, go to what the next project is going to be or how to design the next kitchen.

“I think about where we’re going to be in the future and how to ramp up our social media presence. And I get excited about all the new innovations taking place in our industry. I like to follow other designers on social media and learn from them and ask them questions,” she explains. cc

Telematics and remote tool tracking is making equipment maintenance, theft prevention and data collection easier for everyone involved.

By Andrew Snook

No matter the number of pieces of equipment in one’s inventory, a contractor wants to know where it all is, at all times. Of course, the larger a fleet and crib of tools grows, and the more jobsites a company works on simultaneously, the harder it becomes to keep track of that equipment. To counter these challenges, manufacturers, equipment dealers and rental houses are increasingly adopting various types of wireless tracking tools integrated into the equipment’s electronics suite.

Being able to track equipment in real time offers contractors the ability to know where their vehicles are located on a jobsite and how efficiently they are being used. Telematics are also an excellent theft deterrent.

“Some contractors have multiple divisions within them and will have smaller child companies that will use all the assets [from the parent company] but will get billed for them. For example, the excavation division has an asset right now for X amount of time and will be billed X for that asset,” explains Peter Gibbons, regional technology manager for Finning Canada in Surrey, B.C., adding that he has one customer with 16 different companies under one parent company. “Part of using it is

just keeping track of where all these different types of assets are.”

Equipment can be tagged with locators that can be tracked via cellular or satellite. Gibbons says it typically takes three to five minutes to ping the location of a piece of equipment, depending on the reception in a geographic area.

“They can ping their location to know where those devices are at,” he says, adding that being able to track equipment can aid in its recovery. “If they can’t find it when they ping it and find out it’s in a far-off area, they can contact the police, send them over that data and they can go have a look and investigate.”

Connected monitoring

Gibbons says insurance considerations are another important aspect of being able to track equipment use, especially in the case of a rental house.

“If an accident happens while in possession of a company, it goes on their insurance,” he says.

At Finning Canada, customers can set up telematics subscriptions at various levels for reporting purposes.

“You can have reports every 10 minutes, every hour, every week… we can change a subscription and see every 10 minutes and track a machine as it goes down the highway,” Gibbons says, adding that customers can start with very basic telematics packages and add on various reports as they need them so they do not get bogged down in unnecessary data. “Contractors will set up their job sites and have all sorts of different devices on that site, and we can geofence them. There’s lots of applications for geofencing these days. I can tell when a machine leaves one geofence to go into another geofence. It’s important because they’ll have different groups running the different parts off the site, so when one machine goes to another part of a site, it’s under the responsibility of someone else. It’s basically taking paperwork and turning it into digital and making it much faster.”

“Being able to track equipment in real time offers contractors the ability to know where their vehicles are located on a jobsite and how efficiently they are being used, among various other advantages.”

Maintenance is easy and on time with telematics-equipped machinery. There is also no need to crawl under dirty equipment to check how well it is functioning. Real-time tracking can provide that data to users in an instant.

Tracking the operation of heavy equipment can be especially handy for preventative maintenance purposes.

“We don’t have to call the customer to know the hours. We know your service is coming up,” Gibbons says. “We can call and say, ‘Are you okay with us coming to do the service?”

Before we had to call or drop by, it just wasn’t very productive – and this helps customers stay on top of it.”

Just don’t expect older equipment to

offer the same level of quality data as the newer gear.

“An older generator from the ‘90s or ‘80s, we’re really only going to get hours and location, but when you get into newer machines, you can see engine codes, fuel burns, machines

telling you transmission temperatures, the operator running the machine,” Gibbons says.

Emissions targets

Gibbons says that by tracking utilization and fuel burn, Finning has been able to establish the emissions being produced by vehicles in a customer’s fleets and help them understand the sustainability targets they are trying to meet.

“Sustainability is a big part of the construction industry. A lot of contractor clients want to be a part of the solution,” Gibbons says.

“Older equipment from the ‘80s or ‘90s will not provide the same level of quality data as the newer equipment do. You can see engine codes, fuel burns, transmission temperatures and more.”

Tool tracking

A few years ago, Milwaukee Tool introduced a solution for tracking smaller tools across multiple jobsites called One-Key, an inventory management, security and smart tool solution. Currently, the technology is offered on more than 40 Milwaukee Tools products.

“This targets the whole construction industry, provides inventory management and tool theft solutions,” says Casey Roberts, senior key account manager for Milwaukee Tool.

One-Key is a Bluetooth-based technology with customizable settings that allows the user to track the performance of their tools and keep track of where they are on various jobsites for assistance with inventory management.

