Drywall Tariff in the West

Skyrocketing

Prices May Fall page 12

Canada-Proof Plumbing

A New Heated Pipe System page 42

Retirement?

Who Needs It?

Saskatoon Plumber Still Works at 93! page 14

Special Report

Drywall Tariff in the West

Skyrocketing

Prices May Fall page 12

A New Heated Pipe System page 42

Retirement?

Who Needs It?

Saskatoon Plumber Still Works at 93! page 14

Special Report

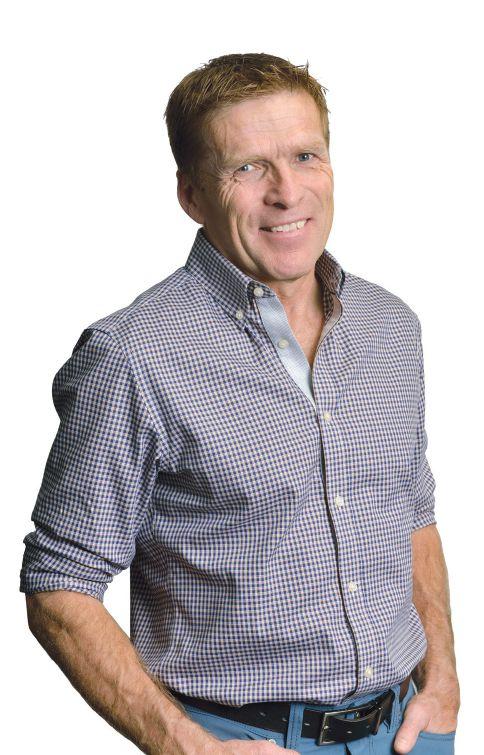

How Martin Mack went from raising cattle to building dream homes Page 24

RENOFOCUS Report 18

Thirty-two of Canada’s contractors shared their secrets – and challenges –at our second annual focus group event.

OUTSTANDING RENOVATOR AND CUSTOM HOMEBUILDER AWARDS

Martin Mack, Concord Homes 24

How this small town kid from Eastern Ontario went from raising cattle to building dream homes.

Paul Gallop, Men At Work Design Build 28 How this once struggling musician changed careers and became a top notch renovator.

Ben Polley and Chris Vander Hout, Evolve Builders 29

How these business partners grew from building straw bale homes to operating a full scale home building firm.

Steve Barkhouse, Amsted Design Build 30 How this Ottawa-area builder expanded from a one man operation to become one of the largest design build firms in North America.

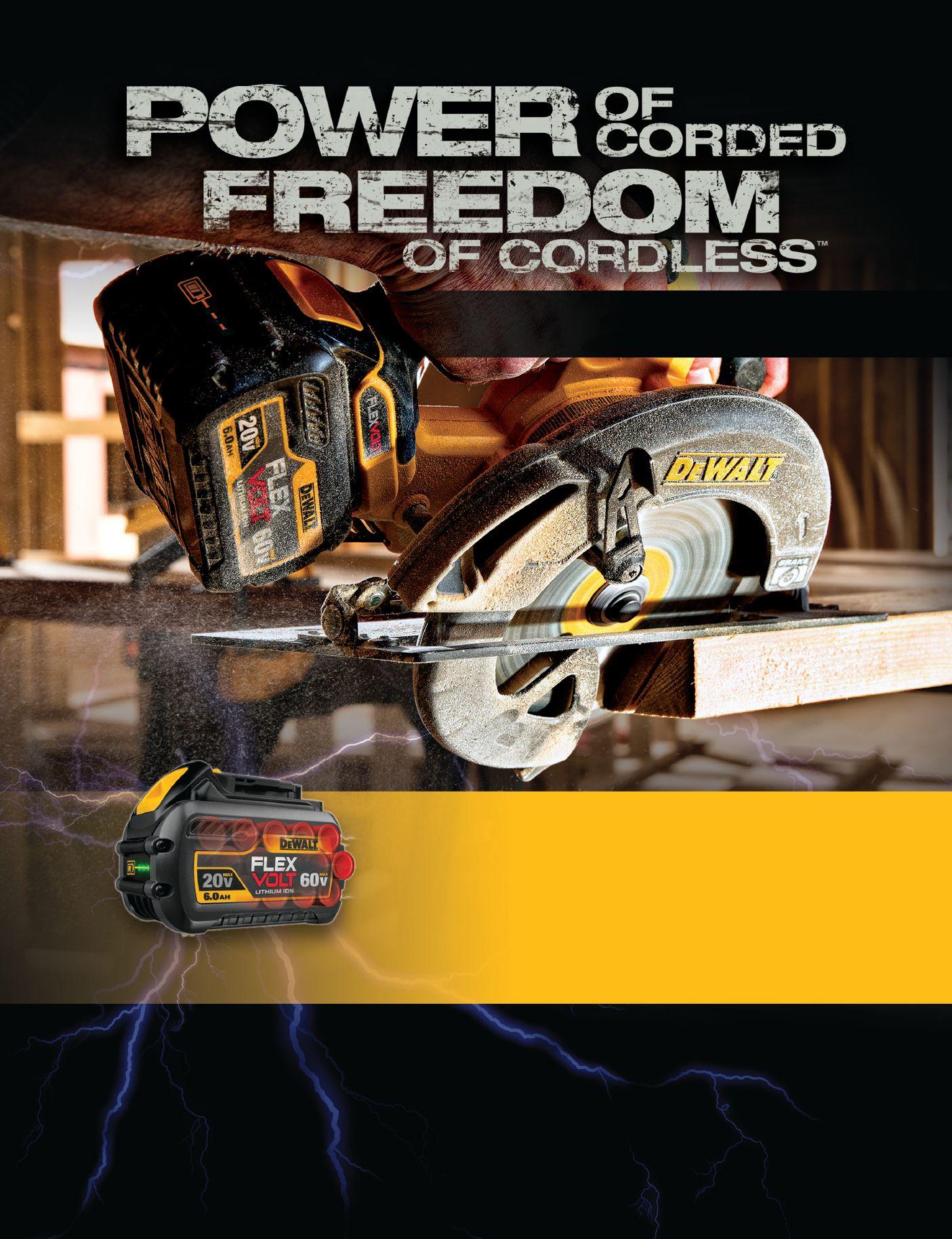

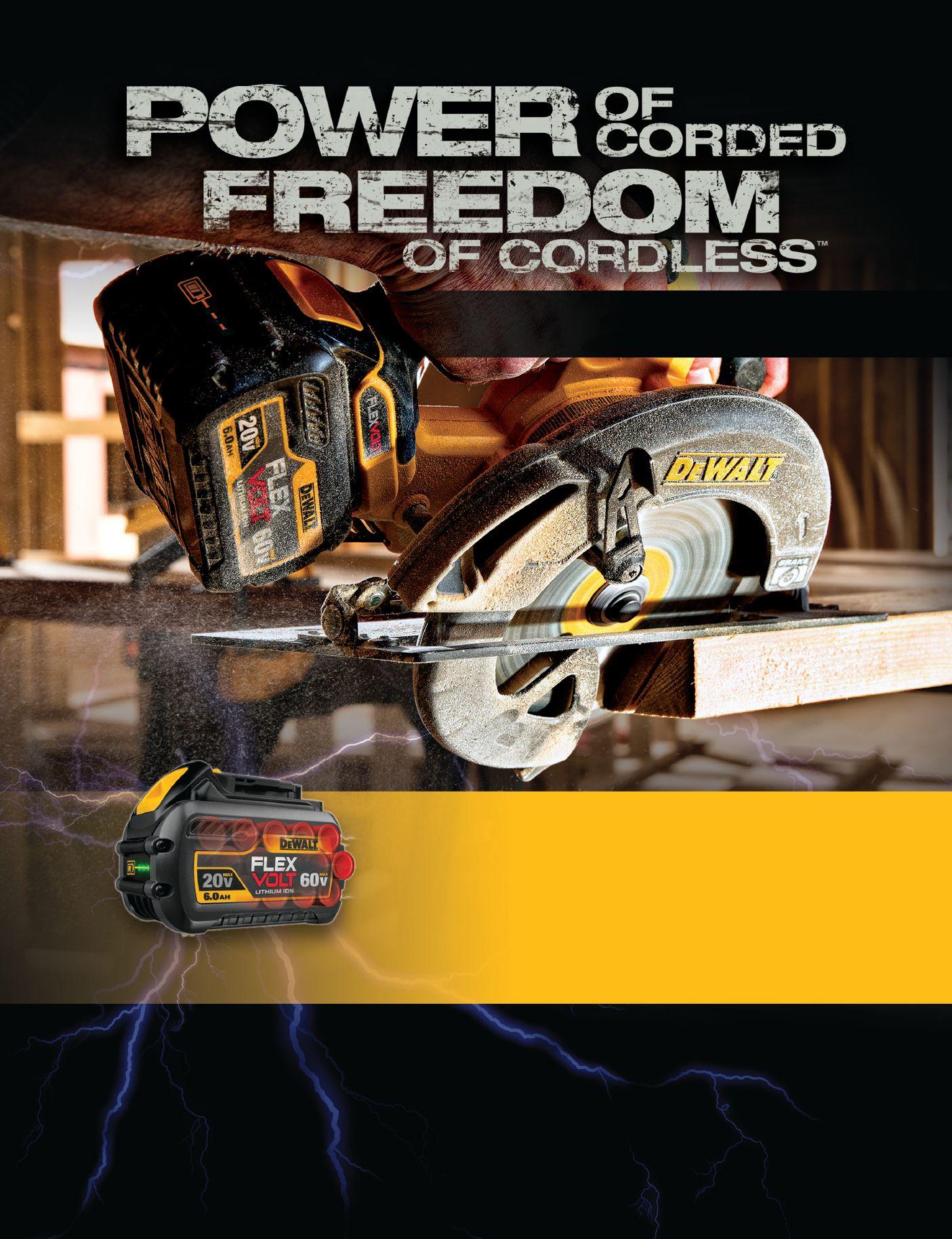

COMPATIBLE

Compatible with all our 20V MAX* tools

WORLD’S FIRST BATTERY PACK THAT AUTOMATICALLY CHANGES VOLTAGE WHEN YOU CHANGE TOOLS.

