Sash Window

Restoration

Reviving a Forgotten Art page 36

World Class

Drywalling

Halifax Firm Wows Prague page 40

Building Green

Affordably

Calgary Contractor Shows The Way page 18

Sash Window

Restoration

Reviving a Forgotten Art page 36

World Class

Drywalling

Halifax Firm Wows Prague page 40

Building Green

Affordably

Calgary Contractor Shows The Way page 18

How Cory Kloos and Desmond Sweeney, Macanta Design Build, rebranded their Winnipeg firm

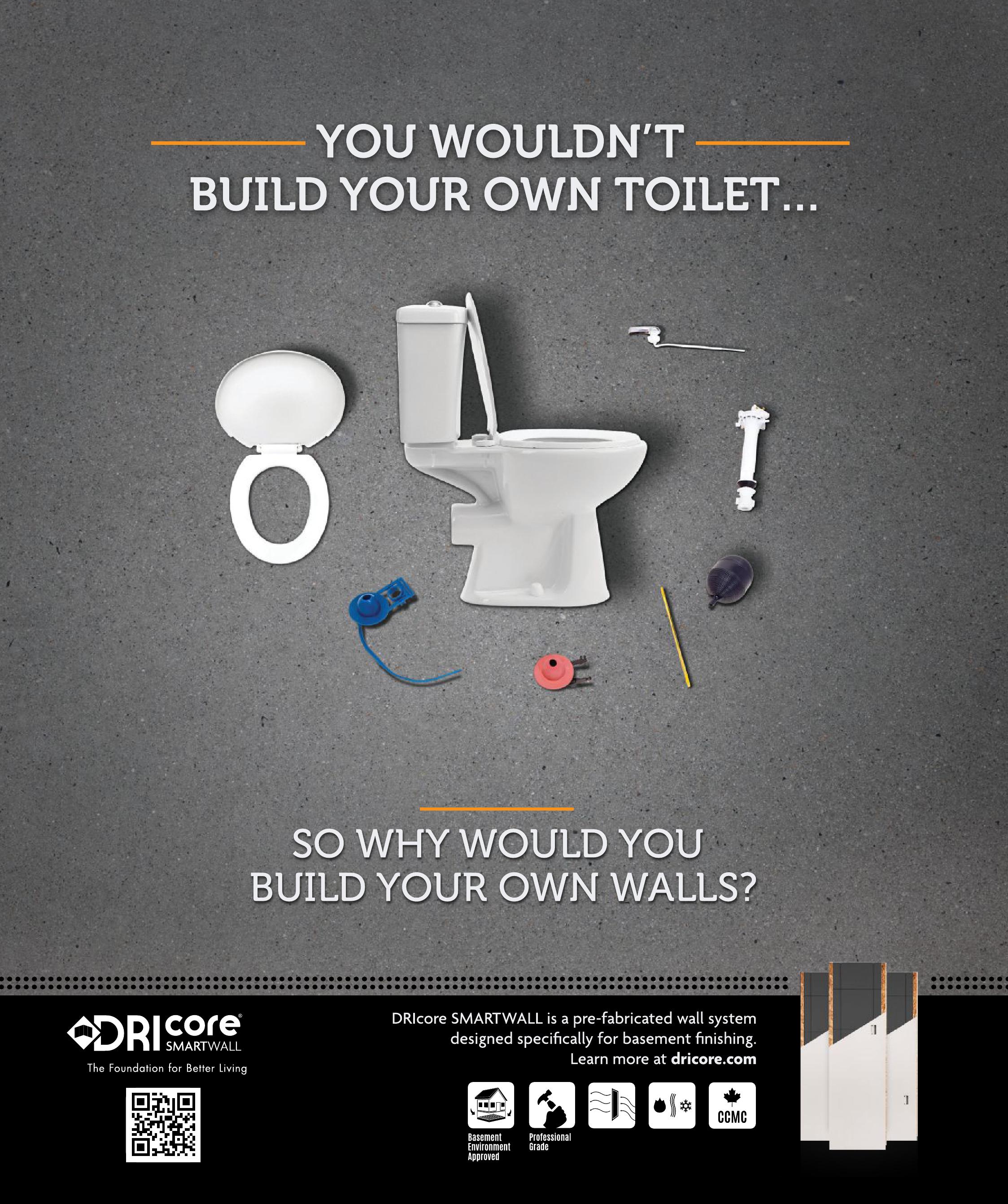

You Build Green, Affordably? 18

according to Calgary townhouse builder Partners Development Group, who work to BuiltGreen specs.

STORY What’s In A Name? 22 Winnipeg renovation contractor Desmond Sweeney, Macanta Design Build, discusses his firm’s recent ‘rebranding.’

Window Sash Bible

A review of window expert Steve Jordan’s how-to book on putting historic windows through ‘rehab.’

with less waiting.

Chris Chisholm, owner of Tartan Interiors, made the finals of an international drywall competition.

Online 10

How to put the Canadian Contractor icon on your phone, for one touch access to our breaking news.

Editorials 8

Rob on the importance of coaching; Steve on knowing your numbers.

Voices 10

The best of the recent online comments at www.canadiancontractor.ca.

Site Notes 14

A contractor in Fort McMurray sees his home and tools destroyed – and gets a boost from DeWalt.

Contractor Law 28

Can you be sued for causing “mental distress” to your homeowner?

Creative Eye: Multiple Ovations 30

A look at The Winton House by Naikoon Contracting, North Vancouver, voted the best in its class by two different home builder organizations.

Stuff We Like 47

Steve Maxwell shows us six tools that make his contracting life easier.

What Would You Do? 58

Send us your solutions to this month’s contractor dilemma and you could win a cool tool package from DeWalt.

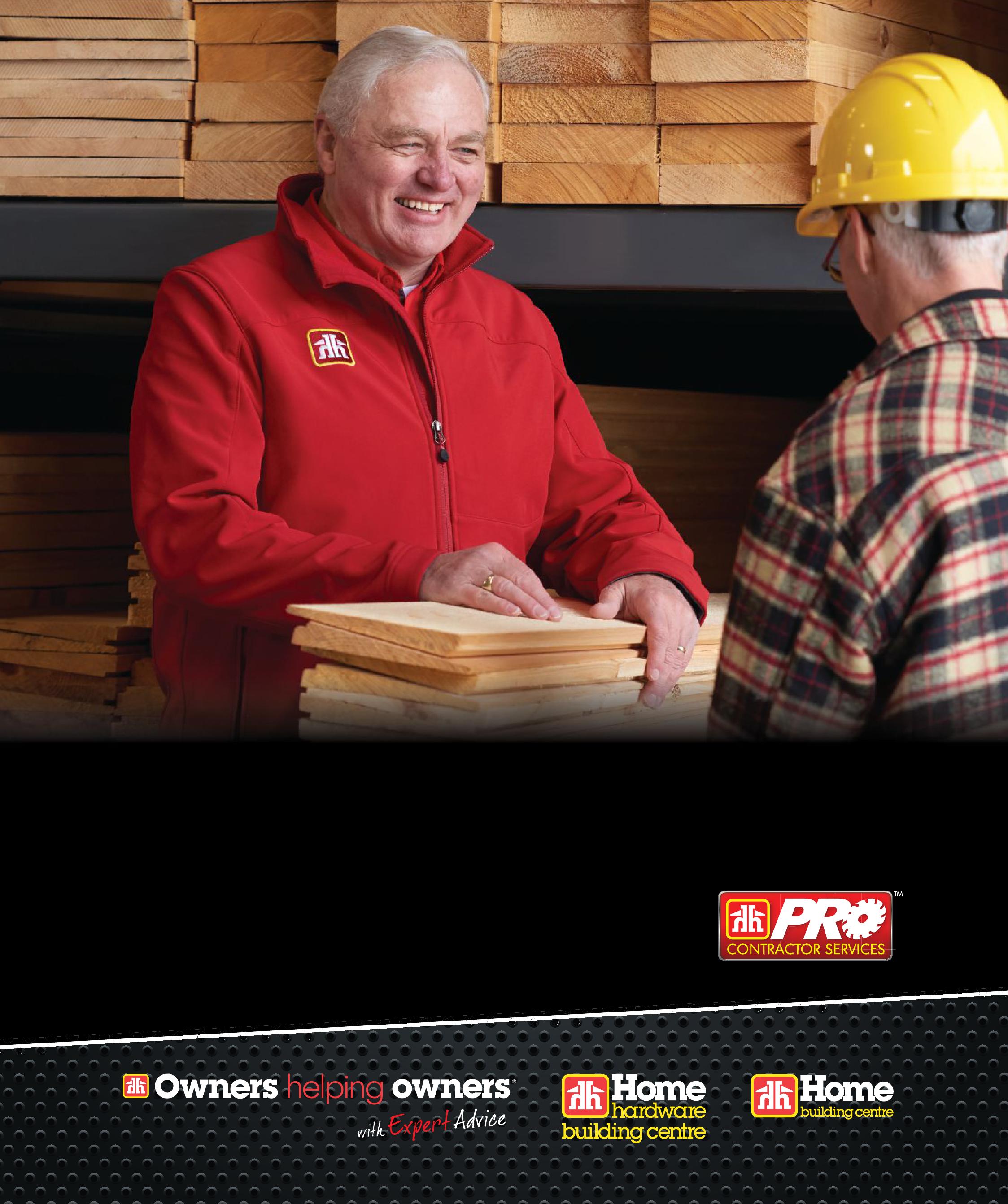

Bob Collins

Home Building Centre – Gravenhurst Gravenhurst, ON

When your reputation is built on quality, you depend on relationships built on trust. That’s why you can trust the Experts at Home Building Centre and Home Hardware Building Centre to provide the tools, materials and services you depend on – from dedicated contractor sales staff and easier ordering through phone, fax or email to job site deliveries, credit services and package pricing. With a relationship built on trust, you know you’re building on a strong foundation.

pronews.ca

Visit us online

• Google Canadian Contractor on your mobile device

• Open the link to canadiancontractor.ca

• When the page opens, tap the menu button on the lower left corner of your screen

• Select “add shortcut”

• Go back to your device’s screen and locate the Canadian Contractor icon (It may appear on one of your later pages.)

