Confessions of an Urban Roofer: What He's Learned in 20 Years Up There

Page 10

Confessions of an Urban Roofer: What He's Learned in 20 Years Up There

Page 10

We met the pros of the future at the Skills Canada Finals in Edmonton Page 18

The Right Way: Air and Moisture Control is Key Page 32

Water Winterizing: This New Canadian Invention Will Help Page 37

Confessions of a Roofing Contractor 10 “Urban mountain climber” Brian Steen talks about the pain and pleasure of his tough-as-nails trade

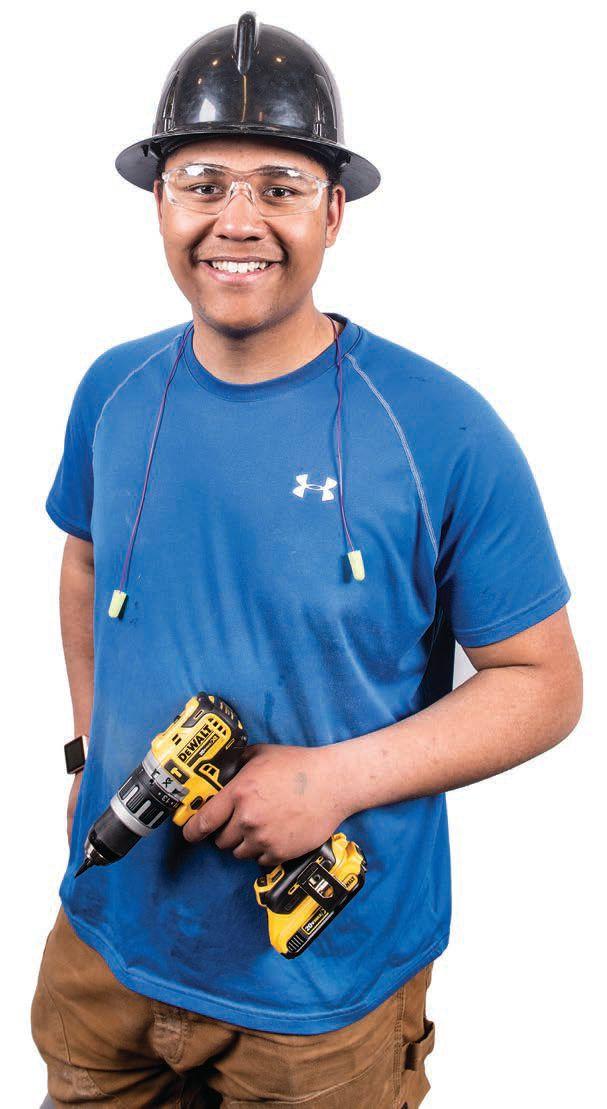

COVER STORY: Young Guns 18 John Bleasby went to the Skills Canada national finals in Edmonton to meet the next generation of pros

The Chester House 24 This month’s photo essay features an energy-efficient new build overlooking Mahone Bay, Nova Scotia

Steve Maxwell 31 Telling the truth; Brick veneer done right; Winterizing cottage plumbing systems

www.canadiancontractor.ca has everything you need to build better and build a better business

Sponsored by IKO

John McLellan runs an absolutely first-rate contracting firm in Claremont, Ontario. However, he wasn’t an overnight success. Tragedy hit John’s family while he and his brother were in their teens. Then, after dropping out of school, he worked a succession of menial jobs before finding out that he had a passion for sales. Watch this video to pick up some tremendous tips that will help you move your own business forward.

Sponsored by Home Hardware

In this ongoing series of instructional videos, Rob Koci, Steve Payne and pro contractor guests describe quick and easy ways to get things done faster and better on your job site. Recent videos include: How to design the perfect 10 x 10 guest bedroom; How to quickly and accurately make perfect cut outs in drywall for electrical utility boxes; How to install perfect crown moulding using a jig… and more.

Sponsored by NUDURA

Building codes across Canada are rapidly changing to accommodate Ottawa’s “Net Zero Energy Ready” (NZEr) mandate. By 2030 – just over a decade from now – all new housing in the country will be expected to be at the NZEr level. What does this mean for you? For one, building with newer technologies such as Insulated Concrete Forms needs to be in your skill set. Watch this video series to learn more.

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Kim Laudrum, Steve Maxwell

Art Director Mark Ryan

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator

Tracey Hanson thanson@annexbusinessmedia.com

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-442-5600 ext. 3543

Tim Dimopoulos, Vice President tdimopoulos@annexbusinessmedia.com

Mike Fredericks, President & CEO

If this is your boardroom, you’re a Pro.

Home Hardware is a nationwide supplier of quality, name brand products to Pros of all trades. Whether you are a homebuilder, a renovator, a plumber or an electrician, Home Hardware is a Pro source for everything you need on your next job.

Dedicated Pro sales staff, job site delivery, home plan services, material takeoffs, package pricing, convenient ordering options, credit services, rewards program, and exclusive e-offers are just some of the benefits we offer!

Sign up today to receive pro exclusive email offers and news. homehardware.ca/en/forms/register

Steve Payne Editor spayne@canadiancontractor.ca

” Being a chef or a contractor is all about the performance.

”

By Steve Payne

As famously contemptuous as Mike Holmes is about shoddy contracting, Anthony Bourdain, the New York celebrity chef and culinary-travel TV show host who died last month, did the same thing for the restaurant industry. Whereas Holmes would say, “Rip it out!”, Bourdain would warn, “Don’t eat that!” Both men became famous and wealthy for their arguments in favour of quality.

The public reaction to Bourdain’s death has been significant. Many people have said that they felt they knew the man personally. A reality TV show has seldom been so real. As he struggled up the truly greasy pole of his line-cook apprenticeships, Bourdain was fired often and deservedly. He became a drug addict and talked about that on his shows, too. Yet he recovered from it all and became successful beyond his wildest dreams.

Bourdain was a survivor of a trade that inflicted serious mental and physical pain on its practitioners. To those status-minded souls who sometimes wonder if they should be in the the trades at all, I highly recommend picking up a copy of Anthony Bourdain’s confessional book about his early years as an apprentice chef. It’s called Kitchen Confidential: Adventures in the Culinary Underbelly.

This marvellous book, now back on the bestseller lists almost 20 years after it first appeared, explains the strange obsession that drives people through the extraordinary stresses of learning to cook in the big leagues. More than that, I think it’s the best book about the psychology of pursuing a trade (as opposed to a “career”) that I have ever read.

Bourdain writes about the pain, stresses and frustrations of his trade and the exhilaration that comes from conquering those adversaries. He pounds home the truth that quality output on a work shift comes from prior preparation of tools and supplies (what cooks call their mise en place). And Bourdain makes it very clear that his trade - and it’s true of ours - is worth the suffering because it’s a meritocracy. You can’t hide garbage work and prosper. You can’t bullshit your way to success. Being a chef or a contractor is all about the performance. That's why it’s worth doing.

We got a lot of online comments about the Conservatives winning the Ontario election. Contractors seem eager for Doug Ford to improve things in our industry…

“Insane amount of BS” under the Liberals

It’s about time that the Ontario Liberals were gone. Let’s see if things will improve in Ontario. Let’s start with the shortage of trades people? Who is to blame? It is the ratios system. It is the province acting like a collection agency on trades people. It is inspections on “compulsory” trades (Ontario College of Trades). It’s an insane amount of BS. Trades people in this province haven’t got much freedom to operate. The nanny state needs to tell the trades people what to do at all times, apparently. It’s comparable to slavery.

Now regarding education, trades training in Ontario falls well short compared to some other parts of the world. Yet some people say that trades people that come here from other countries may have fake licenses. Well, these so-called fakers come here to work. A lot of them speak many languages and have better trades training and experience. So where is the problem?

Our own government is to blame for not listening and for not taking the time to fix things the right way. Instead of serving the province, they instead created an apparatus of tax collection on the trades people. Does this help?

