Building Concern

The opioid crisis Pg. 14

Creative Eye A backyard retreat Pg. 20

Outdoor Living

The 50-year deck Pg. 24

Building Concern

The opioid crisis Pg. 14

Creative Eye A backyard retreat Pg. 20

Outdoor Living

The 50-year deck Pg. 24

Alta Home Garages & More parks it perfectly Page 10

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the digital edition archives at canadiancontractor.ca.

Revisions to the National Building Code are in the works that will mandate targets for energy efficiency in home renovations, not just new builds. Frank Lohmann, director of building science for the Canadian Homebuilders Association, is at the code development table and gives Hammer listeners a sneak peek at what might be coming.

Use constructionjobsite.ca to browse thousands of construction job openings across Canada. If you’re hiring, reach the right people with a post on the job board that is dedicated to our industry.

Oooo...pretty pictures. Follow canadiancontractor on Instagram for photos we don’t have room for in the magazine. Plus links to other stuff we like.

ISSN 1498-8941

Editor Patrick Flannery pflannery@annexbusinessmedia.com

Associate Editor Daniel Reale-Chin dreale-chin@annexbusinessmedia.com

Brand Sales Manager Nav Matharu (226) 931-5095 nmatharu@annexbusinessmedia.com

Account Coordinator Barb Comer bcomer@annexbusinessmedia.com

Audience Development Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com

Media Designer Graham Jeffrey

Group Publisher Danielle Labrie (226) 931-0375 dlabrie@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

By Patrick Flannery Editor

”

” Technology is great when everything is working properly.

I’m writing this in the middle of the Great Rogers Outage of July 8. No Wi-Fi, no cell service and basic cable TV only. It’s unclear to me how such a broad failure across different systems can occur, but then again I’m no telecommunications engineer. I hope this isn’t some kind of Russian cyberattack. I suppose the causes will be made clear in time.

People are out talking to each other on my street. Feels a bit like the early days of COVID. The Tim Hortons Wi-Fi connects but you can’t do anything online, probably because their system is overwhelmed. I can do some things (like write this) offline but, were this situation to persist, I’d be unable to really do my job at all without some major adjustments to how and where I work.

As if it wasn’t clear before, our economy is now almost as dependant on internet access as it is on any other basic service like electricity, roads and fuel delivery. Data is the most valuable commodity in the world if you think about the market price less the cost of acquisition. We fight wars, write laws and contort public policy in order to protect oil supply. Maybe it’s time we take steps to guarantee reliable internet access to everyone and at least provide some kind of backstop when private companies fail? Providing broadband to remote areas would seem to be an important step in this direction.

More broadly, both this experience and the COVID-related supply chain shortages we are all facing have underlined a principle of business that I think has been neglected for at least the last 25 years: contingency planning. Corporations used to be very concerned with insulating themselves against any threats to their ability to deliver their products. Legal, financial, infrastructure, supply chain, personnel, governance, succession – companies would spend significant organizational capital ensuring some level of redundancy or alternatives in all these systems to minimize their exposure to risk. The great waste-cutting initiatives of the late ‘80s and ‘90s (think justin-time manufacturing) eroded these efforts. Then, when they seemed to be broadly successful, reduced them to an afterthought in many companies.

It’s hard now for many of us to think how we’d manage without smart phones on the job site. Firing off a text to tell the client when you’re arriving or asking a co-worker to pick something up from the store is so much faster and better even than a call. Sending and receiving photos...what a godsend when your client needs to describe damage or show you what their present set-up looks like. Plus, the screen light is very useful. It’s not that we can’t work without these things, but when was the last time you had a discussion with your team about what you’d do if they weren’t available?

Like my work-from-home situation, jobsite technology is great when everything is working properly. But if there’s one thing we’ve learned over the past three years, things don’t always work properly. Like insurance, contingency planning is something that costs you a little but seems to to deliver no benefit most of the time. Until it spares you huge costs when the black swan lands on your doorstep.

Side note: As I left to go try the Wi-Fi at Tim Hortons this morning, I left my sleeping teenage daughter a note telling her where I was going and why. I ended with, “Books still work. Read something LOL.” One thing that won’t become unavailable in an internet outage – or even a power outage – is your print issue of this magazine. Call it your contingency for critical industry information in the event of a total war on our information space. LOL...kind of. cc

Inspectors at Ontario’s Technical Standards and Safety Authority went on strike on July 21. The TSSA conducts mandatory safety inspections for most powered mechanical installations in construction and industrial settings.

A statement from OPSEU/SEFPO states that almost 200 safety inspectors with OPSEU/SEFPO Local 546 at the TSSA voted 89 percent in favour of giving their bargaining team a strike mandate. Members are negotiating their first contract after joining OPSEU/SEFPO last year. the union says a lack of co-operation and movement from the TSSA led the bargaining team to seek a strike mandate from members. Among their many responsibilities, Local 546 members inspect elevators, ski lifts, food trucks and amusement park rides. They inspect fuel burning equipment, boilers and pressure vessels, and inspect gas stations, propane dispensing stations and nuclear power plants.

