Contract Clauses That You Should Start Using page 37

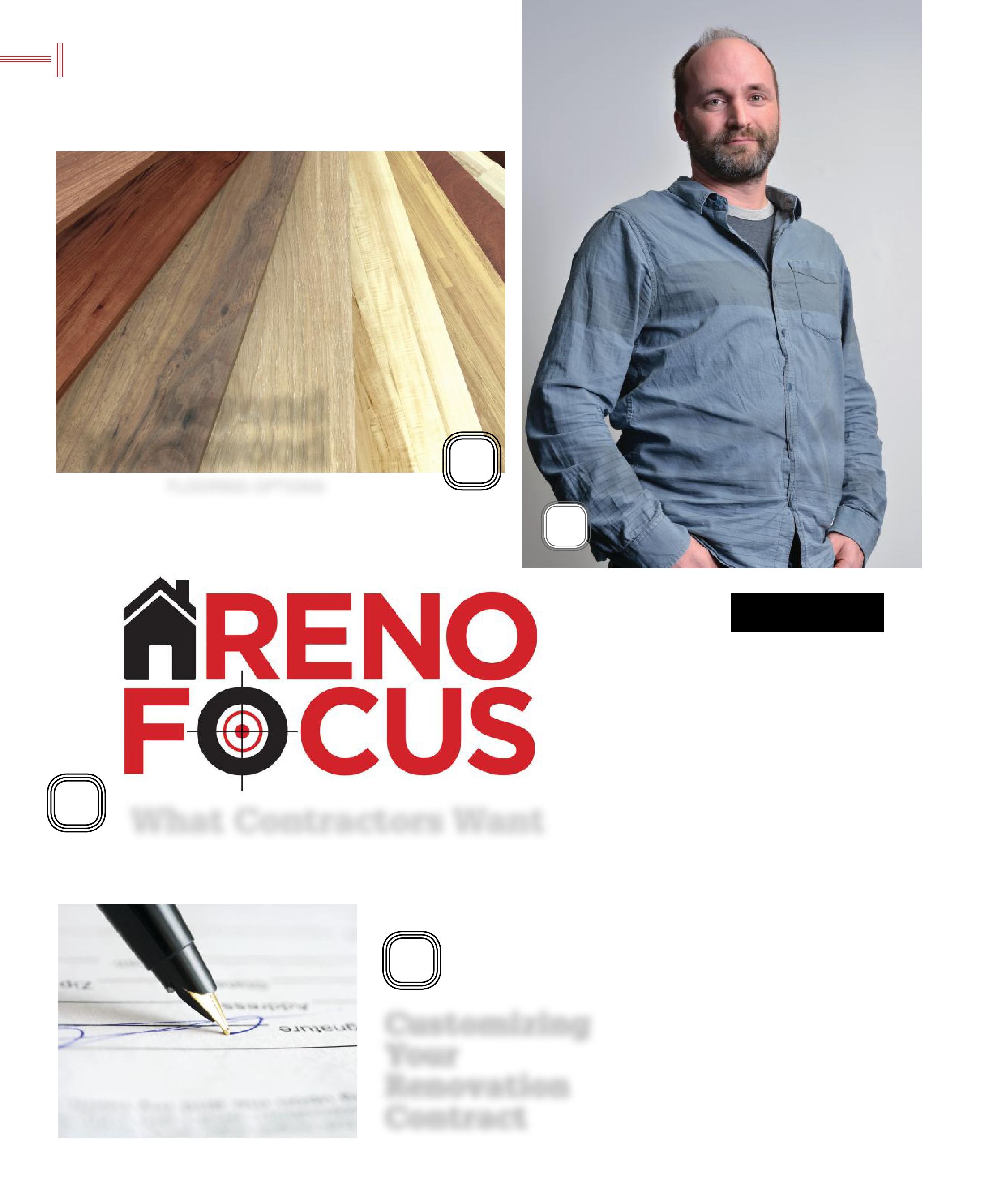

Flooring Alternatives s Beyond Hardwood page 32

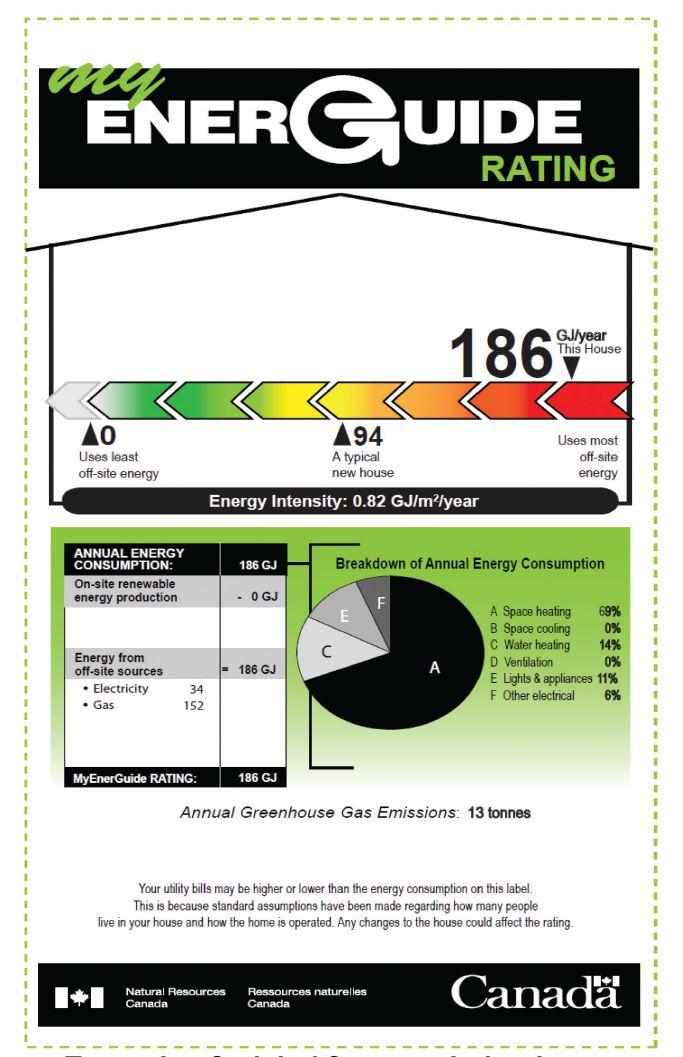

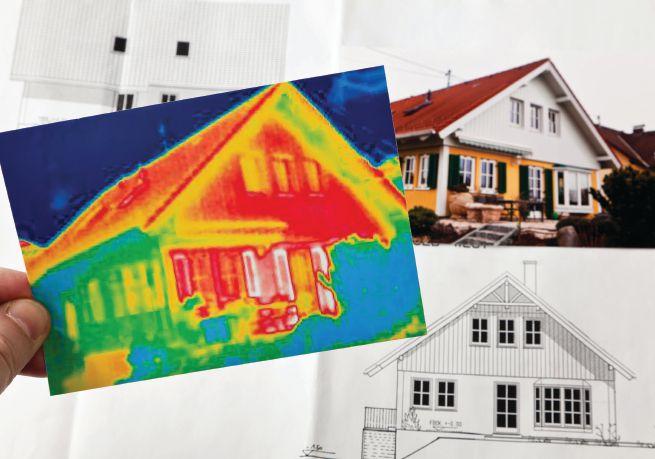

Steve Maxwell EnerGuide For Houses page 49

Contract Clauses That You Should Start Using page 37

Flooring Alternatives s Beyond Hardwood page 32

Steve Maxwell EnerGuide For Houses page 49

Green builder extraordinaire

BEN POLLEY shares his secrets at our RENOFOCUS event

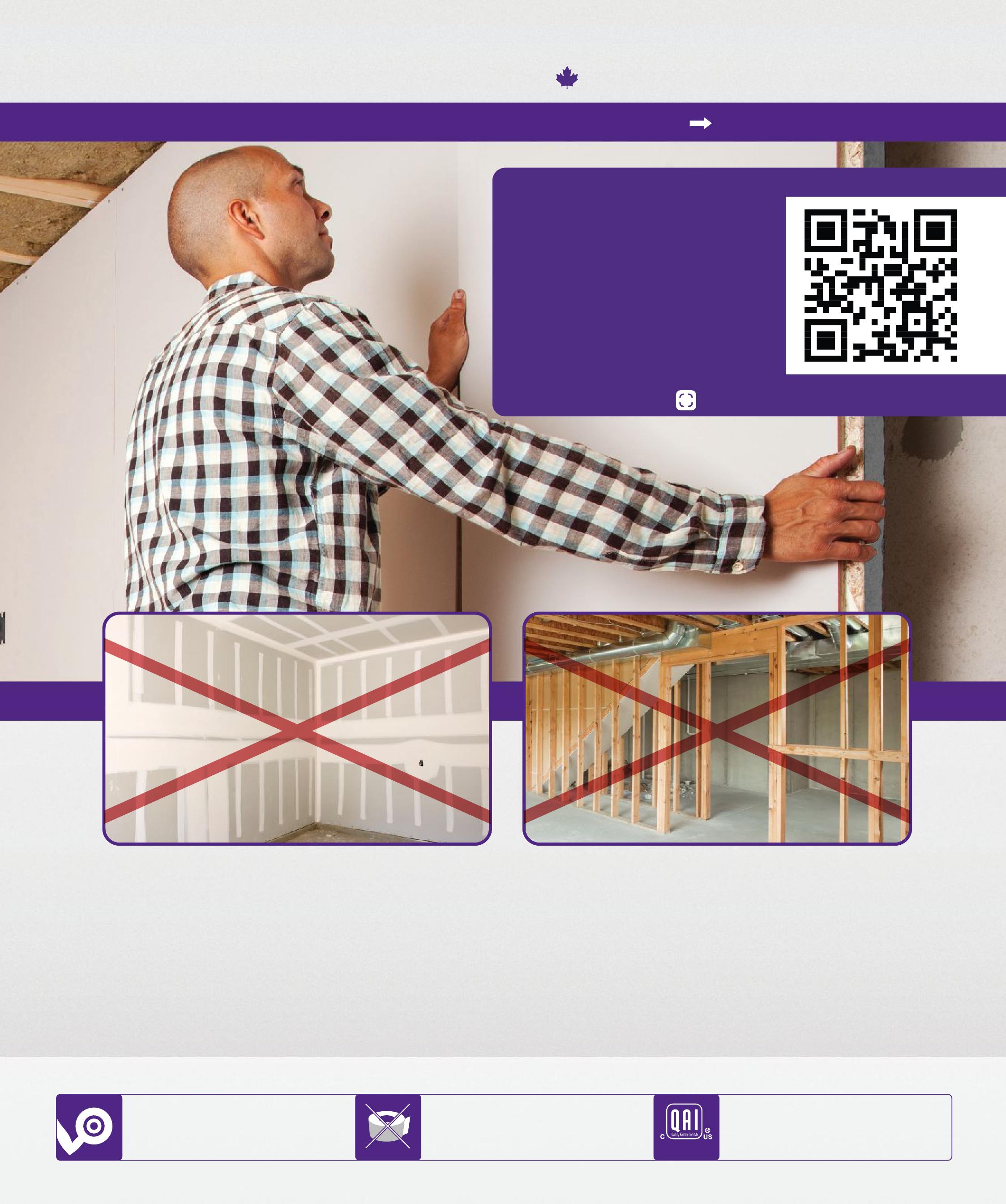

As a professional contractor, being under pressure is nothing new to you. That’s why using products that help you to get the job done faster is a must. DRIcore SMARTWALL® simplifies basement finishing by providing a product that is 5x faster compared to conventional construction methods.

FEATURES:

•INTEGRATED VERTICAL & HORIZONTAL WIRING CHANNELS

•ACCESSORY PANELS CONTAIN ELECTRICAL BOXES.

•MICRO BEVELED EDGES - NO TAPING REQUIRED

•TONGUE & GROOVE INTERLOCKING SYSTEM

•HIGH DENSITY GRAPHITE INFUSED EPS INSULATION

•OSB FRAMING MEMBERS

One of the many conveniences of the SMARTWALL® system is the patented “Micro Bevel” edge detail, which eliminates the traditional taping stage of finishing the drywall surface. The micro bevel requires much less filler to achieve a finished surface, resulting in far less sanding and therefore less dust created.

The SMARTWALL® ChallengeWatch Adam take on traditional building methods with DRIcore SMARTWALL®. Which method is faster? Watch to find out!

Unlike the multi-step process of conventional construction methods, DRIcore SMARTWALL® combines framing, insulation, drywall and a vapour barrier in one fast step. SMARTWALL® panels lock together using a tongue & groove system.

Bob Collins

Home Building Centre – Gravenhurst Gravenhurst, ON

When your reputation is built on quality, you depend on relationships built on trust. That’s why you can trust the Experts at Home Building Centre and Home Hardware Building Centre to provide the tools, materials and services you depend on – from dedicated contractor sales staff and easier ordering through phone, fax or email to job site deliveries, credit services and package pricing. With a relationship built on trust, you know you’re building on a strong foundation.

pronews.ca

Online 8

How to put the Canadian Contractor icon on your phone, for one-touch access to our breaking news.

Editorials 10

Rob and Steve on two inspirational contractors: one ‘Alternative’ and one ‘Old School.’

Voices 12

The best of the recent ‘tell it like it is’ contractor posts from our website.

Site Notes 18

An Ontario project manager sentenced to 3-1/2 years in jail, Mattamy Homes’ latest Net Zero success story, and more from around the industry.

Creative Eye:

Townhomes in the Tundra 40

You think it’s cold on your jobsite? Take a look at this bone-crunchingly frigid project in the Far North of Quebec.

The Happy Painter 46

A profile of Rick Fowler, Spar Construction, Edmonton.

Stuff We Like 49

Steve Maxwell takes a look at the EnerGuide Rating System for houses.

Editor’s Picks 57

Products you need to know about.

What Would You Do? 58

Solve this contractor’s dilemma and you could win an awesome new DeWALT cordless impact wrench.

Visit us online

INSTRUCTIONS FOR

• Google Canadian Contractor on your mobile device

• Open the link to canadiancontractor.ca

• When the page opens, tap the menu button on the lower left corner of your screen

• Select “add shortcut”

• Go back to your device’s screen and locate the Canadian Contractor icon (It may appear on one of your later pages.)

Go to canadiancontractor.ca and type “icon” in the search bar at the top right. The link to the video will pop up.

2016 canadiancontractor.ca | Tel: 416 442 5600 | 80 Valleybrook Drive, North York, ON, M3B 2S9

Canadian Contractor, established in 2000, is published 6 times a year by Annex Business Media.

• Press and hold the icon, and drag it forward page-by-page to the desired page on your device

• Go to canadiancontractor.ca using Safari or your favourite browser

• When in portrait mode, click on the square icon with the “up” arrow that appears at the bottom of the screen

• Chose “add to home screen”

• Click “add”

• The icon should appear on your Iphone or Ipad home screen

Now with one click, you can go directly to the latest news!

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, John Caulfield, Mike Draper, Kim Laudrum, Steve Maxwell

Art Director Lisa Zambri

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator Tracey Hanson thanson@@annexbizmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbizmedia.com