The Liberals destroyed apparently everything they touched. 15 years of total misery in Ontario, and an enormous debt to pay. What a mess. There was never a shortage of crooked politicians in this province.

Questo

The Ontario College of Trades gives us less than the Ontario Ministry of Labour did at many times the cost. After a fiveyear apprenticeship, a six-hour C of Q exam, and 39 years of experience, some clerk is going to take my certificate of qualification away from me? That’s extortion and nothing less.

Randall Holmes

Finally, just before the Ontario election, John Bleasby wrote a post speculating on what life would be like for self-employed contractors under an Andrea Horwath NDP government. John imagined a bureaucratic hell where the unions have taken over everything and a non-union contractor would make more money delivering pizzas for a living. Here is a reaction to that…

I think this scenario is a little over the top. I think the bigger concern is that, with Doug Ford and his radical followers now elected, we will have chaos. He may run a company that was handed to him by his father, but he understands nothing about government and has only slogans for knowledge. We will experience an even wider income gap for Ontarians. Not good for social stability.

Dennis Bryant

John Bleasby in his online posts about the Skills Canada competitions in Ontario and Alberta talked about the looming skilled trades shortage. Some people don’t believe it…

See next page

“Hooked for Life”

“Fusion” is defined as “a merging of diverse, distinct, or separate elements into a unified whole.” So it is with Fusion Stone; the coming together of the beauty, strength, and maintenance free characteristics of traditional stone with the ease of installation and affordability of stone veneer.

Fusion Stone is an easy and budget-friendly way to beautifully upgrade a home, inside and out. Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips and screws. You just screw it to the wall and it’s “Hooked for Life.”

Available in three distinct systems, all backed by a Lifetime Guarantee, Fusion Stone can be installed on both new and existing wall assemblies in any weather.

Skilled trades shortage? There isn’t one! Is there a disconnect somewhere? A few years ago I decided to change careers from driving a truck to something new. Because throughout my life I had always built things and also enjoyed repairing things, I thought the trades would be more suitable than an academic endeavor. So I set to enquire about a possible new career in the trades. No contractor would give me the time of the day. Well, I thought that I may not have much to offer and folks are busy. So I decided to go to school, learn something, show my desire and have at least something to show: dedication.

Now, two years later, I have obtained an advanced trade diploma but I am starting to doubt the wisdom of getting such an education. While my field of studies was electrical I was (and still am) willing to take on something else, as long as I learn and progress. I am not afraid of putting in the hours, sweat, work in the cold or rain but somehow I get the sense that having never used a worm drive saw is taken as my inability to do carpentry.

Alex Goorshkee

More like a work ethic shortage, he argues I find it hard to find good young people to teach and share my 17

years of residential building knowledge. But I also find that the newer generation is not as willing to do the “grunt or greenhorn” work. They expect to be up the work ladder right away. They don’t want to stick out the beginning stages of lugging, cleaning, driving nails. Plus they don’t seem to take the extra steps to show they want to learn more.

I guess I am trying to say I don’t see the “work ethic” with this generation that I used to see in others 17 years ago. They don’t want to work hard to get ahead. They just expect to get things handed to them.

Here’s an example: I now have a company truck. But first, for years, I drove around in my own vehicle for work. I never complained and for that I got rewarded with company wheels. I hear it all the time now: complaining about having to drive 30 minutes to get to work!

Tim Wills

Ratio system in Ontario prevents his firm growing Education is critical and, in my humble experience, the school guidance counselors often direct the failing or less “academically

successful” students toward skilled trades. Our family electrical contracting company does not want those people. As a customer, do you want the most stupid person doing the electrical work in your home?

Our problem here in Ontario is with ratios. At a 3 to 1 journeyperson to apprentice ratio (and at one point 6 to 1) we can’t even replace our retiring journeypeople. There is a terrible shortage of licensed electricians and not enough apprentices. We get many resumes from hopeful applicants who want to become electricians and we need more workers but we can’t hire them due to the ratio.

It is interesting to note that many resumes are from people with university degrees – and sometimes more than one degree. But they have had no luck in securing a meaningful, well paid, satisfying job. This is a barrier to employment.

We sometimes decide not to bid on jobs because we can’t get enough people to do the work. Our governments want to import people from other countries (with questionable credentials and experience) to help with the skilled trade shortages. But shouldn’t

we be giving our own sons and daughters these jobs first? My suggestion is: during election time be sure to find out which party it is that supports changing ratios to enable more apprentices to get great jobs and vote for them.

Dale MacDonald

Industry needs to support Skills Canada

I am the Technical Chair for the recent Skills Canada competition for Individual Carpentry. Just to clarify, we had 23 high school students and 12 post secondary students competing in this category. The gold medal winners advanced to the national Skills Canada competition June 4-5 in Edmonton. (Editor's note: See John Bleasby's report on this event, starting on page 18.) I was privileged to be a committee representative this year representing Ontario. I was surprised not to see any representatives from the home building industry – as well as the carpenters union. I have been a proponent of apprenticeship for many years and will continue to do so.

Len Rance

I’ve spent much of my workday as an urban mountain climber for more than 20 years. This is what I’ve learned.

By Brian Steen

Icomeby respect for hard labour honestly. I was sanding floors and painting by 14, the product of a single mother who had no choice but to embrace hard work herself. I started doing general labour for construction contractors at 18 in cold, snowy (on June 1 in my case) Saskatchewan. By 30, I was the contractor. I got my first Metro B licence, Toronto’s municipal licensing standard, a few years later, in roofing and the manufacture and installation of cabinetry. I upgraded it to every possible endorsement except framing and brickwork (which require membership in professional associations) within two years. Twenty years ago in the midst of a professional lull, my roofer neighbour offered me work. I’ve spent most of my time looking down on the world ever since.

What’s the picture you get in your mind when we talk about roofers? Unruly modern-day cowboys (and girls) with wild hair and wilder eyes? Maybe bare-chested with a joint in one hand, a hammer in the other, and no harness on. I am in some ways a stereotypical roofer. I’m missing a couple of teeth — in my misspent youth, I never let the lack of a bottle opener keep me from a beer. I have two kinds of clothes: those that are covered in tar and those that will be. But in many ways, maybe I’d surprise you. Although my youthful objections to the rote nature of study made me drop out, I was in pursuit of a philosophy degree before I got into roofing. I’m very good at Jeopardy, and I really like sushi.

When I first met my girlfriend, with her white-collar career and pretty clothes, she asked me why I did it. I told her four reasons: urban mountain climbing, origami, puzzle-solving and people. While every roofer gets the urban mountain climbing thing, the origami and puzzle-solving I get through my work as a trouble-shooter and service guy. The people aspect doesn’t appeal to all roofers — some like the job because they never have to talk to anyone except their boss and other roofers. But I love talking to customers and the art of the deal. The origami is, believe it or not, a creative outlet. Bending metal is good for the soul. The puzzle-solving comes from figuring out what’s behind that leak.

I’m not sure there’s a “typical” roofer. I’ve got roofing buddies with little kids who do it to support their families, whose kids are long out of the house who do it to support their bad habits, who never had kids and spent their entire careers going from town to town in the aftermath of natural disasters, fixing the damage so other people’s kids can get a good night’s sleep because their gypsy genes ran deep. I know guys who make a fortune running their own companies and who barely make a living because they only show up half the time.

ROOFERS ARE ALMOST WITHOUT EXCEPTION ALPHA MALES, WITH A FEW ALPHA FEMALES THROWN IN.

A roofer in the highstress GTA market needs a supportive partner. Brian’s sweetheart Annette McLeod is a wellknown automotive journalist.

They all do it for different reasons, and they have only a couple of things in common: they like adrenaline, and they don’t mind working hard. Most of us can’t fathom jockeying a desk for a living.

I have twice run my own roofing company. The first time fell apart when my marriage fell apart; the second fell apart when I tried to do it all on the up and up: pay taxes and WSIB, make my crews pay taxes, have the right safety equipment and training, keep the books spotless, enforce a strict no drugs or alcohol rule, keep the trucks running and all the various personalities in line so the emotional eruptions were minimal.