“What makes this so cool is that you can be as custom and granular as you like, or as generic as you like. It has the ability to tailor to the needs of whoever that user is. It’s not just a user with a crib full of Milwaukee Tool products, it can be anyone in the construction space,” Roberts says. “You can manage excavators, compressors – they can be incorporated into this software, not just Milwaukee Tools.”

While a contractor can use the app on their phone to input all of their tools into the One-Key inventory management software, Milwaukee Tool products equipped with the OneKey Bluetooth solution comes with additional advantages. For example, with a drill, the user can program through the app whether they want to ramp up the RPMs or ramp them down.

“It can get the performance of the tool, provide reports, accuracy of your work… you can actually go in and make sure it reads full hydraulic pressure,” Roberts says.

When a tool goes missing, One-Key takes advantage of its network made up of hundreds of thousands of tools to help locate it. Signals from devices in range of your tool pings you its location, even if its battery has been removed. Bluetooth-enabled tool and equipment trackers offer updates of

the most recent date, time and location for a tool in your network when it comes within 100 feet of the network.

“It’s constantly pinging looking for a tower or app and gives updates to where a tool is within about a 100foot range inside buildings and up to around 200 feet outdoors,” Roberts says. “With One-Key technology

there’s a little bit of a premium cost in the cost of the tool, but nothing more than that.”

The One-Key system also acts as a theft deterrent, as the user can lockout their tools making them useless for the thieves.

“This makes it a lot less attractive to steal the tool,” Roberts says. cc

The company leads the industry in developing innovative solutions that deliver increased productivity, unmatched durability, and an unwavering commitment to its users.

The acceptance of cordless power tools on construction sites is quickly evolving. With the continuous evolution of lithium-ion battery technologies, contractors are more willing than ever to say goodbye to their traditional corded power tools. Cutting the cord on traditional power tools has been made possible by manufacturers that have been willing to embrace lithium-ion battery technology for contractors’ cordless solutions.

Techtronic Industries (TTi), the parent company for Milwaukee Tool, has been leading the pack when it comes to lithium-ion battery technology. Headquartered in Hong Kong,

the company owns a wide variety of quality brands in addition to Milwaukee Tool, including RYOBI, Empire, Stiletto, Hoover and Dirt Devil.

Becoming the world leader in cordless power tools fuelled by lithium-ion battery technology came at a shockingly feverish pace for TTi, as the company had zero market share of the cordless power tool market back in 2007.

One reason for TTi’s success in Canada was the appointment of Craig Baxter as President of Techtronic Industries Canada Inc. Baxter had been immersed in the power tool industry for more than 25 years, working to build a variety of power tool

brands in the Canadian marketplace, including DeWalt, Irwin and Lenox prior to joining TTi.

Baxter joined Milwaukee Tool in 2007 and recalls the amazing transformation of the company’s cordless tool division.

“It’s been a real journey. The company’s overall market share was small single digits when we got started, and now we will reach close to 45% this year,” Baxter says.

He says it was very advantageous that Milwaukee Tool had such a small share of the power tool market when he came on board.

“That was fortunate because, back then, nickel-cadmium was 90 per

cent of the market,” he says. “We had competitors tied to antiquated technologies. We saw the future driven by lithium-ion so we wrote off our 3% per cent market share and focused on lithium-ion. We were able to see and create a future that was far superior in the performance of cordless tools.”

cent of the market,” he says. “We had competitors tied to antiquated technologies. We saw the future driven by lithium-ion so we wrote off our 3% per cent market share and focused on lithium-ion. We were able to see and create a future that was far superior in the performance of cordless tools.”

Milwaukee was first to market exclusively with lithium-ion battery technology. Their first cordless platform was M12 and today M12 leads the market as the largest sub-compact tool platform with over 100 tools. M12 focuses on providing portable productivity for the most demanding trades.

Milwaukee was first to market exclusively with lithium-ion battery technology. Their first cordless platform was M12 and today M12 leads the market as the largest sub-compact tool platform with over 100 tools. M12 focuses on providing portable productivity for the most demanding trades.

Following the success of M12, Milwaukee launched M18 which focuses on performance driven solutions, truly aimed at cutting the cord on jobsites. Today, M18 has over 175 trade focused solutions. The company recently rolled out its latest line of cordless technology with the introduction the MX FUEL Equipment system, a groundbreaking cordless line up that revolutionizes the light equipment market by delivering the performance, run-time, and durability demanded by the trades without the hazards associated with emissions, noise, vibration, and the frustrations of gas maintenance. Each of the solutions on the MX FUEL System go beyond the limitations of gasoline and the inconvenience of cords and operate off one completely compatible system all on the same battery.