The most advanced sliding compound miter saw available, the Kapex is engineered to be light weight and compact. It’s the perfect saw for the workshop or the jobsite. The Kapex features fully-adjustable dual-line lasers that accurately define the cut area. Loaded with a host of time-saving features and a rail forward design that prevents head play, you’ll spend more time working and less time on cleanup with our unmatched dust extraction.

Ben thinks for himself. And for that, he’s priceless. ” ”

Rob Koci Publisher rkoci@canadiancontractor.ca

By Rob Koci

In our 15 years of publication, we at Canadian Contractor have never been kind to green building. As far back as 2007, I wrote an editorial outlining why I believed the Kyoto Protocol was just about the worst political initiative possible. And why “climate change” was nothing more, to me, than trash science used for political purposes by lefties after the Berlin Wall came down in 1981 and their beloved socialism had been proven a failure.

We have run major features on green building over the years, not because we really wanted to but because so many contractors were trying to build green at the time – and as a business magazine, we needed to explore their efforts. But we never drank the green Kool-Aid.

Which would leave you to believe that Ben Polley, one of the premier green builders in Canada, would not have much to share with us, or us with him. Nothing could be further from the truth. Ben was one of the first of 32 contractors we invited to our RenoFocus ‘think tank’, which we held in Toronto at the beginning of December. We just had to have Ben there. You can read some of Ben’s thoughts about the event on page 28.

I first met Ben at the Toronto Spring Home Show about 12 years ago. His company, Harvest Homes, was building a straw bale home inside the show, a fascinating bit of building for a traditionalist like me.

More fascinating, however, was Ben’s ability to balance the demands of new, expensive, often unproven technology with the practical matter of running a successful business. And he somehow had the ability to do it in the most ethical manner and with a smile on his face, while remaining true to his green values.

Despite our radically different views of the world (I have never voted anything but Conservative in my life, Ben has run as a federal candidate for the Green Party), I have always enjoyed comparing notes with Ben. Part of it is his total openness when he discusses the business aspect of being an “Alternative” builder (Ben is right that “Green” is becoming an over-used word). Ben thinks for himself. And for that, he’s priceless.

By Steve Payne

Our contributing editor Steve Maxwell was the first person to write for us about the importance of learning from Old School contractors. HVAC contractor Don Lee, Community Gas Heating, Scarborough, ON, is why I’m writing about this again. Don is somewhere in his mid 70s and still cranks it out, seven days a week.

Why doesn’t he want to retire? He can easily afford it. “I love what I do,” Don replies. “It’s for the customers. I really enjoy the people.” Plus, as Malcolm Forbes once wrote, “Retirement kills more people than hard work ever did.”

I got a chance to chat to Don about his life’s work as HVAC contractor quite recently. My family’s furnace made really horrible noises before shutting down totally, at minus 20C outside, on a Saturday midnight. For various reasons, I hadn’t needed my own furnace guy in 20 years. Don, at that time, was approaching what I thought might be retirement age.

But I still had Don's now-yellowed business card in a drawer. So I phoned the number, expecting someone else would be running the firm by now. At 12.45 am, I answered the phone to hear Don's gravelly voice after all these years. “Steve, it’s been a long time.” I felt slightly ashamed about that. “We’ve got a couple of other emergency calls in the next few hours. But we can come by in the morning.”

In the morning.

At 10 am the next day, Sunday, operating on about 4 hours of sleep, Don Lee and two of his young crew stomped into our house, holding giant McDonald’s coffees.

“How’s your Mom?” Don enquired. He had last serviced her furnace, before she moved away, 25 years ago.

“Thanks for remembering, Don,” I replied. “I bet you even remember the model of the unit.”

“Sure, that Carrier was a beast. Remember when I switched out the drive shaft? That thing did 25 years. They don't make them like that any more. A good model.

So are you, Don. So are you.

” Retirement kills more people than hard work ever did.

”

Thanks to our RenoFocus attendee Neil Damackine for the following online post. To read more about RenoFocus, please see pages 20 through 29.

