Rocking On Down East Award Winner

Page 16

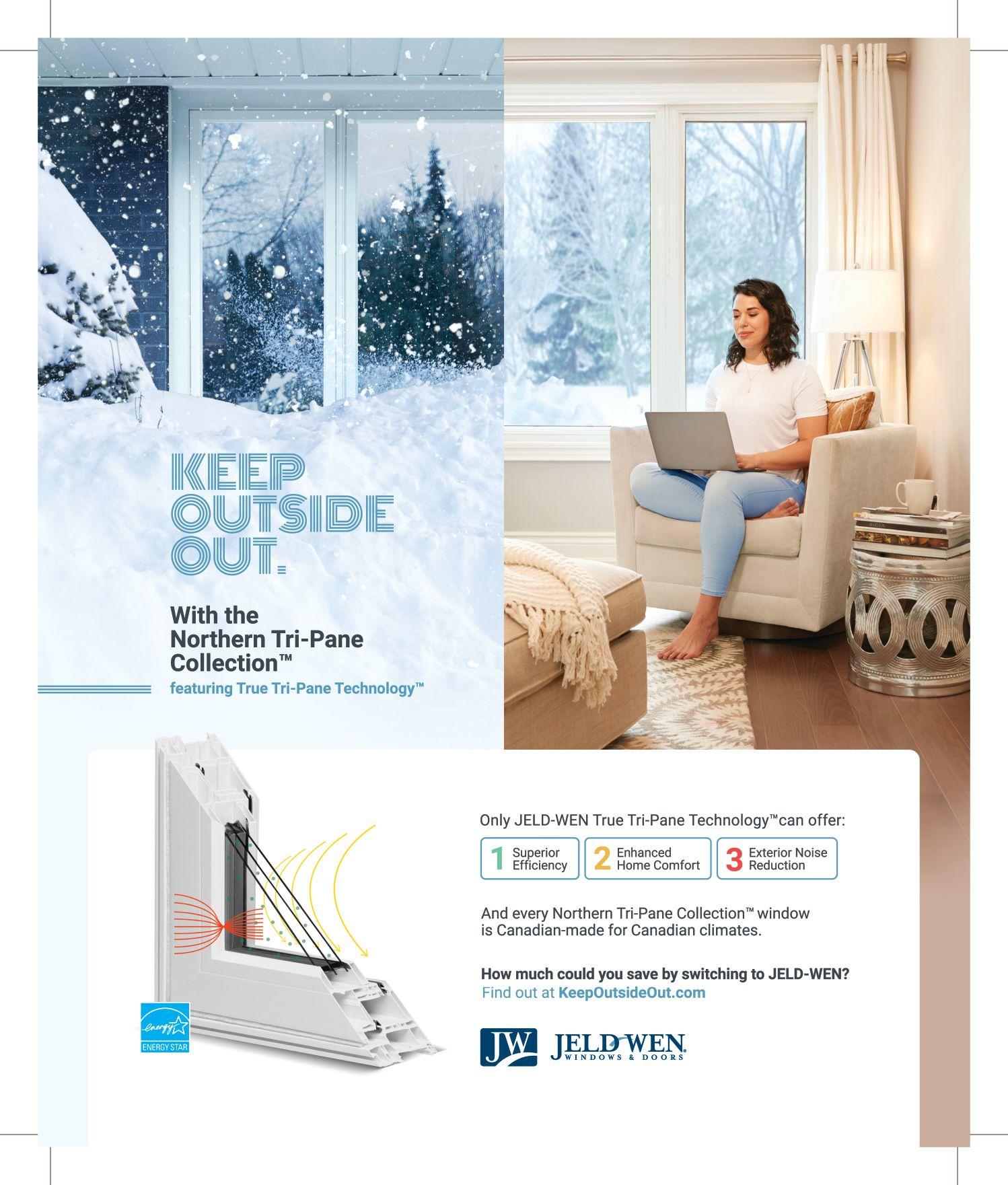

Boost Your Windows Game

Three Steps to Success Page 15

The Dilemma Business or Marriage? Page 30

Rocking On Down East Award Winner

Page 16

Boost Your Windows Game

Three Steps to Success Page 15

The Dilemma Business or Marriage? Page 30

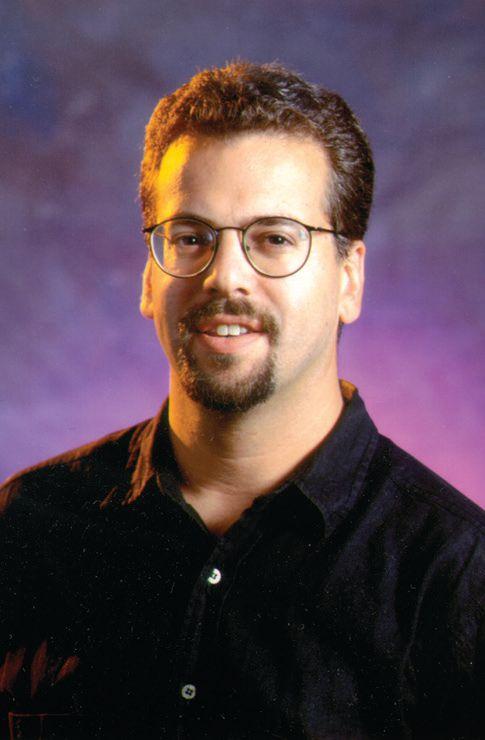

Rob Allan and his contractor coach Mike Draper Page 20

As a contractor, it should be your goal to become the wolf to your clients.

Yes, I know what you're thinking: "why in the hell would I want to be a wolf?" That's a natural reaction. After all, throughout history wolves have tended to be saddled with negative baggage.

There was the wolf that blew down the three little pigs' house. Seriously? What a jerk! And then you've got the one that tried to eat Little Red Riding Hood. Clearly, he was suffering from a social disorder.

There's even been sayings conjured up to perpetuate this off-putting theme: "Oh, never mind him, he's a lone wolf." Or, "It feels like the wolf is at the door." And then there's "Sheesh, were you raised by wolves?"

More socialization issues, associations with sneakiness, and a general sense of impending doom when the wolf is around. Clearly, wolves are in dire need of a major public relations campaign.

However, wolves have a ton of good qualities that are often overlooked: they're courageous; they're known for their protective and caring side; they are determined; and they are proud and tremendous leaders.

The reason I bring this up (oh, are you finally going to get to the point?) is that as a writer/editor that has worked for many Annex media publications over the years, I've gained a certain reputation.

Need someone to come in on a moment's notice and hit the ground running to finish a project? Check. Have an editorial emergency that needs immediate fixing? Done. And now, I'm taking over as the editor of Canadian Contractor, a mag that I've been involved with for 20 years.

Having previously stepped in on numerous occasions to steer various magazines through production — and doing so with the utmost efficiency and expertise — I've been nicknamed "The Wolf."

If the pop culture reference eludes you, you may recall the character that actor Harvey Keitel played in Pulp Fiction. In that movie, Keitel was a problem solver. Have an emergency? He was there in a flash to take control of the situation and resolve it, professionally and expertly.

