Natasha Ferguson: Breaking down walls pg. 10

Creative Eye: Smithwood Builders pg. 18

DE&I: Takling the talk or walking the walk pg. 24

Natasha Ferguson: Breaking down walls pg. 10

Creative Eye: Smithwood Builders pg. 18

DE&I: Takling the talk or walking the walk pg. 24

Optimizing basements for future conversion Page 12

Pumped: Guests of SFA Saniflo Canada experience an immersive factory tour in France.

are you talking the talk or are you walking the walk? 24 Set yourself up for long-term success by looking at DE&I as an opportunity instead of an obligation.

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the digital edition archives at canadiancontractor.ca.

Owen Thompson and Marilena Tricarico of Desjardin’s RenoAssistance join The Hammer to discuss their annual Renovation Intentions survey and what these results can teach contractors, as well as strategy for navigating renovations in today’s economy and climate.

Making sure windows and doors meet fire codes is critical for any builder. An expert team from Jeld-Wen shows us how in this sponsored video.

Follow Canadian Contractor on LinkedIn and stay up to date about industry news, the latest trends and upcoming events.

or changes, please contact Angelita Potal Tel: (416) 510-5113 Fax: (416) 510-6875 Email: apotal@annexbusinessmedia.com Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Kaitlin Secord ksecord@annexbusinessmedia.com

Matharu (226) 931-5095 nmatharu@annexbusinessmedia.com

Audience

Media Designer Graham Jeffrey

Group Publisher Danielle Labrie (226) 931-0375 dlabrie@annexbusinessmedia.com

President/COO Scott Jamieson sjamieson@annexbusinessmedia.com

The basement of my family home was my wonderland growing up. It was decked out in Toronto Maple Leaf paraphernalia and painted blue and white with a maple leaf border wallpaper running through the middle. My parents and I would spend hours in our basement—playing board games, watching movies or whatever elaborate baton recital I had come up with mere moments before. I celebrated several birthdays, rang in many New Year’s, and hosted countless sleepovers in my basement.

As I grew up, I’d tease my dad about having a space dedicated to such a cursed team. I watched as we did away with our blue and white paint in exchange for a more neutral pallet. I observed my toy area being traded in for a desk for my studies. (Don’t worry, we kept the Maple Leaf collection and are still adding to it to this day!)

We transitioned our sacred family space into something we still find ourselves congregating in when I go home to visit. Coming from a family of sentimentalists, change can be tough. Throughout the redesign process, I realized that growing with your space can be easier said than done.

Christopher Smith of Woodsmith Construction Inc. understands this, as he write on his experiences of renovating basements in Toronto’s east-end. He dives into tapping into the full potential of basement remodels. Can something be done to give your client the space they need now with the possibility of a future basement rental property?

” We transitioned our sacred family space into something we still find ourselves congregating in when I go home to visit.

By Kaitlin Secord Editor ”

The future of construction carries on in this month’s profile. Jack Kazmierski spoke with Natasha Ferguson, the principal and founder of Ethelfox Construct Group. Ferguson shares her journey to becoming a tradeswoman, obstacles she faced along the way and opportunities she strives to provide for marginalized groups coming up in the construction world.

Gordon Wornoff circles back to basements as he profiles three-time CHBA award-winners, Smithwood Builders, on their award-winning basement renovation and the importance of collaboration with trade partners.

In this edition’s CON the move, Doug Picklyk covers guests of SFA Saniflo Canada’s experience in an immersive factory tour in France. If you want to hear even more about this, keep an ear out for an upcoming edition of The Hammer, where I’m joined by Phil Warren and Frédéric Boucher to chat more about the trip.

In a new segment, Anna Somogyi poses the question, ‘are you talking the talk or walking the walk?’ when it comes to diversity, equity and inclusion in your businesses. She shares some insight as to how you can improve your approach and execution of DE&I.

Up and coming for Canadian Contractor, we are hosting a webinar on going green and the journey of tackling net-zero on August 30. We’ll be joined by a panel of industry experts to share best practice and mutual challenges when it comes to being net-zero ready. I hope to see you there!

As always, I invite you to pitch me your ideas, send me your latest news, or connect with me to chat about the industry. You can reach me at ksecord@annexbusinessmedia.com.

Until next time, happy reading! cc

By Richard Lyall

Changeis the only constant in life. Those are the simple, yet prophetic words of wisdom from sage Greek philosopher Heraclitus of Ephesus, a pioneering thinker who lived around 500 BC.

The pre-Socratic intellectual obviously wasn’t referring to our present-day construction industry, but the saying could certainly apply today in light of the technology being rolled out.

The Canadian construction industry is presently living in a golden era of change – a time of accelerated technological progress. It is critical that we embrace new digital tools, technical aids, artificial intelligence, digital twinning, and virtual reality software, as other industries have done.

New technologies won’t suddenly solve all of our immediate problems, but they could play a pivotal role in addressing the housing supply and affordability crisis.

All the technology we need – building information modelling (BIM), geographic information system (GIS) mapping, augmented reality (AR), virtual reality (VR) and artificial intelligence (AI), along with tools like drones – are literally at our fingertips and we must began adopting them.

Countries around the world are integrating innovative BIMbased processes, but Canada is the only G7 country without a BIM mandate. If we are left behind, this will result in a drag on our productivity.

Collecting quality data is another important piece of the puzzle, as it allows for better forecasting, decision-making and subsequent market agility. Reliable data and rational information allow developers to know whether changes can be made to a project for the better.

But disturbingly the construction industry is lagging other industries in its adoption and attitude towards bringing new digital technology and tools onto worksites.

A survey of 275 companies by KPMG found that nine in 10 construction companies say that digital technology can help make their labour force more effective, but the survey noted relatively few are actually trying the advancements. While 80 per cent of firms are excited about the possibilities of con-tech and believe that technology will make them more competitive, only 46 per cent indicated they plan to spend more than 11 per cent of their corporate operating budgets on technology and digital transformation in the near future.

Much of the new technology being used in Canada today is for designing projects, often in 3D, but extending it for such things as computer-aided fabrication of materials, is not

happening widely. There are reasons for the slow uptake.

Technology changes so fast that the industry must play a constant game of catch-up. The price tag is also a factor. And it can be costly for small- and medium-sized contractors to invest in digitization.

Some technology is now making its way onto worksites.

Exoskeletons that fit onto workers’ shoulders, for example, are now making an appearance amongst masonry trades to help workers lift heavy loads and do overhead work.

3D printing has made its debut. Habitat for Humanity Windsor-Essex, with the help of the University of Windsor, built Canada’s first 3D-printed home.

Drones, meanwhile, are starting to be used for surveying and assessing repairs needed to masonry work atop tall structures and buildings.

Boston Dynamics developed a product called Spot, a robotic dog that can be used on construction sites. It carries high-tech cameras or laser scanners that can capture data and report back to a user. The techno-pooch was deployed by PCL in 2021.

AI is being used but not nearly enough. It is a tool that can reduce building times and material waste, especially for modular construction. It can also improve communication among team members, forecast deliveries, anticipate transportation problems, optimize how prefabricated components are loaded on trucks, and determine the number of workers and types of equipment needed on site.

