Stressed Out? Going Crazy? Reconsider Your Mental Timelines

Page 22

Manufactured Stone Revisited Why The Newer Products Rock

Page 23

Contractor Dilemma Contest You Could Win a Cool DeWalt Tool

Page 30

Stressed Out? Going Crazy? Reconsider Your Mental Timelines

Page 22

Manufactured Stone Revisited Why The Newer Products Rock

Page 23

Contractor Dilemma Contest You Could Win a Cool DeWalt Tool

Page 30

Veteran design-build contractor Paul Gallop on how he learned to build a team

Page 12

1

COVER STORY: The Boss As Coach 12

Veteran design-build contractor Paul Gallop on how he learned to build a team.

Creative Eye: Etobicoke Equilibrium 16

A look at an Etobicoke, Ontario project that is a hybrid between a rebuild and a remodel.

Steve Maxwell: Keeping Work in its Place 22

Plus: A look at how full-bed manufactured stone is transforming the Canadian building scene; Cool tools from DeWalt; Metaltech ScaffoldBench.

What’s Online 4

Your guide to great videos at www.canadiancontractor.ca.

Editorials 6

Rob on a problem employee; Steve on a curious email he received.

Voices 8

The best of the contractor comments from our online version.

Site Notes 10

Ottawa roofer fined $80,000 for setting two workers on fire; Mattamy Homes branches out; Justin Trudeau worries about male construction workers.

The Dilemma 30

Solve this contractor’s problem and you could win a DeWalt roofing nailer.

Canadian Contractor has hundreds of videos online for serious residential construction professionals…

Sponsored by ITW Construction Products Canada

In this collection of videos, Rob Koci talks to experts from ITW Construction Products about the different uses of specialty fasteners in the Canadian renovation and custom home building industries. Topics include failure mechanisms for screws and bolts, mechanical versus chemical bonds for anchors, concrete pins and thermal bridging solutions.

Sponsored by Home Hardware

This series of videos looks at ways to build better, faster and more profitably. Rob Koci and Steve Payne present a number of construction tips sent into the magazine by Canadian contractors – and they also interview experts from around the industry. Everything on a job site from framing to interior finishing is fair game for Site Tips.

Sponsored by Various Manufacturers

Innovation is the engine that keeps profitable construction companies going. Unless you discover new and better ways to build, you risk falling behind your competitors, and your company may be challenged to compete in the new industry landscape. Buildwire is the place for contractors to see what’s new and improved.

Editor

Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Kim Laudrum, Steve Maxwell

Media Designer Mark Ryan

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator

Tracey Hanson thanson@annexbusinessmedia.com

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-442-5600 ext. 3543

Tim Dimopoulos, Vice President tdimopoulos@annexbusinessmedia.com

Mike Fredericks, President & CEO

Circulation

Rob Koci Publisher

rkoci@canadiancontractor.ca

” You could get 50 per cent more out of this person.

”

By Rob Koci

Ihave a friend who knows he is a bad employee. He puts in his hours but his heart is not in it. Why does he stay? He needs the money and, he admits, he can’t get the same amount elsewhere.

Don’t get me wrong. He is not a “BAD” bad employee. He’s not stealing from the company. He’s not ignoring his responsibilities. He just knows he is not properly positioned where his talents can be brought forward and used productively.

He’s felt badly enough about it that he has gone to his superior and suggested alternatives but they have all been rejected. So he is stuck, running at about 60 per cent efficiency, dreading every day but doing the best he can.

An employee like that is easy to “not see.” You may have dozens of employees and usually it’s only outright incompetence, dishonesty or laziness that really forces you to act. In the middle of the maelstrom that is owning a construction company, the unmotivated employee is just another not-yet-urgent, back-burner issue you may not have time for.

But consider this man for a moment. He’s basically a good person who would prefer to wake up highly motivated to do a job he is better designed to do. And you have the opportunity to make that happen. Is it worth it for you to pay attention? Well, there might be 50 per cent more that you could get from the $60,000 a year he costs you. For a couple of hours of discussion and a bit of reorganization, maybe you could capture that now wasted $30,000. And don’t forget, that’s $30,000 per year, compounded year by year. That’s a lot of value over time.

Listen, the guy is hurting, and he’s hurting you. You’re hurting because unproductive money is going out the window. Have the talk. Find him a better place. He’s willing to compromise so as not to hurt you. You should do the same.

By Steve Payne

Ireceived a sarcastic email last month, suggesting that we change the name of Canadian Contractor to Conservative Contractor. The reader said that we had an anti-Liberal bias that offended him – then he asked us to take him off our mailing list. We did.

I thought it would be useful to devote a few paragraphs here to what we are and what we are not. When we started this magazine in 2000, our idea was to give pro renovators and custom homebuilders a magazine that wasn't constrained from talking bluntly about regulation and taxation in this industry. We wanted to have an outspoken forum where contractors could talk about what was working for them, business-wise, as well as what was making it hard for them to stay in business, including useless regulation and over-taxation wherever they occur.

Over the almost 20 years we have been publishing, we have become a really strong voice for the entrepreneurial, independent contracting firm. It goes without saying that many (not all) of these business owners are fiscally conservative. We do not have a large constituency of readers who are members of the big construction unions but we welcome their contributions, too. We are trying to give our loyal readers a place where they can speak whatever is on their mind.

If we truly were a "conservative" trade magazine, you would not be seeing such a large number of articles from us on Net Zero Energy construction to combat climate change. Nor would you be seeing our frequent articles promoting a more equal balance of men and women in the trades. We will remain a magazine that has no political affiliation, other than promoting policies that are good for the businesses and the well-being of our loyal contractor readers.

Plumber competes with unlicensed “butchers”

It is unfortunate that most homeowners shop for the bargain basement deal and wouldn’t have a clue as to what is proper code… or above code. And most homeowners have no concept of straight, square and plumb – they can only can see the finished bling. They have zero concept of a top-of-the-line foundation or what a professionally-completed mechanical job would entail. A totally proud, licensed installer views his completed work as a symbol of his professionalism and a work of art, for which he/she spent thousands of hours in training.

Unfortunately, most renovations are done without any permits, allowing the butchers to take over that we, the skilled artists of our trades, have to compete with. I am a proud licensed plumber and my work ethic – and the appearance of my completed work – is truly correct and usually above code. It’s unfortunate that the money we as tradespeople pay out to the colleges and universities does not go to putting the butchers out of our industry.

