ENVELOPE Building Technology

CLADDING

HOUSEWRAP

ICFs

INSULATION

ROOFING

SIDING

VAPOUR BARRIERS

WINDOWS

CLADDING

HOUSEWRAP

ICFs

INSULATION

ROOFING

SIDING

VAPOUR BARRIERS

WINDOWS

By Rob Koci

Building envelopes supply three things: Support, Control and Finish.

By themselves all three are simple. Structural support is basic engineering. Climate control is physics and chemistry. Finish is aesthetics. There are experts for all three to provide extensive knowledge to design extraordinary exterior envelopes.

But someone has to build them, which adds to those design challenges, deadlines, price pressures, the personalities of client and the talents or lack thereof of the employees and subtrades on site.

Do you know all you need to know about building superior exterior envelopes? Have you got the right people to build them? Is your staff knowledgeable enough to deliver the best results? The science of building envelopes has advanced significantly in the last 50 years. Have you got the info you need to build them to meet the higher expectations of regulators, clients and inspectors?

Fortunately manufacturers like the ones represented here in our first Bulletin on Exterior Envelopes are highly motivated by competition, certification and genuine passion for quality to provide the most finely engineered products your customer’s budget will allow.

They also know the installation of their products and your understanding of their features and benefits protects both their brand and yours and elevates your company above your competition. That’s why we asked them to provide in this bulletin the best advice and information they have to help you succeed. We believe they have succeeded.

In our feature (page 8), we interview Ben Polley, president of Evolve Builders and a winner of our Outstanding Renovator and Custom Homebuilder Award (ORCHA) 2016. We asked Ben to weigh in on the subject of the new standards for building envelopes. He says what was cutting edge today will be the norm in the near future. More importantly, he sees today’s customers running ahead of the knowledge curve and demanding standards even beyond regulatory requirements. Are you ready?

We couldn’t fit everything there is to know about building envelopes within these pages, but use this as your start and reference guide. We’ll be presenting more information in regular features online under the “Bulletin” banner (canadiancontractor.ca) in the future.

What is cutting edge today will be the norm tomorrow, Ben Polley says

Building Envelope Technology is the first of a regular series of technical bulletins brought to you by Canadian Contractor magazine in partnership with selected manufacturers. For enquiries about advertising in future bulletins, please contact publisher Rob Koci, Publisher, Canadian Contractor, rkoci@canadiancontractor.ca

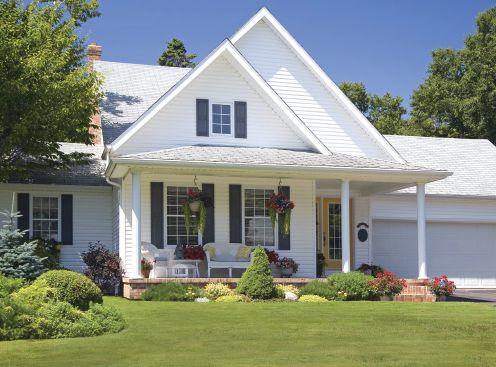

Fact: Mitten vinyl siding, from Ply Gem (NYSE: PGEM), a leading manufacturer and distributor of building products in North America, has been a staple of the building materials industry since 1959. As the leading brand of vinyl siding in Canada, Mitten vinyl siding has a reputation for quality and innovation that can’t be matched.

Fact: With a wide variety of designs and the largest colour palette in the industry, the Mitten vinyl siding line has all the elements customers are seeking on their next siding project.

Each series of products in the Mitten vinyl siding line has its own unique

combination of colours, profiles and finishes. When you’re assisting your customer in finding the perfect look for their home, keep these key features in mind:

Sentry

• Features a cedar-grain texture in a low gloss finish with a distinctive deep silhouette for rich shadow lines

• Premium product line

• 0.44” thick panel, available in 3 profiles and 37 colours

Highland

• Features a satin finish woodgrain texture that is designed to complement a variety of architectural styles

• Most complete product line

• 0.42” thick panel, available in 6 profiles and 19 colours

Oregon Pride

• Features a subtle woodgrain appearance

• 0.40” thick panel, available in 5 profiles and 16 colours

Insul Plank II

• Replicates the look of fiber cement in long lasting and maintenance-free vinyl

• Reduces energy loss from thermal bridging and forms a tight weather bond with an R-Value of 2.44

• 0.46” thick panel, available in 1 profile and 11 colours

Fact: Ply Gem is one of the 100 largest manufacturers of residential windows, doors, skylights and related products, based on sales volume for 2017, as rated by Window & Door Magazine.

Fact: Ply Gem Windows and Doors products, ideal for any home or light commercial project, ensure you can find a product that is just right for the home you are building right now.

Fact: Each product is built with the same attention to quality that’s been the hallmark of Ply Gem since 1943.

Vinyl Windows

• Classic Series

Our Classic Series windows recreate a traditional wood window profile design without the traditional maintenance. Dual glazed insulated glass units ensure cutting-edge performance for these classically styled windows.

• Enviro Series

A robust frame designed for Triple glazed insulated glass units suits both traditional and modern style homes. Advanced engineering ensures year-round comfort.

Aluminum Clad Windows

• Design Series

These Aluminum Clad Vinyl windows offer the best of both worlds: durable, colourful aluminum exteriors with low-maintenance vinyl interiors.

• Signature Series

These Aluminum Clad Wood windows feature hem fir wood interiors, selected for its strength and extraordinary beauty. Durable, colourful Aluminum cladding protects the exterior of the windows.

The typical home has 15 to 20 window openings – and there are many types available. So how do you know which ones to choose? There are a few factors to consider for each window location.

Ultimately, window selection will come down to personal preference and the location of objects near to or around the window. Consider windows in your customer’s kitchen that are over the sink or behind a counter top. Operating these windows requires them to reach over the counter, so hung or sliding windows (where the locks are positioned high off the floor) may be challenging. Using a casement or awning window in these locations may help, as the locks are positioned low in the frames and the operating hardware is mounted at a low location (near the sill).

Also consider what obstructions may exist to the exterior. Is there a sidewalk or patio located directly outside of the window? This presents a danger for someone to walk into when a projecting window is open. In these locations, consider a hung or sliding product.

The type of window can impact air infiltration and heat loss characteristics.

• Fixed (Picture) windows are airtight and inexpensive and can be custom designed for a wide variety of applications. But, because they cannot be opened, fixed windows are unsuitable in places where ventilation is required.

