FOCUS: Building envelope Pg. 20

Creative eye The winning Crescent Pg. 16

Industry forecast What to expect in 2021 Pg. 14

FOCUS: Building envelope Pg. 20

Creative eye The winning Crescent Pg. 16

Industry forecast What to expect in 2021 Pg. 14

Being a franchise owner has its benefits. Page 10

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the digital edition archives at canadiancontractor.ca.

In the latest episode of The Hammer, Canadian Contractor editor Patrick Flannery talks to Jim Mandeville of FirstOnSite about the unique challenges and opportunities of disaster remediation. Visit canadiancontractor.ca for episodes, or subscribe on your favourite podcasting service to listen in.

Kitchener, Ont.’s, Brick & Co. Restorations landed gold for health and safety leadership from the WSIB. And had this slick video about it produced!

Follow @CanConMag or look us up on Facebook to add Canadian Contractor to your daily diet of online interaction.

Let’s start out 2021 with a look at the year ahead, since no one wants to dwell on the year behind us.

Here at Canadian Contractor we’ll be bringing you a new focus - literally. Look for the FOCUS series of features that isolate one aspect of homebuilding and offer technical articles, tips from Steve Maxwell and a selection of new products relevant to the topic. Our first one is on page 20 - FOCUS: Building Envelope. This focus was particularly good to start with because I edit two other magazines centred on this part of the building: Fenestration Review, for window and door manufacturers, and Glass Canada, for commercial glazing contractors.

Also coming up in 2021 is our collaboration with Women In Construction, a big cross-market initiative by our publisher, Annex Business Media, to promote, uh, women in construction. Working with several of our sister publications (Canadian Consulting Engineer, Rock to Road, On Site, Crane and Hoist, Canadian Rental Service, Fenestration Review and Glass Canada) we’ll be rolling out content all through the first week of March celebrating successful women in the construction industry and getting their stories and ideas for how to make this field more welcoming and attractive for female participation.

The week will culminate on March 8 (International Women’s Day) with a live event featuring an online keynote and two panels looking at the successes of the past and charting a path for the future. We talk a lot about labour shortages, both present and upcoming, in these pages. Getting the other half of the population into the game could be a big part of a solution. Look for registration information in your email and do join in to support this important effort. Our very own Stephanie Rota of Carmelin Design Build will be one of the panelists!

More broadly, what does 2021 hold for the Canadian home renovation and custom homebuilding industry? The pandemic has become a way of life and most of us have found ways to continue business while keeping our staff and customers safe from the virus. Many of us have actually flourished, taking advantage of vacation funds redirected to home improvement projects. Supply chains are slowly adapting to the new realities as well and we can hope for more profitable times ahead as materials flow more quickly and at reasonable prices. Of course, no sooner have we adapted than everything is set to change again once a critical mass of the population is vaccinated and restrictions can be lifted.

I predict a massive boom of demand. I’ll also go out on a limb and say residential design may change to demand more indoor/ outdoor spaces that can be opened up for increased air flow and spaced-out seating. My family Christmas get-together was an outdoor affair this year around a bonfire with hot chocolate on the barbeque. And it wasn’t half bad.

What do you see ahead in 2021? cc

” I predict a massive boom of demand in 2021.

By Patrick Flannery Editor ”

Bradley sees the Ontario AODA rules putting a drag on the supply of affordable housing.

Just one more expense to spiral the cost of any type of construction up and up, which will do more to keep people literally outside looking in due to the outrageously unaffordable, unattainable and unsustainable lunacy forced upon us by the (liberal) nanny state . And they wonder why there is no affordable housing.

Bradley

Nathan sees the need, but disagrees with the timing. While I can see the importance of inclusivity in our society, this new regulation puts another requirement and expense on Canadian businesses when many are struggling to survive. We do need to include access to information and services to everyone but the timing is certainly not optimal. We are a micro business (Sunrise Home Buyers) but I can see this requirement eventually working its way down to businesses of all shapes and sizes.

- Nathan

It’s not the boogeyman

Karen is relieved to find out from John Bleasby that the noises her flat roof is making in the night are not some malevolent creature trying to get in.

I’ve had this same issue and it kept me up till 4:30 one night wondering if was something evil or some vengeful or lunatic person was roaming outside. I prayed, smudged and thought of calling the police. I’ve heard animal footsteps running across the roof in the warmer weather. I’m in row housing so I checked to see if there are any attic openings. The thought of expansion and contraction crossed my mind but I’m 52 and never experienced anything this loud before. I’m in a rental and this is the first winter I’ve lived here.

I believe it is a flat roof and the vents are also above my bedroom. All I can say is that this is the second article I’ve read on this subject so I am very relieved that this is a normal thing. Thanks for posting this, was getting tripped out.

– Karen

Ken sees a fundamental choice in our politics between capitalism and communism as part of our debate about unions.

[Increasing the skilled labour supply] will be a difficult task. On one hand we have a surge of skilled migrants, making Canadian economic labour pools saturated with talent. And on the other hand, a deadlock of large turn-of-thecentury businesses with unions calling the shots.

If Canada hopes to ever succeed it may have to find some middle ground on innovation. Japan, Korea, India, and China

have all seen their fair share of rags-to-riches innovation. Canada may have one last chance to get it right as this 10- to 15-year recession looms with COVID and such. One of the greatest changes that happened pre-COVID was where entire media empires became copy-paste news. When the Berlin Wall fell it separated into two distinct ideologies. One ideology lacked a quality of life seen by these media empires, and the wealth provided by freedom of expression. This made capitalism a clear choice. In this new era, the quality of life once again is in question. What system of engineering society will provide the highest quality of life? In Canada we have been united by voting in a socialist health care system that succeeds at caring for the sick and elderly and allowing women to have babies in a clean room. The challenges of living and surviving can be met with capitalism or communism. It is just the perceived quality of such methods that we argue and vote for.

– Ken

In response to “Why does a contractor need a deposit at all?”, Frank makes the good point that many provinces have laws about how much deposit a supplier can ask for. However, the section of law he references here appears to apply only to “direct sales contracts” where a single service or product is bought on the spot. It seems to us construction contracts would normally be considered “continuing service” or “future performance” contracts, so it’s unclear to us if that section applies. Certainly $100 doesn’t seem like enough for a deposit on a home renovation project! Can anyone clear this up? Don’t make us phone a lawyer! Here is the first rule that everyone should know, but often doesn’t – what does the law state in your province? In B.C. the law is 10 percent of the contract value to a maximum of $100, no exceptions. Refer to Section 4 of the Business Practices and Consumer Protection Act. I tell contractors, drop your materials and I will give you a cheque or e-transfer the same day or that night for fair value. Got a guy asking for more? Show him a copy of the law.

– Frank

Mike notes that durability is a hard quality to assess right after a job is done.

My gripe is no one really teaches how to check a company properly. For example, if a repair should last a year, the builder only does well enough to last that time but gives you a reference from a job two years old. The owner says, “They did great work”. I had this scene with roof 11 years ago that lasted only six, had a car motor rebuilt 20 years ago that leaked oil again six months later, or one week ago shopping for tires, read an excellent review, only to see same review on six other brands of tires. What I get from Holmes is that a lot of problems are started by lazy or shady building and code inspectors.

– Mike

A Saskatoon engineer who was a key driver in energy efficiency and conservation in homes was made a member of the Order of Canada in January this year. Harold Orr was part of a team that put together the Saskatchewan Conservation House project back in 1977, during an acute energy crisis. The team from the Saskatchewan Research Council was tasked with building a solar house that could withstand Saskatchewan’s cold winters and hot summers. Canadian Contractor paid a tribute to Orr in its April 2018 issue.