Go to canadiancontractor.ca and type “icon” in the search bar at the top right. The link to the video will pop up.

| Tel: 416 442 5600 | 80 Valleybrook Drive, North York, ON, M3B 2S9

Canadian Contractor, established in 2000, is published 6 times a year by Annex Business Media.

• Press and hold the icon, and drag it forward page-by-page to the desired page on your device

• Go to canadiancontractor.ca using Safari or your favourite browser

• When in portrait mode, click on the square icon with the “up” arrow that appears at the bottom of the screen

• Chose “add to home screen”

• Click “add”

• The icon should appear on your Iphone or Ipad home screen

Now with one click, you can go directly to the latest news!

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Alec Caldwell, Mike Draper, Peter Leonard, Steve Maxwell

Art Director Lisa Zambri

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator Tracey Hanson thanson@@annexbizmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbizmedia.com

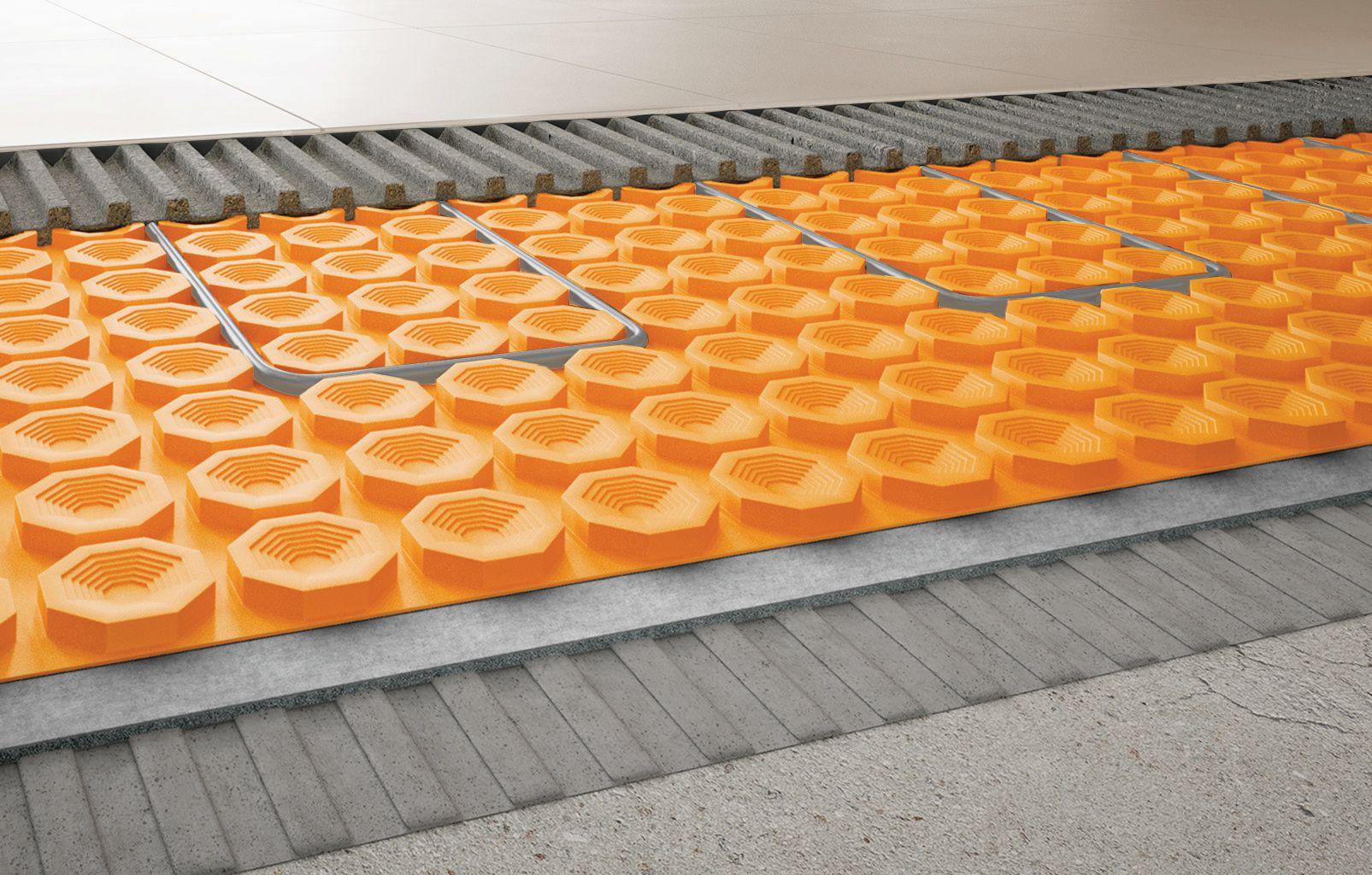

Electric floor warming system with integrated thermal break

Schluter®-DITRA-HEAT-TB is the only electric floor warming system with an integrated thermal break, and is ideal for tiled floors over concrete.

• Heating, uncoupling, and a thermal break in a single layer

• Warms tiled floors up to 70% faster over concrete substrates

• Saves energy by directing heat to the tile, not to the subfloor

• All-in-one system means faster and simpler installation

• Only 5/16"-thick to minimize construction height

10 year warranty!

He missed an opportunity to make me a repeat customer. ” ”

Rob Koci Publisher rkoci@canadiancontractor.ca

By Rob Koci

Before I joined Canadian Contractor, I had put in several decades framing houses and, later, renovating. I will be the first to admit I wasn’t always perfect. Recently, I became a client again myself when I needed some painting done in an area of my house that I had worked on but was fed up with. I wanted a professional to finish it up.

My contractor was technically proficient but needed “customer sensitivity” training. I wanted the space finished. I wanted the stuff I had not done to get done. There was painting and plastering to do. I stood at the entrance of the area that included a bathroom and a bedroom and a very small hallway and said, “I want all this finished.” But somewhere in there, I also said he need not try to improve on the quality of the plaster and then repaint in the areas I had already done.

To keep this short, an area of the bedroom wall about six inches wide came into dispute. We both knew he was going to come back to solve the problem, but in the exchange outlining my justification for wanting it fixed and his for not fixing it in the first place he missed an opportunity to make me a repeat customer.

Though from the beginning he was prepared to fix the problem, he wasn’t prepared to let me go without my acknowledging that he was justified in not doing it if he chose to. He wanted me to acknowledge that he was doing me a favour, not fulfilling a responsibility.

I chalk it up to the pride of youth, but it was bad customer relations. I had to humble myself and essentially say I was wrong before he would fix the problem. I gave him a big middle finger with my inside voice, acknowledged his position, and left it at that.

He was technically good and he’ll do well in his contracting career, but I came away thinking that with just a little coaching, he would do so much better. Good coaching turns good contractors into great contractors.

Mentoring or consulting can fix little things that make big, big differences.

By Steve Payne

About 15 years ago, Tony Flanagan, a Home Hardware dealer next to the Ford plant in Oakville, Ontario, won an award for being the best hardware store in the country.

Tony’s business was super profitable and growing like crazy –even though he was competing with the Wal-Marts, Home Depots and Canadian Tires of the world.

When writing an article about Tony I asked him: “Please give me a single sentence why you are so successful.”

He answered with the most boring – and also the most critically important – sentence ever heard around a business.

“I know my numbers.”

Boy, did he ever.

“I sold $72,340 of stuff from my sidewalk last year,” he told me. (I can’t remember the actual numbers. Tony would.) “I sold $24,320 out of that end aisle display,” he replied – pointing to an area of his store about the size of a phone booth.

He had all these numbers written on little index cards, filed away neatly.

Do you know the numbers on your renovation business as accurately as Tony knew his store?

Do you know how much money you made – or lost – on every single project you tackled?

Can you recite your 2015 total sales, gross profit, overheads, net profit, employee labor costs, subtrade labor costs and marketing costs? Do you know, to the penny, your owner’s compensation and how much the company made – and the difference between the two?

And do you know how this compares to the numbers being put up by the best renovation firms, of similar size, all across Canada?

Sources of financial information on the metrics of running a renovation or homebuilding firm are available from “peer” groups such as Renovantage and Remodelers Advantage, or in simplified (admittedly, crude) form in our own Canadian Contractor Salary Survey, published every April.