• Casement, Awning, and Hopper windows with compression seals are moderately airtight and provide good ventilation when opened. Casement windows open sideways with hand cranks. Windows with compression seals allow about half as much air leakage as Double Hung and Horizontal Sliding windows with sliding seals.

• Double Hung windows are among the most popular type of window, Single Hung windows have only a lower operating sash for ventilation and only one moves.

• Horizontal Sliding windows are like Hung windows except that the sashes are located on the left and right edges rather than on the tops and bottoms. Horizontal

sliding windows open on the side and are especially suitable for spaces that require a long, narrow view. These windows, usually provide minimal ventilation. Double Sliding windows where both sashes tilt in for cleaning, offer the lowest structural and thermal performance of any window. Those with sashes in a track that lift out for cleaning offer better performance.

The material used to manufacture the frame governs the physical characteristics of the window, such as frame thickness, weight, and durability. It also has a major impact on the thermal characteristics of the window. The window U-factor, as given on the NFRC certified rating or label, incorporates the thermal properties of both the frame and the glazing. Since the sash and frame represent from 10–30% of the total area of the window unit, the frame properties significantly influence the total window performance.

Interestingly, where you live does influence these decisions. Different types of windows are more common in each region. Double Hung windows account for 47 per cent of the US market, yet only 10 per cent of the Canadian market. Conversely, casement windows make up 44 per cent of the Canadian market but only 6 per cent of the US market. Remember that casement windows have compression seals to allow for half as much air leakage as double hung and horizontal sliding windows, critical to the cold Canadian climate. However but casement windows cost more than hung and sliders due to the substantial hardware sets required for them to operate.

Ply Gem Windows and Doors are now available nationally across Canada, including new regional programs for Ontario/Atlantic Canada & Quebec. Go to: www.plygem.ca

Awning Horizontal window that opens outward, usually using a crank handle.

Bay/Bow Series of three or more windows that juts outward from the house. The central window may be fixed while the side windows are typically double-hung or casement windows.

Casement Vertical window that opens outward and may feature locks on both the upper and lower parts. Often opened with a crank handle.

Double/Single Double Hung: both sashes move. Hung Single Hung: only lower half moves.

- Provide ventilation even during rain

- Provide ample light

- Often installed above doors or other windows

- Offer a wider viewing angle

- Add style to architecture

- Make rooms appear more spacious

- Ideal for use when creating a breakfast nook or in a master bedroom

- Provide ample light

- Offer a large viewing area

- Ideal for difficult-to-reach areas, such as over a sink or countertop

- Take up little space

- Ideal next to patios or porches

Fixed Available in many shapes and sizes and cannot be opened.

Slider A side-by-side pair of windows that slide side-to-side rather than opening outward or upward.

To simplify your next project, here are some Tips & Tricks to help in 3 key areas of vinyl siding installation:

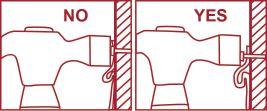

1) Nailing – Vinyl siding can expand or contract ½” or more over the length of a 12’6” piece. To accommodate this movement, follow the guidelines below when nailing your siding to the wall:

a) Don’t drive the nail head tight to the wall. If you leave a minimum of 1/32” (the thickness of a dime) between the fastener head and the vinyl, that will allow the siding to move back and forth as needed.

b) Center the fasteners in the nailing

- Used as picture windows /decorative windows

- Does not provide ventilation

- Offers a contemporary — look

- Ideal for installation near outdoor living areas

slots to permit expansion and contraction of the siding.

2) Cutting – There are three common options when cutting vinyl siding:

a. Circular Saw – To ensure a clean, smooth cut, it is recommended to use a fine-toothed plywood blade, installed backwards in your saw. Be sure to cut slowly.

b. Tin Snips – If you go this route, avoid closing the blades completely at the end of the stroke for a neater, cleaner cut.

c. Utility Knife – Score the vinyl face up with medium pressure and snap it in half. It isn’t necessary to cut all the way through the vinyl.

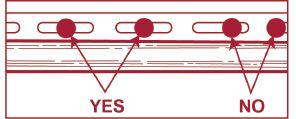

3) Overlapping – Panels must overlap

so they can slide past each other as the panels expand and contract with temperature changes. To allow this movement, panels are made with notches at the end of the nailing hems. For the best appearance, the tips below should be followed:

a) Overlap panels half of the dimension of the factory notch (typically a minimum of 1”)

b) Plan overlaps where they’ll be the least visible

c) Stagger joints at least 2’ from course to course

d) Do not repeat a lap position for a minimum of 3 courses

e) Avoid uniform, stair-step installation patterns that will catch the eye

f) When overlapping, do not nail closer than 6” to the ends of both panels.

For a more detailed guide to vinyl siding installation, visit www.mittensiding. com.

MANUFACTURER & DISTRIBUTOR OF

An interview with green building veteran

Ben Polley , Evolve Builders Group, Guelph, Ontario

By John Bleasby

Canadian homebuilders who think they can keep constructing their building envelopes the old fashioned way are in for a rude awakening. While extreme low-energy consumption standards like Net Zero Energy (NZE) and Passive House are “cutting edge” now, they will become mainstream tomorrow. In this interview, we asked one of Canada’s leading green builders, Ben Polley, Evolve Builders, Guelph, about how the standards are changing for all of us.

There are many standards and certifications out there: LEED, BuiltGreen, NZE, R-2000, EnerGuide and ENERGY STAR, Passive House, and Living Building Challenges. Is it all too muddled to gain traction with consumers and builders?

Think of it like the organic food industry. If we were to jump back in time, say 20 years, the bulk of organic foods were sold through mom-and-pop shops and other non-traditional retailers. They were early adopters and brought forward what was a nascent industry. Over time and through standardization they started to change the larger retailers, and in turn

were bought up by the larger retailers, or became larger retailers themselves.

The same sort of thing is happening in construction under these various certifications. Some are going to survive and some will fall away. However, ultimately each of them has contributed something to the path we are taking. If not for those certifications providing some guidance and a marketing tool for production builders, I don’t think we would have seen the market shift as it is now.

As energy-efficiency awareness increases, how has it impacted innovators such as you?

What I have observed is whereas 15 years ago I would have to spend a significant amount of time educating people on why they might want to consider specific upgrades because of certain energy saving outcomes, the reverse is now true. They’re now coming to us with an expectation at the outset of Net Zero or Passive House levels.

You have said in the past that Passive House concepts are a key starting point. Why is that? If you don’t deal with the energy efficiency issue at the source of the problem, you’re spending more money to put in more expensive equipment. Energy demand will still be high and you’ll be trying to deal with it by using fuel-based solutions.