“The employer has demonstrated a consistent unwillingness to bargain and total disrespect for the process,” said OPSEU/SEFPO president, J.P. Hornick.

The TSSA also posted a statement saying that it hopes to reach an agreement, will continue to respond to serious safety incidents and inspect high-risk sites and that it will make an effort to minimize business disruptions. The TSSA also says that owners of devices, sites and businesses regulated under the Technical Standards and Safety Act remain responsible for maintaining and operating devices safely and for immediately reporting incidents. According

Ottawa launched the first phase of its plan to offer interest-free loans to Canadians planning upgrades that will have a significant impact in reducing their homes’ environmental footprint. The program will provide interest-free loans of up to $40,000 per household to help finance eligible retrofits. Applications for the loan opened to eligible Canadians on June 17. According to Natural Resources Canada, eligible applicants include homeowners who are applying to the Canada Greener Homes Grant (which launched on May 27, 2021) and active applicants at the pre-retrofit EnerGuide evaluation stage with the Canada Greener Homes Grant. On Aug. 31, NRCan will open applications to other homeowners who already received a grant or requested a retrofit EnerGuide evaluation under the grant and want to apply for remaining retrofits that have not been started. Canadian homeowners with proof that the home is their primary residence can apply for the loan. Homeowners will have to receive a pre- and post-retrofit EnerGuide evaluation to measure the energy efficiency of their home. cc

to the TSSA, all of its non-inspection services such as engineering, examinations and licensing will remain available during the strike.

“In order to prevent a strike, the TSSA bargaining team provided OPSEU a full proposal which includes all terms for a first collective agreement and offers inspectors excellent health, dental and pension benefits, and salary increases for a multi-year agreement,” said Laura Desjardins, vice-president of human resources. “Unfortunately, the union stopped negotiating directly with TSSA after the first few meetings and gave indications of their strike intentions. We are concerned with OPSEU’s deliberately false communications that suggest we are not bargaining in good faith.” cc

Daniel Reale-Chin has joined the Canadian Contractor team as associate editor. In the role, he will assist editor, Patrick Flannery, with all aspects of content production for Canadian Contractor’s print, online and social channels. Reale-Chin brings a background in the financial press to the role, having prepared reports for Investment Executive and editing articles for Investor’s Digest. He’s a graduate of the University of Toronto’s professional writing program and lives in Toronto.

“Daniel is a valuable addition to the team and is bringing lots of enthusiasm and can-do spirit to the role already,” said Flannery. “He’s got his first article already under his belt and his writing skills are outstanding. I think we’re all going to enjoy the stories and insights he brings us as he gets to know this exciting industry.”

“My dad works in drywall, my uncles were mechanics and I come from a family of contractors. I’m excited to learn about some of the projects our readers have helped make happen and maybe pass down some knowledge at the next family dinner,” said Reale-Chin. cc

The Canadian Construction Association partnered with the Canadian Apprenticeship Forum on a federal government initiative for apprenticeship training. The initiative will enable small and medium-sized employers to offer more apprenticeship training opportunities. Minister of Employment, Workforce Development and Disability Inclusion, Carla Qualtrough, announced the $247 million investment for apprenticeship development at the CAF’s National Apprenticeship Conference in Halifax on May 30. CAF received $45 million of that funding to administer grants to employers across the country who

hire new first-year apprentices in 39 Red Seal trades. The program officially launches in September. The financial incentive will give small and medium-sized employers $5,000 per apprentice per year for a maximum of two apprentices per employer. The funding only applies to new apprentices and the amount is doubled if the apprentice identifies as being from an underrepresented group. The CCA announced that it would be promoting the program to its members and construction employers across Canada. Part of the CCA’s announcement follows:

The need to build workforce

capacity has been a central focus for CCA and our members. Skilled tradespeople cannot be created overnight. The construction industry needs to recruit 309,000 new workers over the next decade, while 75,000 new apprentices need to be hired per year in the next five years to meet the demand for Red Seal trades. This program will provide support to employers wanting to hire apprentices and promote the skilled trades as a first-choice career for youth, women, Indigenous peoples, LGBTQ, immigrants and foreign workers.

Information on the program is available at talentfitshere.ca. cc

Small business confidence fell for the fourth month in a row, according to the latest Canadian Federation of Independent Business Business Barometer. The three-month index fell nearly eight points to 46.7, while the 12-month index fell nearly seven points to 52.7 in July.

“Businesses are really feeling the pressure of inflation right now, with both price and wage increase plans at all-time highs and growing concern over labour shortages and input costs, particularly fuel and energy,” said Simon Gaudreault, chief economist and vice-president of research at CFIB.

“Worse still, they don’t feel heard – only 16 percent believe the federal government understands the cost pressures they face, according to a recent CFIB survey. It’s no wonder they are feeling anxious about the future.”

