Energy Efficiency Labels For Homes Who Owns and Controls Them?

Page 16

A Skinny House In Winnipeg

We Revisit a 1980s Classic

Page 28

Pick Up Trucks and Work Vans

We Review the 2018 Model Year

Page 34

Energy Efficiency Labels For Homes Who Owns and Controls Them?

Page 16

We Revisit a 1980s Classic

Page 28

Pick Up Trucks and Work Vans

We Review the 2018 Model Year

Page 34

Lindsay Haley’s Precision Contracting, Brockville, Ontario has a special formula for success

Page 24

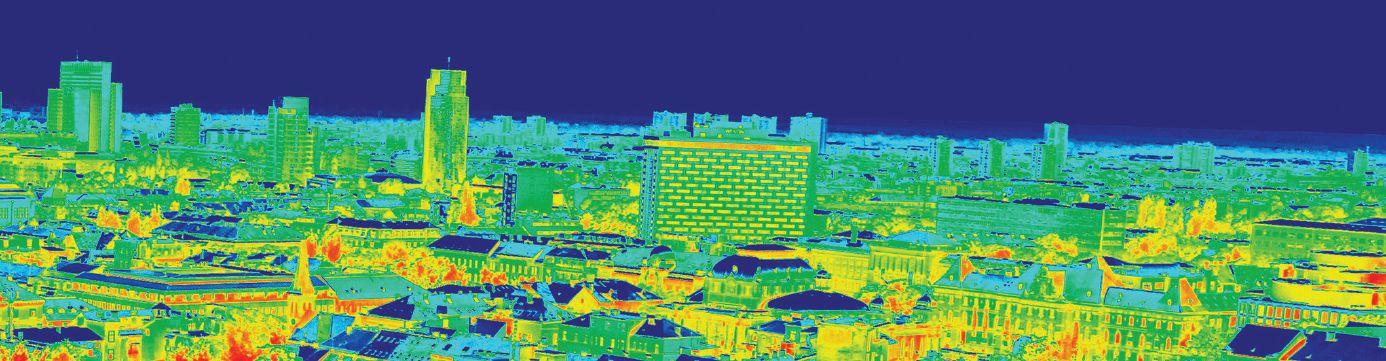

Residential Energy Efficiency Labels 16

Sifting through the alphabet soup of R-2000, Energy Star, NZEr, Built Green and many others.

A Solar Panels Primer 20

Contributing editor John Bleasby answers some important questions about small scale installations.

TAKING IT TO THE NEXT LEVEL 24

How Brockville, Ontario’s Lindsay Haley has been making some good moves for his design-build firm.

The Thinnipeg House 28

We go to Winnipeg to revisit one of the 1980s pioneers of the narrow house trend.

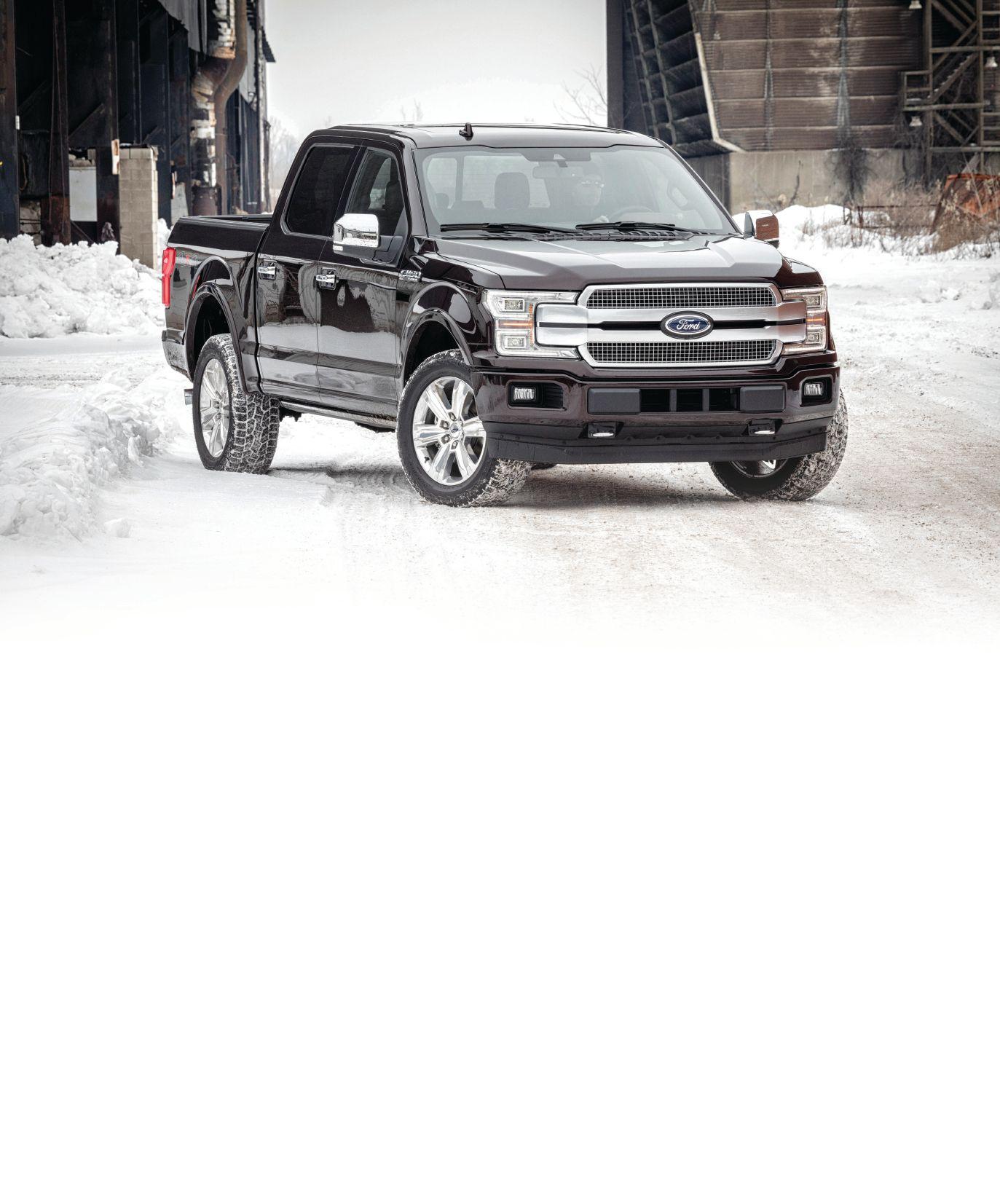

Pick-Up Trucks and Vans 34

Our annual look at the best of the work vehicles for renovators and homebuilders.

An accountant suggests that, for our industry, a December 31 year-end may not be ideal.

The best employees act like they own the business. ”

Steve Payne Editor

spayne@canadiancontractor.ca

By Steve Payne

“In my hour of darkness, in my time of need, Oh Lord, grant me vision. Oh Lord, grant me speed.”

- Gram Parsons, In My Hour of Darkness

That's what successful contracting is all about, right? Having the vision to see what needs to be done. And then getting it done on time. Simple. If you have the faith, maybe. But the speed thing, that one is always a tough proposition. Nowhere more so than in the services end of the business. Plumbers, they feel the squeeze of time pressures more than most. So do the HVAC service companies. It's get in, fix it, bill it and get out, racing against the clock all the time.

Speed is everything. Especially in the winter when furnaces break in the middle of the night. Or pipes freeze. When my 84-year-old mom called me late in the night, three weeks ago, and said that her hot water wasn’t flowing any more, I mentally ran through the odds that she could end up with a burst pipe - and a nasty flood. Luckily, one of Canada's largest HVAC service companies had the service contract. They would be there within two hours.

My mom lives several hours away and lives alone. The firm in questionnow owned by one of the wealthiest Hong Kong businessmen on the planet - did indeed get a young lad out there on time. Showing up on time was the only thing they got right.

The service technician checked out the water heater and declared it fully functioning. It wasn't producing any hot water because the intake pipe was frozen, was all. Not his problem. Not his firm's problem. "You will need to call a plumber," he advised as he headed out the door cheerfully.

I let loose a loud cascade of profanities after I hung up the phone when my mom told me what had happened. I attempted to call the idiot service company in question. Nothing but voicemail, of course.

At one o'clock in the morning, I located a plumber with excellent HomeStars reviews in my mom's town, and was delighted that he answered the phone. "I've got a bunch of calls first, but I'll be there first thing in the morning," he said.

As opposed to the multi-billion dollar corporation, this young man owned his own business. A business of one employee, as far as I could tell. By 8 am, this young entrepreneur had unfrozen my mom’s hot water pipe. It was blocked just three feet from the hot water tank. It took him 15 minutes. The previous firm could have done it as easily.

Why didn't they? To solve that mystery, all you have to do is look at how the two individuals were being evaluated - and how much they cared. The owner-operator was being evaluated on customer satisfaction. Period.

Rob Koci

Publisher

rkoci@canadiancontractor.ca

By Rob Koci

The demise of print media has been predicted annually for some 30 years now. It is not likely to happen. In the case of Canadian Contractor, we know that the paper version you hold in your hands fits perfectly on the top of your truck’s dashboard. It’s frankly easier on the eyes, more comfortable in your hands and you don’t have to worry about battery life.

But we only come to your door in paper six times a year. Digital is cheaper and quicker to send and takes less time and effort. Our weekly newsletter does the job of keeping you informed with shorter stories that you can digest along with your lunch at Timmies or in line at your local Home Building Centre.

But sometimes our blogs can be too long even for that. And sometimes, you want a little entertainment with your double-double. Social media does that, but we will do more…

This year, we are developing what I like to call Canadian Contractor TV. Every week, we’ll send a new video to our 19,000 contractor subscribers that provides insight into some aspect of your working life. Home Hardware will bring you Site Tips once a month. ITW, makers of Paslode, GRK fasteners and Tapcon, have sponsored a series called All About Fasteners. Typar and Velux have forthcoming series on the exterior envelope. Watch for them. These videos will arrive in subscribers’ inboxes every Thursday morning at 6:00 am throughout the year.