“As contractors we go through hoops of fire…”

My contract has a standard clause requiring the homeowner to provide all city-issued work permits and that is generally standard in my area (Quebec) although I am aware that service standards and the follow-up of post permit issuance inspections carry different responsibilities for contractors in other areas. If the work is non-structural interior renovation I don’t push it beyond the initial enquiry. But the moment it’s either structural or involves electrical or plumbing, there’s zero negotiation if a permit is required and I’m very willing to walk away.

I make it crystal clear at the beginning of any job that because all work is done by appropriately licensed workers and subcontractors it’s all documented and taxed in a paper trail that ultimately shows where the work has taken place and who’s paid for it. The takeaway I stress to the client is there are no secrets if you want guarantees and value that’s transferable down the line. As contractors we go through hoops of fire to get all the right licences, permits, collars and shots for the pleasure of working – so I just don’t want the hassle of being told to stop before I’m finished. Let alone being tangled up in someone else’s drama! Neil Damackine, Construction ND, Terrebonne, QC

One of our recent “What Would You Do?” business cases was called The Permitless Rich Kid. We asked you how you would respond to a major client, with lots of money, who wanted you to go ahead with significant work without permits. We were not talking about minor stuff, either. This case study involved a fullon major rebuild of a blue chip mansion – a very lucrative project with weeks of work for your crew. The winning reply, from Jim Walowski, JSW Construction, Coldstream, BC, is summarized at the bottom of page 58 in this issue. Here is another idea from our valued contributor Jim Baird, an Ottawa contractor, bringing up the idea of an indemnifying letter.

“Once asked to sign the letter… they changed their mind.

It’s possible being asked to sign a letter indemnifying the contractor from liability may cause the homeowner to realize the benefits of having a permit. I used this method years ago when I

came across a concerning electrical issue a client felt there was no need to correct. Once asked to sign a letter acknowledging the repair was declined by them, they changed their mind.”

Jim Baird, First Place Renovations, Ottawa

Profit sharing was one of the many topics that we all kicked around at the RenoFocus conference. It had its opponents among the contractor-owners in attendance, all of which have loyal and dedicated staff that are clearly valued and respected. Here is a post from Desmond Sweeney, one of our RenoFocus participants…

The free time provided at the RenoFocus conference was exciting indeed — being able to throw ideas around with, and get feedback from, other business owners proved invaluable. I left with a head full of new ideas.

Regarding profit sharing: In the past I’ve worked for companies that have had profit sharing. There were good years with bonuses, and bad years with none. These good and bad years occurred regardless of how much effort I put forth. Some years I felt under-rewarded. Additionally, bonuses were based on company performance; average workers received the same as exceptional workers. I don’t think I’ll ever implement profit sharing in my company, at least not in this traditional way.

I’ve also worked for companies where performance-based bonuses were used. I liked this better as I felt I had more control. However, depending on the size of the bonus, for smaller companies such as mine this can be difficult on cash flow. Even if the company has a bad year, superstars exceeding performance expectations get rewarded. The key to this is to define attainable (but not easy) performance expectations for each staff member. And, of course, to plan to have a few extra dollars earmarked for this to bridge the bad years.

I have heard that nobody will treat your business the same as you do, unless they have skin in the game. For a long time I thought this meant that, short of giving up partial company ownership to an employee (and thus sharing both extra money and costs), I’d never find someone to fully depend on. But I’ve learned that qualitative rewards such as great company culture, non-monetary perks, etc., can sometimes go farther than a few extra bucks. This is where my company’s current focus is. And in the construction industry, this can also extend to sub-trades.

Desmond Sweeney, Red Seal Builders, Winnipeg

And a reply to Desmond from a fellow RenoFocus attendee, Matt Smith…

“As owners, we need to keep in mind that we provide our valued team with full-time work consistency…”

I second Desmond’s philosophy on this – company culture, voice appreciation and non-monetary perks are all value-adds that we use as well. We would be interested to understand if a small company uses another format that would not create an expectation from the employee at the yearly Christmas party… In addition, we aim for two to three team building events as well as picking up the bill for bi-weekly breakfasts and random coffees for site meetings.

As owners, we need to keep in mind that we provide our valued team full-time work consistency with great working conditions and above competitive wages. We feel that is fair. As a side note, at the beginning of December, CRA requested us to provide them with invoice entries from 2013-2014 (3,500 of them) of which they now need 170 hard copies… I wonder if I can ask my lead carpenter to give me a hand?!

Matthew Smith, Mapleridge Homes, Chelsea, QC

Back in November, our contributing editor John Bleasby posted an online story about the continuing scarcity of women in the home building and renovation trades. John wondered why this was still the case, years after women have allegedly broken most other employment barriers. John’s article attracted one of the bolder reader posts we have seen lately, from our loyal contractor subscriber Marten Burghgraef, who is no shrinking violet...

Why do we need more women?

“I’m not sure why anyone would want to push for more women in this industry… It is a tough, physically demanding industry. I don’t see it as a macho thing but guys and gals talk to each other differently. When a female steps into a male conversation she is usually left scratching her head and wondering why we talk the way we do and still get along. Not a lot of luvvy dovey stuff here. Of course there will be the exception but this is the way I see it. For me, seeing a male nurse is still weird. I still think of nursing as a female dominated industry and don’t see a push for more males there.”

Marten Burghgraef, Dutch Touch Construction

And then came the replies…

women

It is the differences that make us better. My wife and I work together in our renovation business. Our abilities complement each other. She provides a design sense that I can’t see until she shows me the way. I bring the implementation of her design to the table. The construction industry needs more of this type of collaboration.

Brad, harmonydesign.ca

“Women don’t expect ‘luvvy dovey’!”

I couldn’t just let your post about women in the trades go by without a comment. I am a licensed construction and maintenance electrician and I own an electrical contracting company. I have been in the construction trade since 2003. And I am a woman.

I feel the need for a rebuttal to Marten’s post. Women in the construction trades do not come to work expecting anything “luvvy dovey.” I’m not even sure if that is a valid term or what exactly he is referring to. We have lots of love at home from the families we are supporting. The only reason a female is scratching her head about your “male conversation” is because she can’t figure out why you are arguing in circles about something simple that she has already solved. Marten says, “It is a tough, physically demanding industry.” Yes it is… but so is nursing, which he noted was a “female dominated industry.”

Let’s compare the two. Both are physically demanding. Both involve clients that should be treated with respect and care. Both require attention to detail. Both involve heavy equipment. Both involve becoming better at your job with experience. Both have a good pay cheque.

Hmm, I haven’t found any gender-specific reason why either job couldn’t be done by either gender... other than attitudes like your reader’s. Unfortunately, there is still a lot of that Old Boy’s Club attitude in the world, even in 2016. Women, however, are breaking down that club, which is the exact reason why we “want to push for more women in this industry.” A woman in the construction industry is there for job satisfaction and a pay cheque, the same as a man in the construction industry.

Janet Crowther, girlpowerelectrical.ca

ONTARIO WSIB

How to legally avoid WSIB, as a renovator

According to my figures, if I was to get stuck in the WSIB’s system

our to work.

Our windows are crafted for style and engineered for performance. Let’s work together to give homeowners the best of both worlds.

Low-E glass for enhanced performance.

There is a reason JELD-WEN is the go-to brand for so many experienced professionals. Visit your local JELD-WEN dealer to get started on your next project.

Eye-catching custom window shape for style.

as a contractor, I would be paying about $6,000 a year for the rest of my career. Currently, I do whatever it takes to stay exempt… in a legal manner. Most of my renovation work is directly for the home owner, therefore my little one-man company is exempt from paying WSIB premiums or having a registration number. I’ve spoken to their agents a few times about “the rules.” Their program really limits my business but, of course, they do not care about that.

Whenever a contractor wants to hire me for a residential job I have to inform them that I can only deal directly with the homeowner financially. I have to decline commercial work altogether, although one company that wanted to use my services put me on their payroll and I would work as an employee for a few months. I suppose this is the only way to stay “exempt.” In order to protect my customers in case of an injury I have a real disability policy that covers me 24 hours a day whether at work or not – and it costs me one quarter of what the WSIB would. Instead of forcing a contractor to pay into WSIB, the government should have developed a law where all contractors are required to have a certain type of insurance plan and listed an assortment of businesses that could provide such a policy. It would be fair and honest in a business sense, which is what Canada is supposed to be all about, not the corrupt and unreasonable “system” we are subjected to now.”

Ron

Editor’s note: We obviously cannot (with the confidentiality of medical records, no media outlet could) verify the claims of medical malpractice by the following online poster. The Altum Clinics operate in some dozen locations in Southern Ontario. We have no evidence that they are unprofessionally-run, let alone fraudulent, and the opinions printed below are strictly those of our online subscriber. However, these types of public complaints about WSIB-affiliated doctors are widespread, not just on our online portal, but in multiple media outlets. Is there something seriously wrong with the way WSIB investigates its claimants’ medical status with its ‘own’ clinics?

“Do not go to the WSIB’s clinic!” WSIB sent me to their Altum Clinic. I had a torn meniscus resulting in an unstable knee. I should have had surgery to trim the meniscus but WSIB’s doctor did not recommend it. Within 11 months, my cartiledge was stripped down to the bone by the damaged meniscus. I now have advanced stage arthritis in this knee, largely due to this doctor’s negligence. I found out after the fact that unstable knees should have arthroscopy.