So being The Wolf has its positive connotations as well. You may never get rid of a body, clean blood, brain bits and guts out of a car, and then having said car demolished (thankfully, I am rarely asked to do this myself), but you get the point: it should be every contractor's goal to embody these lupine characteristics, and become an indispensable and go-to resource within your community.

Need a full reno done? No need to check the Yellow Pages (I know, so old school). Just call The Wolf. Time to refresh the bathroom (and not simply because Uncle Jack just came out of there after eating four cans of chili)? The Wolf's your man.

If we all aspire to be more wolf-like perhaps we can finally start swaying the general public perception of our industry.

No, this is not a simple transition. I get it... you have certain clients that are pigs, and you'd love nothing more than to huff and puff and blow their house down (perhaps with the assistance of a carefully situated brick of C4).

But don't forget that you're a professional... a pillar of the community... you're "The Wolf."

Applying those lessons to your business (and avoiding — or at least minimizing — the times you devour innocent people when the moon is full) will go a long way towards ensuring your future success. cc

” You may never have to get rid of a body.

By Rob Blackstien Editor ”

Canadian Contractor has hundreds of videos online for serious residential construction professionals

Sponsored by Home Hardware

This series of videos looks at ways to build better, faster and more profitably. Canadian Contractor presents a number of construction tips sent into the magazine by Canadian contractors – and they also interview experts from around the industry. Everything on a job site from framing to interior finishing is fair game for Site Tips.

Canadian Contractor interviews Vaughan, Ont.-based contractor Andrei Sosnovsky, who talks about how hard work and a love of building are the keys to his success story.

Sponsored by Various Manufacturers

Innovation is the engine that keeps profitable construction companies going. Unless you discover new and better ways to build, you risk falling behind your competitors, and your company may be challenged to compete in the new industry landscape. Buildwire is the place for contractors to see what’s new and improved.

Editor Rob Blackstien rob.blackstien@rogers.com

Contributing Editor Steve Maxwell

Media Designer Mark Ryan

Publisher Steve Payne 416-219-9949 spayne@canadiancontractor.ca

Account Coordinator Barb Vowles bvowles@annexbusinessmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-510-5182

Tim Dimopoulos, Vice President tdimopoulos@annexbusinessmedia.com Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Want adventure with purpose? Travel the world and use your skills to empower others!

Canadian Contractor and World Vision are providing the opportunity of a lifetime. Experience SkillTrain – Canadian trades professionals training young Rwandans. Experts in carpentry, plumbing, welding, electricity and masonry are needed.

WINTER 2019 • RWANDA, AFRICA • LIFE-LONG IMPACT

Be a part of the action and change a community for good. Are you part of this team?

E-mail skilltrain@worldvision.ca to learn more.

Back in 2016, we wrote an article about why the Building Code isn't free, and it's long been a source of contention among contractors.

It's just like the Chinese policy for executions

The government imposes a building code, but the only way you can know what the code says is by purchasing it! This parallels the Chinese government policy of sending a bill to the family of the executed criminal in order to pay for the bullet used in the execution. Makes no sense.

Gene Regulations should be free

I completely agree all government regulations or those that are enforced by a quasi government agency like ESA should be available for free online.

Paul Denyer

Back in 2015, we solicited opinions on Mike Holmes' declaration that "no good contractor needs more than 10 per cent to start a job." The responses poured in... and continue to do so.

Right you are. Mike Holmes has made his money on trashing contractors and feeding his big ego. Good for him, not good for anyone else that is actually in the industry. Every contractor and customer is different and there should not be statements made for someone who should know better that says otherwise. I am sick of him and his trashing of the industry and using fear mongering to get rich himself.

I wonder if he is related to Trump?

A reader sheds light on the realities of doing things the way we outlined in a 2018 video.

Thanks for the info. Polyurethane is great stuff, but not the easiest to work with. It would have been interesting to have

more info on how to also finish the bead (top, visible surface). I believe urethane and other hybrid caulks and the popular “Mulco Supra” are never to be tooled nor applied like an Arcyric Latex, etc.

The former require a Convex Bead, while the other calls for an “hour glass” type bead (this is per manufacturer's technical instruction).

Most info about using back rod says it works to create the “hourglass” bond, which works with this video's instruction of doing “1/2 of joint width for joint depth”… but, how well does this work with the polyurethane and Mulco Supra requirement for Convex (bubble-like) bead?

Finally, new installations are far easier than old replacement caulking jobs where old material gaps, bad workmanship, etc., requires using caulk for just as much of a visual detail (and cover-up) and as a sealant. These cases seem to always require tooling to get wide gap coverage. Is this not a problem for nontoolable caulks like polyurethane or using backing rod? Other than installing some “trim filler” detail, I’d like to see a follow up video on these contradictions between caulk tooling/beads with backer rod and a video on real-world “cheating” that is called for on wide gaps where backing rod won’t work (lack of depth, etc.)... no, it's not the right way, but customers on many jobs refuse the expensive, correct fix.

Joe White

In the fall, we wrote an article about Mike Holmes stating that most contractors are good guys. It certainly elicited its share of responses, including this one, from the "Oldest Plumber in the World."

Mike apparently never had any trade recognized training and would be fined for doing any of the compulsory trades in Saskatchewan. The application of his suggestions is offensive to our registered apprenticeship program.

I would repeat my admonition to beware of working in Saskatchewan in any compulsory trade without registering in such trade and providing a journeyman level certificate to your customer.

Lorne Figley

Here's what we learned at the nation's largest homebuilder/renovator show

TheHomeBuilder & Renovator Expo was held in the Toronto Convention Centre over a three-day span in early December and Canadian Contractor was there to sniff out useful news for our readers.

Growing RenoRun adds new features

RenoRun, the Montreal-based developer of the construction material delivery service app with the same name, has launched a Pro version, the first subscription service of its kind.

Standard pricing for contractors is $60 per delivery, but by signing up for RenoRun Pro, they will be eligible for unlimited deliveries for just $100 per month.

The company was launched in 2017, expanding to Ontario later that year. The basic concept was borne from the challenge contractors faced when they suddenly ran out of a specific product needed to finish a job and would lose costly man-hours by having to send skilled workers to a building supply store to pick up more materials.

Instead of incurring that “massively costly” loss of a supply

run, contractors can simply download the RenoRun app and order materials that will be delivered within two hours, says Chandal Nolasco da Silva, RenoRun’s Content Director.

It’s insane the amount of time and money and inefficiency that goes into simply getting your materials to your job site,” she says.

In terms of quality control, the company has hired employees with industry experience that know how to properly vet product to ensure contractors are getting the best possible materials.

“We’ve got pickers inside Home Depot who are experienced in the building industry, so they’re going for the best quality materials,” Nolasco da Silva says.

“We will not send broken drywall, we will not send cracked lumber. Everything’s straight, they’re eyeing it.”

Dubbed by the press as the “Uber of Building Materials,” RenoRun has internally adopted the moniker.

Offering delivery drop-off service between the hours of 8 a.m. and 6 p.m., the company is run by CEO and long-time contractor Eammon O’Rourke and its early success has not gone unnoticed by the investment community.