The FLEXVOLT™ battery's ability to automatically change between two voltages gives users a serious advantage when it comes to efficiency. It's the battery that not only powers, but improves the runtime** of our DEWALT® 20V MAX* tools, so you don't have to invest in a whole new system. It's the battery that brings the power of corded to a new lineup of 60V MAX* and 120V MAX* DEWALT® tools so you can finally work on a fully cordless jobsite. Built Guaranteed Tough®, Built by DEWALT®.

EXPANDABLE

Brings power to a whole new lineup of tools

POWERFUL

Combine two 60V MAX* batteries for revolutionary cordless freedom

Online 6

How to put the Canadian Contractor icon on your phone, for one touch access to our breaking news.

Editorials 8

Rob and Steve talk about different paths to contractor success

Voices 10

The best of the recent online comments at www.canadiancontractor.ca, the most outspoken forum in the industry.

Site Notes 12

An update on the Western Canada drywall tariff which has skyrocketed gypsum prices; Women in construction; Saskatoon man is world’s oldest working plumber.

Creative Eye 32

A stunning riverside build near Moncton raises the bar for all contractors.

Heated pipe systems: Plumbing that withstands the Great White North.

What Would You Do? 46

Send us your solution to this month’s contractor dilemma and you could win a cool tool from DeWalt.

Instructions for Android

• Google Canadian Contractor on your mobile device

• Open the link to canadiancontractor.ca

• When the page opens, tap the menu button on the lower left corner of your screen

• Select “add shortcut”

• Go back to your device’s screen and locate the Canadian Contractor icon (It may appear on one of your later pages.)

Go to canadiancontractor.ca and type “icon” in the search bar at the top right. The link to the video will pop up.

Volume 18, Number 1 January/February 2017 canadiancontractor.ca | Tel: 416 442 5600

80 Valleybrook Drive, North York, ON, M3B 2S9

Canadian Contractor, established in 2000, is published 6 times a year by Annex Business Media. PUBLICATION MAIL AGREEMENT #40065710

• Press and hold the icon, and drag it forward page-by-page to the desired page on your device

• Go to canadiancontractor.ca using Safari or your favourite browser

• When in portrait mode, click on the square icon with the “up” arrow that appears at the bottom of the screen

• Chose “add to home screen”

• Click “add”

• The icon should appear on your Iphone or Ipad home screen

Now with one click, you can go directly to the latest news!

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Alec Caldwell, Mike Draper, Peter Leonard, Steve Maxwell

Art Director Lisa Zambri

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator

Tracey Hanson thanson@@annexbizmedia.com

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbizmedia.com

Tim Dimopoulos, Vice President tdimopoulos@annexbizmedia.com

Ted Markle, COO tmarkle@annexweb.com

Mike Fredericks, President & CEO

Circulation

email: lmalicdem@annexbizmedia.com

Tel: 416-442-5600 ext 3547

Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

Subscription

Annex

Officer

Bob Collins

Home Building Centre – Gravenhurst Gravenhurst, ON

When your reputation is built on quality, you depend on relationships built on trust. That’s why you can trust the Experts at Home Building Centre and Home Hardware Building Centre to provide the tools, materials and services you depend on – from dedicated contractor sales staff and easier ordering through phone, fax or email to job site deliveries, credit services and package pricing. With a relationship built on trust, you know you’re building on a strong foundation.

pronews.ca

Our NextLevel sessions have been 16 years in the making. ”

Rob

Koci Publisher rkoci@canadiancontractor.ca

By Rob Koci

Self-employment means freedom, right?

Well, in certain ways. But it’s certainly not freedom from responsibility. It’s responsibility to the nth degree.

If you are a self-employed contractor you know this. You know that a lot of people are relying on you.

Your employees rely on you to keep them in groceries and rent. Your customers expect you to build the house of their dreams on an outhouse budget. Your municipality loves it when you build, sure, but they expect you to build within their very strict, sometimes burdensome, sometimes arbitrary rules. Your community expects you to be respectful of its culture and values.

And if all these demands isn’t enough, how about the demands you place on yourself? To do the right thing, to build a quality product, to take care of your kids and your spouse. To retire well. To stay healthy. It really IS all on you.

Nervous?

Most of you are not, because you welcome these challenges. When others look at such a list of responsibilities, they shudder. You don’t because for you, it is all worth the independence that being in business affords. Simply put, you are more comfortable leading than following.

One of the benefits of being a leader is you get a chance to see, up close and personal, all of your weaknesses. You discover quickly there is stuff you don’t know. There are talents you don’t have. There is stuff you just don’t want to do (or you do it badly). You learn that part of leadership is knowing when it’s time to ask or help.

The whole point of Canadian Contractor is to provide that help. One of my frustrations over the 16 years that I have been involved in this magazine is that the help we can provide in a magazine is limited.

That’s why we have launched NextLevel Peer Groups. You’ll see it advertised in the magazine and on our website. It is an opportunity for you to connect with other contractors doing similar work from noncompeting markets for help, advice, and that little bit of peer pressure you need to get long term strategic things done.

It’s a big step up from publishing a magazine, but we know it is the only real way for you to be successful. Join us. Call me at 647-407-0754. Or email me at rkoci@canadiancontractor.ca. I’ll tell you more.

By Steve Payne

The Canadian home improvement industry lost a true giant from the hardware and building supply side on Dec. 17 when Home Hardware founder Walter Hachborn died at the age of 95.

This genial, bow-tie wearing gentleman – along with his business partners Henry Sittler and Arthur Zilliax – founded the hardware and building supply co-op in St. Jacobs, Ontario in 1964. But the roots of the business extended way back to 1938 when Walter, then 16 years of age, went to work as a stock boy at Hollinger Hardware in that town. He was always thinking of bigger things, even back then.

The three men founded their hardware store network because, as Walter frequently recalled, family hard goods stores were going out of business by the hundreds in the 1950s because of the emergence of big discount chains and department stores – many of them American.

Walter’s idea for saving the small town family-owned operator was forged from six simple words: “There had to be a way.” He found his co-op idea in the pages of a trade magazine for American hardware store operators. With persistence, charm, exceptional hard work andabove all - optimism, Walter willed Home Hardware into existence.

The reason I’m writing about Walter in this space – and not about some specific renovation or home building issue of the day – is simply because of the tremendous effect that Walter had on me when I first interviewed him in 1999.

He was 78 years of age at that time, presumably in semi-retirement. Yet he ran up the stairs at Home Hardware head office, ahead of me, like he was 25. I couldn't keep up with him though I was half his age.

Walter was – although it’s a cliché – from the Old School. He was equal parts entrepreneur, business ethics preacher and community leader.

And when he offered business advice - as he constantly did - he did it in a gentle, humorous way. His aphorisms - dozens of them - were as folksy as can be, yet may be worth more than most MBA lectures.

One way to entertain customers is to listen to them.

One of the most difficult things to give away is kindness. It is usually returned.

For more on Walter, please Google ‘Walter Hachborn' at www. canadiancontractor.ca and you will find an online tribute. Please feel free to leave your own recollections of the man.

”

At press time, Ontario was just two weeks into Premier Wynne’s new “cap and trade” carbon tax. Almost immediately came a post on our site from Questo, who called the whole thing “insanity.”Award-winning green builder Ben Polley, Evolve Builders, Guelph was quick to reply… (Read more about Ben on page 29.)

I agree with Questo’s comments to the extent that cap and trade is highly exposed to politicization/political interference with good policy decisions. By contrast, however, I would argue that not all taxes are bad taxes – it should all be about societal benefit against cost. To that end, BC has implemented a simpler carbon tax. Since doing so, I believe that their economy has outperformed all other major (by population) provinces, while their carbon intensity has declined at or near the top of all provinces per capita. Win win.

Ben Polley

Evolve Builders, Guelph, ON

“Fusion” is defined as “a merging of diverse, distinct, or separate elements into a unified whole”. So it is with Fusion Stone; the coming together of the beauty, strength, and maintenance free characteristics of traditional stone with the ease of installation and affordability of stone veneer.