Bradley Zimmer

His mechanical firm unionized “without a vote”

I am a small contractor in a mechanical field. Recently my company was unionized without a vote: just stolen away from me in the middle of the night. My employees were skilled tradesmen, made good money and were given a ton of perks they couldn’t get anywhere else. When the Application to Certify was allowed by the OLRB (Ontario Labour Relations Board), all my guys quit and went off to other companies, and that didn’t matter. Now two office staff, and three people who didn’t want to join a union but were never asked or given the option, will be out of a job, plus two other people who share a building with us because we won’t be able to split the rent.

My company works in a sector that is traditionally non-union, so I am now completely uncompetitive from a price point of view. I guess I could go after work at inflated prices for the various levels of government in this province, but I would just feel dirty. I don’t actually have an issue with unions, but in Ontario the way things are currently working, the unions run the show. It is dirty, sneaky, underhanded and unconstitutional in my opinion. It is just a mess. I have to restrain myself from going on a pottymouthed tirade. Just a joke.

John

As an electrical contractor in Winnipeg, I can’t stress enough to homeowners how much homework, recon or digging you have to do in order to understand whom you are about to hire – and especially whom you are about to let into your home. Anyone can show up to your door and be anyone they want to be for five minutes. And then collect your deposit. I understand that it should not be this way but in today’s reality, it is this way.

Before I do business with any other contractor or company, I start with a provincial Court of Queens’ Bench search (or a “QB Search” as I call it). This allows me to see any type of transaction they have had with the law since 1984. Since opening my company, the one thing I have learned is that a business is an extension of its owner’s character. If they have been lazy before, they are probably running a lazy business, too – one that will not work. If they are a wool puller, I’m sure the unsatisfied customers will have been lining up. And when this happens, you end up in court with them every time.

Each customer has to take on the responsibility of finding the correct contractor for their job. When you’re spending that kind of money, please invest in the right resources beforehand and start researching from day one. There are people out there, every day, preying on people who don’t do their homework. So please, people, invest the time to do your research. Here are some pointers in order to establish who is likely to be a good contractor.

1) QB Search (see above)

2) BBB (Better Business Bureau)

3) References

4) Company Registry

5) NO CASH! Expect to pay taxes. Every reputable company will charge them.

Stan Connolly, Connco Electric, Winnipeg

BEFORE I DO BUSINESS WITH ANYONE, I DO A PROVINCIAL COURT OF QUEEN’S BENCH SEARCH.

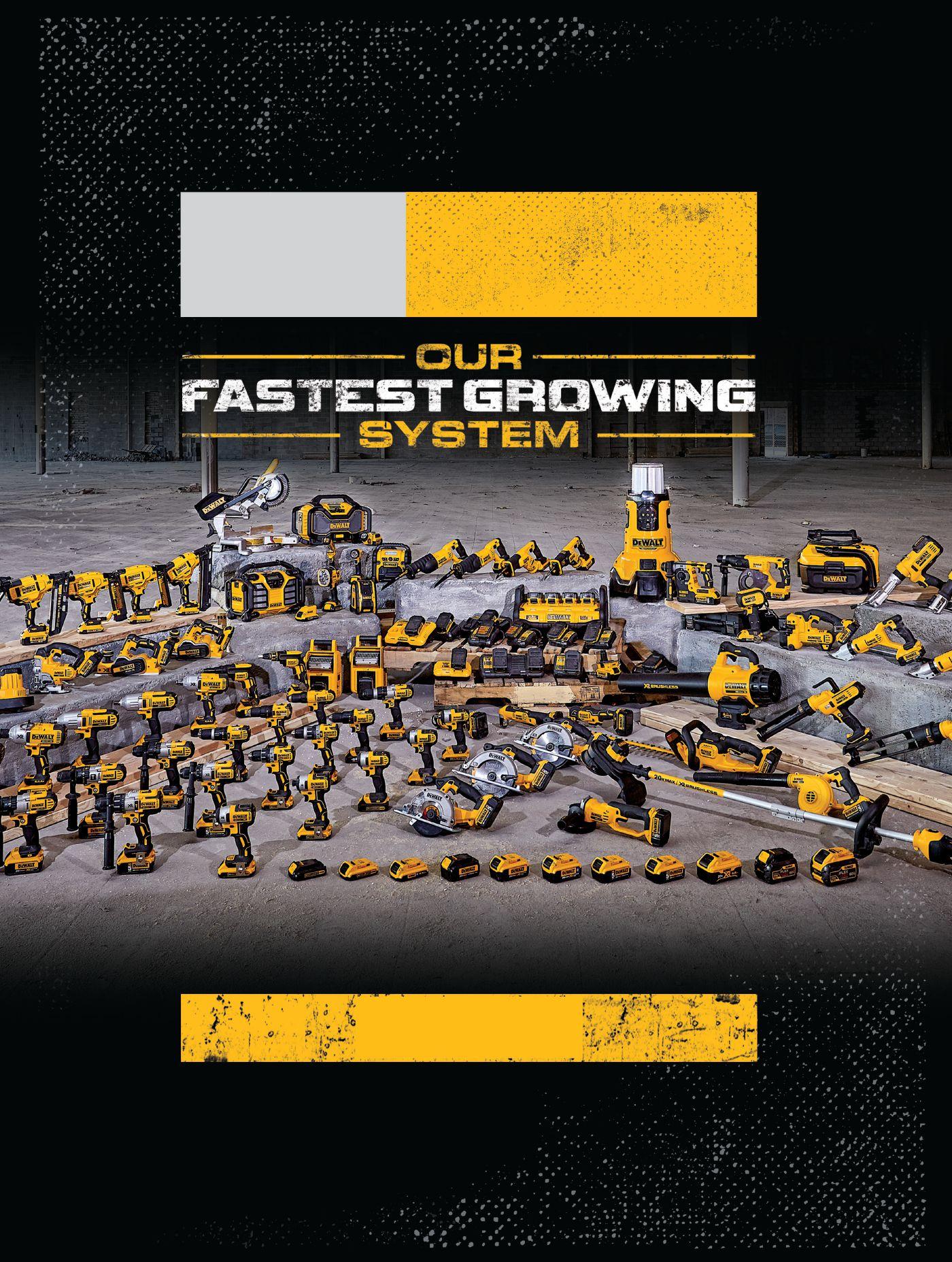

GET MORE DONE™** with 180+ PRODUCTS in the DEWALT 20V MAX* line. All tools come with upgraded features, superior ergonomics and use Lithium-Ion batteries. For extreme performance, step up to the XR® series and get advanced electronics, extended runtime and faster application speeds.