Digital twinning is another tool that is starting to be used. The technology was recently used to solve construction issues on a Canada Post processing centre in Toronto. Digital twins can help developers, architects and engineers figure out better ways to build a structure and test changes on the fly that can speed up and improve construction.

A $1.32-million, five-year pilot is now under way in Simcoe County that will explore how digital twinning technology can help with visualizing land and building investments, predicting affordable housing needs, developing sustainable cities, and aiding in municipal operations.

RESCON and other groups, meantime, are pushing for digitization and streamlining of the development approvals process. Reports have indicated that lengthy processing times for development applications have added up to $50,000 to the price of condo apartments since 2020.

I am hopeful that the adoption of technology and digital tools will pick up steam in the construction industry. Construction is too important an industry to be left behind. cc

Richard Lyall is president of RESCON. Contact him at media@rescon.com

By James Hong

In a recent edition of Canadian Contractor, an article talked about Canada’s transition to net-zero and the use of storing carbon in concrete. The bad news is that the concept, idea, and responsibility to accomplish net-zero can feel overwhelming especially in an industry known for high carbon emissions.

The good news is that net-zero is being achieved in Oslo, Norway and continues to increase and thrive in its efforts and outcomes. What started as a concept for zero emission construction sites was achieved and has continued to have further successes with effects directly improving other industries and the quality of life for the citizens.

Tackling carbon emissions is no small feat. The buy-in by government, manufacturing, business, and regulation is staggering. When enough incentives are presented to all involved, the uphill road becomes a direct route to success.

Oslo had no electric construction equipment prior to their first pilot project just three years ago. What started as one part of their plan to reduce greenhouse gas emissions by 95 per cent by the year 2030 is now a major contributor for reduction affecting the construction industry, electric vehicle manufacturing and sales and quality of life.

It took a comprehensive Climate Budget policy with targets measured in CO2 emissions, an aggressive procurement drive and cooperation from all stakeholders including those in construction willing to adapt and take a ‘make it work’ attitude.

Marit Hepsø, the city of Oslo’s sustainability manager for the Building and Construction Procurement Department, speaks about power charging challenges and information on tapping the grid. I asked him how zero emission construction equipment is charged and by what means, grid verses charging station. Hepsø said it varies depending on the capacity in the grid locally. Some contractors have used battery and/or mobile superchargers, others connected directly to the grid. Electricity supply is a complex process, arranging temporary electricity supplies, especially 400 V this may lead to delays.

A good process is to involve power grid operators in early planning and throughout the project. Charging problems and limitations of the supply grid may lead to increased charging times. Consider the composition of the machine fleet by choosing battery and cable/battery-powered electric

machinery to resolve charging capacity problems. Other ways to reduce the load on the supply grid may be through the use of a battery container, the use of district heating to heat and dry structures and arranging one’s own energy generation in a building project’s early phase.”

Heidi Sørensen, the brains behind Oslo’s success, reports on New York’s recent climate budget announcement along with London and Edmonton this past fall. At last count, there are 40 cities with plans for a climate budget and more global sharing by webinars, talks, planning committees and conferences, are making the move to accomplish a net-zero future. cc

James Hong is an OHS consultant, writer and journalist.

23_004908_Canadian_Contactor_AUG_CN Mod: July 7, 2023 9:39 AM Print: 07/21/23 11:19:30 AM page 1 v7

The Ministry of Housing and Diversity and Inclusion announced over $1.7 million in funding through the National Housing Strategy Research and Planning Fund (NHSRPF) for the new research initiatives selected from applications across Canada.

The fund, administered by the CHMC, allows recipients to address key information and knowledge gaps in National Housing Strategy priority areas, to better understand the housing needs of Canada’s most vulnerable populations.

The NHSRPF “provides support to not-for-profit organizations, registered charities, Indigenous organizations and Indigenous governments for housingrelated research,” to promote interest, involvement, and capacity building in housing research outside of government.

The fund provides financial support for research through four different streams: Planning Activities, for initiatives that support the planning of research activities; Individual Research Projects, for initiatives that address specific knowledge gaps; Programs of Research, for initiatives that include multiple projects; and, Knowledge Mobilization, for initiatives undertaken to communicate research. cc

to construction’s evolving needs’

BuildForce released their annual report, which highlights its findings about and response to construction’s evolving needs.

The annual report found that 20 per cent of the existing construction labour force are expected to retire between 2023 and 2032. There are an estimated 299,200 new workers needed by 2032 to keep with the pace.

With the influx of workers to the labour force, BuildForce has grown their e-learning catalogue to 155 courses.

BuildForce Canada received funding from the Government of Canada to “develop an online construction industry data hub.” It is expected to launch March 2024. cc

Technical Safety BC’s 2022 State of Safety Report and Annual Report “detail the safety challenges that have impacted British Columbians over the past year, including the ongoing climate crisis, as well as safety priorities that have emerged as the province continues to adapt to a post-pandemic normal,” states a news release.

In 2022, TSBC investigated 81 incidents.

The safety priorities identified in this year’s State of Safety Report include work by unlicensed individuals, the potential dangers of working near gas lines, and the impacts of climate change and extreme weather.

Unlicensed Workers

Technical Safety BC investigated multiple incidents in 2022 caused by unsafe conditions created by unqualified

workers. The findings state that many of the unqualified workers were advertising themselves as “handy people with the skills to complete renovations cheaply” through social media.

TSBC investigated 24 reports of gas leaks from damaged gas lines in 2022, including seven incidents that resulted in explosions causing extensive damage and injury.

In 2022, there was an increased number of incidents that were the result of “poor safety behaviour, including using outdoor appliances indoors when trying to heat homes, and installing unsafe,

overloaded, or unpermitted electrical systems to power equipment like heat pumps and EV charging stations.”

Highlights from the State of Safety report include: A three per cent decrease year-over-year in installation permits, including a 19 per cent decrease in installation permits under the boilers, pressure vessels and refrigeration technology, and a 12 per cent decrease for installation permits in the gas technology, possible indicators of the economic slowdown and effect of fewer housing starts; and in total, 112,645 operating permits and 155,620 installation permits were issued. These numbers reflect a six percent increase and three per cent decrease, respectively, from 2021. cc

Join a completely Dealer-Owned company today.

Dealers share and participate equally without the influence of any external shareholders. Harness our massive buying power, comprehensive distribution, national brand recognition and marketing support.

Ferguson’s trajectory from daycare apprentice to corporate executive was anything but a straight line.

This construction industry entrepreneur is changing the landscape for future generations of tradespeople.

By Jack Kazmierski

Natasha Ferguson got her first taste of the trades long before her first day in elementary school. Her father used to own a number of houses in Toronto, and would often pick her up from daycare and bring her with him to job sites where he would work on one of his properties, recruiting her assistance, where appropriate.

Today, Ferguson is the principal and founder of Ethelfox Construct Group, a Toronto-based construction company made up of four divisions: Ethelfox Construct, Sky Limitless Roofing, Garden Landscaping, and TKO Demolition.