Staffing is always an issue. We had one guy who

It won’t come as a surprise that drug and alcolhol abuse is a problem in the roofing business. I’m not sure if roofers are drawn to drugs because of the way they are, or if they’re drawn to roofing because they’re on drugs. Ba dump.

It’s dangerous; the construction industry overall accounts for a fifth to a quarter of all workplace fatalities. It ranks third for workplace injuries, behind health and social services and manufacturing. According to the US National Survey on Drug Use and Health sponsored by the Substance Abuse and Mental Health Services Administration (Canadian numbers are harder to come by), roofing also boasts the second-highest level of alcohol abuse and the sixth highest level of drug abuse. Clearly the combination is a recipe for disaster.

I tried hard to enforce a strict no drugs or alcohol rule on my job sites, but it wasn’t easy. When I heard from one customer that two of my guys had come down from the roof reeking of pot, I had two choices: send them home or finish the job. With other jobs lined up for this crew and other crews already occupied, I had no one else. I switched a couple of guys around and finished the job. I’m not saying it was the right thing to do, but under the circumstances, it seemed like the only thing.

There’s an old joke in the industry: how do you get all your roofers to show up on Friday? Don’t pay them on Thursday. The signs of substance abuse can include absenteeism, high turnover, poor work quality, impulsiveness, dodgy hygiene and aggression among others. Unfortunately, none of those things are uncommon among roofers, whether they’re straight or not.

Remember, though, that some empathy is called for. Roofing is (sometimes literally) backbreaking labour, and it’s a slippery slope from Advil to Percocet when you need to keep the pain at bay to keep working. This has been a sticky wicket for me, not because I’m a proponent of drug use, but I am a big proponent of autonomy. I don’t want to tell anyone how to live their life. But I do want to control my own jobsites.

vehemently didn’t want to pay taxes, although he was only too happy to take advantage of publicly funded methadone treatment. He had a family, and I’m soft-hearted, but I stuck to my guns (and he, verbally at least, stuck to his) as long as we reasonably could, until he head-butted another employee in a fit of temper.

Staying on the books is always a struggle too. Roofers can get day work off the books for $300 to $500. They can be lured into employment with some promise of stability and the onus of all the pesky details taken off their plates, but to ensure someone took home $52,000 on the books, it cost me close to $100,000. Homeowners carry those costs, and it contributes to a vigorous black market. It’s hard to compete against a guy with a ladder and a pickup truck, when neither he nor the homeowner is interested in paying taxes.

Roofing is not for the faint of heart. It’s very hard work, the body takes a beating, and handling roofers is like herding cats. They go off in all directions at once and you’re pretty sure they’re laughing at you.

I’ve never met a roofer who didn’t think he was the best. At everything. Roofers in my experience are almost without exception alpha males, with a few alpha females thrown in. They’re leaders or think they should be leading. They tend to be loudmouths and have an opinion on every topic. They also tend to be generous not just with those opinions, but in other ways as well — providing for the pack is part of the alpha’s role — and blessed with robust

if a little out-there senses of humour. They’re charismatic, passionate, intense, (just maybe) a little pushy and prone to occupying all the available space around them. A bunch of roofers together would make most introverts cry. They have a tendency to be aggressive and can use anger to influence. Their natural impatience can be useful in getting things done, but it can burn people out.

Alphas, like people everywhere, run the gamut from dysfunctional to exceptional.

Dealing with alphas can be complicated, particularly when the boss is an alpha too. An employee who says, “Don’t worry about it. I’ve got this” may be perfect for some, but we alphas want to know the details, and still want control over how it gets done.

In motivating an alpha workforce, competition can be your friend; a friendly bundle-battle can be a great way to get things done, but it can backfire and have the whole team running over each other and creating a big mess to clean up, either literally

or figuratively. It also helps to have a clear picture in your own mind of what you’ll accept. If your crew tends to lose it when things go south, make it clear that you won’t stand for it. And then don’t. Like Dr. Phil says of children, pick your battles, but once you’ve picked one, never lose.

Those who act aggressively and talk too loud to show dominance may not be actual alphas, but rather wannabes who think they should be and are trying to exert social influence over others — not born leaders, but those who want to lead and try to intimidate others into following. Sometimes they can be disarmed with a simple confrontation. Like schoolyard bullies, they tend to back down when challenged.

In general, I’ve found that dealing with bad behaviour starts with a conversation. If you have to deal with someone who is critical about everything you’re doing or who bad mouths the company, for example, start by asking what’s going on. Maybe there’s trouble at home or their health is in jeopardy. Asking what their end game is, what they hope to accomplish with the behaviour, can be enough to get them reflecting on it. A couple of hours or a half-day off (with pay) to think about it can work too — “Go home and think. Let me know tomorrow whether you really want to work here. We have invested a lot in you and you in us, and we want it to work but it’s not working right now.” If they’re

really in denial, you’ll know soon enough, and that’s time to cut your losses and start the hiring process again.

If all else fails, find yourself a roofer with a few years under his toolbelt. In an interview about their book The Alpha Male Syndrome from the Harvard Business School Press, authors Eddie Erlandson and Kate Ludeman say those who have a lot of alpha strengths tended to also have a lot of alpha risk. In their research, they positively correlated age to alpha strengths and negatively to alpha risks.

I came back to Toronto from a stint in Thunder Bay about four years ago to take a job with a big roofing company, one of whose highly recognizable trucks is probably somewhere in your neighbourhood right now. I left because they paid me using some incomprehensible algorithm that saw me taking a draw each check, of some seemingly random amount of their choosing. It didn’t matter that I kept track of my hours — they were in a position to pay what they wanted, and if you questioned it, there’d be another roofer along any minute.

When running my own business, I figured the best way to get good roofers was to make them myself. I tried to hire younger workers whose good attitudes may have outweighed their experience. Soft skills are a lot harder to teach than hard skills. It worked — for a while. Once they’re good, they start to think they don’t need you anymore. Once they got their feet under them, they were itching to get out on their own. Some made it. Many didn’t. But that’s the workforce diluted again, as these guys try to put together their own crews, often poaching from yours. In hindsight, maybe I should have required the signing of a non-compete agreement, but just getting them to show up is 50 per cent of the battle and unless you’re prepared to enforce it, it’s valueless anyway.

I know the mistakes I made. It was important to me to see that these guys got paid, which meant we sometimes didn’t. I’d pay them out of pocket and wait for the customer’s check to clear.

The roofing universe is pretty small. If you run into a roofer in the Toronto area, chances are that if he doesn’t know me, he knows someone who does. It’s the same with roofing contractors. We all know most of them, we mostly know all of them, and if we haven’t worked for you yet, it’s just a matter of time.

I’ve done a lot of work as a subcontractor, and it has its ups and downs. On the one hand, if you’re not good with people (or are missing more than a few teeth and haven’t had a haircut since

Festool’s diamond saw blade cuts all fiber-cement materials quickly and with superior performance. It is the ideal solution for precise, efficient work when used together with Festool’s TS 55 REQ and TSC 55 REB track saws.

the ‘90s), having someone else manage the sales and marketing is great. And although you may have to pony up your own WSIB and deal with staff who are looking for cash at the end of the day, having someone else handle the rest of the paperwork is appreciated. We like to build stuff. We don’t like to fill out forms. It’s nice when someone else is handling the trade-juggling that can happen when the homeowner has multiple jobs on the go too.

The downside is that the contractor is likely making more money than you, and it often feels like you and your guys are doing the lion’s share of the work. Every good thing you do on the job is building someone else’s reputation. I’ve also had to come up with tens of thousands in payroll weeks before I got the money back, if I ever did (and in fairness, I usually did; my complaints about subcontracting were compensated by the steadiness of the work). We once worked on a should-have-been lucrative church, and the pastor decided he didn’t like what we were doing. The contractor didn’t have a problem with my work, but his client did, and after some secret negotiations to which I wasn’t privy, my client informed me that the $8,000 we thought we had coming wasn’t coming at all. Ever. We had to eat it. I understood, believe it or not. If he wasn’t getting paid, he wasn’t going to pay me, but I still had to pay my crew.