Fusion Stone is an easy and budget-friendly way to beautifully upgrade a home, inside and out. Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips & screws. You just screw it to the wall and it’s “Hooked for Life”.

Available in three distinct systems, all backed by a Lifetime Guarantee, Fusion Stone can be installed on both new and existing wall assemblies in any weather.

“Mike Holmes has done a great job exposing the joke that is the home inspection industry."

Ontario has moved to provincially regulate home inspectors. We think this needs to happen everywhere in Canada. In the meantime, here’s yet another home “inspector” horror story.

Mike Holmes has done a great job exposing the joke that is the home inspection industry in Canada. Working with realtors, many home inspectors main mission was not to “Blow the Deal,” leaving would-be homeowners with a house that was full of defects. I spoke to an Ontario home inspector about his qualifications. His answer: “I worked for a guy and took the course.” Big deal. One guy from a well-known franchise in the Toronto area told me that my eavestrough needed to be moved away from the house to avoid damage to the foundation. They went into an underground piping system that went into a pond in the subdivision. He was told to never set foot in my house again.

A. Robert Cook

Building codes a multi-million dollar business

We have talked often about the madness of making contractors (or anyone) pay to access the National Building Code. Other jurisdictions in North America (not all of them) offer their codes for free. Sergei Milhailenko implies Canada should be more like Washington State, where the building code is free online.

Issuance of the building codes become a very good business for those who are the publishers: government. Updates every five years sell thousands of copies for hundreds of dollars each. It’s a multimillion dollar business for the minor changes they are doing.

Also consider, that these codes still have some major mistakes. Like, for example, the design wind load for Vancouver: 1998 q1/30 – 0.44kPa; 2006 q1/50 – 0.48 kPa; 2012 – q1/50 – 0.45kPa. This is also valid for other Canadian cities. It costs developers, contractors and customers a lot of money.

Now the first version of the Canada Building Code was issued in 1940 or 1941. And it wasn’t changed until 1965, as far as I know. For 25 years we worked under the same code.

Another sample is Washington State in the U.S. Their code is available (free) online for anybody who wants to see it.

Sergei Milhenko, P.Eng.

Ontario’s new ‘Working at Heights’ card stopping him putting a new guy to work

Alec Caldwell has written many posts about Ontario’s new, mandatory Working at Heights qualification. Alec’s organization (www. carahs.org) offers this training, but Richart wishes there were even more places to get his guys certified…

I think that the new Ontario Working at Heights training is a great course for all construction workers to take. I make it mandatory for all of my employees. But here is the problem: We all know that there is a huge shortage of people going into the trades. Yesterday I hired a new person to start but he didn’t have the Working at Heights training. I made a few calls to local training facilities/companies but no one was offering the training until mid-January 2017. There were some places a 2-3 hour drive away from our location but that was it.

So now what? My attempt to hire a new employee has probably gone up in smoke as he can’t work until he has the training. Working without the training for a few weeks is an option but not for us. Anyone got any thoughts on this?

Richart

A reply to Richart

A 2-3 hour drive to obtain training to start a new job is not bad. I’m sure if you gave the guy the option to start earlier but he had to travel for the training, he would take it. A day’s labour for traveling to and from a training course is not really a big deal to have someone working safely a month earlier than otherwise possible. I guess it depends how badly you need him. Anyways, just my two cents: Have a great day!

Derek Laurinat

Another reply, from Alec Caldwell

Great post and if you’d like to call us, Richart, I’m sure we can drop your guy into one of our classes. We’ve got room in this coming Monday class or next Thursday’s class. We get constant high praise for our Working at Heights course. We keep everyone engaged in many ways. Read our course reviews at www.carahs.org. Or reach us toll free at 1.866.366.2930.

Alec

Hairstylist finds common cause with contractors

Before the Ontario College of Trades (OCOT) started “regulating” her industry, Edith paid $60 every three years for her hairstyling credentials. Now it’s up to over $400 in that time period. She posted this on our website…

My name is Edith, and I am a hairstylist, and in good standing with the OCOT. I, and many other people, feel that the OCOT should be removed. They are not a college. They don’t train people in any trade. Whereas we used to pay a fee of $60 every three years we are now forced to pay $136 every year to the OCOT. And if we can’t afford to pay it, we are being fined. And then we can’t even work because the OCOT will then put us as inactive on their website. In my opinion, this is extortion – which is illegal! I know of many people who have lost their jobs because of OCOT.

The employees at OCOT are rude and talk down to us tradespeople. They are no help at all – if you can even get ahold of a real person there. They just tell us to go on their website, which is no help either. The OCOT are overpaid, glorified answering machines! They wouldn’t know how to do real work. But they are really good at putting honest, hardworking people out of work.

Edith Knox

The NUDURA ICF Series features our patented innovative DURAMAX Technology®, the largest standard ICF block in the industry, allowing the placement of 12 square feet of wall area in one building step. Our DURAMAX Technology® results in faster installation times, less waste and a reduced amount of seams allowing builders & contractors to save time on labour.

Register for a training class near you or visit nudura.com/icfseries to learn about our other innovative features.

nudura.com 1-866-468-6299

Trade authority in Ottawa recommends lowering of import taxes to 43 per cent from previous rates as high as 275 per cent

By John Bleasby

Afterformal hearings into the price of drywall, the Canadian International Trade Tribunal (CITT) recommended Jan. 19 that Western Canada drywall import tariffs – currently as high as 275 per cent – be reduced to 43 per cent.

The tariffs were imposed on a temporary (“provisional”) basis by the Canadian Border Service Agency Sept .6 on drywall coming into the west from the U.S. The action was the government agency’s response to a “dumping” complaint from CertainTeed Gypsum Canada, the sole manufacturer of drywall in Western Canada. The firm argued that its plants in Vancouver, Calgary and Winnipeg were being unfairly competed with by US product priced significantly lower than it was sold for south of the border.

Contractors and builders argued at the CITT hearings that their businesses were being adversely affected by drywall prices that, according to Canadian Contractor tracking, have risen up to 80 per cent in some markets.

The CITT report addresses regional market competition, the harm already done to the building industry, and the impact on the Fort McMurray rebuilding in particular. However, little was detailed concerning how these issues would be managed.

In addition to a drop in tariff, the CITT calls for refunds of tariffs collected since September 2016 to “cooperating importers.” Furthermore, the report suggests a “tariff holiday” extending to July 4, 2017

to compensate the building industry for losses incurred by the sudden imposition of the provisional high tariffs last fall.

It was further suggested that the Regional Municipality of Wood Buffalo (which includes Fort McMurray) be given an extended tariff holiday to December 31, 2019, the length of time estimated to re-build the homes and businesses destroyed by fires last spring. It was felt that under-insured homeowners in particular should not suffer the hardship of “higher gypsum board costs taking away from other insurance funds available for other building components, contents and living expenses reimbursements.”

It unusual that such emphasis was placed on the impact of tariffs for end users in a CITT report of this type. However, federal finance minister Bill Morneau was heavily lobbied by contractors, home building associations, and drywall installers directly impacted by new market pricing and product availability. This provoked the minister to request that the CITT give these matters serious consideration. It is not yet known whether the finance ministry will adopt the recommendations contained in the CITT report.

To discourage importers from taking advantage of the tariff holiday by bringing in vast amounts of drywall product, the CITT recommended that a baseline of import volumes be established, using the year 2013, a year the CITT said was “arguably untainted by dumping.”

All-in-all, any refunds, tariff holidays, and historical volume baselines will require detailed and complex calculations, record keeping, and application processes. No details or suggestions were outlined regarding how these matters would be handled, or who would be responsible.

The CITT report recognized that “dumping” had occurred, and accepted in

[A LACK OF COMPETITION] COULD ALLOW CTG TO RAISE PRICES FURTHER… SUCH A PRICE WOULD ALLOW CTG TO EARN A RETURN ON SALES IN WESTERN CANADA WELL ABOVE THE AVERAGE RETURN OF COMPANIES WITHIN THE SAINT-GOBAIN ORGANIZATION.

part evidence submitted by CertainTeed, a wholly-owned subsidiary of French building products company Saint-Gobain. However, the CITT believed continuing high tariffs might “risk making U.S. imports uncompetitive in Western Canada, driving U.S. imports out of the market.”

Given that CertainTeed (CTG) had already raised their prices by 30 per cent, the CITT believed a lack of competition “could allow CTG to raise prices further… Such a price would allow CTG to earn a return on sales in Western Canada well above the average return of companies within the Saint-Gobain organization.”

Despite concerns for the loss of business, revenue, and profits suffered during the high tariff period, the CITT suggested that all end users, including consumers, must adjust to any future cost increases. The report said that while drywall is not a significant cost component in a new house, eliminating the tariff completely would simply “lead to a resumption of injurious dumping of gypsum board in Western Canada.”

The One Series by NUDURA is the industry’s first multi-link form offering builders and architects unmatched versatility for projects designed using ICFs. The One Series is ideal for pools, stairwells and anywhere only one side of foam is needed by combining traditional forming methods and Insulated Concrete Form technology.