If you’d like more information on any of these, please email me at spayne@canadiancontractor.ca.

” Peer groups like Renovantage and Remodelers Advantage can help.

”

Here are just two of dozens of online posts we have received about Fort McMurray. For more on the situation, please see page 14.

Edmonton firm recruiting for Fort McMurray cleanup is not messing around

I applied to a posting by a firm out of Edmonton and was told that I have to be a resident of Edmonton. The pay is $15 an hour. It's four to five workers in a room and you have to sleep on the floor after a 12-plus hour day. If you complain you will be forced to leave Fort Mac in a taxi back to Edmonton at your cost and any monies owed in wages will be reduced to minimum wage…

Now most of these homes would have been insured – that would mean clean up and rebuild. Canadians donated $30-million plus to the Red Cross. And government matched that, so the total should exceed $60 million. Where is this money actually going if most of the residential cleanup and rebuild is covered by insurance? Is this whole thing a sham? Is Fort Mac getting shafted big time?

Christopher

After reading your online interview with the Alberta Minister of Economic Development and Trade, it occurred to me that time is a very important aspect in this situation. It’s only five months until freeze up. By then, buildings under construction will need to be at least to the lockup stage – with all essential ground work done. Or costs are going to spiral upward and production per man is going to drop. No man can fight two battles as well as one. There is a massive amount of work to be done in the Fort Mac area alone, so Albertans had better strap on their fastest runners and go for it. And if they can get some help from others, well, be grateful. Remember, the fires aren’t out yet [at time of writing in May] and flood season is nigh. Luck to you all.

Steve Northridge

Steve Maxwell wrote an editorial in our last issue called “Avoiding the Young Contractor Trap.” He pointed out that the physical stuff you do at 23 – if you plan to stay on the tools “forever” – can become a real grind at, say, 53. Hence the importance of building a real company where you have don’t have to punish your body when you are older: You are the president/

owner, not the labour. Your business can run on “auto pilot.” Sam Granata didn’t like this idea one bit…

“What’s wrong with a man getting old pushing a wheelbarrow ?”

I’m 50, still have brawn and brains and enjoy what I do. Started with one employee and will retire with one. We are the true builders who love what we do, not the businesses that run on auto pilot. If I had brains to run what you call a “true business,” contracting would be the last one on my list. I don’t see what’s wrong with a man getting old pushing a wheelbarrow instead of a pen. I’m proud of what I still build myself everyday.

Sam Granata

Here is Steve Maxwell’s reply to Sam…

Thanks for your note, Sam. Good to hear from you. I’m 53 and I love pushing wheelbarrows (and other manual work). I did that yesterday and I will do it again today. My point in my article was just that building a little team where you are not the only leader gives you flexibility. You can push a wheelbarrow if you want, but your livelihood doesn’t depend on it. If you’re hurt or sore, or want to take a vacation with your wife, or take a sick day, or go see your grandkids at the track-and-field days at their school, you can. Your operation can still generate income for you even when you’re not pushing a wheelbarrow. Anyway, just some thoughts. I hope you have a good day.

Steve Maxwell

Neil Damackine, Construction ND, Terrebonne, Quebec, posted this article online, in which he shared his recent experiences with two unnamed lead generation services.

“The pros and the cons of paying for leads.”

I was doing pretty good without any type of outside lead generation when a landscaper friend of mine told me about his lead generation service and even referred some customers that he had served. I found the quality of his clients to be high so I decided to sign up with his service. After about a year using two different lead generation services, here are my observations. The common sales pitch began with: Our clients expect to pay a little more and we only give the lead to three contractors. The reseller’s team of “owner representatives” sent out the leads

to several contractors and took the first three who bit. Then they usually collected the submissions and presented them all to the client for a decision.

The lead generation companies I dealt with were paid two different ways but either way I felt I would be better to re-qualify every lead to get the whole picture. Flat fee leads were between $5 and $50. Refunds were available if the lead was nonresponsive or the contract had been given before I established contact. Commission leads were paid only if I converted the lead but a commission was expected for any future work for the life of lead.

The pros of this service were: I got ‘no effort leads’ in the inbox.

The cons of this service were:

1. Flat fee leads were generally dubious in quality but there were some pearls in the rough.

2. Commissioned leads cost up to 10 per cent on smaller jobs!

3. Commissions continued to all future work requested by the “owner’s” client.

4. A few “owner representatives” were competent and nice to work with. But others didn’t know how to qualify prospects and submissions properly, let alone distinguish who was best suited for the work. Or they simply didn’t care because they were making a commission on the job no matter which contractor got it! The clients were not all properly vetted and it seemed a lot like the dumb leading the blind to see an inexperienced owner representative mismanage a lead (apologies to anyone who is offended by my lack of political sensitivity).

5. I insisted on doing my own presentations but I found many of the clients who needed the most care were reluctant to make decisions without their “owner representative” (re-read 3-4!).

6. All the contractors were supposed to be vetted but I calculated the winning bids

from a few different jobs (requiring specific license categories and trades certifications) to discover they were below cost on labour and material — even before adding cost of sales and mark up. This left serious questions as to the qualifications and techniques of the winning “contractor.”

In the end, here is my verdict. Many lead re-sellers are OK for a handyman looking for a few bucks but not so good if you’re a professional contractor with a long term perspective. I like to give back to my clients so I find it crowded whenever a third party’s costs constantly overshadow the cultivation of a long-term client relationship way beyond the initial work.

I think there’s room for professional lead re-sellers and I’m fine purchasing a lead for either a one-time fee or a single reasonable commission, but looking ahead I’m concerned that the high cost of sales being paid to a non-construction third party is creating an industry monster that’s going to damage contractors and job quality. At least, so far I’ve seen nothing to convince me otherwise.

There is an increasing prevalence of renovation services by contractors who resemble telemarketers more than building professionals. A number of renovators accept these terms without a thought to the destitution of their markups – and subsequent ability to give back to the client and build their businesses. This adds up to nothing more than a smoke screen – and money taken out of the client’s budget for basically nothing in return.

The end is predictable: front line contractors becoming disposable products – with no claim on the relationships they’ve built with clients – in continual servitude to the marketing “contractor.”

In conclusion, most of what I’ve experienced from lead marketers is what I wanted to get away from when I started my own company. Renovation marketers slice

Brian Schon is enjoying more success today than any time in his 30 year career.

Just before Christmas 2014, Brian Schon picked up the Nov/Dec issue of Canadian Contractor and something caught his attention. It said, “Canada’s first truly national brand name in home renovation and homebuilding using a unique business system.” Brian thought, “I’ve been looking for something like this for years.” Like most contractors, Brian was experiencing challenges operating a contracting business. He was successful, but was wearing too many hats. He couldn’t break through beyond building a few houses a year and was unhappy with the rising risks and constant cash flow crunch.

Soon after reading the article, Schon met with Alair and has gone on to own Alair Homes London Grand Bend in Ontario. Today Brian’s business is more profitable with a greater variety of projects and less risk. Brian now owns national-brand power that has elevated his business to new heights. When asked of his decision to join Alair, Brian responded, “Alair is such a simple concept; it’s easier and smarter and it’s basically what every contractor should do, yet most never know about an opportunity like Alair.”

To learn more, visit www.alairfranchise.com and download the 2016 Edition of “The Smarter Way to Own a Construction Business.”

the renovation pie a lot thinner for the most important people at the table, the client and the construction professionals. It’s far better that renovation and construction business owners invest the cost of sales money into proprietary marketing and lead generation. Because once the client relationship is established, both renovator and client will benefit far more together without the constant financial servicing of a bloated elephant overshadowing the room!

Neil Damackine

Construction ND, Terrebonne, QC

A recent sponsored post by Jeld-Wen talked about different methods for arriving at a fair price. Quebec contractor Matt Smith sent us this interesting reply.

“We avoid giving clients bullets to shoot us.” When it comes to determining price there can be a fine line between the two billing methods of (a) Time & Materials plus Overhead and Profit and (b) Lump Sum.

We have the best luck using more of a lump sum to avoid giving clients bullets to shoot us. We have Infrastructure on one line and Allowances on another, with mark-up built into Total Project Value.

Here are some of the things we focus on for all projects: Open communication, proper design, clear scope of work, estimated fair price for the scope outlined and sufficient mark-up to cover our overhead and profit – to stay in business. We try to listen more, play fair and make the client into a raving fan.

Matt Smith

An anonymous Toronto area contractor received the following “Request for Quotation” from a prospective customer. He shared it with us. (“Ask other contractors if they would try to work with such a client,” he said.) We posted it, and got 17 NO replies and one MAYBE. (We have deleted any information that could identify the customer.)

1. I am interested in getting a free written estimate for renovations to my residential property in _____ sub-district of Mississauga,

Ontario.

2. While the work may start later (as per written renovationcontract) I want the estimate as soon as possible.

3. As advised by legal counsel (to avoid getting sued, IF the visitor slips-falls, etc., while on my property), BEFORE the contractor-renovator steps on my property (which commences at the driveway connected to the public sidewalk) to do an inspection (of required repairs to generate the currently accurate estimate), I require:

(a) the attached liability-waiver signed (a draft copy is attached)

(b) a photocopy of the liability-waiver of the individual (that evidences that the individual has currently valid liability insurance coverage).