Continued on Pg. 12

• Is significantly stronger in holding the structure together than competitors

• Has the complete data for the inspectors

• Is ACQ tested and approved to prevent call backs

Withdrawal

Up to 23% higher

Up to 30% higher

Up to 90% higher

Pull Through Lateral Strength GRK versus Competitor Brands

Up to 112% higher

Up to 24% higher

*Comparison based on published data of 4 top competitor brands

The Golden Standard of Structural Wood Fasteners Tension Shear

Continued from Pg. 9

In fact, the company recently secured a round of Series A funding of $22.5 million, a cash infusion that will help fuel expansion plans.

After opening in Toronto, RenoRun expanded to Austin, Texas, later in 2018, and will soon add a fourth city — probably in the United States and likely in the second quarter of 2020. Nolasco da Silva suggests there could be a second launch before the end of 2020 as well.

Ultimately, the company aims to expand nationally within Canada, but it first plans to saturate the Toronto market, she says.

On top of delivering anything that will fit in its trucks or on a flatbed, among the new features the company has recently launched are: Saturday deliveries; and walk-in service (instead of merely dropping off products outside, RenoRun will bring the products inside the job site).

RenoRun is currently using the tagline “We got your back,” and the play on words can be applied to both the business and physical support it provides contractors, Nolasco da Silva says.

“We want people to understand that we’re different,” she says.

“Every interaction that you have with us is going to be pleasant. We’re just here to make your life better. Stay on the job, let us bring you coffee, let us do the heavy lifting, let us destroy our truck.” cc

Barrie, Ont.-based insulated concrete forms manufacturer Nudura was showing off a recently released higher R-value (R35) version that's designed to meet Net Zero standards that will be coming with the 2022 Building Code changes.

"We're way ahead of the game," says Regional Sales Manager Pierre Brideau.

Featuring Durafold technology, the XR35 has a higher R value thanks to its 4" EPS panels and newly designed fastening strips, making the product more energy efficient but retaining its light weight.

The fastening strips are 5/8" below the surface and feature a diamond pattern for easy and quick fastening of interior or exterior finishes. The XR35 is currently available in an 8" core, but the line will be expanded in 2020, he says. cc

Amvic goes eco

Amvic Building System also had something new to display with its Amdeck Eco floor and roof system for modular construction.

Vice President, Technical Services Gary Brown says this is a residential product consisting of lightweight 2 x 8" x 8" panels of in place formwork built with Type II closed cell EPS.

It can be used to build one-way, reinforced concrete slabs that are perfect for low-rise residential or small building applications. Installed between industrial walls, Amdeck Eco features integrated slots for dimensional lumber wood joists that employ a shoring system to support temporary construction loads.

The insulated concrete form for floor system is perfect for using underneath a garage in situations when a customer wants a bonus room, Brown says. He says advantages for contractors include:

• Amdeck Eco accepts standard 2' x 6' lumber for framing and temporary support;

• 8" high insulation;

• Interlocking is fast and easy; and

• The product sits directly on top of structural walls. Brown says Amvic is also developing an insulated exterior panel that incorporates furring strips for a siding application. By combining insulation and furring, "you're not doing two separate jobs," he says.

We also found time to attend a seminar entitled "Avoiding Costly Building and Renovation Mistakes: Plan for Your Profit." Featuring speaker Michael Upshall of Bolton, Ont.-based Probuilt Design + Build fame, the seminar covered a ton of ground and offered plenty of great tips to help contractors succeed.

Expect to see nuggets of wisdom from this session presented over time on our site in 2020.

Correction

In the last issue of Canadian Contractor, the copy gremlins were up to no good. In the Creative Eye section on page 28, there were four photos in the right-hand column that were not properly attributed to yet another ITW "Show us your project" runner up, Evolve Builders Group of Guelph, Ont. Our apologies to Ben Polley and his team. If this snafu proves anything, it's that we are not perfect, which we're sure is news to most. cc

DISCLAIMER: Not evidence-based or rooted in any sort of statistical measurement of actual show size. But we promise it’s going to be really, really big. Please address all complaints about this ad to our editor, Pat Flannery, who would be happy to buy you a beer at the Oktoberfest party at the show on Oct. 20. This is the fine print, why are you still reading this? Really, go register at canadianrentalmart.com so you don’t miss out on Canada’s Big Ass (sorry, “largest”) rental show. See you there!

HE WON $5,000 IN GRK FASTENERS AND A PASLODE NAILER!

Tosay that Ben Crocker was surprised to take home the top prize in the ITW "Show us your project" contest is an understatement.

"I had actually kinda given up on the thought of winning. I was intrigued to see what kind of a project could have beaten the one that we had completed," says the Vice President of St. Thomas, Ont.-based D.F. Crocker Ltd.

For its efforts, the company won a year's supply of GRK screws and a Paslode nailer.

Not only will the company be fully stocked with GRK fasteners, but news of the award rippled through Crocker's business circle.

"A bunch of my regular sub trades and the guys at the local Home Hardware store were tickled to hear that we won as well," he says.

Crocker explains that the framing screws are always in demand, but the larger structural screws really open up some options for them as the company recently bought a portable sawmill.

"This accompaniment of fasteners will allow us to experiment with different timber frame structure projects," he says.

Crocker has tried competing products but says the GRK "fasteners are very hard to beat."

Because they're structural screws, they have a much higher

Contractor Ben Crocker, St. Thomas, Ont., won our Canadian Contractor/GRK Projects Contest.

sheer load capacity than conventional screws, he says. "The fact that you can run the screws in very close to the end grain and not split out the framing material makes them extremely versatile," Crocker says.

They'll save time and money by eliminating the need to pre-drill.

Here's what Crocker won:

• 9x3” 9,500 ct;

• 10x4” 3,000 ct;

• 12x5-5/8” 1,200 ct;

• 5/16”x4” 400 ct;

• 5/16”x5” 450 ct;

• 3/8”x8” 400 ct;

• 3/8”x10” 50 ct;

• 3/8”x12” 50 ct; and

• Paslode impulse nailer.

"The diversity of fastening options will be nice as we do a lot of one-off renovation/addition type work where we need fasteners of all sizes," Crocker says. "Knowing that you have a good supply of these fasteners will allow us to focus on simply completing the job in a way where we are extremely confident it will not fail." cc

By Steve Maxwell

Newand replacement windows are something every contractor has to deal with, but windows are unique because they have a powerful potential to cause trouble. A lot can go wrong with installations, not all of which is the fault of the windows themselves. That’s why it pays for you to learn how to steer clients away from questionable choices and towards ones that you know won’t cause trouble. Use the three-part process here and call-backs for windows won’t be one of the headaches you need to deal with.

Step 1: Educate your client

The No. 1 issue with new/replacement windows is condensation. Homeowners see their precious new windows sweating on the inside during cold weather and immediately think the windows are faulty or you are. Uninformed clients get especially ornery when they pay good money for replacement windows, only to find that condensation is actually worse. “What’s the matter with you?” they might say. “Can’t you install windows correctly?”