Register for a training class near you or visit nudura.com/oneseries to learn more about the One Series.

nudura.com 1-866-468-6299

Lorne Figley, a working plumber in Saskatoon, turned 93 on Jan. 22. And he has no intention of retiring.

By Doug Picklyk

Courtesy of HPAC Magazine

ACanadian has landed in the Guinness World Records as the oldest actively employed plumber. Now 93 years old, Lorne Figley of Saskatoon, SK has no intention of laying down his wrench any time soon.

It was Figley’s daughter, Tricia Koob, who filed the application with the Guinness organization. She started gathering background information in October 2015, thinking she would be able to surprise him last Christmas.

“What do you get a [then] 92-year-old man who has everything?” asks Koob, adding, “I truly believe my dad is an absolutely amazing man.”

The application process turned into a significant project requiring invoices and testimonials from clients to prove Figley was a working plumber. “It was quite a journey,” she says, but it was a journey that ended this past September, almost a year after she began, when her father’s world record status was confirmed.

Figley’s plumbing career began in Saskatoon after he returned home from World War II, where he served with the Canadian forces in Holland. He completed his sheet metal apprenticeship in 1947, and then together with three other young men

started up a business in 1951, Broadway Heating Ltd.

In the following years Figley completed additional Red Seal certifications in steam fitting/pipe fitting, plumbing, refrigeration and air conditioning. He later bought out his partners and has run the business since. For a short while in the 70s he put the business on hold and went up to the Northwest Territories, but he returned to Saskatoon to resurrect Broadway Heating and he has been at it non-stop.

Figley told the Guinness World Records folks that he hasn’t retired because he likes to keep busy. And Koob confirms that in late November as the colder weather was approaching he was out every day doing service calls.

Upon receiving confirmation of the record from Guinness, Koob contacted the local media and Saskatchewan Polytechnic in Saskatoon, of which Figley is an alumnus. “It was a real story here in Saskatoon for about a month and a half,” she says, “Poor old dad, he was just exhausted.”

Saskatchewan Polytechnic presented Figley with a lifetime achievement award and also created a $500 apprenticeship scholarship award in his name, presented

to the student with the highest grade in the plumbing apprentice final exam. Figley has also offered up his own award for the top student in the sheet metal apprenticeship program.

“He’s humbled and tickled pink,” says Koob. “He’s had a big grin on his face.” And Figley still has no plans on retiring. As he said to the Guinness World Records group: “Working helps keep my body fit and my brain sharp. I hope to die with a pipe wrench in my hand.”

Figley turned 93 on January 22 and pledges, together with his daughter, to keep his paperwork in order and his world record secure.

Doug Picklyk was a contributing editor to HPAC Magazine (where this article first appeared) before joining Canadian Consulting Engineer magazine as editor.

LAt 38, having worked in an office as a secretary for 10 years, Diane Logan went out to work on a frigid Alberta job site as an electrical apprentice. And she’s never looked back.

ast January, 38-year-old Diane Logan did what she describes as a complete 180. After ten years as a secretary, she traded in her office wear, layered up in two pairs of long johns, a parka and quilt lined hardhat and headed out to work as an electrical apprentice. Logan was hired by Willbros Canada to work at a modular yard in Nisku, Alberta. While there were some bitterly cold days when she wondered if she was doing the right thing, Logan says she didn’t second-guess for long.

“It was hard work, but I absolutely loved it. I wanted to feel that I’d achieved something at the end of the day. Working in the trades gives me a huge sense of accomplishment, and the feeling that for the first time I have a real career.”

Just over 300 km away, Lori Blanchette, also 38, is building and dismantling structures for KBR Wabi at its Fort Hills extraction project. With a little coaxing from her brother, she made the career move from payroll clerk to scaffolding apprentice nine months ago, something she wished she done sooner. Blanchette’s advice to women thinking about the skilled trades is simple.

“Stop thinking about it, and just do it. Work hard, be determined and you will succeed.”

As members of the Progressive Contractors Association of Canada, Willbros and KBR Wabi are among an increasing number of construction companies making a concerted effort to attract more women to their skilled workforce. PCA encourages its member companies to hire, train and mentor women by forming partnerships whenever possible with Women Building Futures. PCA is a strong supporter of Women Building Futures, a leading organization that provides women with the basic training they need to get started in the skilled trades. Since March, KBR Wabi has hired 16 women through Women Building Futures.

“With as many as a quarter of a million construction workers retiring this decade, construction companies want and need women to help fill that skills vacuum,” said Darrel Reid, Vice-President of Policy and Advocacy at the Progressive Contractors Association of Canada. “Never has there been a better time for women to launch careers in the skilled construction trades. The opportunity is definitely there.”

While the number of women in construction is growing in Canada, the proportion of women who make up in the skilled trades workforce remains at about 4 to 5 per cent.

This story was provided courtesy of the Progressive Contractors Association of Canada.

The Integrated Series from NUDURA combines building products that work in conjunction with our line of Insulated Concrete Forms or independently to provide maximum energy efficiency. Our Integrated Series offers Ceiling & Floor Technology, HYDROFOAM ® Radiant Floor Insulation and our unique RetroFit Insulation Technology.

Register for a training class near you or visit nudura.com/integratedseries to learn more.

nudura.com 1-866-468-6299

Canadian Contractor’s second annual focus group conference, held Nov. 27-29 in Toronto, gathered together 32 of the country’s top renovators and homebuilders to discuss what’s working, what’s not – and what’s next. And our sponsoring manufacturers gained valuable insights on how to better serve their pro customers.

By Steve Payne

It’s a fundamental of business – possibly the only business tip you really need: Listen to your customers! To that end, Canadian Contractor invites our customers (contractors and advertisers) to a now-annual focus group event each fall: RenoFocus.

Our 2nd annual RenoFocus occurred in late November at Le Germaine Hotel at Maple Leaf Square, downtown Toronto. The business conversations were productive for everyone. The social events forged new friendships. Here at the magazine, we were once again awed by the passionate dedication to their craft exhibited by this year’s group of contractors. For these pros, building – and building their business – is clearly a calling, not just

a career path.

The 32 contracting firms selected to attend this year (flights and accommodations courtesy of our sponsors) were, as is our policy, from predominantly non-competing markets from Atlantic Canada to Vancouver Island. By gathering non-competing business owners together, discussions about pricing, margins, labour costs and business strategies could occur in a completely open and frank way.

For the manufacturers, it was an opportunity to discuss their (and in some cases their competitors’) products in confidential focus group sessions, kick around possible new products, and generally take the pulse of the contractor customer base. Customers will

tell you more in a focus group – especially when one gets to break bread with them and unwind in the bar – than can ever be obtained from field sales staff, surveys or at trade shows.

Geographical differences showed up clearly at the round table sessions, in terms of which contractors were enjoying better regional economies. Southern Ontario contractors are still enjoying the most sustained period of real estate price increases in more than 30 years. Those pros from the Greater Toronto Area had fewer problems in marketing and selling and greater challenges in finding, training and retaining good people.

As we all know, not everyone is enjoying that kind of a market. In Alberta, the depleted energy industry has slowed renovation and homebuilding activity and discussions from Western contractors tended to focus more on marketing and selling. This also showed up in discussions with contractors from British Columbia which –at least in the Greater Vancouver Area – remains “cooled off” by

Three trends continue to develop. We saw them at our 2015 event and they were back in full force this time. One, the most successful contractors continue to gravitate towards a designbuild model. Working with clients from the conception of their dream build, rather than coming in as pure contractor handed designs from a third party architect, is now becoming the norm for many pros. Secondly, fully integrated builder software is now baseline: almost every one of these highly successful contractor attendees has been through the growing pains of introducing such systems. And finally, sustainable building practices – even up to the level of Net Zero Energy Ready (NZEr) are becoming mainstream. As Ben Polley tells us every year – more and more customers are prepared to invest deeply in energy-efficiency when they build a home – and so sustainable building practices are no longer fringe but simply good business.

What we did not hear from this year’s attendees – at least not extensively – were complaints about under the table competitors. Extremely professionally run, these firms were not even remotely competing on price but rather on their expertise, people and systems. Customers that wanted to cut corners and pit these operators against each other in a race to the bottom, profit-wise, weren’t going to stand much of a chance of hiring these particular professionals.

New to this year’s RenoFocus was a spin-off group of meetings called NextLevel. NextLevel is a “Peer Group” initiative. Simply put, contractors from non-competing markets get together, open up their books to each other, and become each others’ “board of directors” on getting better numbers, building better businesses – and making the business work for the owner, not the other way around. NextLevel is a co-production of this magazine and the contractor training organization Renovantage, led by our resident

“contractor coach,” Mike Draper. For more on Next Level, please see page 22. (If you would like to find out how you can join a NextLevel group, please email Rob Koci, rkoci@canadiancontractor.ca.)