Ferguson’s trajectory from daycare apprentice to corporate executive was anything but a straight line. In fact, she took quite a detour on her way to running her own construction firm. “I actually didn’t get into the trades right away,” she admits. “After school, I went into corporate communications, and that was my life for about 15 years.”

Eventually, the stressful world of corporate communications took its toll on Ferguson, and she decided that she needed a change. Her husband at the time was a roofer and a tradesman, so Ferguson decided to start a roofing company with him. “That was back in 2012, and that’s when my journey back into the construction industry picked up,” she says.

Fortunately, Ferguson had a decade-and-a-half of corporate communications experience under her tool belt, which she put to good use to get her new roofing business off the ground. “I was well-versed in how to start a company,” she says, “and that branding experience paid off. I took what I had learned in the ad world, and I brought it over to construction.”

Her ability to build a brand, and to distinguish her company from others was key to getting the new business off the ground. “There aren’t a lot of well-branded construction

companies,” Ferguson explains. “Most contractors don’t even have a website. I knew that going into the industry, and my knowledge about communications and branding was a big win for me.”

When Ferguson wasn’t busy building her brand, she was in the thick of things, working shoulder-to-shoulder with her husband on the roof. “I got up on the roof, and I was really excited about it,” she says. “He taught me a lot about roofing, and that was my life for about three years.”

Soon, however, Ferguson realized that she would need to expand her business and offer more than roofing services. “Since roofing is very seasonal, every winter we’d be poor,” she says. “That meant we’d have to take the worst jobs ever, just to make ends meet. I remember one winter shovelling four feet of snow off someone’s roof and thinking to myself, ‘How did I get myself into this?’”

Sometimes, the reality of the situation was just too much for Ferguson to deal with. “There were times when I would be sitting in the car to get warmed up, and I would just start crying,” she recalls. “I thought to myself, ‘Three years ago I was in high heels and suits, and now I’m dirty and on a roof shoveling snow.’”

While that type of pressure may dissuade many, Ferguson doubled down and was determined to continue to grow and succeed. Eventually, she took over the business, ran it on her own, and she even hired a roofing crew to do the work.

That success led her down the path to expanding her business even further. “A few years in, we started getting asked a lot about landscaping,” she recalls. “So I started to teach myself about horticulture, and by that time I had also gotten into hardscaping, and that’s actually one of my favourite trades. So now, we were doing landscaping and hardscaping, and I couldn’t believe how much people were willing to spend on it. We were thriving.”

By 2016, Ferguson says her business was doing very well. She would upsell her roofing customers to buy landscaping or hardscaping, and vice versa. With her corporate communications background, she was able to market her businesses effectively, and she was becoming really well known as the go-to person for siding, roofing, landscape architecture and hardscaping needs. In 2018, Ferguson added renovations to her repertoire of available services.

After coming face-to-face with discrimination and racism, as well as the sense of loss that resulted from the passing of her step-father, and soon thereafter, her mother, Ferguson decided that she needed to refocus and to double-down on her efforts.

Prior to her passing, Ferguson’s mom told her not to be upset when she faced discrimination. Instead, her mom asked her, “Why don’t you do something about it?” Those continued on page 22

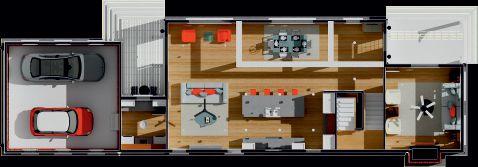

By Christopher Smith

Workingin Toronto’s East-end, I tend to see a lot of older homes with unfinished or poorly finished basements, so the need for my clients to reclaim these dungeon-like areas is usually a pressing one.

This has led to a lot of basement renos over the years and until recently, we went about them in one of two ways. The first was to renovate the basement space to serve the family residing in the home and the second was to create a secondary apartment space to generate income. I tend to lean heavily towards family-centric basement spaces for clients.

This singular approach towards basement renovations makes the most sense, as it best serves our clients’ current needs. The question is: Are we tapping into the full potential these spaces offer? What if we could give our clients a remodeled basement and the possibility of a future rental income source? The short answer is we can, and it is not that hard to do so. All it takes is a clear understanding of the requirements for an accessory apartment in an existing space and some extra space planning.

It might be time to consider creating basement spaces with rental conversion optionality built in. There is no reason that today’s single-family space can’t become tomorrow’s multi-unit housing. With a bit of extra planning and consideration, this could be an

achievable goal for all basement renovations moving forward. Of course, the possible optionality of a future basement apartment should be an easy sell but how do you do it without blowing budgets?

In today’s competitive rental market, rental space is in high demand. Based on trends in population growth forecasted over the coming years, they will be in high demand in the future too. The problem is that you need your basement space renovated today and with a growing family, you need that space for yourself.

Adopting a dual-purpose basement renovation strategy can allow you to serve your client’s current space

requirements and provide potential future rental income. Given the current housing shortage, I would argue it is time to overhaul our traditional approach towards renovating basements and view these renovations with a different lens. One that positions us, as contractors, to offer a superior product that delivers enhanced value to our clients.

How we get there is surprisingly straightforward, thanks to Part 11 of the Ontario Building Code, which outlines the compliance alternatives our basements need to meet. There are compliance alternatives that really make it easy to have your cake and eat it too.

Please make sure to check the codes and requirements for your area, as they might differ from the ones I am referring to.

For this article, I will focus on the main requirements under Part 11 for fire ratings, HVAC, exits and plumbing. Given this is a future conversion, it is important to understand that we are considering the space an existing space, which means the requirements are different than if it was new construction, which is why Part 11 and not Part 9 apply. This doesn’t get you off the hook in any major way, but it is important to note the requirements for an accessory apartment in an existing space vs. a new one are different. For quick reference, I use TACBOC details BO2a and BO2b as they provide the information graphically, which I find helpful.

“It’s time to overhaul our traditional approach towards basement renos and view them with a different lens”

Let’s start with fire separations, as a few things fall into this category. We must keep in mind that we are dealing with both fire separations and penetrations.

Using interconnected smoke alarms throughout the home and fire-rated cones in all pot light holes covers 90 per cent of what you need to worry about. You will need to add a

20-minute rating for the door opening that is shared with the rest of the home but beyond that there isn’t too much else. A 30-minute rating is required for all unit separations, which is standard half-inch drywall, something you would be doing either way with any finished basement space. I like to upgrade here just because with the older homes, I deal with 5/8 inch type X drywall, which tends to work better at flattening things out, thanks to its rigidity.

No matter what drywall you choose, how you deal with any penetrations in that surface does matter. Metal boxes for all electrical connections are a must and, in most cases, fire donuts for your plumbing penetrations could also be required. Metal boxes for lighting have never been the best option for basements but now you can stick with pot lights if you want to by installing fire cones at the time of conversion. Fireblocking needs to also be considered as your fire rated protection must be continuous. The best approach I have found to deal with this is to double up your top plates. Doing this removes the need to run strips of drywall over the partitions during framing as a double top plate meets the fire stop requirements for even a

small and medium-sized businesses can apply for support from the Canadian Apprenticeship Service. In addition to the grant, build your future workforce with:

45-minute rating.