Only 32 percent of businesses say they are in good shape, while 20 percent say they are in bad shape. Full-time hiring plans continue to narrow, with 20 percent of firms looking to hire over the next three months and 17 percent looking to lay

off staff. Average price increase plans (4.7 percent) and wage increase plans (3.4 percent) are still coasting at historically high levels. The major limitation on business growth is by far labour shortages (52 percent for shortages of skilled workers and 39 percent for semi- or unskilled workers). Fuel and energy costs have maintained their spot as the top cost constraint currently affecting the majority of small firms (76 percent). All provinces and nearly all sectors experienced short-term drops in optimism this month, but businesses in Ontario (44.7) and Newfoundland and Labrador (45.7), and those in agriculture (37.7) and retail (38.7) were the least optimistic. While hospitality businesses (59.1) posted the highest sectoral confidence level, they experienced a ninepoint drop over last month.

“These indicators should serve as a serious warning to governments that businesses are struggling,” added Andreea Bourgeois, director of economics at CFIB. “They should be factoring this into their economic and policy decisions.” cc

Concrete workers in the lower mainland of B.C., returned to work on June 24, after a five-week-long strike that began on May 20. Nearly 300 employees from Rempel Bros. Concrete, Ocean Concrete and Allied Ready Mix were represented by Teamsters Local 213 and the International Union of Operating Engineers Local 115. IUOE reported that its representatives and Rempel Bros. Concrete negotiators struck a tentative deal on June 23 that included a 15-percent wage increase over four years. The workers on strike included concrete plant operators, concrete mixer truck drivers and other staff. Bargaining between the two sides started on Jan. 7 and Jacquie De Aguayo, former chair of the Labour Relations Board, mediated recent talks to reach the agreement. cc

On July 25, the government of Canada announced an investment of over $2 million to three organizations that are advancing energy efficiency in buildings in Ontario. The projects include:

• Over $1.3 million to Fanshawe College of Applied Arts and Technology, in London, to retrofit the Kestrel Court Student Residence, a 25-year-old complex, into a net zero-energy facility. Fanshawe College also contributed $1.25 million, bringing the combined project cost to more than $2.5 million.

• $365,000 to Indwell, in Woodstock, to support the construction of Blossom Park Apartments, a new, 34-unit, high-performing multiunit residential building using the BuildSmart prefabricated envelope technology to help inform local and national net-zero energy codes. The

Canada Green Building Council, Canada Mortgage and Housing Corporation, Oxford County and Passive House Canada also funded the project, bringing the total cost to more than $7.3 million.

• $350,000 to Enwave Energy Corporation, in Markham, to support the development of the Enwave Geothermal Community Energy System, which will supply low-carbon geothermal heating and cooling to 300 residential homes. The project also received financial support from City of Markham, Mattamy Homes and The Atmospheric Fund for a total project cost of $818,367.

Federal funding is being provided through Natural Resources Canada’s Green Infrastructure – Energy Efficient Buildings Program. This program supports improvements to the design, renovation and construction of homes

and buildings. The government is advancing the development and implementation of building codes for existing buildings and new net-zero-energy-ready buildings through research, development and demonstration projects in London and across the nation. The government of Canada is also developing a Green Buildings Strategy, which they say will create local jobs and help Canada move toward a resilient, net-zero emissions buildings sector by 2050. The strategy will be focused on increasing the rate of building retrofits, ensuring buildings are resilient and net-zero ready from the start and supporting systems change for the buildings sector of the future. Further engagement on the strategy with partners such as provinces and territories, Indigenous governments and municipalities will take place before it is finalized in 2023. cc

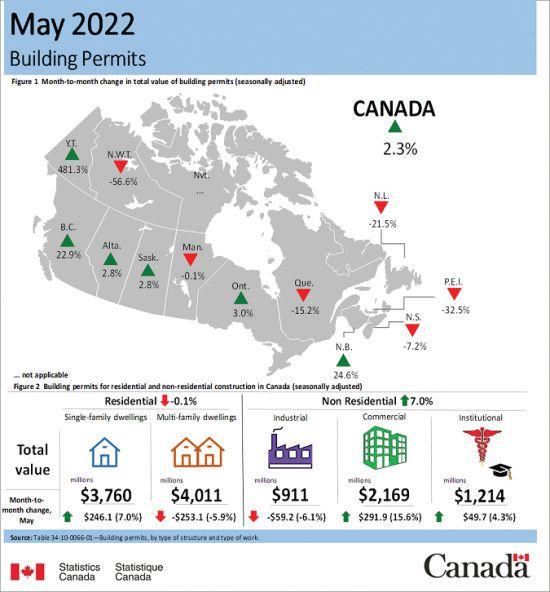

Statistics Canada reported that the total value of building permits in Canada rose 2.3 percent in May to $12.1 billion. The non-residential sector increased seven percent to $4.3 billion, while the residential sector edged down 0.1 percent to $7.8 billion. On a constant dollar basis, the total value of building permits increased 1.8 percent to $7.7 billion. Residential permits edged down 0.1 percent to $7.8 billion in May. Increases in Ontario and British Columbia were offset by losses in seven other provinces. Construction intentions in the multi-family component decreased 5.9 percent, with Quebec returning to more normal levels. British Columbia saw a 10.1-percent increase, which is partly due to a $112 million permit for a condo building in Surrey. Single-family homes have continued their comeback since the COVID-19 pandemic downturn and longer-term secular decline, increasing seven percent in total value nationally. Overall, the number of new units created decreased 3.4 percent compared with April. The decline in the multi-family component (down by 6.4 percent) was partially offset by the increase in the single-family home component (up by 5.4 percent). cc

Building custom garages keeps Alta Home Garages & More dancing.