Not yet a subscriber? Don’t miss out! Go to canadiancontractor.ca, scroll down to Subscribe, and it will take you 30 seconds to sign up.

Contributing Editors Rob Blackstien, John Bleasby, Steve Maxwell

Art Director Mark Ryan

Publisher Rob Koci rkoci@canadiancontractor.ca

ISSN 1498-8941 (Print) ISSN

(Online)

Account Coordinator

Tracey Hanson thanson@annexbusinessmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-442-5600 ext. 3543

Tim Dimopoulos, Vice President tdimopoulos@annexbusinessmedia.com

Ted Markle, Chief Operating Officer tmarkle@annexbusinessmedia.com

Mike Fredericks, President & CEO

Circulation

The world is changing. And so are we.

As ROXUL, our products have always contributed to the energy efficiency of spaces. And this will continue. But with the world’s energy consumption expected to rise 50% by 2050, is this enough? We don’t think so. United under one global name, we can address this

trend with more sustainable solutions. It’s a bold leap forward we’re ready to make.

We are the leader in stone wool insulation.

We are ROCKWOOL.

For more about what this change means for you, visit rockwool.com/hello

ROXUL is now

Just before Christmas, Ontario announced its Green Ontario rebate program. Contractors who register with the program can access millions of dollars in energy-efficiency grants. We reported that, at first glance, we were happy we saw no requirement for applicants to belong to the Ontario College of Trades. We were soon corrected by the ever-vigilant independent contractor Mark Mitchell.

“I threw the application out”

Actually Steve, I looked into the rebates I could offer for certain heat pumps. They lost me when asking for my OCOT card for refrigeration. I don’t recognize these people as my overlords, so I threw the application out. It seems the IESO is brainwashed into believing that OCOT is in charge of certifying refrigeration mechanics.

Mark Mitchell

In June last year, Caroline, a homeowner, wrote to us about her battles with the City of Toronto Forestry folks. She is has retained a homebuilder to build a new home on her 60 foot lot. All is going well, except for Caroline’s dealings with the City tree protection folks. (We are not sure why she took that one on herself rather than having her contractor deal with it.)

Caroline wanted to replace one of the two Norway Maples on her property with three new trees, at her sole expense. The one tree that would be removed, would allow for a double driveway. The City said no – and that the driveway she wanted to build would have to bend around the tree. It would have to be a skinny, single driveway at the road, then expand to a double driveway in front of the garage. Caroline emailed us the following update, six months after she began the process.

“Trying to do the right thing – and getting punished!”

Back in June I contacted you about cutting a city of Toronto tree down. Well here’s my update. No, don’t get excited: it’s not solved. It turned out that we had to go to Committee of Adjustment for the most minor of minor variances. That happened today and they passed our building plans. BUT we can’t get a permit to build until Forestry sort out this tree. And we can’t deal with that until we get the CoA letter in 20 days! As it stands right now, Forestry has told CoA to deny our building variances! Right now Forestry is

adamant that no living tree will be cut down. Forget the fact they messed up 60 years ago and planted two trees on our property, when every other lot on our street only has one. So we are being punished for their mistake.

For the record, the tree in question is a Norway Maple. It’s in fair shape, at best. It’s not even a native tree – as Forestry now wants to see planted. We have offered to plant three trees in its place!

There is no logic to this policy. It is too blinkered and ignores the fact that many people just cut their trees down and/or pave right around their trees. But here we are, trying to do the right thing, and getting punished. Crazy!

Caroline

In our last issue, we carried an advertising supplement on Interior Finishes, with a sponsored story about skylights. We then got the following post, online, from contractor Larry Carter who said he had had some bad experiences with drafts.

Skylight education needed

Skylights are one of those products that contractors sell to homeowners that usually end in disappointment. The contractor often does not understand the impact a skylight will have on the room in which it is installed but they do not want to discourage the customer because they need/want the business.

The first – and probably the only thing – a homeowner needs to know is that, in a Canadian winter, warm air rises into the skylight, cools and then returns to the room. This creates a constant draft created by circulating air.

I had a construction instructor that installed a skylight over the desk in his study to let in the beautiful sunlight. The cold draft was so bad that he could not sit at the desk.

As construction professionals I believe it is our duty to educate homeowners so that they can make informed decisions.

Larry

We then got a reply to Larry from VELUX, a leading Canadian skylight manufacturer…

Hi Larry:

We could not agree more that it is important to educate homeowners to help them make informed decisions. Old style skylights, like domes or clear glass without argon or low-E have cooler inside surfaces and the sense of a draft or cold is possible

If this is your boardroom, you’re a Pro.

Home Hardware is a nationwide supplier of quality, name brand products to Pros of all trades. Whether you are a homebuilder, a renovator, a plumber or an electrician, Home Hardware is a Pro source for everything you need on your next job.

Dedicated Pro sales staff, job site delivery, home plan services, material takeoffs, package pricing, convenient ordering options, credit services, rewards program, and exclusive e-offers are just some of the benefits we offer!

Sign up today to receive pro exclusive email offers and news. homehardware.ca/en/forms/register

on a cold winter day. The same issue can arise with old or poor quality windows. This is one of the reasons to purchase energyefficient skylights and windows – to ensure thermal comfort of the home’s occupants. Better insulated skylights and windows are warmer in the winter, as well as quieter, and help save money on the heating bill.

Arethea Harris

National Marketing & Communications Manager

VELUX Canada Inc.

In January, we reported about a London, Ontario renovation contractor who was heavily fined for violating a customer’s legal right to a “10 Day Cooling Off Period” after signing a contract (see page 12 in this issue). Here is a comment about that.

Where is the protection for the contractor?

This is where the contractor went wrong. The Ontario Consumer Protection Act (OCPA) states: “In cases where consumers sign a contract for $50 or more, at their home, the act provides for a 10-day cooling-off period to cancel a home renovation contract without cancellation fees.”

In my opinion, the OCPA should be rewritten… but our Ontario politicians’ brains are apparently short-circuited.

Now, when no money has exchanged hands, OK have a cooling off period of 10 days or more. But when money enters the picture, in the case of the customer cancelling the contract, the contractor should be compensated for the material already purchased plus labour and fees. All of this should be declared in the contract.

Protection under the law should be for everyone, including trades, small businesses, large businesses and so on. Not just the

consumer. But apparently some have more equality then others.

Joe

Here is a comment about Marisa Lazo, the 23-year-old Toronto 'Crane Girl,' who climbed a crane as a prank and then got stranded up there, last April. She shut down a job site for a day and tied up multiple emergency service units during her early morning rescue. A Toronto judge decided not to convict her on any of the multiple charges that police laid against her.

Not sure if I totally agree with the judge. She shut down the work site for the day causing costs to the site developer and a day’s loss in wages among the site’s workers and sub-trades! Also causing the city costs for emergency workers for the rescue and possibly taking time away from real emergencies.

I think she should have been ordered restitution to some extent including many hours of community service to reflect on her actions. Possibly some of the service work would have given her a more positive outlook on life, helping her through her emotional state. I don’t think she needed a permanent criminal record or anything serious.

Derek Pallister

Editor’s Comment: Actually, Ms. Lazo had been required to do community service hours, which she completed before her appearance before the judge. The judge commended Ms. Lazo for cooperating fully with the court's directions.

“Hooked for Life”

“Fusion” is defined as “a merging of diverse, distinct, or separate elements into a unified whole”. So it is with Fusion Stone; the coming together of the beauty, strength, and maintenance free characteristics of traditional stone with the ease of installation and affordability of stone veneer.

Fusion Stone is an easy and budget-friendly way to beautifully upgrade a home, inside and out. Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips & screws. You just screw it to the wall and it’s “Hooked for Life”.

Available in three distinct systems, all backed by a Lifetime Guarantee, Fusion Stone can be installed on both new and existing wall assemblies in any weather.

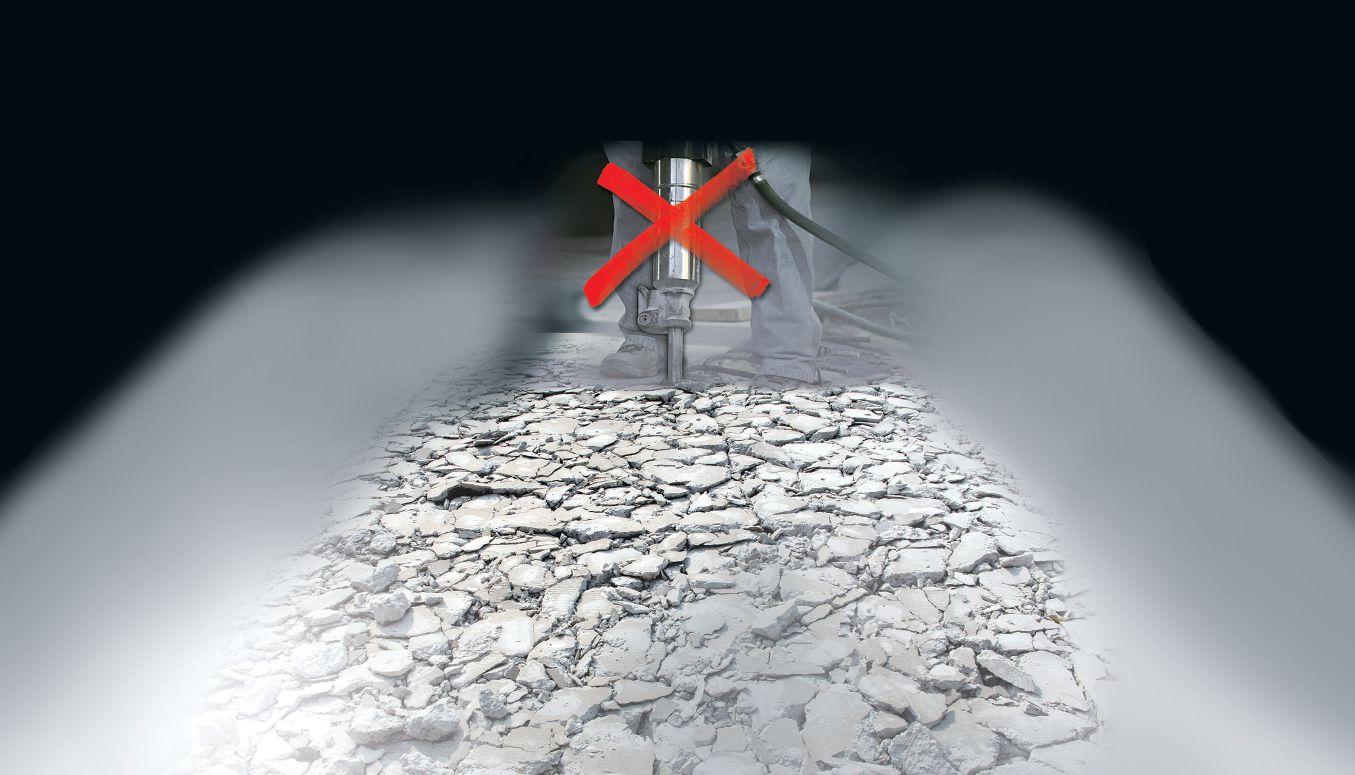

Benco Concrete Inc. and owner ordered to pay $5,000 in fines and restitution

Asfar as Sheldon Benson is concerned, he did nothing wrong. His customer wanted concrete work done on their driveway, they signed a contract, and Benson took a deposit of nearly $1,100. When the customer later asked to cancel the contract and have the deposit refunded, Benson refused.