(c) For security reasons, I shall meet the contractor at a public location, and after he has provided me the above-noted (satisfactory) paperwork, I shall take him to the property.

4. Some of the work that needs to be done includes damages by seller-renter, estimated by a certified home inspector to be approximately $32,800.

Following is an estimate of approx. cost of work that needs to be completed to provide adequate move in condition for said property:

Patch damaged drywall / ceiling and paint throughout the house – $ 5,000

Replace damaged ceramic flooring and replace carpet – $ 6,000

Replace damaged doors – $800

Replace damaged light fixtures, switches & receptacles –$1,500

Replace damaged roof sheathing – $5,000

Replace damaged kitchen cabinets and countertops – $9,000

Repair dryer and kitchen stove ducting – $300

Repair damage to basement entrance retaining wall – $2,000

Repair damaged downspout – $300

Replace damaged porch canopy – $500

Repair cracked glass in basement window – $20

Replace kitchen exhaust fans – $400

Replace damaged kitchen and shower faucets – $300

Replace bath tub – $500

Replace damaged appliances – $1000

Total – $32,800

Additionally, there appear to be other UNDISLOSED damages created by seller-renter, such as to plumbing – including leaking pipes - that were not discovered during the visual inspection by inspector, and were discovered later. I require these to be itemized too. These include (a) other general wear and tear – for example,

front porch re-construction and (b) other possible repairs to make house ready to sell.

Name Withheld

Here is the first replay we received, sent in by Phil Peters…

“I wouldn’t touch this with a ten foot pole!”

These itemized demands are not just red flags. The whole discourse screams, DANGER, KEEP BACK, YOU COULD GET HURT!

I would most certainly respectfully inform this person that my company is not able to quote his job, but thanks for the offer. Every time through the years that I went against my gut-feeling as alarms were going off it didn’t end up pretty. When work is a bit short one can be tempted to tempt fate only to get pummeled with a repeat life lesson.

Phil Peters

But a more measured response came from Cory Kloos, Macanta Design Build, Winnipeg If that name sounds familiar, it should! Cory is on our cover for this issue, and you can read about Macanta on page 22.

Over the years I have met all sorts of people. The one thing I have learned from meeting so many different home owners, business owners, and decision makers is not to judge a book by its cover. Had I always done that, I would have missed out on what were some great opportunities, and great sales. Sometimes, people can come across as one thing (for so many reasons), but end up being something totally different. I never consider meeting someone new a waste of time, even if it turns out we are not a good fit for that person, or them for us.

What I do believe to be incredibly important is very clearly defining what types of project (both dollar size and type) your company does. You cannot be all things to all people, nor can you make a profit doing that.

Once you have established and defined your niche, responding to a lead such as this becomes very simple. Our company, for example, defines itself as “the transformation specialists.” We excel at large, complex renovations and additions requiring full service design build with a minimum dollar value.

Because we have defined this, responding to a lead such as this becomes very simple and offers a fair explanation to the potential client. For example, I may have replied to this specific

lead saying:

“Thank you so much for taking the time to contact us. While I appreciate the opportunity to meet with you and discuss your project, our company does not complete projects similar to what you have described. Our minimum project size is typically X, and some examples of what we normally complete include Y. Can I help by passing your name and number on to another contractor that is able to take on this type of work?”

I have found that people are often ecstatic that we offer to help by putting them in touch with somebody else, and on a few occasions we have received very good qualified leads in the form of a referral just for being polite and helpful.

Cory Kloos, Macanta Design Build, Winnipeg

In September 2014, following a Toronto house-under-renovation collapse that killed the lone worker in the basement doing underpinning, we heard from seveal contractors warning that too many “interior renovations” firms are taking structural risks. We still get posts about this tragedy, and here is a recent one.

“A recipe for a major disaster.”

Our company solely performs the following tasks: demolition, excavation, form and build at the same time. We went from working for investors (home flippers) to end users. Our clients know, hand-in-hand with us, what the liabilities are before we start, and we communicate closely with them until the hazards are tamed. Yesterday’s poor building practices are just that poor. There also old structures which require extensive work when replacing.

I’ve never seen a home flipper worry about safety. I’ve seen excavations collapse where the client would do anything to avoid the cost of shoring (which we perform).

I’ve been involved in residential construction now for more than 20 years. We work closely with engineers on projects. I call it a duck when I see a duck. (Which usually scares the client, and kills my opportunity to get the job.)

An interior renovator tackling an old Toronto structural renovation is a recipe for a major disaster.

Maybe this is a city issue and can be regulated from an inspection perspective? Regardless, we can’t keep letting cheap labourers pay with their lives because of the lack of regulations –and because of “thrifty” investors.

Joe, Clearwater Construction, Toronto

Mariano Guillen had been building his GC business in Fort McMurray for 8 years – until he, like so many in the fire-ravaged city, lost almost everything he owned.

By John Bleasby

Having lost most of his tools and equipment in the inferno, Mariano Guillen (left) was stunned by the actions of Stanley Black & Decker Canada, who sent David Veilleux (right), their service branch manager out of Edmonton, to deliver new DeWalt tools to Guillen so he could help rebuild the city.

The fires that swept through large parts of Alberta this spring, forcing the evacuation of 80,000 residents around Fort McMurray, were a disaster on a scale hard to imagine. Thousands lost their homes and businesses; everyone had their lives disrupted in ways that will take years to

restore.

Canadian Contractor’s on-line coverage of the challenges facing the local contractor industry received tens of thousands of ‘reads’ and dozens of comments through which we met renovation contractor Mariano Guillen,

owner and operator of A.R. Guillen Construction.

Our interview with Mariano, which published online in early June and have reprinted here (see page opposite), struck chords of sympathy with our readers. We are happy to report that through the generosity of Stanley Black & Decker Canada, many of the tools Mariano lost in the fire have been replaced with new DeWalt products. As a result Mariano can not only begin to help customers and neighbors in Fort McMurray rebuild their homes but also rebuild his business and provide for his family.

Greg Weston, Director of Marketing of Stanley Black & Decker Canada (Global Tools and Storage Division) told Canadian Contractor that he was moved by Marino’s particular situation. “To hear the story of a young man who has come to this country to start a new life and then had this happen, that really struck me on a personal level. We had an immediate and heartfelt reaction.”

While the company’s outreach is potentially life-changing for Mariano, Weston himself remains modest. “Our ability to do something for Mariano is relatively small, but it gets him back up and running so he can do his part rebuilding his community; we’re more than happy to do it.”

At the same time, Weston realizes that there will be many other contractors in Fort McMurray with challenges ahead. He advised Canadian Contractor that the company “has been formulating plans in cooperation with various agencies to assist local contractors get back on their feet, and to find out how we as a corporation can assist in the rebuilding of Fort McMurray over the next several months.”

Of course, other organizations are helping local contractors get back on their feet in Fort Mac, too. The Regional Municipality

of Wood Buffalo (RMWB) and Economic Developers Alberta (EDA), with financial support from the Canadian Red Cross, announced they will be providing $1,000 grants to small businesses that meet eligibility criteria.

However, applications and grants take time. For Mariano Guillen, the support provided directly by Stanley Black & Decker Canada is very significant since it is both immediate and focused on what he needs to re-build his livelihood.

“I am very excited," Mariano said. "I wasn’t expecting this. I have work already lined up and I’m ready to start! I really want to thank the company for making this happen for me. I thought I would have to build up my life again from nothing, you know?”

Mariano immigrated to Canada from Nicaragua in 2003 and made Fort McMurray his home eight years ago. Nothing brings the magnitude of the fear and loss suffered by Mariano and his young family to a human level better than our following interview with Mariano after his first visit back to Fort McMurray at the beginning of June.

Your neighborhood was last allowed back into Fort McMurray. What did you find when you returned?

We were living in the Abasand area, in a row townhouse. Everything was destroyed completely to the ground. So we went to see it and it’s just a mess. Everything had fencing around it, everything was covered in ashes. There is nothing left, just the concrete pads, that’s all. It was really, really bad to see.

Were you able to retrieve any of your possessions?

No, nothing. Some people were going in, but you had to have special protection because there were chemicals they

sprayed over the ashes so the ashes would not fly away, right? But I took pictures, I took videos.

Where have you been staying all these weeks you’ve been kept away? When we got out of Fort Mac we were just looking for a hotel, but we couldn’t find one. So we ended up going to the Royal Canadian Legion in Fort Saskatchewan for a while. I’ve never seen anything like this in my life. I said to my wife that now I know how the homeless feel. They feel alone, right? They have nothing. You feel like there is no hope.

We’ve been in a hotel now for over a month and it’s been stressful. It’s like being in a cave. Fort McMurray is my home town now. Our baby was born there. We've been there for eight years. I’m really desperate to go back. It’s been really hard to find a place to stay, to rent, but I found a basement apartment with parking. I couldn’t get a full house, it’s too expensive.

Were you able to save your tools and equipment from the fire?