By Jack Kazmierski

Unlike some contractors who tackle a wide variety of projects, Alberta-based Alta Home Garages & More has a more niche-based approach to business. As their name implies, ever since the company was founded in 2017, they have focused their efforts on building truly exceptional garages.

Stan Berezovsky, managing director of Alta Home Garages & More says that although he and his two

partners, Wes Ogari (the broom air-guitarist above) and Ross Podgurskyi, are willing and able to do custom home builds and renovations, their bread and butter is garages.

“Building custom garages is our number one product,” Berezovsky says, “and there’s a big market in Alberta since most homes are lane homes, which means they don’t have a garage.”

While some of his customers need nothing more than a practical and functional garage with enough room to store a car or two, others want to take the idea of a garage

beyond the ordinary.

“You can’t really call them garages, at a certain point,” he admits. “They’re not just for parking a car. Sometimes they’re used to store a car collection. Sometimes they’re a man-cave or a gaming room. Other times they include a shop where the customer can work on his hobbies. A lot of times they will use them as a place to work on their cars, so we set them up with a high ceiling and a car lift.”

The end product can be truly outstanding, complete with a heating system, specialized lighting, as well as a sound system. “All kinds of fancy and fun stuff,” Berezovsky adds. “We even built a garage specifically for a bus-sized RV.”

Each of the custom garages Berezovsky and his team of 30 employees build have some sort of unique feature, he explains. Most of the time his staff can handle all the requirements of the job, but sometimes outside help is needed for certain specialities.

“We do most of the work ourselves,” Berezovsky adds. “We have a full-time electrician on staff, we have a fulltime concrete crew and excavation crew. On some of the more complex projects we consult with an engineer who can tell us the best way to handle something.”

Building cozy garages in a climate as harsh as Alberta can be a challenge. “We need to consider how the humidity levels are constantly changing,” Berezovsky explains. “The temperatures are also constantly and sharply changing, and that contributes to a lot of movement in the ground and in the materials.”

He adds that he has developed techniques that allow him to cope with the temperature and humidity extremes. “For example, we use a 10-millimeter vapour barrier membrane in between the sub-grade of the slab and the rebar where the concrete is going to be poured, so that moisture can’t get through and the slab stays dry. This certainly prolongs the integrity of the slab.”

Going the extra mile allows Berezovsky to offer a solid warranty. “No other company does this because it’s an extra step,” he says. “It takes effort and money to buy those materials, but it’s just one example of how we do things differently. We are the only company that is offering a lifetime warranty on our builds.”

While garages/man-caves are their specialty, the “& More” part of Alta Home Garages & More includes another niche product: basements. Most contractors do basements, but Berezovsky and his team specialize in legal basement suites.

“Not many companies can tell you that they can build you a legal suite,” Berezovsky says, “and there are many reasons why. It’s a lengthy and complex process with the municipality and, usually, even the companies that do legal suites will tell the customer to hire a consultant to help them with their permits. But we do all that work for them. We know the rules and we take care of all the

complex issues so that the client doesn’t have to worry about anything.”

Berezovsky adds that his quotes are specific and completely transparent so that the customer knows what he is paying for. “We provide a detailed quote,” he explains. “A lot of companies will tell the customer that it’s going to cost $50,000 to finish their basement, for example, but the customer doesn’t really know what that price includes. So we break it down, item by item. The customer always knows what to expect.”

An itemized quote is a must, according to Berezovsky, because there may be a big difference when quoting a regular basement renovation versus a legal basementsuite build.

“If you just told them that a regular basement is $30,000, but a basement suite is $60,000, they’ll be shocked and wonder why it’s twice the price,” Berezovsky says. “A detailed quote will help them see where the rest of the money comes into play: they’re going to need a separate HVAC system, a separate kitchen, a sealed mechanical room and so on.”

Berezovsky’s sales team takes the time to explain all the details so that the customer knows what’s needed in order to legally rent out their basement to a tenant without worrying about legal implications or other problems down the road.

22_001597_CN_Contractor_AUG_CN Mod: July 19, 2022 10:14 AM Print: 07/28/22 4:48:05 PM page 1 v7

“Contractors who don’t have experience building legal basement suites will often do the work, and then, when the project doesn’t pass inspection, the customer has to pay for the work to be done again to code,” Berezovsky adds.

Keeping up with demand

Berezovsky has tapped into a lucrative niche in Calgary. He says the demand for legal basement suites is huge, and that his company sometimes has trouble keeping up with requests.

“The government is not simply enforcing laws that require a basement to be legal for a tenant,” he explains, “but they’re also offering incentives to homeowners by

waiving permit fees, for example. So they want you to legalize your basement suite because they understand how important it is because of safety concerns, first and foremost. Homeowners are also conscientious, and actually want their basement rentals to be legal.”