Two employees were set ablaze on a residential roofing project when the adhesive glue used in the installation of the roof membrane caught fire in July 2017. One worker received critical injuries, including burns to the arms, legs and torso. The other worker avoided serious injury, while a third escaped unharmed.

As a result, Ottawa Permanent Roofing Inc. was convicted last November and ultimately fined $80,000 at a sentencing hearing in January. According to an Ontario government media release, “Ottawa Permanent Roofing was hired by a homeowner to supply and install a new roof on a two-storey residential home, including a second-storey balcony… There was no fire extinguisher on the balcony, no written emergency procedures for the project, and workers lacked an adequate means of egress from the balcony during an emergency.” The company was not represented in court at the sentencing.

The company was found guilty of three violations of Ontario’s Occupational Health and Safety Act. Under Section 17 (1) of the Regulation for Construction Projects, “A constructor shall establish for a project written procedures to be followed in the event of an emergency and shall ensure that the procedures are followed at the project.” Furthermore, under Section 52, “fire extinguishing equipment shall be provided at readily accessible and adequately marked locations at a project,” and “at least one fire extinguisher shall be provided…where flammable liquids or combustible materials are stored, handled or used.” The third violation was failure to provide, under Section 71 of the regulation, adequate means of egress from a work area to permit the evacuation of workers during an emergency.

According to files available online from the Ottawa Better Business Bureau, Ottawa Permanent Roofing had a long history of complaints relating to contracts and refund service issues. “Consumers allege that Ottawa Permanent Roofing requests payment upfront for services but fails to complete the work and fulfill its contractual obligations,” the Ottawa BBB says. “Consumers further indicate that requests for refunds are either ignored, or the company provides reimbursement in the form of a cheque, which is then dishonored as a result of having insufficient funds.”

Ottawa Permanent Roofing Inc. opened in 2014, was incorporated in 2016, and had an alternate business name of 9590072 Canada Inc. Named as company owner and customer

contact was Ms Hanan El Badry. When contacted by the Ottawa BBB concerning the numerous complaints, Ms. El Badry was initially cooperative, claiming that she “personally reached out to every client and has made arrangements to have their roofs completed this spring, while some are going to be given progress payments through the company’s lawyer as a sign of good faith until the work is completed in the spring.” Nevertheless, the BBB report continues, “While the company endeavored to work with BBB, in efforts to eliminate the identified pattern of complaints, the pattern remains and no alternative steps have been taken by Ottawa Permanent Roofing.”

The Ottawa Police Service Organized Fraud Unit began investigating Ottawa Permanent Roofing in January 2018, according to fraudinottawa.blogspot.com. In early November last year, they arrested and charged Ms. El Badry, 27, in Ottawa. A company employee named Hugh Arnold, 61, was arrested and charged in Kelowna, B.C. on a Canada-wide warrant and placed in custody. Arnold had represented himself to customers as “Anthony El Badry.” Both individuals have been charged with 45 counts of fraud over $5,000 and four counts of fraud under $5,000. Each charge relates to an individual client. Ottawa Police said they have concerns that there are other victims who have not yet come forward. Canadian Contractor is not yet aware of the trial date. As for the company itself, Ottawa Permanent Roofing is now listed online as “Permanently Closed.”

John Bleasby

Mattamy Homes branches out to southeast Edmonton EDMONTON, Jan. 7, 2019 /CNW/ – Mattamy Homes has annouced that it has acquired “a position in the desirable Aurora neighbourhood that will enable the company to bring its unique, thoughtfully designed townhomes to market in southeast Edmonton.”

The acquisition is a six-acre infill project consisting of two serviced multi-family sites (that will eventually be combined into one). Mattamy purchased the property from Melcor Developments for $5.6 million, with the deal having closed on Dec. 14, 2018.

“We’re excited about creating something special for homeowners in southeast Edmonton,” says Don Barrineau, Mattamy’s Alberta Division President. “These townhomes will showcase Mattamy’s signature design style and will add a real

architectural flair to the Aurora neighbourhood.”

Mattamy will be building 126 units on the site, expected to be three-story, rear-lane townhomes similar to the company’s highly successful Park Series in the Allentown community. The still-tobe-named Mattamy community in Aurora is expected to open for sale in September 2019.

The Aurora neighbourhood is a coveted location for its park spaces (the Mattamy site will have park space on three of four sides) and proximity to schools (brand-new Shauna May Seneca K-9 school), major transportation routes (two minutes south from Anthony Henday Drive) and a wide variety of commercial and recreational amenities (Heritage Pointe complex within walking distance).

“All of us at Mattamy are looking forward to the opportunities this project can create for the company to venture into more infill opportunities,” says Barrineau. “Overall we think it’s a great example of the enthusiasm we have for the Edmonton real estate market and how committed we are to a long and prosperous future here.”

Steve Payne

Trudeau discusses “gender impacts” from male construction crews working on pipelines

The setting was sunny Buenos Aires, Argentina. The event was the recent G20 meeting of world leaders. The audience was a friendly forum of women.

The quote from Canadian Prime Minister Justin Trudeau, however, resonated northward and across Canada, as he mused on the potential for social imbalance when male construction workers enter a rural area. But he said more than that..

Here’s exactly what Trudeau said, just as he said it, unedited or corrected for grammar.

“So, there’s all sorts of shifts we’re making because we know that you cannot succeed as a society if you are holding back half of your population. And looking at all the different barriers and moving forward on reducing them, on eliminating them as well, as a government body, looking at how every different decision can have an impact on women in a positive or a negative way. Even big infrastructure projects, you know, might now say, well, what does a gender lens have to do with building this new highway or this new pipeline or something? Well, you know, there are gender impacts when you bring construction workers into a rural area. There are social impacts because they’re mostly male construction workers. How are you adjusting and adapting to those? That’s what the gender lens in GBA-plus budgeting is all about. These are all things that we’ve been doing, not to be

THERE ARE GENDER IMPACTS WHEN YOU BRING CONSTRUCTION WORKERS INTO A RURAL AREA...

PM JUSTIN TRUDEAU

nice or to be better or to be moral, but to be smart about getting the very best out of all of our citizens and making the very best out of our economy, because women entrepreneurs tend to make better choices than others — we’ve seen it study after study. So, this is all something that I see the world moving on in many ways. Leaders are moving on. But the business community needs to wake up and move on as well.”

John Bleasby

The last time Canadian Contractor checked, only a small minority of our 30,000 residential contractor subscribers used one of the “big” construction management software systems.

Why do so few renovators and custom homebuilders use one of these “enterprise” business/construction management systems? After all, they’ve been on the market for at least 25 years.