“When we looked at conventional houses, we identified three major components to heat loss: the insulated portion of the building (windows, walls and ceiling), the basement, and air leakage,” recalled Orr during that

Credit: CBC Saskatchewan

interview. “Adding insulation alone only reduced the heating needs by about 30 percent. We had to deal with the other two components: basement and air leakages.”

These were handled in a straightforward manner. First, a gradebeam and pile foundation was used, thereby eliminating the basement.

Second, given his expertise on air leakage, Orr agreed to personally install the project’s air barrier. The result was an air tightness level that was extraordinarily high for a home anywhere in the world at that time. While home construction costs were modest for 1977 at approximately $60,000, the solar system added another $65,000. Orr contrasted that substantial additional capital cost with his estimate that heating the home conventionally with natural gas instead would have cost only $25 per year. The lesson learned was that by insulating the windows, walls and ceilings concurrent with insulating (or eliminating) the basement and installing an effective air barrier, the home’s energy consumption could be reduced by 90 percent. cc

In its Nov. 30 fall economic statement, the federal government included a promise to support energy-efficient home retrofits. Natural Resources Canada has released some details of what the Our Action Starts at Home initiative will look like, though the program is not available to homeowners yet. According to the NRCan website, the program will be retroactive, covering retrofits started as far back as Dec. 1, 2020. It will “complement” efficiency rebates offered by provinces and other jurisdictions. The initiative will provide

700,000 grants of up to $5,000 for eligible retrofits and one million free EnerGuide energy assessments. Homeowners will have to get an EnerGuide audit before becoming eligible for the grants. They will also have to document the work done, including before and after photos. The website states NRCan is working to train enough auditors to meet the anticipated demand. The organization is also promising lowinterest financing options in addition to the grants. No word on when the initiative might actually launch. cc

Some construction supplies, pressure treated wood in particular, are in very short supply throughout Atlantic Canada. One of the largest suppliers of building materials in eastern Canada is Kent Building Supplies, a subsidiary of the J.D. Irving Company. Mary Keith, vice-president of communications for Irving said in an interview that, “the supply issues are the result of increased consumer/ contractor demand and this is a challenge for both U.S. and Canadian home improvement stores.”

In the shiretown of Guysborough, N.S., Bob Cook owns and operates the only building supply store, a franchise of Home Hardware. “Treated wood, from what they are telling

me, is basically impossible to get unless you have previous commitments,” he explained.

Local contractor Danny Procure, proprietor of D. Procure Construction, said the shortages haven’t affected his business to date. “We are still getting our supplies. I just got a complete house package for framing. There are certain items that are not available such as pressure treated material and actual plywoods, OSB is still readily available but plywoods are not. Pressure treated is really the biggest thing that is giving us trouble,” said Procure. cc

- Lois Ann Dort, Local Journalism Initiative Reporter/ Guysborough Journal

The total value of building permits rose 12.9 percent to $9.4 billion in November, the third-highest value on record – with the highest value having been reached in April 2019. Much of this growth was led by large permits for multi-family dwellings in British Columbia and Ontario, and an office building in the city of Toronto. The value of residential permits rose to new heights in November, increasing 10 percent to $6.4 billion and breaking the previous record set in Sept. 2020. Every province posted gains in this sector, except for Nova Scotia and Prince Edward Island, which reported slight declines. British Columbia led the way with a 27.8 percent increase, while Ontario has shown strength in each of the last four months, at or near record levels for the province. Multi-family dwellings rose 14.8 percent to $3.5 billion. The majority of the growth came from British Columbia (41.3 percent), specifically municipalities in Vancouver Island and in the census metropolitan area of Vancouver. A $376 million permit issued for Sugar Wharf Condominiums in the city of Toronto contributed to the record high reported in Ontario ($1.6 billion). Single-family permits increased 4.4 percent to $2.8 billion in November,

EllisDon’s Alliance of Black Employee and Leadership launched the inaugural Shaping the Future Sponsorship Program enabling Canadian students to share its vision for a community that is more inclusive of the Black experience and without racism. This initiative will serve some of the most underrepresented and underserved communities in different areas of Canada.

“Helping to create a world free of racism and discrimination is a very important goal for EllisDon. It is so important to encourage students to help shape a path forward and help create an environment that’s more BIPOC inclusive,” said Kieran Hawe, COO and executive vicepresident of construction operations, ABEEL.

As part of this program, students will engage in meaningful dialogue about how they see racism manifest in their own lives and what steps everyone can take towards a less hateful future. Student teams from across the country will use a creative medium of their choosing to bring their ideas to life, including creative writing, non-fiction writing, photography, music, video or visual arts.

“We want to thank all the educators and staff members from across different schoolboards in Canada that are working tirelessly in a time like this, marred with COVID-19 and social injustices, to ensure that through a program like

continuing the strong upward trend observed over the past six months, with values well above pre-COVID levels since August 2020. Quebec (12.7 percent) recorded the largest gain, while Nova Scotia was the only province to post a decline (8.5 percent). cc

this we can jointly pave the way to an awesome future,” said Samuel Ajobo, chair of ABEEL.

The initiative has been rolled out across four different schoolboards in Toronto, Calgary, Ottawa and lower mainland British Columbia led by Denroy Jackson and Siju Ewhubare, both community outreach leaders for ABEEL. The fifth region, Edmonton, is underway. The hope is to roll it into other areas of Canada and eventually the rest of the world, where EllisDon lives and works. Winning teams from each region will be provided with resources and bursaries that will be distributed to their communities, to their schools and to the students themselves. These will include access to mentorship opportunities (EllisDon-led or via strategic partnerships). The company’s hope is to inspire and empower the next generation of city planners, engineers, project managers, superintendents, and many other construction professionals. cc

In 2020, the Western Retail Lumber Association invested in an economic impact study to justify a Home Renovation Tax Credit as a strategy to support economic recovery. At the end of 2020, the Saskatchewan provincial government announced a 10.5 percent tax credit on up to $20,000 of home renovation expenses. The program runs retroactively from Oct. 1, 2020 to Dec. 31, 2022. WRLA will continue to advocate in the other

provinces as well for an HRTC. The federal government, as part of its Fall Economic Statement 2020, also announced an energy retrofit program. The WRLA, in addition to several partnering stakeholders, advocated for an eco-retrofit program either in the form of tax credits or grants. The 2016 census identified 4.5 million dwellings that require minor or major repairs. WRLA noted that it is pleased to see that the federal government listened to recommendations from the industry and its partners and will support economic recovery while taking action towards climate strategy. The proposed program will provide $2.6 billion over seven years to help homeowners make energy-efficient improvements to their homes. cc

In preparation for its launch in early 2021, the Home Construction Regulatory Authority posted new licensing fees along with guidelines for builder conduct and consumer complaints. Effective Feb. 1, the HCRA is being designated by the Ontario government as the regulatory authority under the New Home Construction Licensing Act to assume responsibility for regulating and licensing the people and companies who build and sell new homes in Ontario. HCRA posted the licensing fees that will fund the new system as well as guidelines detailing how it will work.

“The HCRA will enforce high professional standards for competence and conduct in the homebuilding industry, giving new home buyers confidence in one of the biggest purchases of their lives,” said Tim Hadwen, interim CEO of the HCRA. “We will also ensure consistency across the sector, curtailing unethical and illegal builders and maintaining a fair marketplace.”