Following the success of M12, Milwaukee launched M18 which focuses on performance driven solutions, truly aimed at cutting the cord on jobsites. Today, M18 has over 175 trade focused solutions. The company recently rolled out its latest line of cordless technology with the introduction the MX FUEL Equipment system, a groundbreaking cordless line up that revolutionizes the light equipment market by delivering the performance, run-time, and durability demanded by the trades without the hazards associated with emissions, noise, vibration, and the frustrations of gas maintenance. Each of the solutions on the MX FUEL System go beyond the limitations of gasoline and the inconvenience of cords and operate off one completely compatible system all on the same battery.

This latest innovation in cordless tools and technologies shares the same successful approach as its predecessors: Milwaukee Tool’s unwavering dedication to its end users.

This latest innovation in cordless tools and technologies shares the same successful approach as its predecessors: Milwaukee Tool’s unwavering dedication to its end users.

“We obsess with end user engagement,” Baxter says. “Our core trades share pain points that result in the forward-thinking solutions that we bring to market. Back in 2007, we focused on plumbing, electrical and mechanical contractors. Since then, we have adopted some additional verticals, including transportation, automotive and the residential contractor. We speak to hundreds of users within those verticals and develop solutions that are very tailored to those individuals and their needs.”

“We obsess with end user engagement,” Baxter says. “Our core trades share pain points that result in the forward-thinking solutions that we bring to market. Back in 2007, we focused on plumbing, electrical and mechanical contractors. Since then, we have adopted some additional verticals, including transportation, automotive and the residential contractor. We speak to hundreds of users within those verticals and develop solutions that are very tailored to those individuals and their needs.”

For example, Milwaukee is launching a number of new products designed for residential contractors, and we’re seeing immediate success in our solutions for them,” Baxter says, adding that Milwaukee Tool has entered the laser-measurement market, as well as recently launching a rear-handle circ saw, a framing nail-

For example, Milwaukee is launching a number of new products designed for residential contractors, and we’re seeing immediate success in our solutions for them,” Baxter says, adding that Milwaukee Tool has entered the laser-measurement market, as well as recently launching a rear-handle circ saw, a framing nail-

er and several other tools designed with residential contractors in mind. “There’s more to come in terms of tools we’re launching for residential and general construction.”

er and several other tools designed with residential contractors in mind. “There’s more to come in terms of tools we’re launching for residential and general construction.”

Baxter says the do-it-yourself or retail segment of the power tool market has never been a focus for Milwaukee Tool.

Baxter says the do-it-yourself or retail segment of the power tool market has never been a focus for Milwaukee Tool.

“We are focused on our core trades. That has allowed us to focus on professional grade products—everything from the battery through to the software that enables the battery to speak to the operating end of the tool,” Baxter says.

“We are focused on our core trades. That has allowed us to focus on professional grade products—everything from the battery through to the software that enables the battery to speak to the operating end of the tool,” Baxter says.

Developing hundreds of successful product solutions for users over the past 15 years has been made possible by listening to our core trades’ frustrations, needs and limitations. Milwaukee invests tremendous time with their users in order to understand the demands on the jobsite, ultimately providing solutions leading to a more productive and safer jobsite. Simply put, Milwaukee Tool is not a manufacturer, they are a progressive problem solver.

Developing hundreds of successful product solutions for users over the past 15 years has been made possible by listening to our core trades’ frustrations, needs and limitations. Milwaukee invests tremendous time with their users in order to understand the demands on the jobsite, ultimately providing solutions leading to a more productive and safer jobsite. Simply put, Milwaukee Tool is not a manufacturer, they are a progressive problem solver.

“We continuously rework prototypes until the users tells us we got it right and, that’s why so few of our products fail. We will simply not launch a product until it’s right,” Baxter says.

“We continuously rework prototypes until the users tells us we got it right and, that’s why so few of our products fail. We will simply not launch a product until it’s right,” Baxter says.

Milwaukee Tool’s new MX FUEL Equipment System also features the company’s REDLITHIUM and REDLINK Plus Intelligence technologies. These innovations allow the user to optimize their tool performance and overload protection using total system communication between the tool, battery, and charger.

Milwaukee Tool’s new MX FUEL Equipment System also features the company’s REDLITHIUM and REDLINK Plus Intelligence technologies. These innovations allow the user to optimize their tool performance and overload protection using total system communication between the tool, battery, and charger.

Another user benefit of Milwaukee Tool’s battery platform is the 100% compatibility of their lithium-ion batteries, with any tool they have ever launched within their M12 and M18 platforms. Their tool/battery interfaces have never changed.

Another user benefit of Milwaukee Tool’s battery platform is the 100% compatibility of their lithium-ion batteries, with any tool they have ever launched within their M12 and M18 platforms. Their tool/battery interfaces have never changed.