However, under Ontario’s Consumer Protection Act (2002), a contractor can’t do that. In fact, a ten day ‘cooling off period’ is part of contract law across Canada; this is where Benson tripped up.

On October 26, the court found that Benson and his company Benco Concrete Inc. of London, Ontario provided a contract to clients in nearby Kitchener that “did not include required language about rights under the Act.” According to the notice of conviction issued by the court, “Mr. Benson kept the deposit despite the consumers’ multiple attempts to cancel the contract.”

Benco and its owner were ordered to pay $5,000 in fines and restitution.

Canadian Contractor asked Benson for his version of events. “It’s really simple. I went and signed a contract with these people,” he said. “Our contracts say there is no refund on deposits. I bought a bunch of material. They called up and actually lied about the time frame they had requested. I went to their house, not only once but twice, one time at seven o’clock in the morning, at their request. After bending over backwards, and having some outlay of expenditures towards the job, all of a sudden they wanted to cancel everything as if nothing ever happened. And I said no.”

There is often confusion among

THE 10 DAYS COOLING OFF PERIOD ALLOWS A CUSTOMER TO CANCEL A CONTRACT WITH NO FINANCIAL PENALTY

consumers about the differerence between deposits and contracts. Canada’s Office of Consumer Affairs website advises consumers that in terms of deposits, “If you change your mind, you are not, by law, entitled to get your money back. Be sure to ask what the conditions are before you put down a deposit, and only put down the minimum amount required.”

However, a contract is different. The website goes on to say, “Contract law is a provincial and territorial responsibility. Your province or territory may have legislation that gives you more rights when you buy specific products or services. For example, all jurisdictions in Canada give consumers 10 days to cancel most contracts made with a door-to-door salesperson… In some provinces and territories, there is an automatic cancellation (or cooling-off) period for certain types of contract… The cooling-off period is valid whether the company tells you about it or not.”

This is where Benson went wrong. The Ontario Consumer Protection Act states, “In cases where consumers sign a contract for $50 or more, at their home, the act provides for a 10-day cooling-off period to cancel a home renovation contract without cancellation fees.”

Benson did not appear in court to answer the charges. “I wasn’t available to go to the hearings,” he told Canadian Contractor. “I had bigger fish to fry that day.”

When asked if he might change the way he does things, following the fines he received, Benson said, “I can’t just change it to support people who straight-out lie. If somebody goes and says they requested a refund within ‘x’ amount of days and it’s not true, I don’t know what I can change.”

We can learn even more about contract law from Benson and a dispute that ended up in court back in 2010. The lesson in that case is that a general contractor is responsible for the workmanship of those working under their direction. Benson and his company became entangled in a lawsuit concerning a pool and patio installation in Kitchener. The patio installed by Benco developed cracks. As reported, testimony from an engineer stated that, “the cracks were caused by excessive water in the concrete mix combined with poor installation techniques.” Ashton Pools, the project contractor, ended up being ordered to pay the client $36,000 in restitution. “The evidence is that Ashton directed the work of Benco employees,” the judge wrote. “Ashton Pools is, therefore, liable for the work of Benco.”

In the meantime, Benson told Canadian Contractor that his company is carrying on successfully, with no reported set backs or repercussions resulting from the October conviction.