The fact is, if a modern double or triple pane window sweats, it’s a sign that indoor humidity levels in the home are too high in winter. And the better those new windows seal, the less outside air will get into the house, the higher indoor humidity levels will get, the worse condensation will be at a given outdoor temperature. This is why condensation is often at least a little bit (sometimes much) worse after new replacement windows are installed with better sealing. There’s less natural ventilation (AKA, drafts). Tell your clients all this before the new windows go in and you’ll have a much better chance of leading them to an actual solution to window condensation (an HRV always works), instead of just being a lightning rod for misplaced blame.

These days there’s no need to guess when it comes to recommending windows your client can count on. This is especially true here in Canada because of something called Windowwise.ca . It’s a certification program created by the Siding and Window Dealers Association of Canada that includes a

list of specific window products that meet physical certification standards. Besides poor energy performance, weak window design can cause trouble. And yes, modern windows sometimes have design flaws right from the factory.

Step 3: Install windows right

Even with cans of spray foam on every building site, it’s still possible to install windows badly. In fact, as good as spray foam is, it can actually lead to the nasty problem of window binding. Even so-called “low expansion” spray foam is often strong enough to bow windows inward so they won’t open or slide properly when that foam is fully expanded and hard. You can eliminate this with these installation tips:

• Only use spray foam made for window and door installation -- this type delivers the least amount of expansion pressure. Ordinary low expansion foam is often still too strong for safe window installation;

• Install wooden props or spreader clamps to brace window jambs so they can’t bow inwards under foam pressure: The larger the window, the more important props are. Also, be sure to leave the props in place for at least 24 hours after foam injection. Foam will continue to expand a bit for a while, even after it's hard. I use Quick-Grip clamps with reversed jaws as spreader clamps for window installation props; and

• Inject foam in stages: Shoot an inch or so of foam into the farthest recess of the gap between window and rough frame, then move on to the next window and do the same. By the time you’re done all the windows, that first shot of foam will be getting hard after expansion is complete. Only then do you add more foam. If the window jamb is wider than 4", fill the gap completely in three separate passes. Incremental foam injection greatly reduces the chance of inward window bowing. cc

Tour this award-winning project by Newfoundland builder S&L Porter Homes

By Steve Maxwell

Porter has been building homes in Newfoundland for 30 years, and when he and his crew at S&L Porter Homes began working with a client in Portugal Cove, N.L. in early 2019, no one knew they’d end up building an award-winning home together. On November 16, 2019, the 1,550-square foot project took first place at the 11th annual Canadian Home Builders Association Newfoundland Berg Awards in the 1,500- to 2,200-square foot category. Learn how this striking, ultramodern project happened in this exclusive Canadian Contractor interview with company founder and contractor Porter.

Q: What’s the back story on this project?

A: The clients had a concept in mind for style, details and some of the features they wanted. Knowing this was going to be a unique build, we spent a lot of time reviewing architectural designs for both the interior and exterior of the house – three months in all. Product options were laid out and discussed at length, many plans were drafted and altered until the physical layout and building products were settled on. The client participated heavily in the research of the heating system as well as the tech upgrades found throughout the house. Only when we identified a stable budget did we start building. The whole project took nine and a half months from planning to move in – three months for planning and six and a half months for construction.

Garage door: GARAGA classic black

Decking: brown pressure-treated with aluminum balusters

Heating system: Daikin model 3MXL24RMVJU

Fireplace: Valor heat shift propane

Domestic hot water: standard efficiency electric heater

Smart features: smartphone control of lighting and HVAC

Stair railings: cables and fittings from Bezdan.com

Kitchen cabinets: custom-made from Alberta

Q: Newfoundland isn’t called “The Rock” for nothing. Did you have any unusual geological challenges on this project?

A: This is a new subdivision and though there was enough soil to accommodate an eight-foot-high basement under the actual building footprint, shallow bedrock elsewhere on the site did affect electrical, sewer and water hookups. We avoided any drainage issues with weeping tile around the entire foundation, tied directly to town storm sewers.

Q: What kind of efficiency detailing was applied to this house?

A: Although the home has not yet been independently tested for energy efficiency, design modelling software gave us a good understanding of the energy performance we could expect. With R60 of insulation in the attic, EnergyStar windows and doors, plus reduced thermal bridging on exterior walls, this turned out

to be one very efficient home. Our normal way of minimizing thermal bridging is to wrap the house in rigid foam insulation on the outside face of all exterior walls, but this wasn’t an option given the client’s budget. Instead of a typical 16” on centre wall stud spacing, we went with 24” on centre inch.

Q: What sort of mechanical ventilation systems are in this home?

A: We installed a heat recovery ventilator, and the home is heated and cooled with a Daikin ductless heat pump with three distribution heads. Even though it’s rated to put out just 24,000 BTU/hr., this system is very efficient and designed to work in cold temperatures. The return on the client’s investment will be four, maybe five years tops (compared with conventional resistance electric heat), verses 10+ years pay-back on an airto-air system.

Q: Are there any particular products or techniques used on this project that stood out for you?

A: The exterior of the home is completely maintenance-free, starting with a European PVC siding product called SAGIWALL. It’s like vinyl siding but better. It comes in convincing wood grain patterns, it expands and contracts minimally with changes in temperature, it’s impervious to mold, it’s fire rated and never rots or attracts insects. Manufactured in Portugal, SAGIWALL is made to work with companion product SAGIREV for soffit, fascia, corners, J-mold and H-mold. I find both these products great for our extreme Newfoundland climate. The materials worked well with the particular dimensions of the home, but care has to be taken when considering where these pieces are used since it comes only in 12’ and 19’ lengths. Minimizing waste is key since the product is expensive and because our provincial supplier only stocks limited amounts of material.

Q: Does S&L Porter Homes specialize in any particular part of the housing market?

A: Our main focus is building homes for first-time buyers and also for those downsizing into a smaller place. The exact breakdown changes from year to year, but in 2019, 40 per cent of our builds were for first time buyers (including this project), 40 per cent were downsizing and 20 per cent were neither.

Quite often our first time homebuyers are working on a very tight budget, especially in this economy. Our job with these custom builds is to find the most economical design with the most economical finishes to suit the budget. An example of this would be to keep the footprint smaller and do partial

development in basement to give clients additional living space at minimal cost. As well, sometimes while working with the client, we can utilize a smaller square footage and still achieve their goals.

Q: How many homes do you build each year and what size of crew do you have?

A: I founded the company in 2002, with myself and 10 employees today. We have four carpenters, one labourer, a heavy equipment operator, a sales department and a client service department. The “L” in the company name comes from my son Lucas. He’s currently in college studying business marketing. When he’s done he’ll join the company and eventually take it over.

We typically build about 10 homes a year; 80 per cent of these are custom from the ground up and 20 per cent spec. Back in 2007, I formed a land development company with a longtime friend. We’re currently into our third subdivision with a total of 110 lots and are ready to receive approval on a 47-lot subdivision in the spring.

One way we keep our projects on track is by investing a lot of time before the build starts, going over plans and the construction process. We also use a tracking system to keep our clients on budget. If they make a request that would be costly, we can let them know exactly where they stand budget wise. This solves a lot of problems before they happen.

Q: What is it about this project that you like best?