According to Randy Margalith, the creator of a new, free app called GC RENO, it’s not that these well-known systems aren’t good.

They are good!

But they are too complicated for many users who are coming to these systems for the first time, Margalith says.

“They have lots of features and they have many platforms, so why aren’t more contractors using them?” Randy says he asked himself when he set out to create GC RENO. “Many contractors just aren’t at that level of complexity,” was his conclusion.

GC RENO takes contractors immediately into the world of renovation project management on a mobile phone platform, with all of the basic tools, without a steep learning curve. For more information, please go to www.gcreno.ca.

Steve Payne

Veteran design-build contractor Paul Gallop on how he learned to build a team.

By John Bleasby

It might be hard to be humble if you had been as successful as Paul Gallop. Men At Work Design Build, the Toronto-based firm Gallop started with his wife, Sherret Nosanchuk, nearly 30 years ago, now has 42 employees and runs up to 20 projects concurrently. Yet Gallop describes his career in self-effacing terms.

“I didn’t plan to be in this business,” Gallop told Canadian Contractor. “When I started around 1990, Toronto had just suffered its worst real estate collapse. I didn’t know any better. It was probably the dumbest possible time to get involved in anything to do with the housing industry.”

At the same time, Gallop has recognized opportunity when it has come knocking. “There’s been an extraordinary construction boom, and escalation of property values. A lot of incredible opportunities have come my way, especially in the city of Toronto over the last decade or so. But all of these things were simply good luck — there was no element of preparation.”

Company growth can be a doubleedged sword. On one hand, there is the instinct to grow one’s company. In fact, failure to do so might appear almost regressive. Yet, some companies grow too fast or don’t grow correctly in the right areas. Some entrepreneurs simply aren't prepared to handle the challenges of growth. Did Gallop have such similar challenges during his company’s periods of growth?

Gallop answers clearly, yes. He openly describes his firm’s ups and downs, particularly during a period of rapid expansion in the late 1990s. “It was an example of checking off virtually every box for doing things wrong and not following sensible practices as far as business growth was concerned,” he recalls. “I was grossly under-qualified. We had no capital to fund growth; we were operating on a shoestring. I didn’t realize at the time just how expensive

it is to grow. We hired too many people too quickly; we didn't have the proper systems in place to handle the new people. All of the things that could go wrong as a result of that did go wrong. It was a very expensive and stressful experience that took a long time to recover from.”

Nevertheless, Gallop persevered and his company survived. After a serious retrenchment spanning several years, he transformed Men At Work from what was then a one-man project supervision service relying entirely on sub-trades to a vertically integrated design-build company, right down to in-house architecture and engineering.

Gallop agrees with the suggestion that

re-boot, he also admits that it hasn’t been a perfectly smooth ride evolving from a one-man operation to a staff of over 40. “We have probably made some of the same mistakes, or at least in some cases have paid the consequences for trying to grow quickly.”

How did Gallop achieve such a radical makeover and reach this current level of success? It started, he says, with a simple question shortly after he turned 50. “What are we going to do with this thing? I'd had so much experience in so many aspects of this industry. Was this all just destined to continue forward as a small practice until I reached retirement age, or should we somehow try to leverage that experience into something more substantial?”

I DON'T THINK I'M EVER GOING TO FEEL THAT WE'RE DONE, THAT WE’RE FINISHED GROWING, OR THAT WE'VE GOT THE COMPANY EXACTLY THE WAY WE WANT IT.”

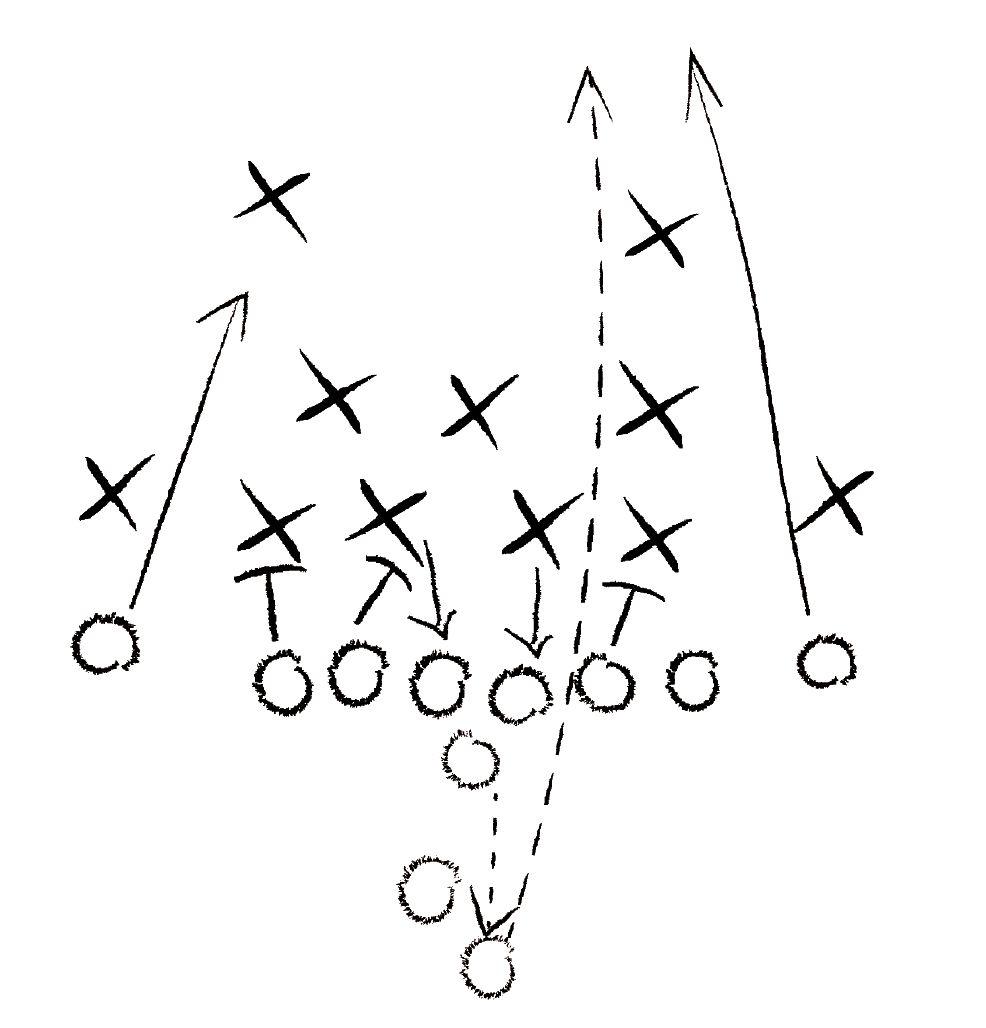

his role today resembles a professional football coach. While he holds overall responsibility for the company’s direction, he’s delegated authority and responsibilities to a team of core managers who, like defensive, offensive and special team coaches, run the more detailed day-to-day aspects of Men At Work’s multiple projects. “I still do a lot of firefighting,” he says. “There may be problems on a job site that I have to help resolve or give guidance, but it’s less and less a case of me being involved in the actual management of the projects or even the management of the people who are managing the projects.”