There was yet another addition to this year’s RenoFocus agenda. With all due respect to the large number of exceedingly valuable contractor awards given out every year across the country (most of them by superbly run regional home builder associations), we at Canadian Contractor have always wanted to see a specifically business-oriented contractor award in this country. We wanted to establish a new award for residential contractors that celebrates management excellence as well as construction and design achievement. So we created the Canadian Contractor Outstanding Renovator and Custom Homebuilder Awards – ORCHA, for short. Sponsored enthusiastically by German power tool manufacturer Festool, the ORCHAs were presented at our Monday night gala. These first-ever ORCHA winners were all superbly managed

firms – each with attributes that are unique in their market. Congratulations to Martin Mack, Concord Homes, Amherstview, ON, our inaugural ORCHA Gold recipient. Martin is featured on the cover of this issue, and on page 24 you can read about how he built his business from the grassroots (literally). Congratulations also to our ORCHA Silver winner, Paul Gallop (Men At Work Design Build, page 28); and our two ORCHA Bronze winning firms – Ben Polley and Chris Vander Hout (Evolve Builders Group, page 29) and Steve Barkhouse (Amsted Design Build, page 30).

Overall, RENOFOCUS succeeded for both the contractors and the sponsoring firms who supply them with product. One participant, in fact, was both. Peter Douglas, Douglas Design Build, Charlottetown, PEI, provides a cloud-based bookkeeping solution for contractors called JobSite PRO.

“I found RENOFOCUS to be a really excellent experience in both my roles there,” Douglas said. “I found my fellow contractors

to be engaged in the process and full of great feedback. I really enjoyed the fact they came from all across the country and from a wide range of backgrounds and experiences. I would jump at the chance to participate in this event again.”

Another company, Spectrum Brands, was represented at the event by Adam Findlay. He, too, underscored the importance of focus groups in getting to know customers.

“Our first time at RenoFocus was a successful one,” Findlay said. “The chance to learn from custom home builders, renovators, and contractors provided invaluable information for us a company. As we continue to realize growth with our Pfister brand and get underway with our new showroom brand, Fortis, we were thrilled to take advantage of the opportunity. In the coming months we will take what we learned and apply it to how we refine and communicate the tremendous value and quality propositions that our products can bring to those who can use them the most.”

If you are a contractor who would like to come to this year's RenoFocus (Nov. 26-28) please email rkoci@canadiancontractor.ca.

DOUGLAS ABBOTT

Village Builders Inc. Creemore, ON

STEVE BARKHOUSE

Amsted Design-Build Stittsville, ON

ROSE BARROSO

Barroso Homes Etobicoke, ON

MURRAY BELL

Thor Developments Inc. Calgary, AB

KEVIN BLAIR

Alair Homes, Collingwood, ON

LAURIE BLAIR

Alair Homes, Collingwood, ON

MICHAEL COCHREN

Cochren Homes Limited Oakville, ON

JORGE CRUZ

Barroso Homes Etobicoke, ON

KEN DAHLEN

Keith Dahlen Construction Ltd. Coldstream, BC

NEIL DAMACKINE

Construction ND Terrebonne, QC

PETER DOUGLAS

Douglas Design Build Charlottetown, PE

MICHAEL FOBERT

Traditional Styles Coboconk, ON

PAUL GALLOP

Men At Work Design Build Ltd. Toronto, ON

JOSEPH GELUCH

Naikoon Contracting Ltd. North Vancouver, BC

ANDREW GORHAM

Advanced Building & Renovations Inc. Fredericton, NB

LINDSAY HALEY

Precision Contracting Brockville, ON

JOSHUA KLEIN

Naikoon Contracting Ltd. North Vancouver, BC

BRAD LOUNSBURY

Lounsbury Group Toronto, ON

RICHARD LYSTANG

Rococo Homes Inc. Spruce Grove, AB

MARTIN MACK

Concord Homes Amherstview, ON

NICK MAIDA

Georgian Custom Renovations Inc. Mississauga, ON

JOSEPH MAZZUCCO

A. Mazzucco Construction Toronto, ON

STEPHEN MORROW

McMorrow Construction Ltd. Saskatoon, SK

GAVIN PARSONS

Parsons Family Homes Vernon, BC

MARLENE PARSONS

Parsons Family Homes Vernon, BC

AARON PLUMB

Classic Home Improvements Victoria, BC

MIKHAEL POLISCHUK

Alair Homes Regina, SK

BEN POLLEY

Evolve Builders Group Inc. Guelph, ON

JAMES POORT

Abacus Designs Custom Carpentry Inc. Waterdown, ON

DANIEL ROLFE

S. Maric Construction Winnipeg, MB

ANDREI SOSNOVSKY

Sosna Inc. Vaughan, ON

RICHARD ST. LAURENT

Peak Improvements Ltd. Edmonton, ON

MICHAEL VAN DEN BOSCH Bosch Services Ltd. Burlington, ON

CHRIS VANDER HOUT

Evolve Builders Group Inc. Guelph, ON

SCOTT WOOTTON

Kawartha Lakes Construction Lakefield, ON

LES YOCHIM

BelVan Construction Edmonton, AB

Each of these participating contractors received a winter construction jacket courtesy of CertainTeed Gypsum Canada.

By John Bleasby

Lindsay Haley (Precision Contracting, Brockville, ON) is a young man with a successful business. He has nine full-time employees, 15 subtrades on call, and a 10-year track record of pleasing clients. However, he’s not resting on his laurels – he wants to continue to grow. That’s why he joined NextLevel, the “peer group” sessions put on by Canadian Contractor magazine and contractor business coach Mike Draper of Renovantage. In these meetings, contractors share their business challenges with each other –including opening up their books and comparing numbers. The first NextLevel meeting was held during RenoFocus in late November. We asked Lindsay for his thoughts.

What attracted you to sign up for NextLevel ?

Contractors are often perceived as ‘Chuck in a truck’ type operations – running around without proper insurance, WSIB and so on. However, what legitimate operators struggle with are answers to the everyday questions. We’re not just in the homes working, trying to meet client expectations; we have to operate a business. We lack exactly what NextLevel offers: a peer group where we can ask each other questions about how to deal with certain situations.

What type of things did you discuss at your first meeting?

We talked a lot about policies and practices. We’re a very

diverse group, so everyone can bring something different to the conversation, which is fantastic. What we have in common is that most of us are doing residential work. What’s hard about our job is that every day is different. It’s the greatest thing about our job as well! Nothing is cookie-cutter. Every house is different, every client is different and their needs are different. The competition is fierce in contracting, plus we have employees to pay, and government regulations to follow that are constantly changing.

NextLevel requires a willingness to open up your business to examination by others. Any reluctance to do that?

The guidelines are very clear about that, and that’s the only way it can work. We are all holding ourselves accountable. Given the commitment of time and money, I am determined to make full use of this opportunity. I have expectations not only from the organizers but from the group.

How have the discussions proceeded so far?

We’ve started to establish a commonality in terms of business styles so we can really dig into some of our individual issues. So far, NextLevel has exceeded my expectations: I’ve already made some huge changes based on our discussions, and I’m starting to see the returns. cc

By John Bleasby

on’t let Martin Mack’s boyish appearance deceive you. He’s a veteran of over 20 years in the contracting industry. His calm, quiet manner fronts a determination to keep his custom designbuild company, Concord Homes, based near Kingston, ON on a trajectory of continued growth and success.

How’s he doing so far? Well, winning the gold at Canadian Contractor’s inaugural Outstanding Renovator and Custom Home Builder Awards (ORCHA) is national confirmation that Martin’s business practices excel in terms of vision, management, marketing, staff training and other business-oriented best practices.

Success at any level is almost always the result of good leadership. If you ask Martin, he’ll tell you that a key to his success is the work ethic he learned growing up on his family’s farm. “My dad still runs a full-time beef cattle farm, and he’s 73,” says Martin. “He probably works more hours than I do. There’s no plan for him to slow down. I can’t remember the

last time he took a vacation.”

Working a farm also means doing all that’s required to get things done. It’s no wonder then that when Martin started out as a one-man operation back in 1999 with three credit cards and $1,500 in his bank account, he’d take on any task necessary to keep clients happy, even cutting their grass. Today it means offering clients a design-build program that is remarkable in its vertical integration.

Transitioning from a builder bidding on other people’s designs to a complete design-build contracting operation was a key decision Martin made several years ago. He sees it as vital for not only differentiating his company from the competition but for providing his clients, and his own company, complete control of all aspects of the project.

“So many clients were coming to us with their own design,” explains Martin. “Many of those designs were not taking into account how we like to build in terms of structure and energy-efficiency. Consequently, we were going back and adjusting the designs to the way we build.”

It also helps clients tremendously in terms of budget and expectations.

“People would come to us for a price on their design, we’d tell them, and they’d go, ‘Oh! I didn’t know it was going to cost that much!’ Then the questions would be, ‘How can we get the price down? How can we make changes?’ Since we were doing the design work to make those changes, it just made sense to put ourselves into a position where we could be a part of the design process itself.”