Licensing fees will cover all costs for the HCRA to oversee a new modern licensing regime for builders and protect consumers when making the biggest purchase of their lives – a new home. A new regulatory oversight fee – a flat fee paid on a per-home basis – will enable the HCRA to continue monitoring licensed builders and vendors; identify and act against illegal and unethical builders; manage the complaints process for consumers; provide educational materials; and maintain the Ontario Builder Directory as the official source of background information about Ontario’s more than 5,000 home builders and vendors. In developing the new fee structure, the HCRA endeavoured to keep costs to builders and vendors from rising significantly. Guidelines posted on the HCRA’s website include: Guide to Good Conduct for Builder/Vendors and Consumer Complaints Guideline. The HCRA is taking over the licensing function from Tarion Warranty Corporation. Tarion will continue to deliver Ontario’s new home warranty and protection program, backstopping the coverage provided by builders to purchasers of new homes. cc

Effective Jan. 1, the Access for Ontarians with Disabilities Act requires websites for non-profit, public and private companies with over 50 employees to meet a wide-ranging set of requirements for accessibility or face fines of up to $100,000 per day for corporations and $50,000 per day for directors and owners. The requirements are extensive and there are very few websites in this industry that would comply. Text needs to be convertible to large print, braille, speech, symbols or simpler language. Video and audio must have captions available. Simplified layouts must be offered. All functions must be accessible with a keyboard only without use of a mouse. These are just a few of the requirements. By law, new and significantly refreshed public websites must be made accessible if you are a private or non-profit organization with 50+ employees; or a public sector organization. The organization that controls the website must meet the accessibility requirements. Complete details are available on the Government of Ontario website. cc

21_0179_CN_Contractor_JAN_FEB_CN Mod: January 6, 2021 3:26 PM Print: 01/12/21 3:22:01 PM page 1 v7

By Andrew Snook

Matt Chuba always had a passion for building. Watching and working with his grandfather when he was very young, spiked his interest in the construction industry.

“He was a Polish immigrant that came over on a boat in 1956 with $20 in his pocket. He ended up being a big concrete foreman. He built a lot of downtown Toronto and was even part of the CN Tower’s construction,” Matt says. “He was a big inspiration.”

Matt continued to find the building process fascinating throughout high school. So much so that he had planned on going to university to become an architect. But that plan changed the moment he sat down in an architect’s office for his co-op placement.

“After sitting behind a computer screen for eight hours, I realized it wasn’t for me,” Matt says. “My parents were getting their kitchen done at the same time and I saw the guy building the cupboards and it looked interesting, so I asked him for a co-op placement.”

That co-op placement turned into a regular summer job throughout high school. After graduating, Matt left Oakville, Ont., and moved to B.C. to join the carpentry pre-apprenticeship program at the College of the Rockies Cranbrook Campus in Cranbrook, B.C.

Matt moved back to Ontario shortly after graduating the program and worked as a trim carpenter for several years.

“We joined Alair because we felt that transparency was important in our core values.”

He eventually realized that he wanted to start up his own business, so he reached out to a friend he was doing projects with and they formed Seafare Construction, a home renovation company based in Oakville, Ont.

Matt and his business partner ran Seafare Construction for nearly a decade before they were approached by Alair Homes, a custom home building and renovations company with franchises throughout Canada and the U.S.

“At the time, my first business partner and I had gone our separate ways and my brother, Mark, had stepped in,” Matt says. “Shortly after that, my brother and I were operating Seafare when Alair approached us. They had seen some reviews of us on Google. We decided it was a good fit.”

Now into their second year operating as Alair Homes Oakville, the Chuba brothers are enjoying being part of the franchise.

“Alair is trying to change the residential construction industry,” Matt says. “We are 100-percent transparent with our clients. They see all the bills from the subcontractors we get and use on their jobs. We build their budgets with them.”

This transparency in the billing process with clients was a major reason the Chuba brothers decided to opt into the Alair Homes franchisee system.

“We joined Alair because we felt that transparency was important in our core values. Everyone thinks contractors are there to rip you off – to take your money and run. Bad news spreads faster than good news, so we wanted to align ourselves with people who had the same mindset we did, and that’s where Alair came in,” Matt says.

Alair has 55 offices across Canada with 99 partners (most offices have two owners). In the U.S., there are about 140 offices. Having all these different franchise owners can be an advantage for anyone looking to network with other industry professionals that they can bounce ideas off of.

“Every Wednesday, every office calls into a conference call and there’s lots of brainstorming. The CEO leads the call,” Matt says. “In Ontario, project managers working for all the offices have another call once a week, or twice a month, and sit there and brainstorm ideas with each other.”

Before joining Alair, the Chuba brothers were working 100hour weeks. Matt says that joining the company has given them the opportunity to scale their business and it has helped reduce the number of hours they need to work, when compared to being the owner-operators of Seafare Construction.

“Now with the scalability, I’ve stepped back. My brother focuses on sales and I focus on the operations of the company,” Matt says. “At Seafare we were doing five jobs a year, and now we’re doing 15 jobs this year, and we’re growing… so I think Alair was a great route for us. It’s made a huge difference.”

Matt is married and has young children. So, getting the additional time back in his schedule has been extremely important to him.

“We were working hard every day on the tools, and every job took longer than you thought. We were working evenings and weekends. Trying to keep up with our schedule was costing us our family time,” he says. “Alair came in at the right time in our lives to make that change.”

At Seafare Construction, the Chuba brothers were performing major renovations and were looking at custom home building as a long-term goal. By joining Alair, the brothers were able to feel comfortable making the jump into that market.

“It was the kick in the ass we needed,” Matt says. “We knew that was where we were headed, but it would have taken us five to 10 years to get there. But with Alair, and the guidance they could present us, it’s much quicker. We’ll be building our first custom home next year. It’s been a good move.”

Pricing strategy

Matt says that one of the worst ways a client can price out a custom home build or major renovation project is by a price

per square foot, and he avoids that with his clients.

“Square-foot price to build a home is one of the most dangerous ways to build a home. We plan it all out ahead of time, so the customer knows what their house is going to cost before we put a shovel in the ground,” he says. “We do a feasibility study with the client and get a wish list of what they really want and why they are building this home or doing this renovation. Then we work with them and figure out what they want and then give them a price range. A master bathroom, for example, could be anywhere from $30,000 to $60,000, or more.”

Matt says giving clients all the prices up front and letting them decide what they want is important for making them comfortable throughout the process.

“Renovations and home building are extremely stressful,” he says.

Building through the pandemic

When the COVID-19 pandemic was declared in March, the Ontario offices kept in close contact with each other.

“Through that start of COVID, Ontario offices were calling in every Monday to go over best practices on how to keep our tradespeople safe on jobsites,” Matt says. “It was extremely challenging. When the pandemic hit, we were like everybody else – glued to the television wondering what’s going to happen. Our clients were the same way. We had five jobs we were ready to start construction on within weeks, and people were calling us saying, ‘I just got laid off, so I’m not ready to spend this money right now.’”

Not wanting to put additional pressure on the clients, the Chuba brothers held off on those projects and waited until the clients were ready.

“All of those people came back in the summer and said, ‘We’re ready to go,’” Matt says. “We’re still fighting this battle, playing catch up from the three months when a lot of people stopped working.”

A major hurdle for catching up on projects has been

disruptions throughout the building materials supply chain.

“Our concrete company shut down for three months – March, April and May –and then had to catch up starting in June. Then there were the lumber shortages and when pressure-treated lumber was more expensive than gold,” Matt jokes. “I renovated my own home and couldn’t get two-by-sixes, two-by-eights, two-by-10s or plywood. I’d ask the store. ‘When is the truck coming?’ and they’d say, ‘We don’t know.’

“A permit for a small renovation that would take seven to 10 days to get is now taking eight weeks to get… it’s been a struggle.”

“Talking with our flooring guys, they were saying, ‘We have 10 sea containers coming from Europe and we don’t know where they are,’” Matt says. “They could be stuck in a port in Europe or Montreal, and they didn’t know when they could fill the order, because nobody knows where it is. COVID has been quite interesting, to say the least.”

Although most construction has been listed as an essential service in Ontario, some of the key services that allow the sector to function productively are not, which has created additional delays for contractors.