This doctor tried to convince me I had pre-existing arthritis. Another orthopod assured me, when I initially had the injury, that I had no existing arthritis in the knee. WSIB’s doctor then tried to mis-diagnose me with a much minor patella tendonitis to cover/ delay the diagnosis of chondrosis/arthritis. He refused to order anything which would cost WSIB, except grueling physio. Things which would have helped me, such as orthotics, a knee brace, massage therapy or chiro, were denied me because – as he put it –WSIB would not approve.

Anyone having a work-related injury, do not go to WSIB’s clinic. You will have a poorer quality of care than if you go to an OHIP clinic. In my opinion, WSIB clinic doctors have crossed the line from fiscal budget restraint to malpractice and outright fraud: ready to misdiagnose workers to prevent/delay claims.

Sabina

The National Building Code of Canada costs $295 for a print version. If you think you can save money by ordering an e-book (a PDF), forget about it – that’s $295, too. An online subscription? $182 a year. Quite a few contractors are fed up with all this…

“Leave it to government bureaucracy…”

Leave it to government bureaucracy to make regulations and then make you pay to see what they are. I know many good contractors who have lost a lot of money because they didn’t know about updates to the code, especially regarding energy efficiency.

Gordie Eldridge

“If it’s the law for us to follow the codes…”

I agree totally. If it’s law for us to follow the codes it should be against the law for people to charge money for the rules that we are to follow.

Dustin Wood

“It must make too much sense to have it available.” All codes should be available online for free. When you’re trying to get something done all you need is to be able to search it but no, you have to buy a code book for $300 to use a couple times before the next one comes out… It must make too much sense to make it available. I mean is selling the books more profitable then the fire inspector or building inspector making several trips to a job site? Canada has one of the most inefficient work forces in the world. I wonder why, when everything gets done twice.

Mike

For more than thirty years, DuPont™ Tyvek® has set the performance standard and today it protects millions of homes in North America.

Our weather barriers are made using a unique process that fuses polyethylene fibers into a strong uniform web structure that provides superior air and water hold-out while letting moisture escape. Whether you’re building a new home, or residing or remodeling an existing one, insist on DuPont™ Tyvek® for superior weather protection.

The difference is DuPont™ Tyvek®

Project manager at Toronto swing stage tragedy sentenced to 3-1/2 years in jail

Vadim Kazenelson, the project manager for Metron Construction, was sentenced on Jan. 11 to 3-1/2 years in jail for his role in the Toronto swing stage tragedy which took the lives of four workers and seriously injured a fifth on Christmas Eve 2009.

Kazelnelson had already been found guilty last June on four counts of criminal negligence causing death, and one count of criminal negligence causing bodily harm. Kazenelson is appealing his conviction and is out on bail.

In handing down the sentence, Justice Ian MacDonnell said that Kazenelson had “decided it was in the company’s interest” to allow his men to work in “manifestly dangerous conditions.” Indeed, Kazenelson had a close-up view of the untied-down nature of his crew. He was, in fact, handing tools to his men when the swing stage broke in two. Kazenelson managed to cling onto the 13th floor balcony as the other men plunged.

Ontario Federation of Labour (OFL) president Chris Buckley lauded the jail sentence. “Bosses cannot expect that it’s all about money,” he said. “Families have been destroyed here. This is not just about profits any longer. This is about the health and safety of workers.”

The aftermath of the tragedy caused a significant increase in Ontario Ministry of Labour (MOL) construction site safety inspections that continues to this day. One particular safety blitz by the MOL involved inspections of 2,800 sites in 90 days. 784 of those sites were closed. The MOL has continued to find widespread violations of provincial regulations re: guardrails, scaffolding, fall protection systems, worker training and records, ladder use and many other issues.

The swing stage tragedy was also a catalyst for the launching of Ontario’s new Working at Heights Standard that came into effect on April 1, 2015.

The MOL continues to sends its message out, most recently with its Zero Tolerance directive to its inspectors in November 2015. This affects all individuals found violating the Occupational Health and Safety Act in commercial, industrial and residential construction projects.

Alec Caldwell, www.carahs.org

Former TV contractor in Alberta faces 180 charges under Fair Trading Act

Service Alberta hammered contractor Bruce Hopkins, the former host of the defunct TV show Remodel It, with 180 regulatory charges under the Fair Trading Act, Dec. 4. Hopkins, who in addition to his contracting firm owned the

company that produced the show, has vowed to fight the charges. They followed the bankruptcy of his two companies last year. In November 2014, Service Alberta received 27 complaints from clients of Hopkins, claiming total losses of some $5-million.

The charges include operating without a prepaid contractor licence, misleading consumers, and failing to provide refunds.

Though hardly a household name among Canadian TV celebrity contractors, Hopkins had a life story – frequently repeated on the show – that invited sympathy and admiration. He had risen from drug addiction and homelessness, he said. After a long period of recovery, he had become a professional renovation contractor – one with an apparent heart of gold.

“He was homeless. A friend gave him a job fixing up houses,” the narrator of one Season 3 Remodel IT episode says. “He got pretty good at it. He went from needing help to helping people.” But now, Service Alberta is claiming – 180 ways – that Hopkins helped himself to his clients’ money.

It’s not the first time Hopkins has been in legal trouble. He was first criminally convicted with walking away with down payment money and assets, without providing the construction services agreed to, as far back as 15 years ago.He told the Calgary Herald last year that his severe drug addiction in the 1990s was to blame for that particular episode.

Steve Payne

Zero Net homes (ZNE’s) are the talk of the residential landscape across Canada, and now North America’s largest privately-owned home builder is officially part of the movement. A striking new 1,658 sq.ft. house in Calgary’s NE community of CityScape, built by Mattamy Homes, is the first of five similar residences to be completed by spring 2016.

“This flagship project will help pave the way for Mattamy, as well as other production homebuilders, to make Net Zero homes available in more communities,” said Brad Carr, president, Mattamy Homes Canada.

Net Zero Energy homes are energy-efficient residences that generate as much energy as they consume on an annual basis. Mattamy's Calgary build featured innovative technology such as advanced insulation (the Owens Corning CodeBord Air Barrier System), Plygem triple-pane windows, a Mitsubishi Cold Climate Air Source Heat Pump; a Rheem High Efficiency Domestic Hot Water Heater, an Eyedro real-time energy monitoring system, and 40 SolarMax photovoltaic panels.

“The net zero project aims to prove that existing technologies

can be utilized to make these ultra-efficient homes available at a community-scale,” said Andy Goyda, Canadian builder lead and marketing development manager for Owens Corning Canada.

Natural Resources Canada's ecoENERGY Innovation Initiative, along with major partner Owen Cornings Canada, have generated $4 million in funding and in-kind contributions, and are teaming up with the building industry to construct at least 25 ZNE homes across four provinces: Alberta, Nova Scotia, Ontario and Quebec.

“Mattamy is proud to be one of five builders, and the only builder in Western Canada, selected to participate in this initiative, leading the way towards a more eco-friendly and sustainable future,” Carr said. Mattamy will also be enrolling all five homes in the Canadian Home Builders’ Association’s Pilot Net Zero Energy Home Labelling Program.

“A Net Zero Energy home loves you back,” explained Bard Golightly, past president of the CHBA. “It shelters you from rising utility costs, it delivers exceptional comfort, it works better, and it lasts.”

As the Canadian population ages, professional renovators are going to find a lot of money down in the basements of older homes. That was one of the conclusions that could be drawn after listening to Ted Tsiakopoulos, a regional economist with the Canada Mortgage and Housing Corporation (CMHC), who spoke at the Toronto Housing Outlook Conference in November.

Ontario is a $25-billion renovation market, Tsiakopoulos said. A big part of that market is the renovation of basements –oftentimes due to the addition of a basement apartment. This is partly because the price of housing stock is so high in Ontario that “boomer” parents are likely to be motivated to renovate to provide basement living accommodations for their children, until they can get established at work or save for a house.

Affordability and the relative shortage of real estate listings are also behind the trend, Tsiakopoulos said.

CMHC stats quoted by Tsiakopoulos show that the 55- to 63-year-old age bracket occupy 1.1 of the 3.7 million households in Ontario. Only 20 per cent of those people are expected to downsize. 40 per cent of them are expected, rather, to do significant renovations, including full-on basement renovations.

Our annual salary survey, which only takes about 15 minutes to complete, is now online at canadiancontractor.ca. You could win a FESTOOL Trace saw, same model as a right, for filling it out!

A

Saw will make this ‘HanDeeMan’ even more efficient in his work!

Oakville, ON, contractor James Vasilakos, owner of HanDeeMan, is the very happy new owner of a FESTOOL Track Saw. James won the prize in a random draw conducted by Canadian Contractor, with everyone who replied to our recent online RenoFocus survey entered in the draw. The strictlyconfidential answers were shared with FESTOOL and other sponsors of RenoFocus, as the firms gathered feedback from the marketplace to use in their new product development. Canadian Contractor congratulates James for winning this very cool tool (editor Rob Koci purchased one recently and raves about it). And we thank FESTOOL for sponsoring this prize.

Thirty-two contractors. Six product suppliers. A contractor coach. A building supply chain. Two days picking each other’s brains. Our first ever Canadian Contractor ‘focus group’ event, held in Toronto Nov. 29 - Dec. 1, yielded surprising new insights into our industry.

By Steve Payne and John Bleasby

Morethan a hundred contractors across Canada asked us to select them to come to Toronto for Canadian Contractor’s first ever manufacturercontractor focus group sessions, RenoFocus 2015. We wish we could have hosted them all. The 32 contractors we were able to invite confirmed our longheld view that our industry has the brightest possible future. The commitment to our industry shown by these home building and renovation professionals was truly oustanding. Everyone obviously had multiple jobsites on the go back home – many with tight end-of-year deadlines – and yet everyone got passionately engaged in sharing their experiences with fellow attendees.