John Bleasby

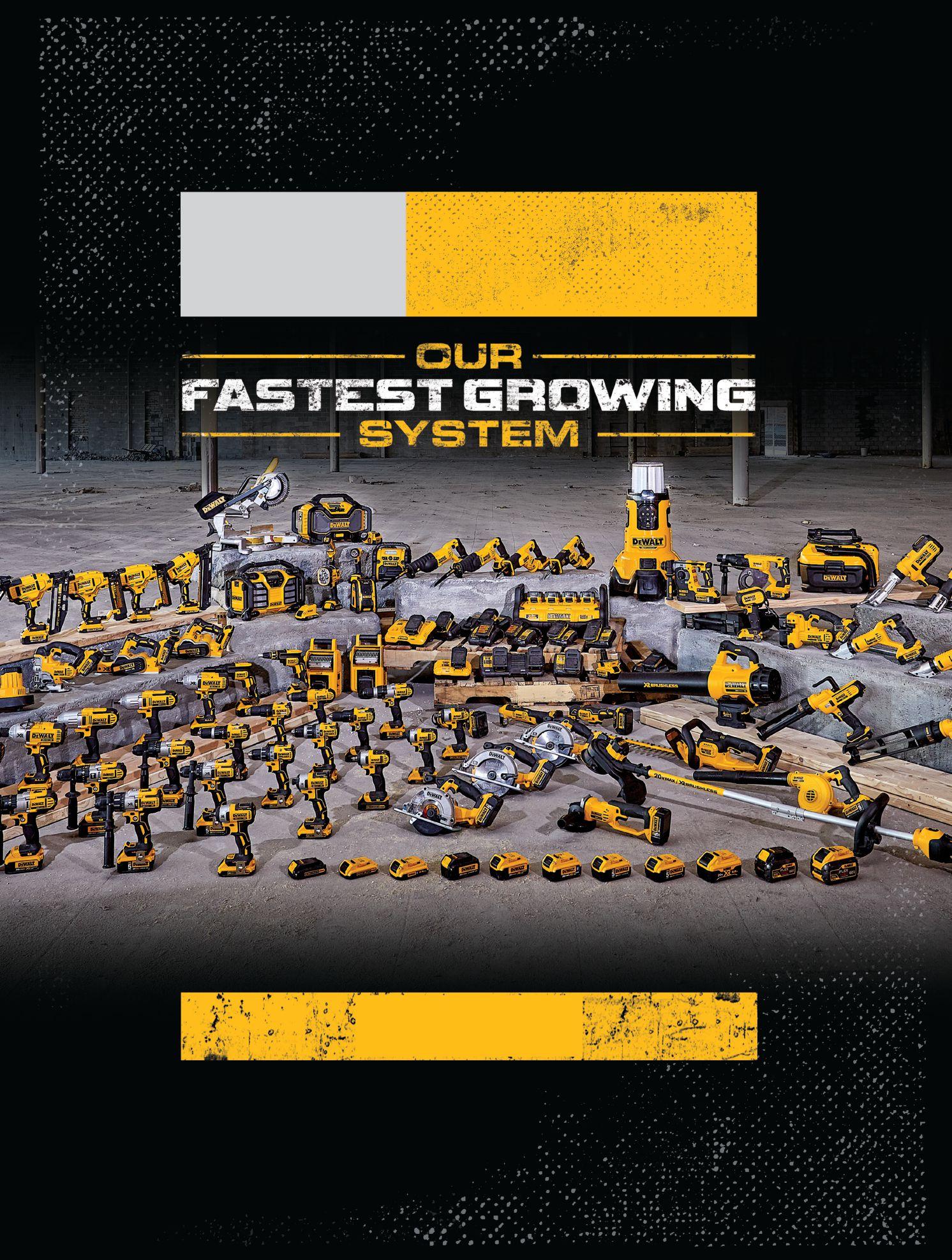

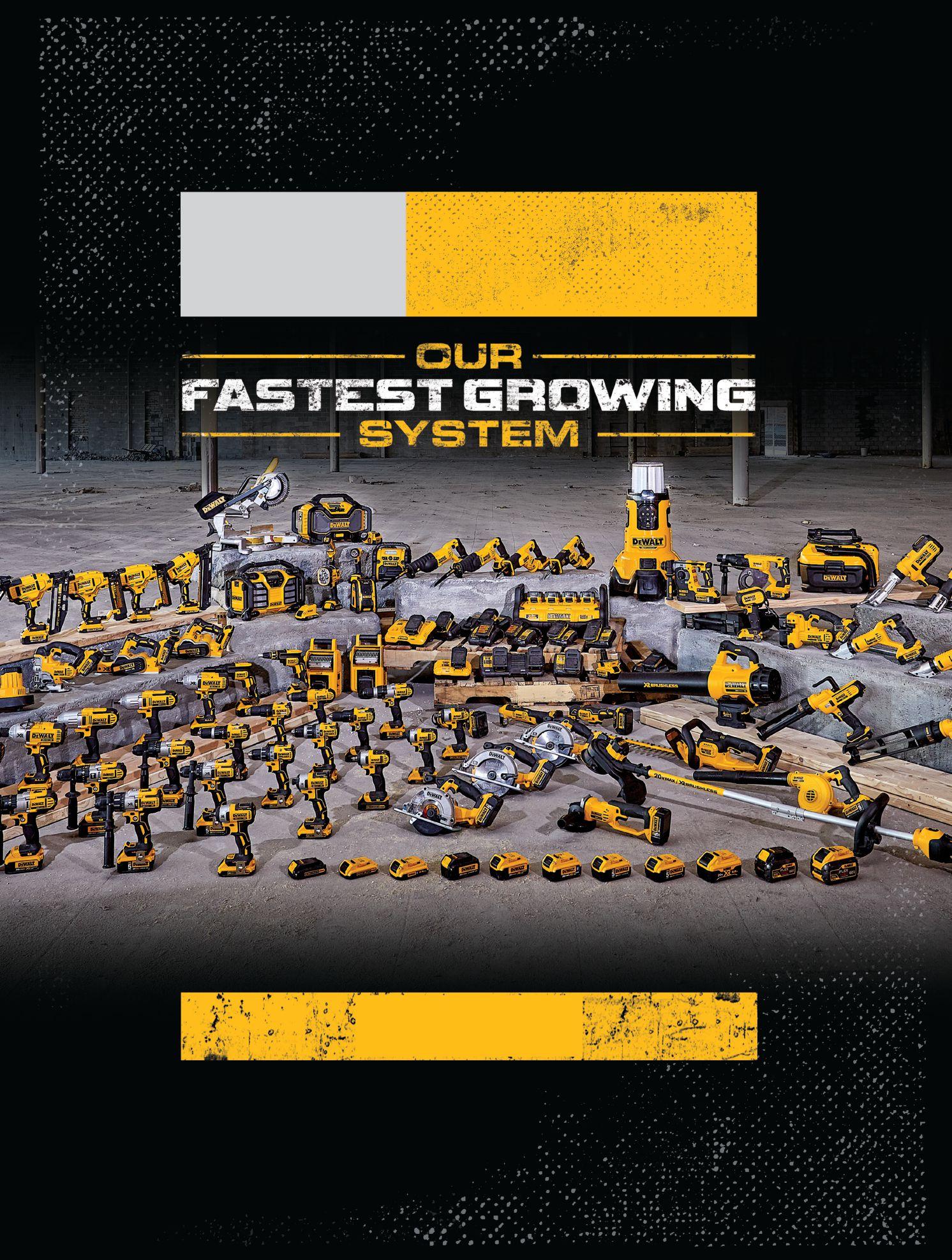

GET MORE DONE™** with 100+ PRODUCTS in the DEWALT 20V MAX* line. All tools come with upgraded features, superior ergonomics and use Lithium-Ion batteries. For extreme performance, step up to the XR® series and get advanced electronics, extended runtime and faster application speeds.

Afterrapid growth and incredible success throughout Quebec, RenoRun, a Canadian born smartphone application that delivers building materials to contractors on demand, has launched in the Greater Toronto Area. And the reception has been nothing short of game changing.

By putting an entire building material library of over 50,000 products into contractors’ smartphones, RenoRun ensures that they can order and receive last-minute materials within two hours. This same-day feature alone makes the application and service the first and only of its kind available to the construction industry. RenoRun charges the same prices as in-store and a fixed delivery fee.

“Empowering contractors” is what Eamonn O’Rourke, veteran contractor and CEO of RenoRun, considers the “DNA and driving force“ behind the service.

“We’ve been bowled over with the response we’ve received since opening our GTA location,“ O’Rourke said. “We have contractors wondering where we’ve been all their lives! It feels great to be having such a positive effect on these guys, and helping them with their efficiency.” There is free coffee for the entire crew included with every delivery, speaking to the brand’s relevance and understanding of their user base.

RenoRun does not disclose their numbers, but they did tell us that their GTA user base has been growing at nearly 1,000 per cent month over month since they launched in October. With more and more contractors leveraging mobile technology to conduct their business, the Toronto launch proved that there’s both a real need and a high demand for such a service in the industry. In fact, the introduction to the

Toronto construction community was so outstanding, that RenoRun has since tripled their initial delivery territory throughout the region due to overwhelming demand.

Satisfied customers throughout the GTA are already speaking out.

“RenoRun has changed the way we work,” said Alan Heron, Alan Heron Homes. “With their service, they allow us to keep key personnel on the job and alleviate costly trips to suppliers. RenoRun allows us to get our supplies in two hours and helps reduce impulse buys at the store. It also forces employees to stop and think about what they need for the job rather than making multiple trips daily to suppliers. Deliveries with a smile and free coffee! A great service long overdue.“

Due to the success of the GTA launch, RenoRun has turbocharged their expansion plans across the rest of Canada – and into the U.S. – slated for early this year.

For more information visit renorun.ca or download the free app on the Google Play Store or Apple App Store to join the construction revolution.

Create Exceptional Outdoor Living Spaces with Fast Driving, Code Approved Fasteners from GRK™

Frame with Ease and Confidence

Speedy Lag Bolt Alternative with Immense Drawing Power.

Smallest Head on the Market for a Clean Finish.

No Pre-Drilling. No Mushroom Effect. TREX SELECT® APPROVED

FASTER INSTALLATIONS- no pre-drilling. Innovative, patented features are specially designed to reduce torque and bite instantly for effortless fastening.

NO STRIPPING, NO SPLITTING, NO HEAD POPS- no wasted time on the job site. High tensile, torque and shear strength allow for immense drawing power out performing most other competitive fasteners.

BUILDING CODE APPROVED- for structural use in treated lumber. All GRK screws have been evaluated for structural and AC257 corrosion resistance to be in compliance with IBC/IRC specifications. That’s why all our fasteners come with a limited lifetime warranty, so you can rest assured your installations will withstand the test of time.

Energy Efficiency brand names for residential housing have proliferated in recent years. Here is a contractororiented guide to that alphabet soup of eco-building standards – from R-2000 to Net Zero Energy Ready – and everything in between.

By Paul Duffy

Are you confused by the proliferation of Energy Efficiency and Environmentally Appropriate housing labelling programs? You are not alone. The quickening pace of technical innovation, new materials and systems, along with code changes, and morphing consumer demands has left many builders wondering: “What’s next?”

Many builders, particularly the ones with more grey hair than not, remember early initiatives like the R-2000 program with their lofty predictions that “one day all houses will be built this way” or “one day this will be Code!” and find comfort in the fact that these predictions didn’t come true. Or did they?

While it is true that relatively few houses go through the formal process of labeling (unless there is some sort of government grant or utility incentive involved) many of the technical components of super energy efficient construction have become the norm, specifically:

• Higher levels of insulation

• Better windows

• More airtight construction

• Advanced/high efficiency mechanical systems

• Mechanical ventilation systems

You would be hard pressed to find any homes being built in Canada today without most, if not all, of these features. The exact

menu of preferred features varies by region and even within regions according to the availability of products or proximity to certain urban amenities and utilities. In most regions, builders on more rural sites are more likely to be pushing the envelope on “off the grid” type features.

If you are trying to lead the pack, or get out in front of innovations, where should you be focusing your energy? Here are a few things to consider.

Several provinces have taken to telegraphing where the Code is going in the years ahead so that builders can experiment and get ready for Code changes when they arrive.

• In Ontario, the last two Code cycles have not only included the new provisions pertaining to current requirements, but also how those requirements will change approximately five years from now. The Ontario Building Code (OBC) 2022 Code changes have already been released.

• British Columbia has produced its new “Step Code” containing no less than five incremental sets of requirements: steps on the path to greater energy efficiency. The notion is that a certain percentage of builders will choose to build homes above the basic level, with guidance from the Code

experts as to what constitutes the next step.

• In other provinces, the vision is more traditional—relying on known “brands” like R-2000 and Energy Star to set forth a package of requirements that goes above Code in what constitutes a step up from Code minimums driving new levels of energy efficiency. The evolution of technical standards for these programs has become a source of confusion for many builders. The technical standards for an Energy Star home are not the same in 2017 as they were back in 2010 or 2005. So as a consequence, the meaning of the label on the home becomes confusing.

Thus Code change, above-Code programs and labelling are frequently tied together. In fact, there are several places where various provincial Codes specifically mention some aspect of an above-Code program as a compliance alternative. For example, a registered R-2000 or Energy Star house might be deemed to comply with the energy provisions of the Code, etc.

Is this a problem? The short answer is that a lot of people are not sure. You might ask, if the government writes the code and the above-Code program was developed in conjunction with the government, what’s the problem?

THE FOLKS WHO WRITE THE BUILDING CODE ARE PRIMARILY RESPONSIBLE FOR PUBLIC SAFETY, WHILE THE FOLKS WHO DESIGN ENERGY PROGRAMS ARE PRIMARILY RESPONSIBLE FOR ENERGY POLICY.

Start by considering that the folks who write the Code are primarily responsible for public safety, while the folks who design energy programs are primarily responsible for energy policy, you begin to get some idea of where this alliance might take you in some weird, if not undesirable, directions. If the policy folks are pushing energy efficiency, why not require that all appliances in the home be energy efficient (say Energy Star labelled) appliances? When did it ever become the mandate of the Building Code to tell consumers what computer or kitchen appliances to buy? Sure, it makes the work of the policy people a lot easier, but is that really the role of the Building Code?

Then consider that many energy efficiency programs are delivered, not by the government, but by industry associations and even private delivery agents who carry out and are responsible for the work. It’s not difficult to imagine situations where the referenced program, and therefore the Code, would default to requiring contractors to be members of a particular trade association, buying group or contract with a particular supplier. Even the more liberal thinkers might have a problem with where this could go.

Who owns these programs?

Finally, there is the issue of who owns these programs and what are their motivations. Often people don’t realize when they are crossing the boundary from a government-run and -overseen program to a program driven by a private sector business plan with less transparent objectives. It’s worth noting that the names of some of these programs and labels are often very confusing, appearing at first to be aspirational — if not even noble objectives. But not always clear as to how these programs are run and where/how they derive their funding.

• R-2000 is a program developed by the federal government in conjunction with the Canadian Home Builders Association (CHBA). The feds provide some funding but the CHBA raises other revenues though fees to builders, consultants and others tied to the program. Membership in the CHBA is not a requirement but it is encouraged.