“I know Doug Ford made construction an essential service, but then the building departments aren’t necessarily an essential service and are working parttime,” Matt says. “So, a permit for a small renovation that

would take seven to 10 days to get is now taking eight weeks to get… it’s been a struggle.”

Clients haven’t been thrilled about the project delays.

“Clients are unhappy about it, but it’s out of our control. We’re trying to do what we can. At the end of the day, they’re spending money with us and they want it done,” Matt says.

Adding to the challenges of getting projects completed are all of the new safety precautions that have had to be put in place.

“We’ve had to change our processes around,” Matt says. “We put hand sanitizer stations and Lysol wipes in every site. Only one trade is allowed per job at a time. We have signins for all of our jobs saying who was here and how many people we would need to contact [if someone tested positive for COVID-19].”

Although the Chuba brothers are excited about where their futures will take them with Alair Homes Oakville, they aren’t looking to expand quickly while the pandemic is active.

“We don’t want to grow too fast, more at a nice rate so I can still handle it. The stress of this year was enough,” Matt says. “This year will definitely go into the memory banks as, ‘I never want another one of these again.’” cc

+ Less than 8 lbs. + 180˚ flexibility + 100% comfort

FEATURES:

• Full Force System - Random orbital movement in combination with unique pad design enables Mirka to leave out brushes. 100% of sanding pressure actually goes to sanding

• Brushless Motor Technology - Enables compact design and no need to change carbon brushes, less downtime. Constant speed under load, no loss in efficiency under heavy pressure.

• Dual Suction Points - Less dust in the air and clean abrasive cuts better

• Bluetooth® Technology - Monitor vibration exposure and register for additional warranty with only a few clicks.

mirka.com

E. sales.ca@mirka.com

Experts discuss what to expect in 2021 and beyond.

By Sukanya Ray Ghosh

As the world grappled with COVID-19 in 2020, most industries everywhere felt the brunt of the many lockdowns and supply chain disruptions. With most construction-related activities deemed essential across Canada, the home renovation sector experienced a surprisingly positive year, all things considered.

“Early on in 2020, we saw a drop of about 22 percent of activity, and then we saw a very strong rebound. We expect 2020 will finish off with little to no dip as compared to the year before, when the final numbers roll in,” noted Kevin Lee, CEO of Canadian Home Builders’ Association.

He added that in 2019, reports showed that direct and indirect jobs in the renovation sector were over 111,000, contributing $85 billion in economic activity. The 2020 figures are expected to be about the same.

Predictions for the year ahead

Industry experts note that the home renovation industry has been on the upward curve of growth for quite a few years now.

According to Lee, it has been growing in recent years at a rate faster than the overall economy. He, therefore, expects this trend to continue in 2021, along with the surge in renovations seen last year.

“I don’t think anybody saw the renewed interest in home renovations that came as a result of the pandemic. But it makes sense with people working from home, attending school from home, exercising at home and entertaining outdoors, among other things. It was an unexpected side effect of the pandemic and we do expect that to continue into 2021,” he explains.

Lee also adds that as per recent surveys, one third of Canadians are planning to complete significant home renovations or repairs in the coming year.

Canadian FinanceIt CEO and founder Michael Garrity has similar predictions for 2021. Garrity’s first prediction is that this year will continue to be defined by the pandemic. The industry will continue to deal with the positive, as well as negative consequences of COVID-19.

“We’re going to be wrestling with the pandemic all the way through quarter one and two in Canada, maybe even into quarter three before we begin to see light at the end of the tunnel,” he says.

Garrity notes that unlike 2020, however, the industry will not be surprised by it. Everyone is better prepared and more organized to deal with issues such as supply chain constraints and labour interruptions, for example.

As people are forced to stay in due to the ongoing health crisis, there has been an overwhelming focus on the home space. Garrity predicts that there will be continued high demand, especially for small jobs.

“People stayed home, looked around and got frustrated. They focussed on the things that they wanted to get fixed. It is a good story for the industry, especially for small jobs,” he explains.

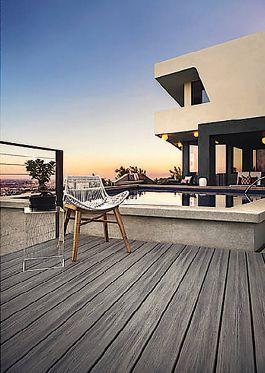

Garrity’s adds that 2021 is going to be the year of the staycation.

“People understand that their outdoor space around their home is going to be where they want to focus. They’re not planning trips to Barbados or Florida. They’re wondering whether they want a pool or should they put a hot tub in. Do

they redo their backyard and build that outdoor cooking area that they’ve always wanted? I think there’s going to be a real push for the beautification of the outdoor space so that people can come together safely and enjoy a home-based vacation. Yeah, I believe that’s going to be a huge trend in 2021.”

Garrity, himself occupied with a complete backyard renovation, notes that people realized in 2020 how illprepared their yards were to entertain people.

He adds that a fourth trend he has seen is a rise in demand for financing home renovation and improvement projects. He predicts that this will continue in 2021 as it would be easier for some people to pay on a monthly basis for 10 years instead of the full amount upfront.

What should contractors expect?

Vaccines have been rolled out. The country has already started walking on the path to eventual recovery. This means that the economy will also eventually improve from the current situation.

Lee notes that since people will continue working from home for at least the short and medium term, contractors can expect continued interest in improving their home spaces – both indoor and outdoor.

In its Fall Economic Statement in Nov. 2020, the federal government promised $2.6 billion in support for energy efficient home retrofits. Lee notes that the CHBA is particularly excited about this move as it has been advocating incentive programming to help people make smart decisions about how they invest in their renovations. Additionally, the association will be targeting a million EnerGuide home evaluations. Therefore, Lee recommends that in 2021 home renovators think about having good partnerships with the EnerGuide evaluators.

Lee notes that there are certain trends that are ongoing and are going to be amplified because of COVID.

“There was already a slight trend towards less open concept design, but we think that will really continue because sound transmission is becoming an issue as people are trying to perform multiple functions at home. It’s maybe two adults trying to do their jobs from home or kids attending online school. We expect more special purpose rooms like home offices, home theaters and certainly more of an emphasis on outdoor living,” he explains.

Lee notes that 2020 also saw an uptick in single detached houses, a trend that had been going down and moving more towards multis. This changed as people looked at their futures and realized that they maybe didn’t need to be in the office every day or they could live further away from their offices. Since renovations often happen right after the purchase of new homes, the trend suggests more incoming opportunities for home renovators.

As people reacted to the pandemic, another change that came up was a preference for digital interactions. According to Garrity, companies in 2021 will think about how they can accelerate digital connections with their customers, facilitating meetings, discussions and even payments digitally.

“2021 is expected to be a busy year for home renovations but things might slow down in 2022.”

Lee notes that an ongoing issue that renovators are familiar with and can expect to see even in 2021 is the challenges on the lumber supply side. There is an ongoing shortage and the prices are going up in the lumber markets because of the strong demand from renovation and new construction, both in Canada and in the U.S.

“With very strong demand on both sides, we unfortunately expect those lumber prices to continue to be high. So, from a renovator perspective, that’s going to be an important part of pricing. Makes sense, potentially, to go to cost plus contracting. Order well in advance. You have to manage expectations for the clients as well, because we saw these shortages derailed project times,” Lee says.

Change is the only constant

The year 2020 turned out to be a gamechanger all around. The home renovation industry is certainly feeling the impact and influence COVID-19 on how people think about their home spaces today.

Every year, the CHBA does a homebuyer preference study. The study focus on what people are looking for and what they want to do with the renovations.