Building dream garages and basement suites is not a race to the bottom for Berezovsky and his partners. In other words, they don’t compete on price. “Not only are our prices not the cheapest out there,” he explains, “but we let the customer know ahead of time that we will not be their cheapest option. We explain why to them as well, so they realize that if they want to go for the cheapest quote, and if quality is not as important to them, then we will not be a good fit for each other. On the other hand, if quality is important to them, and they understand the value of spending more, because we are investing a little more on our end, then we have something to talk about.”

Part of Berezovsky’s approach to market is to start with an elevated standard of construction that assures a quality result from the get-go. “Our standard package includes a lot of things that would be considered upgrades with other companies,” he explains. “For example, all our garages come with a curb wall. That is an additional step, and it’s not cheap to do. It takes time. But we refuse to construct any building without it because we understand that down the road, years from now, when the snow melts, it’s going to go inside your garage. So even if you have pressure-treated bottom plates, it will not help because of the amount of moisture.”

Berezovsky says his competition will lower their prices as much as possible so that the customer is happy, but

they’ll also leave out critical elements like the curb wall, without taking into account what that means for the building years down the road.

Another standard is 40-amp electrical service, which Berezovsky says is a must if the homeowner decides to buy an electric car in the future. “You don’t know if you’re going to need a charger for an electric car in the next few years, so we might as well do it now, instead of later when you would have to redo your whole system,” he says. “You’ll have to dig another trench and redo the whole feed from your house to the electrical in your garage, just so you can charge your electric car.”

With numerous dream garages, legal basement suites, and other projects under their belt, Alta has earned a reputation in Alberta as the go-to contractor for these niche projects. While they got their start in Calgary, they have more recently expanded into Edmonton, and continue to be committed to quality work and customer service.

When asked about when they’ll expand beyond Calgary and Edmonton, Berezovsky explained that he and his team have enough on their plate for now. “We are extremely busy,” he concludes. “Every time I think about expanding the business, I have to remind myself just how busy we are with the markets we currently serve.” cc

The Nudura line of insulation products provide solutions for maximizing energy efficiency, providing greater protection from the elements and minimizing noise, while providing a comfortable home for your family. With a full range of products to meet every insulation need, from our Integrated Series for roofs and floors to our Nudura ICF Series for your homes structure, these proven products will provide you with the home you have always dreamed of, with added benefits over traditional construction. Explore the Anatomy of a Nudura Home.

A 2017 report suggests that 100,000 productive years of life were lost due to premature opioid toxicity deaths.

Opioid deaths are on the rise in Canada’s construction industry

Andrew Snook

Canada’s opioid overdoses are on the rise and it’s an issue that is trending upward within the country’s construction sector. One region where massive spikes in opioid-related deaths in the sector are taking place is within the country’s most populated province.

According to the recently released report, “Lives Lost to Opioid Toxicity among Ontarians Who Worked in the Construction Industry,” the numbers have been climbing fast.

The report, created on behalf of The Ontario Drug Policy Network, The

“While the industry represented 7.2 percent of the people employed, 33 percent of those employed at the time of their deaths due to opioid toxicity worked in the construction sector.”

Office of the Chief Coroner for Ontario/ Ontario Forensic Pathology Service and Public Health Ontario, stated that Ontario reported 2,460 opioid toxicity deaths in 2020, a staggering 60-percent increase from 2019. It also states that Ontario’s construction sector is significantly over-represented

in the number of opioid toxicity deaths since the beginning of the COVID-19 coronavirus pandemic in March 2020.

While the industry represented approximately 3.6 percent of the province’s population and 7.2 percent of people employed in Ontario in 2021, 33 percent of those who were employed at the time of their deaths due to opioid toxicity worked in the construction sector.

The report points to the rigors of the type of work being performed as a contributing factor:

The physical demands of construction work may explain why construction workers are prone to injuries and chronic pain, which may contribute to opioid use. In addition, the mental challenges associated with long hours and precarious, competitive

and stressful work environments may also contribute to opioid use among people working in the construction industry. The precarious or occasional nature of some construction work may also make the construction industry a more accessible field of employment for people who use substances, compared to other sectors. Furthermore, the high proportion of men, particularly in younger age groups, may explain the clustering of opioid-related harm in the construction industry, as these are demographic groups that tend to be most affected by opioid toxicity death.

“Construction workers and anyone working jobs with very high physical demands, that’s where you’re going to see more injuries,” says Jan Chappel, senior technical specialist for occupational health and safety at the Canadian Centre for Occupational Health and Safety.

When breaking down the age distributions of construction workers in the sector that died of opioid toxicity in Ontario between 2018 to 2020, the report states that 60.1 percent were between the ages of 25 to 44, while 31.4 percent fell between the ages of 45 to 64, 6.6. percent were 25 years of age of younger, and 1.9 percent were 65 years of age or older.

During that same time period, 98.4 percent of the people employed in the sector that died of opioid toxicity were male.

When it came to the origin of the opioids directly contributing to opioid toxicity deaths in construction worked between 2018 to 2020, 79.2 percent were non-pharmaceutical opioids (overwhelmingly fentanyl and fentanyl analogues). Solely pharmaceutical opioids contributed to nine percent of opioid toxicity deaths of construction workers, while a combination of pharmaceutical and non-pharmaceutical opioids accounted for 11.7 percent of opioid toxicity deaths of construction workers.