AND THEY LIKE WORKING HARD.”

Contractors may transfer too much project risk to small subs with little ability to bear those risks. On the other hand, subcontractors may not concern themselves enough with the reputation and quality assurance of — or the enormous expense incurred by —the contractors who hired them.

The relationship between contractors and subcontractors is fraught, but building and sustaining quality relationships goes a long way toward mitigating any negatives. When times get tough, every subcontractor is grateful for the big company with a lot of money that can keep the jobs coming in.

In a 2013 Journal of Construction Engineering research article out of the UK, the quality of the relationship between contractors and subcontractors was found to have a direct effect on outcomes, which shouldn’t come as a surprise. The report identified traditional contractor/subcontractor relationships as ineffective

and fragmented, found that customer expectations were not being met, and that nobody was making enough money. The answer, they suggest, is collaboration. Contract terms are often so strictly (and sometimes litigiously) applied that nobody is thinking about building long-term relationships, they’re just thinking about getting the next job done, and yet an enduring relationship with key subcontractors was paramount to success. The research found that a more collaborative process delivered lower building costs for clients and higher profits for contractors, protected the contractor’s profit margin so they were able to better deliver on quality, and resulted in shorter overall project times, to name just a few benefits.

A clear understanding of what’s expected and open communication go a long way when dealing with subs. I’ll deal with almost anything provided I know what it is. Largely concerned with maximizing profit, contractors often look for the best price from their subcontractors but that, too, can be shortsighted. Selecting subs based on value — a combination of good work, good price and good attitude — was found to be a much more effective mechanism to sustaining business.

Maybe as a contractor you’re frustrated that your subs never seem to have enough people on site. But we’re frustrated because we brought the whole team only to discover that the trade before us didn’t finish what they said they would, and I’m paying my guys to stand around. Working together to plan and develop a whole project, not just being brought in for a few days to bang on a roof, tends to mean more accurate estimates of job duration too, and that means fewer delays on your jobs.

Not that it’s easy. According to the report, “Even on projects where clients buy into the idea of collaboration, main contractors and subcontractors have struggled to drive these principles all the way to project completion. Relationships soon degenerate once it is perceived that potential profits may be eroded, and without recourse to the long-standing relationships between them, such relationships break up.” Hey, if it was easy, we’d all be rich. By focusing on mutual interests though, the blame culture that exists between contractors and their subs can be mitigated, and that’s good news for clients.

So the next time you look up and see those urban mountain climbers doing their thing, think of me. I’m all the way human, with all of the failings and flaws that entails, but I also care about the work I do, care about how my work contributes to your company, and love a good a conversation about Kant. cc

Brian Steen is an independent roofing consultant and general contractor. briansteenconstruction@gmail.com

The Skills Canada national competition, which recently took place in Edmonton, showcased some of Canada’s most talented young tradespeople. But there are nowhere near enough of these young contractors coming through the pipeline. John Bleasby reports on the efforts contractors, schools and governments are making to develop

are shouting it out – “Skilled Trades Crisis!”

Numerous studies suggest that over the next ten to 15 years, Canada can expect a wave of retirements from all manner of skilled trades, particularly in residential construction. At the same time, there is an apparent shortage of newly-trained workers on stream to replace them.

Solving the skilled trade shortage is a complex issue involving many players across the country: elementary and post-secondary education systems, government, labour regulatory boards, industry, and unions. While these players often seem to work at cross purposes, a common thread shared is recognition that the successful recruitment of a new generation into the trades means battling preconceived notions concerning the nature of the work itself and promoting the career opportunities that can lie ahead.

Yet, Canada being Canada, bringing these players together in a cohesive manner is made all the more difficult due to the diversity of economic cycles coupled with variances in government and educational policies from coast to coast. At times, employers, government agencies and those looking for work seem to live in separate universes. Many contractors in the new home and home renovation industry speak of a disconnect between the skilled trade workers they need and the availability of suitable applicants and apprentices.

“We’ve advertised for the last three months and have yet to hire a skilled trade person,” one contractor says. “We’ve conducted several interviews – some never even bothered to show up.” It works the other way, too – apprentices complain they can’t find work. “When I respond to an ad, I am often told that they‘ve already received a few dozen to a few hundred applications. Does that sound like a shortage? Am I missing something?”

Adding to the complications are obstructive, inconsistent government and labour regulations across the provinces, particularly when it comes to apprenticeship training. Both employers and apprentices complain that government agencies often seem out of touch with industry needs. Some employers express concern that variations in apprenticeship programs across provincial jurisdictions mean they can’t always be sure of the actual qualifications of an out-of-province applicant.

Regional variations in economic cycles will always cause apprenticeship recruitment problems due to supply and demand, but there’s nothing quite like the journeyman-to-apprentice ratios mandated in Ontario. While most provinces have loosened

CONTRACTORS OFTEN SPEAK OF A DISCONNECT BETWEEN WHAT THEY NEED IN A YOUNG WORKER, AND WHAT THE SYSTEM IS PROVIDING THEM WITH.”

A MAJOR HURDLE TO BRINGING ON NEW TALENT.

up their ratios in recognition of the need for more skilled trade workers, Ontario employers sponsoring carpenter apprentices are required to have one journeyman for the first apprentice. A second apprentice requires three additional journeymen, and a third apprentice requires four additional carpenters. “For a company of 20 people, this is really difficult,” one Ontario contractor explained. “Many companies just wouldn’t have the numbers to be able to take on apprentices.” These are by far the most restrictive ratios found in any province or territory — ratios oneto-one or even less are the norm.

Take Alberta, for example. In 2011, the province took the important step of reducing journeyman-to-apprentice requirements. In carpentry, for example, each journeyman can supervise two apprentices. This has significantly impacted the ability of Alberta builders to bring the new generation onto their worksites. A representative for Alberta’s apprenticeship program put it this way; “With the number of retirements expected over the next ten years, why would we have ratios that can’t keep up with required replacements?”

Contractors reluctant to take on apprentices cite concerns beyond shortages of qualified applicants and mandated training ratios. They worry apprentices will leave after the company’s training investment has been made, worry about interruptions to work scheduling due to absences for class time, and about the lack of wage subsidies to offset the drop of productivity while training a new worker.

Certainly there is a lack of a coordinated approach nationally or even provincially. Numerous bottlenecks, hassles and regulations frustrate employers and apprentices alike. Yet at the same time, there are ideas, initiatives and programs that have had many positive outcomes across the country that everyone can learn from.

One of the few points on which educators, government, labour and regulatory boards, industry, and unions all seem to agree is that the battle to win the hearts and minds of the new generation must begin at a young age.

This awareness campaign has been gaining momentum in several jurisdictions at the elementary school level. For example, hundreds of elementary students up to Grade 8 were recently bussed to a tiny village in Simcoe County north of Toronto for a day-long Skilled Trades Expo. Cleverly, the district school board extended the expo’s hours into the evening to allow parents to visit with their children and learn more about the trades directly from local industry, post-secondary schools and union organizations. Given the huge influence parents have over

their children’s education, informing and exposing the entire family to the trades is vital to any successful effort to increase apprenticeship enrollment.

Once in high school, youth apprenticeship programs operating in several provinces allow school students to work alongside skilled trade workers on a part-time basis or over weekends and holidays, earning credits towards both their high school diplomas and on-the-job portions of their formal postsecondary apprenticeships. The attraction for employers is that the journeyman-to-apprentice ratios do not apply in these youth programs. Neither do the pay scales. This allows employers to more easily assess young men or women before any formal

Nowhere are the abilities and motivation of young trade apprentices more evident than at the Skills Canada competitions across the country. It’s a showcase of the best of the best. By the time contestants arrive at the national championship level, the young men and woman have already succeeded by winning in their provincial or territorial arena. “They’re skilled, they're driven, they want to work, and they're excited about the trades,” says Shaun Thorson, CEO of Skills Canada. “This is a great opportunity to connect with the future workers who will do well for

commitment is made to support their formal apprenticeship.