“It’s a labour-intensive business that involves seeing the project space, cooperating with the homeowner, designing and customizing, and then ultimately doing all the hard, heavy-lifting to get it done. But I think 2020 is the year that digitization has accelerated in every business. Our businesses have to change as well. There’s never been a better time and I think that the companies who take on technological advancements are going to be much better positioned. Digitization makes your job easier and makes your customers feel safer,” says Garrity.

The CHBA, through its annual homebuyer preference survey, is seeing a trend towards more and more emphasis on the digital marketplace for evaluating home builders and renovators.

“So, websites and social media are really important for businesses to stay ahead and to have the best chance of getting the best business,” says Lee.

The CHBA also sees an aging-in-place trend that had been ongoing before the pandemic but strengthened further after. “With all of the challenges of retirement homes, more people are interested in aging and living in home for as long as they can,” explains Lee.

CHBA is planning on launching more training and resources for its renovator members to inform them about all the aging-in-place technology and awareness they will need to do these renovations.

Garrity notes that 2021 is expected to be a busy year for home renovations but things might slow down in 2022. “That means, for 2022, your business better be set up to be highly competitive when demand starts to recede,” he says. cc

Maric Homes discusses taking the gold for Creemans Crescent.

By Gordon Wornoff

F or nearly 50 years and over two generations, the Maric Homes team has built hundreds of homes in the Winnipeg area. In the fall of 2020, Maric Homes scooped a Gold Award for their project at 116 Creemans Crescent in West Winnipeg. The award came from The Manitoba Homebuilders’ Association who organize a “Parade of Homes” twice a year in Winnipeg. Maric Homes’ president, Dan Rolfe, and Peri Maric, vice-president of architecture and design, discuss their win and what it takes to earn the prize.

How did this project come about? What was the inspiration? What are some of the features? This home is 2,260 square feet. It’s on a corner lot, which is great. We try to build homes that complement the landscape.

In terms of design, we’re progressive. We try to stay on the cutting edge. But we also add that accent that harkens back to something that everyone can understand and recognize.

In Manitoba, there’s a gigantic cottage country population; every other person has somewhere to go. There are thousands of lakes and everyone goes off to the cottage on the weekend. A very familiar architectural style you see in the Interlake and Whiteshell regions are these A-frame houses or slightly raised gable houses with rake windows that match the gable and the roof lines: angled architectural windows, centrally located, usually.

We did a modern twist on that look. We did these huge gables with big windows that match the rake. We modernized it by including a flat roof

detail that added some horizontal inspiration into the design. Also, we placed the rake windows off-centre. By including some asymmetry, we’ve added some visual interest. The raw shape of the building looks like the cabin you would have gone to in 1975. That was the initial concept with the house.

We vaulted the ceilings on the inside, just like you’d see at a place up in Falcon Lake or Grand Beach. It’s a nice edge to reference a historical building style. But you don’t want to have it look dated. Like the board and batten for instance – it’s a very common cladding system that’s been around for a century. So we used it, but painted it black so it has this deep, rich, heavy presence on the street. And we combined it with brick, another very traditional building material, in a very traditional brick colour - that

kind of rusty brown. The exterior has this traditional look, placed in a modern fashion, and it looked really cool. We were really happy with how it turned out.

One interesting interior product we’ve included in this house is microcement. It’s a very, very thin cement product, about five to seven millimetres thick. You can see it in the bathrooms and on the fireplace.

Your award comes from the MHBA’s Parade of Homes.

Can you describe the Parade? It’s been going on for 30 years. When a new development is being built in the Winnipeg area, clusters of building lots at the entrance are set aside for registered homebuilders to put up display homes.

The Parade of Homes happens each

spring and fall and allows for customers to walk through 100 to 150 homes built by roughly 30 builders. The great thing about the Winnipeg market is that it’s a 20-minute city. I can access the city’s north, south, east, and west ends by the ring road and see tons of displays.

It gets a ton of traffic, the fall being more active than the spring, but we might get 400 to 500 people through there on a Saturday.

There are times where we’ll have one or two homes in the Parade of Homes, and upwards of six or seven in other years. Sometimes we’ll run a home through one cycle of the spring and fall and then into the spring again. It all depends. If we’re selling five or six or 10 houses inside a development, it can make financial sense to leave these display homes open for a year or even

two to generate business and then sell it. We can certainly say it pays for itself.

Opening day for the Parade of Homes is huge. There’s been so much promotion about it. The communities all know where the show-home strips are. The residents know. People have been following your Instagram stories. They all know there’s a new building display. Anticipation gets built. There’s a lot of upfront promotion and we’re all there every year on opening day at noon. It never fails. All these people come out. They’ve gotta get the first glimpse; it’s such a cool thing.

Every builder puts their best foot forward and is excited to show off the latest and trendiest materials and designs. On opening day, we’ve got our full team there, with a support team of real estate staff.

Is there a big squeeze on subtrades in the weeks before the Parade of Homes?

Absolutely. There’s only so many resources in our city. We have our trade sets that work for us. We try to keep them very busy. Otherwise, certainly they’d get headhunted, no doubt about it. Certainly in the weeks before the opening of the Parade of Homes, there’s not a subtrade or builder that’s getting

any sleep. It’s really chaotic, you’re pressing to get everything completely perfect on five houses that need to open that day. These houses are fully landscaped, furnished, interior décor is spotless. It’s quite the show.

It’s fun to see all the builders in the weeks before working like crazy. We’re out there at 3 am pressure washing driveways, and not just employees. Everyone’s spouses, I’ll take anybody.

I have a seven-year-old and she helped carry magazines and newspapers and it helps a lot. It’s great.

Wow, the Parade of Homes sounds like a big part of Winnipeg’s home building business cycle. Yeah, absolutely. 100 percent. It’s huge. And it’s not only us. I would suggest we almost have the busiest and most competitive markets per capita

across Canada. Especially for the demographic.

But that’s one of the things that keeps us motivated. That keeps the fuel burning inside of us. To continue to work at the highest level that we do. It’s a very competitive marketplace in Winnipeg. We talk about this all the time. Being the small demographic that it is, being the healthy market that it is – our competition is in our face. And we’re in the face of all the competition as well. There’s a lot of builders that aspire to what we do. But we can’t build every house in Winnipeg – we’re not made for that. But when it comes to attracting the right type of customer and building the houses that we like to build – there’s stiff competition.

Do competing builders research each other’s products?

We are proud of our position. We’ve been in business for 50 years. We’re one of the leaders in our industry and there are a lot of followers. We see a lot of designers coming through. We see a lot of people coming through, looking for ideas and that’s a feather in our cap.

If the competition wants to crawl into your pocket to see what’s going on, well, we’re proud to be that builder who others measure themselves against.

But we’re all chasing some type of bar. The Maric ownership group tries to go on a retreat once a year, or every couple. We do home tours, whether it’s in Las Vegas, Kelowna, Scottsdale, Toronto. We go and see what other people are building around the continent. And we go and take note of particular details, craftsmanship and materials. We try to get a really broad sense of where we stand with the product we’re putting out.

We try to be aspirational. We keep our sights set in Manitoba, but measure ourselves outside of it. It helps us continue to grow and to be a leader.

What is the business footprint of Maric Homes? What’s the backend like?

Currently we have 18 employees. And that includes both our new home luxury team and our renovation team. There is

a second-generation ownership group – the kids and families of the original founder took over 11 years ago. The founders are passive owners with a smaller minority stake and the secondgeneration ownership group has the vast majority of shares.

Ever since that transition happened 11 years ago, we’ve been steadily growing the business and a lot of that new growth is coming from our

renovation division. The last three to four years we’ve been focusing on that – really turning it into a business. We put up 20 to 30 custom homes each year. We also usually have about 15 large renovations ongoing.