A: One big thing is that we closed this house on budget. That was not easy. Another challenge we all met well was with communications. Any custom project like this requires a lot of talking, but since the homeowner works on off shore equipment out in the sea, this was difficult sometimes. Many decisions about design elements and products had to be made by email or message. cc

Need help achieving your goals?

Canadian Contractor recently sat down with Mike Draper, the contractor coach, and one of his clients, Rob Allan, to discuss the dynamics of their relationship, how it works, and the benefits contractors receive.

Want more? Read the entire interview at Canadiancontractor.ca.

Canadian Contractor: What do you do with Renovantage for Contractor Coaching?

Mike Draper: Basically it's working with contractors to help them achieve the goals they have for their business or help them overcome challenges they may face in their own business that they haven't been able to do on their own. And they just need an outside advisor or coach to help them through it.

CC: How does one-on-one coaching work?

MD: One-on-one coaching is working directly with the owner of the contracting business on an intense basis together to help achieve the goals at a faster rate than they would have if they just did it on their own.

CC: And then you have peer groups?

MD: Correct. The difference with peer groups is it's other contractors within the industry, typically noncompetitive contractors. So they're willing to openly share information and share their books and procedures and systems and things like that with each other. Those tend to be less intense, but they're good in that they give the contractors an opportunity to look at others and compare what they're doing.

CC: How many contractors are in a typical peer group?

MD: It can range from three to eight.

CC: There's probably constructive criticism, so contractors sort of have a board of directors?

MD: That's actually a great way to look at it. It's a board of directors from the outside and they're people within the industry that all have slightly different ways to run their business. And each contractor can pick out the best of everybody's.

CC: So now we're going to bring in one of Mike's clients, Rob Allan. Tell me about his business.

MD: He does really, really good quality work. We helped him put systems in place so the business can run a lot more without Rob having to be there all day long every day on site.

CC: Now Mike's going to talk to Rob about some of the things they've been able to do together.

Rob Allan: RBA is a construction management company. We run higher end projects, new builds, restorations, renovations, that type of business. As far as the range of project, I never say there's a project too small or too big. I kind of frame this up as if there's a need for project management, we can help.

MD: What do you mean by project management?

RA: Construction management, which means we'll help do preliminary budgets, we'll do tendering, we'll keep the project on

I THINK COACHING AND REALLY UNDERSTANDING WHAT YOU WANT TO DO WITH YOUR GOALS FOCUSES YOU ON THE BUSINESS.

track, we'll make sure it's built properly at a high level of quality, deal with all the consultants from city inspectors, architects through to engineers, and final survey. I think coaching and really understanding what you want to do with your goals focuses you on the business. For me, what's important is to really spend time with clients, be very accessible, communicate a lot. That's a simple sentence, but it can change how you set up your business. I spend a lot of time in front of my clients. I visit all my job sites every single day. I think that's a point of differentiation and our clients really appreciate that. It could be two minutes, but you capture a lot. When you're speaking to someone, it's obvious you're engaged in the project. So that's what I really try to do and stay involved from start to finish.

MD: There's two contractors going down to the wire for a job; why would they select you? What's your differentiation?

RA: Again, communication, build a company in a way that we have a resource to pick up the phone or to answer questions. Never take on too much work. I've got a cap on how much work we'll do at any given point. So I'm not too diluted and can still be there for the client from start to finish and making sure we answer all the questions. Another thing that we do is we'll work with many different architects and interior designers, so we're not restricted to one style. Often you'll find some contractors that will use the same architects and designers and end up with the same product.

CC: How did you meet and what's the basis of your relationship?

RA: I was searching for a long time to find a coach and I found Mike through a network of contractors online and through some strong recommendations.

MD: That's a pretty typical way that I find most of my clients is through recommendations from existing or past clients.

CC: What was the key thing that made you believe you want to get some business coaching?

RA: The reason was I felt that I was at a certain level of sophistication within the business and I was looking to take it to the next level. I come from a corporate background through 15 years of experience. I've seen how larger companies operate. I couldn't see why we couldn't get there, but I didn't want to go through the long, drawn out timeline. So I found Mike. MD: Rob is unique in that he does have a corporate background.

Most contractors are self-made and were trades that were on the job and decided to go into contracting for themselves. Rob came at this from a completely financial background perspective and I think it was on the operational side where some of the challenges were... how to streamline the business so it could run without Rob being there daily, all day long.

CC: What are the big achievements so far in your relationship?

RA: A lot... Mike's helped immensely. The coaching process is fantastic right off the hop. For me the biggest thing is looking in the mirror and setting your goals. That was the first thing Mike said was "you're telling me all this stuff, but put it on a piece of paper." Goal setting is huge. It sounds easy, but it's not. We got through that and then focused on what I wanted to do with my business and personal life. That was huge for me, and it trickles down to everything. It was really doing the things I procrastinated with. Mike makes you accountable and it forces you to do the things that are easy to tuck away and forget about. You know they're important, but when you know you're meeting with Mike, you have to get it done. Probably one of the biggest problems that we had was there was a lot going on. We had different processes for everything. We would have a different reaction for everything that we did, all very positive stuff. But to remember how to do things differently every time, it became very chaotic. Mike came in and focused us on putting in a process and making it consistent and repeatable. Through the process of doing that, it allowed us to communicate that message to our clients and repeat that. MD: I remember this one instance when we were in the middle of the coaching session and your project manager walked in with a bundle of cheques and said, "Hey Rob, can you sign these?" And you put them down on the table and you're signing and saying "I don't know what I'm signing." Because there was no process at the time to match an invoice to a purchase order and therefore you're just trusting the project manager that things are being done correctly.

RA: Yeah, I remember. Not a good feeling at all. Big cheques being cut without a process and you're just keeping your fingers crossed. That's not the way that I wanted to run the business. You really helped put processes in and then we continued to improve.

CC: How does Mike keep you accountable?

RA: Based on my sports background (he had a football scholarship at Indiana), I'm used to following a coach and any success I've had has been with a really good coach. So when you're out there floating on your own as a business owner making good things happen, it's nice to have a coach to keep you focused. At a very high level that's what it is. Mike brings focus with something as simple as booking weekly and monthly meetings. You know that's in your schedule, you lock it in, you set aside the time and you

know you have some homework to do. I think I tried to translate that sporting experience into business. So it was simple for me to kind of say, "well you know what's at the top, that's the coach who helps really guide the players." That's kind of how I view it. Mike's been a huge help for that.

MD: From my perspective, having someone like yourself that's willing to learn, to change and to implement the things that we talk about and stay focused on the end goal is amazing.

CC: What's a typical coaching session like?

RA: I don't think there's a typical session. It can vary depending on what you're trying to achieve. Your goal setting dictates the path and then you prioritize your business needs. For example,

if it was financially related, we would on a fairly regular basis make sure that our financial statements are done and printed. We'd analyze that and then compare it again on a pretty regular basis to make sure we're tracking the right direction.

CC: What's the relationship like between Mike and other professionals you may have helping you like your accountant?