Our clients are really keen on reducing demand at the start. They are most are interested in Passive House principles such as extraordinary insulation, but with particular attention to air barrier detailing to prevent losing heat in the winter or cool in the summer. Those things are non-mechanical and have one-time initial costs which are quantifiable. All they ever do afterwards is save money.

How has increased awareness changed the discussion of costs versus benefits with your clients?

It has changed the conversation, changed mindsets. Our clients all have very different expectations from site to site. However, increasingly and over the last 18 to 24 months, the starting point requested by clients is Passive House or Net Zero. Only if we can’t achieve that within their budget does it start dropping away.

If the various certifications are due for a shake-out, how about a shake-out of builders themselves, particularly the stragglers?

We understand that the province of Ontario wants to bring all new home construction to Passive House NZE-ready standards by 2030, less than 13 years from now. That probably means many of the builders you describe as ‘stragglers,’ people who have been in the industry so long that they don’t

care to change, will be gone by that point through attrition. They can’t exist. Even the followers really can’t exist. The youth we’re seeing coming into the trades want to be early adopters or innovators and have a real interest in non-conventional building and better methods. The problem they encounter more often is that their teachers don’t know how to do it.

Are the various energy-efficiency building courses available something all should consider, even a builder as advanced as your company?

A few of us here recently took the certification course required to be Passive House builders. After the first day, I was disappointed; I was expecting some fairy dust to be sprinkled on me. However, on the second day I started to realize that we were very, very close, and that the incremental costs of change would be low. And that’s the point regarding innovators and early adopters: if they’re already doing a lot of these things, the change is going to be so shockingly little and surprisingly effective. I came back to the office feeling newly energized. It was very exciting to learn all these things that are out there of which I was not aware that are hugely impactful and easy to deploy.

For a innovative builder like you, determined to stay ahead of the pack, is Net Zero Energy really enough?

Going forward, I feel we are moving so quickly towards the concept of Net Zero Energy that the terms of reference will start to change. We will one day soon be talking about Energy Positive homes, those that actually put back more than they take out.

It has changed the conversation, changed mindsets. Our clients all have different expectations from site to site.

Time studies show that RigidStack lap siding built on LP SmartSide with its heavy duty spline installs up to 22 per cent faster than standard 16’ lap. Diamond Kote re-manufactures LP SmartSide into a hidden fastener siding system that offers a more efficient installation. The end result is a flawless finished product that can be enjoyed for years to come. Available in 30 prefinished Diamond Kote colors with a custom colour option backed by a 30Year No Fade Warranty.

Contractors are constantly on the lookout for better, easier, and more profitable ways to provide quality products and performance to their customers. Fusion Stone can help with that – proven consumer appeal, multiple indoor and outdoor applications and ease of installation are just the beginning. A patented innovation, Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips & screws. Look for their new profile www.fusionstone.ca.

Nichiha offers a line of panelized fiber-cement siding installed with special clips that hold the panels away from the sheathing to provide a rainscreen exterior to control water intrusion and increase the durability of the entire wall system. The NichiProducts line is 55 per cent fly ash by weight. The panels are ship-lapped on four sides and have the appearance of bricks, shakes, or stone. (A lap siding is also available.) Most panels come in 6’, 8’, or 10’ sections, in heights ranging from approximately 8” to 18” and thicknesses ranging from 1/2” to 1”. Depending on the product, they offer a 30year or 50-year transferable warranty.

A building wrap like NovaWrap Aspire is a critical element in the building envelope system which is the physical separation between the interior and exterior of a building, just like a jacket provides you protection on a wet or windy day. Installed behind the exterior cladding, NovaWrap reduces both air and water infiltration into the building envelope preventing drafts and water damage. The material science of the coating enables NovaWrap to be breathable, allowing water vapour to escape should it get into a wall system, but still act as a barrier against air infiltration Unlike Grade D or felt building papers, NovaWrap does not absorb water, is much stronger, and is UV resistant

Drawing inspiration from the Canadian outdoors, LP announces two new LP CanExel Prefinished Siding colours for 2017 Barnwood and Timberwolf . LP CanExel siding now offers 21 beautiful colours, each with an advanced multicoat, heat-cured finish for durable beauty. Also new for this year is LP CanExel Ced’R-Vue 6-inch Snap Lap offered in eight top-selling colours. This 6-inch profile provides a sleek, stylish appearance and comes in 12-foot planks. For ease of installation the planks have an alignment notch on the back of the board and a nail line.

BP Enermax Four-function Panel - Vapour Barrier, Insulation, Soundproof and Air

Home comfort is a combination of several factors: air infiltration and moisture permeability, together with insulation are the most basic. BP Enermax is the only structural board that combines these factors with a quiet environment, an integral part of the “total” home comfort equation. Efficient, environment-friendly and affordable , these all-natural wood fibre panels are the ideal solution for residential projects like home theatre, playrooms, and laundry rooms.

James Hardie fiber cement siding offers beauty and character

James Hardie fiber cement offers the beauty and character of wood, as well as resistance to weather, insects and flame spread. Where available, ColorPlus technology includes a factory-applied, baked-on finish that lasts up to two times longer, has 30 per cent better fade resistance and provides optimal color accuracy.

IKO Ener-Air Wall Insulation is a rigid, polyisocyanurate foam insulation with high thermal properties. It is constructed from closed cell polyisocyanurate foam core bonded on each side to coated fiberglass facers during the manufacturing process. IKO Ener-Air is designed to be a non-structural sheathing in cavity wall, stud wall or cathedral ceiling construction. It is a dimensionally stable air barrier with a high water vapour permeance and excellent water shedding capabilities. The product is lightweight, easy to handle and can be sized with ease.

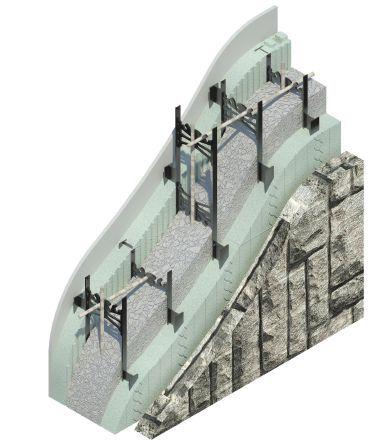

NUDURA’s integrated philosophy is simple: Provide service, value, quality, and a cutting edge ICF wall product.

“Building technology has seen rapid advances in recent years, with owners, architects, designers, and builders looking for newer, more efficient ways to build more energy efficient and environmentally friendly projects.”