Everything fire related that is not shown in the TACBOC details can be found under Part 11 compliance alternatives.

Given that both uses of your client’s basement spaces will need HVAC, I would recommend a forced air system, which tends to be the case for most homes anyways. The advantage it provides here is that under Part 11, the future rental space can share the existing forced air HVAC system, with the addition of a smoke detector in either the main supply or return duct. Keep in mind that your HVAC design must meet the requirements for both uses so it is important to consider the eventual layout to ensure adequate heating for all final rooms and spaces, including return air requirements for the final space.

An essential aspect to consider when planning for future rental conversions is providing kitchen, bathroom, and likely laundry facilities. These future plumbing requirements must be incorporated into the initial design. Consulting with a professional plumber can also help you navigate

the intricacies of drain and venting specifications. Ensuring that your anticipated plumbing fixtures are within a suitable distance to a vent and main stack is crucial. With some thoughtful planning, you can align future kitchens with existing bathrooms or laundry rooms or in certain scenarios, route future plumbing lines toward nearby mechanical rooms. Investing some time into addressing these potential plumbing needs upfront can make the conversion process significantly smoother in the future.

In most of my cases, a shared exit that goes through the home is all that exists and the option for a dedicated walkout is usually not in the cards. If this is the case for you as well, then you must provide an exit in the form of an egress window to meet the exit requirements. I would recommend putting it in whatever room/area of the basement that would eventually become a bedroom. This helps in two ways, as it meets the natural light requirements for the room and gives anyone sleeping a quick way out if there ever is a fire. Your main door to the rest of the house would also have to be a 20-minute rated door and depending on how high off the finished floor the egress window it is might also

need steps, but beyond that, you should be covered.

Exits are easy, given that an egress window is probably your best option as it is cost effective and meets the requirements. If you have a bedroom space already planned, then it will be required anyway. If not and you are showing an office or something like that, then I would recommend adding it to that room which should eventually become your bedroom space.

The next big area is space-planning, which also ties into exits. In my area, 90 per cent of the basements don’t have space to put in a separate dedicated exit or even a shared one so we go with door number three and install an egress window. Make sure to read the TACBOC detail carefully before placing your egress window.

In some cases, they can add to other parts of their homes and make it work, using the passive rental income to help pay for the home renovations, but this, unfortunately, is the minority of cases. Single-family homes usually tend to remain that way to maximize the usable space for the homeowners.

A basement renovation is nothing new in my part of the world; it is probably one of the top renovations clients ask for.

Basements in my area need a lot of work to bring up to par and so in most cases we are given a blank canvas to work with. Everything gets moved and replaced, foundations are underpinned, and mechanicals are re-routed. It is what the space tends to become that got me thinking over the years. In most cases, it is designed and built for extra family space because it is desperately needed with cramped quarters on all other floors. There is nothing wrong with that but over the years we have had a housing crisis like no other – rental space is very expensive and hard to find. The need for additional housing has never been greater and this trend shows no signs of changing.

The problem is that with the high

costs associated with these renovations, clients had to choose between satisfying their need for more usable space or gaining rental income. Rental options tended to win out a fair bit of the time because income is income at the end of the day, and additions could usually add much-needed space elsewhere in the home.

For years, we have treated these two options as pretty much mutually exclusive but after a careful review of some of the compliance alternatives listed in Part 11 of the Ontario Building Code, we realized this wasn’t 100 per cent accurate. With a bit of forethought and careful consideration in the planning process, we can create a family centric basement space that is easily convertible to a basement apartment space in the future.

Much like everything, the devil is in the details.

We must ask ourselves “what if we could offer something more than just a nicely finished basement” “What if we could also provide the possibility of a rental conversion in the future?” “How would we do it in a way that gives the needed flexibility for each use case?”

If possible, we could add a significant number of new rental units to

market by simply converting basement spaces, making today’s single-family home into tomorrow’s much-needed multi-unit. As it turns out it is very much possible and doesn’t require much planning to execute.

At first glance, these two cases are seemingly mutually exclusive but are not so far apart.

Whether on its own or in combination with other additions to a home, a basement renovation always gives great bang for your buck. Over the past few years, we have realized that we have been limiting ourselves to just thinking about our clients’ current needs and not paying much attention to how we can address the possible future ones, especially when it comes to the convertibility of the basement space from single family to multi-unit. What does it really take to make sure that every renovated basement space can be converted into apartment space, if and when the need becomes available?

What if we could design and build with two plans in mind? A purposebuilt space for today and a conversion opportunity for tomorrow. We have done lots of basement apartments over the years, but they are few and far between when compared to the family-oriented basement spaces we have done. Tomorrow offers something

wholly different. Studies show people tend to downsize as they get older and the needed space of today becomes the unused space of tomorrow.

I am hopeful that by applying this more strategic approach to our basement renovations, we can unlock added value in every project. Allowing us to not only create inviting family spaces but also lay the groundwork for potential incomegenerating units. By ensuring we have our bases covered, with fire ratings, HVAC, exits, plumbing, and space, we can successfully integrate future rental conversion possibilities into our current renovations.

As we continue to operate in this ever-evolving housing landscape, let’s embrace the change and rise to the challenge. Let’s rethink our traditional approach towards basement renovations, and instead, let’s design and build with the future in mind. Ultimately, our ability to deliver enhanced value through strategic basement renovations isn’t just good business sense; it’s a commitment to serving our clients better today and tomorrow. Providing an attractive prospect for many homeowners especially considering the current housing shortage, one which carries the added potential of setting you apart as a forward-thinking contractor who not only meets the needs of today but also tries to anticipate your client’s future needs. Something that in today’s competitive marketplace, could be a deciding factor. cc

Christopher Smith is the owner and founder of Woodsmith Construction Inc, a design and build renovation company that has specialized in working with older homes in the east end of Toronto since 2001. His passion for everything to do with older homes was rooted in his early childhood experiences working on Victorian homes in Cabbagetown with his architect/builder father. He is a Red Seal Carpenter and a BCIN registered designer. Woodsmith Construction has completed a wide range of projects, including full-home renovations, additions, and restorations.

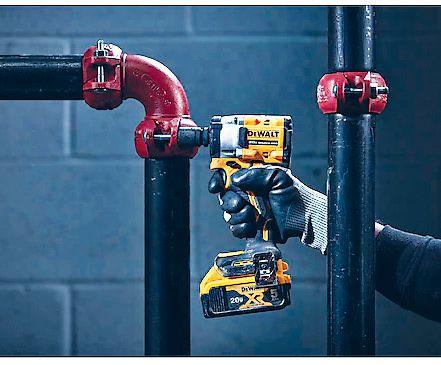

By Doug Picklyk

SFA Saniflo Canada has a story to tell.