Publisher Rob Koci's concept for RenoFocus came as a result of mutliple requests over the years for Canadian Contractor to survey readers about the state of the industry. What was working for our contractors? What was not? Are contractors building differently today than they were ten years ago, and how? What products and services do contractors need but cannot find?

Our sponsoring product suppliers wanted to know about the 4 P's of the marketing mix: product, place, price and promotion - especially for new products in development. We also knew that contractors also deal with these same 4 P’s: everyone in the industry is bringing a product to market, whether you are a new

home builder, a renovator or a sub trade.

Oh, and we should mention on more P - profit!. The best contractors in Canada (measured in terms of longevity, production, quality – and their reputation) continue to make a very decent profit, year after year, despite the challenges of a fluctuating economy and regulators apparently hell-bent on raising the cost of doing business. How do the best-run contracting businesses do things differently? Why do they prosper, when others break even, downsize, or even go out of business? How do their owners get the best out of their people? RenoFocus was designed to answer as many of these questions as possible, as well as to provide value for the contractors who came to the event, by helping them develop ongoing relationships with like-minded, similar size companies in other areas of the country.

Now that our first RENOFOCUS is behind us (we are doing it all again later this year, see page 47), we would like to thank each contractor who took the time to travel to Toronto, the sponsors who paid the freight for this fact-sharing mission, and the fine folks at the Le Germain Hotel Maple Leaf Square.

Our contractor-participants were generous with their time as our editorial staff asked personal, sometimes intrusive questions about each of the contractor’s businesses. We got at least 20 ideas for future editorial content (expect feature articles or online posts on many of the below, as the months tick by). The quotes below are real, but unidentified, to protect the anonymity of the contractor.

1. Which is the best contractor software? (“We still haven’t found one system that does it all.”)

2. The project that goes south: a rite of passage? (“If you haven’t lost more than $10,000 on a job, you aren’t yet a real contractor.")

3. Online reviews. (“One really bad online review won’t kill you. Let me tell you about mine.”)

4. Retaining key employees. (“Entrepreneurs will learn from you, and then leave. You want ‘intrapreneurs’: employees that think like entrepreneurs but want to do it within your firm.”)

5. Work/life balance. (“If you don’t get some regular down time, you’re not going to be able to stay in this business.”)

6. Having a vision for your firm. (“Do you know what size of

company, and what kind of profit, you are looking for? You really need to know.”)

7. Cost-plus versus fixed billing.

8. The perfect ways to handle change orders.

9. Time management systems. (“The GTD system – Getting Things Done – changed my life.”)

10. What are you reading about the industry online? (“Canadian Contractor!”)

11. Who are you following (in the industry) on Twitter?

12. Joining a contractor peer group.

13. Reporting cash competitors to the CRA. (“Sure, I’ve snitched. This guy stole my job, working cash, and I nailed him.“)

14. Whatever happened to the ‘contractor discount’? (“Every line of my monthly statement from my building supply yard has a different discount. It’s hard to figure out what my overall discount really is...“)

15. Product failures: Who’s responsible – dealer, manufacturer, or contractor?

16. Building envelopes and insulation. (“What I used to think was cutting-edge, is now just standard code.”)

18. Customized renovation contracts (see page 37 in this issue for our coverage of this topic).

19. Photographic methods to document the real-time progress of a job.

20. Your “exit” plan: selling your business upon retirement.

The opportunity to learn from these successful business owners was not lost on event sponsors, given that our RenoFocus contractors were highly qualified and articulate. As Alec Thompson, marketing director for Home Building Centres put it, “None were sitting back. They were very engaged. They had a lot to say.”

Scott Carpenter, Ontario sales manager for ICF supplier Nudura, was equally impressed. “The contractors were very knowledgeable and understood a lot of the challenges regarding building codes and changes to the industry. They were also receptive to new ideas.”

Companies sometimes differ when it comes to their individual

objectives for focus groups. For example, timing was important for Roxul’s David Smith, both in terms of marketing verification and as powerful forward drivers for R&D. “It just so happened that in the fall of 2015 we were asking questions that could only be answered by the guys in the field. One of the more important things we learned was how insulation was being talked about between the homeowner and the contractor.”

Roxul’s North American marketing manager Dan Giansante concurred: “We also needed to understand if we, as a manufacturer, have delivered the materials and education for contractors to effectively have those energy conversations with their clients. And was it provided in a format useful to them?”

On the other hand, ITW Construction Products used RenoFocus to introduce specialised fastener technology in a new way. Said the company's marketing and innovation manager Alam Lam:“We’ve done the traditional focus groups before when we’ve had customers behind a glass wall. However, this is the first time we’ve done a focus group for this type of product. RenoFocus was very important to us in terms of product development, validation, testing, and that sort of thing. It was good to get an unbiased perspective.”

RenoFocus’s geographic diversity provided the sponsors with a unique opportunity, something Nudura’s Carpenter found exciting: “The fact that the contractors came from coast-to-coast was particularly valuable to us, particularly from a corporate standpoint. It allowed our marketing personnel attending to understand where new opportunities exist across the country and therefore gave us a better understanding of where to focus our brand awareness strategies.”

Beyond the focus sessions themselves, important connections were made between product suppliers and opinion-leading builders from across the country. “We have been able to network with people,” explained ITW’s Lam. “It was more than just a onetime event. We’ve been connecting with some of the contractors after the event who were open to testing new products.”

Would they do RenoFocus again? All sponsors agreed that the RenoFocus experience was not only valuable but one that would be worth repeating. Raising the bar is an on-going process. All shared Home Building Centres’ Thompson’s view: “There is invaluable feedback to be gained from end users like those at

RenoFocus.” ITW’s Lam agreed: “Absolutely. It’s important to continue this effort.”

Our RenoFocus contractors seemed to enjoy the event, both professionally and personally. “I knew that we, as contractors, would take valuable knowledge back with us. Even though we may be from different parts of Canada, we are all in the same industry with the same challenges and rewards. It was really great to be involved in this event,” said Dave Anderchek, JABA Construction Ltd., Saskatoon. “The support staff, the venue, the atmoshere could not have been any better.”

“I really enjoyed the focus group experience,” said Geno Scopeletti, Carick Home Improvements, Toronto. “There was really good contractor camaraderie amongst all the groups. I can truly say I met some really interesting colleagues and made new friendships.”

RenoFocus 2016 will take place Nov. 27-29 at the same fine downtown Toronto venue: Le Germain Hotel at Maple Leaf Square. Once again, 32 contractors will meet with some eight suppliers of building products and services – a fresh opportunity to take the pulse of this industry and develop new relationships.

ANGUS STEWART

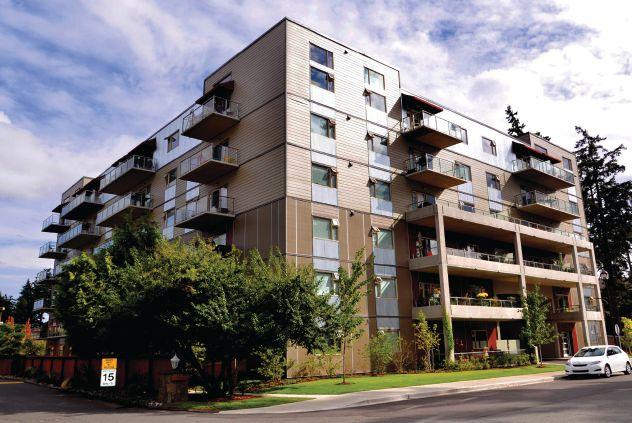

Timber Hawk Homebuilders Victoria, BC

JOHN FRISWELL

CCI Renovations North Vancouver, BC

ROBERT GRIESDALE

Blackfish Homes North Vancouver, BC

MARIE SOPROVICH

Aquarian Renovations Edmonton, AB

FRANK GORDON-COOPER

Kurmak Builders Calgary, AB

DAVID LITWILLER

Litwiller Renovations and Custom HomesCalgary, AB

DAVID ANDERCHEK

JABA Construction Saskatoon, SK

DESMOND SWEENEY

Red Seal Builders Winnipeg, MB

SHANE VAN BARNEVELD

Shane Renovations Ancaster, ON

PAUL KEOGH

Keogh Construction Loretto, ON

BEN POLLEY

Evolve Builders Group Inc. Guelph, ON

LOU ORAZEM

Inspire Homes Caledon, ON

STEPHEN GREER

Harvis Barklay Investments Inc. Mississauga, ON

PAUL GALLOP

Men At Work General Contractors Ltd. Etobicoke, ON

DAMON BENNETT

Bennett Building Co. Etobicoke, ON

RICHARD SPEARE

Speare Construction & Contracting Barrie, ON

DEREK NICHOLSON

Derek Nicholson Incorporated Toronto, ON

BRENDAN CHARTERS

Eurodale Developments Inc. Toronto, ON

GENO SCOPELLETI

Carick Home Improvements Toronto, ON

BRAD LOUNSBURY

Duffy & Associates Toronto, ON

DAVE MCGREGOR

Con-Tech Restorations DKI Toronto, ON

JEAN MCGREGOR

Con-Tech Restorations DKI Toronto, ON

DWAYNE BUTLER

Master Edge Homes Markham, ON

JOHN MCLELLAN

John McLellan Contracting Inc. Claremont, ON

MARTIN MACK

Concord Homes Amherstview, ON

STEVE BARKHOUSE

Amsted Design-Build Stittsville, ON

HERBERT LAGOIS

Lagois Design Renovate Ottawa, ON

MATTHEW SMITH

Mapleridge Homes Chelsea, QC

BRIAN CAMPBELL-KELLY Renovco Inc. Laval, QC

NEIL DAMACKINE

Construction ND Terrebonne, QC

DANIEL MACKAY

Dan Mackay Construction Debert, NS

BARRETT RISSER

D. Risser’s Construction Ltd. Lunenberg, NS

Thank you to our sponsors

Of the 32 contractors at our RenoFocus round table sessions,

Ben Polley, was the hands-down champion of all things “green.”