Introduced to the market in 2001, NUDURA ICFs are now the world’s leading ICF system. Based in Barrie, Ontario with two manufacturing facilities in Canada (Granby, Quebec & Coaldale, Alberta) and one in the United States (Columbus, Georgia), NUDURA produces insulated concrete forms (ICFs) that provide design professionals, architects and contractors a more efficient way to build stronger, energy efficient, comfortable, disaster resilient and environmentally friendly building envelopes.

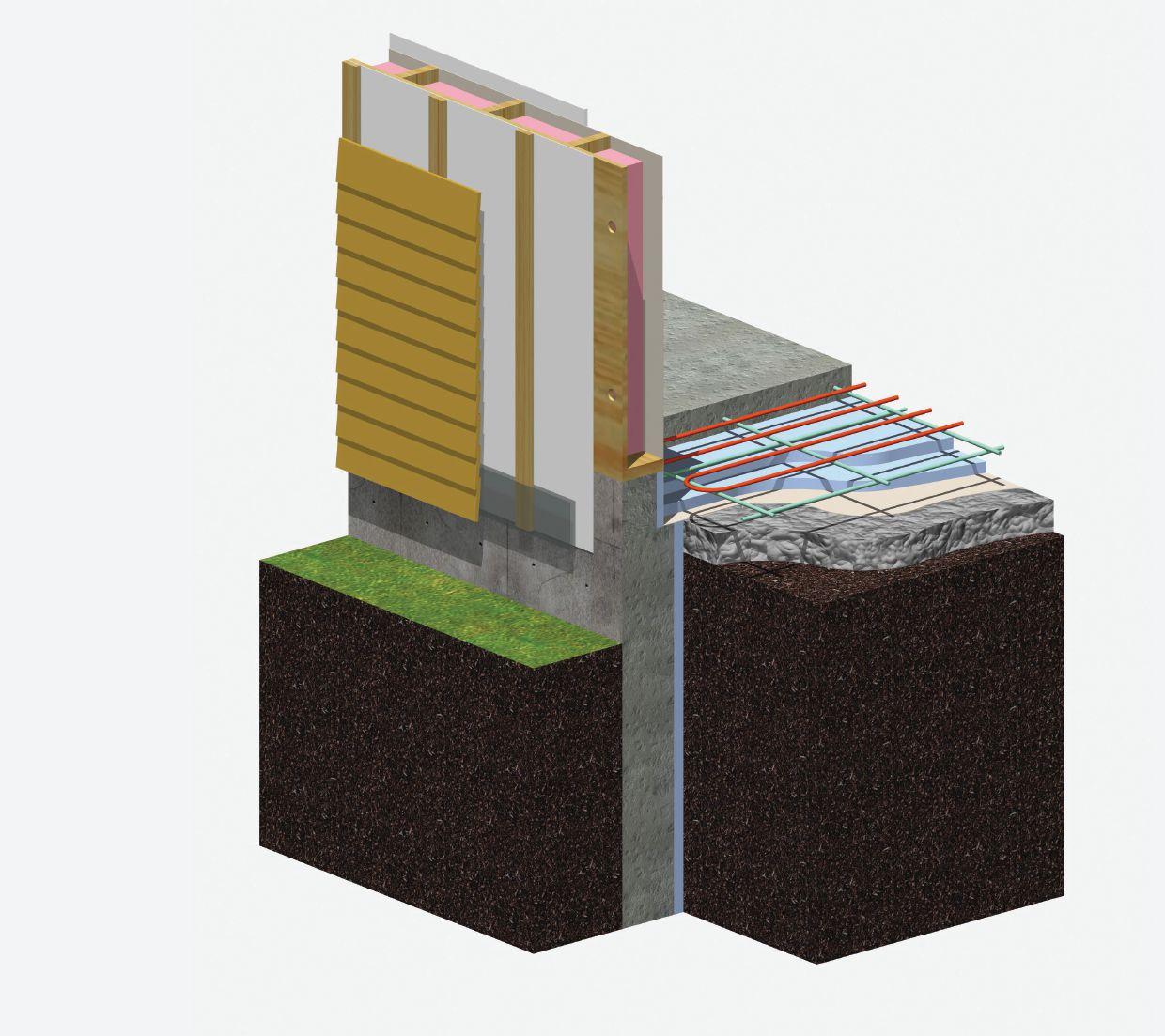

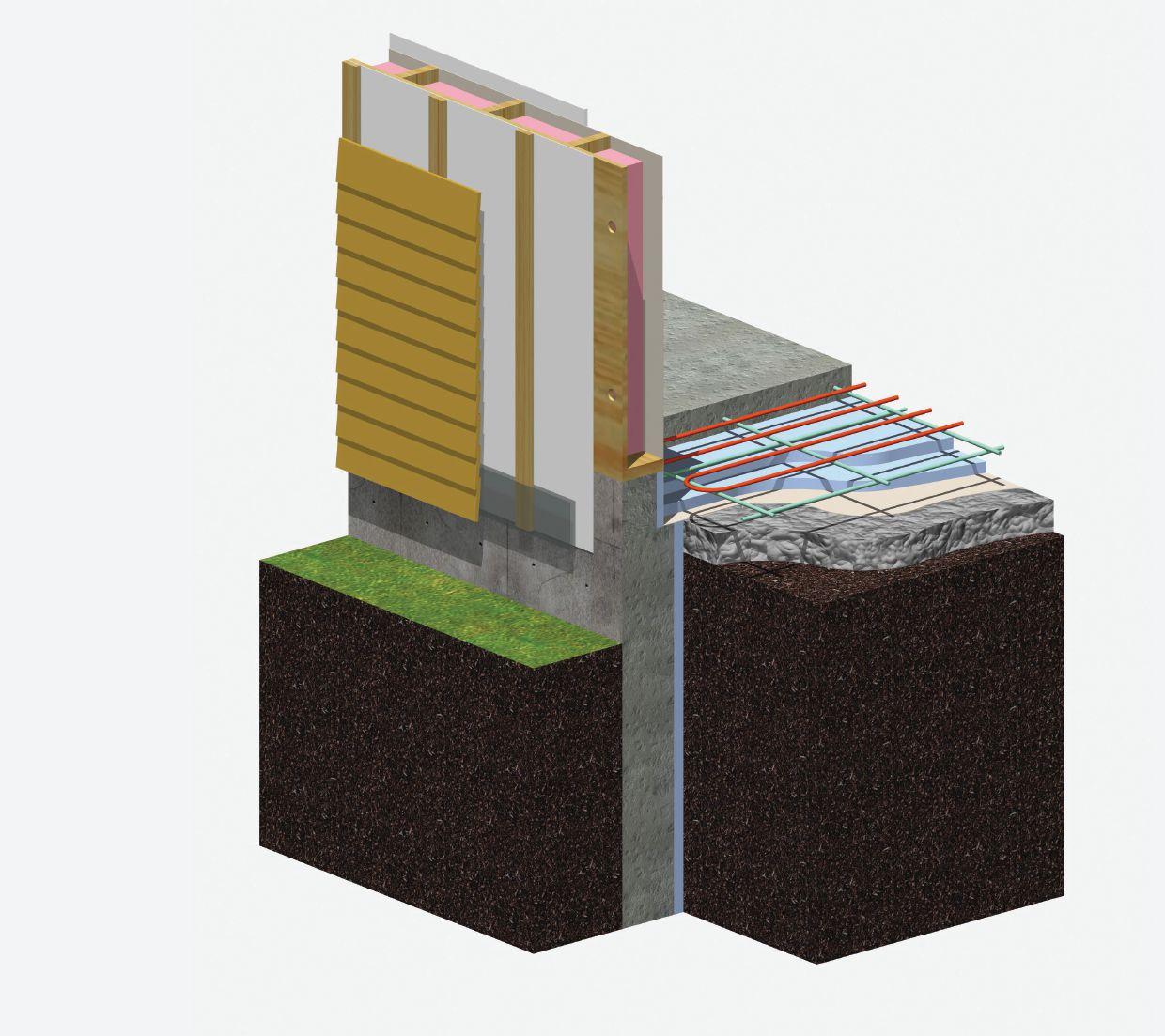

ICF construction

The ICFs consist of two stay-inplace panels of Expanded Polystyrene (EPS) connected with NUDURA’s innovative, hinged folding web. There are four different ICF series (see sidebar) and accessories to cover every building need. All of the series feature the NUDURA innovative DURAMAX, DURAFOLD, and DURALOK technologies and a 4-Way Revers-

ible System technology to make building easier and faster.

The forms are stacked, reinforced and then filled with concrete and rebar (amount of rebar depends on job and building code requirements), creating a solid reinforced monolithic concrete wall. NUDURA offers form thicknesses consisting of 4”, 6”, 8”, 10” and 12 inches along with a variety of form shapes to accommodate all types of building requirements and designs.

With NUDURA ICFs, once the poured concrete is cured drywall installation on the inside and exterior finishes are simple and quick. There is no need to go back and insulate or spray in foam because the ICFs take care of six building steps: form system, wall structure, insulation, air barrier, vapor barrier and interior/exterior finish anchorage.

Building technology has seen rapid advances in recent years, with owners, architects, designers, and builders looking for newer, more efficient ways to build more energy efficient and environmentally friendly projects. A NUDURA home or commercial building’s superior energy performance is the result of