• The Energy Star program was originally developed by

OFTEN PEOPLE DON’T REALIZE WHEN THEY ARE CROSSING THE BOUNDARY FROM A GOVERNMENT RUN AND OVERSEEN PROGRAM TO A PROGRAM DRIVEN BY A PRIVATE SECTOR BUSINESS PLAN WITH LESS TRANSPARENT OBJECTIVES.

the Department of Energy (DOE) in the US. The federal government licensed use of the name and technical requirements of the program and in turn negotiated regional delivery arrangements with “service organizations” across the country. Some are industry associations, others are private companies. There are also arrangements with utilities and others to promote energy efficiency goals under the Energy Star banner. The Energy Star label is used to describe a variety of products that go beyond houses, including so-called “white good” appliances, consumer electronics and other energy consuming products. Each product category is its own program with different financial arrangements and delivery mechanisms.

• The LEED program is one developed by the Canadian Green Building Council, a private organization of stakeholders with interests in energy efficient / green construction. It is selffunded through fees, sponsorships and training revenues.

• The Net Zero Energy Program was developed by the Net Zero Energy Coalition and the Canadian Home Builders Association. The program receives major funding from several major sponsors with specific interests in promoting their products and/or their proprietary technologies.

• There are a number of smaller programs with links to regional associates and private interests. These include Built Green, Green Globes, and other programs keying on words like Green or Environmental to describe attributes they seek to highlight.

It comes as a surprise to many people that words like Green Building, Net-Zero, LEED or even R-2000 are labels that might

have proprietary owners, private sponsors and even copyright protection.

The fact that something might have a proprietary owner, private funding or non-governmental affiliations doesn’t make it a bad thing. What is problematic is when this is not clear, not transparent, and not subject to the same kind of scrutiny we give all private sector claims. The key is disclosure. And when the disclosure is less than well known, the operating assumption has to be buyer beware.

Most home builders are small businesses with limited marketing and name recognition in their markets. The idea of piggybacking their brand on a better known brand or label holds significant appeal. I have heard of several builders who adopt the attitude of building their brand on the credibility of major suppliers, utilities, mechanical suppliers, door and window companies, insulation companies, etc. Their advertising is reminiscent of what I like to call the NASCAR approach—labels and logos scattered liberally across the page in the belief that somehow this builds name recognition or credibility for their brand.

Others focus on one or two key features, unique or premium features in their market, to underscore their commitment to quality. In today’s market, that might be something related to high tech electronics, an indoor air quality package, or something unique like spray foam insulation to set them apart.

Consequently, an energy label — a label adding third-party credibility to the unique product they are building — might have applicability and usefulness to both approaches. But are any of these labels going to dominate, particularly in the medium to longer term? That is difficult to answer. The pace of Code change is becoming too rapid to predict with any degree of certainty; so programs that are above code are even more difficult to forecast. This is leading some builders to question the value of a label.

Others are questioning the value of energy programs. At the core of several rating programs is an underlying bias against fossil

fuels and a bias towards electrical fuel sources. The reasons for the bias are varied, but they often relate to the belief that electrical energy can come from “non-polluting” or green sources. However, the dollar cost of “green” electricity is quite high. So, while energy savings might be achieved, cost savings are not. It is difficult to justify energy efficiency if the investments in energy measures aren’t at least partially off-set by cost savings.

A growing trend is simply energy rating buildings without necessarily opting into any energy efficiency program. This avoids paying fees for labels, listings, and other services that are difficult to assess in terms of added value.

In the U.S., where the housing market is even more fragmented than in Canada, there are many more labeling programs available for builders to pick and choose. Faced with a virtual smorgasbord of choices for labeling their houses, the Leading Builders of America (LBA), a group comprised of the top 100 builders in terms of numbers of houses built, have opted to energy rate all their houses. The LBA claims to represent the builders building 80 per cent of the new houses built in the U.S.

In the U.S., the rating scheme of choice is the Home Energy Rating Scale or “HERS” scale for short. Every point on the scale represents a one percentage point change in energy consumption relative to a home built to the 2006 Building Code. Move from HERS 100 to HERS 80 and that represents a 20 per cent saving in energy. HERS 0 aligns with zero net energy consumption.

The rationale for rating your houses is simple; the prescriptive measures in the Code add numerous costs that are not necessarily justified on any particular house in terms of the energy saved. By measuring performance, you naturally focus on measures that deliver the most savings per dollar spent and you logically end up with a more cost-effective, energy-efficient home for your specific site.

In the U.S., the rating scheme is HERS. In Canada, the scheme could just as easily be based on EnerGuide ratings, or fuel savings. Michael White, president of RGL Building Consultants, an energy rater who has done thousands of home ratings for the EcoEnergy Program as well as for Energy Star compliance, estimates that in the near future the majority of his clients will be rating their houses specifically for Code compliance, not

AT

for participation in any energy program. Michael’s team uses Hot2000 software (used for the EnerGuide scale) specifically for this purpose.

John Godden, president of Clearsphere consultants, has gone in a different direction. His team has pioneered using the HERS scale in Canada. He indicates that his client list includes many of the major builders in the Greater Toronto Area, and they are all seeing the need for and benefits of rating their houses for Code compliance regardless of whether they ever receive a label relative to a specific energy program. He points out that, for the last two Code revision cycles, the Ontario Building Code has specifically recognized the HERS software, specifically programs like RemRate and Energy Gauge, to evaluate code compliance.

Both Godden and White are active in CRESNET, a nonprofit organization aimed at professionalizing and promoting the benefits and skills required to rate houses. While energy programs, home labels and government grants come and go, the skills and tools required to rate houses remain constant and continue to grow. CRESNET promotes training and accreditation related to:

• Computer modeling

• Air tightness testing

• Inspection skills and tools

The world of energy programs may look like it is not going to get sorted out any time soon, but my guess is that the business of rating house performance as a basis for implementing costeffective energy efficiency is only going to grow. So, too, the need for skilled evaluators and raters, to carry out those assessments, will become an important part of house design and quality control.

Paul Duffy is Vice President of Engineering for Icynene.

Have you got a prospective new build customer going gaga over solar? Here are some important questions to consider.

By John Bleasby

Ifyou’re like most contractors – especially if you’re a custom homebuilder – you will have noticed that solar power comes up more and more frequently in your conversations with clients. With skyrocketing electricity prices in some regions of Canada, new building standards such as Net Zero Energy Ready (NZEr), and a growing environmental consciousness among the public overall, solar is definitely getting more media attention than ever before. Plus, the cost of solar panels has dropped substantially. So, go ahead, right? Not so fast! Here are some commonly asked questions about solar, and brief answers that contractors should be able to relay to clients.

1. Why is solar all the rage these days?

Canada’s commitment to move toward a Net Zero Energy Ready building code by 2030 has definitely juiced up the residential solar power industry. NZEr will take insulation of the building envelope well beyond the current code. The tightness of the resultant building envelope will also mean increased attention paid to interior air quality (IAQ). However, what about the final leg of the journey beyond mere ‘NZE-ready’ to energy self-sufficiency? Momentum seems to have swung towards photovoltaic arrays (PV arrays) mounted on the roof as the system of choice. Solar generated electricity has strong appeal. It can be

co-joined in a net-metering program where available, stored in batteries to meet household plug demands, or used to drive nonfossil heating systems for living space and water.

2. At what stage should a rooftop solar installation be considered?

Solar PV arrays are expensive and have a 25-year life expectancy, making their installation a major commitment. Planning should begin as early as possible. Optimal performance from a solar installation requires orientation of the house and its roof surfaces for maximum exposure to the sun. The home’s location on the site plan, roof slopes and configurations and potential shading from trees or adjacent buildings are all best addressed as early as possible.

3. What are the structural issues?

Builders should take a look at Natural Resources Canada’s forthcoming Photovoltaic (PV) Ready Guidelines which expand on the existing Solar Ready Guidelines. The new PV Ready Guidelines focus on the photovoltaic-related builder considerations in preparing new high-performance homes for the addition of large solar PV arrays. “To assist with making new homes ready for solar PV installations, we have identified design and loading

considerations that carry over from the existing Solar Ready Guidelines and focus on aspects that are unique to large surface area PV arrays,” said Jeremy Sager, Housing Team Project Officer at NRCan’s CanmetENERGY office in Ottawa. For example, the additional weight of PV arrays as well as associated wind and snow loads should be considered in the truss design. NRCan’s PV Ready Guidelines , while limited in design input, will suggest a “design dead load” of an additional 0.17kPa (3.5psf) for solar PV arrays and mounting hardware, down from the 0.24kPa (5 psf) recommended in the current Solar Ready Guidelines. Other references are made to the National Building Code’s Structural Commentaries.

The PV Ready Guidelines also make reference to, for example, array layouts that have been highlighted by the CSA to allow roof access and pathways related to the firefighting needs of different roof types. The pathway best practices may mean that earlier installations that covered every square foot of roof surface would become a thing of the past.

Beyond that, builders can make use of the Truss Plate Institute of Canada’s (TPIC) Technical Bulletin No 7, which contains detailed specifications for designers, builders and installers. The bottom line: it is highly recommended that builders advise truss manufacturers at the engineering phase if a solar installation is being considered.

Snow loads vary due to historic snowfall levels in different geographical locations. Theoretically, a steep roof should shed more snow than a shallow or flat roof. It is also suggested that snow sheds more easily from solar panels than from a shingled roof. Nevertheless, snow can be trapped above and under the panels on any roof. Although the TPIC says panels should not be mounted more than four inches above the roof surface, recurrent melting and freezing could impact on both loading and on the watertight integrity of the roof itself because of ice damming risks. Wind loading can be an issue, too. Depending on prevailing winds and roofline, there can actually be a lift factor that needs to be taken into consideration.

5. What roofing materials should be used underneath the arrays?

Many retrofit solar installations are installed on top of existing asphalt shingles. This can present a conflict between expected lifespans; solar arrays have an effective lifespan of about 25 years, longer than many popular roofing materials. Given the expense of removing an array to repair or replace a roof, it makes sense to consider replacing the roof with a material with a similar lifespan before installing the PV arrays. Many experts suggest steel roofing — some brands are warranteed for as long as 45 years. PV arrays and steel roofs also partner well due to the availability of puncture-free clamp-on brackets.

Homeowners should also talk to their insurance agents. There is no universal treatment of solar arrays within the home insurance industry. However, not advising your insurer about a rooftop solar installation could result in difficulties if a roofrelated claim arises.