The rising opioid issues in Ontario’s construction sector are on a similar trend to British Columbia, where it was reported that 20 percent of opioid toxicity deaths that took place in 2021 were employees within the

construction sector.

In 2021, according to a B.C. Coroners Service report, B.C. experienced 2,265 illicit drug toxicity deaths (up from 1,747 in 2020 and 984 in 2019). From 2019 to 2022, the percentage share of drugs involved in illicit drug toxicity deaths were:

• Illicit fentanyl and analogues: 85.6

• Cocaine: 45

• Methamphetamine/amphetamine: 41.9

• Other opioids: 22.8

• Ethyl alchohol: 26

• Benzodiazepines: 13.9

• Other stimulants: 2.9

While the number of opioid toxicity deaths in B.C. have spiked since the beginning off the pandemic, the

In Ontario, opioid-related deaths rose by 60 percent in 2020 from 2019.

construction industry was over-represented well before COVID-19 came to Canada.

According to government of British Columbia Coroners Services report, “Illicit Drug Overdose Deaths in BC: Findings of Coroners’ Investigations,” published on Sept. 27, 2018, 55 percent of those who died of an overdose in B.C. between 2016 and 2017 (and were employed at their time of death) were working in the trades and transport industries. This is another massive over-representation of those employed in the trades and transport industries, considering it was reported that those industries made up 15 percent of people employed in the B.C. 2016 Census.

In addition to all of the tragic deaths that opioid use is responsible for across Canada, it is responsible for billions of dollars in losses. The Ontario-based report stated that in 2017 it was estimated that across all sectors there was $4.2 billion in lost productivity due to opioid use in Canada. This number was reached due to “100,000 productive years of life lost due to premature opioid toxicity deaths.” One

can certainly argue that those losses have only skyrocketed since that time.

According to the government of Canada report, “Opioidand Stimulant-related Harms in Canada (June 2022),” a total of 29,052 people have died from apparent opioid toxicity deaths between January 2016 and December 2021. Of those deaths, 88 percent took place in Ontario, B.C. or Alberta.

The report notes that elevated rates have been observed in other areas of the country, including Yukon and Saskatchewan (Manitoba’s data was not available at the time of the report). Fentanyl was involved in 86 percent of Canada’s accidental opioid toxicity deaths in 2021 (81 percent of those were non-pharmaceutical).

For employers who suspect an employee may have a “drug problem,” Chappel suggests focusing on assessing the employee’s behaviours on the job and drop the word “problem.”

“Employers should be assessing if that individual

can do their tasks safely at that time, on that day, at that moment,” she says. “We hesitate to use the word ‘problem’ when you’re talking about addiction. You really can’t diagnose that unless you’re a medical professional or a counsellor, so what we encourage employers to do is focus on what they’re seeing, and if that behaviour is a safety concern.”

Chappel encourages employers to evaluate their employees as they go about their day-to-day tasks.

“Does the person have the ability to perform that job or that task safely? Can they drive the machine? Can they operate the machine? Can they use a sharp object? Are they having trouble making decisions and judgments that affect safety? And then, use that assessment to ask if that person is able to conduct that job safely?” Chappel says.

they can,” Chappel says, adding that there are many other organizations that have resources available for employers and employees.

One free downloadable toolkit available is “Substance Use and the Workplace: Supporting Employers and Employees in the Trades,” which is available on the website for the Canadian Centre on Substance Use and Addiction.

“We hesitate to use the word ‘problem.’ We encourage employers to focus on what they are seeing and if that behaviour is a safety concern.”

Chappel encourages employers to develop programs and policies so that every instance of impairment is addressed similarly and in a clear manner.

“Employers may offer employee-assistance programs, if

The toolkit was designed for supervisors, managers, human resources professionals, unions, associations and related organizations, while also containing ready-to-use resources for employees. It includes resources for employers and workers to help prevent substance use harms; educate about substances and their effects; address employee substance use; find services and supports, and access related information about key reports and organizations. cc

For any questions related to the toolkit, the CCSA can be contacted at workplace@ccsa.ca.

By Casey Edge

Canada’s deputy prime minister, Chrystia Freeland, recently said, “One of the things that I am most concerned about as someone who — it shocks me to say this — is 53 years old, is the intergenerational injustice. We had a better shot at buying a home and starting a family than young people today, and we cannot have a Canada where the rising generation is shut out of the dream of home ownership.”

Yet, only three years ago, Evan Siddall, the former CEO of Canada Mortgage and Housing, said, “Our dream of home ownership is static and regressive. We need to call out the glorification of home ownership for the regressive canard that it is.”

billions of dollars from housing.

The B.C. government charges property transfer tax up to three times on the development of one new home. Their revenue for last year was $3 billion, up from the previous $2 billion. In Toronto, homebuyers pay two land transfer taxes – municipal and provincial. How do politicians in Toronto talk about housing affordability with a straight face? Many building permit fees are calculated based on the cost of construction which includes the rising prices of materials like lumber, labour and other factors with no relationship to the cost of inspections.