Vertical integration at Concord Homes also means an in-house team of nearly 20 certified tradesmen that includes tile setters, carpenters, flooring installers, even his own excavation crew and equipment. “We’ve had miniex equipment for close to ten years, but about five years ago we decided to buy our own excavator and now do 90 per cent of our own excavations, including back-filling and landscaping. It’s an integral part of building. The ability to control another aspect of the building process makes it easier for the team. It’s part of our philosophy. Most contractors are turning to a sub-contractor base, but when I set up Concord Homes, it was to be an employee-based company. We are heavily reliant on our employees and our team, and keeping as much as possible

in-house. It’s better for controlling schedules, for controlling quality, and for communicating with the client.”

However, Martin’s focus on in-house vertical integration required a new emphasis on scheduling and systemization, something Martin recognized he needed if he was to manage his growth path. That led him to apply to attend RenoFocus 2015, where Martin connected with business coach Mike Draper of Renovantage. The two have been working together ever since.

“Martin had a very successful business before we started working together,” says Draper, “so what we’ve been able to do is transition things into a more systemized business that isn’t so reliant on Martin. It’s a big challenge personally and culturally for most business operators in construction to get employees to take ownership and develop systems they can work with.”

Agreeing to ‘let go’ of total one-man control was worth it, and were obvious to Canadian Contractor’s ORCHA panel as they reviewed the dramatic yearover-year increases in Concord Home’s revenue, profits and retained earnings. “Before I started working with Mike,

there was one schedule and it was in my head,” says Martin. “I never had a written schedule for 20 years, so couldn’t share it with people. The systems Mike helped put in place means that everyone on the team, including the client, has access to the schedule.”

Martin has taken his vison of a vertically integrated operation to yet another level by purchasing and inventorying building lots and older homes both in the City of Kingston and outlying areas. “We might see a large property with severance possibilities, for example. We’d buy the house, renovate it,

severe the lot, sell the renovated house, and retain the newly severed portion so we can offer it to a future client. We’ve probably done that two or three times a year over the past four years. We’ve also bought country properties and subdivided them into lots.”

Although maintaining an attractive web site through the professional design, listing, and SEO expertise of Yellow Pages, Concord Home’s reputation and word-of-mouth strength is its most important marketing tool. That, and the visual impact of a matching fleet of corporate vehicles and site trailers,

Most home building and renovation companies start the same way. A skilled, dedicated craftsman develops a good reputation, finds more and more work, and eventually starts hiring employees to keep up with the increase. Yet being so close to the action itself and enjoying being ‘on the tools,’ makes it difficult to realize the dream of running a growing company that can be sustained for years. That’s where business coaches like Mike Draper of Renovantage step in. They can provide perspective, help define goals, map out a business development plan, and make sure the plan is followed.

But don’t make the common mistake of confusing a business coach with a business consultant. “A consultant goes in, and over a very short period of time comes back with recommendations outlining various things a business needs to do, and then leaves the owners to make those changes,” Draper explains. “A coach will connect with the owners frequently each month over a long period of time, constantly working on goals they themselves have defined. The coach provides direction and guidance. It’s ultimately what they want out of the business that’s important.”

project signage, plus sponsorship of local sports teams and charitable events has kept Concord Homes in the public eye throughout its prime market territory. “We have a strong local presence,” says Martin.

Pushing the limits of his company’s future potential as well as his own is part of Martin’s instincts. He compares developing Concord Homes to his five-time participation in the 250 km Marathon des Sables desert race across the southern Moroccan Sahara. “I love adventure racing like I love my business. I love pushing myself.” cc

Draper’s coaching technique is customized to the needs of each owner, with follow-up provided in dedicated and regular oneon-one telephone sessions. But it’s not the only way. Mike van den Bosch, owner of top-rated, Burlington, ON-based renovation contractor Bosch Services Ltd. has used both one-on-one personalized coaching as well as group sessions involving other small business owners experiencing similar growth pains. Van den Bosch believes both approaches have value. “At the end of the day, business is business. There’s always cross-overs, policies and procedures that can be shared and learned from.”

Mike Draper helped Martin Mack’s Concord Homes become the Gold Award winner at this year’s ORCHA Awards by assisting in the development of a systemized approach to home building. Coaching helped Mike van den Bosch identify his profit centres and ultimately to focus his business on interior renovations. The value of coaching is clear to both. Says van den Bosch, “I stopped dreaming about success and started working hard towards being successful.”

HK & HKC - Miter saw precision, in the size of a sidewinder. Yes, it’s that good.

ORCHA SILVER WINNER

It’s not exactly a “rags to riches story,” but’s it’s close. Here is how Paul Gallop, Men At Work Design Build, describes his 27-year journey in our industry:

“I entered this industry the way I think many people do, with a Grade 12 education and no formal or construction or business training. I had a curiosity for how houses are built. And after a 12-year career as a struggling musician, I realized I was going to have to hang up my guitar and start doing something a little more concrete to make a living.”

“With 27 years now in the home renovation industry, entirely selfemployed,” Paul says, “I have elevated myself from a self-taught handyman earning $20,000 a year, to building a highly-respected, multi-award-winning design-build home renovation company.”

Paul’s Etobicoke, Ontario firm did some 26 projects this past year, with gross revenues approaching $6-million, a huge 50 per cent increase on his previous year’s revenue.

Yes, the GTA housing and renovation market is on fire. But it’s also true that the competition in the Toronto market is brutal. And the temptation to cut regulatory costs in the usual (cash) ways has made the market a very unlevel playing field.

Yet Paul is a contractor who makes terrific money playing by every single government rule. As he says, “I believe that my firm effectively demonstrates that a little guy can build from nothing and prosper in this business without cheating or bending the rules. We’ve been audited by WSIB twice, by CRA twice, and had numerous visits to our sites by Ministry of Labour inspectors. We have never been fined or charged a single dollar. We hold this forth proudly as a testament to our diligent and honest business practices, record keeping and respect for proper government compliance.”

Paul’s business success is mirrored in the honours he has received from our industry. For example:

Men At Work has more than a thousand satisfied customers. The firm has flawless ratings on Homestars and Houzz.com.

The industry at large has taken notice of the firm's excellence. Men At Work was named 2012 BILD Renovator of the Year and it has been a finalist the last two years. The company won the Ontario Home Builders Association best renovation awards the last two years.

South of the border, the company has been a bronze medallist the last two years in the Qualified Remodeler Master Design Awards for North America. cc

ORCHA BRONZE WINNER

Canadian Contractor wrote its first story about Ben Polley 15 years ago. Ben’s then-business, Harvest Homes, was a constructor of straw-bale homes. Though these were ultra “green,” many people –including us at the magazine – wondered if Ben could actually sustain a real business with such a fringe-of-the-market product.

Fast forward another dozen years. We at Canadian Contractor ran another incredible story. Ben had not only succeeded in the straw-bale homes business, he was now successfully selling straw-bale school portables (brand name: MoBEE). Many people wondered if that could continue to succeed, too. Maybe they needed to meet Ben Polley.

Ben starts with a deep faith in the vital importance of green building. And he challenges us: Do we want our children, grandchildren and great-grandchildren to have a planet that is habitable? Green building is difficult. At first glance, it seems it raises costs through the roof. But as Ben argues, these costs are paid back in reduced energy bills. And in countless even more important ways.

Over 15 years, Ben’s company has vastly increased its service offerings to the extent of becoming a full service builder. A new parent company – Evolve Builders

Group Inc. – was established in 2006.

Harvest continued as a straw bale wall system specialist. Evolve, meanwhile, was fashioned as brand that would deploy construction methods of any type – not limited to straw bale – so long as the projects included elements of environmental friendliness, human health or energy efficiency.

Now, with Ben’s business partner Chris Vander Hout, Evolve is enjoying record sales and a growing reputation – not only within Canada – but globally. Ben has represented Canada’s residential green building sector at international conferences.

Evolve’s team of 19 full-time staff has been built carefully. The majority of their senior managers have owned their own construction businesses – oftentimes in competition with Evolve. Ben and Chris further leverage their field staff’s abilities through a non-traditional site supervision system called “Even Flow Management.”

“Our targeted hires and the Even Flow system deliver extraordinary flexibility and scalability to our operation,” Ben says. “At times of peak work, we can quickly add new skilled or semi-skilled staff to be overseen by our wealth of supervisory capacity.” cc

ORCHA BRONZE WINNER

Founded in 1989 by Steve Barkhouse, Amsted Design Build in Stittsville, Ontario has grown from a single-person operation to a multiple award-winning contracting firm that employs over 30 people while completing more than 30 projects a year.

In 2015, in fact, Amsted completed 43 projects with revenues in excess of $5-million. That made it one of the 550 largest renovation firms in North America as measured by Remodeling magazine.

And there’s more: Amsted’s sister company, Restore-All Corporation, operates in the booming insurance restoration market.

Steve Barkhouse is a marketing – as well as a building – expert. He and his team have brilliantly developed three offices across Ottawa that Amsted calls its “Living Rooms.” These locations showcase the firm’s work and provide a convenient client meeting location. They gain significant walk-in traffic and build community awareness for the Amsted brand.

Steve’s firm’s mission reads: “Our mission must be to exceed the expectations of our customers – whom we define as clients, partners and fellow employees.”