While the brand is widely recognized for its macerating toilet solutions that enable versatile washroom placements, there is much more to discover about how the company has leveraged its pumping technology to develop an array of products catering to domestic, commercial and industrial needs. In early April, SFA Saniflo Canada welcomed a group of customers to Paris—home of its parent company SFA Group—to foster a deeper understanding of the global organization and shed light on the direction of the growing Canadian operation.

The guest represented companies ranging from sales agents and wholesale partners to mechanical contractors, all of whom had experienced significant business growth in their partnership with Saniflo over the last five years. Phil Warren, managing director of SFA Saniflo Canada, expressed his delight at finally being able to showcase the collective strength of the company’s global group to its Canadian partners who provide unwavering support on a daily basis.

The feature event was a tour of SFA Group’s manufacturing plant in Brégy (an hour northeast of Paris). The factory is a multi-building integrated pump manufacturing facility producing finished packaged products.

Upon arrival, visitors experience a working showroom featuring the breadth of the SFA Group offerings. Display areas showcase products including macerating toilets, drain pumps, condensation pumps, grease interceptors and more.

Warren, who has been with the company for a decade and has led the Canadian operation since November 2019, hosted the tour group with Regis Saragosti, CEO of SFA Saniflo North America.

From the showroom, guests enter the motor manufacturing division, an area which produces upwards of half-a-million motors per year for residential and lifting station pumps.

While people operate on the periphery, up to 85 per cent of the manufacturing is automated. A conveyor transfers raw iron stator cores into a caged station where robotic arms manipulate the iron cylinders. Insulators from rolls of mylar are punched out and positioned, and fine copper wire is drawn from spools to create the windings.

The process travels from station to station delivering a near finished product. Workers complete final connections and inspections before the final motor is charged and tested.

In the same building, a recently added clean room

manufactures circuit boards. An automated process places the small components on the board before feeding it through a specialized welding machine. The boards are manually tested and programmed before moving to final assembly.

A separate building houses a complete plastic injection molding operation. An overhead highway of tubes delivers raw pellets to the necessary molding machines where the parts are formed.

A vault of over 400 molds allow the company to reintroduce parts into production when necessary. Plastic casings, fittings and gaskets are all produced in this factory.

Final assembly of the products and testing is done by hand. The watertight casings are tested with compressed air to ensure there are no leaks.

An on-site laboratory is consistently cycling finished products to ensure durability and quality. The factory also

hosts a major warehouse for finished products. Logistics and shipping around the world begin in Brégy.

The Canadian customers on the tour were pleasantly surprised by the extensive and self-contained production of SFA in France. The company’s complete control over their processes left a lasting impression on attendees.

While the tour participants appreciated the sights of Paris, Steve McCrary (Lambert & Bégin) expressed his amazement at the SFA factory tour. Witnessing the dedication SFA puts into crafting reliable products bolstered their confidence in conveying the SFA story to distributors and contractors.

Frédéric Boucher (Plomberie EPF) was particularly impressed by the factory and assembly plant.

Phil Warren emphasized the message they convey to customers, highlighting SFA’s status as a manufacturing company rather than just an assembly company. This distinction allows SFA to stand behind their products, ensuring their performance. “SFA prioritizes manufacturing pumps as their core business, investing every dollar into developing and perfecting their pumping business.”

The SFA Group was founded in 1958 in Paris with the invention of the macerating pump, and after establishing itself across Europe, the company’s entry to North America began by setting up a Canadian office in 1988 and the USA office in 1998. The Canadian operation continues to operate independently while working very closely with SFA Saniflo USA.

“The corporation is investing a lot in North America, giving me the power and support to develop the market,” says Saragosti, who adds that the Canadian operation has been a growing and dynamic force under the current leadership of Warren.

“The growth we’ve had in Canada has been the result of hiring the right people, developing better programs in the marketplace for our partners, and creating more awareness in the industry,” says Warren. In the past year, the operation has grown in headcount; adding three business development managers, two regional sales managers and increasing its expertise in its after sales division, including projects, to cover all regions of the country.

The broad message Warren reinforces is the diversity of potential applications with the Saniflo product line.

“We’re not just a toilet company, we’re a pump company offering solutions for people with industrial, commercial and residential applications. You can add or relocate any drain and plumbing fixture anywhere you want.”

Warren has been evangelizing the applications of the SFA Saniflo product range for years, and has uncovered opportunities in the hydroponics market, restaurants, and when the pandemic struck, creativity led to applications within temporary field hospitals or any industrial or institutional sites with short-term or long-term needs.

“I didn’t realize the size and potential of the market until I had a deeper understanding of the whole line and the reach that it can and does have,” says Richardson from Centon, who has been representing Saniflo in most of Ontario since 2019.

The depth of the Saniflo product line in Canada covers residential and commercial bathroom needs through its existing line-up of macerating and grinding pumps, above floor plumbing solutions with its various drain pumps and lift stations, as well as its condensate pumps for HVAC applications. Yet opportunities for expansion still exist as the company has more products in the pipeline in Europe.

“Our ultimate goal in the next 10 years is to be able to bring as much product as we can to North America,” says Saragosti, acknowledging that it will require product development and certification for North American standards.

“It took time to create awareness of our current Saniflo product line and to remove the brand notion that we’re just a toilet company,” Warren added. “Now we’re ready to come to the market with new products and new technologies, so stay tuned.” cc

By Gordon Wornoff

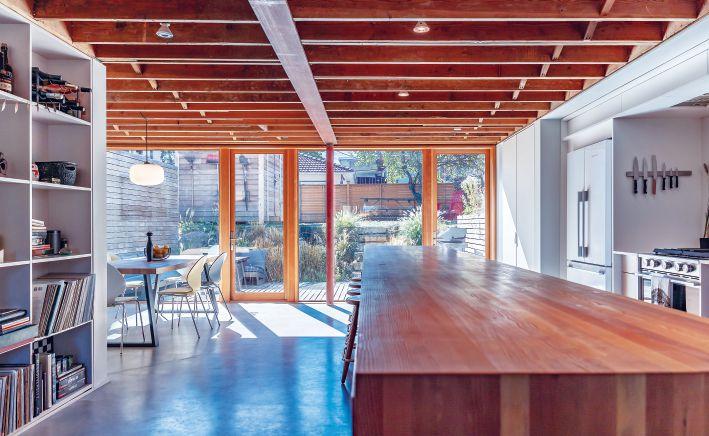

JimSmith, of Smithwood Builders, recently earned three separate National Awards for Housing Excellence at the Canadian Homebuilders’ Association Awards Gala –for Best Detached Custom Home under 2,500 square feet, Best Custom Kitchen, and Best Basement Renovation.

Smith’s award-winning basement is in a Vancouver neighbourhood of 1960s homes. Beneath the original green stucco bungalow is a basement design that makes so much sense when you see it, you wonder why the country isn’t full of these. Jim offers up the details in this feature interview.

The following is an interview between Gordon Wornoff and Jim Smith. It has been edited and condensed.

How did this project launch?

We were lucky to work with a great architect on this project, D’Arcy Jones Architects. We had done a couple projects with them in the past, and they knew we were quite capable of the modern aesthetic and refinement they were after. They introduced us to the homeowners – a family with two young kids. The family had been in the house for a while, loved the neighbourhood, and wanted to change things around to better accommodate their present needs while also planning for their future.