I’m sure you’ve heard many horror stories about family businesses but we’re happy to buck that. We’re a really close team. It’s a great place to work and we’re all lucky in that regard. cc

Building a house with net zero energy, zero toxins, zero carbon and zero waste.

By Gordon Wornoff

Chris Magwood builds high-performance houses where success is measured in zeros. One of Canada’s most informed and strategic alternative builders, Magwood recently completed a “Zero House,” in a collaboration between Ryerson University’s Architectural Science Department and Magwood’s building school, The Endeavour Centre, in Peterborough, Ont.

The Zero House consumes net zero energy each year, has a net zero carbon footprint, produced zero construction waste and contains zero toxins in the indoor air quality. Zero House was erected for display at the EDIT Exhibition in Toronto in 2017 and then reassembled and sold to a client for a permanent home.

Magwood and his team approached the goals of this project – keeping the zeros tight – using a variety of tactics from traditional artisanal techniques, Ontario Building Code compliant standards, and a few high-tech components.

“It’s all pretty conventional stuff. It’s wood framing, it’s structural sheathing, it’s nails and screws. We haven’t stepped into the crazy world of squirting it out of a 3D printer or anything like that,” says Magwood.

The 1,100-square-foot house is prefabricated, built in modules in a controlled shop-setting. The R70 roof and R60 floors are built like plywood torsion boxes with engineered trusses running inside them and packed with blown-cellulose.

The R40 walls are double two-by-four studs with 10 inches of blown cellulose, or a combination of straw bale and cellulose insulation. These 10-inch walls are then sandwiched between one and a half inches of rigid insulation sheathing.

The Zero House project explored multiple alternatives to XPS rigid foam insulation (blue/pink) or EPS (white dots). Rigid foams do significant harm to the atmosphere when they are created and therefore embody a large amount of carbon.

The team installed some two-inch cork exterior rigid insulation panels (R7.2) from Jelinek Cork in Oakville. The cork insulation “works really well in place, but the panels weren’t compatible with 16-inch framing, so we had to install extra blocking so they didn’t break during transportation,” says Magwood.

Another exterior insulation they used is a panel made of recycled wood fibres. SONOclimat ECO4 is manufactured in Quebec, is R4 and is recyclable at the end of its life. At one and a half inches thick in four-by-eight sheets, it was compatible with the wall framing. Magwood says comparable fibreboard insulations are predominantly from Europe, boast higher R values and have a tongue-and-groove system that creates an effective air barrier and results in far less cutting and fastening. “Somebody in North America should figure out how to make a European-style fibreboard like that because it seems crazy that in the land of trees we don’t make better wood products.”

The team also experimented with Mycofoam – a fungi-

based product that arrives as a packet of spores and dry culture. They mixed up the culture with water, spread it on the exterior of the straw bale SIP. Under plastic, the fungus slowly breeds and develops. The team let it grow until it reached one and a half inches – the same thickness as the neighbouring fibreboard exterior insulation. Once uncovered, the product dries and maintains a rugged bond with the straw. After testing, they found the Mycofoam layer to provide an R6 thermal break on the exterior of the straw bale wall.

According to John Straube at the Ontario Association of Architects, an average new home will passively leak its own volume in air twice an hour when a difference of 50 Pascals of pressure is present. Older homes leak eight to 12 air changes at the same pressure differential. A requirement to be a Passive House is 0.6 air changes. Zero House achieved 1.05, so the team was thrilled with the results.

In building, controlling the air flow through the walls increases energy efficiency. Controlling the vapour flow prevents mustiness and decay from forming in these tight envelopes and cavities.

The Zero House manages vapour by building with straw and using smart housewraps and interior membranes that allow vapour to travel through the wall assembly and dry to the warmest side. In a comprehensive and effective airtight building envelope, one must account for the vapour transmission. In a standard build, Typar or Tyvek on the exterior is a breathable membrane that repels water, but allows vapour behind it to transmit out. The six millimeter poly on the inside can risk trapping vapour in the wall assembly where mould can form. “The building science part of the way we build is what nobody ever talks about, but it’s just an insane advantage…you can put eight pounds of water into a cubic foot of straw bale in dispersed form. There’s so much storage capacity with the capacity for drying in both directions. For people who don’t care about these materials for any other reason, they should think about them from a durability and building science perspective,” says Magwood. The crew installed Intello vapour control layer on the inside and Mento 1000 from ProClima on the exterior. These are similar to industry-standard housewrap and vapour barrier, but are engineered for performance and durability. All European products. They taped all seams with Vanna tape from ProClima and used AFM Safecoat as a nontoxic alternative to acoustic sealant.

Another unfamiliar product the team installed is made from recycled juice boxes. ReWall was designed as an alternative to drywall which wouldn’t need to be replaced when water damage occurs. ReWall also solves the problem of trying to recycle drinking boxes, which requires substantial energy and water to isolate the different materials in the composite – paper, plastic and waxes. “It was great stuff but unfortunately it’s not being made in that format anymore. The company was sold and now they only make panels for flat roof applications,” says Magwood. For interior ventilation, Magwood used Lunos ductless energy recovery ventilators. In simple terms, the system is two cannisters on opposite ends of the home. Each one

contains a two-way fan and a ceramic core. They work in tandem on a control timer. One exhausts and heats up the ceramic core with inside air. The other brings in fresh, outdoor air. They stop, they switch directions, and the warmed ceramic core warms the incoming fresh air before it enters the home. The heat exchange averages over 90 percent. No ducts to penetrate the airtight wall systems.

Another tactic for keeping the wall assemblies as airtight as possible was to strap the interior walls to allow for electrical service to run on the surface of the air barrier and minimize penetrations. In this way, future electrical upgrades can occur without disrupting the air barrier.

Similarly, the Zero House sports BiPVCo solar panels which adhere directly to standing seam metal roofing so the owners can skip the aluminum racking which penetrates through the roof. In one of Ontario’s last microFIT contracts, the homeowner receives a cheque from the utility company for all the energy created by the PV system.

The Zero House crew selected electric on-demand tankless hot water for the house. They installed an EcoSmart 24-kilowatt unit that brings cold well water up to 125 C as it passes through. For temperature control, the team went with an electric Daikin air-source heat pump. The conditioned air is pumped into the house by two wall-mounted units: one upstairs and one downstairs.

For the purpose of net zero energy costs, the choice of windows is crucial. Fibreglass is more stable than vinyl, resulting in less energy loss due to shrinkage in the winter and unwanted air gaps. Zero House includes Inline triplepaned windows and doors. Fibreglass also doesn’t rot, making it a more durable option than other materials with a shorter lifespan. With the 13-inch walls, “we just got the biggest outside extensions they offered: seven inches. That was set out to be flush with the finishes, which meant the window unit itself was set back in the insulated space,” says Magwood.

Looking through a window to the future, Magwood sees panelization happening more in performance building and residential building. “It doesn’t require advanced 3D printing technology, there’s no weather, no wrapping in the rain, trying to tape wet surfaces. Instead of two months disruption on a street, it’s one day. A crane comes and the building is up. You start putting services and finishes in it,” he says. “I’m not coming up with these wild or crazy ideas and they cost 10 times as much or they’re really inconvenient. We have to build things for the price that somebody is willing to pay for in the existing market. It can’t be exotic and it can’t be time consuming, but it can be different,” he says. Magwood says another valuable aspect of panelization is “it changes buildings from these things that have a certain lifespan. And then we’re done and we just smash them to pieces because it’s too hard to do anything else with them,” he says. “We could take the whole thing somewhere else. Or we can combine parts of it with other parts to create a whole new building. It means, on one hand, we have this zero waste goal at the construction phase. But it also kind of means, in theory, that building could have hundreds of years of life span in multiple forms,” says Magwood. cc

What caught our interest

trex.com

Trex, a brand of wood-alternative decking, is ending the year with acclaim. The company’s Trex Cladding product has won awards based on its high engagement rate among architects, engineers and contractors over the past year.