By John Bleasby

It only made sense that Ben Polley would be invited to Canadian Contractor’s RenoFocus 2015. It’s not just Ben’s 17 years’ experience as an estimator and a green building contractor: in 2006, he and partner Chris Vander Hout founded Evolve Builders Group, an integrated team of planners, educators, researchers and artisans based in Guelph, Ontario.

As opposed to ‘green,’ Ben refers to Evolve as an ‘alternative’ builder. The group’s custom projects across Ontario showcase the energy-efficient, healthfriendly materials and techniques that are destined to become mainstream tomorrow. Their leadership in this emerging field has captured the attention of national media and environmental experts from the world of

green construction.

But what about Ben’s own expectations for RenoFocus? “My hope was that I would learn more about the relative mark-ups and margins others apply to various elements of their business. And to be honest, I didn’t expect this type of information would be revealed, necessarily.”

In fact, RenoFocus more than delivered on Ben’s hopes, in large part due to the openness of other attendees. The specialised nature of Evolve’s services, materials and philosophy might have given rise to speculation concerning any commonalities between Ben’s business and that of his fellow attendees. It turns there was much to learn from one other.

“I thought it was remarkable that, to a person, everybody I spoke to about their approaches to certain issues answered forthrightly and with information that was perhaps even proprietary,” Ben said. “Maybe it was because we were from different geographic regions or due to the distinction between the services we offer.”

For Ben, a key learning point was business systemisation, an issue with which all builders and renovators need to deal in order to be consistently

profitable and successful, yet a subject on which many remain split. “Anecdotally, I learned there were businesses that, like us, had yet to systemise their processes and were hesitant to increase the margins required to make those investments. In contrast, there were others who had afforded their investment in these systemised processes by providing appropriate margins in their work in order to ensure their businesses were viable in the long term.”

The very open discussions that evolved both informally in groups or in private conversations provided Ben with the perspectives he needed. “It was really beneficial for me to learn from similar sized businesses that had succeeded in developing good systems to ensure consistent margins.”

Ben was, however, quick to point out that business coach Mike Draper’s ’90 Days to Profitability’ session that concluded RenoFocus 2015 was also very important. “Although I understand basic business principles, I perhaps lack the business vocabulary to explain my decisions to my associates back at the office. Things we do in our company as second nature, and that I do as an individual instinctively, were validated

to a great degree by Mike.”

Similarly, the sponsor presentations added great value to Ben’s RenoFocus experience, particularly those which were formatted to gain feedback. “Learning about others’ experience with particular products significantly increased my product appreciation, even for products I previously thought I understood,” Ben said. Exposure to new-to-market or precommercialization-phase products was also important.

“It’s part of our company positioning to be market knowledge-leaders.”

If learning how to become more consistent with project profitability and enhanced product knowledge were not important enough takeaways for Ben, an added bonus were the relationships formed with like-minded home builders and renovators across the country.

”We will be getting in touch, with the expectation that in the future we can use each other as sounding boards for ideas and to compare solutions to specific circumstances.”

Would Ben want to attend the next RenoFocus? “Absolutely!” cc

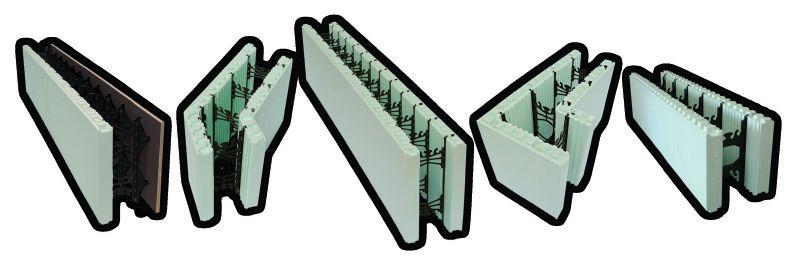

At NUDURA, size does matter. NUDURA standard forms feature DURAMAX Technology™, the largest standard ICF block in the industry, allowing the placement of 12 square feet of wall area in one building step. Our DURAMAX Technology™ results in faster installation times, less waste and a reduced amount of seams. Building Has Evolved at NUDURA, allowing builders & contractors to save time on labour, which is money, with the biggest block on the market.

Learn about our innovation and how NUDURA can reduce your labour costs at a NUDURA Training Academy installation course, nudura.com/trainingacademy.

Your renovation client wants you to replace all their old carpets with hardwood – or perhaps engineered wood. Or maybe one of the higher-end laminates. Now is the time to consider all the options – including some of the up-and-coming flooring materials that have their own special benefits.

By John Bleasby

Not long ago, wall-to-wall carpeting was the height of residential elegance and fashion. Now, it’s widely considered passe. Hardwood is the flooring material your clients will probably think of as their high-end choice. Engineered hardwood is widely considered the second best. And laminate is often seen as the cost effective choice. But those three choices aren’t the only ones your client can make.

The world beyond these three categories of wood flooring is vast, particularly if you are open-minded. Bamboo, cork, linoleum, vinyl, and even concrete are all excellent flooring materials. Budget, fashion, and durability – particularly with respect to location – can guide your choices. Let’s start with a quick word about wood flooring.

The hardness of solid hardwood is measured by an index called the Janka Hardness Scale. The Janka number measures the force (in lbs) required to embed a 1.28 mm steel ball into the wood, to the ball’s maximum width. The Janka numbers of wood species vary, depending on where the wood is being sourced, but the highest Janka number we could find is 5,060 for Australian Buloke. We don’t know anyone who has used it. (If you have, let us know how hard it was to cut!) Maple comes in at about 1450; pine has a Janka number around 700. The softest reported number we have seen is 22 for Cuipo, a tree from Central and South America. (If you’ve built with that, let us know how the legal proceedings are coming along.)

While the luxurious look and feel of solid hardwood flooring cannot be denied, engineered hardwood flooring offers certain advantages, specifically dimensional stability and suitability over a variety of sub-floors. However, be aware: one of the keys to engineered wood quality is the thickness of the hardwood top layer. Most engineered wood in Canada has a top layer thickness of between 2 mm and 6 mm. The industry average is below 4 mm. You will pay more for thicker top layers – and the methods for bonding that top layer to the substrate vary and will also affect price. Your third ‘wood’ choice, laminate, has little or no solid wood in it at all; it is nothing more than a plastic or foil photographic wood image glued to the surface of an (often) fiberboard base plank. Although cost-effect and a big hit with DIYers, laminate has earned itself a somewhat downmarket reputation. Some of the new, higher-end laminates are changing this. But now let’s move on to the really interesting options beyond the world of wood.

While the hardwood industry may level criticisms at bamboo flooring, bamboo is in fact a worthy competitor to traditional solid wood. Eco-conscious designers and builders around the world have been drawn to bamboo because of its eco-friendliness and LEED certification. The most reputable manufacturers are IEQ (Indoor Environmental Quality) recognised, ISO-audited and FSC (Forest Stewardship Council) approved.

While ‘bamboo’ itself is a 100 per cent naturally occurring plant, most people are surprised to learn that bamboo flooring is a manufactured product, fabricated by treating, cleaning and then soaking individual strands of bamboo in a binder and then pressing or weaving the components together under high pressure. The woven strand planks are typically many times harder than oak, with Janka numbers that can almost jump off the

charts.

Although bamboo is usually seen in lighter shades that allow its fibrous grain pattern to show, colours can vary from light natural to very dark by means of a carbonisation or heating process. The popular ‘edge grain’ pattern gives a very linear look while the ‘flat grain’ products give a wavier pattern resulting from exposure of the bamboo knuckles. Hybrids of colour and grains are also available, along with stair nosing and trim pieces to complete a bamboo installation.

Although bamboo can cost significantly less than solid plank or quality engineered hardwood flooring, beware of bamboo flooring at ridiculously low prices: it’s a red flag. Our research reveals, in fact, a fairly minimal price difference between big-box store bamboo and bamboo flooring available directly through quality importers. A quality importer can also certify the presence of acceptable or even zero levels of urea-formaldehyde in their bamboo products

Bamboo shares many of solid hardwood’s features and installation limitations. Always research the nature of the factory pre-finishes, and remember that, like hardwood, entrance halls, bathrooms and mudrooms are not the most suitable locations.

Cork flooring has been going in and out of style for more than a century. Now available in a huge range of patterns and installation options such as solid or engineered planks, and rolls, cork is bursting back into favour due to its retro appeal. Cork also gets high marks for eco-friendliness since, like bamboo, it is a renewable resource. Incidentally, Portugal accounts for more than

half the world’s cork production.

While cork is not ideal for every area of the home, it definitely has its place. Its springy and flexible structure, which allows it to bounce back from small nicks, makes it a good choice in kitchens. A cork kitchen floor reduces the chances of broken glass, is warm underfoot, and provides surprising fire resistance. Cork is also great at muffling sound. Because cork doesn’t accrue dust and contains suberin, a natural substance that fends off mold, mildew, rot and pests, it’s ideal for allergy sufferers. In short, cork will deliver a beautiful floor surface that can potentially last for years. Cork generally costs less than most hardwoods, and is in about the same price bracket as quality bamboo. But be aware: low density (i.e., low priced) cork should be avoided.