As Adam Smith, operations manager for Barrie Welding and Machining north of Toronto explains, “A new young person coming into our operation will probably work at least one year before we make the offer for an apprenticeship, to see if they are a fit for us and if they have an aptitude.” If they pass their apprenticeship programs, Adam’s company reimburses the apprenticeship course fees.

Contractors don’t know the opportunities

Sadly, there is often an educational disconnect between companies and programs. Many contractors simply do not know

themselves and who will do well for the contractors.”

It’s also a continuation of the education theme, a great place for visitors including over 6,000 students, to have a hands-on, skilled trade experience. “We continue to place a great deal of importance on the competition element, of course,” says Thorson. “However, we are now looking at the visitor experience. How can we engage those students who are in close proximity to the competition that may have had no exposure to a trade or technology? How can we put tools and materials in

their hands and give them a very handson experience that might challenge them to investigative a little more?” Skills Canada calls this initiative Try-A-Trade, and encourages all their exhibitors to incorporate a hands-on element into their displays. It’s an educational experience that individual contractors can take to their local school district level. “That sensory experience will remain,” says Thorson. “What did it feel like, what did it smell like, what was the weight? All of those elements will rest with them a lot longer and hopefully inspire them.”

SOME 6,000 STUDENTS. MANY GOT HANDS-ON EXPERIENCE WITH THE “TRY A TRADE” INITIATIVE.

what promotional opportunities and resources are available to them. That disconnect in the apprenticeship-employer pipeline is most evident when one hears anecdotes concerning how employers and young apprentices can’t find each other. Gloria Evans of Employment Ontario’s office at Georgian College in Barrie, Ontario sees the problem regularly. “The big challenge locally is finding more employers,” she says. “There is definitely a return on their investment, however it is very difficult for them to see that up front.” Her job is to be the go-between for employers and apprentices. “My perspective is that both parties need to come to the table, be open-minded and ask, ‘How can we make this work?’” Evans’ and other Employment Ontario offices across that province are often a well-kept secret, a lost opportunity for both parties.

Robert Heron, 29, Yellowknife, Northwest Territories. Skills Canada National Competition, electrician, bronze medal.

Regional and provincial residential building associations have been largely absent from skilled trades discussion. As a result, the home building industry is often left unrepresented at many skilled trade events. That leaves it up to individual contractors to find successful solutions at the local level and become engaged.

Initiatives to attract young people to the trades and towards an individual company can be tailored to one’s own market conditions. It doesn’t need to be complicated — contractors simply need to take some proactive steps. Obviously, taking a display at a local job expo is a good start, but there’s more if one is inclined. For example, award-winning builder Naikoon Contracting in Vancouver offers bursaries for high school graduates pursuing trades training at the post-secondary level. Reid Heritage Homes, an Ontario-based production builder, oversees the construction of a student-built home in one of their developments each spring. Many company owners or key employees attend and speak at high school trade awareness events, or teach at community colleges. One contractor makes the company workshop available to their community.

Each of these initiatives offers those contractors and builders a leg up in identifying the most talented and motivated new workers in their area. It should come as little surprise that among the contractors spoken to, it is those with the highest level of local engagement who have had the highest level of success in attracting and retaining skilled trade workers.

Looking for the silver bullet to the skilled trade crisis in residential construction industry? Given the governmental, geographic and economic disparities across the country, perhaps the solution is for contractors to become better educated and aware of the many individual good ideas around the country and then adapt them to the local level.

cc

An ocean front new build that was a finalist for the 2018 CHBA National Awards, under 2,500 sq. ft. custom homes category

By John Bleasby

Chester House (Nova Scotia)

Design: AmaDesCo Design (Branko Mizerit) and Whitestone Developments (Andrew Watson and Tamara Barker Watson)

Photos: Shelley Wyman (finished project), Whitestone Developments (construction)

Theterm “an environmentally correct home” is usually associated with adherence to the high energy efficiency standards that have quickly created a new benchmark for home design and construction in Canada. However, it also means right-sizing the home to the true needs of the client. The Chester House is an exemplar of that thinking. “Our clients didn't want square footage that they were paying for but weren't going to use,” says Tamara Barker Watson, co-owner of Whitestone Developments with her husband Andrew Watson. “For example, they didn't want a formal dining room — they wanted one big open finished area.”

Halifax-based Whitestone is a developer of custom, semi-custom and spec homes, and the winner of a multiple awards on both the

The main entry is accessed by gently sloped pre-cast concrete steps. New Brunswick hemlock was used generously on the exterior in combination with black PVC panels. Internal roof drainage made the clean roof line possible.

national and provincial stage. The Watsons started the firm in 1995 and adopted R2000 as their standard in 1998, long before it became fashionable. It’s proven to be a successful strategy. Today, Whitestone builds 30 to 40 new homes each year, often on land owned or controlled by the company.

The Chester House combines the efficient use of space while embracing comfort and luxury at the highest level. Nominated for the 2018 CHBA National Awards in the under 2,500 sq. ft. custom home category, the house overlooks a protected inlet on Mahone Bay near Chester, Nova Scotia. The living spaces are spread over

two wings on separate levels that slope toward the water. Rooms are oriented to feature stunning views of Mahone Bay on three sides, the obvious focal point of this home.

Dealing with an ocean climate is always a challenge for builders. The clients had owned the vacant land for a period of time prior to construction, building a dock and small boathouse as a land base for their sailboat. Although no demolition was required and excavations did not encounter rock, Barker Watson says the most challenging part of the project was getting the foundation in place due to the weather conditions associated with

the ocean setting.

“It’s kind of a combination of an R2000 house and passive house,” says Barker Watson. “The build is an R2000 build, the orientation is like a passive house.” While the polished concrete floors with their hydronic, oil-fired, in-floor heating system cost the building a few energy points, they in fact turned out to be beneficial in an unexpected way. “The sun heats the slab during the day, and in turn the heat is dispelled at night,” she explains. “We really didn't expect as much benefit. Once, when the system boiler ran out of fuel after a storm, the house temperature only

dropped two degrees.”

All windows, including the huge floor-to-ceiling main level windows represent the height of energy efficiency — triple pane, low-e coated, argon gas filled, and insulated vinyl casings. The home’s low profile design and the natural materials used on the exterior allow the building to blend, not dominate, the natural beauty of the property. Light colored walls and brightly polished concrete floors mix with natural wood trim and accents to create a bright interior atmosphere that flows seamlessly to the outdoors.

The main floor features an open 17 x 25 foot dining and kitchen space, and a master bedroom with adjoining master bath and walk-in clothes closet. The two children’s bedrooms, games room, gym and utility room on the lower level wing are linked by a spectacular staircase accented with a wall of New Brunswick hemlock. This richly coloured wood is also used generously on the home’s exterior.

While the structure itself is conventionally built using 2x6 wood framing, closer examination reveals the typical over-

The interior and exterior blend into one because of the floor-to-ceiling windows across the oceanfront wall. The propane fireplace is double-sided, for all-season use.

code standards set by Whitestone for its homes. Spray foam on the exterior walls and underside of the roof deck delivered insulation values of R40 and R50 respectively. Additional insulated sheathing was used on exterior walls to enhance the R-values and to eliminate thermal bridging. The poured concrete foundation wall and floor slab were insulated with rigid foam board. Low VOC materials were used throughout.