6. How should a builder deal with the installation itself?

It’s a bit scary when IKEA starts selling solar PV array systems, as they have in the UK. Solar array systems are not DIY projects — they require design, engineering and installation by specialists.

Partnering with a reputable solar installer is vital. A licensed electrician also needs to be closely involved — some installers include that service, too. Conduits leading high voltage lines to control panels and shutoffs must meet electrical authority specifications. Depending on the contract with your client, these solar installation specialty services can be either part of a total turnkey offering or set aside separately. However, Reiner Hoyer, a former contractor who now coaches others, offers words of caution: “When you recommend someone outside to join the project and everyone’s happy, great. But the minute something goes wrong, it’s the contractor’s problem. You are taking on extra liability and responsibility.”

7. What about Return on Investment (ROI)? Can a PV solar array pay for itself through a net metering program?

The financial model for residential solar is evolving, and quickly. While most provinces have a net metering program for residential solar installations, they vary by region and they are constantly in flux. Many exchange kilowatt hours put into the grid with those taken from it. However, some won’t allow any positive balance to be carried forward into the next year. Other programs offer a year-end payment for excess power put into the grid. Integrating residential solar power into local power grids isn’t always assured, either. It’s important to check the programs available in your area.

The specific financial implications of any given installation need to be thoroughly analyzed. Software such as the PVWatts Calculator, developed by the US. Department of Energy (available on-line), allows architects, system designers, and even homeowner themselves, to estimate the energy production potential of a PV array for their roof, given its size and specific geographic location. The reports the software generates can form the basis of further detailed ROI analysis. (Canadian Contractor has done just that, using this author’s own home. Go to our web site at canadiancontractor.ca to read our findings under various financial scenarios.)

Needless to say, government subsidies significantly impact the ROI of residential solar installations. Installation grants in tandem with attractive net metering programs had been a huge boost to the solar industry until recently. However, most provincial grant programs are dormant now. One exception is oilrich Alberta which, last August, announced 30 per cent rebates up to $10,000 for new residential installations. But currently,

in most areas of the country, homeowners must bear the full costof solar panel installation. The result has been that, without the generous incentives of the past and a ticket price between $25,000 and $30,000 for a professionally-installed 11 kWh system, the residential solar industry is experiencing a slowdown as homeowners balk at the expense.

9. What about these Tesla solar tiles I keep reading about?

Solar PV arrays if seen from the street do not add curbside appeal. That’s why so many people are buzzing over solar roof tiles — with the photon-gathering cells under coloured glass shingles, they look like normal roofs. In fact, Tesla’s solar roof tiles have been so well-received by consumers that the company has received millions of dollars in advanced deposits. However, important questions concerning Tesla’s tiles remain largely unanswered. “When will they be available?” (No one knows for sure, but not in Canada until at least 2019). “How much will they cost?” (A lot, roughly twice the cost of a PV array, based on latest estimates). “How are they installed?”(According to Tesla’s patent application an entirely new roof underdeck is required, so they are not an easy retrofit item.) There is also a question of efficiency — Tesla’s photon efficiency is at best only 75 per cent of standard PV arrays. Furthermore, while Tesla may be the first to bring solar tiles to market, they won’t have the market to themselves for long; competitive products are already in the works.

10. I hear a lot about power storage batteries. What’s that all about?

Power storage units are being marketed today as part of a residential power management system beyond the storage of solar-generated power and as emergency back-up. For example, in provinces that offer discounted time-of-day pricing, power can be downloaded from the grid during off-peak hours for use during high-peak times, making it possible to reduce overall electricity

costs. However, at issue is investment cost versus potential savings over time. Battery systems currently cost between $6,000 and $10,000 for a fridge-sized household unit capable of storing between 9.8kWh to 14kWh. However, with a warranteed lifespan of 10 years, the ROI is questionable. Prices will drop over time and life spans may improve, but at present can enough money be saved to justify the expense?

There’s a massive surplus of electricity being generated globally from all sources, driving wholesale prices down. At an auction in December 2017, Alberta procured future power contracts from new wind farm projects at a weighted average price of 3.7 cents per kWh. Prices are even lower in other parts of the world. Those bargain rates haven’t worked themselves down to consumers, not yet anyway. However, the ever-upward price assumption for electricity off the grid may be incorrect. This squeezes the ROI model for individual residential solar systems even further. Concurrently, the cost-per-watt efficiency for electricity produced by solar panels is improving dramatically and will improve even more over the next few years, by as much as two-fold by 2020 according to a recent McKinsey & Company report. Yet many pundits believe the future lies in neighborhood solar farms rather than stand-alone individual solar systems on rooftops due to optimized orientation and economies of scale. It’s a tug-of-war in many directions at once.

Small scale solar installations on residential homes are complex and expensive projects. Costs are high; subsidies have dropped off; ROI is uncertain. It’s important for your customers to review their motivations to install solar in the first place. Are

they interested for environmental or financial reasons? If it’s to address their personal environmental consciousness and reduce the burning of carbon fuels, there’s no reason to wait. However, if it’s to save on current energy costs and potentially enjoy a positive ROI over the life of the system, a close examination of the financial implications must be made.

No matter what, the Canadian residential construction industry is being directed towards a NZE-ready future by government mandate. At issue is how stand-alone residential solar solves the energy generation portion of the NZE equation. Given the speed of innovation, the sun may indeed be rising on solar power’s potential, but its shape in 15 years when NZE-ready building codes are a reality is not yet clear.

Lindsay Haley is in the vanguard of young residential contractors who are constantly pushing to improve their business models. “We are looking for a seamless process,” he says. “If the process is broken, product quality will broken, too. We want our process to be second to none.”

By John Bleasby

Lindsay Haley established Precision Contracting in Brockville, Ontario 13 years ago. He is one of a new breed of residential contractors who are successfully integrating design-build into their business models. At 36, Haley is energetic, ambitious, and continually thinking of ways to improve both his business processes and his clients’ project experience.

Key to Haley’s forward planning is the recent purchase of a 15,000 square foot building. It’s a major departure from the 1,500 square foot rented facility where he and his wife Jenn previously operated the 10-employee firm. It’s been a catalyst for the evolution and expansion of the firm.

“What this building has allowed us to do over the past six

BEING A MEMBER OF THE NEXT LEVEL PEER GROUP ALLOWS ME TO BOUNCE MY IDEAS OFF OTHERS WHO ARE IN SIMILAR SITUATIONS. HAVING SUPPORT FROM A GROUP OF PEER ADVISORS IN MY BACK POCKET IS A POWERFUL THING.”

months couldn’t have been imagined before,” says Haley. “The design and build aspect has really come to life. For example, we can now bring our customers together with our engineers and designers in private meeting rooms with TVs on the walls. We can bring up products and go over design aspects. We never had this before.” This important interaction is also acting as a springboard to take on larger and more complex contracting projects, while at the same time never forgetting the smaller remodelling work that brought Haley’s company to this stage.

“My vision for this company is to be a full service building and remodelling company,” Haley explains. “We have a process, and we want our customers to know what to expect from that process.” New real time project management software will play a key role as projects move forward, integrating customers 24/7 with the project management team and office staff. Even if out of town, clients can use their mobile devices to see what’s happening in real time, and to send messages and requests.

“What we want to do is bring everyone together from start to finish in a seamless process. Client stress comes out of the process itself; if the process is broken, product quality will be

broken, too,” says Haley. “We want our clients to know that our process is second to none, which in turns means the overall quality of our product is second to none.”

Branding plays an important role going forward. A new corporate logo was introduced two years ago, and a new website and Facebook presence was introduced last year. Haley also recently produced what he calls a comprehensive What To Expect package. “It explains to clients how we’re going to take them on this new journey. We are very excited about it.”

Haley’s ambitions and progress have been cultured to a great degree by his commitment to the NextLevel coaching and peer mentoring program introduced by Canadian Contractor two years ago. A group of eight contractors meet regularly in person and via conference call, combing through every aspect of each firm’s operations – right down to their balance sheets and profit and loss statements for each job. Each contractor has, through this peer group, a virtual Board of Directors to monitor each aspect of their operations. “It’s allowed me to bounce my ideas off others who are in similar situations,” says Haley. “Having support from a group of peer advisors in my back pocket is a powerful thing.”

Given the seasonality of the homebuilding and renovations industry, ending your fiscal year on December 31 may not be the best decision.

By Mahyar K. Hansotia

Choosing a year-end for your corporation is something that should be considered carefully – and strategically. Many business owners choose a calendar year-end due to its simplicity, and because it’s the general standard. But depending on the circumstances, many businesses are able to shift their fiscal year end so that it doesn’t fall on Dec. 31.

And whether you’re an entrepreneur who has incorporated a small business or the head of a large company, there are number of advantages to choosing a non-calendar fiscal year-end, not only when it comes to paying taxes.

In Canada, whether or not you can adopt or change your fiscal year end depends on the structure of your business. A corporation’s fiscal year is established when the first corporate tax return is filed. With few exceptions, you’ll need permission from the CRA to make the change, which may be approved for “sound business reasons.” Incorporating a new company is the ideal time to think about which year-end will be most beneficial for you, taking the following factors into consideration:

Each business usually has a period during which it's particularly busy. By coinciding the fiscal year with the end of your busy season, or during your slow period, you’ll benefit from the quiet time to ensure all receivables have been collected, the books are closed and, if you have inventory, you’ll have much less to count. This will also better match up income and expenses to help offset taxes, a tricky situation that contractors often experience depending on which reporting method they use. While contractors are usually busiest during the summer, many also offer other seasonal services to stay busy during the winter months such as snow removal, energy efficiency services or indoor remodeling. In this case, having a fiscal year end in February or March may be helpful.

Many businesses often create multiple corporations for tax and legal purposes. Having a different fiscal year-end for each may

make sense based on the business type and seasonality, and will also alleviate a timing crunch after the year end when all financials must be reported. For example, if you create a company on June 1, 2017, you can have a year-end of May 31, 2018. Corporate taxes are due within a couple of months, and the tax return, which must be filed within six months, would be due by November.