“Being able to put the same battery into all of the tools in your crib is very compelling to our user base,” Baxter says.

“Being able to put the same battery into all of the tools in your crib is very compelling to our user base,” Baxter says.

Power tools tend to go missing on jobsites for a variety of reasons, so keeping track of them was another

Power tools tend to go missing on jobsites for a variety of reasons, so keeping track of them was another

factor Milwaukee Tool considered when developing its MX FUEL line of product solutions. As part of the company’s intelligent solutions strategy for contractors, Milwaukee Tool developed the ONE-KEY app that allows for the remote tracking and inventory management of the user’s power tools.

factor Milwaukee Tool considered when developing its MX FUEL line of product solutions. As part of the company’s intelligent solutions strategy for contractors, Milwaukee Tool developed the ONE-KEY app that allows for the remote tracking and inventory management of the user’s power tools.

“Contractors want to keep track of when that tool leaves a crib. They want to know it’s coming back at the end of the day,” Baxter says.

“Contractors want to keep track of when that tool leaves a crib. They want to know it’s coming back at the end of the day,” Baxter says.

Another advantage of using Milwaukee Tool’s line of intelligent tools is the ability to measure the productivity that a tool has delivered during a workday or shift.

Another advantage of using Milwaukee Tool’s line of intelligent tools is the ability to measure the productivity that a tool has delivered during a workday or shift.

“It’s important to understand that the technology involved in cordless tools today allows us to maximize each tool’s performance,” Baxter says. “The software for the battery and the operating end of tool speak to each other. We have figured out how to build intelligence into the tools, and maximize productivity by doing so. Contractors can download and understand a tool’s real-world performance. That is an advancement that’s really only taken place in the last five years. We blazed a trail there. We’re on our fourth version of the software in our products, and our competitors are just trying to figure it out now.”

“It’s important to understand that the technology involved in cordless tools today allows us to maximize each tool’s performance,” Baxter says. “The software for the battery and the operating end of tool speak to each other. We have figured out how to build intelligence into the tools, and maximize productivity by doing so. Contractors can download and understand a tool’s real-world performance. That is an advancement that’s really only taken place in the last five years. We blazed a trail there. We’re on our fourth version of the software in our products, and our competitors are just trying to figure it out now.”

Milwaukee continues to forge the path as the leader in lithium-ion battery technology and is working with its end users on creating solutions that will continue to allow their contractor base to complete more work in less time.

Milwaukee continues to forge the path as the leader in lithium-ion battery technology and is working with its end users on creating solutions that will continue to allow their contractor base to complete more work in less time.

Yet, despite Milwaukee Tool’s popularity among contractors for producing world-leading power tools, the company does not consider itself a power tool company.

Yet, despite Milwaukee Tool’s popularity among contractors for producing world-leading power tools, the company does not consider itself a power tool company.

“We look at ourselves as a solutions and productivity company,” Baxter says. “That changes the way you approach your research with the user. What has really separated Milwaukee is our obsession with disruptive innovation—new-to-world solutions so compelling to our core trades that we’ve built enormous equity with them by launching one solution after another.”

“We look at ourselves as a solutions and productivity company,” Baxter says. “That changes the way you approach your research with the user. What has really separated Milwaukee is our obsession with disruptive innovation—new-to-world solutions so compelling to our core trades that we’ve built enormous equity with them by launching one solution after another.”

“There are solutions today that we are working on that will bend your mind,” Baxter says.

“There are solutions today that we are working on that will bend your mind,” Baxter says.

To learn more about Milwaukee Tool’s solutions and products, visit www.milwaukeetool.ca

To learn more about Milwaukee Tool’s solutions and products, visit www.milwaukeetool.ca

By Gordon Wornoff

InNovember, Canadian Contractor closed submissions for the 2020 GRK Contest where one lucky Canadian contractor won $5000 worth of GRK fasteners and a Paslode XP framing nailer.

The winner, Jayeson Hendyrsan, is one of Canada’s most adept craftsmen in building mass walls from lightweight concrete. He is a co-founder of Hempcrete Natural Building, on Bowen Island, B.C.

How did you first start out?

I had been doing construction in Vancouver and then moved out to a small island off the coast of Vancouver in 1999. I wanted to build a home from alternative materials and experimented with lightweight concretes. A friendly neighbour was an engineer with a PhD

in concrete. He was from England, where hempcrete was more commonplace. He advised against using straw as a concrete additive because it rots.

So, we built our first house with hempcrete in 2002. It was a ranch style and it was a big risk at the time. We had two carpenters helping us and the one guy didn’t like it at all. I thought he was going to bail at any moment.