I saved some but there were so many of them destroyed. I was working on a house also in Abasand and quite a few of my tools were there, and that house was completely burned down to the ground. I was working there and did not know about the progress of the fire. My wife called me and she was crying over the phone and saying “Did you see what happened?” I asked her what was wrong. She said: “Just go outside and see!” What I see is all the smoke and flame coming behind the buildings. So I grabbed my truck and trailer and went home as fast as I could. When I got there, my wife just grabbed our baby and a few things. There was smoke everywhere, getting into the houses. I was coughing, my wife was

coughing, and we were worried for the baby.

Now, of course, people want you back in the city to help rebuild their homes. It must be frustrating for you?

Yes, there are people who are waiting for me. They know me; I’ve done work for them. What has made me very upset is the day I went back to Fort Mac I saw a bunch of companies I’ve never seen before, right? I did not see many local companies, maybe one or two. These new companies are all over the place. They have huge trailers, big trucks. Other local contractors have been affected by the fire. I’m not the only one. We have to buy new things before we can work again. We have to get maybe a loan from the bank, or find someone to borrow money from.

There are concerns that outside contractors will take advantage of the residents of Fort McMurray during the re-building. What are your observations? Everyone one wants to get their place looked after, but it’s kind of disappointing when you see these new companies here. Maybe they don’t do the work properly, right? They are coming just to take the money from the people and they don’t care about problems later. They’re just cutting corners. I already see the comments on Facebook about it. That really makes me feel so bad, because I’m from Fort Mac, right? I’m a local contractor and I do care for the local people. I will see them every day. I’m not just saying this for me. I’m saying it for everyone here.

As indicated on the opposite page, thanks to Stanley Black & Decker Canada, Mariano was reequipped with DeWalt tools the first week in July. He is back on the job in the fire-stricken city.

KPMG takes the pulse of the Canadian real estate market Canadian real estate developers and builders remain confident that 2016 will be “another positive year.” That’s the conclusion of a national industry survey published recently by international accounting firm KPMG.

While observing that the drop in oil prices will mean regional adjustments, the report suggests large scale foreign investment will be attracted to Canada “to take advantage of both opportunities to acquire real estate [and] a currency play should the Canadian dollar recover some of its lost strength.” Furthermore,

YOU’RE SEEING IT AT BOTH ENDS OF THE AGE SPECTRUM

survey participants feel “Canada is also considered a ‘safe haven’.”

Demographic shifts twill also impact the future direction of the residential market across Canada, according to Lorne Burns, Industry Leader, Building Construction and Real Estate for KMPG. Referencing CMHC data, Burns told Canadian Contractor: “Over the last 30 years, the highest growth rate in any family housing unit is that owned by a single individual. Not couples, but one individual.”

Even so, home ownership is often postponed by many now entering or new to the job market. According to the survey, “Millennials who witnessed the impact of the financial crisis on housing are either currently unable or unwilling to purchase a home or have at least decided to delay the purchase. Many millennials see home

ownership as an anchor that limits their mobility rather than as an aspiration. Additionally, many do not have the credit to qualify for a home loan, as the average credit score for college grads with a Bachelor’s degree is just four points above the minimum required to obtain a home loan.”

“You’re seeing it at both ends of the age spectrum,” says Burns. “People are getting married later, they’re living single, and at the other end of the baby boomer spectrum you have single, maybe widowed or separated individuals who are living on their own.”

In order for single-family home building activity, and indeed average house size, to increase inside urban areas, Burns feels there has to be an abundance of affordable land. “In any of the major Canadian markets, that is usually the constraint. In Toronto and Vancouver, for example, if anything you’re seeing single family homes being assembled and turned into multi-family. I don’t know if I’ll ever see a single-family development in the City of Vancouver proper in my lifetime or the next several lifetimes,” Burns said.

The KPMG report says that recent shocks to Canada’s economy that began in the oil patch have been mitigated by high consumer activity. “Consumers continued to spend at a steady pace in 2015, despite the unemployment rate rising above 7 per cent.”

The risk to this positive big picture that has trickle-down potential to smaller players in the residential construction industry is the high level of debt currently carried by many Canadians. Borrowing rates are at low levels, despite regular warnings of up-trends. And as the market value of many homes increases, dramatically in some cities, equity lines of credit are funding home improvements as

well as other consumer purchases.

Contractor Credit Card Purchases to Fund Your Kids’ Education?

If you’re like most contractors and builders in Canada, many of your business expenses like materials, equipment rentals and gas are purchased with a credit card. It’s also likely that you are collecting travel points with these cards, lots of them, perhaps directly through programs like TD Visa Travel Rewards or the popular Aeroplan. Together with your personal card purchases, you likely have quite a stash.

Imagine if you could invest in your children’s future by using those travel points to pay for university and college tuition rather than for holiday travel or electronic gadgets. That is what is now being offered a new program called HigherEdPoints.

The program was conceived to help all parents faced with ever-higher tuition costs each year. However, those in the homebuilding and renovation industry are uniquely positioned to benefit since they charge so much on their credit cards. “It’s an excellent use of their loyalty points,” says HigherEdPoints founder Suzanne Tyson.

It’s a concept ideal for a company owner like Chris Loftus of Toronto-based Method Homes. Loftus’s son is entering his first year of higher education this fall. Loftus’s company’s corporate TD Visa cards accumulate thousands of points each year – in addition to points on his personal TD Visa. “We’re spending well into six figures on our cards,” Loftus said. “I use my points to redeem the $250 HigherEdPoints voucher online in the TD Rewards catalogue, then go to the HigherEdPoints website, input my voucher number, select the university, and the payment goes through directly. It’s very easy.”

HigherEdPoints can also be used for repayment of OSAP loans in Ontario, and Student Aid Alberta loans. Additionally, at many institutions, HigherEdPoints can be used for residence fees, meal plans and other campus fees.

Furthermore, Aeroplan offers an education point-pooling program in a student’s name, allowing relatives or family friends to gift points in increments as low as 1,000 miles. Once 35,000 miles are accumulated, a HigherEdPoints voucher worth $250 can be redeemed and directed to the university.

Loftus also sees the potential to use HigherEdPoints to fund continuing the education of his employees. “That seems like a really interesting idea. It could be great,” he said. cc

We recently presented John Harsevoort, owner of Harse Homes, a custom builder and renovator in Burlington, ON, with a brand new Festool TS 55 Track Saw. John won our random draw for being one of 400 contractors to fill out our Salary Survey (which ran in our March/April issue). Canadian Contractor would like to thank Festool for their support of our magazine – and for making our reader a happy man. “It’s a very cool saw to have,” Harsevoort told us. “A terrific product.”

PHOTO BY LARRY ARNAL

You can tell by its authentic cedar-grain texture. You can tell by its deep prefinished colours. You can tell by the beautiful way it stands up to harsh weather. You can tell it’s CanExel. Discover your perfect siding colour at canexel.ca.

Partners Development Group have built over 425 price-point-friendly townhomes certified with the Built Green label – without sacrificing quality.

The URL of the Partners Development Group website is arrivehome.ca – a departure from those firms who insist on their company name as their website address. A focus on sustainability runs throughout the website – but green building is just one of this Calgary home

builder’s areas of concentration. Two other values – affordability and quality –have also driven this firm forward. The company wasn’t always green. Founded in 1998 by current president Greg Gutek, the company began with smaller-scale, conventional projects

for most of its first decade. As new building practices were developed, the growing Partners team researched green methods and technologies to build more responsibly, while finding the way to feasibly accomplish this in the firsttime home buyer’s market. In 2010, this

Alan Quinn describes Partners’ initial entry into sustainable building through a process he describes as a “cost per point” analysis: putting dollars to points, informed by the Built Green checklist, to determine what green features they could integrate while remaining affordable.

effort began to see Partners differentiate themselves from other multi-family builders.

“We wanted to do better, strive to be better,” says Alan Quinn, vice president of construction. “Building to code as a minimum wasn’t enough. We wanted to

challenge ourselves and know that this was the future of Partners Development Group. How can you not feel good about that?”

And so they talked to their customers. The responses reinforced the path they were on. Inspired by those younger than

him, Quinn also listened to his nieces, nephews, and other young people wherever he found them. He wanted to know what was on their minds. Home ownership was at the top of their lists with affordability being a major preoccupation. But in addition to concerns about price, Quinn also noticed that this next generation were critical thinking customers who were looking for ways to live more sustainably.

Out of these conversations, a new mission for Partners Development Group began to take shape. How could they simultaneously make home ownership a reality for young Albertans while also developing their townhome communities in an environmentally responsible way?

Quinn recalls: “I was visiting my niece and her husband in Lethbridge, early 2009, and they were saving for a down payment on a home. It was very important to them to have a green, sustainable home apparently. They found that the products they were looking at were out of their budget. We discussed what “green” options were most important to them, and after a long list, Partners set out a goal to enlist as many items as possible while maintaining an affordable price point for their main purchaser base – the first-time home buyer.”

Partners set out to prove that affordability doesn’t have to mean a lesser quality build. This is where durable, quality homes and sustainable building practices intersect. Many people are unaware that sustainable builds don’t have to be cost prohibitive. Quinn describes their initial entry into sustainable building through a process he describes as a “cost per point” analysis: putting dollars to points, informed by the Built Green checklist, to determine what green features they could integrate while remaining competitive

in the marketplace for their largest demographic - the first-time home buyer.