At the same time, while Gallop recognizes that the lessons learned earlier were important to his company

A key decision was committing to the type of company Gallop wanted Men At Work to be. “We wanted to have more control, to embrace our identity as a design company as much as a building company,” he says. “We had been selling design services for many years before, but it was really something we wanted to bring into focus more intensely going forward as an in-house part the company's identity.”

Now 58, Gallop credits the U.S.-based contractor peer group Remodelers Advantage for giving him the confidence to take his company to a new level — Men at Work 2.0, he calls it. “Perhaps more significantly than developing in-house capabilities was the acceptance that the company must stop revolving around

me if there was to be any longevity and opportunity for the company in the future.”

That meant bringing onboard those who could make change happen. “If the company was to have some runway beyond my own personal tenure here, we had to bring in people significantly younger than me with energy, ideas and vitality.” Gallop once again describes himself as simply lucky. “It wasn't the case where we went looking for a particular kind of person to fill any particular role, though,” he says. “They just fell into our orbit for one reason or another. They struck me as really good people — ambitious, smart, pleasant, great communicators, and obviously with some relevant experience, expertise or education that made them appropriate to join us. However, it was their personal characteristics that were so attractive.”

Going forward, Gallop sees himself walking a managerial tight rope. “I’ve been trying to teach and lead by example,” he explains. “At certain times, that might seem like micro-managing. Honestly, this is one of the things I’m struggling with the most — recognizing when I’m talking too much, when I'm interfering, when I'm doing more harm than good, versus being too distant. It’s really easy to say, “Well, it doesn’t matter — let them just figure it out on their own.’ That's me not micromanaging. But very quickly that can appear to be me not caring, or failing to provide corrections, leadership or support. I’m struggling with that balance every day.”

Gallop credits his core team for not only creating a progressive, positive culture but for reinvigorating his own enthusiasm. However, letting good people go ahead and make decisions is challenging for many company founders. It’s where Gallop feels somewhat at a disadvantage for not having had a mentor to show him how to lead. “That’s where

(IN THE LATE 1990S) IT WAS AN EXAMPLE OF CHECKING OFF VIRTUALLY EVERY BOX FOR DOING THINGS WRONG AND NOT FOLLOWING SENSIBLE PRACTICES AS FAR AS BUSINESS GROWTH.”

I'm stumbling the most and where I’m having varying degrees of success, with a degree of doubt coupled with a lack of confidence. I'm supposed to be the leader, but I sometimes feel like I’m not worthy.”

Yet despite this declared selfdoubt, Gallop has created a corporate philosophy that maintains his one overriding principle. “We take the long

view,” he explains. “When there's money on the line, we’ve learned that by taking the view of customer satisfaction, no matter the cost, it will have been the right thing to do in the long run. It will be the path of least resistance anyway. It will feel better, even if we’ve lost money on the opportunity today. Ultimately, customer satisfaction trumps everything else and

pays dividends in the end.”

Gallop has made a serious effort to communicate his outlook to ensure that it’s understood throughout the company. “It’s been refreshing to a lot of them, I think. Some have told tell me over the last few years that they assumed if they did something wrong they might get fired, or at the very least have a major problem. They were terrified. When that was not the outcome, it developed a lot of trust, goodwill, and faith. It’s encouraging for them to know they can take some risks and don't have to come back to me for permission for every situation they encounter.” That level of trust and team backup no doubt has resulted in Gallop being able to both attract and retain good people. After all, he readily admits that he’s made mistakes himself. His message to staff has been simple — “Solve the problem, move on, try to learn from it, try not to make the same mistake again. Always keep the company’s priorities in mind: customer satisfaction first, expediting second, making money third.”

Today, Gallop’s personal commitment remains strong. “We set goals several years ago that I hoped to accomplish by the time I was 60. But in fact I don’t really have an end date in mind. I’ll probably see myself working myself to the grave!” He’s also communicated to his core staff that he considers them central to the company’s future. “I foresee them becoming an increasingly important part of the company’s forward strategy. What we’re going to do from here forward will depend a lot on what the core team itself wants. In that regard, I’m in the process of building their confidence and business education so they can take on more leadership roles and responsibilities in order to do that. But personally, I don’t think I’m ever going to feel that we’re done, that we’re finished growing, or that we’ve got the company exactly the way we want it.”

cc

By John Bleasby

Contractor: Men At Work Design Build, Toronto

Building Designer: Keith O’Brien

Interior Specialist: Natalie Venalainen

Project Manager: John Cera

in Toronto’s west end has undergone significant changes during the housing boom of the past two decades. Long regarded as an upscale area featuring large lots and spacious mid-century homes, there have been many expansive, high-quality rebuilds along the borough’s leafy, winding streets.

However, not everyone wants a remodelled or replacement home built to the maximum allowable footprint. In the case of this corner lot residence near James Garden by the Humber River, the owners faced a triple quandary, explained contractor Paul Gallop, president of Men At Work Design Build. “Was this to be a renovation, or a tear down and rebuild? The husband works in finance and analyzes everything, but he was really struggling with this. That's one reason we were brought to the table in the first place — they were attracted to our design-build options.”

Ultimately, the decision to remodel versus rebuild was based on both budget factors and style. It was to be, in fact, a hybrid. The owners liked many things about the way the home’s appearance and how it was shaped. It was a matter of finding ways to expand and update in the most cost-effective manner possible. Another factor was a number of recently-completed updates — a new front entry door, some window replacements and new landscaping, for

Opening up the living and dining space required a network of beams on the ground floor. “There was quite a bit of structural work to make the whole thing work,” said Gallop. “ We had the extra challenge of removing the outer layer of exterior brick, putting up new brick, and then adding framing on the inside of those walls to allow for increased insulation.”

example. “If it ain't broke, don't try to fix it,” is the way Gallop described the owners’ outlook.