The architect had a great idea to move the main living area down to the basement and then put bedrooms and an office on the main floor. When these 1960s era Vancouver homes were built, the living space was usually upstairs and then you had this basement that didn’t really fit in. Maybe you put some

bedrooms down there, but the ceilings are not really high enough.

We removed an addition someone had put on the back, and we opened up the backyard and put in a recessed space with huge glass doors. The backyard has a southern exposure, so when they’re down there in the kitchen or living room area, they have so much natural light coming in through those doors.

Now each of the kids can have their own bedroom. The husband works from home, so a functional home office is integrated on the top floor. There’s flexibility for them to stay in the neighbourhood they love, and for their family to live comfortably and to grow together in that home.

What were some of the main challenges and successes on this build?

It’s a bit to wrap your head around living downstairs like that. The work required was substantial because you’re

changing a lot of the mechanicals like the plumbing and the electrical. But we had those conversations early on and it made sense from a budget standpoint to go that route.

We wanted to maximize the ceiling height in this space, so we dug down as far as we could. In Vancouver, the setbacks between this era of houses is minimal. Excavating from the outside presented too many challenges so we installed new perimeter drains on the inside to manage water. In the end we gained four inches of headroom and added a well-insulated slab with radiant heat.

Of course, we had a few point loads to transfer from a couple of steel beams to hold everything up. In the past, we’ve lifted houses on steel beams and wiped out the foundation and built fresh, but in this case the budget didn’t allow for it. So, we had to get the steel into the house and into place in pretty tight quarters.

It was another challenge to keep

enough head room in the space. The architects had done this before, where they didn’t drywall the ceiling, so you see the joists and the diagonal shiplap fir subfloor above and it feels more open. When we’re putting steel beams in there and running mechanicals and cutting this old material, we need to make sure it stays nice and appealing. This was one of the first times we worked with a company out here called Unbuilders, and their sister company, Heritage Lumber. They rescue old lumber and resell it. We bought some old lumber that matched the joists and blocking and patched in where we needed to keep that consistent 1960s look. It’s not an easy process, making something look both old and really good.

We beefed up the insulation everywhere, thickened the walls up. By no means is it a passive house, but it’s probably 56 times more insulated than a typical house from that era.

Now they have a very dry, comfortable, well-insulated space with radiant heat.

You’ve won multiple awards this year. In the Vancouver market, there is some stiff competition. Tell us about that.

We’ve won a bunch of awards this year, including three on the national level which was a huge honour. We also won a number of awards from our local Homebuilders’ Association in Vancouver (HAVAN) - including Custom Home Builder of the Year. We were also nominated for eight provincial home builder awards called Georgies. We didn’t win any of those unfortunately, but it was still pretty nice to be nominated, especially in the category for Custom Home Builder of the Year. It’s been a great year for us and I’m pretty proud of the work.

There are some amazing builders here that we know through the Home Builders’ Associations, and we see them around and chat with them. We appreciate each other’s efforts to build sustainable, high-quality projects that will last a long time. We’re lucky to be part of this community and lean on these guys for knowledge and experience and

there’s enough work that we can share ideas and cooperate to some extent.

How big is your company? How many projects a year do you complete?

Right now, we’re 22 people. That includes myself and all the carpenters, project managers, and apprentices. Typically, we have seven to eight projects on the go at one time, although we’ve recently slowed down to ensure we’re not spread too thin. We’ve found in the last few years, a lot of people are moving away from Vancouver for cost-of-living reasons. We have awesome trade partners - electricians, plumbers - and they’re experiencing the same thing. We don’t want to spread them too thin either. Moving forward, we’re looking at five or six projects a year that run really smoothly and efficiently without waiting on another trade or anything.

What are your goals for the business?

For the next ten years, we are going to focus on building high quality homes as sustainably as possible. We’d like to be doing net-zero builds, LEED certification, passive house, taking advantage of all these certifications and associations so that we’re building homes as healthy and as clean as possible. We want to build a house that will stand up for 100 years and its high quality and high performance. We want our homes to stay out of the landfill. Even if the client

doesn’t want solar panels or geothermal, we can still ensure sustainable materials go in the wall assemblies, windows, and we use correct installation practices.

My wife and I had the chance to build our house about seven years ago. We were able to incorporate a lot of highperformance components. We’ve lived through it and seen where maybe some extra costs upfront can pay off later, when your bills are low in the dead of winter and your house is still quite warm.

We want to keep thriving with our trade partners as well. I want to stress that it’s not just Smithwood. We consider our trade partners an extension of our team. We try to work with the same guys, the same crew on as many projects as we can because they know what to expect from us and vice versa. And so, it’s everyone working together to create a top-notch project. We’ll have plumbers, drywallers, and electricians giving us a heads up about a small deficiency somewhere or something that could go unnoticed because we’re all pulling in the same direction. I always tell prospective clients it’s not as easy as ‘get three quotes and pick the lowest one.’ Sometimes you’ll pay a little bit more for a sub trade, but if you look deep down at the cost-effectiveness of having a strong, unified team, the value is exponential sometimes. We all want to keep working on these kinds of projects, so we’re all invested in doing a good job.

We have a new hire who joined us from the UK this year. He knew one of our guys and wanted to come and join the crew. Of course, I Zoomed with him a couple times before he came to help get him set up. Once he got to Vancouver, I mean, it’s a big city and it’s difficult to find housing. But he was chatting with an electrician on our site - another young guy – and they were looking for a roommate. And next thing you know, one of our guys is living with a bunch of guys and one is an electrician we use quite often. The guys are all trying to help each other out as much as possible.

It’s a cooperative effort to build these dream houses for clients, and our main strength is our team who reinforce our common goals. cc

LANDMARK CLIMATE FLEX certainteed.com

Landmark ClimateFlex is a polymer-modified asphalt shingle by CertainTeed. The shingle offers a Class 4 rating for protection against hail damage and is available in classic shades and natural wood or slate including six colorways: Burnt Sienna, Heather Blend, Moire Black, Resawn Shake, Colonial Slate, and Weathered Wood. Landmark ClimateFlex is available in Ontario, Manitoba, Alberta, and Saskatchewan.

RYOBI™ 18V ONE+™ ryobitools.ca

Part of the WHISPER SERIES™, this new air cannon is designed to be 55 per cent quieter and has 35 per cent greater air velocity than the previous model. At a maximum of 53 dB, this fan is quiet enough to be used indoors and outdoors without distraction. With up to 2,300 CFM, airflow is delivered through three-settings and a 225-degree pivoting head. This fan provides the cordless convenience of 18V ONE+™ compatibility - working with any RYOBI™ 18V ONE+™ lithium battery. It can also be powered by a standard outlet with the included power adaptor.

SUNTOUCH INTRODUCES WIFI THERMOSTAT suntouch.com

SunTouch, a Watts brand, introduces the latest addition to its Smart & Connected thermostat line, the SunStat CommandPlus thermostat, a glass front and touch screen unit which connects to a home’s Wi-Fi system and allows customers to remotely access and control their floor warming system using the Watts Home app. The thermostat features automatic clock settings and warm weather compensation and shut down.