The home turned out so well it energized us. We dramatically increased our efficiency on the next build. Since then we’ve built over a dozen single family dwellings, multiple outdoor projects, hempcrete art projects, commercial projects. We incorporated in 2006.

We had a large crew for our first house and it took us three months to finish the hempcrete portion on a

1,000 square foot house. Our second, 2,200 square foot house took us nine weeks with half the crew. Now, if we have a good-sized crew, we can do a 2,500 square foot house in 10 days. We average between four and 12 employees at a time, and we subcontract a lot.

We were focused on single family dwellings up until about three years ago. I realized I was never going to solve the problems of the world – or even problems in my community – by building one-off houses. These houses are very time- and energy-consuming so we looked at ways to affect the housing supply crisis in a positive way. We were a boutique company, ready to grow – so we put energy into creating designs that could be implemented anywhere in the country. We have models from 300 square feet to 1,200 square feet.

hempcrete builder.

Our first project like this was a design collaboration with a friend in Alberta. You’ve got frost-heave and uneven terrain out there, so it’s a common solution to build small houses on skids. I also built something like this at my own place, so we’ve done a few prototypes before this one.

We call this a “not-so-tiny” house.

We’ve kind of gone underground for the last three years, developing these prefab designs. It’s been an intense and prolonged R and D process to work out all the kinks. We also started building hempcrete houses on metal frames. Like a little mobile chalet.

You won the GRK Grand prize for a hempcrete home on a metal frame. Tell us some of the details.

It’s about 1,100 square feet with the addition. It’s a cute little two-bedroom house. As far as I know, it’s the first hempcrete home of its kind built by a licenced hempcrete builder and fully insured by a new home warranty. This is so key – no one else has gone to this extent with hempcrete – to become a licenced, insured, commercial

A tiny house can be a Cinderella fantasy for people who want to tow around their home like a trailer yet still be able to preserve a batch of tomatoes or process wild game. There’s no kitchen for that. We think the minimum size should be 600 square feet for a home with a modest footprint that can support a resilient lifestyle.

We built the house under a very large construction tent in a gravel pit. We pulled it out, put the roof on it and finished everything. We sold it and delivered it to the client’s place. They wanted a larger kitchen so we built an addition on-site.

This is one of our potential models for a housing solution. The whole idea is that all the expensive stuff – the mechanical, the heating, the electrical, the plumbing – would be delivered in

the two-storey box. Then you’d have the ability to hang one-storey additions off all four sides potentially. Our website shows all these conceptual plans. That house is almost entirely built from GRK screws. The whole roof is fastened with #12, four-inch GRKs –that’s my favourite for framing. For earthquake resistance, our double top plate assembly is #12, four-inch screws into the first plate and the RSS three-eighth by six inches into the second top plate. We have four screws fastening the top plates into each twoby-six stud.

Europe is way ahead of us. They’re building row-housing, Costco’s, Walmart’s, industrial spaces out of hempcrete. In the early 1980’s, the French got onto the hempcrete. They sampled old Roman aqueducts and architecture and found it was a mixture of hemp, lime, oyster shells, volcanic ash, and whatever else they had. They had discovered how to make concrete that lasts thousands of years. In Europe, because land is so expensive, developers own, maintain, and rent out

office space, storefronts and dwellings as a source of income. They are drawn towards energy efficiency, low maintenance costs, and longevity in their projects because they are involved for decades and decades. In North America, developers build and sell and walk away.

We’re building carbon-neutral, earthquake and flood-resistant, soundproof, fireproof, mould-proof, rotproof, carpenter ant-proof houses on par, or potentially less than a new build nowadays. It’s a mass wall system made from fibre-reinforced lightweight concrete wrapped around a traditional timber frame or metal frame structure. We get rid of the exterior cladding, the vapour barriers, the insulation, the spray foams, the drywall – all of these things that take so much time and energy to erect but also to make. We don’t talk about energy input and the carbon cost of producing and bringing vinyl from overseas… and then throwing it in the landfill in 20 years. I’ve got the numbers on hempcrete and it is carbon-neutral and in 20 years can even be carbon-negative.

What are some problems you see within the building industry?

Bureaucracy and insurance have taken over the building industry. Don’t get me

wrong, I’m part of the system, and I love our insurance provider, WBI, they’re amazing. But this is a real example – I have a friend who was forced to spend an extra $200,000 to create an additional 10 percent efficiency on his project. They aren’t even counting carbon inputs. All these good intentions have been trodden by actual outcomes. I have it from three sources high up in boardrooms of large insurance companies that the failure rate of these complex, airtight building systems based on mechanical efficiency are starting to show a significant failure rate. I know a Vancouver guy high up in the homebuilding insurance industry who just bought an older condo for a higher price rather than a newer condo for a lesser price because of the risks associated with new construction.