The corner lot itself provided unique challenges to the Men at Work design team directly related to improving access to private outdoor spaces. “One of the big issues with the property was the way it was configured,” Gallop explained. “There was really no way to get to the large yard area on the west side of the house without going down a rather unattractive rear walkway along the side facing the neighbor. The solution was to rebuild and relocate the garage closer to the street.” Although successful, that required delicate negotiations with the City, and applications for variances due to street setbacks.

The added 465 square feet of new main floor living space created behind the new garage became the family kitchen, which now connects beautifully through sliding doors to the yard. A twopiece powder room and study were added near the main entrance.

Another 865 square feet of new area on the second floor over the relocated garage allowed for the addition of a huge master bedroom suite with an adjoining master bath and walk-in closet, bringing the total number of bedrooms on that level to four. A laundry room was also relocated from the basement. The bathroom, bedroom and family recreation space in the basement were left more or less untouched, with any newly added area becoming an exercise area.

A top priority for the clients was the addition of a new kitchen to the main living area that would allow a natural connection with the private side yard.

The original charm of the house was successfully secured, as requested by the clients, by retaining both the centre hall/second floor landing plan and the outward appearance of the house itself. This became particularly challenging in terms of exterior detailing. Most of the existing windows stayed in place, notably the bow window at the street front. However, given the significant amount of new construction, the original painted brick façade and cottage-like upper siding needed specific attention. “We talked

about painting the new brick to match the old, but that just didn't feel right to everyone,” said Gallop. Inspection revealed that the original solid brick walls were, in fact, two courses thick — an internal structural brick wall supporting the floor platforms and roof assembly, and an outer brick decorative facing. “The decision was made to retain the brick supporting wall, but to carefully remove all the outer brick and replace it with the same new brick cladding used on the new construction areas.” A combination of Hardie concrete shingling and board completed the exterior look. Nevertheless, Gallop said significant engineering work was required so that the main level could be opened up yet still be support the other structural elements.

This particular projects stands out for Gallop as further validation of his decision made several years ago to develop the company based on a design-build business model. “It was a successful design-build in that it did the right thing for the customer on this lot, pulling together all the variables into a practical outcome that worked.” cc

The clients treated themselves to a spacious new master bath on the second floor, as part of their bedroom suite addition over the garage.

Want adventure with purpose? Travel the world and use your skills to empower others!

Canadian Contractor and World Vision are providing the opportunity of a lifetime. Experience SkillTrain – Canadian trades professionals training young Rwandans. Experts in carpentry, plumbing, welding, electricity and masonry are needed.

WINTER 2019 • RWANDA, AFRICA • LIFE-LONG IMPACT

Be a part of the action and change a community for good. Are you part of this team?

E-mail skilltrain@worldvision.ca to learn more.

By Steve Maxwell

Theworld is faster, more demanding and more competitive than it used to be, and I find that staying sane in the 21st century requires mental and lifestyle strategies to match. The best of these don’t hide reality but rather remind me more firmly what reality actually is. Something I call the variable mental timeline is my favourite.

At any given moment in our lives, things can get overwhelming. The more pressures and deadlines you face, the more debilitated you can feel. For some people the turmoil in the head and heart degenerates into a destructive spiral. This is where I find that imagination can give great relief.

While it’s true that there’s usually nothing you can do in the immediate term to get rid of life’s demands, there’s no reason you need to think about them all the time. The fact is, the amount of productive “thinking time” required to deal even with large challenges is usually quite limited. The rest is destructive “worry time.” Here’s a simple strategy I’ve found to deal with that. Whenever I find it stressful to think about big, challenging and possibly ugly realities on my timeline, I imagine these things don’t exist until some work or action is required of me. After that, it’s back to intentional amnesia for that issue. The technique of shortening one’s mental timeline on purpose really does work. Capable, ambitious, conscientious people, in particular, often get over-spun

because they think about too much at once. It’s like food. A normal mouthful of roast beef is great, but try to eat the whole roast in one gulp and you’ll choke. It’s impossible and it’s the same with life’s challenges. Shorten your time perspective enough to reach a sane balance. Try it!

In some ways, your inner self is like a cordless drill. It’ll work fine for a while, but eventually the battery needs to come out and sit idle in the charger. Every moment you think of life’s hard things

I find it essential to completely unplug every Sunday. It’s like shortening my timeline down to zero for everything I have going on in my working life on that day. I never let myself work or even think about work on Sundays even though I sometimes dearly want to get things done. It’s a mental discipline, and like all disciplines it involves paying a price to get something more valuable. In this case, it’s an especially great deal. Just don’t go and do the really foolish thing and

I HAVE LEARNED TO SHORTEN MY MENTAL TIMELINES AND CONCENTRATE SOLELY ON THE TASK AT HAND.”

unnecessarily it prevents your mental “battery” from sitting in the charger. There’s great stamina in a shortened time line, but you need to cultivate the inner skill to make it happen. Success takes practice because your mind will keep trying to eat the whole roast beef at once. But the more you practice your shortened mental timeline, the more you’ll trust it and the less your mind will try to make your perspective too long. The more you’re able to forget issues where no immediate action is possible or necessary, the more you’ll be able to accomplish with a light heart.

Want to know a powerful secret I’ve discovered? Shortening my timeline during the week works great, but it would never be enough on its own. That’s why

convince yourself that you “can’t” take Sundays off. So often the word “can’t” actually means “won’t.”

One of the most ancient sources of wisdom advises complete rest every seven days and it’s golden. I didn’t always follow this wisdom, but after working seven days a week until the mid-1990s, I now know I’ll never go back. Do all your work in six days (not five), but the seventh day is for rest.

Isn’t it strange how so much of the world claims to be concerned about diet, exercise and “healthy living” while at the same time ignoring the old boundaries designed to keep work and worry in its place? Could this neglect be why we’re seeing an epidemic of debilitating anxiety, especially among young people? cc

By Steve Maxwell

In1975, my parents had a garage built onto our house, and part of the project involved adding manufactured stone to the front of the entire building. This stone was meant to give a classic flare to the 1950s suburban bungalow and it did, at least from a distance. But even as a 12 year old, I remember thinking how fake this stuff looked close up. Now, more than 40 years later, I’ve spent thousands of hours building with stone and I’m surprised by something. Even as an experienced stone mason standing a few feet away, I have a hard time telling today’s best manufactured stone from the natural stuff. It has become amazingly authentic. During the time since that garage project years ago, Ontario has become home to a handful of stone manufacturers that offer very authentic looking products. What they do is so good it has transformed the home building scene even beyond Canadian borders.