When it comes to declaring bonuses for you and your employees, having a year-end from July onwards can help postpone personal income tax to the following year, while accruing the immediate benefit of reducing the corporate tax paid in the current year. For example, an August year end will allow a corporation to claim a deduction for bonuses accrued and save corporate taxes. Since bonuses can be paid up to six months after year-end, say the following February, the bonus will not be taxed for the individual until it is received the following year.

As with any seasonal business, there is demand and supply, and resources are often stretched. Material will usually cost more,

and be in short supply, or quality contractors harder to find, when everyone is clamoring to get their renovations done all at the same time. Between personal income tax and corporate tax returns, accountants are notoriously busy due to the various deadlines from February to June for both personal and corporate filings. Being off-step with the majority will mean better planning opportunities, more personal attention and quicker turnaround. A September year-end, for example, will allow time to assess your financial situation and be able to better incorporate any tax planning, including the declaration of any bonuses or dividends, and the filing of any T4/T5 slips by the required deadline.

Given that every business owner’s situation is unique, it’s a good idea to consult your legal advisors and accountant to help determine the best structure for your business – as well as a yearend that provides the greatest advantages.

Sobel and Company, Professional Corporation is focused on business owners of small- to mid-sized companies, as well as large corporations, who are looking for financial acumen and strategic business expertise over and above traditional chartered professional accountant services. Contact Mahyar Hansotia at mahyar@sobelandco.com.

Winnipeg, Manitoba

Architect: Cohlmeyer Architecture Limited (Stephen Cohlmeyer)

Contractor: Winnipeg Building & Decorating Ltd. (Don and Glenn MacAngus)

Urbanresidential density, infill housing, laneway and garden suites. While these terms are now part of everyday residential construction conversation, they are not recent concepts; maintaining neighborhood character while maximizing valuable urban land were talking points back in the 1980’s.

“As a young architect, those discussions were in my world and in the wind already,” recalls Winnipeg architect Stephen Cohlmeyer. As proof stands Cohlmeyer’s striking 1986 single family home design in Winnipeg’s River Heights. It’s a 1,900 sq. ft., free-flowing family home located on what was considered an unbuildable sliver of land within a mature residential and commercial area. The lot had been purchased in 1985 by Glenn MacAngus, son of Cohlmeyer’s office landlord, for a mere $3,000. “Make it buildable, something people will notice. That was our assignment,” Cohlmeyer says. Glenn and his father, Don, both contractors, would construct the house. Research revealed the lot had been ‘platted’ (a surveying term) in 1910. Since it had never been owned by any neighboring property owner, city covenants assured the right to build, no matter what zoning regulations were in place. “Once we had established the right to build, we obeyed the zoning regulations in terms of setbacks and heights,” says Cohlmeyer, while acknowledging that the design went to the absolute allowable limits.

While the building is only 13’-9” wide and technically fronts on a quiet residential street, it has a massive 80 foot exposed side including the attached garage, facing south onto what Cohlmeyer describes as a commercial village street. Exposure to Winnipeg’s intense year-round sun was a challenge from the standpoints of both design and materials. “The heat gain in summer would have been a killer if we had put a lot of glass on that southern face. We

kept it modest but there’s still a fair bit,” he says, which allows an abundance of natural light to radiate into the home throughout the full arch of the day.

With the benefit of 30 year hindsight, Cohlmeyer acknowledges a few things he might change today and many others that would stay just the same. In terms of space utilization and flow, he remains pleased. “I would design it again. What I’ve learned over the intervening years is it is nice to have different ways to move around a house — different spaces and ways to experience them.”

The living space is divided into five levels, which avoids major stairwells. The open tread stairs enhance the home’s room-to-room flow. “The movement through the house is pretty relaxed. We designed with the assumption of family potential. Kids can zip all over the place. In fact, over the bedrooms on the intermediate upper level is a big interior roof with a ladder leading to a play area with a round window.” And at nearly 13 feet clear across, the rooms are surprisingly spacious. A large rear deck over the laneway-access garage allows private entertainment outdoors.

The original cedar lap strake siding was double-coated with solid oil stained on both sides prior to installation, and has required refinishing only once in 30 years.

However, building technology has evolved since the 1980’s. The 2x6 exterior framing and batt insulation is consistent with much of today’s construction. However, continuous exterior insulation and air space between the cedar lap strake siding and the plywood sheeting underneath, and improved ventilation techniques in restricted attic spaces,

were not part of the 1980’s residential construction mainstream. “Heat gain as well as heat loss would be an issue to explore on such a sunny lot,” Cohlmeyer adds. “I think we would look more aggressively at passive solar techniques, in the hope that we could reverse things.” At the same time, many elements of the home were leading edge for the time.

The double-glazed windows were early versions of designs using low heattransferring materials as space bars between the glass layers — a feature seen in so-called ‘Smart Windows’ today. Batt insulation in the walls was R20, and R40 under the roof. Solid hardwood and ceramic tile flooring were selected, not the wall-to-wall broadloom popular in the day. While plain by today’s standards, the rectangular natural wood trim is extensive, adding warmth to the clean interior lines of the home.

Heating and ventilation systems are more sophisticated today as well. There were no HRV systems in the 1980s; heating was traditional forced air natural gas, with central air conditioning added for warm weather

comfort. As basic as that system sounds by current standards, Cohlmeyer says it was effective, never too hot or too cold on any particular level during the year. At the same time, the gang-nailed, parallel chord pre-engineered trusses were used for the floor and roof structure allowed ducting to pass through, thus eliminating the need for bulkheads, a feature preferred in modern homes today. Thirty years on, the house passes the test of time in more ways than just its striking appearance. The house still remains in the MacAngus family. Glenn and his wife moved in after construction, lived there for 10 years, and rented it out until recently. It is now undergoing interior décor updating, waiting for Glenn’s brother and family to move in.

You always want “the right tool for the job,” and that includes one of a contractor’s most important tools, the work vehicle. It can be hard to choose with so many on the market, but that also gives you a wide range of sizes, engines, features and capacity so you can find the one that’s best for you.

Full-size trucks may seem like an obvious choice, but if you do a lot of light-duty jobs, you may also want to consider adding a midsize to your fleet. This year, we’ve also included full-size and compact cargo vans as well. Here’s what’s available for the 2018 model year.

By Jil McIntosh

Ford gives its F-150 a makeover for 2018, including an all-new 2.7-litre turbocharged engine, new front-end styling, and a maximum 13,200-lb. towing capacity.

The F-150 is available in Regular Cab, SuperCab or SuperCrew, each with two box lengths. Engine choices are a 3.3-litre V6; 2.7-litre EcoBoost V6 making 400 lb.-ft. of torque; two versions of a 3.5-litre EcoBoost V6 making 470 or 510 lb.-ft. of torque; and a 5.0-litre V8 making 400 lb.-ft. All use a ten-speed automatic transmission.

Later in the model year, the F-150 will also be offered with a 3.0-litre Power Stroke V6 diesel engine.

Available features on F-150 include blind spot monitoring that accounts for a trailer, 360-degree camera, and lane-keeping assist. Maximum payload tops out at 3,270 lbs.

Redesigned with an aluminum body for 2017, the Super Duty comes as the threequarter-ton F-250; one-ton F-350 with single or dual wheels; and 1.5-ton F-450. Two engines are available: a 6.2-litre V8 making 430 lb.-ft. of torque, or 6.7-litre Power Stroke turbodiesel with 925 lb.-ft. of torque. The Super Duty can tow a maximum 21,000 lbs. conventional, and 27,500 lbs. with fifth-wheel.

Ford offers two work vans. The full-size Transit comes in 150, 250, 350, and 350 HeavyDuty, in three lengths and three roof heights. Engine choices are a 3.7-litre V6, 3.5-litre EcoBoost V6, or 3.2-litre Power Stroke five-cylinder diesel. The E-Series Econoline van, which the Transit replaces, is being phased out and is only sold as a cutaway or chassis cab.

The compact Transit Connect Cargo Van uses a 2.5-litre four-cylinder engine with sixspeed automatic transmission. Its maximum payload is 1,610 lbs., and it offers up to 4,219 litres (149 cu.ft.) of storage space.

Almost all of General Motors’ work vehicles are available as either Chevrolet or GMC models. They’re mechanically identical but have slightly different styling, and the list of features in each trim level varies by brand.

The full-size Chevrolet Silverado and GMC Sierra are mostly unchanged from 2017. All models now receive a standard rearview camera, and the tire pressure monitoring system has a “fill alert” to indicate you’ve added enough air to a tire. The eAssist option, a mild hybrid system that provides an electric power boost to the gasoline engine, is available across the country following its earlier, limited introduction.

Both brands come in Regular, Double or Crew Cab, with a 4.3-litre V6; 5.3-litre V8 making 383 lb.-ft. of torque; or 6.2-L V8 at 460 lb.-ft. All engines have cylinder deactivation for fuel efficiency. Maximum towing capacity is 12,500 lbs.

Heavy-duty models come in 2500 or 3500 configuration, with a 6.0-litre V8 making 380 lb.ft. of torque, or 6.6-litre Duramax V8 diesel at 910 lb.-ft. Maximum towing capacity is 20,000 lbs. conventional, and 23,300 lbs. for fifth-wheel.

Midsize truck models are the Chevrolet Colorado and GMC Canyon, with 2.5-litre fourcylinder, 3.6-litre V6, or 2.8-litre four-cylinder turbodiesel, which makes 369 lb.-ft. of torque. Maximum towing capacity is 7,700 lbs., while payload tops out at 1,574 lbs.

The company’s full-size work van comes as the Chevrolet Express or GMC Savana. Available in 2500 configuration, it uses a 4.8-litre V8, 6.0-litre V8, or 2.8-litre four-cylinder Duramax diesel that makes 369 lb.-ft. of torque. It can tow up to 10,000 lbs., with a 4,192-lb. maximum payload.

Chevrolet also offers a compact van, the City Express, which is a rebadged version of Nissan’s NV200. It uses a 2.0-litre four-cylinder engine, with a top payload of 1,500 lbs.

Designed primarily for consumers, Honda’s SUV-based pickup could be a good choice as a light-duty fleet addition, such as for service calls. It uses a 3.5-litre V6 making 280 horsepower, with a front-biased all-wheeldrive system that sends torque to the rear wheels as needed.