The home’s exceptionally clean lines are the result of a flat roof that is sloped inwards towards four internal roof drains, thus eliminating any visible eaves or drainage. There are plans for a rain water collection system for gardening purposes in the future, a feature often seen on Canada’s West Coast that is becoming increasingly popular in the Maritimes when city water services are not available. “It just makes sense to capture your own water and reuse it,” says Barker Watson. She added that the clients also intend to build a guest home at some point, but in the meantime are delighted with the Chester House as it stands. “When the clients are happy, our world is perfect.” cc

Place an order on www.PaintSuppliesDirect.ca for minimum $150 and receive Free Shipping AND this great bucket of supplies worth $135 for FREE

LIMITED QUANTITIES AVAILABLE Bucket will ship separately from regular product order

1 - 5 Gallon (20L) plastic pail with lid

1 - 118mL bottle Krud Kutter Cleaner/Degreaser

1 - 946mL buttle Krud Kutter Brush Wash

1 - Dentec Dual Cartridge Respirator

1 - Preval Spray System

1 - 10.1oz (300mL) Tube Dupont Exterior Window/Door/Siding Sealant

1 - 10.1oz (300mL) Tube Dupont Interior Kitchen & Bath Sealant

1 - Dynamic Infinity 240mm x 10mm

Microfibre Roller Refill 2 - Dynamic 2½” (64mm) Solomon Professional Angle Sash Brush 2 - Task Medium/Fine Sanding Blocks 2 - Dynamic 4” Mini Trim Roller Refills 1 - Pintar Supreme 240mm x 13mm Lint Free Roller Refill 1 - Professional Painter Magazine

- Canadian Contractor Magazine 1 - $25 Free Voucher for Paint Supplies Direct 1 - 10% Discount Code for Paint Supplies Direct BONUS: FREE Paint Supplies Direct T-Shirt

There is no such thing as a ‘white lie’ when you are trying to run a truly professional contracting firm. All untruths are equally corrosive.

By Steve Maxwell

Backin June I got an email from a woman wondering about roof shingles. It reminded me how easy it is for contractors to destroy their own credibility with white lies. Earlier on I’d recommended a certain brand of shingle to this homeowner, but the contractor didn’t want to use them. “They’re a half inch shorter than standard shingles,” he told her. “And this means more cutting to match lengths and hide nails. It’ll cost you more.”

Really? A 1/2” difference in shingle length is going to be so much more trouble and expense? No doubt this contractor has his reasons not to use the shingles I had recommended – and I believe those reasons would not sound good if spoken plainly. Maybe he has some special arrangement with a particular supplier of another brand that gives him a discount. Maybe he’s just frightened of the smallest change in his work routine. I don’t know, but cooking

ONE WHO IS FAITHFUL IS VERY LITTLE IS ALSO FAITHFUL IN MUCH. AND ONE WHO IS DISHONEST IN VERY LITTLE IS ALSO DISHONEST IN MUCH.”

up some fancy sounding nonsense about shorter shingle length is asking for trouble. And he’ll get it, too. Why would any homeowner want to do business with someone who isn’t honest in the little things?

So that is what I told the homeowner. As a famous carpenter once said about 2,000 years ago, “One who is faithful in a very little is also faithful in much, and one who is dishonest in a very little is also dishonest in much.”

To be fair, every contractor definitely needs to steer clients away from their own silly ideas sometimes. This is especially true in the age of the Internet, where everyone is an expert, and homeowners

expect the world because they saw it on Pinterest. The thing is, using lies – even dishonest excuses about little things like shingle length – isn’t the way to protect clients from themselves. Nor is it the way to get what you need. Eventually what goes around, comes around. The universe was designed to operate much better on honesty in all things, even the little things.

Our world is awash with lies, so much so that we usually don’t even see them any more. And while going with the deceitful flow is a common policy these days, doesn’t this also mean that honesty in the little things is one way you can shine more brightly? cc

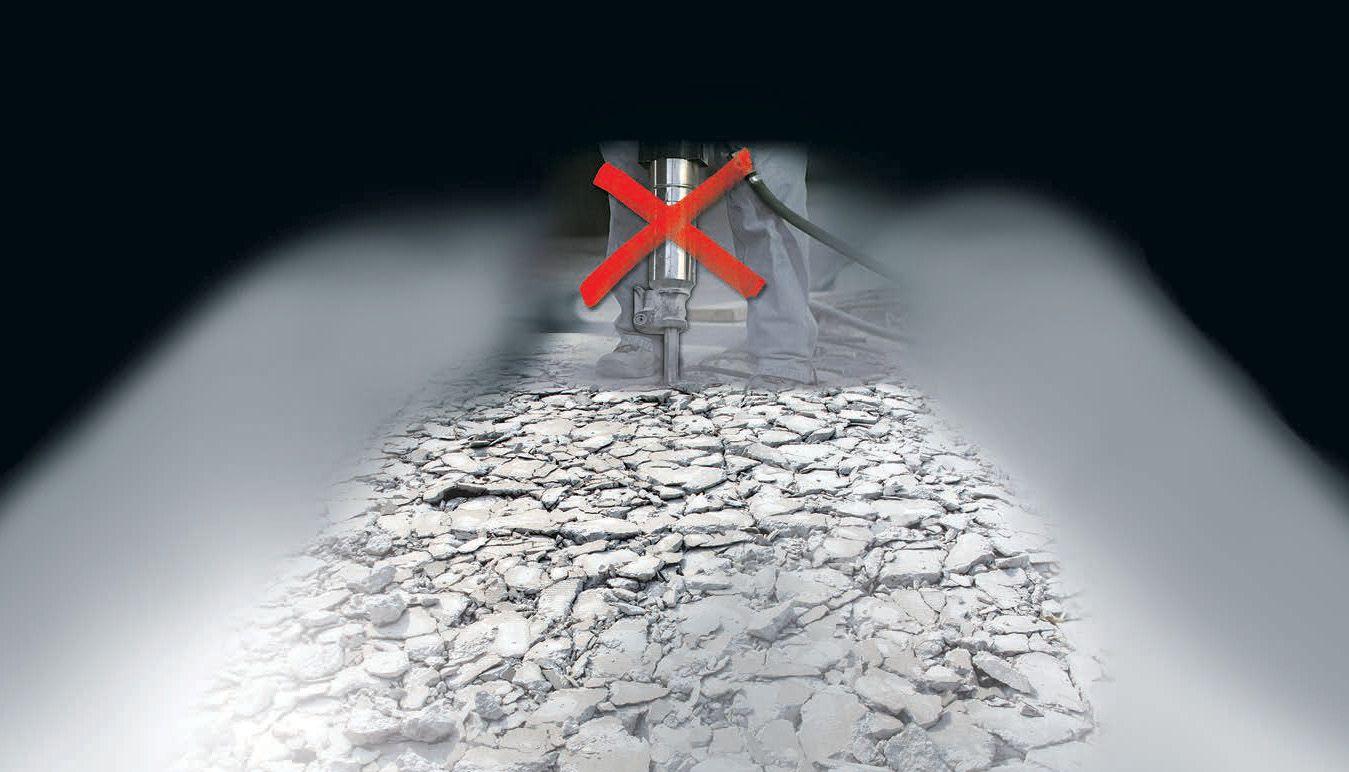

Brick Veneer is one of the most common exterior cladding treatments in Canada. Making sure it will endure through decades requires specific attention to air and water control.

By Steve Maxwell

There’sa reason brick veneer is considered one of the premium exterior wall treatments in Canada. It’s long lasting, maintenance-free, it boosts energy performance and resale value, and it looks great. The thing is, a brick veneer job needs to be laid down with specific installation details in order to endure. And while bricklayers are supposed to know and follow all the best details on their own, as a contractor you need to be your own watchdog. Ultimately, the reliability and quality of all areas of a project is your responsibility.

One of the biggest differences between a top quality brick veneer job and a bad one comes down to moisture control. This is especially true in Canada, with our legendary freeze-thaw cycles. Besides

the need to keep brick at least 6” above the soil surrounding the building to avoid splashed water, the heart of moisture control begins with how the all-important air space is dealt with.