NUDURA forms working in conjunction with the thermal mass of a solid concrete core to provide one of the most energy efficient and airtight wall systems available. The recent thermal study released by the Insulating Concrete Forms Manufacturers Association (ICFMA) and conducted by CLEB Laboratories showed that building

The NUDURA ICF series

A leader in ICF innovation and technology. It offers users the ability to combine a variety of products during the building process.

The industry’s first multi-link form system that enables the creation of a fully exposed concrete surface that extends to the face of a standard NUDURA form panel.

Plus Series

The Plus+ series product line introduces an innovative way to build custom R-Value walls. Comprised of two new products: Plus Forms and R-Value Plus inserts.

Integrated Series

This series includes proprietary floor and ceiling technology, HYDROFOAM Technology, Retrofit Technology and more. The series work in conjunction with NUDURA’s ICFs to provide maximum energy efficiency.

with ICFs provides 58 per cent better R-Value/RSI and 60 per cent more in energy savings compared to a traditional 2x6 wall cavity.

NUDURA ICF walls have met and most often exceeded statutory building codes around the globe and NUDURA is tested to the highest standards, providing the customer with the safest, most comfortable project possible.

Visit nudura.com or call 1-866-468-6299 for more information or to find a distributor in your area and learn more about using insulated concrete forms on your next project.

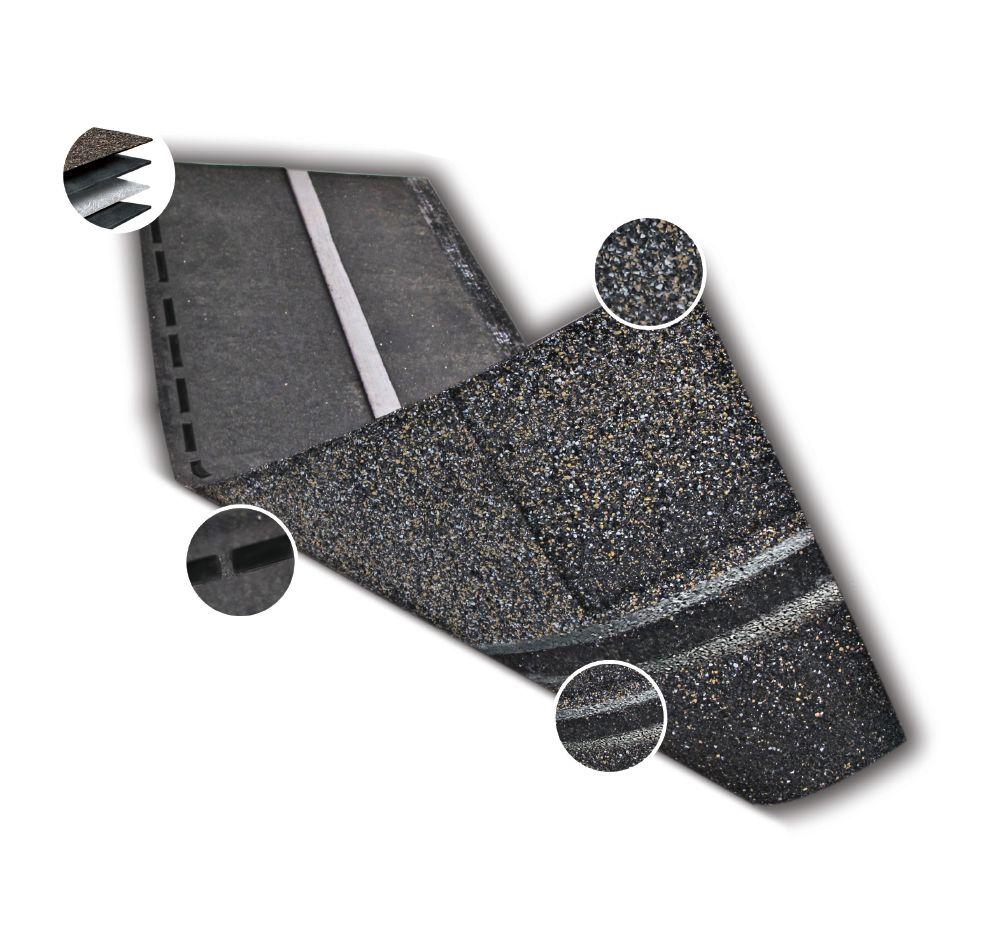

When it comes to selecting the right roofing material for your homeowner customers, there are multiple features to consider. Among the top considerations are weather performance and installation attributes, as well as aesthetic characteristics. Recognizing this, IKO has designed its popular performance shingle line, IKO Dynasty shingles with ArmourZone, with benefits that deliver on these key attributes.