The town of Saanich, B.C. had a permit fee surplus that approached $2 million in 2021, higher than in 2017 when 40 percent more homes were constructed. So their revenues increased while the demand for inspections decreased. Sooke, B.C., reports revenue of $904,623, an 81-percent increase over their projected budget of $500,000, not including revenue from re-zoning, development permits, subdivision fees and plumbing permits.

These contradictory statements from senior officials exemplify Canada’s dysfunctional housing predicament. Housing has become a matter of political posturing and flavour-of-the-month, while also serving as a cash machine for the government. Freeland had a better shot at buying a home 30 years ago because three levels of government weren’t using homebuyers’ mortgages as a big source of revenue. There was no GST, which today adds $50,000 to the cost of an average new home in B.C. Freeland could have offered to assist housing affordability by indexing the GST New Housing Rebate to today’s prices, first promised by the federal government when the GST was introduced in 1991. Instead, Freeland and other governments continue collecting

Check your own municipality’s annual financial report to examine their annual revenue from building permit fees while they claim the need for increased development cost charges and community amenity contributions. Some municipalities double dip, demanding significant “green space” from a development while including parks in the DCC’s.

While government coffers overflow, permit approvals slow to a snail’s pace. Elected officials promise improvement but the process only gets worse as more regulatory hurdles are added. Politicians bemoan the lack of housing supply and affordability, while raking in massive revenues at the expense of homebuyers.

It’s a bit much listening to Freeland refer to “intergenerational injustice” while doing zero to apply fairness to her own GST-rebate program for new housing. It’s time for some real intergenerational justice. cc

Casey Edge is executive director of the Victoria Residential Builders Association.

By Steve Ryan

In the winter edition of Canadian Contractor, we anticipated that concern for inflation was going to trigger an increase in borrowing costs for both contractors and their customers. Sure enough, that is what is happening, which is hardly an indication of my forecasting skills. It was kind of a forgone conclusion. The take-home from that article was to position yourself to serve the most resilient segments of the residential construction market. Borrowing costs would lead to a downdraft on construction markets, but the effect would not be uniform across all segments.

It was all pretty general stuff, and other than to suggest you get ready for change, there wasn’t much offered on how to do that. So what’s my point? Well, as with any disruption, along with risk comes opportunity. That January article suggested you position yourself for a new reality in the business. Here’s how I read the tea leaves.

For the past 10 years or so, many established neighbourhoods have been dominated by infill housing and redevelopment. Nice homes on underutilized lots have more value for redevelopment than as resale homes. While residents might have enjoyed the sense that their property increased in value, they also discovered that effectively they are living in a building lot. With a high likelihood that the house will be torn down and replaced the motivation to invest in renovations or upgrades evaporates. Oh, we know all the arguments that renovations should be for the owner’s own enjoyment, and it is unrealistic to expect a 100 percent return when the property is eventually sold. But if you are looking at recovering zero percent on that upgrade because it adds nothing to the value of your “tear-down,” it changes the math.

My own plans for a $50- to 60,000 ground floor refresh are back on now because the redevelopment frenzy in my neighbourhood has cooled off, maybe for good. I don’t plan to sell any time soon, but I also realize that when the time does come I may be selling into a balanced market. Buyers will include people looking for a house to live in and they will have choices. My house will benefit if it is more up-todate and I will see some return on my renovation investment. I won’t recover 100 percent but it won’t be money down the drain either.

The short form of all of this: there is a segment of the

renovation market about to emerge. If you are concerned that your traditional market is softening, then do some homework and make some cold calls. Find the neighbourhoods that are more than 40 years old. Especially those that have seen infill redevelopment. Those properties are not simply building lots now. Like me, many residents are ready to consider home improvement as long as it offers some enduring value.

Finally, let’s look at why these newly motivated home owners might change their outlook. Like anyone selling into a balanced market, you want an edge. Whether or not you can get a higher price, you want to give buyers a reason to prefer your product. When a property is being sold as a place to live, rather than as a building lot, then the advantage goes to the home that offers something special. The same goes for you and your business.

You may be heading for a balanced market, where it takes more than answering the phone or simply being available to secure the next job. If you don’t want to be chasing business at any price, then customers will need a reason to prefer your product. As much as you might believe you have that edge, you need to be objective about how prospective customers will know that. Pretty much everyone claims quality and service beyond compare, so you need something more than promises to convince a buyer. Marketing jargon calls this your value proposition. cc

Steve Ryan is managing principal of MMI Professional Services.

The team at Green Roots Landscaping are creating award-winning backyards in a lowmaintenance package.

By Gordon Wornoff

Every spring, Landscape Ontario celebrates the most creative and finely crafted outdoor living projects in the province. This year, Green Roots Landscaping won the Award of Excellence for their backyard build, “Patton” in Ottawa. Ryan Crompton, designer and co-owner of Green Roots, speaks about this project.

Please tell us a little about the project, the clients, and how this all came to be?

We’ve been a landscaping company since 2010, but this is the first time we’ve submitted a nomination package to Landscape Ontario. We thought this job encompassed what they would be looking for because it has so many different elements within a fairly small backyard.