Cork’s wide range of rich textures, tones and bold colours is unique and exciting, and cannot be duplicated by other materials. However, cork must be selected wisely for the most appropriate locations. Areas of dampness or high humidity, like bathrooms and laundry rooms, need serious prior consideration regarding potential water leakage and infiltration.

Obviously, the pliable nature of cork means that it can sustain hard to repair damage from heavy furniture. Colours can fade in sunlight. It is susceptible to damage from some pets. Crumbs, dirt and other detritus can scar its surface over time if it is not swept or vacuumed regularly. Recommended cleaners must be used, with damp-mopping preferable to wet-mopping. Also, cork needs re-sealing with protective coats of polyurethane or wax sealants every few years. Even pre-finished cork needs periodic maintenance.

There’s something very institutional about the notion of concrete floors. However, with the ability to be coloured, textured or polished, concrete can in fact offer both style and practicality, making it an interesting alternative not only to hardwood but to stone and tile as well. Even a basement’s concrete slab, the unloved cousin of flooring, can be buffed or waxed and left shimmering with possibilities.

In main floor living spaces, concrete applied as an overlay to a subfloor brings a unified appearance to the entrance foyer, hallway and living area trio, especially when extended outdoors. It can buffed shiny, left flat, or coloured and textured in numerous ways. Colours can be mixed into the initial mix or added afterwards as an acid stain applied to resemble natural stone. Likewise, textures and patterns can be created in concrete at time of installation through etching or handwork with nearinfinite variation. These patterns are not only aesthetically

pleasing but can also be deployed to reduce risks of slipping – in bathrooms, for example.

While the coolness of concrete underfoot is best appreciated during warmer seasons, area rugs can be used as a seasonal solution. The good news is that concrete is perfect for radiant floor heating. Although concrete may take a little time to warm up, heat is retained longer.

Like tile or stone, concrete is a very unforgiving surface when glasses or plates are dropped, and it can become tiring underfoot. Although easy to clean with a mop and pail, spills should be cleaned up immediately to prevent staining. Floor sealants should be reapplied every three or four years, or re-waxed more often than that.

Fundamentally, it is cost that drives the popularity of coloured or patterned interior concrete floors. Concrete is clearly more

economical than granite, slate, marble, ceramics or porcelain. It’s also a recyclable, eco-friendly material, given that concrete does not deplete natural resources and is usually locally made and mixed, thus reducing transportation costs. Indoor air quality is improved since concrete inhibits mold, mildew and odours, and contains no harmful Volatile Organic Compounds (VOC’s).

Linoleum goes way back to 1855, patented by Englishman Frederick Walton. However, Walton never trademarked the name (Waltoneum could have become a household word), so linoleum became a generic term. Linoleum’s components of solidified linseed oil, powdered cork, powdered wood flour, limestone, jute, and pine rosin are all renewable and recyclable, one reason why it remains popular today. Staticfree and non-allergenic, linoleum is sturdy, very water- and wear-resistant and, if installed over a suitable substrate, will last for years since colours go through the entire depth of the material. Linoleum can be quite comfortable under foot and is a good choice beyond laundry rooms and bathrooms. Bold home owners might be tempted to use linoleum in halls, entrances, even living rooms. However, the low cost of the flooring material itself is counter-balanced somewhat by the relatively high cost of professional installation.

Don’t confuse linoleum with vinyl! Vinyl appeared in the 1960’s and is not as environmentally friendly as linoleum. Its main ingredient is polyvinyl chloride (PVC), a concern to many, as is the fact that PVC is currently almost non-recyclable. While the range of vinyl colours and inlaid patterns is impressive, pricing can vary greatly. Issues to consider are: thickness of the tile or sheet, depth of inlaid patterns, and surface printing versus full depth colours, all of which impact pricing and quality. Low price is often an indicator of poor quality. Since poor quality vinyl will not last, the recycling issue and the replacement ‘nuisance factor’ are worth consideration.

The good news is that vinyl flooring is much easier to install than linoleum, well within the range of most contractors. Click or glue-down tiles and even sheet products are easily installed over a variety of substrate surfaces. Vinyl is also virtually non-reactive, meaning you can clean it with anything. These factors, plus the range of design possibilities, are bringing vinyl back onto the list of flooring possibilities for kitchens, bathrooms, family rooms, basements and laundry rooms.

Flooring options beyond solid hardwood have never been more creative, varied and price competitive. While there is no silver bullet single solution, the fun is in the selection! cc

As a contractor, your ‘standard’ renovation contract should evolve over time to head off issues you’ve had in the past. Here’s how some contractors have fine-tuned the most important legal documents they possess.

By John Caulfield

During

its first few years in business, Construction ND, a seven-year-old residential and commercial contractor based in Terrebonne, Que., used contracts that, according to its president Neil Damackine, were little more than “loose agreements” with clients.

But he started taking a closer look at that contract three years ago, after getting burned by one customer for a couple of thousand dollars over a change order, for which Damackine ended up paying subs out of his own pocket. He didn’t assert his legal rights, either, he says, because “I was too busy at the time.”

Since then, Damackine has relied on a contract he’s crafted himself, and which he describes as “an ongoing process.”

The days when contractors took on jobs with just a handshake and no paper trail are over. Contracts lay out, as clearly and succinctly as possible, a project’s scope of work and cost. (Getting customers to read those contracts before signing them is another story.)

It’s also true that contractors like to tinker with their contracts’ language, adding clauses here and there to address specific jobs or potential liabilities.

Conversations with a number of renovators and custom homebuilders across the country reveal that they cobbled together their contracts from various sources – trade association documents, “how-to” books, gut instincts. It’s rare, though, when contractors consult lawyers to

vet contracts to see if clauses being added are actually legal.

Contractors readily acknowledge that the clauses they insert into standard contracts are more like preemptive warnings, rather than direct threats, about what could happen if customers delay projects, are delinquent on payments, and so forth.

At the very least, special clauses set the ground rules for such common matters as change orders and dispute resolution. And in more cases, clauses let clients know what’s expected of them, as much as what the contractor will deliver.

Another clause informs customers that if crews uncover what they suspect is asbestos, they will stop work immediately pending laboratory tests. If necessary, an asbestos removal protocol will be set up, as the province mandates.

Mapleridge Homes, a design-build firm based in Chelsea, Que., over the years has developed a checklist that its reps review with customers so “they can expect the unexpected, and if something happens they aren’t jumping up and down and calling the cops,” says Matthew Smith, the company’s owner.

Project management contracts often spell out what a contractor will and won’t do. For example, one of Construction ND’s clauses stipulates that customers are responsible for removing snow from driveways and door fronts so a jobsite is accessible during working hours.

One clause instructs customers to “plan ahead to do without water or power if workers short the lines.” Another recommends that homeowners “try to stay

out of the construction area,” for their own safety. Customers should expect superiorto-industry standard building practices and execution, but not perfection. And when construction begins “there will be plenty of dust and dirt.”

The biggest addition to Mapleridge’s contract in the past two years has been the limits it places on customers’ emails and texts. “As soon as they sign up with you, you become their 24-hour hotline,” quips Smith. Before adding this clause, he was getting calls on Sundays and emails “at all hours of the day.” His checklist also asks homeowners to appoint one person in the family to be the official contact with Mapleridge’s authorized representative.

Smith concedes it’s “tricky” telling customers who are spending tens of thousands of dollars on a project that they can’t communicate with the company

No contract is bulletproof. There are always unforeseen circumstances that fall outside of even the best-crafted agreements. But as contractors keep striving toward that ideal pact, which protects their interests without alienating customers (too much), we offer five wish-list clauses:

• The homeowner can only ask once when the filled dumpster loitering in their driveway will be hauled away.

• When discussing the price of the project, customers are prohibited from looking a salesperson directly in the eye.

• Any homeowner who posts a grievance on social media without attempting to resolve the problem with their contractor gives said contractor the right to post the homeowner’s financial information, including credit history, online.

• Flu, arthritis, and allergies are considered “bad weather,” and the contractor has no control over delays created by them.

• Damages caused by roofers who slip on rafters and put their leg through the homeowner’s living room ceiling are considered “Acts of God,” for which the contractor bears no liability.

whenever they feel like it. “I’m still working on this.” The good news is that he’s never actually had to tell a customer to back off. “But at least this opens the conversation.”

One reason why customers have so many questions, says Smith, is that they have “too many choices.” Hence, their propensities to request changes in the middle of projects that can put schedules in jeopardy.

Contractors have gotten very specific about managing change orders. Amsted Design-Build in Stittsville, Ont., breaks out a job’s product specs onto separate attachments to its contract. No changes are permitted unless they are in writing, and no single or cumulative change over $500 can be made without a signed approval by the customer and the company. For changes under $500, Amsted can make them, and then show proof to the owner at the weekly client meeting.

D. Risser’s Construction Ltd., in Lunenburg, N.S., recently initiated a written contract for change orders, with payment for changes due in the following billing cycle - every two weeks during a reno or new build. Project manager Barrett Risser adds that his company asks homeowners to buy all lighting fixtures and most plumbing fixtures themselves, so that personal tastes don’t bog down the selection process.

Harvis Barklay Investments Inc., a design-build firm based in Mississauga, Ont., with 25 years’ experience, goes so far as to state in its contract that customers can choose only so many paint colors per room. (It must be working, because the company hasn’t had to say no to any customer’s choices yet, says Steve Greer, Harvis Barklay’s president.) The contract includes links to manufacturers’ product brochures, which “give the client the opportunity to see the price, so that if he wants to go with another product, we can compare value.”