Imagine that, treating employees as

customers!

If you think this is “out there,” well, it’s true. Consider this: Steve has the names of those employees who have achieved five years of service engraved on paving stones lining the walkway to its head office!

“We will accomplish [our mission] by committing to our shared values and by achieving the highest levels of customer satisfaction. In this way we will ensure that our profit, quality and growth goals are met.”

Steve starts with values and how people should be treated and from there proceeds to profit and growth. Because Steve believes that profit and growth are side-effects of other behaviours, not abstract things that appear out of thin air.

Steve has one overriding philosophy for Amsted Design Build: “We do what we say we are going to do.” cc

Architects

Pierre Gallant Architect Inc.

Architects 4 Limited Moncton, NB.

General Contractor

Doncor Construction & Renovations Ltd., Moncton, NB.

By John Bleasby

Photos by David Corkum

Architect Pierre Gallant’s clients gave him specific requirements for their new home beside the Petitcodiac River southwest of Moncton. Most critically, they wished to “work with” the existing topography of the private riverside site, taking advantage of the views, integrating the slope, and saving the mature grove of spruce trees. They feared a traditional development approach would destroy the trees and require considerable fill to build a suitable house pad.

“We walked the site,” says Gallant. “What was interesting was that among the mature spruce trees, we found a natural pathway which became the driveway that led to the house site. There was actually an opening in that grove for the house itself. Very few trees were cut down. We had a lot of room.”

For living space, the couple requested a custom three-bedroom home, with 2,500 sq. ft. of liveable space in a contemporary design incorporating several energy efficient and

Continued on next page

sustainable strategies. With their children away at school and returning only for family occasions, guest accommodation separate from the master suite level was desirable.

The narrow and sloped site clearing dictated a long house concept oriented north and south, built over three levels, each focused on the river; a lower family room level (which includes mechanical functions and garage parking), a middle living space level with guest accommodation, and an upper master bedroom suite. A bridged entranceway at the main level, built of galvanized steel leading to a copper-coloured, metal sheathed mid-level main entrance, introduces a textural contrast between steel and glass with wood and sandstone, a treatment that continues throughout the exterior and interior.

On the riverside face, steel beamed balconies with glass barriers meet the massive three-storey sandstone fireplace and exterior wall on the north face.

The dramatic wedge shaped copper-coloured steel roof balances this warmth and drama.

The master suite has a private walk out rooftop. Although originally conceived as a green roof, in fact the plants are grown in pots, not soil, making it more of a rooftop garden. The upper roof has a solar panel array. A system of scuppers drain all the roof sections, with chains used as a drip controls to prevent staining of the shiplap, six-inch pine board siding.

Despite the highly contemporary look, the house structure itself is not extraordinary. “It was very much a conventional, standard approach to the

Continued on next page

OPPOSITE PAGE: Sloping northwards, the 600 ft deep by 100 foot wide lot levels off to become lowland along the river’s edge. The southern boundary, sloping away from the street, is populated with a mature spruce grove. The small building at the bottom right is a dog house.

LEFT: The central staircase treads are rich cherry wood, which provide a striking contrast to the metal runners framing railings.

build,” says Gallant, starting with the 2x6 wood frame atop a poured concrete foundation. “The only change was the upgrade to higher insulation values, R30 in the walls and R50 in the roofs. We incorporated rigid foam thermal breaks between the siding and framing, and gave attention to the latest air barrier technology and better window seals.”

Throughout the home, doors and windows are commercial-grade product featuring thermal breaks. “Thermally broken windows and doors are high end,” explained Gallant. “I feel the commercial products are superior. They’re the only way to deal with the weather we get in the winters here. And we did like the look.The materials, such as the metal frames, were all natural galvanized.”

In addition, the design employs several internal energy-efficient and sustainability strategies such as LED lighting throughout. A geothermal heat pump system provides both in-floor heat and air conditioning, in combination with HRV venting. A fan system circulates air either way between the lowest and highest levels, important not only for cooling but when portions of the three-level wood-burning fireplace

LEFT: A three level working wood fireplace, faced with Hillsborough sandstone quarried only a few miles away, continues to the north side exterior wall. Cork flooring was selected for most living space areas. There were issues beyond heating issues. There were the clients’ dogs. “They were sliding and trying to maintain their footing,” says Gallant. “There was wear-and-tear because of it.”

OPPOSITE: Kitchen cabinetry was made to measure, built by contractor Don Landry’s brother-in-law, a custom cabinetmaker.

are used. The open main stairwell also provides significant air movement.

Flooring choices impacted the overall effectiveness of the in-floor heating system. While both tile and engineered hardwood were chosen for entrance foyers, bathrooms areas and bedrooms, cork was used in all other areas. Which came with its own challenges to the heating technology.

“Geothermal is a great system but the water temperature in the pipes is only 103 degrees, not very hot,” said Donald Landry, the GC. “Cork is too much of an insulator, so the system didn’t create enough heat transfer to warm up the house properly. The unit ran hard. One heat pump was air, the other was radiant in-floor. There were times when the owner had to use the air to get enough heat out of the system because the floor wasn’t enough. We ended up running in a couple of extra lines to cast iron radiant heaters as support.”

With its spectacular river views and mature trees, the ‘Long House’ stands as a riverside sentry of stone, steel and glass. cc

With its industry-leading walkable surface, the portfolio of Tyvek® Protec™ engineered synthetic underlayments provide you and your crew with a high-performance product and greater confidence on the job. It’s an ideal combination of protection and performance for your customer.

DEWALT

12" Sliding Compound

Mitre Saw Page 45

MEGAPRO

Ratcheting

Screwdriver

Page 45

How to install water supply and drain pipes in shallow soil conditions Page 42

By Steve Maxwell

When I began building in the mid-1980s in rural Ontario, every professional roofer used a hammer and nails. No one fastened shingles with air nailers until the mid-1990s, and even then just a few bought into the newfangled technology. I even remember diehard roofers in the 2000s explain to me why they figured they could finish a roof faster with a nail pouch. Yeah, right. The ability of people to fool themselves has no limit, but there’s a lesson here.

Once upon a time the cost of roofing in a given area was based on the assumption that every roofer used a hammer and nails. The early adopters of shingle nailers enjoyed windfall profits because their efficiency was so much higher than the community of hammer roofers whose bids set the market price in their area. As more and more roofers adopted pneumatics they could make money at lower bids. Competition did what it always does. It drove prices down to the point where we are today. No professional roofer can support themselves and a family these days driving nails by hand. The windfall profits generated by early shingle nailers are gone and this technology is now mandatory for being in the roofing business. Consumers benefit financially from lower roofing costs and the elbows of roof contractors last longer, but air nailers no longer boost profitability beyond the norm because they are the norm.

The lesson here is simple. Every revolutionary, efficiency-

boosting commercial technology has a life cycle that goes from big profit boost to no profit boost. It’s the quest for windfall profits that drives people to adopt new technologies in the first place. The length of this life cycle depends on how fast the majority of people adopt the new technology and this varies depending on where you work. I’m told that roofers in Alberta started using air nailers nearly 20 years before roofers in my little backwater did.

The days of revolutionary changes in tools that can double worker productivity in a given area are either gone forever or hardly ever happen. There are no more hammers to replace with air nailers, but this doesn’t mean there are no more windfall technologies. These days windfall profits are more likely to come through the kind of information technology that connects good contractors with clients who appreciate quality and are willing to pay for it. How long will the windfall profits from videos, photos, and online testimonials on a website last? If I know anything about the contracting business, probably until this generation of contractors has retired and been replaced. After that, a .com presence, video testimonials about your work and instant online accessibility to clients will be as ordinary a part of the contracting business as your truck.

steve@stevemaxwell.ca

By Steve Maxwell

Beating the realities of winter is one of the challenges you face as a Canadian contractor, and things can get especially tricky when it comes to plumbing. Entire regions of this country don’t necessarily have the soil cover to protect water supply pipes and drain lines from freezing year-round. I’ve wrestled with shallow-soil building situations since the mid-1980s, I’ve tried a number of different approaches, and some of the best freeze-protection plumbing solutions I’ve found come from a small Canadian company in the land of rocks and trees.

Lorne Heise started out as an electrician, but after he and his wife Robin left the bustle of Toronto to live in the soil-poor, cottage-rich region of Muskoka, Ontario, they founded a company called HeatLine (heatline.com; 800-584-4944). I first tracked Lorne down in 2011, following stories I’d heard about his water line freeze protection products installed around the world. You’ve probably never met anyone who gets as excited as Lorne does about the quintessential wintertime challenge of keeping pipes frost-free. Imagine spending a good part of each week inventing solutions for efficiently heating pipes! That’s Lorne’s life and he’s good at it.

When it comes to keeping pipes from freezing, water supplies and drain lines are two different animals. The risks of freezing are unique and so are the solutions. Both situations rely on electric heating cables, but the similarities end there.