Roofing systems are a home’s first line of

defense against inclement weather. And with an increase in harsh storms and severe wind activity in recent years, selecting the right roofing system with weather-performance attributes has become even more critical. As such, IKO Dynasty shingles feature the innovative “ArmourZone” technology, which provides superior wind resistance to help avoid high-wind blow-offs.

The ArmourZone is reinforced by a tear-resistant, woven band that helps provide resistance to high winds and carries a limited wind warranty of up to 210 km/h (130 mph). Additionally, the ArmourZone provides fastening strength over a greater surface area of the shingle, helping to resist nail heads from pulling through the shingle in high winds.

Another feature of Dynasty’s construc-

tion is our Fastlock sealant strips, which are thick and aggressive to promote a strong bond between shingle courses. They also promote a strong bond to the shingles below, as well as extraordinary performance with radiant heat from the sun.

The ArmourZone also offers an enlarged nailing area that makes installation faster, easier and more accurate. Two nailing lines that are 1-1/4” apart identify the ArmourZone, which is 40 percent wider than standard 7/8” roofing shingle nailing zones and easily guides installers to the shingles’ wider nailing surface for correct nail placement.

Also, since they are manufactured in IKO’s special “Advantage” size, Dynasty

Our mat is coated top and bottom with weathering asphalt, then surfaced with coloured granules. It’s heavy-duty for exceptional durability and structural integrity.

Our shingles have our Fastlock sealant along their bottom edge that helps prevent wind-driven rain from getting underneath them. When activated by the sun’s heat, it gets extra-tacky and creates a strong bond to help ensure maximum protection against wind uplift, blow-off and water penetration.

shingles also have a larger exposure (57/8”) than most competitors’ comparable products (5-5/8”). With 100 square feet of coverage per three bundles, installation of Dynasty shingles not only is faster and easier for contractors, but also lowers job costs associated with excess materials and labour.

The roof may account for up to 40 per cent of the visual surface of a home’s exterior, affecting a home’s curb appeal by how it complements exterior elements

We embed colourfast Algae Resistant granules into our shingles to help inhibit the growth of blue-green algae that can cause unattractive black stains, streaks and discolouration.

such as cladding, the natural environment and more.

IKO Dynasty shingles with ArmourZone are offered in eleven diverse, high-definition colours, which are applied using an advanced colour blend technology process that enhances any home façade with a dynamic, artful roofscape.

Contractors and homeowners alike can appreciate Dynasty shingles’ deep shadow bands and dimensional profile that help to create depth of field and texture. Designed to complement any

it’s a 1-1/4” wide nailing surface for correct nail placement reinforced by a tear-resistant woven band that provided even more fastening strength over a wider surface area of the shingle. Nails applied in this area are optimally positioned to help resist nail pull-through and shingle blow-off in high winds.

style of architecture while appealing to a homeowner’s individual sense of style, Dynasty shingles can make a home stand out from the neighbourhood or even blend into its natural surroundings. An additional feature, built-in algae resistance granules, helps to inhibit the growth of blue-green algae.

For more information about IKO Dynasty shingles with ArmourZone and IKO’s full suite of residential roofing solutions, visit www.iko.com/na.