Advances in the quality and authenticity of manufactured stone is partially responsible for the explosion in popularity of stone for residential and light commercial projects. Design variety is another reason. There are a surprising number of visual choices that fit into the category of “full-bed stone” provided by a handful of Canadian companies that are leaders in the world. Winning projects that include stone can boost your reputation as a contractor and your financial bottom line, but that’s probably not going to happen unless you understand today’s stone scene.

The term “full-bed manufactured stone,”refers to an installation of man-made stone elements created in factories. These elements are 90 mm thick and rest on some kind of foundation ledge. This stone is tied to the building by brick ties, and there’s an air space and weep holes at the bottom, just like with brick veneer. The main difference is the shapes, sizes, textures and patterns of the different stone options. Despite installation similarities, the visual effect of stone is quite different than brick – different and more varied.

“Ontario is traditionally a very strong masonry market,” explains Blake Palmer, sales rep with Permacon, a leading Canadian stone manufacturer. “It’s only natural you have some of the largest and strongest companies in this province. Competition breeds innovation and the requirement that the materials produced are to the highest quality.”

“We ship our products to almost all four corners of North America,” explains Bob Sanders, director of marketing and sales with Shouldice Designer Stone. “Canada is our largest market but our long history in the US gives us strong markets there, too. Manufactured stone allows for a more streamlined and productive installation, while still allowing a stone mason to be creative.”

One of the challenges with full bed stone for you as a contractor is helping clients choose. It’s not as simple as it seems because there’s so much variety, ranging from traditional broken ashlar patterns, to field stone to modern styles that look like natural, unfaced stone layers with no visible mortar. One reason

When you’ve got a client interested in exterior masonry, let them know how the various options can be combined more easily than before. Brampton Brick is one manufacturer that has a particular focus on combining stone and brick so it fits together dimensionally with complimentary colour palettes. “The design of homes has become more complex,” explains Elliot Bender, VP business development and

today’s manufactured choices look so authentic is because they’re copies not fabrications.

Bradstone began as a UK company that came to Canada in 1984, and they’re one of the firms that have advanced the look and quality of full bed stone options a lot. “We start by buying natural stone”, explains Brad Miller, sales manager for Bradstone, “then we hire a stone mason to dress and mathematically organize a pattern. This also allows for enough stones that vary in size and texture to avoid repetition. We make an imprint of each stone, then make moulds for wet-cast coloured concrete.”

marketing with Brampton Brick. “Exteriors have more architectural features and are using a range of different materials. We’ve really focused on designing our brick and stone masonry products to work together in terms of texture, colour and size to make it easier for homeowners, designers and masons to bring a vision to life. Whether you seek a look that’s contemporary, traditional or somewhere in between, we have lots of options for you and it’s all made here, locally and for our climate.”

Although all full-bed stone is similar in some ways, each option is manufactured in a unique way. “Arriscraft has been producing full-bed stone since 1949 and we’re the only company in North America to produce what is called a calcium silicate stone,”explains George Winsor, sales manager with Arriscraft. “We don’t use moulds. Instead, we compress fine grains of sand, lime and oxide pigments under steam and pressure. What normally takes a natural process a long time to complete, we condense down to 10 hours. Our unique technology makes our product inherently stable, resulting in a more natural, weathertough product that’s warranted for life.”

The further along work progresses on a project, the more likely you are to run into concerns about project cost. The more money that’s been spent, the more likely clients are to cheap-out by changing the plan. This is one reason people opt for less

expensive, non-masonry options when some kind of masonry is clearly a better financial and environmental choice. Sometimes the premium reputation of stone scares some clients off before they even look at the numbers. The thing about manufactured stone is that it’s an “investment feature” as opposed to a “cost feature.” Investment features yield more benefit than they cost over the long run. Not many building choices fit this description, and the added cost of manufactured stone is minimal when you look at the larger picture.

The difference between the price of a full-bed stone exterior versus, say, vinyl siding, adds about as much to mortgage payments as the cost of a daily cup of coffee. Full bed stone boosts resale value, it eliminates the need for exterior maintenance, lowers insurance premiums and reduces energy consumption. The long service life of masonry means that it’s also the most environmentally friendly option going. Manufactured stone costs more than brick (about $5 to $6 per square foot plus installation) but less than quarry stone. It’s this reasonable cost that’s the biggest single factor behind the exploding popularity of stone in residential and commercial projects. cc

If you’re aiming to win jobs that involve premium masonry exteriors, you should also take full advantage of the sales power of using premium masonry accessories and telling prospective clients about them during your sales process. Any client interested in full bed stone will probably appreciate your use of premium masonry ties and weep screens if you explained it to them. Simpson Strong-Tie offers the best heavy-duty, widely available masonry ties I’ve seen so far. Their BTH tie can be bent to accommodate different wall gaps up to 3” wide. It’s also stronger than regular zigzag ties and grips into the masonry more securely.

Full-bed stone requires weep holes just like brick veneer does. Weepa (weepa.com.au) is an Australian company that makes the best weep hole screens I’ve seen. Their stainless steel product is particularly durable, impressive and can be opened for cleaning. They’ll ship to Canada, too. The big advantage for you of building with high-quality accessories like these is the way your credibility goes up when you show clients the care and quality you work into the little things.

Back in April 2005, DeWALT launched a cordless jigsaw that had the ability to cut flush right into corners with the right kind of blade, and I remember how delighted I was by this new feature. I used that jigsaw for years and still haven’t forgotten it. Fastforward 14 years and I found myself wondering if the new 20V D-handle DCS334 cordless jigsaw I was unboxing back in January would still have that great flush cutting capability. It does and more. A thoughtful upgrade of that old flush-cutting saw is why the new DCS334 is worth me telling you about. Besides being small, compact and light in weight (5 lbs 15 oz with a 5 Ah battery on my scale), the dual-control variable speed feature works better than most. Vary the speed within a specific range with the amount of trigger pull you squeeze, or change the speed range of the tool with the control dial just above the trigger. Tool-less blade changes happen with a flip of a lever on the front of the

This tool is the latest version of the kind of inertia finishing nailers DeWALT has been making for about 15 years. Inertia nailers use battery power to spin an internal flywheel that drives nails, so you’re free of hoses and cords. The DCN662 offers evolutionary improvements over the original versions of DeWALT inertia nailers I’ve used, and three things stand out for me with this model. First, the line of sight of the nail exit port is excellent. I don’t ever recall seeing a finishing nailer that let’s you so clearly see where nails are coming from. If you value the ability to place nails exactly where you want them on trim, you’ll like this gun. Second, the nailing tip has a nice, big, rounded plastic protection bumper on it. DeWALT takes this feature seriously enough that they put two spare bumper tips clipped on the back of the magazine. And third, the DCN662 is fast and powerful. 16 gauge nailers have an advantage over 18 gauge models because they can shoot 2 1/2” fasteners instead of just 2,” and the DCN662 fully sunk these longer nails into 2” hardwood in my tests, both in single fire and bump-fire mode. Tool-less jam clearing and the

saw, and two LED lights illuminate the cut zone clearly. This saw uses DeWALT’s 20 volt or 60 volt lithium-ion batteries and the high friction rubber overwrap on the D handle feels great. My only complaint is that this tool can’t sit upright on the back of the battery. I have four jigsaws in my shop right now and this is currently the one I’m most likely to grab first. $389 street price here in Canada with a 5 Ah battery and charger. A barrel-grip version is coming out soon, too.

ability to use both 20 volt and 60 volt batteries makes this nailer part of the larger DeWALT cordless tool family. Canadian street price $529.