“The premium aesthetic and ultra-low maintenance of our rainscreen cladding product have definitely attracted the attention of architects and business owners, which has enabled us to seamlessly expand our footprint in the commercial building arena,” said Adam Zambanini, president of Trex Residential Products.

Designed to make hardwood planks obsolete in modern rainscreen systems, Trex Cladding is made from the company’s Trex Transcend deck boards and can be applied vertically or horizontally to lend a modern look to any structure. The open-joint facade system promotes airflow while providing a worry-free armour with visual appeal. Available in three board lengths and a variety

A SPLENDID SERIES

everlast.altitudewindows.com

The Everlast Altitude Plus Window Series

Designed for impressive performance, elegance and durability the Everlast Altitude Plus window series sets a high standard for aluminum windows. This window features extruded aluminum profiles interior and exterior connected to the thermal insulation system called the “performance core,” representing the core of the window. The performance core is a new proprietary engineered material, designed for specific tasks, offering improved dimensional stability and higher deflection temperatures, resulting in increased strength. Also featuring mitred corners assembled with gaskets, corner keys all crimped together, this window series has achieved Energy Star certification. Low profiles make this suitable for today’s modern homes. Altitude Plus also meets the CW classification, meaning mid-rise buildings with institutional application. It provides the possibility of multiple assembly and opening configurations. The product is available in casement, awning or fixed-window designs. Combination windows are achieved using either structural mullions with continuous frames or modular construction. The frame depth is four and a half inches. The standard sash depth is two and seven-eighth inches with a height of

of colour options, Trex Cladding features a proprietary nine-element surface formulation that produces a natural, wood-like grain pattern with a durable and resilient finish. Unlike wood, Trex Cladding boards resist fading, staining, scratching and mold – and won’t rot, warp, crack or splinter. No sanding, staining or sealing are ever needed. Just an occasional soap and water cleaning will keep boards looking like new for decades. Furthermore, the product is backed by a 25-year fade and stain warranty for both residential and commercial projects. Adding to its appeal, Trex Cladding is made from 95 percent recycled materials and is easy to install using conventional tools and methods. Boards are approved for 24-inch-on-centre furring strip spacing, which means faster installation and lower installed costs. Additionally, the highly impact- and scratch-resistant material is tested to withstand hurricane-force winds and is code compliant for structures under 40 feet in height in most jurisdictions.

one and three-fourth inches and designed for 31millimetres one three-sixteenth inches glazed units in dual or triple pane. Cardinal glass in various low-E combinations are available to achieve desired performance. Mullions are 1four and nine-sixteenth inches deep. Installation clips make for quick and easy installs as well. The Altitude Plus window series provides home renovators and custom home builders with a competitive edge.

The Heatlok Soya HFO closed-cell insulation product leverages Honeywell’s latest Solstice Liquid Blowing Agent technology. This new HFO blowing agent is an environmentally conscious blowing agent produced with a zero-ozone depletion potential and a global warming potential of one. It also has a high R-value: R6 per inch.

“There’s a demand for HFO based product as builders, architects, specifiers and general contractors are looking to design and build with the future in mind. Our building science teams have been in front of the building and design communities explaining the impact of the blowing agent change and preparing them for the switch to an environmentally friendly high-performance spray foam,” said Simon Baker, president of Huntsman Building Solutions.

spray insulation has a broad range of advantages over its predecessors, which includes better airtight building envelopes, stronger structural support, moisture control and higher energy cost savings. The product provides high performance options for projects in the commercial and residential space. It’s also been tested as an exceptional air barrier, vapour retardant, water barrier, thermal insulator and flood resistant.

Huntsman Building Solutions’ Heatlok Soya HFO

iko.com

IKO announced the release of an updated and upgraded version of its Roof Viewer tool. Roof Viewer is an intuitive software that utilizes artificial intelligence technology to show users a vividly realistic rendering of how any given house would look when complemented with the IKO roof of their choice. The robust software enables users to upload an image of their home or to choose from over three-dozen stock house photos available on the Roof Viewer site. Roof Viewer includes 18 colour options throughout seven different IKO shingle styles. The featured shingle styles include Dynasty and Nordic from the popular Performance line, and the suite of IKO Designer shingles, which mimic the look of natural slate tiles or cedar shakes. Roof Viewer, which first launched in 2003, has earned its reputation as a vital tool for both homeowners and roofing contractors during the shingle style and colour decision-making process. The Roof Viewer user experience has been redesigned for homebuyers in the 2020s. Roof Viewer can be found on IKO’s North American residential website and is easily accessible via a standard web browser on a desktop computer or smartphone. The featured homes offer a wide variety of styles that include colonial, ranch, Victorian and more. Once a house is selected, home-exterior details, such as colours for window and door trim, can be

“Our own Heatlok Soya HFO closedcell product contains a total of 22 percent recycled plastic and renewable soya oil content. Just one of our resin drums contains up to 3,000 plastic bottles that are diverted from landfills. The installation generates zero waste, zero trash on the jobsite and the product adapts to all surfaces, shapes and volume. There is no packaging, the system is sold in liquid form in returnable or recyclable containers,” said Doug Brady, vice-president of global innovation and product management at Huntsman Building Solutions.

selected to reflect the user’s home or personal preference.

“This software is designed to provide both homeowners and contractors with a seamless and enjoyable experience that helps ease, what is for some, a difficult decision,” Williams continued.

However, to ensure complete satisfaction, IKO suggests viewing several full-size shingles and an actual roof installation prior to final colour selection as the shingle swatches and photography shown online, in its brochures and in the Roof Viewer tool may not accurately reflect shingle colour and do not fully represent the entire colour blend range, nor the impact of sunlight.

By Steve Maxwell

If you compare the exterior design and styling of today’s new homes with what was common in the 60s, 70s and 80s, you’ll see a definite visual improvement. Classic lines, reduced maintenance and better value for the dollar come from three building innovations that are here to stay. Consider these for your next new build or major renovation and you could end up with a project that enhances your professional reputation every time someone drives by and takes in the curb appeal.

Full-bed manufactured stone Natural stone has been called the king of building materials, and this means both high quality but also high cost. Today’s manufactured stone is an answer to the problem of expensive natural stone and it manages to combine exceptionally authentic looks with an installation cost that’s closer to brick while also requiring labour that’s less skilled than working with natural stone. Any bricklayer can install complicated manufactured stone products because the component stones are all meant to fit together with minimal cutting and hammering. If you haven’t taken a close look at modern manufactured stone you’re probably in for a surprise. The best is even more authentic than products that were made just 10 years ago.

Canada happens to be a world leader in the manufactured stone sector, and each company has developed unique manufacturing processes. That said, the bottom line is the same for all: Make great looking stone more widely affordable.

I’ve worked with natural stone for 30 years and I can’t tell today’s best manufactured stone from natural when viewed from normal distances. One reason it captures the authentic appearance of stone is because it’s thick, not thin and glued on. In the industry, the term “full bed” means that the manufactured stone components are just under four inches thick from front to back. This creates a more authentic look around corners and openings than glued-on stone

substitutes, while still using the same approach for support and tying to a wood frame that you’ll find with brick.

Complex roof designs When the Canadian homebuilding industry emerged from World War II, roof trusses skyrocketed in popularity because trusses go up faster than rafters and they require less skill to install. The problem with those original manufactured trusses is that they led to boring, ugly, low-slope roofs on boring houses. Fast-forward several decades and if you didn’t know better, you’d swear that Canadian homebuilding sites have been invaded by armies of highly skilled roof framers. Interesting, complicated roofs are popping up in new subdivisions all over the place, and the source of the striking beauty is 21st century truss design.