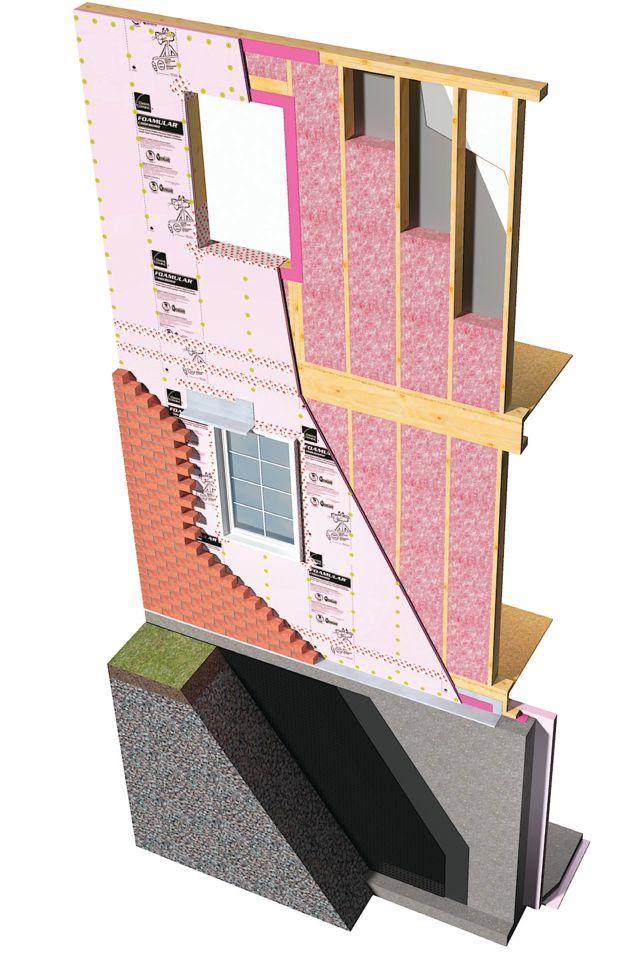

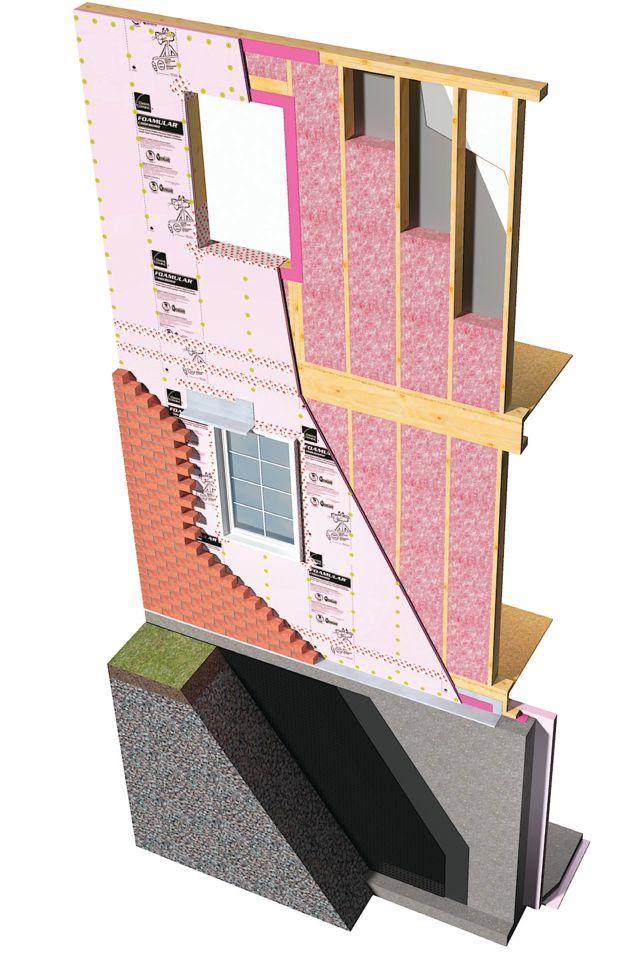

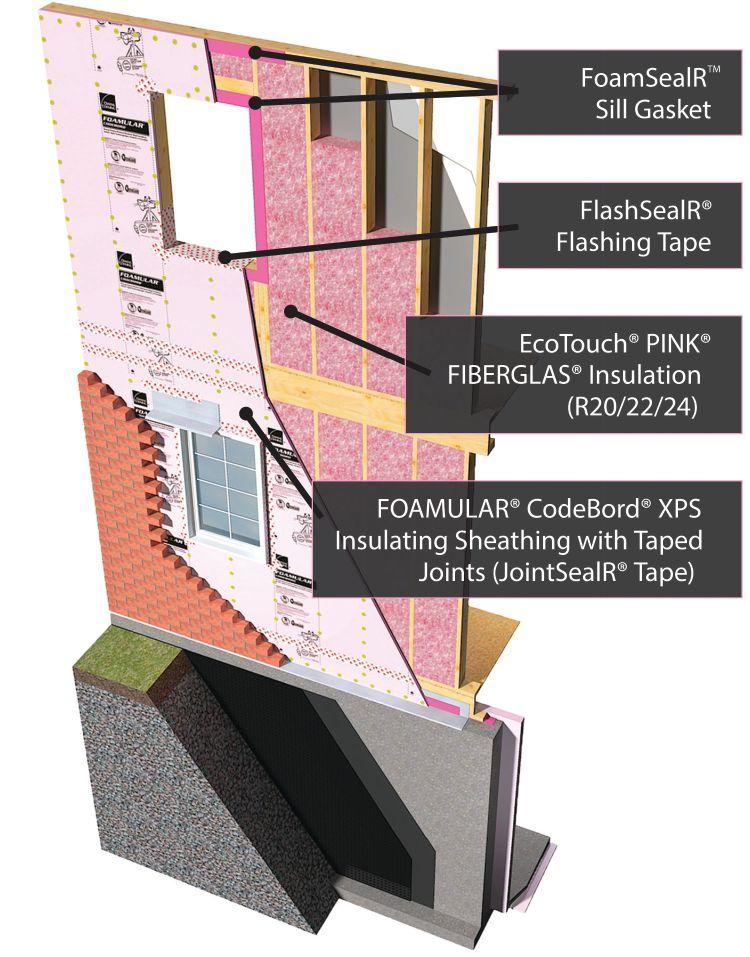

As provincial energy codes mandate higher insulation levels in new houses, builders face the challenge of constructing high performance wall systems that are cost effective, easy to

build, and have no hidden consequences. Increased insulation plus improved air tightness is an effective way of reducing heat loss while addressing occupant comfort. To this end, builders can incorporate high performance batt insulation

(R-19, R-22 or R-24) in wall cavities with conventional sheathings (OSB or plywood). Alternatively, a combination of foamed plastic insulated sheathing and high-performance batt insulation can be used.

Increased insulation plus improved air tightness are an effective way of reducing heat loss while addressing occupant comfort.

A major benefit of foamed plastic insulating sheathings (over wood sheathings or directly on wood studs) is a significant reduction of heat loss from thermal bridging. In a typical two-storey house, the exterior wood framing represents approximately 16 to 20 per cent of the wall area as is poorly insulated. Exterior foamed plastic insulating sheathing addresses this thermal bridging and reduces heat lost through the structure. It will also minimize the risk of condensation by warming up the cavity.

Research has demonstrated the benefit of adding exterior insulating sheathings to minimize the risk of condensation in exterior wall assemblies.

Some builders are concerned that a double vapour barrier results if exterior foamed plastic insulating sheathings is used in combination with a 6 Mil polyethylene va-

A major benefit of foamed plastic insulating sheathings is a significant reduction of heat loss from thermal bridging.

pour retarder on the inside. A recent study at Canada’s National Research Council (Report on Properties & Position of Materials in the Building Envelope for Houses and Small Buildings, no. A1 004615, December 2014) looked at the risk of moisture condensing in wall assemblies with exterior foamed plastic insulating sheathings compared to reference wall assemblies using OSB exterior sheathing. Stud cavity insulations were fibrous batt type (R-19 and R-24). Both exterior foamed sheathing over OSB or attached directly to the exterior face of wood studs were examined. The R-values of the exterior foamed insulations used were R-4, R-5 & R-6 and the water vapour permeance of the insulations covered a range of values from 2 (very low) to 1800 (very high) ng/(Pa.sm2).

The key observations included the following:

There is less risk of moisture condensation in walls with R-19 compared to R-24 fibrous batt insulations in the stud cavity because the temperature of the interior face of the exterior sheathing (OSB or foamed insulating sheathing) is colder with R-24 batts. Thus, adding exterior insulation in combination with R-19 batts is a good choice.

Adding exterior insulation in combination with R-19 batts is a good choice.