Last year’s winner of the ITW projects contest: Stephen Cartwright

Last year, contractor Stephen Cartwright of Canadian Waterfront Services, Ltd. won $5,000 of GRK fasteners and a Paslode nail gun. Stephen sent us photos of this beautiful boathouse and boat port he built for a client at Gloucester Pool, Muskoka, Ontario. If you’ve got your own completed project that used GRK fasteners — no matter what type of construction it is — let us have a look. You, too, could win the grand prize.

Your

Go to CanadianContractor.ca, search ‘2019 Project Contest’ and click on the link. You will want to attach at least 3 photos of the project you are entering. Tell us a little bit about the project — and how GRK fasteners were used in it.

This terrific new product is not only a rolling scaffold unit, but also a work station, chopsaw bench and heavy-duty shelving unit.

By Steve Maxwell

Metaltech makes industrial scaffolding in their Laval, Quebec plant and you’ve probably climbed on their stuff at one time or another. My own collection of scaffolding is mostly made by Metaltech, and this past fall they launched what they call a ScaffoldBench. I’m impressed because this product does different things well. Besides being a rolling scaffold unit, the Scaffold Bench is also a work station, chopsaw bench and heavy-duty shelving unit.

Imagine a 6 foot-long rolling scaffold frame. A wood-and-metal platform provides a work surface on one side, and a quick-release

system for holding a chopsaw to the platform on the other. There are also adjustable outfeed rollers that provide support for long planks being cut and the whole thing rolls on large, lockable casters that work better than I expected over less than smooth outdoor surfaces.

Assembling the ScaffoldBench took about an hour. The fit of all parts was good and the engineering strong. While most readymade work benches follow flimsy, homeowner-grade engineering, the ScaffoldBench is made by people who understand how commercial gear needs to be manufactured. My only complaint is the plywood used for the platform on my unit. It looks like indoorgrade material and one layer of surface veneer was bubbling a bit and coming loose as I took it out of the box. Not a big deal, and probably not something you’ll find on all units.

The ScaffoldBench is light enough that two people can easily lift it and parts are easily stowed in the back of a truck. The basic ScaffoldBench kit I’ve been using cost $380 from Home Depot and comes with one wire shelf. The frames can accommodate more. Even if you only ever used the ScaffoldBench as heavy duty shelving, it’s still more economical than industrial shelving and just as strong. Another accessory that caught my eye is the tool shelf. It hangs off one of the frames and provides a surface to hold tools and supplies. If you’re tired of working from substandard benches on site, this thing will probably make you smile. cc

Contractor Andy Roy’s brand-new year-end staff bonus program hasn’t worked the way he planned. His idea was to financially reward his crews based on a point score system. Points would be awarded for meeting deadlines, staying on or under budget, and meeting client satisfaction criteria. However, no one seems happy.

The problem seems to be that many of Andy’s points categories have not meshed well, resulting in uneven rewards within the company. Crew supervisors are pointing fingers all over the place: at estimators who didn’t do their jobs properly, sub-trades who let the company down, suppliers who were late shipping special orders, and clients whose change orders impacted project deadlines — basically things beyond their control. Instead of being pumped up going into 2019, Andy’s staff is disgruntled.

What should Andy do? See the options at right.

In our November 2018 contest, we asked how a contractor should handle a client’s wife who now objects to the noise and disruption caused by workers and their tools? Jimmy Drum has commenced a basement renovation for Sue and Gerard Mezzieros, but now finds himself caught between Sue’s frequent demands for less noise and the need to keep his crew working efficiently and happily.

Everyone submitting a proposal felt a meeting was required between Jimmy and the clients. The question was: How much compromise, if any, was appropriate?

The winning proposal was submitted by Dan Sageman of Carolinian Construction, Grand Bend, Ontario. “Jimmy has already quoted the job and all of Sue’s requirements will add cost,” wrote Dan. At the same time, Dan outlined ways that Sue’s concerns could be resolved without too much expense or trouble. After all, he said, “As project managers, we need to respect that some folks are sensitive to the noise and disruption of renovting. The line I use often is, ‘You have to break some eggs to make an omelette.’ ” Congratulations, Dan! You will receive a DeWalt 20V MAX* XR® Brushless Jigsaw (retail value $389).

1. Pay the bonuses this year, but scrap the idea entirely after that. Incentivizing time, budgets and quality is impossible.

2. Reward each element separately, not as a combination.

3. Keep with the plan, but seek input from the staff as to how the calculations should be made.

4. Something else (please describe).

HOW TO ENTER

Email your answer to John Bleasby (jbleasby@canadiancontractor.ca)

The best contractor-submitted entry, as judged by our panel, will

The best contractor-submitted entry, as judged by our panel, will

a DeWalt DW45RN 15 Degree Coil Roofing Nailer (retail value approx. $400).

The winner will be announced March 12, 2019 on our website.

The Cimarron® line of toilets packs Kohler’s powerful AquaPiston® flushing engine beneath the hood. The 3 to 2 ratio between valve intake and outlet harnesses the natural force of gravity to deliver a high-octane flush for virtually plug-free performance. KOHLER.com/Cimarron

With the dependable versatility of Transit, plus the power and capability of F-150, Super Duty® and F-650/F-750, Ford’s lineup of commercial vehicles makes achieving your ultimate business goals possible.

• Super Duty has best-in-class* max. payload of 7,640 lbs

• F-150 has available class-exclusive^ features like Pro Trailer Backup Assist

• Transit has 3 lengths, 3 heights and 64 cargo congurations

• Transit Connect has a compact footprint, and a maximum cargo space of 145.8 cu ft†