More and more builders are including stunning roof designs in their projects, yet they’re doing it within ordinary building budgets employing carpenters with ordinary skills. And the key behind all this is computers. By harnessing information technology to design, cut and assemble factorymade roof trusses, the housing industry now offers both stunning, intricate roof lines and more affordable home ownership all at the same time. Where the term “truss roof” used to be synonymous with plain, low-slope, ho-hum houses, computer-designed trusses now offer the low-cost possibility of steeper roof pitches, space-enhancing dormers, vaulted ceilings and bonus-rooms over garages in areas that would otherwise be clogged with two-by-four webbing and metal nail plates.

Synthetic trim and details

There’s a reason so many of the classic home designs of yesteryear included complicated exterior trim and detailing, and there’s a reason this fell out of favour as the homebuilding industry became more streamlined. As nice as it all looks, traditional, ornate exterior trim and molding was not only expensive to install, but expensive to maintain and required exceptionally skilled labour to build. Solving the problem of high cost, high maintenance and high skills is why synthetic exterior trim and detailing is becoming more popular. It provides all the classic good looks that are indistinguishable from solid wood, but with a rot-proof surface that either needs no painting, or holds its paint longer and better than wood. Cellular PVC is the generic term for the most common brands of synthetic exterior trim, and it’s different than regular PVC for one reason. Air pockets worked into the PVC during manufacturing change the consistency of this material quite a bit. It cuts better than solid PVC, you can sand it, drive screws into it, and it takes and holds ordinary latex paint even better than wood.

Curb appeal sells and there are more ways than ever to boost it in the projects you take on. cc

By Casey Edge

The Trudeau government recently announced plans to introduce a new foreign buyers tax, claiming it will create housing affordability. But to understand rising home prices, we need to drill down to the numbers.

Canada is undergoing some of the fastest population growth in our history. Statistics Canada reports our growth is twice as fast as the U.S. and U.K. Canada’s population was 37,589,262 in 2019, up 531,497 over 2018. This corresponds to just over one new person added every minute. According to Statistics Canada, this “is due largely to permanent and temporary immigration” where Canada admitted 313,580 immigrants, “one of the highest numbers in history.” In welcoming immigrants, we have an obligation to ensure there is sufficient housing, presently neglected by federal and provincial governments. That is where the responsibility rests: with the policy makers. From 2015 to 2019, Canada welcomed more than 1.5 million immigrants. The federal government plans to admit 401,000 in 2021; 411,000 in 2020, and 421,000 in 2023.

In 2019, Canada’s housing starts were 197,000. At an average of two people per household, 400,000 immigrants would account for all of Canada’s annual new housing starts. Add the millennial generation, now starting families and a demographic about as large as the baby boomers, and the supply is obviously insufficient for the demand. Also add the fact that municipalities, not Canada’s federal and provincial governments, make decisions for land use, rezonings, development and building permits. Municipal councils are entirely disconnected from federal and provincial immigration policies. This is a recipe for spiraling housing prices in many cities and especially Toronto and Vancouver, where the majority of immigrants settle.

Ottawa’s new tax target, also a favourite of the B.C. government, is foreign buyers and speculators. B.C. has launched a Foreign Buyers Tax, a Speculation/Vacancy Tax and a School Tax (really a land tax, nothing to do with schools), yet home prices continue to rise. Caught up in the taxes are families in Kelowna and other regions paying thousands of dollars annually for their vacation homes –homes that have been in their families for generations. Not exactly speculators.

Housing is a big source of revenue for government, so they always welcome another tax, while deflecting attention from their policies.

So far federal and provincial politicians have ignored the

impact of slow, municipal development processes, including Toronto and Vancouver, double digit increases to development cost charges; rising inspection and permit fees (based on rising construction costs, not inspections); double land transfer taxes charged by Toronto and Ontario; new building regulations including B.C.’s ill-advised Step Code; and the list goes on.

A new study by the CD Howe Institute called “Gimme Shelter: How high municipal housing charges and taxes decrease housing supply” reveals development charges, land transfer taxes, and density bonus payments are partial drivers of reduced supply and soaring prices. They have added $644,000 to the cost of a new home in Vancouver and an average $230,000 extra in Toronto, Victoria and other cities across the country.

Solutions for affordability require a change in land use, including more accountability by municipalities to senior levels of government.

For example, some U.S. states, such as Oregon, have passed legislation overriding restrictive single-family zoning to allow multi-family projects. Portland permits up to six homes on most residential lots.

Canada lacks similar solutions mostly due to provincial politicians disinclined to step on the toes of municipal councils, often from whence they came.

We also need a cap on taxes, fees and new regulations that only serve to boost prices as outlined by the CD Howe Institute.

All Canadians, including immigrants and millennials, are challenged by unaffordable housing created by three levels of government intending to squeeze every last dollar from the market, and specifically homebuyers.

Several decades ago, there was no GST, Land Transfer Tax or the endless municipal fees and amenities required from today’s new housing. But governments could not balance a budget and began using housing as a cash machine.

Politicians are Canada’s new royalty, insulated from the harsh economic realities experienced by most Canadians. An example is this year’s pay increase for MP’s during a pandemic while many small businesses lay off employees and even permanently shut their doors.

The first step is for all homebuyers and builders to reject new taxes by Canada’s royalty, falsely claiming to create more housing affordability. It’s just a new royal tax on our nerves. cc

Casey Edge is executive director of the Victoria Residential Home Builders Association.

Barry’s province has issued a new set of COVID lockdown orders that he finds confusing and vague. He’s pretty sure he’s able to continue the jobs he’s on presently, but whether he can start his next project is unclear. The permit is in place and the contract was signed weeks ago, but work had not actually begun before the order came down.

The frustrating part is he can’t seem to get a straight answer from anyone on whether he’s allowed to go ahead. Government officials and his MPP just parrot the government press release and refuse to address his specific situation. Various friends and family all have different opinions. His lawyer recommends erring on the side of caution - easy for him to say, he doesn’t have Barry’s bills and workers to pay.

Barry knows he could stop work but he suspects his customers might use that to get out of their contracts and go to the competition. He also doesn’t want to lay off his crew and potentially lose some of them. He’s tempted to go ahead with the work but he knows there are $50,000 fines waiting out there if he’s caught violating the lockdown rules. All it takes is a phone call from an irate neighbour...

Last month’s Dilemma featured Kyle and a botched roofing job gone public on social media. Readers agreed that direct contact with the customer is the answer, but Gregory Pynn from Halifax said it best...

Rather than engaging in any public mudslinging on social media with the client or subcontractor over the botched job, Kyle’s best course of action in this situation is to own the mistake and take the opportunity to turn a negative into a positive. After all, as the contractor, he is ultimately responsible for the error even if he didn’t personally perform the work.

Once he has conversed with the client to diffuse the situation and to hopefully regain some trust, he should use his own social media to tell the story of the unfortunate mistake and use follow-up posts to document the process of completing the repair work to the very highest standard possible. Rather than focus on the details of how the mistake occurred or which subtrade is responsible for what, Kyle should focus on the solution and keep the attention on the final outcome. Publicly thank the client for the opportunity to make things right. Through this process, Kyle can take control of the narrative of the situation, put his integrity, professionalism and workmanship on display and demonstrate to his small town who he is and what his company stands for. In the end, Kyle will have a great redemption story to share on his own social media and perhaps even those once-angry clients may be willing to follow-up their damaging posts with a more positive story of how Kyle went above and beyond to right a wrong.

Congratulations, Gregory, enjoy your new DeWalt 20V Max circular saw!

1. Full steam ahead with his lawyer on speed dial.

2. Try to negotiate with his customers for delays to the work. Start work on those who refuse to accept any delay.