M18 FUEL 1/2” HAMMER DRILL/ DRILL DRIVER WITH ONE-KEY milwaukeetool.ca

The M18 FUEL ½” Hammer Drill/ Drill Driver with ONE-KEY™ was designed to deliver 30 per cent more power. At 6.9 inches in length, Milwaukee’s new hammer drill also features adjustable AutoStop technology to deliver bind-up protection. Designed to prevent over-rotation in application, this new machine learning technology offers adjustable low, medium, and high sensitivities, offering users the capability to create customizable RPM settings via the app. The hammer is also equipped with ONE-KEY technology, allowing users to sync the tool wirelessly with their mobile device or desktop via the free ONE-KEY app. Users can upload data and history to create custom reports, identify where and when the tool was last seen, and track the utilization and service intervals of the tool to maximize uptime and maintain inventory.

MCI PEEL-OFF COATING FOR CORROSION AND ABRASION PROTECTION cortecmci.com

MCI Peel-Off Coating is an acrylic water-based coating for temporary protection of non-porous surfaces against physical abrasion, weathering, and corrosion. It is low VOC (0.2 lbs/ gal [24 g/L]) and may be applied by spray, roll, or dip. When no longer needed, the coating can be peeled off the surface and disposed as solid waste. MCI Peel-Off Coating can be tinted to several basic colors to blend in with or stand out from the surrounding environment. It offers UV resistance for outdoor applications, in addition to temporary protection from salt and chemical induced corrosion. Although water-based, MCI Peel-Off Coating will not be softened or penetrated by most solvent-based paints.

The ATOMIC 20V MAX* 1/2 inch

Cordless Impact Wrench was designed easily to handle various fastening projects. It offers up to 300 ft-lbs of max fastening torque and 450 ft-lbs of max breakaway torque. Choose between four-speed settings including Precision Wrench™ control feature and Timber Screw™. This Cordless Impact Wrench comes with an LED work light for visibility in dimly lit spaces.

CSA ARVADA WORK SNEAKER keenfootwear.ca

KEEN Utility’s CSA Arvada is designed for jobs requiring constant movement and long hours. The athletic shoe design features compression-resisting KEEN.ReGEN midsole is designed to return 50 per cent more energy than standard EVA foam. They feature breathable mesh uppers, an asymmetrical carbonfibre safety toes and an EH-rated oil-and-slip resistant outsole. The CSA Arvada are available in both men and women sizing.

The GHS 25 ear protection have an ANSIrated noise reduction rating of 25 dB and was designed to allow users to hear ambient noise with a listening volume up to 79 dB. They can be combined with Bluetooth technology, and features a microphone, simple touch controls and have a battery life of up to 13 hours.

saniflo.ca

Saniswift Pro® is a compact drain pump designed for residential and commercial applications. Pre-assembled system with two-inch low inlets with built-in check valves. Featuring a heavy-duty chemical-resistant enclosure, it also incorporates a water detection system (air pressure switch). Capable of discharging gray water from a kitchen sink, shower, dishwasher or washing machine up to 14 ft vertically or up to 140 ft horizontally to the sewer line.

continued from page 11

inspiring words rang true in Ferguson’s ears, and in 2020 she rebranded her company, naming it after her mother and daughter. Ferguson was also inspired to start a non-profit organization, A Woman’s Work. “It’s the first all-women’s trade school in Canada,” she says. “We launched it last year, and we had 300 women enroll.”

Today, Ferguson is on a roll, going from success to success. “We have over 15 different partnerships with Ellis Don, Local 27, the PDSB [Peel District School Board], Milwaukee Tools,” she adds, “It’s been crazy. We have a training centre running right now in East York, and we are slated to open six more training centres across the GTA [Greater Toronto Area].”

She also has a show in the works, and she has filmed a TV commercial for a well-known retailer. “I have been given the opportunity, and built a platform, where I advise the government. I’ve literally become the face of women in the trades, and I’m advocating for women in the trades,” she adds.

The bigger picture Ferguson sees the bigger picture and believes that she may be able to offer a solution to some of the challenges facing

the construction industry and the trades in general.

“With all the workers retiring, who is going to fix your toilets or repair your roof?” she asks. “One of the reasons why there are so few people getting into the trades is because we’re not utilizing women and we’re not utilizing the underserved racialized communities. Discrimination runs deep, from local unions to employers, and I can speak to this because I’ve experienced it.”

Her efforts to teach and empower women are key to helping women pursue opportunities in this industry. “We’re teaching women that not only can they be a part of this industry, but they can be entrepreneurs in it,” Ferguson said. “If I told you that I could teach you how to drywall in eight weeks, and that you can go out, patch a few holes, and make $1,200 for the week, that’s empowering.”

The response, thus far, has been impressive. “We put together the classes, we ran our pilot program in November, and it was absolutely amazing,” Ferguson says. “I was featured on Global News, a lot of women came out, I had a pregnant woman there, as well as two women who drove from Montreal to take the course. And believe it or not, I have bootstrapped this entire thing and am funding it myself right now.”

Not only is Ferguson teaching women about the trades, but she is walking the walk by employing women in her own construction firm. “Sixty per cent of my staff are female,” she says.

She has big plans for the future and hopes to expand her training program to other provinces, as well as into the United States. Moreover, Ferguson believes that we need to rebrand the trades, starting in elementary school.

“We have this idea in our heads that trades people are stupid,” she explains. “You should be in the corporate world, but if you’re dumb, oh, you need to get yourself a trade. But I’ve been in both industries, both corporate, and here, and I can tell you that you need a lot more smarts to do this, because you are problem solving, you’re dealing with clients, and you’re also doing physical work.”

Parents also need to be taught the truth about the trades. “That’s why we’re launching a program for kids,” Ferguson adds. “We’re very excited about it because we want to change the way parents think about blue collar versus white collar. There’s a lot of work to do here, and it’s not going to happen overnight, but one person doing something is better than no people doing anything at all.”

Unlike Ferguson, who was exposed to the wonders of the trades at a very young age, most children today aren’t, and most are taught that the trades are only for those who can’t pursue a corporate job. Moreover, the trades are seldom an option for women. Ferguson is hoping to change all that, and if her ability to persist in the face of adversity is any indication, she is likely to succeed in her endeavours. cc

Set yourself up for long-term success by looking at DE&I as an opportunity instead of an obligation.

By Anna Somogyi, Diversity, Equity & Inclusion advisor, Cooper Equipment Rentals

It’s easy to talk about the importance of diversity, equity, and inclusion (DE&I) in the construction industry. But the reality is many female workers still earn less than their male counterparts; transgender employees still have to choose between male and female bathrooms; job descriptions continue to cater to malefocused abilities; and the “suck it up, Sally” mentality from management still exists.