Of course you know there’s got to be

an air space between brick veneer and underlying wall frames, but that’s usually where understanding (and attention to detail) begins to taper off. What’s less obvious is how that air space can be mismanaged during brick installation to the point where the air space doesn’t function properly. One common

mismanagement issue has to do with failure to allow for mortar squeeze-out. Even the neatest brick layer in the world will drop mortar while they work, and when this happens in the space between the brick and wall frame, it can short-circuit the drainage action of that space. Even six inches of hardened mortar buildup at the bottom of the space will slow or prevent the drainage of water that gets behind the wall.

The best way to ensure that dropped mortar doesn’t clog brick veneer air spaces is by applying a ventilation screen or mat against the wall before bricks go on. Some systems cover the entire wall, and other systems keep drainage open just by sitting at the bottom of the air space. To work properly, the ventilation screen needs to connect with weep holes in the bottom of the wall, one missing vertical mortar joint every three or four bricks along the bottom.

Water is sneaky stuff, and that’s the reason to install flashing between the bottom layer of bricks and the top of a foundation, extending up the wall frame at least 6”. Without this flashing, water can do one of two nasty things. First, any liquid water that drains down in the air space is just as likely to leak back into the building as it is to drain out the weep holes. Flashing ensures an outward flow only. And second, flashing ensures that

Advances in building wraps have made it possible to have your cake and eat it, too. Today’s best wraps provide very durable protection against liquid water, while also allowing water vapour to pass through them if drying of the underlying wall frame becomes necessary. A building should be waterproof before brick goes on, but breathability is a big bonus, too.

water hitting the outside of the bricks doesn’t sneak into the joint between the brick veneer and the foundation. Since the flashing extends beyond the building with a lip, it encourages water to drip down on the outside of the foundation, just like it’s supposed to.

These days “flashing” isn’t usually the sheet metal that gave this item it’s name years ago. Now flashing is much more likely to be a flexible, synthetic membrane laid on top of the foundation

wall before the first bricks go down. This works fine and is code compliant, but copper is still considered the best option. Copper resists corrosion, lasts forever and since it’s rigid it can be bent to create an angled extension that ensures water drips beyond the foundation.

These are missing mortar joints at the bottom of the brick veneer designed to let water out from between the brick and the

From time to time you’ll meet clients who want the old-fashioned look of antique, reclaimed bricks. That’s understandable, but it also presents a danger that you need to explain. Reclaimed bricks usually come from buildings that were made entirely with brick – no wood or steel wall frames involved, just multiple thicknesses of solid brick, two, three or four bricks interlocked together. In vintage buildings like this it wasn’t unusual for only the exterior bricks to be fired to the point where they don’t absorb enough moisture to be in danger during winter. Cheaper, more porous brick could have been used for all the rest. It’s entirely possible that some inner bricks can get mixed up with an order of reclaimed antique brick, leading to flaking and spalling of that brick in time. Your clients need to know this.

mark soffit height on wall before brick installation

brick tie

brick tie spacing at least every 16” up wall studs

brick tie nail penetration at least 1-1/4” into wall studs

breathable waterproof building wrap

non-woven ventilation and drainage layer

building wrap overlaps steel lintel

steel lintel

flashing over lintel and under bricks and lapped underneath building wrap

weep holes

allow 1/4” free space between end of steel lintel and mortar

cast window sill

flashing extends under cast window sill and under window

1” air space

stud frame wall

brick tie

rim joist

base flashing either flexible synthetic or bent copper

bottom of air space free of mortar and open to weep holes

brick at least 6” above grade

weep holes every 3 or 4 bricks

wall frame, but the standard practice of leaving weep holes open is risky because they can let in insects and mice. Small rodents have no trouble squeezing into the 3/8”-wide width of an open weep hole. Protection against vermin is why weep hole vents were made. The best I’ve seen are built from stainless steel and can be opened for inspection and cleaning. Every time you aim for uncommon quality in your projects it’s a communications opportunity. Put bestpractice brick veneer details into action, then let your clients know with photos and a quick note. You’ll be more likely to impress the right kind of people this way, helping you get the best kind of jobs in the future. cc

Brick veneer seems solid, but technically speaking it’s not supposed to bear any load beyond itself. This means you’re never supposed to bolt a deck directly to brick veneer. So how are you supposed to support a deck in cases like this? There are different takes on the challenge, most with significant problems:

• Support the deck from the main foundation down below the brick. This is easier when the brick is only a few courses above the foundation, but still not simple.

• Bore an oversized hole through the veneer, then anchor the deck into the rim joist of the floor frame with a lag bolt or compression bolt. In practice, this still can put a load on the brick veneer as the bolt bends downwards under the weight of the deck. Also, if you tighten the lag bolt too much in this application, it could crack the brick because of inward pressure of the deck floor frame.

• Remove brick so the deck floor gets bolted directly to the house frame. I’ve only ever heard this suggested by engineers. Who is going to open that can of worms in the real world?

• Make the deck fully self-supporting. This is the least controversial approach and makes good sense. No inspector will complain if the job is done right and a complete deck foundation eliminates any chance of water infiltration into the house.

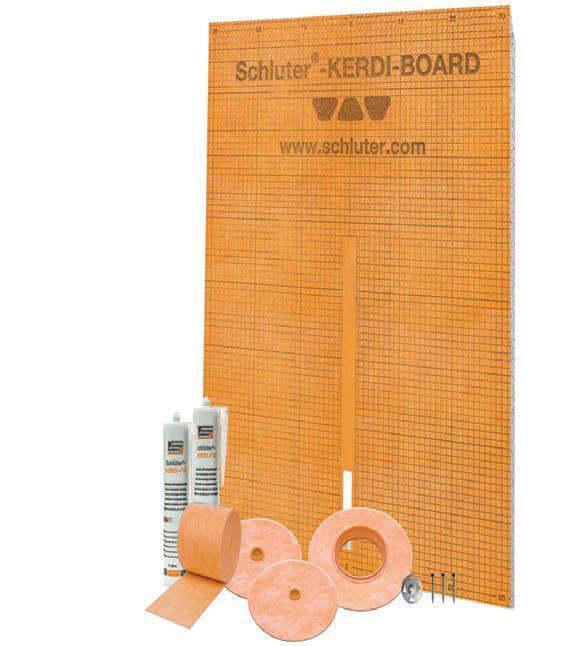

If you’ve ever used Schluter products to build a shower or tub surround, you know how well they work. I’ve never used anything that even comes close to the performance offered by this system for tiled installations. Kerdi-Board panels for walls, ceilings, benches and built-ins are light weight, they cut dustlessly with a knife and they hold tiles securely. Kerdi-Band membrane offers a simple way to waterproof joints, using nothing more than thinset. Kerdi-Fix is a sealant that creates a waterproof connection where walls meet a shower base or tub. Most shower and tile surround jobs involve all these components, so Schluter combined them into their new Kerdi-Board Kit. The boxed collection also includes mounting screws and washers, a seal to waterproof 4-1/2” valve bodies, plus 1/2” and 3/4” pipe seals for where they exit the tiled area. Throw the box in the back of your truck and get going for $617. cc

The problem with outdoor wood is that it’s more of a pain to keep finished than many people realize. This is especially true for the kind of clients you may be dealing with more and more often these days – people who want to minimize the amount of maintenance they have to deal with in their lives.

Eco Wood Treatment (www.ecowoodtreatment.com; 888-738-5516) is an ideal option for creating good looking exterior wood without the need for regular refinishing. It’s also very easy for you to apply as a contractor. I’ve been using their original product on my own projects for years and it works great. Dissolve this powder with water, spray, roll or brush it on bare wood. It’s nontoxic and has no odour, except for the slight smell of iron. Over a period of weeks and months this treatment turns wood surfaces a nice, even weathered grey colour. “Even” is the operative word here.

Unlike natural weathering that varies from nearly black to splotchy moldcovered light brown depending on the exposure, an Eco Wood surface is refined and simple. You only ever apply this stuff once. It works on decks, docks, fences and any other outdoor wood surface. The only drawback is the informal look it creates. There’s no colour, as such, just an even medium or dark grey, depending on the wood type. Western red cedar turns fairly dark in time, and so does white pine. Eastern cedar turns a medium grey, and pressure treated wood gets light grey.