All wall systems incorporating foamed insulating sheathings, with or without an OSB interlayer, result in lower risk of moisture condensation than the reference walls sheathed only with OSB and no exterior insulation. Walls with foamed insulating sheathing installed over the OSB showed a slightly lower risk of moisture condensation than walls without the OSB interlayer. For cold, dry zones like Ottawa, the risk of condensation was low regardless of whether OSB was used as an interlayer and regardless of the vapour permeance of the foamed insulating sheathing.

For the coldest and driest zones like Edmonton, the risk of condensation was low for walls with OSB plus foam sheathing regardless of the vapour permeance of the insulating sheathing. Walls without the OSB interlayer showed the risk of condensation was slightly lower with a more vapour permeable insulating sheathing, but all those in the vapour permeance range examined performed better than the reference wall that used only OSB.

For the mild, humid, coastal zones like Vancouver and St. John’s, for walls with and without an OSB interlayer, the risk of condensation increases as the vapour permeance of the foamed insulating sheathing increases. This is because the higher outdoor water vapour pressure (humidity) is pushing the water vapour into the wall cavity. Less vapour permeable foamed insulating sheathings will reduce the risk of condensation inside the wall.

This research has demonstrated the benefit of adding exterior insulating sheathings to minimize the risk of condensation in exterior wall assemblies. Accordingly, section 9.25.5 of the NBC 2015 edition, “Properties and Position of Materials in the Building Envelope,” will be modified to reflect the added benefit of adding exterior insulation.

This work clearly shows that the fears of a double vapour barrier are unfounded in most of Canada— even when low vapour permeance exterior insulating sheathing is used—as long as the sheathing has a minimum thermal resistance of R-4. Builders using OSB structural sheathing can also rest assured that adding foamed insulating sheathings on the exterior side of the wall assembly will not result in increased risk of condensation; in fact, the risk is reduced. Exterior insulating sheathings help keep wall cavities and critical surfaces warmer thus reducing the risk of condensation. As added benefits, this also makes homes more energy efficient, increases durability and improves occupant comfort.

About the Author

Salvatore Ciarlo, P.Eng, is the National Codes/ Standards and Technical Services Director at Owens Corning Canada. He has 23 years’ experience in the building materials industry and holds a bachelor’s degree in Civil Engineering specializing in building science and has a professional degree in Architectural Technology. Sal sits on several provincial and national code committees. He can be reached at salvatore.ciarlo@owenscorning.com.

There are many insulation products on the market designed for use as continuous exterior insulated sheathing in residential construction. However, there are several important differentiators in using stone wool rigid board.

It’s an important part of overall “hidden” comfort of a high quality home.

Using stone wool rigid board on the exterior of the sheathing results in residential buildings that consume less energy. It is designed to minimize the flow of heat through the enclosure and reduces thermal bridging. This will help builders and homeowners achieve better effective (in-situ) performance of the assembly, rather than

relying on the ‘nominal’ R-value stated on packaging.

Additional benefits include excellent fire resistance.

Stone wool rigid board product like ROXUL COMFORTBOARD™ 80 is fire resistant to 1,177°C. It can act as a fire resistant barrier around the envelope of the structure, protecting the life safety of the occupants, as well as their investment. Fire resistant exterior insulation is especially important when using combustible claddings, in wildfire zones and in residential developments with close lot lines or in multi-family construction, as it helps mitigate against fires spreading from house to house.

When installed on the exterior, stone wool rigid board can help reduce the outside-in

sound transmission, improving occupant comfort in areas near highways, railroads and airports. It’s an important part of overall “hidden” comfort of a high quality home.

Importantly, if used in sufficient thickness, stone wool rigid board used as continuous exterior insulation will raise the temperature of the sheathing to reduce condensation potential on the interior of the sheathing, which can cause mould, rot and odours. This approach also creates a vapor permeable assembly with drying potential to the exterior, preventing moisture in the assembly from becoming trapped.

The benefits of exterior continuous insulation are supported by building science.

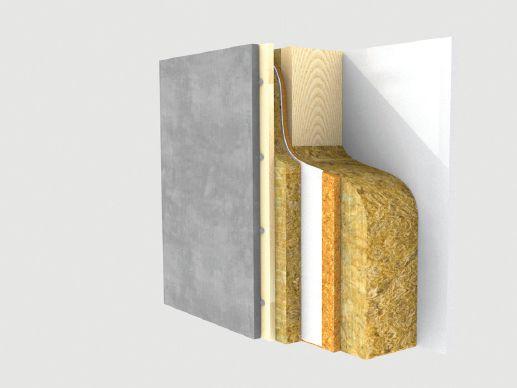

An optimal wall assembly, incorporating stone wool rigid board as continuous exterior insulation

details (pictured,

• Drywall

• Vapor control layer if needed

• 2 X 4 studs

• 3.5 inch stone wool cavity insulation between the framing

• Wood sheathing

• Weather-resistant membrane

• Stone wool rigid board exterior insulation

• Wood furring strips, secured with screws into the structure

(Note: Furring strips act as a substrate for the cladding attachment and benefit the system by creating a drained screen which is best practice for rain control in residential construction using insulated sheathing.)

• Cladding

Yet building science also tells us that not all products are created equal. Material selection and good design are vital. Stone wool rigid boards can offer significant performance advantages that homeowners value. Forward-thinking builders and renovators, meanwhile, are realizing there is opportunity in early adoption, as a growing contingent of homebuyers and homeowners seeking upgrades appreciate innovative, sustainable solutions that provide greater energy efficiency, increased safety, comfort and long-term durability. It’s well known that some things are worth that little bit extra.

Thomas Hackett manages the Technical Support Center at ROXUL INSULATION. He is responsible for overseeing the technical support function for ROXUL products in various applications throughout North America.

A BETTER WAY TO BUILD YOUR HOMES –AND YOUR REPUTATION.

Your reputation is built, or crumbles, long after the keys have been handed over. That’s why projects like The Edelweiss Home – Canada’s first LEED® v4 home, and second in the world to achieve Platinum status – rely on the continuous insulation of ROXUL® COMFORTBOARD™ exterior sheathing. Its vapour permeability enables your wall assembly to dry to the outside, providing your clients with durability and comfort. See why ROXUL is a better fit for your next project at roxul.com/comfortboard

When price is dictated by time and time is dictated by speed... SIZE MATTERS.

At NUDURA, size does matter. NUDURA standard forms feature DURAMAX Technology®, the largest standard ICF block in the industry, allowing the placement of 12 square feet of wall area in one building step. Our DURAMAX Technology® results in faster installation times, less waste and a reduced amount of seams. Building Has Evolved® at NUDURA, allowing builders & contractors to save time on labour, which is money, with the biggest block on the market.