RA: Full transparency as far as I'm concerned. We've had sessions with the accountant where we could drill down and make sure we've got accurate information. If it's a question that I couldn't answer or it was just not clear, we could get that answer. I made it clear to everyone that the coach was very much a part of the team.

CC: Sometimes your coach will ask you to do things you don't want to do. How has that worked for you guys?

RA: I don't think it's easy ever to hear something you don't want to. But I think you have to stay open. It's the reason you have a coach -- to tell you the tough things. So I appreciate it a lot and I don't disregard it. I would really focus on the things that came out of our sessions and make sure we fixed them. Sometimes those were hard things and, what it really did is help me determine what I want to do with my business and the direction that I wanted to go.

MD: At the end of the day, any of the changes are to support the goal of the contractor. So in Rob's case, there may be some areas where I would push hard to get him into a spot that may not be in his comfort zone, but a zone he wanted to be in and he did very, very well and was able to change the outlook of the company and obviously the impression he gave to the marketplace.

CC: Mike, what was Rob's biggest strength and what was his biggest weakness that needed shoring up?

MD: The challenges were really more on the operational side, helping streamline the business so it ran more without Rob being involved on day to day transactions. The number of phone calls that he used to get when we were sitting in coaching calls was huge. Now there are almost no calls coming in because he has a team in place to handle that. That's critical for clients to know they have somebody they can call that's available and dedicated to their project. Rob's working on multiple projects at a time and by no means could he be the expert on every little detail on every project. That's where the project management team comes into place to take over and give the client somewhere specific to go.

CC: Talk about the group sessions, the relationship with other contractors in your peer group.

MD: Another thing that's unique for Rob and a couple other of my clients is that they do one-on-one coaching and also do a small peer group of three contractors in this particular case. Rob's had the opportunity to get out and visit two other contractors in non-

BIG CHEQUES BEING CUT WITHOUT A PROCESS AND YOU'RE JUST KEEPING YOUR FINGERS CROSSED.

competing markets to see how they run their business. In this particular case, all three run their businesses quite differently, so there's been an opportunity to learn from the other two.

RA: I agree, but if I take five steps back, finding a peer group was critical to me as part of the coaching. I find that it doesn't exist a lot in this industry and was difficult to find. When I found it and Mike put the group together, it was exactly what I was looking for. It's fantastic. Why try to invent something on your own? Share ideas, be transparent with people that you can trust and then learn from one another. It's been critical for me. I've developed friendships with these guys and we visit each other socially now. We chat, we share business ideas. Everyone should be doing it.

MD: I'd like to hear a bit more about how your business changed financially over the years and what's it done for you personally?

RA: Business is good. We've got great projects, really good clients. At a point in the business now, we can really select our projects. Not to sound arrogant, but I think it's good to be able to have a good relationship going into a project with your clients.

MD: And clients are happier now?

RA: Clients are much happier. At the end of projects, I used to get a little worried, it's a long drawn out process. Now, we have raving fans and business and profitability are good. It's kind of on our terms now, in the sense that it meets the goal -- it's not just busy for the sake of being busy. It's busy with a clean sightline to what we're trying to achieve.

CC: You were involved in a business partnership that went separate ways? Tell us about that, why you did it, and the role of coaching and making those decisions.

RA: It was a partner in the business. We ran the business for about six years, I think it was very successful. We took that business from zero to a substantial size, becoming pretty prominent in the areas we were working. Part of the reason we brought Mike on was to help through the growth curve and see where we could take the business. Mike was a very big part of that and seeing what we could do as a partnership together. What we discovered through individual goals of myself and my partner, was we had different paths that we wanted to go down. Mike was able to help us navigate through that. For me, what it did was, I determined that I really wanted to go out on my own and build a business with systems and processes that really could stand on its own in time. It was an incredible experience. Partnerships are tough, so

that's always difficult to go through. Mike helped me through that and I don't hold any poor feelings towards my previous partner. We just decided it was time to go on a different path. I think some people get stuck in that for a long time and don't do anything about it. Mike, without telling me what to do, was just helping me navigate what I wanted to do.

MD: I don't think you're the only contractor with a business partner that at some point in time has to look forward and say, "are we on the same path or do we want to go down different paths?" To make that change is very, very difficult. You guys loved working together and worked really well together. It was just time to go different directions. I'd say it's as tough as breaking up a marriage, breaking up a partnership like that. Not an easy task.

RA: Not easy to go through. It's doesn't end in one day... you don't make a decision and then it ends, it takes a couple of years to wind down something that was old and crank something up that's new.

MD: Do you ever look back and think you made the wrong decision?

RA: No. I don't think I made the wrong decision. I think maybe if I had done this six years ago, then that's what I regret. Why didn't I do that six years ago? But sometimes you have to go through things to learn and move forward. Again, that's sort of where I would tie back to coaching. Anybody that's going through this right now, there's no bad time to start coaching. I think, for you to set your goals and determine if you're in the right situation or if you're not, get to the bottom of it sooner than later and then move forward.

MD: I remember one of the tough decisions for you once you had decided you wanted to go out on your own was to actually do it on your own versus try to find another partner and do something else. It took some time to overcome that and say, no, you can do this all on your own. You don't need to be with anybody else.

RA: Yes, I think that's very critical. It was my default to go and work with a partner. But yes, you helped me through that and it was very clear that that's not what I needed.

Mike: In fact, I think your clients like it better now too.

Rob: I think so, yes.

business itself, about their feelings and their goals and the impact it's having on them emotionally. And without that information, it's really hard to determine what's the right path moving forward. So when I'm looking for clients or looking at a new prospect, I'm looking to see if they're coachable, are they willing to be open and transparent about what's really going on in the business?

RA: If you want an honest answer and you're spending the time to be coached, then get it all on the table. What are your personal goals? What are your financial goals, what are your business goals? Then everything in between. I threw it all up there to Mike and kind of said "Is this emotional or is this business?" And when you understand that, it influences your decision. It helps you get to your goal. If you're going to do it, I think that's 100 per cent the way you should be. I think it's probably difficult for some people when they're reviewing their financial statements. They're maybe embarrassed or are very proud. But get it out there because it all ties together.

MD: If we don't have the full disclosure on the financial information, as Rob mentioned, because the contractor's shy about what the numbers are, how do we help them if they're not willing to share those numbers? Those are critical. At the end of the day, it's all about analytics and being able to make decisions based on the numbers that are in front of us. Contractors have personal goals and family goals that they want to achieve and the business is there to help them achieve it. cc

Full company name: Renovantage Inc.

Location: Based in Ontario - operating all over Canada. There is no office as everything is virtual.

Year founded: 2012

Full company name: RBA Projects Inc.

CC: Let's talk about the honesty thing. Nobody wants to tell their boss the actual truth, complete disclosure. How important is that to have?