Greer notes that it’s not uncommon for projects to slow down when homeowners can’t make up their minds about a certain product or color. Consequently, Harvis Barklay’s contract warns clients that they will be on the hook for electricity, water, or gas costs related to delays they create.

“It’s always a challenge to get the homeowner to make decisions early enough to keep the job on schedule,” says Steve Barkhouse, president of Amsted Design-Build. And he doesn’t feel guilty about his contract warning customers about possible charges from delays they cause. “We do a lot of ‘carrot’ stuff; this is a ‘stick.’ ”

Timber Hawk Homebuilders in Victoria, B.C., has added a protective clause to its contract which states that if homeowners do any of the work themselves, or hire their own subs for different stages, that could potentially affect the schedule and lead to delays that Timber Hawk has no control over.

Timber Hawk is like many contractors that are taking a harder line in their contracts about late payments. It gives customers 15 days to pay an invoice. If they’re late, “we stop the job, and give them five days to pay before we’ll start again,” says owner Angus Stewart.

Timber Hawk and Amsted state in their contracts that they have the option of charging customers an extra 2 per cent per month for late payments, although both companies rarely, if ever, exercise that clause, say their owners.

Special clauses sometimes touch on marketing parameters and how pros handle construction defect complaints from their customers.

Amsted’s contract covers whether the homeowner will let the company to take pictures of the project, distribute

promotional flyers while the job is in progress, and allow other potential customers to visit the house. “It’s really an incentive for us to do a good job,” says Barkhouse, who notes that customers rarely refuse these marketing requests.

Amsted offers a five-year warranty on its work, and states in its contract that it follows Tarion Warranty Corp.’s

IT’S REALLY AN INCENTIVE FOR US TO DO A GOOD JOB

performance guidelines, which include definitions of what constitutes a construction defect. “This is a starting point” to resolve any disputes, says Barkhouse, and gives homeowners more clarity about the quality of work they should expect. “A client will see a nail pop and not call us because we did a great job overall. Now, they can look online and see what’s a defect,” says Barkhouse.

In this age of social media, contractors can’t afford to have a disagreement with a customer blow up in their faces and go viral. However, none of the pros contacted for this article have quite figured out yet how they might rewrite disputeresolution clauses in their contracts to keep disgruntled customers from seeking redress on the Internet.

But that hasn’t stopped Smith of Mapleridge Homes from working on such a clause that ultimately would encourage customers to come to him first with a problem “before posting it on Facebook.” cc

Kuujjuaq, Northern Quebec

Project Architect: Fournier Gersovitz Moss Drolet, Montreal

By John Bleasby

No region of Canada presents more challenges to construction than the far north. Daytime winter highs averaging -20C and summer highs of only 18C are just the start. Harsh winds, blizzards and permafrost require new approaches from design through to execution.

The four-unit townhouse development of Nunavik Village in Kuujjuaq, Quebec (population 2,375), built in 2005-2006, represent a new vision for northern housing. The Kativik Regional Government (KRG) sought a design concept to address the dual purposes of government staff housing plus local training and employment. The KRG turned to Montreal architectural firm Fournier Gersovitz Moss Drolet (FGMD) to lend their three decades of experience with the extreme conditions of the north.

Construction costs run at a high premium in Canada’s isolated north. Located on the Koksoak River, Kuujjuaq has no road access whatsoever. All raw materials must be imported by barge in the summer. Senior FGMD partner Alain Fournier estimates the cost of each 1,000 square foot, 2-bedroom unit between $400,000-$500,000.

Continued on next page

THIS PROJECT IN THE FRIGID FAR NORTH OF QUEBEC WAS AN ENGINEERING AND CONSTRUCTION CHALLENGE

Permafrost presents several challenges to design and construction. In-ground infrastructure is impossible; treated water and sewage storage under the buildings is serviced by truck. Heat is provided by a shared oil-fired furnace; electric heat is prohibited.

The townhouse project in Kuujjuaq used the proven technique of concrete footings poured over a one-metre deep compacted gravel base, which acts as an insulator to reduce any potential shifting due to heat transference. (Footings placed directly atop the permafrost risk having building heat-loss slowly melt the permafrost near the surface causing instability, much like holding an ice cube in one’s fingers.) However, climate change over recent decades and the resultant warming of the upper grade levels has required increased use of drilled piles as deep as 15 metres into the permafrost. Screw jacks on top are used for any adjustment or fine tuning.

Grouping the townhouses into four side-by-side units does more than enhance heat retention via shared interior walls. Colours and staggered individual entrances heighten the privacy and individuality of each townhouse unit as well as adding aesthetic appeal. Building orientation parallel to the prevailing snow-bearing winds is ideal in this environment, allowing the scouring action of winds to help clear the often heavy accumulations of snow from entrances that otherwise can present security issues.

Continued on next page

Left: Exterior siding is steel sheeting and high-density wood composite. Entrance decks and stairways are built from pressure-treated wood on a steel frame.

Bottom RIght: The townhomes were constructed by local labour.

Protection from Nunavik’s harsh environment starts on the outside. Experience has shown that ventilation openings exposed to the elements allow the extremely fine, dry snow of the far north to invade interior air spaces where it can only cause damage. For example, the slightly canted roofs, topped with a modified bitumen membrane, are ‘hot roofs,’ meaning there is no air space between the insulation and interior ceilings that would allow the snow to sneak inside. HRV systems are installed to replenish fresh air inside each unit.

The exterior siding is a combination of steel and pre-finished high-density wood composites. Fournier admits the jury is out on the long term viability of the composite material, but to date there have been no issues. Pressure-treated lumber and steel were used for the walk ups, decks and railings for structural reasons.

Insulation values of R33 in the walls, R30 in the roof and R48 in the floors above the permafrost grade must be combined with air-tightness due to the constant high winds. “Thermal bridging is enemy number one” says Fournier. Cold conduction can, in the extreme, cause structural damage.

“Ten years later, the Kuujjuaq prototype has served as a model for subsequent KRG multi-plex developments extending beyond staff housing into the domain of social housing,” says Fournier, confirming the validity of both the design and execution of the project. cc

Above: Built-in storage and counters maximize living space in the 1- and 2-bedroom units.

Above right: The shared mechanical room under the main floor houses water/sewage storage and the shared furnace and water heater. Bottom right: The architects had three decades’ experience with projects in the Far North.

He’s been 43 years on the brush – and he’s still having fun. Rick Fowler, the go-to pro painter at disaster restoration firm Spar Construction, Edmonton, doesn’t take himself too seriously.

By John Bleasby

My conversation with Rick Fowler is punctuated with a lot of laughter; he might be the easiest-going tradesman you’ll ever have on a site. But he’s also a totally meticulous and disciplined tradesman. Rick has been painting since 1973, the past 20 years exclusively for Spar Construction of Edmonton, a specialist in fire, flood and vandalism restorations.

That’s a long career in painting. What got you started? It was easy. It was the best offer I could get out of high school. I had a young family and virtually no skills, so I had to buckle down and find something quick.

You’ve been with Spar for over 20 years. You must love the work? I tried so many things over the years. Just before joining Spar I ran my own commercial business for two years, and found it stressful to say the least. I had four guys, worked longer hours than any of them, and actually made less than they did on some jobs. I didn’t need that.

What makes disaster restoration painting different from regular painting?

Matching colours is my biggest challenge. I’ll spend several hours trying to establish the right colour and sheen.

How do you keep your clients stress free during a disaster restoration?

You’ve got to handle them with kid gloves. But I have an advantage: I’m always the last guy on the job. I’m the one who makes it all look pretty again.

There has to be more to it than that! Well, there is one thing: I would say 50 per cent of the insurance customers ask me to do ‘one more little thing’, while I’m there with my brush out. I have a rule: if it will only take half an hour, I’ll do it and won’t charge them. Half an hour is nothing.

And they’ll be so happy they’ll never complain about anything afterwards.

Do you hum or play music when you paint?

I have a classic iPod with 6,000 tunes on it. I love the Blues, rock music, folk music, country from the 40’s and 50’s. If the customer is home, I’ll rarely put it on a speaker; I’ll use my earphones. If I’m working alongside others, I’ll ask them first.

In terms of product, do you get what you pay for?

Over the years of looking at products from all over the world, I have to say that the top line products are pretty damn good. And over the years, you get to know who has the best products for the best price, and particularly the products that do almost anything.

Is there such a product out there?

Some are good in one situation but will have a fall-down point somewhere else. Maybe one product will perform differently with a different colour. It will work every day but then, say, with a certain colour, it’s no good. After working with colours all over the chart, you learn which products work best in a given situation.

How many years of painting do you have left in you?

Probably forever. I’m very physically active. I ski, mountain bike, do combat archery twice a week. I don’t mind painting. All that hard work helps. It keeps me in good health. cc

We are looking for 32 contractors from across Canada who want: FREE

• Travel to Toronto

• Hotel

• Food

• Entry to Construct Canada AND Contractors who can share their business and product challenges.

“ Whether it was being involved in discussions or just listening to the other contractors and being involved working, writing, and talking about our challenges and triumphs, it showed how professional we are in our industry. Great all round! ” - A 2015 RenoFocus Contractor BE A VOICE FOR OUR INDUSTRY | NOV. 27-28-29

RenoFocus is a series of focus-group sessions behind closed doors in which manufacturers and suppliers gather market information from successful contractors.

Do you have what it takes to be a RenoFocus contractor? go to www.renofocus.ca to fill out the application. Please put RenoFocus in the subject line

By Steve Maxwell