If you’re at a large company, you may have started tackling DE&I – developing a strategy or hiring a DE&I manager as a first step. But are you really driving change in your company? For smaller contractors who don’t have access to these types of resources, thinking about DE&I can be even harder, just one more thing to add to your to-do list.

But those hiring challenges you’ve experienced in the last few years are only going to get worse. A more diverse workforce means you can focus on innovation rather than stagnation, tapping a wider pool of talent to address future skills/labour shortages while keeping the employees you have. When job seekers consider a company, the ultimate question they ask is, “do I fit in there?” It’s hard to answer “yes” to this question when they don’t see anyone like themselves on your team.

Addressing these issues is a big commitment, but it can pave the way for a better future for your company. If you find yourself on the DE&I path but you’re unsure which direction to take, you’re not alone. We went from a company of 50 employees a decade ago to now more than 1,000 and our diversity messaging looks a lot different today. Here are a few ways you can start to move the needle in your own company.

The first step is talking to your people Offering employees a few DE&I training courses just isn’t enough anymore. You need to develop, educate, and train your talent in a cycle that encourages growth, change and

commitment. The first step is talking to your people. Ask them what they feel. Do employees, especially those who identify with minority communities, feel safe with their leaders and teammates? Can they go to work and feel comfortable and free to be themselves? Having a place to work that nurtures respect, inclusivity and openness is the best thing you can do to ensure the wellbeing and mental health of your employees. This psychological safety is especially crucial in male-dominated industries like construction.

Come to understand different perspectives and solutions and ensure your employees understand their wellbeing is important. Continued training in all areas of the company is key to success. Pre-boarding, on-boarding and ongoing employee education all matter. And as your company grows and changes, you may need to revisit these efforts. In the early days of your journey, you can also start to look at your relationships with customers, your community and education institutions.

Be accountable and take actionable steps for change

It’s easy to find examples of how big companies are changing their hiring strategies and putting more effort towards bringing in diverse talent. While these stories are great to hear, they usually don’t involve tactics that small businesses can use – most simply don’t have the resources, consultants, budget, and staff that the big guys have.

Starting with one or two initiatives that promote diversity and awareness is the best approach; implementing too many programs at once can be overwhelming. It could be as simple as reviewing your interviewing processes and removing biases from job descriptions. Remember to look at your social media accounts too and ensure you promote an inclusive environment in your posts.

Having appropriate bathrooms and change areas can be another focus. Many women have horror stories about the

state of bathrooms on construction jobsites. Ontario recently proposed amending rules about bathrooms on construction sites to make them cleaner, safer and to be provided for women. We would go a step further and encourage workplaces to consider gender neutral bathrooms and change rooms for those who identify as transgender or non-binary.

Make sure leadership is on board

If you’re really serious about DE&I, it must be backed by leadership. Do the values of your company, driven by your CEO, reflect what you’re showing the world? If your CEO isn’t practicing what they preach, you’ll never reach your goals. True change can take both time and a financial commitment. If your leadership wants to take DE&I initiatives to the next level, the parity certification from Women in Governance at your organization’s position on the gender parity spectrum, your current culture and commitments, and the actions that can yield the best results.

It’s important your employees understand what you stand for, what you expect from them, and why you are going down this path. There are countless ways diversity can benefit your company, but being specific can help keep workers engaged and minimize scepticism. Most importantly, ensure your guidelines are clear and that only employees who follow them

can be part of the team.

You’ll never get your entire organization to take part in, or even believe in, what you’re trying to achieve. Companies that “force” DE&I on their people often fail, because they’re telling people what to do without the context or tools. If you’re following your guidelines, you will have some hard lines on what’s unacceptable. For those who are simply unsure about some aspect of your policy, it’s important you approach them out of curiosity rather than judgement. Try tailoring your approach, showing transparency about why a specific program or initiative is happening. To handle attempts of denial or derailment, consider the different perspectives workers may have, anticipate the threats they may perceive because of your initiatives and address these proactively.

Remember: Opportunities don’t grow from a culture of “sameness”

Take a look at your employee base and see whether it reflects the communities you serve, or wish to serve, as a business. If it doesn’t, it’s time to ask yourself why. Remember, diversity is not just about gender or race – it’s about different ideas and opinions from backgrounds and life experiences that don’t look like yours. These perspectives matter and can often benefit you as a business. cc

Parker is in the middle of a significant basement renovation for his client, Rosemary. She has recently been re-inspired with a new vision and wants to pivot the design and general remodel. This pivot will incur significant additional costs and labour that were not originally allotted for in the timeline or budget. Rosemary is willing to increase the budget marginally and give Parker more time to complete the project based on her new vision.

The pivot includes techniques and elements that Parker’s company does not specialize in. Bringing in additional trade partners would require additional permits – which would jeopardize his timeline for upcoming projects. What should he do?

Henry brought on Jess, who was ambitious and outgoing when she was first hired. Recently, she has started being late for work and become quiet and reserved. Henry speaks with Jess about her change in behaviour and Jess explains she has been feeling underestimated and isolated by the “boys club” of the family business, so has not felt comfortable coming and being at work. What should Henry do?

If Henry only hired Jess in order to get the wage subsidy and to fill his staff needs to expand his capacity to handle more and bigger projects, he may take a second look at his business model. His business success may be gauged in how well his employees enjoy participating in his company, a different bottom line. A new employee can have a hard time breaking into a tight family business, may not understand the unwritten forms of communication and how to learn the ropes. Family businesses have entrenched ways of doing things and conversing with each other as most male dominated work cultures do. And if this family itself is male dominated, it may be a toxic work environment. But the issues may not even be gender based. Henry should not assume this. Only Jess can tell him. Henry needs to find out more from Jess if she is willing to share with him. What can she identify to him about her skill set that she feels could be valued more? What changes can he make to the allocation of job tasks to her or her colleagues that would bring out her strengths? After he has listened to her, he may tell her what he has recognized as her strengths. He needs to affirm her. Henry is the leader of the company and would do well to set an example for the other employees by affirming her. He could hire more women so Jess is not so alone in this male environment and the staff could be benefited by other perspectives, ways of communication and doing things. Only after he has affirmed her will he gain her respect to enable her to hear him explain whatever the consequences are to the business when she is late or has longer breaks. This may be an opportunity for Henry to expand the type of business and reputation his business has. It is easy to see that construction is about lumber, tools, design, and profit. But construction business can be first about people: relationships with suppliers, clients, staff and trades. These are the things at the end of the day to be most proud of.

If Henry is only interested in growing and advancing the status quo, his best choice may be to admit to Jess that his business is not a good fit for her. And the loss may be his as she will find another situation that she will thrive in.

1. Work with Rosemary to rework what’s been done using the extra budget.

2. Communicate with Rosemary that it is not possible to rework the plan, finish the basement as per the original plan.

3. Give up the contract, encourage Rosemary to find a team who can accomplish what she is asking.

4. Something else?

If you have a solution to dilemma, email your entry to ksecord@annexbusinessmedia.com and put “Reno redo dilemma” in the subject line. Include your email information in your response. Please don’t post your response in the comments section on our website.

Entries close September 18, 2023. The winner will be announced in our October issue.