I’ve heard from separate boardroom sources that the large construction companies are planning business models around repairs to the brandnew Smart buildings that have failed. We can be too clever, we can be too smart and too complex. We put too much faith in poorly executed buildings. Any serious builder should be using inexpensive, high-performing, long-lasting materials. We should be making houses that last at least a hundred years.

I had a professional contractor from France help me on my second hempcrete build and I said, “we’re doing some very quality work here.” And he said, “Not really.” He pointed out that we ran conduit through our walls for electrical wiring, but once we got into the rafters, our wiring was stapled as is common practice here. He said, “In a hundred years, you’re going to want to change your electrical wiring, and you’ll have to rip your ceiling down. That’s not very smart.” Our goal is to run full electrical conduit now. That comment to me has been a driving force of what we’re doing.

We’ve got an environmental solution to solve the housing supply problem on a big scale. In the next 24 months, we will be in position to start on a large development project that will incorporate grey water recuperation, all-natural materials, high-efficiency heating, proper design so we don’t need cooling. It will be a carbon-neutral development, 10 to 40 houses in total.

Our plan is to go to an area that needs housing and provide better quality for significantly less than a mainstream house. We’ve already proved this.

When we pull the forms off the hempcrete walls, the reaction is always the same – the workers or the clients get this big grin on their face and they want to touch it. People don’t rush up to touch vinyl siding. cc

GRK judges were blown away by Hempcrete’s amazing Hemp House project. Now Hempcrete takes home a new Paslode Cordless Framer and selection of premium fasteners from GRK valued at $5,000.

GRK Fasteners is proud to support innovative contractors across Canada.

Structural thermal breaks support and insulate the cantilevers of a Whistler Mountain residence.

By Tracy Dacko, marketing manager at Schock North America

Perched on the hillside of Whistler Mountain – one of North America’s top ski resorts – the 20,000 squarefoot Kadenwood residence complies with stringent energy efficiency and seismic requirements. Its footprint is a four-sided polygon with sweeping views of coastal mountains and alpine lakes.

The four storey ski-in/ski-out structure features an elevator that transports occupants from the entry level to the ski slopes 50 feet below. The top three storeys have year-round accommodations for the homeowners and separate suites for three other families.

The building is a study in concrete cantilevers reminiscent of Frank Lloyd Wright’s Falling Water, whose cantilevers appear to float above a waterfall.

“We wanted to cantilever the top two floors over the ski slopes and toward the views, so that when in the house you felt you were floating in the clouds,” explains senior technologist Eric Pettit of the Vancouver, B.C. architecture firm Openspace.

When Kadenwood construction began, he says that building codes in Canada encouraged the use of structural thermal breaks to mitigate thermal bridging and with the current B.C. Energy Step Code the building would have to include them to meet the high energy-performance target.

A rendering of the Kadenwood Residence shows an array of cantilevered elements in both concrete and steel.

Cantilevers impart high rotational and shear forces, especially in the mountains of western Canada due to the district’s snow loads of 176 pounds per square foot, compared to design loads of 134.3 psf in low-lying Vancouver, which is 200 km to the south. The designers needed cantilevered structures that could not only carry those loads, but also meet seismic requirements of the region.

“The whole structure is concrete –from the basement to the roof,” says concrete contractor Graham Roberge of Alpen Construction, subcontractor of Bradner Homes. “We used about 2,616 cubic yards of concrete and a million pounds of (reinforcing) steel on the project.”

Given the high thermal conductivity of concrete and steel, and its high surface area exposed to Whistler’s frigid winter temperatures, the design team needed to mitigate thermal bridging and its unwanted effects.

To prevent thermal bridging while supporting cantilever loads, the designers specified four types of structural thermal breaks. For the balcony and roof elements, the team specified Schock Isokorb concreteto-concrete modules. Each onemetre module consists of a block of rigid insulation penetrated by stainless steel rebar, which ties into the rebar of the interior slab and the cantilevered balcony. The insulation separating the interior and exterior slabs, together with stainless steel rebar that is one-third as conductive as carbon steel rebar, reduces heat loss at the penetration by up to 90 percent, according to the manufacturer. These modules are interspersed with a different kind of Isokorb concrete-to-concrete thermal break modules that transfer horizontal earthquake forces as required in the region.