MD: Part of coaching is the person that's being coached needs to be completely open and transparent about what's going on within the business. Sometimes, as a coach we get into some things that go beyond just the

Number of employees: Three

Services provided/specialty: Contractor, trade and supplier business coaching through one on one coaching and peer group facilitating

Family: Yes

Hobbies: Kiteboarding, waterskiing, snow skiing, snowmobiling

Life/work balance: Great life/work balance

Location: Toronto (GTA)/Muskoka

Year founded: 20 years of experience, second year in business for new company after partnership change

Number of employees: five

Services provided/specialty: construction management services, new construction, renovations, additions, landscaping management, design-build and interior design facilitation

Family: married with two kids (17 and 14)

Hobbies: cottaging, boating, alpine skiing, water skiing, mountain/road bike riding, hockey, construction, design, travel, fitness/training

Life/work balance: Very important. Set ambitious but, realistic goals, work hard-play hard, family first (always), take time to recharge your battery (travel, fitness, friends), circle yourself with great friends and people that support your goals

MILWAUKEE 2874-22HD M18

Pipe Threader Kit

The look of railings, stair frames, handles and fixtures made of black iron pipe isn’t for every client, but a surprising number of people really like this style these days. You can make money with it, too.

A necessary part of custom iron pipe fabrication is the ability to cut threads. This is where the world’s first cordless pipe threader comes in. At first I wasn’t impressed with the 2874, but now I love it and in the course of changing my mind, I learned a pair of key tips that I'll pass along to you.

Made to accept standard Ridgid pipe threading dies, this 18-volt tool makes quick work of cutting threads in pipe from 1/2” to 2” in diameter. Tighten a locking clamp onto the pipe as it sits in a pipe vise, lube the end of the pipe with cutting oil, slip the threader over the end of the pipe, then switch it on. As the machine rotates the die, it cuts curls of metal from the pipe, leaving perfect threads behind. At $2,400 for the tool plus two 12.0 amp-hour batteries, charger and support arm, this is not

It’s hard enough dealing with the practical side of being a contractor without also adding the hassles of getting paid. This is where something called Square (www.square.ca) is helping contractors in a big way. It’s a card reader and app that works with the smartphone or tablet you already have, allowing you to accept debit and credit card payments on site.

Square puts you in the driver’s seat when it comes to payments because you no longer have to wait passively for a client to pay a traditional invoice. “Would you like to pay now by card?” The ability to say this one, simple thing in person at the end of a job has improved the collection rate of real contractors I’ve spoken to.

“We struggled to get paid in a timely way,” says Calgary painting contractor Jon Bryant, “but we’ve solved this problem now. All our crew leads carry a Square card reader. When customers agree that a job is complete, they have the option to swipe their card and payment goes immediately into our business account. Strange, but callback rates have also gone

a cheap product, but it can pay for itself in a couple of decent railing jobs.

So what are those two tricks for using it? First, always run the machine full blast. Throttling back with the variable speed control during a cut can cause it to overheat when cutting big threads. And second, don’t reverse the die partway through the operation. Just keep threading forward, let the curls of metal built up in the die, then back off completely when you’re done, and viola -- perfect threads. There's a five-year warranty on the tool and three years on the batteries. Check out baileylineroad. com/37592 to watch a video of this threader doing its thing. cc

way down since we got our crews outfitted with Square,” he says.

“It seems that people are more content about a job when they’ve paid for it.” The Square Reader for accepting magstripe credit cards is free and the Square Reader for contactless and chip is $59 and accepts credit and debit cards. Fees are 2.65 per cent for credit card transactions and 10 cents for debit transactions. cc

By Paul Duffy, M.A.Sc., P.Eng.

It wasn’t that long ago that buying windows was a relatively simple process: Step 1 - choose your frame type (wood, aluminum, or vinyl); Step 2 - choose glazing (single, double or triple); and Step 3 - choose your manufacturer. Providing you had similar frames and glazing, you felt confident comparing manufacturers.

If you were a contractor, you had your preferences based on personal experience, but there was a lot of “opinion” involved in choosing products. I frequently heard things like: “I don’t like xxx (you fill in the name) windows because they leak;” or “I don’t like wood windows because they rot;” or “I don’t like vinyl windows because they warp;” or “I don’t like aluminum windows because they are prone to condensation;” or “I don’t like triple glazed windows because they are too heavy,” etc.

Worst of all, it was hard to compare products let alone manufacturers. Just because choosing a window was simple didn’t mean the process wasn’t flawed.

The fact that so much of the comparison was based on opinion and experience meant that there wasn’t really an objective way of evaluating products and improving performance. Regulators and manufacturers knew they had a problem. To move the technology ahead, they needed window standards that measured performance versus specifying physical characteristics.

If the measurements captured thermal performance, energy performance, wind resistance, condensation resistance and air leakage control, it might finally be possible to compare window types, manufacturers and innovative technology fairly and objectively.

That was the idea behind the development of the CAN/CSA A440 window standard. Envisaged as an “omnibus” standard for all window types, it was designed to measure performance in the key areas in which windows had historically had problems and set targets for manufacturers to meet. With a clear roadmap

covering how products would be compared, manufacturers set out to build better windows.

Then an interesting thing happened. Window frame designs evolved from a singular frame type (such as wood or vinyl) to become hybrid materials (e.g., metal clad wood, or steel reinforced vinyl, or thermally broken aluminium, and even fiberglass windows). Testing revealed the importance of these options in terms of performance. New options also crept in for things like glass coatings, thin intermediate films, Argon and even Krypton filling between the glazing layers, and better spacers separating the glass/films.

Suddenly, consumers, builders and renovators had more and better choices for windows.

So from this short description of history you can probably guess I am pretty impressed with the system Canadians came up with for rating windows. And if you have looked into buying windows recently, you probably have noticed other ratings on windows coming from some manufacturers. You may even encounter products manufactured by American companies, or products manufactured by Canadian companies for both the American and Canadian markets. What’s going on?

Well let me start by saying that building physics don't change just because you cross the border, but it does make sense to manufacture windows close to where they are being used, be that north or south of the border. For economics of scale, Canadian companies wanted access to the U.S. and vice versa.

In terms of technology, provided the window meets the performance requirements of our Codes, for an Ontario builder or renovator it probably makes more sense to use a window manufactured in New York versus one manufactured in Canada on the west coast. (I remember the disturbing story of one Ontario builder who spend tens of thousands of dollars to import windows from the west coast only to find that the process of transporting them over the mountains had caused all the window seals to fail!)

The CAN/CSA A440 standard is gradually being replaced by a new harmonized standard for North America called AAMA/WDMA/CSA 101/I.S.2/A440-8 NAFS – the North American Fenestration Standard. Complete harmonization between the two standards, and the CAN/CSA A440 standard is cited in Code, so for the time being, windows manufactured for the Canadian market also have to meet the Canadian supplement CAN/CSA A440S1-09.

The most striking change introduced in the harmonized standard is the grading of windows for the intended use. This makes sense because windows in tall buildings are subject to higher wind pressures, are more exposed to wind-driven rain, stack effect and other forces. The harmonized standard sets out the following grades of window:

• R – windows designed for single homes or townhouses;

• LC – windows designed for low rise apartment buildings; and

• CW & AW– windows designed for high rise and commercial buildings.

This simplifies the choices based on application, but if you want to drill down, windows meant for the Canadian market also have detailed performance measurements based on either CAN/ CSA A440 or the Harmonized AMA/WDMA/CSA 101/I.S.2/A440-8 NAFS Standard with the Canadian Supplement.