The Ridgeline can tow a maximum of 5,000 lbs., with top payload of 1,570 lbs. Its bed is made of non-corrosive composite material and includes a locking trunk under it, while its tailgate opens both conventionally or sideways like a door, making it easy to access the load. The interior also contains considerable storage space, and the rear seats are on folding legs so that items can be placed under them while passengers sit up top.

The German automaker offers two vans, both of them available in cargo configuration, for those who prefer an alternative to a pickup truck. New for 2018, all Mercedes-Benz cargo vans include a standard rearview camera.

The Sprinter, which was the first European-style work van to come to Canada, comes in 2500 and 3500 ratings, both in two wheelbases and three body lengths. The 2500 offers standard and high roof heights, while the 3500 comes in high roof or super-high roof. All models use a 3.0-litre diesel engine making 325 lb-ft. of torque, with a five-speed automatic transmission. Unique among current work vans, the Sprinter can also be ordered with four-wheel drive.

The Metris is sized halfway between a compact and fullsize. With an overall height of 189 cm (74.4 inches), it’ll fit into underground garages where taller vans might not fit, along with a tight turning radius. It uses a turbocharged 2.0-litre gasoline engine with seven-speed automatic transmission, making 208 horsepower and 258 lb-ft of torque.

Nissan’s commercial offerings are virtually changed for 2018, save for some minor trim tweaks.

The largest pickup is the Titan XD, which Nissan says “spans the gap” between half- and three-quarter-ton trucks. It’s rated at a maximum 12,038-lb towing capacity, and while some half-tons can tow more, the XD handles it easily and could be a better choice for consistent towing near the limit. The XD uses a 5.6-litre V8 making 401 lb-ft. of torque, or 5.0-litre Cummins V8 diesel, rated at 555 lb-ft.

The Titan half-ton also uses the 5.6-litre V8, rated here at 390 horsepower and 394 lb-ft. of torque. It offers a maximum towing capacity of 9,220 lbs., and payload of 1,610 lbs. Both the Titan and Titan XD come in Single Cab, in 4x2 or 4x4, or

as a Crew Cab in 4x4 only, and both are covered bumperto-bumper for 5 years/160,000 km.

Nissan also offers the midsize Frontier pickup, with 2.5litre four-cylinder or 4.0-litre V6 engine, and a maximum towing capacity of 6,700 lbs. It’s available as a King (extended) Cab with standard bed and in two- or fourwheel drive, or Crew Cab in two bed lengths, and in 4x4 only.

Two vans are available. The full-size NV uses a 4.0litre V6 or 5.6-litre V8 and comes in 1500, 2500 or 3500 configuration, with standard or high roof, and a maximum payload of 3,890 lbs. The compact NV200 uses a 2.0-litre four-cylinder engine, with a top payload of 1,480 lbs.

Offering its 1500 half-ton pickup, and the heavy-duty 2500 and 3500 models, Ram is largely unchanged for 2018. There are new topline Limited Tungsten Edition trim levels, new connectivity with a WiFi hotspot, and a remote switch in the bed to turn on the LED box lights.

The Ram 1500 comes in Regular, Quad and Crew Cab with three bed lengths, while HD models are Regular, Crew or Mega Cab, in two bed lengths. All trucks come in 2WD or 4WD.

Engine choices in the 1500 are a 3.6-litre V6; 5.7-litre Hemi V8; or 3.0-litre V6 EcoDiesel, making 420 lb-ft of torque. Both the 2500 and 3500 use the 5.7-litre V8; a 6.4-litre Hemi V8; or 6.7-litre Cummins inline six-cylinder diesel. The Cummins diesel can be ordered with a manual transmission if desired. Depending on the truck and transmission, the diesel makes between 660 to 930 lb-ft. of torque. Maximum towing for the Ram 3500 tops out at 31,210 lbs.

Available features on certain models include locking bedside RamBox storage boxes, a fold-out flat rear floor, and four-corner or rear-levelling air suspension, although its weight cuts into the payload.

Ram also offers two vans, the full-size ProMaster and compact

ProMaster City. The ProMaster comes in 1500, 2500 and 3500 configuration, with three wheelbases and two roof heights, along with chassis cab or cutaway. It’s the only full-size with front-wheel drive, which gives it a low step-in and floor height, and its square styling maximizes cargo space. A backup camera is standard. Engine choices are a 3.6-litre V6 or 3.0-litre inline four-cylinder EcoDiesel.

The compact ProMaster City is also front-wheel drive and uses a 2.4-litre four-cylinder with nine-speed automatic. Maximum payload is 1,901 lbs.

Toyota makes a few trim changes to its full-size Tundra for 2018. All models now come with the company’s Safety Sense-P, which includes adaptive cruise control, lane departure alert with steering assist, automatic high-beam headlamps, and pre-collision braking with pedestrian detection. There’s also a new grille and headlamp design, LED daytime running lights on all models, and a TRD Sport Package edition.

The Tundra comes in Regular or Double Cab in two- or four-wheel drive, and as the CrewMax in 4x4 only. The 4x4 Double Cab offers a 4.6-litre V8 making 310 horsepower and 327 lb-ft. of torque, while all other models use a 5.7litre V8, rated at 381 horsepower and 401 lb-ft of torque.

Towing capacity ranges from 6,493 to 10,196 lbs in 4x4 configuration, and with a maximum payload of 1,710 lbs.

Standard features on all trim levels include a rearview camera, touch-panel audio, locking tailgate, heated mirrors, and manual-levelling headlights.

Toyota’s smaller Tacoma pickup also gains the Safety Sense-P program on all models. Available in Access Cab in 4x2 or 4x4, or as the Double Cab in 4x4, the Tacoma comes with a 2.7-litre four-cylinder or 3.5-litre V6, depending on trim and configuration. While primarily considered a consumer truck, its smaller size may work for several applications.

FLEXVOLT Cordless Air Compressor

Page 48

MILWAUKEE

M18 FUEL

Cordless Mitre Saw

Page 48

IN YOUR NEXT PROJECT Page 44

By Steve Maxwell

Asfar as I can tell, the height of my physical fitness happened in November 1982 when I was 19 years old. Or at least that’s one time I noticed a particular pinnacle of fitness. I’d been going to college for a few months at the time, and I’d been in the college gym lifting weights three times a week.

On the day I’m telling you about, I was wearing a heavy knapsack on a hike. I was walking back to the car, late for a dinner date, when I remembered I’d forgotten my axe in the forest. That’s when I ran back to get it.

The thing about weight training is that you don’t expect it to help you run better. It makes you stronger, sure, but not necessarily for running, right? That’s where I was wrong and why I was surprised. I ran and ran and ran with the heavy knapsack on my back and I almost didn’t get tired for the half mile or so to get where the axe was lying on the ground. I ran all the way back to the car and I felt like a super hero on a good day. It was great. My legs did what legs are supposed to do. My arms and back and shoulders hardly even noticed the knapsack. All this wasn’t just because I was 19, either. I’d run before and it hurt. I was surprised how strong I was. The training had paid off. If no one ever got tired running, would anyone ever walk?

Fast-forward 35 years and I’m benefitting from strength training with weights again. I have my son, Robert, to thank for it. He’s 27 now and has taken weight training seriously for years. He knows all the right techniques and he

EVEN A WORKING CONTRACTOR – ON THE TOOLS EVERY DAY – WILL NOT GET CONSISTENT PHYSICAL EXERCISE OF THE RIGHT KIND. THIS IS WHY, IN MY SIXTH DECADE, I’VE RETURNED TO STRENGTH TRAINING WITH WEIGHTS.

coaches people professionally in person and online at something he calls www. manfactorytraining.com.

My life has plenty of built-in exercise, but there are two reasons it’s not as beneficial as intentional weight training. First, a lifestyle of exercise doesn’t always happen regularly. You might work hard for a week or two, then spend the rest of the month doing light work. Fitness goes up, fitness goes down. The exercise of work doesn’t necessarily cover all the muscular

bases, either.

If a doctor handed you a bottle of pills that made you feel like a fit 20 year old, would you take them? “One pill, four times a week”, the prescription would read. The thing is, it takes 30 minutes to swallow the pill. That’s the way I look at my weight sessions. Open the bottle, take half an hour to gulp down the pill, then enjoy the benefits during your work day and afterwards. You might find it worth a try yourself.

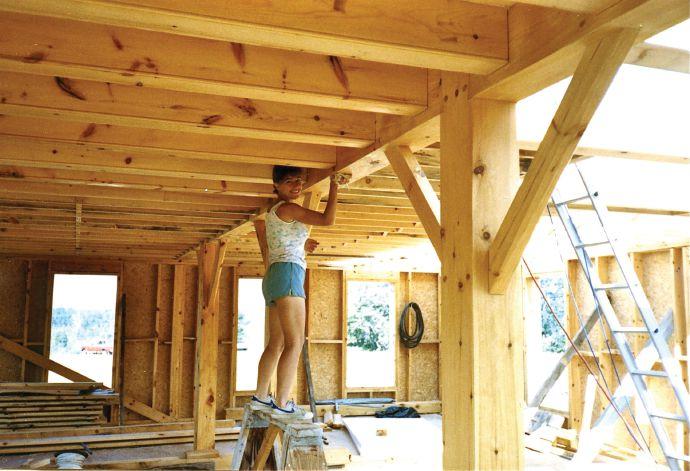

Three practical ways to expose the beauty of structural wood in your next project

By Steve Maxwell

Canadaprobably grows more big trees than any other country in the world, but you’d never know it by looking at Canadian houses. Even though wood is always involved in construction, it’s typically sawn into boring, uniform 1-1/2” planks, spiked together with no thought for appearance, then hidden under drywall. That’s too bad because the reality is that it’s never been easier to incorporate majestic, visible timbers into renovations and new construction. This isn’t the kind of thing that makes sense for every project, but for clients interested in adding wood in a rustic way, the techniques you’ll see here are perfect. Over the last 30 years I’ve used various unconventional methods to incorporate timbers into my building projects and it’s paid off. Here are three I particularly like.