Above several windows the architects incorporated concrete “brows” that overhang a short distance similar to a sunshade. For these small cantilevers, the design team specified Isokorb concreteto-concrete thermal breaks for slab edges. The stainless steel rebar penetrating the insulation block ties into the interior slab rebar. On the exterior side, the rebar forms into a loop to support the small cantilever. The fourth Isokorb thermal break used connects concrete to steel at the steel balcony that cantilevers from the concrete structure over the entry area. The stainless steel rebar on the interior side of the module is wired into the floor slab rebar. Once cast in concrete, the exterior threaded side of each rod is bolted to steel balcony beams using backing plates and high-strength stainless steel nuts.

Roberge estimates his crew installed about 1,000 feet of concreteto-concrete thermal breaks and 30 concrete-to-steel thermal breaks.

Increasing the temperature of structural penetrations on the interior

side of the insulated envelope also prevents condensation and mould growth. Pettit explains: “Because of the thickness of the slab and the sheer volume of cold material connected to warm material, there’s a threat of icing and frosting inside the building. The structural thermal breaks improve envelope performance in those areas.”

While the alpine climate on Whistler Mountain averages a nippy minus 14 to minus seven Celsius in mid-winter, temperatures also fluctuate dramatically year-round due to the region’s proximity to the temperate coastal region, exacerbating problems of

condensation and mould. “Whistler isn’t like Alberta where everything freezes until spring. There is a constant freeze and thaw cycle,” Pettit says. “Humidity in the house can start to condense on the cold surfaces and cause problems.”

Openspace began specifying structural thermal breaks in 2014 when designing another Whistler Mountain project. “On that building, we were trying to figure out how to hang heavy concrete cantilevers by designing our own bolt-on details. When we happened upon the Isokorb products, I was excited,” Pettit says. “They were the perfect solution to the problem.” cc

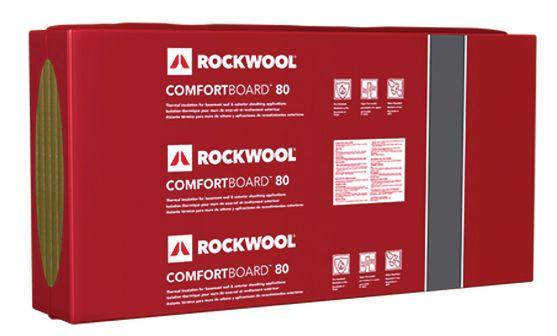

rockwool.com

Comfortboard 80 is an exterior non-structural insulation sheathing that provides a continuous layer of insulation around the commercial or residential building envelope. This product is specifically engineered as exterior nonstructural insulation sheathing for high performance commercial or residential wall systems. Comfortboard 80 can be easily cut with a bread knife. It is non-combustible with a melting point of approximately 1,177 degrees Celcius, features excellent sound absorbency and is vapour-permeable. Comfortboard does not rot or promote the growth of fungi or mildew. It has low moisture absorption and is chemically inert and non-corrosive. The water-repellent material is CFC- and HCFC-free both in the product and the

manufacturing process, made from natural and recycled materials. cc

bosch-thermotechnology.us

Bosch Thermotechnology has introduced its Singular Boiler series, delivering optimal comfort and hot water in one simple solution. The Bosch Singular Boiler series includes the Singular 5200 and Singular 4000 solutions, delivering 5.2 and four gallons of hot water per minute, respectively, giving users the ability to operate multiple showers and other hot water applications simultaneously. Featuring a 95 percent AFUE rating and a turndown ratio of up to 10:1, the units include simple, four-digit displays

and dual stainless steel heat exchangers. In addition to optimal hot water output, the Singular 5200 unit offers 140,000 BTU input for space heating, while the 4,000 unit offers 80,000 BTUs, delivering the ideal low-cost, high-value solution across a variety of residential needs based on home size. The units also feature an internal circulator and the capability for outdoor reset. The Singular Boiler system was designed with simplicity in mind, making for easy installation and use. The Singular Boiler Series is Energy Star-rated. cc

evw.ca

EuroVinyl Windows and Doors designed the TripleGreen Plus glazing option to suit applications where the home benefits from having bright clear glass to illuminate the space along with the comfort benefits of energy-efficient triple glazing. Shown here are north-facing tilt-turn windows in a newly restructured home office space. TripleGreen Plus can also be installed in casement and awning window designs. These windows are certified Energy Star Most Efficient and qualify for homeowner rebates under Canada’s Greener Homes Grant. EuroVinyl windows are steel reinforced for up to three times the structural strength of a non-reinforced sash. The frames are engineered for pressure-equalization, allowing moisture to escape quickly and protect the glass seal. Shadow-grooved frame and sash corners create a smooth finish. cc