To satisfy the demand for a fancier alternative, Eco Wood Treatment came out with a semi-transparent coloured version. It comes with the same envelope of powder that weathers wood by chemical reaction when mixed with water, but there’s also a small bottle of dye. Mix the dye and the water with the powder, then apply it the same way as the original. I usually use a pump-up backpack weed sprayer for this job. I haven’t seen how the semitransparent formulations last over years, but it looks much more formal than the original. The only drawback is that colour versions aren’t supposed to be used on deck surfaces that get foot traffic because the abrasion wears off the colour.

Available from Eco Wood directly, or at Castle, Home Depot, Home Hardware, Lowe’s, Rona and others. $25 for enough original powder to make one gallon of product; $90 for enough to make five gallons. cc MAXWELL’S

If you’re hired to winterize a cottage, there is a Canadian product that can help you with the pipes and plumbing. Called The Clozer, it will make the work safer, easier and faster.

AskCanadian cottage owners what their least favourite part of cottaging is and their answers usually come down to winterizing water systems and priming them again in spring. Cottagers aren’t usually plumbers, so most of the ones I know leave in the fall with a feeling of dread. “Did I get all the water out? Will my pipes and plumbing be okay next spring? Will priming be a nightmare again next season?”

Eliminating worry and uncertainty is what a Canadian invention called The Clozer (www.theclozer.ca; 855-592-5888) is all about. It’s a simple system that some of your clients will love you for recommending. Designed and manufactured by 40-year veteran Ontario plumber Brian Feeney, it’s a portable, flowactivated electric pump unit with a built-in antifreeze reservoir. The pump connects to ordinary valves spliced into the hot and

THESE TWO

ONE FOR WINTERIZING A COTTAGE’S PIPES AND ONE FOR PRIMING THEM AGAIN IN THE SPRING, OUGHT TO BE

IN EVERY COTTAGE COUNTRY CONTRACTOR’S TRUCK.

cold lines at the water heater, then forces non-toxic antifreeze through all parts of a water supply system as taps, fixtures and appliances are turned ON one at a time. Turn a valve OFF when the flow changes from clear to the pink colour of the plumbing antifreeze and The Clozer pump shuts off automatically. No going underneath cabins to empty supply pipes, not even drain pipes. Let a little antifreeze go down the drain after water from the last valve is displaced and it’ll freeze-proof the drain trap, too. It takes less than an hour to do a typical home or cottage and most people save a couple of hundred dollars a year compared with calling in a pro to drain the system.

Displacing all water in the hot and cold lines with antifreeze eliminates the hazard of freezing pipes for your cottage clients, but it’s also the only reliable way to protect washing machines, dishwashers, ice and water systems in fridges and tankless water

heaters. Fancy items like these aren’t made to be reliably drained, and they’re appearing more and more often in cottages these days.

Feeney has designed two versions of his portable pump system, The Clozer Original does the same job as The Clozer II, except it’s heavier duty, more for professional use. Both hold 15 litres of plumbing antifreeze. That’s not enough to do the average home, but the reservoir is easy to refill on the fly.

Since winterizing indoor supply lines in seasonal systems is only half the battle, Feeney created something called the TC-3 to make priming the intake line of seasonal water systems easy in the spring. The TC-3 fitting connects to the intake line that draws from a lake, river or well, located just downstream from the pump. The TC-3 is made to connect to 1/4” diameter plastic tube that extends all the way down inside the intake line to the foot valve. Connect The Clozer to the TC-3, fill the reservoir with water, then turn it ON. The pump fills the intake line from the foot valve up through the tube, displacing air in the system that comes out the vent valve in the top of the TC-3. Repeat the process again in the fall using antifreeze instead of water and you can winterize a water system without wrestling with pipes, foot valves, submersible pumps or any of the other nonsense that makes cottage owners doubt why they own their place. Pump leathers and O-rings last much longer if they’re kept wet all the time, too. The whole thing makes sense for snowbirds who leave their city house empty all winter. Shut off the water supply, fill all the lines with antifreeze and there are no worries about pipes freezing and bursting in the event of a long-term power failure. cc

By John Bleasby

Peter Seidenberg and his son Rolf have a reputation all over town as firstclass tilers. Homeowners are lucky if they can book the Seidenbergs for their bathroom, hallways or kitchen floor work. Their quality comes at a price, but people are prepared to pay. That includes Sergio Fabiano. Fabiano owns a couple of businesses including a five-person carpet cleaning business, and he flips houses. He considers himself a big shot, and has the big mouth to go with it. He openly boasts about his success and how he’s rich enough to own a big house with a 60-foot pool and a pool house. Fabiano called up Peter one day and said, “My daughter is getting married in three weeks and the reception is at the house. My wife wants the tiles in the pool house changed. You need to get this done right away. I don’t care about cost.” Peter and his son had done the original tile work, so they felt a loyalty to this important client. However, if they go immediately to Fabiano’s house, it means stopping work on a new custom house for an elderly couple about to move in.

What should Peter do? See the options at right.

All contractors should be so lucky to have clients who want to pitch in. Or should they? In our May/June issue Dilemma, Jeremy Pudney’s young clients, the Howards, are keen to help on their 1920s renovation. However, they’re now causing problems and delays for the professionals on site. How does Pudney curb their enthusiasm in a way the Howards will understand? Should he carry on and work around them? Explain they have to coordinate their schedule with his so everyone is working more efficiently? Explain the delays are costing him lost time and added expense and that they have to back off the site completely? Or something else?

Thank you to everyone who submitted a proposal. They were well conceived, well written and full of great ideas. Every proposal received spoke to the need for better communication. However, Jax Bailey of Prince George, B.C. hit several additional nails on the head. Jax correctly noted, “Pudney’s business license and WCB are at risk.” Furthermore, “the clients also might not be building to code.” Bottom line: “The Howards need to understand that they have hired professionals who are knowledgeable and skilled in their trades.”

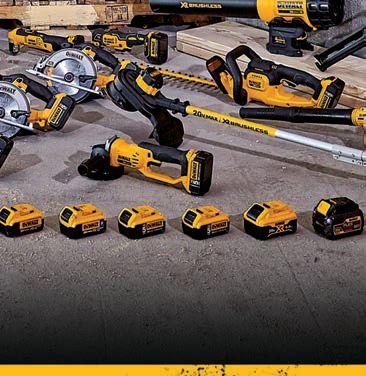

Congratulations, Jax! You will receive two prizes from DeWalt! (1) A DeWalt 20V MAX 1.2” Mid-Range Impact Wrench for high-powered use in compact and hightorque applications and (2) a DeWalt 20V MAX Jobsite Fan.

1. Tell Fabiano to take a hike. He has to wait in line like any other customer.

2. Send son Rolf over to see if there is some way they can get both jobs done by splitting up.

3. Drop the custom house job and look after Fabiano so he doesn’t bad mouth Seidenberg.

4. Something else (please explain).

Email your answer to John Bleasby (jbleasby@canadiancontractor.ca) by August 29. The winner will be announced August 30 on our website.

Your suggested solution can be one of the above ideas, a combination, or your own idea entirely. Please explain your reasoning in up to 300 words of text. The best contractorsubmitted entry, as judged by our editors, will

DeWalt’s rugged jobsite sound system, the TSTAK Radio + Charger, featuring a USB charger and AUX port, and a large storage and battery compartment.

By installing DuPont™ Tyvek® Building Envelope Solutions, you are building your reputation as a contractor who uses superior materials from a company that stands behind them. You also benefit from the support of a network of DuPont™ Tyvek® Specialists who are available to assist on the jobsite to help you deliver superior performance and lasting value for your customers. Trust your next job to DuPont™ Tyvek®.

Tough. Tested. Proven. | That’s DuPont™ Tyvek® Building Envelope Solutions. construction.tyvek.ca