Window performance required in codes varies based on type of building and climate in which it is situated. How do you compare the other measures of performance? Here is a quick primer on how to use the available ratings:

• U-value is the inverse of R-value. A higher U-value represents a higher rate of heat loss. Better windows will have a lower U-value.

• SHGC or Solar Heat Gain Coefficient is the fraction of solar energy passing through the window. A window with a lower SHGC has a greater tendency to block solar heat gain.

• VT is a measure of the visible transmittance of light through the window. The higher the VT, the greater the amount of daylight passing through.

• Air Tightness is measured in classes from A1 through A3, with A3 being the most airtight.

• Water Tightness is measured in classes from B1 through B7. B7 is the most waterproof.

• Wind Load Resistance is categorized with values from C1 to C5. C5 has the highest resistance to wind.

• Resistance to Forced Entry is also broken into groupings; F1 is the minimum level and F2 is the highest level of resistance. So you now have information to compare your window options. Can things still get screwed up? Yes, absolutely, because any product can get messed up with a poor installation. Usually, the issues fall into three broad categories:

1. Product selection: I assume that the previous discussion gives at least some guidance on getting your product choices right. It can get complicated, affecting HVAC sizing and other issues. You might want to engage an expert—more about that later.

and water ingress into the concealed elements of the building. With water comes rot and corrosion. The results can be disastrous. The need for proper training of installers is critical to getting windows that perform.

Recognizing that proper installation goes hand in hand with better windows, most manufacturers participate in a program for training and certifying installers called “Window Wise” provided through SAWDAC – the Siding and Window Dealers Association of Canada. The program provides:

• training of installers;

• random inspections; and

• certifications of installations for warranty purposes.

Most Canadian manufacturers participate in the Window Wise program and support its use. Proper installation of windows could be the focus of a whole other article so, for now, I am going to leave it at installers have to be properly trained.

2. Window sizing: Simply understanding that windows are usually the least thermally efficient elements of your building is an important step. In most new houses, the opaque walls have five to 10 times the thermal resistance (R-value) of the windows and in the summer can be responsible for huge temperature swings affecting comfort and air conditioning loads. Most experts agree that when window areas exceed 15 per cent of wall area, comfort problems and other performance problems become more pronounced.

3. Installation: Beyond the windows themselves, the rough openings can be responsible for considerable air leakage

Window performance also can have a huge impact on heating and cooling loads as well as distribution so I also recommend that major renovations including window replacements be accompanied by an energy/heat loss/gain analysis. If you have ever worked with programs such as the R-2000 Program, EnergyStar, EcoEnergy, etc., you will have some idea of the expertise I am suggesting is needed.

Finally, you may also be aware that window retrofits qualify for some grants and incentives provided by various governments and utilities across the country. You will notice I left this point to the end of this discussion. I don’t think the grants are significant enough to drive customers to change all their windows simply because grants and incentives are available, but there is probably enough money available to help you pay for the experts you need—qualified designers and contractors—to do it right. Most grants and incentives come with a requirement that a qualified expert review and sign off on the installation. I would recommend searching for a local energy evaluator or rater in your area.

In a new house or in a renovation, good quality windows can be the “icing on the cake” that produces stunning results. A high quality window installation can also boost your reputation and referrals. Take the time to do a proper job so your customers won’t be disappointed—deliver high performance that matches the beauty of your work. cc

Karl Crabbe's contracting business has endured some lean times in recent months, and could really use a big score to help turn things around. His wife works as a receptionist for a very rich, but notoriously cheap doctor.

Knowing that Karl needs work, the doctor wants to hire him to do a major renovation on his house — exactly the type of project he needs to spark a recovery for his firm.

In discussing the potential project with his project manager, Karl learns from him that this same doctor stiffed a contractor a few years ago by hiring him to do a job at his cottage and after winding up being unhappy with something, he refused to pay the contractor. Things got ugly, and it wound up in small claims court, where the contractor was only able to recoup some of his losses and suffered a big hit.

Karl asks his wife if she knows anything about this previous project, but she hasn't heard a word about, and actually doesn't believe it even happened, going so far as to defend the doctor given that he's throwing Karl a lifeline. She's upset that Karl is questioning the hand that could feed him. She maintains that her reputation with her boss will be irreparably damaged if Karl turns down this project.

Karl's business could really collapse with another hit, but given that his wife has drawn a line in the sand, if he doesn't take this project, his marriage could take an even bigger hit. What should Karl do? See the options to the right.

Last issue, Jeffrey Black had an employee relationship go south after work dried up, and the employee turned vindictive, going as far as employing a lawyer to address his situation.

Dwayne Butler of Markham, Ont.-based Master Edge Homes, is this month's winner for going through all five options and assessing the effectiveness of each approach.

1. Ignore the letter: This should never happen and as a business owner you should always deal with the issues at hand regardless of the severity, so no.

2. Ask him to retract: Mellon will not retract the letter because he is upset and you cannot change that, so no.

3. Talk with clients: This is a must! Black must meet with the clients and discuss the situation in person. Black was the reason why they hired his company so there is already a trust factor there that will be comforting to the clients, so yes.

4. Engage his own lawyer: Black should contact his lawyer to get some direction but I don’t think it is necessary to sue Mellon unless he continues to be a problem for Black and his company. So this is a partial yes.

5. Something else: Black needs to lay Mellon off and move on.

Well delivered, Dwayne. You'll be receiving your 20V compact circular saw with 5.0 ah battery and 20V compact reciprocating saw shortly. Congratulations!

1. Take the job and hope for the best.

2. Refuse the job and prepare for a lot of nights on the couch.

3. Tell the doctor he can't do it, but will recommend someone else for the job.

4. Take the job and insist on the bulk of the money up front.

5. Something else.

If you have a five-point plan for Crabbe, email your entry to rob.blackstien@rogers.com and put “Crabbe dilemma” in the subject line. Please don’t post your plan as a comment to the Dilemma post on our website

Entries close March 13. The winner will be announced on www.canadiancontractor.ca on March 27.

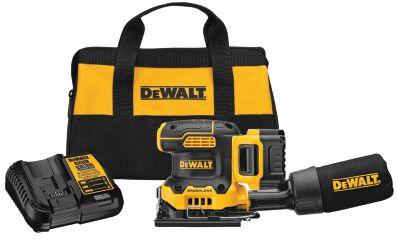

1) DEWALT 20V Cordless Router Price: $249

2) DEWALT 20V Cordless Quarter Sheet Sander Price: $249

The Cimarron® line of toilets packs Kohler’s powerful AquaPiston® flushing engine beneath the hood. The 3 to 2 ratio between valve intake and outlet harnesses the natural force of gravity to deliver a high-octane flush for virtually plug-free performance. KOHLER.com/Cimarron

BEST-IN-CLASS MAX. AVAILABLE TOWING 37,000 LBS*

BEST-IN-CLASS AVAILABLE DIESEL TORQUE 1,050 LB-FT**

BEST-IN-CLASS MAX. AVAILABLE PAYLOAD 7,850 LBS^ AVAILABLE CLASS-EXCLUSIVE PRO TRAILER BACKUP ASSIST TM†