That analysis saw Partners going to their trades, and in some cases, being greeted with backlash. Nonetheless, they remained committed – this was the way of the future – and the trades came on side. There was trial and error for some product lines, but they worked through it together and found what worked the best for all. They introduced new construction techniques and technologies – from recycled content in the materials, to the way the building materials are handled and disposed of, to utilizing higher insulation and finishing techniques, to the use of advanced mechanical systems for air quality. They offered better Energy Star appliances and fixtures that consume less energy. They were able to build affordable homes that have lower operating costs than conventional developments, all in a professionallymanaged, community setting.

Partners Development Group innovated by understanding their requirements, the purpose of new technologies, the cost benefit, and the actual demands of customers. They went on to demonstrate the close relationship between quality and sustainability with the incorporation of such features as low-maintenance exteriors, sustainable landscaping designs, and efficient garbage collection systems, to name a few.

When Partners originally integrated Built Green at the onset of their sales process for their ARRIVE townhome development at Skyview Ranch, northeast Calgary in 2010, it was an education process. Their sales managers were trained through the Built Green certification program alongside their

construction crews. Purchasers were asking valid questions about being what “certified Built Green” really meant: they needed to know this wasn’t a fad or a gimmick. When the sales team described the make-up of the party wall, for instance, it had people knocking on the other side of the wall of the neighboring show home, and the build spoke for itself.

While many buyers were clearly drawn to these ARRIVE Skyview Ranch townhomes by price point and location alone, after living there for a few months many realized how fortunate they were to have such a solidly built home – and silence from their attached neighbours! Bill and Kathy Hannah, as an example, have been living in this first Built Green development of Partners since 2012. “We were probably here half a dozen times or more watching the construction to see how the homes were being built before we decided to buy,” Kathy says. Bill adds: “When we walked around the first time and saw they were using spray foam insulation in the garage it really blew me away. I felt that if the builder was willing to go that extra step and not be overpriced, then this was a good choice.”

Building sustainably has allowed Partners Development Group to pass on cost saving benefits to customers. Improved efficiency means long-term cost savings on water, electricity, and gas bills. A Built Green home should save a minimum of approximately 10 per cent in annual utility bills, compared to a codebuilt home. Cumulatively, the savings can be substantial.

Built Green says that a home certified in their program will benefit from an increase in market and resale value. And indeed, recent research has shown that homes with green certification sell for

After doing their analysis, Partners went to their trades, and in some cases, were greeted with backlash. Nonetheless, they remained committed – this was the way of the future – and the trades came on side.

close to 10 per cent more on average than homes without green certification. Fast forward from 2010 to last spring when the consumer demand for sustainably built homes was further reinforced with the release of the 2015 Canadian Home Buyer Preference National Study. Conducted and produced by Avid Ratings Canada in partnership with the Canadian Home Builders’ Association, homebuyers were asked their opinions on the desirability of various forms of energy conservation in their homes. 49 per cent of them cited green home certification as a “must have,” while an additional 29 per cent saying they really wanted certification. Quinn reflects back to earlier days and knows that his firm has been ahead of the curve for some time. Partners’ steadfast commitment to sustainable building has led to it erecting over 425 Built Green certified homes, all of which are Gold and Platinum certified. Today, all their builds are Built Green certified. As a company looking to the future, Partners Development Group continues to strive for the best home building results, while inviting their purchasers to “arrive home.” cc

TSC 55 Cordless Tracksaw - Beveled, mitered or straight. Sacrifice the cord, not cut quality.

The name of a contracting business means a lot more than you think. Which is why Cory Kloos and Desmond Sweeney decided to change the name of their Winnipeg renovations firm from Red Seal Builders to Macanta Design Build Inc.

INTERVIEW BY STEVE PAYNE

We first met Desmond Sweeney, one-half of the ownership team at Macanta Design Build Inc., Winnipeg, during Canadian Contractor’s RenoFocus sessions in Toronto last November. At that time, the firm was doing business as Red Seal Builders. When we did our reporting on the event, Desmond asked us to refer to the company as Macanta. This interview came out of those discussions.

How do you divide duties between you?

Cory is responsible for everything that is technical on the construction. So he’s involved with design, he brings all his building expertise to ensure that customers get the most value from the project. He manages the site on a day-to-day basis, making sure the trades have what they need – and ensuring everything is managed in a high quality fashion. I’m more involved on the back end. I take care of the finances, make sure people get paid, run the schedules looking 4-5 weeks out, make sure the trades have plenty of notice, make sure materials are on site when we need them. We also have a site super. After that, we sub everything. So our specialty is using our process to (a) design and (b) manage the project. We use specialists for the actual construction.

Tell us about your previous career.

I was a computer guy. I originally started working for a software company. I was managing a bunch of their web projects. And then I transitioned to formal project management, managing a team that built software at a manufacturing company. At school (University of Manitoba) I did my first year in electrical engineering. Then I transferred over to commerce (Asper School of Business).

What about Cory’s background?

Cory doesn’t have formal university training. His experience comes from hands on. It’s a great combination for us: we think it’s our “secret sauce” (laughs). We’ve been friends since we were kids. We’re both 33 now. Cory started working for a builder when he was 17. Pretty quickly he went out on his own because, as he describes it, he felt as if he was working for one of those builders who are… the ones Mike Holmes warns you about. He did trades-type stuff on his own for a few years and then, in 2007, he decided, as he puts it “to start a real business.” I came aboard with him in 2013.

So I assume you brought a few systems and technology things with you?

Actually, Cory already had things more technologically advanced than a lot of other construction companies! He always had the plans digitized but the website got enhanced when I came on board – and we started to use more software tools to coordinate the work. One thing we did heavily focus on when I came aboard is to refine our unique process. Four of the fastest runners in the world can lose a race because of one bad baton pass. We've put a process in place that ensures a smooth hand off from one project phase to the next.

we see what we do. Our customers are taking the largest chunk of their cash they are ever going to spend, for something they want to improve their daily lives. And helping them to stretch that money to the farthest, giving them pleasure for that expenditure, that’s the goal.

So why did you move off the name Red Seal? Why not just Red Seal Design Build, rather than Red Seal Builders, as you were before? Did the Red Seal apprenticeship administrators get on your case?

No. Although that surprised me, actually. Maybe they didn’t have that name trademarked! But Red Seal was very much centred on being a “builder.” And we were being approached with a lot of third-party plans. Most of the projects were great, but most plans are not, from their very nature, developed to the point where you can fix a price right away without having to deal with a lot of change orders down the road. Or where we would need a lot of clarification. And we also saw lots of plans where the design was absolutely beautiful, but it would cost a tremendous amount of money to build it that way. And we felt the customer could have gotten better value by going in another direction on the design – and probably get to the same level of enjoyment. So we decided that, to properly serve our customer,

we needed to be involved in the design from the start. So we rebranded, and developed a unique process to manage the entire project from design through construction.

You were doing no design-build work before?

Oh, we were doing some. But also building from a lot of third party plans that we had had no input in.

On the rebranding from Red Seal to Macanta, were you concerned that your old brand equity – as they say in marketing-speak – was going to be abandoned. And your new brand – and its reputation –would have to be developed from zero?

We were concerned about that, yes. It was one of the biggest discussions we had as to whether we even should rebrand. You could actually draw a supply and demand graph, where one line (Macanta) is going up, and one line (Red Seal) is going down. Macanta began at zero with absolutely no reputation and Red Seal was alive and well. But we went ahead. We told our existing clients – and obviously any new leads that came from Red Seal – that we were now operating under Macanta. And we continued to use Red Seal to generate leads while Macanta was getting on its feet.

What are your most successful methods for generating new leads? Definitely referrals. We do get leads from our website, from TrustedPros and from the Manitoba Home Builders’ Association. But by far our best prospects come from referrals from customers. Doing well by one customer, it will often lead to their neighbour, or their mother or their uncle, for example, wanting us to talk to them. And referrals are important because of all the TV shows focusing on bad contractors. Many people are just not willing to find a contractor on the internet, by looking at the top searches on Google. They are becoming much more discerning.

Do you make it a point to ask for referrals?

We have done that. But generally they come to us on their own.

How do you decide with the client on what is the realistic budget from the outset?

It’s a combination of education and then simply building trust. Early on, Cory educates them on what projects cost. So he’ll talk about similar things we’ve done and what they cost, what the “expensive” options are and what they cost – and what the more cost-effective routes are. And once the customer is educated, they trust us a little bit more. And they will trust us to tell us their real budget.

What is your average project size?

They are all over the map but, generally, a minimum of $100,000. Our average project is over $250,000 but that will always change based on leads that come in over the next 3, 4, 5 months.

Do you price Lump Sum, Cost Plus, or some other pricing method? We do Lump Sum. We take the finished construction drawings and we bid them out to our subs – not to the industry in general but to the people we trust. We take their costs, roll them up, and the present the customer with one number for their project. What kind of renderings do you provide to the client? Most of it is generated in Auto-CAD and it will generate perspectives.

Do you leave any allowances for, say, lighting plans or finishes, or do you want everything completely figured out to the dollar? Sometimes we use allowances, but they're realistic and often based on our standard products. Our preference, though, is to bolt it down for every single detail. So the client could go away on vacation and when they come back, their dream renovation is completed – that’s the panacea.