se.com

To help manage electricity use, Schneider Electric has created WiserEnergy, an integrated monitoring system for residential homes. The internet-connected device tracks and monitors energy activity and use to provide real-time, easy-tounderstand data so homeowners can make their homes greener and more efficient – all through a convenient mobile-app. Wiser Energy can help Canadians identify extra electricity consumption from having the oven and stove on more often while cooking and entertaining friends and family; understand how much electricity is being used from having an electric fireplace or air conditioner; and leave the house with peace of mind they remembered to turn off the hair straightener or clothing iron. Wiser Energy easily connects to a residential electrical panel and Wi-Fi network. Over time, the system learns about a home to identify appliances and energy use patterns. Wiser Energy can help homeowners determine how they can change their habits to use energy

smarter. Canadians can keep tabs on home activity from anywhere with an easy-to-use mobile app, so they can know when the garage door is opened, when the clothes are dry, or whether the sump pump is running. They can reduce electricity bills with live energy tracking and detailed views by appliance, leading to lower energy consumption. Wiser Energy is powered by the Sense app, whose intelligent home energy technology interprets the power usage and activity of devices in the home. cc

Allison has been in the construction contracting industry her whole life. Her grandfather started the family business in the ‘60s and her father grew it into a successful concern. Allison worked with the crews in the summer all through high school, then went to college for an architectural technologist diploma. Another stint in the business, touching just about every aspect, then back to university for an MBA. After graduating, her father, who was looking to retire, installed her as general manager. This has gone well. Then one day she gets a disturbing report. A woman sends an email complaining that a worker on one of Allison’s sites whistled and yelled suggestive comments as she was walking past. The email includes a description of the person that identifies him as one of their reliable older employees that has worked for the company for over 15 years.

Allison is appalled. She herself has never had any problem with the individual, but she has always been the boss’s daughter. Of course she’s always overheard the “locker room talk” that goes around among the guys. She didn’t hear very much of it, but is now forced to consider that this may have been because people were being careful around her because of who she is. Now her workers are embarrassing her company in public and may be harbouring attitudes that would make it very uncomfortable in the company for any woman trying to deal with them as equals.

Gary Jans of Ray-Jans Construction in Cornwall, Ont., wins for his advice to hard-luck Adam, based on personal experience.

Well, it might not be what Adam wants to hear. But at the end of the day, he is going to have to endure and slug it out one way or another. Having started out in this business during lean times, my business partner and I also ran into a similar scenario. We started in 1987 with two old pickup trucks and some basic tools and in 1997 we basically had to start over with poorer financial conditions than when we started. We did go for the first option of “sucking it up” and borrowing privately at a high interest rate and worked our behinds off. We are in a small town and word gets around quickly. We earned a lot of respect from our community by honouring our commitments and displaying our work ethics. There were other hurdles along the way, however, the bright spots out shined the dull moments and each step along the way is a learning experience. You build off of that experience and move forward. So, yes, hard work does turn things around. We now operate five companies with a workforce of 16 people and will retire comfortably in the next two to three years. If Adam’s real passion is construction, he won’t be happy doing something else and the other options are just cop-outs. It won’t be easy, but with hard work there is a pot of gold at the end of the rainbow.

Give the prize to Adam or a deserving start up contractor if my article is a winner. I wish them all the best.

Since we always do what we’re told here at Canadian Contractor, we’re giving away Gary’s prize of a DeWalt 2400 PSI electric cold water pressure washer to a new contractor who sends us the best photo of themselves at a job that needs a pressure washer. Get your photos in by July 30 to qualify. Must have been in business less than two years!

1. Nothing. Construction workers catcalling from job sites is nothing new and women should have thicker skins.

2. Fire the individual responsible and deliver a stern warning and a round of mandatory sensitivity training to the rest of the staff. Draft a heartfelt apology reply to the complainant.

3. Confront the individual privately and collect his side of the story. Warn him that behaviour of this kind is not allowed. Keep it at that level and leave the rest of the staff out of it. Send the complainant a reply noting the issue is “being dealt with internally.”

4. Something else?

HOW TO ENTER

If you have a solution to Allison’s dilemma, email your entry to pflannery@annexbusinessmedia.com and put “Allison’s Dilemma” in the subject line. Please don’t post your response to the comments on the Dilemma post on our website.

Entries close Aug. 9. The winner will be announced in our Sept/Oct issue.

is a breakthrough product which can be used to prime over existing stains left by mould, mildew, moss, fungi and any other odour causing bacteria*. *This product contains an mildewcide to prevent any growth on the paint film only. The Mould Stop Primer is ideal for non-porous interior and exterior surfaces such as drywall, concrete, masonry, painted metal and non-porous wood.

www.rustoleum.ca/zinsser