As long as a drain pipe is sloped consistently and drains completely it might never get blocked with ice, even if it’s fully exposed underneath a raised building or buried by insufficient soil to keep the pipe above 0°C. But hope can be a dangerous thing when it comes to plumbing. If a blockage develops during winter in an otherwise reliable pipe, or frost builds up enough to clog the flow, it’s bad news. A 4-inch sewer line frozen solid with “ice” might not defrost until the robins have been back for weeks in most parts of Canada. And if something this ugly happens on one of your projects, you’ll look about as good as the stuff clogging your client’s sewer line.

Believe it or not, the most common place for rural sewer lines to freeze is just up the main pipe from the septic tank. That’s not what you’d expect given the fact that septic tanks generate considerable heat, right? Trouble is, it’s this heat that indirectly causes blockage. Warm sewage temperatures lead to high-moisture air wafting up the sewage line from the tank. As this very humid air cools in the pipe, the moisture it holds condenses out as frost. Extended periods of cold weather can trigger enough frost to plug the pipe solid and fill it with sewage that freezes. Once this happens, every drain in the house becomes useless for a long time. An electric heating cable can defrost a problem like this, but only if it extends all the way to the septic tank.

So how do you make sure drain lines never freeze when you don’t have enough soil? It comes down to electric heating cables and there are two options: external and internal. Until recently, external was the only choice for drains because plumbing codes prohibit any electric cable from being located inside a drain pipe. The danger that code authorities are concerned about is the remote chance of an explosion caused by a spark surrounded by volatile sewer gases. External application of heating cable also side- steps the chance of pipe blockage caused by sewage debris grabbing onto an internal cable and building up, but there are factors to be considered when installing an external cable. Besides the fact that the external approach is difficult to install around buried drain pipes, the transfer of heat to frozen water is inhibited by the pipe wall.

Earlier this winter I installed two types of drain line heating cables. One fastens to the outside of a fully exposed insulated pipe underneath a building on raised piers, and the other sits inside a buried drain pipe. HeatLine is unique in the world of heat trace systems because they have the only system that is cCSAus approved for use inside black and grey water drains. Their Retro-DWS system I installed includes a self-regulating heating cable that’s sealed inside a 1/2” diameter HDPE pipe. Technically speaking the cable is not inside a drain line, it’s inside a pipe that’s inside a drain line. This makes it okay for cCSAus certifications.

Another handy feature of the in-pipe approach is that you can push the heating cable a long way. You don’t need to fish it. In my own situation I easily pushed the pipe 130 feet from the building to a septic tank through a 4” PVC pipe. I’ve heard of situations where Retro-DWS was pushed a whopping 400 feet by hand without buckling.

There are many ways to keep water supply lines from freezing when they can’t be buried below the frost line, but the trick is making it all happen reliably and with minimal electricity use. The first time I installed a HeatLine product for one of my projects was back in 2011. The situation involved a 55-foot run from a drilled well on a site with about 12” of stony soil above bedrock and I used a product called CARAPACE. It’s a 200 PSI high density polyethylene pipe with a self-regulating heating cable molded into one side.

In this case “self-regulating” means the heating cable increases heat output as needed in areas that are cold. One location on the cable may be drawing very little power because it’s naturally warm, while a colder section may be drawing more to prevent the pipe in that section from freezing. Coupled with a thermostat system that turns the entire system OFF when pipe temperatures rise above freezing and you have very frugal use of electricity.

The installation I put in included preformed foam pipe insulation around the water supply line, all encased in a 4” ABS pipe for physical protection. Where the water line turns upwards and goes vertical as it entered this particular home built on piers, I replaced the preformed foam sleeve with spray foam insulation injected into 3/8” holes in the ABS. I couldn’t make the curve inside the ABS with the sleeve insulation, but the spray foam injection did the trick. With the thermostat sensor located inside the coldest part of the installation (the vertical part above ground), the electricity switches ON less than half the time, even in the coldest weather.

Your projects only succeed as well as the weakest link performs, and frozen plumbing systems can cause no end of headaches. To see the job where I installed both the internal and external drain pipe heating cables, visit baileylineroad. com/freeze-proof-drains.

I’ve been using a 7 1/4” DEWALT cordless mitre saw for a couple of years and I’m surprised how often I reach for it instead of my corded chopsaw. At least when the cuts aren’t too big. Cordless mitre capabilities are a nicer feature than you might think, and it’s one reason the new DEWALT DHS790 120V MAX cordless/corded 12” sliding compound mitre saw will probably be a hit. Another reason is features. I found this model well designed as I used it in my shop, with everything you could want. It bevels in both directions, it’s got 60º mitre capacity, stops for 22.5º and 38.5º bevels. There’s also the LED Cutline blade light – a personal favourite of mine ever since this feature came out with it years ago. The ability to run on either two 60V batteries or corded power is the thing that’s turning heads towards this model right now. One less cord to hook up, trip over and store later is an advantage. So is the fact that you can use either of the 60V batteries to power any DEWALT 20V tools. At a $1000 street price, you’ll probably soon see this saw on jobsites everywhere.

There’s no shortage of interchangeable screwdrivers in the world, but most are junk. I know because I get lots of screwdrivers to test and few live up to the demands of tradespeople. The Megapro line is different. The brainchild of BC tool entrepreneur Hermann Fruhm, their made-in-Canada ratcheting screwdriver was launched in 2004. It’s got a great handle shape, the ratcheting mechanism is fine and strong, and 6 bits (with 12 tips) are stored in a sliding holder that slips into the handle. I cut a Megapro apart to see how it’s made inside and I’m impressed. The interface between metal parts and plastic is well engineered, and I expect the hardened ratcheting mechanism will last for years of hard labour. Of course, the ultimate test of any interchangeable screw driver comes down to two things: how easy is it to swap bits, and how comfortable is the driver to turn. The Megapro wins on both counts. The selector ring and rotating end cap are a pleasure to use. At a street price of $50, this may be one of the most expensive screwdrivers you can buy. It’s probably also the best. Visit baileylineroad.com/mega-pro-driver to see the insides of the driver up close.

Leonard’s client has offered his guys some off-book work. Should he intervene?

Leonard Zarky’s five-man masonry team has been doing interior and exterior stonework on a large weekend home for over two months. His wealthy client Tony Snell has become a familiar sight during this time, getting to know the guys pretty well. In late-September, and with the project nearly complete, Snell approached Leonard about having these strong young men do some unspecified ‘grunt work’ over the next few weekends for cash. Initially, Leonard had no problem. After all, weekends are their time, not his.

However, after the first weekend Leonard learned that his guys were in fact asked by Snell to get in the cold

water without any protection, dredge out the wet boathouse by moving large rocks lying at the bottom, pile them along the shoreline, and do a bit of silt removal with rakes and shovels. This bothered Leonard. He knows it’s illegal to dredge or move material from a lake bottom without an environmental permit. Secondly, the work is far more dangerous than he had thought. If one of his workers gets injured working offbook for Snell, they’re uninsured, plus it could put his team down a man.

What should Leonard do? See the options at right.

Our most recent contest (November/December issue) found Dave Ullman in a five-year process of handing his successful contracting business over to his 24-year-old son, Billy. Billy was intrigued by an offer from former wealthy client Ken Morgan, who’d like to joint venture with the Ullmans in buying, renovating and flipping houses. Billy saw this as a way to expand the company and make his mark. Dave was unsure if he and Billy should go in this direction.

Our panel looked at a number of well-considered proposals, but ultimately selected the cautious approach put forward by Matt Brown of Telos Construction Ltd., Abbotsford, BC which included the following remarks:

“If Billy truly sees investor partnerships as an integral part of his future business plan, maybe a one-time ‘trial run’ project agreement with Morgan could be a positive experience,” wrote Brown. “Dave needs Billy to understand the importance of a solid business plan moving forward that will help him to focus his attention where it needs to be, and not to lose focus due to what may initially appear to be an attractive opportunity.”

Congratulations, Matt! You win a DeWalt Cordless/Corded 20V MAX* Bluetooth® LED Large Area Light (DCL070), retail value of approximately $479.

1. Explain the risks to the guys, and advise against doing the work.

2. Report his client to the Ministry for doing illegal dredging and shore work.

3. Turn a blind eye and let the boys make up their own minds.

4. Tell his client this is wrong, and suggest he goes about the work legally next year.

5. Something else.

Please include an explanation of your proposed resolution.

HOW TO ENTER

Email your answer to John Bleasby (jbleasby@canadiancontractor.ca) by March 8. Your suggested solution can be any of the above ideas, a combination, or your own solution entirely. Please explain your answer in up to 300 words of text.

The contractor-submitted answer chosen as our winner will

a new DEWALT 12V self-levelling Green Laser with a retail value of approximately $499.

If you think that underpaid contractor might be YOU, get yourself a seat at our NEXT LEVEL contractor peer group sessions.

At NEXT LEVEL, renovators and homebuilders open up every aspect of their businesses: Their books, their strategies for growth, their hopes and dreams for the future.

In a sharing and coaching environment, contractors just like you are able to find ways to become more profitable – and to take their businesses to, yes, the next level.

To find out more, contact Rob Koci, publisher of Canadian Contractor Cell: 647-407-0754

Email: rkoci@canadiancontractor.ca