With today's ultramodern designs, we are seeing lots of steel and glass with wide open spaces, very clean. There are a lot of cantilevers, big spans for joists, big glass – a lot of engineering. Do you build that way?

Personally, I like the ultramodern look. Cory prefers the classic, traditional look. But because we are 100 per cent in the renovation market, where we are expanding existing homes, we are finding that the customer wants to get a new, fresh, clean look – but not necessarily have it totally contrast with the existing. So this is one of the more difficult things in renovation – to make the new structure fit into the old.

Have you and Cory needed to finance the business to expand it?

No. We actually structure our business a little different than many contractors do. We operate sort of like a law firm does. We take a retainer and deposit in advance and then spend that money –and then at the beginning of a new phase, the customer provides another deposit. This takes a ton of trust from the customer to us. But it also guarantees that we are spending Customer A’s money on Customer A’s project. There’s no crossover. We’re not taking Steve’s money and spending it on Ben’s project because we ran over on Ben’s project. These are our customers’ life savings to some extent. It’s a high degree of trust.

Do you use a standard renovation contract, say from the home builder’s association, with modifications – or did you develop your own contract completely from scratch?

We built one from scratch with a lawyer.

Do you buy, develop and sell your own properties?

We aren’t doing any spec building at the present time. We are much more involved in helping people take their existing houses and make them new again.

Might you do it in the future?

For sure we talk about it from time to time. It would be neat to build a Macanta house on spec but it would also be higher risk.

What is your longer term plan?

We want to increase the average size of our jobs, increase the number of jobs that we are doing, and just continue to build. It’s fun. It’s challenging. We learn from our mistakes, like everyone else. When we get a glitch, we update a checklist somewhere, so we won’t make that same mistake again. Continuous improvement. We want to continue to perfect our unique process. cc

WE DECIDED THAT, TO PROPERLY SERVE OUR CUSTOMERS, WE NEEDED TO BE INVOLVED IN THE DESIGN FROM THE START. SO WE REBRANDED, AND DEVELOPED A UNIQUE PROCESS TO MANAGE THE ENTIRE PROJECT.

Realistic matte finish. Reliable PermaTech protection.

Rich colors, low-gloss formulation, and micro-texturing give Horizon® Symmetry™ Decking a stunning matte finish. Four-sided PermaTech® surface provides lasting durability. All backed by 25-year warranties, and only from Fiberon®. Learn more at fiberondecking.com

By Alexander C. Bjornson

often deal with claims for deficiencies from owners. Most contractors do not realize that in certain circumstances they could be held responsible not only for the cost of remediating a deficiency, but also for damages for mental suffering caused by the inadequate construction.

Awards of “general damages” such as this are still part of a developing area of the law and are only granted in limited circumstances. One type of general damages – those for mental distress – are recoverable where such damages were in the reasonable contemplation of the parties at the time the contract was made, and an object of the contract was the “peace of mind” of one of the contracting parties. The degree of suffering must be enough to warrant compensation. Damages for mental distress arising from breach of contract are generally not awarded where both parties are sophisticated commercial entities.

Damages for mental suffering were awarded in a decision coming out of Newfoundland and Labrador: Hickey’s Building Supplies Limited v. Sheppard, 2014 NLCA 43. In this case, the Sheppards wanted to build a retirement home. To move around, Mrs. Sheppard relied on a cane, a wheelchair, or had to crawl on the floor. It was very important to the Sheppards to have a home that gave them pleasure in their retirement and also provided suitable accommodation for Mrs. Sheppard’s needs. Although the building contract did not explicitly require a level floor, the Court found that the Sheppards had contracted for one. The contractor was fully aware of Mrs. Sheppard’s medical and disability issues and knew that the Sheppards wanted floors that were level and continuous.

This was reflected in the contractor’s notes, discussions with the Sheppards, and the installation of special features to accommodate Mrs. Sheppard.

Instead of a level floor, there was a quarter-inch difference between the tile and hardwood flooring in the home. While the contractor conceded this difference existed, it argued that this was permitted under the National Building Code, which incorporates accessibility standards. By simply adding transition strips, the flooring was compliant with the Code and the written terms of the contract.

The Court found that the contract required level floors because the contractor knew of the Sheppards’ requirements for floors that were level and consistent. Consequently, the Sheppards were awarded damages for the cost of remediating the floors.

A majority of the Court of Appeal also agreed that the uneven flooring warranted an award of general damages for mental distress. Mrs. Sheppard’s circumstances made it foreseeable that failure to live up to the terms of the contract would cause distress. As conceded by the counsel for the contractor, an object of the contract was peace of mind. The contractor understood the psychological benefit that the Sheppards had contracted for. While any construction project should result in a floor that is hazard-free, it was particularly foreseeable in this instance that mental distress would result from the deficiency. Turning to whether the degree of mental distress warranted compensation, the majority noted that Mrs. Sheppard spent more time at home than most people and the inconsistent flooring required her to go about her activities in a state of fear and

anxiety associated with the risk of tripping. She was particularly vulnerable because of her compromised balance and fragility. Mr. Sheppard also suffered from the risk of tripping and bearing the worry and concern over his wife.

Concluding that an object of the contract was “peace of mind,” the contract had been breached and the degree of distress warranted compensation, the majority of the Court of Appeal upheld the trial judge’s award of $15,000 to the Sheppards jointly.

It is clear from the Court’s reasons that in rare circumstances, where a party has contracted for “peace of mind,” failure to satisfy contractual obligations may lead to damages for mental distress. This decision is particularly applicable to contractors dealing with individuals rather than commercial entities. Contractors can mitigate the exposure that may be faced in “peace of mind” contracts by clearly drafting exclusion language. For owners, the decision underscores the importance of having their construction requirements set out in the contract. If the Sheppards had ensured that the level flooring specifications were stipulated clearly in the contract, the litigation could have potentially been avoided.

This article is for information purposes only and may not be relied upon for legal advice.

Alexander C. Bjornson is a lawyer at the law firm of Borden Ladner Gervais LLP. He practices in the area of commercial litigation, with an emphasis on contract and construction disputes. This article first appeared in the October 2015 issue of On-Site magazine (www.on-sitemag.com).

Builder: Naikoon Contracting Architect: Synthesis Design

By John Bleasby

Collaboration in a home building project has different definitions and can deliver different outcomes. In the case of The Winton House, an active, three-way collaboration between contractor, client and architect resulted in spectacular results both visually and environmentally.

The clients had purchased a 6,100 sq. ft. lot in North Vancouver with the intention of replacing an older bungalow. They had a number of personal ideas and objectives, including some“must haves.” They first approached highly-regarded Naikoon Contracting who suggested that based on their requirements, they engage Synthesis Design as architect. Naikoon and Synthesis Design had successfully teamed up previously and hold a high level of mutual respect.

Continued on next page

Naikoon Contracting, North Vancouver, certainly knows how to win applause from both their customers and the industry-at-large. Their recent Built Green Platinum project, The Winton House, shown here, was a multiple award-winner at both the 2016 Ovation Awards (Greater Vancouver Home Builders’ Association) and the 2016 Georgie Awards (Canadian Home Builders’ Association of BC). All told, Naikoon won almost a dozen awards at these showcases, including Custom Home Builder of the Year and Renovator of the Year. They even won awards for two other projects. Wow!

The clients’ approach to the design concept was a synthesis in itself: the husband was very contemporary in outlook, favoring concrete and other modern elements, whereas his wife wanted a more traditional look – in particular, a steep-pitched roof. “We had to find a way to blend those ideas, and determine which ideas the clients were passionate about and which they were willing to concede,” explains Synthesis architect Curtis Krahn.

The couple pitched their visions to each other at initial meetings with the contractor and the architect. “This type of communication is our most successful way to establish client requirements,” explained Naikoon’s president, Joe Geluch. “It was a great collaboration,” said Krahn, who said even the couple’s children got involved. (Their six-year-old daughter said, “This is what happens when you have ideas!”)

The client couple are very conscious about their health and how they live and have a keen awareness of the environment. The project naturally evolved into a highly-sustainable one, featuring roof-mounted solar panels, a radius green roof, 75 per cent LED lighting, a 4,200 litre rainwater collection tank buried in the back yard, radiant floor heating and heat pumps. The project utilized locallysourced Douglas fir timbers and Western Red Cedar. Naikoon was able to achieve 94 per cent waste recycling on the project.

Visually, the project successfully

THIS

Six-year old daughter of the owners

Top Left: 12 feet of bi-fold window panels and a servery window open the interior directly to the concrete slab patio and hot tub. Kitchen counters are concrete; island cabinets were crafted from re-purposed demolition material. Engineered oak flooring was used the entire main level.

Centre: A green roof over the garage is both aesthetically pleasing from second floor windows and easy to maintain.

Below: Exposed fir beams with cedar planking on the overhang. The exterior siding is horizontal and vertical stained cedar with large exposed fir beams at focal points.

blended both the modern and the traditional, giving the house a 21st century chalet appearance. A curved, south-facing green roof over the garage was an aesthetic choice that melded the wife’s attraction to traditional roof angles with the modernity favoured by the husband. “The green roof reduces pollutants, increases bird activity and helps cool the house,” Krahn said.

Local height restrictions and setbacks were design challenges.

“North Vancouver has several different neighborhood zones,” Krahn explained. “The issue that always comes up is maximizing the height within those guidelines. As a result, we often design the house from the top down. Here, by dropping the lower grade down a bit, we were able achieve interior ceiling heights of ten feet on the main floor, eight up and eight down.”

The home has four bedrooms and two bathrooms on the upper floor, a main floor powder room, plus two bedrooms and a bathroom on the basement level, accessible through a family entertainment area at the base of the open main staircase.

Noteworthy are the bi-fold glass wall panels which open the home’s interior to the large exterior covered patio, with a similar kitchen window treatment, allowing the entertainment area to blend seamlessly into one. cc

Above: Main staircase dual stringers are welded steel with fir treads. The openness of the stair core allows light to flow throughout the house. The 1x3 slatted divider was milled from scrap fir beams.

Right: Re-purposed wood from the site was used to construct detailing in the main floor powder room. The powder room vanity counter is Caesarstone.

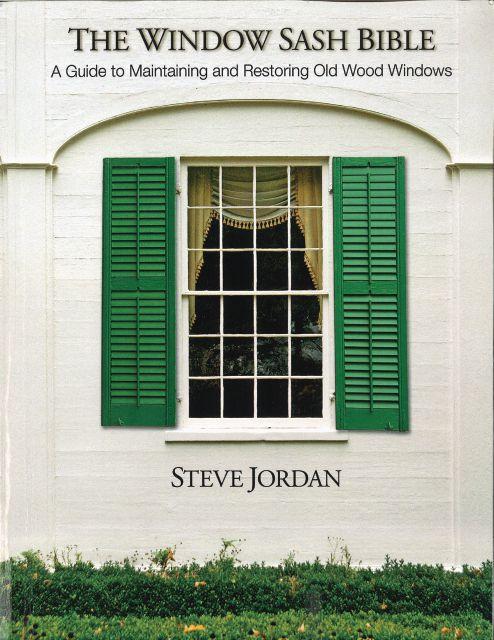

Book Review by Steve Payne

Whenyou’re renovating an old house, it’s sometimes a good idea to replace the original sash windows with state-ofthe-art fenestration. But on other occasions, you may want to preserve the heritage of the property and restore – rather than replace - those old wood windows.

In fact in some cases – if the property is really historic – to automatically replace the sash windows would be to disfigure the building itself.

But if sash window restoration sounds like the work of a window ‘rehab’ specialist – and beyond your own competency –take heart. By publishing The Window Sash Bible: A Guide to Maintaining and Restoring Old Wood Windows, Rochester, NY-based contractor Steve Jordan has gone a long way to giving you all the tips and techniques you need to do the job yourself.

A graduate of Cornell University’s Historic Preservation Program, Jordan has been in the old house restoration business for forty years. For the past twelve years, he has exclusively repaired and restored historic windows. His says his goal in writing and self-publishing The Window Sash Bible is “to prevent the thoughtless destruction of historic windows by bringing to light their enduring yet often overlooked qualities as opposed to the short-term lives of modern replacement windows.”

One of the main themes of The Window Sash Bible is that sash windows built prior to 1950 were generally designed to last a lifetime. This 247-page book, superbly supported by illustrations and

photographs, takes the layman through all aspects of repair, maintenance, upgrade and restoration of old or historic windows.

The book covers the restoration of many different types of sash windows from the 1800-1950 time period, including those artifacts of a lost age – the early nineteenth century window sashes made by specialty sash-makers. These mystical types were among the most respected of all home builder trades.

The Window Sash Bible contains numerous helpful diagrams of sash window components. If you don’t know a ‘stub-tenoned munting’ from a ‘blind stop’ – or a ‘drip reglet’ from an ‘ogee sash extension’ – this book will help. (Just namedropping those terms to your client ought to get you the job, first try!)

The author provides delightful historical details about the earlier wooden windows and the challenges they provide. For example: “Early window sashes were made without glued joints because, as previously noted, weather resistant glue didn’t exist. Frame stability depended on quality construction – mortise and tenon joints, wedges, wood pins, and rigidity from the glass and putty.”

This glueless construction, Jordan continues, means that as these systems age, casements can tend to gradually

sag at the latch side. This problem can be severe – requiring reconstruction of the sash, or it can be remedied with a few simple measures. Jordan then provides detailed instructions on what to do in either case.

Typical problems in renovating wooden windows are all covered in detail. For one example among dozens, Jordan details three principal techniques for loosening stuck or sticky sashes without damaging the structure or breaking the glass. The various arrangements of sash weights and cords and discussed, with reference to specific manufacturers. There are important sections on putty, lead- and zincencased (technically, zinc-camed) windows

and how to identify different eras of old glass.

For those who assume that old wooden windows probably do a lousy job keeping the weather out, Jordan proves this wrong with the longest chapter in the book –Chapter 5 – in which he covers the minutiae of weather-stripping at great length.

The author covers typical carpentry repairs – and just to prove his point on the heritage value of the most historic wooden windows, points out that they were made with old-growth wood: original forest material. Many of these old-growth species were “exceptionally rot resistant while second or juvenile growth lumber of the same species are not,” Jordan remarks

Still want to rip out those early 19th century windows? Jordan doesn’t lack for emotional power when he reminds the modern renovator about who built those oldest windows and under what circumstances. Yet he talks as persuasively of the merits of restoring 1950s windows as he does about those 1830s ones.

In later chapters, the author does an excellent job covering storm windows, screens and shutters. After this, he has an excellent primer (pun intended) on how to paint wooden windows – including another gem: how to use “The Bull’s Eye Method” to determine the original sash or trim paint color.

Finally, if you just have to rip out those wooden windows, after spending at least an hour reading Jordan’s labor of love on

why you don’t really want to, the author gives you a short section on what to look for in replacement units.

The extensive glossary to this book explains all the terms that sound like they are from another planet. Only window terminology is this beautiful: Ogee, Ogee Lug, Oriel Window, Ovalo… This book is a worthwhile purchase for any renovation contractor in Canada who faces wooden window repair or restoration. Which includes just about all of us.

The Window Sash Bible: A Guide To Maintaining and Restoring Old Wood Windows by Steve Jordan. 2015. Publisher: Steve Jordan, Rochester, NY, 2015. ISBN 9-781505-299144. To order a copy, visit www.windowsashbible.com.

allweatherwindows.com

The Horizon 7100 series from All Weather Windows is a superior slider and single hung solution with the industry’s best feature set and a natural addition to our lineup of high-performing windows. The Horizon 7100’s versatile range of customizations gives builders, dealers and homeowners the ultimate flexibility in design while offering the durability and energy efficiency All Weather Windows is known for.

BENEFITS OF HORIZON

Triple pane option

Designed with a true 1/2” air space, these triple pane windows provide more insulation than dual pane when it comes to energy efficiency, allowing for lower heating costs, virtually no condensation and an excellent sound barrier.

Colour available

Renolit EXOFOL FX comes with a 10-year warranty and offers bold, durable colour by using a high-performance, acrylic-based exterior film that is permanently bonded to both the exterior PVC window frame as well as the sash, allowing for uniform colour throughout the unit.

Did you know that your plumbing subcontractor can install a DHW (domestic hot water) solution that will give your clients almost-instant hot water from the faucet?

For more information on technologies like this please visit www.hpacmag.com, the website of our sister publication, HPAC.

Withseasonal water shortages and ever-increasing domestic water service and utility costs, more and more families are looking for domestic hot water (DHW) solutions.

In Canada, homeowners pay for domestic water three different ways. They pay for the water as it enters the home, they pay to heat it up, and then they pay for it to go down the drain into municipal sewage. What if you could reduce some of these triple water costs for your clients, and put some extra money in your own pocket, too?

And what about those long wait times for hot water to reach the tap, especially in larger homes with long runs of supply pipe? Wouldn’t it be nice to get that hot water flowing almost immediately?

Fortunately, today’s plumbing professionals have solutions to this waiting and wasting of water. This technology, along with the increased consumer awareness of the need to preserve valuable natural resources, provides you with an up-sell opportunity that many of your customers will absolutely love you for. And since this hot water solution is affordable, why not give your customers another reason to be delighted with your work?

You can apply this technology on custom homes or renovations whether or

not you have open access to the existing piping. This article will give you the basic information you need to explain the technology to the homeowner. Let’s have a look at some case studies…

Homeowner Lincoln Kaiser and his wife decided it was time to enlarge their home. The renovation project added a second floor with four new rooms including a full bathroom.

Because the new second floor bathroom was quite a distance from the existing water heater, their contractor immediately recognized that there was going to be a challenge that he would need to address. Because their home was older, with trunk-and-branch plumbing piping, he knew their wait for hot water in the new bathroom could take four or five minutes.

Being environmentally conscious, the Kaisers had stated that they wanted to make sure that they were doing their part to limit wasted water, while at the same time reducing their wait time prior to jumping in the shower.

As the scope of the renovation work provided the contractor access to the existing plumbing piping system, the simple solution was to install a dedicated return line to the water heater and a

recirculation system that senses when sufficient hot water is in the plumbing lines.

“This single, inexpensive improvement brought the most noticeable enhancement to our quality of life in the home,” Lincoln Kaiser said upon completion. “We now have the convenience of instant hot water at the showers every morning,” added his wife.