The clients were very receptive to the design, which prioritized eliminating as much of the maintenance as possible. In their neighbourhood in Westboro, it’s very

flat, so the job was as much about drainage as it was anything else. We created a below-grade dry well and chose a permeable patio paver called Aquastorm that allows surface water through to the underground cavity to manage the water – not only from the roof line, but also from the sump pump. At a glance, it looks like a green space with thyme growing between pavers, but there is some serious infrastructure underneath.

I suspect this is part of the reason

Landscape Ontario chose us, because it balances the site drainage while including the landscape elements that clients want: a basketball court, a deck for dining and cooking, a lounge area, a bench in a private area within the garden and a sauna. Next spring, we’ll be installing a three-season office.

This client found us through the website Houzz. We’ve won the Houzz award for seven years running and get a significant amount of work through this website. I know we were in competition with other landscapers for this sale, but our approach to design is a little more technical than the average landscaper. We do a very accurate 3D rendering that portrays what the client will actually see in reality.

Please talk about your design process.

I think about landscaping as if I’m creating a frame for a house. If a frame for a painting is too gaudy, it throws off the painting. If the frame is too minimal then the painting shows up too much. It’s about creating a balance. Usually, clients want a “main floor” outside – a living room, a dining room and a kitchen. However, these clients wanted a striking but low-maintenance garden, a large lounge area, a deck with a built-in kitchen counter and a sauna.

After the initial conversations, I recommend materials that will suit their home. Our designs aren’t static. Once I submit them, we meet over Zoom a few times and tweak the designs together to customize it to exactly what they want.

It is my job to make sure the function is correct – the flow of traffic makes sense, it’s easy to use, it’s a welcoming, inviting space. But I must also get the form right and make it look good because that is what sells the project. People really want the look but if it’s maintenance-heavy, if it’s hard to navigate on a daily basis, then it’s beautiful for the first day but bothersome throughout the property ownership. Missing the function is bad for your reputation and you don’t get repeat customers.

I’ve seen some landscapes that have not prioritized functio. Have you encountered these? All the time. Often we are brought in to tear out existing landscaping. Let’s say there’s a deck that is interesting and has a few different layers and multiple things going on – each time there’s a step you are interrupting the plane. Each individual level is not large enough to be functional. Obviously you must listen to the client and take their ideas into account, but a deck must be large enough to contain outdoor couches or a full outdoor dining set.

What were some challenges on this build?

Once we finish the design, we move on to the planning stage. This stage is critical to minimize challenges down the road. In this case, we needed to excavate and create a dry well to collect the water, but also to feed the thyme and then direct the rest to the ornamental garden to feed those plants so you don’t end up with bog-like conditions.

After these considerations, we needed the other elements addressed – the low-voltage lighting, the wiring for the sauna, the helical piles, the subcontractors. This process is critical so you don’t have to go back and tear out your own work.

Tell us about the materials in this project.

I like to add as many different elements as I can, given the client’s taste, including stone, plant material, wood or faux wood, glass, metal, fire, and water.

This design is full of lighting. We set up lighting on timers so the clients don’t have to do anything to enjoy their backyard – they look out every evening to an inviting property, ready to use. The built-in stone benches have lighting in them, so in the evening, there is a golden hue, defining the outline of the lounge area. We used glass for the deck railings and integrated lighting in the steps.

To keep the deck low-maintenance, we went with TimberTech’s polymer Azek deck boards in Mahogany. You never have to stain or reseal this product; once it’s installed, that’s it. We also have Corten steel planters. It will take on rust and develop a deep patina, but it doesn’t deteriorate.

The sauna is a new kind of wood: thermally-treated ash. Producers use sustainable woods like ash or pine –we use a company out of Michigan. Usually, you wouldn’t be able to leave ash outdoors, but the industry developed an environmentally friendly process that cures the wood

with heat and steam. So, ash will endure the elements for 25 to 30 years like cedar would; it’s more of an engineered product. It has more of a distinctive grain to it than cedar does, so that definitely adds visual interest.

The sauna is best used in the wintertime so we chose a smooth brick to make shoveling snow easier. This brick is the best choice from a

functional standpoint, but also fits the modern aesthetic.

Do you think about climate change when designing these outdoor spaces and selecting plants and trees?

Both myself and my foreman are certified Fusion professionals, which is a program Landscape Ontario devel-

oped with the City of Ottawa to deal with stormwater. Just as we’ve done on this job, the goal is to allow stormwater to stay on the property rather than overburden our city infrastructure. You want water to leach downwards, back into the groundwater, feeding the water table, rather than being dumped into the Ottawa River through the storm sewers.

So now we direct rooftop water through downspouts to underground cisterns, drywells or to a rain garden – a garden of flood-friendly plants at a lower plane than the rest of the front or backyard. We also look for plants that are heat-tolerant or salt-tolerant if they are put near a driveway. We try to keep things as lowmaintenance as possible, so our

“If it’s hard to navigate on a daily basis, it’s beautiful for the first day but bothersome throughout the property ownership. Missing the function is bad for your reputation and you don’t get repeat customers.”

clients are enjoying it rather than working on it. But, another key aspect is to use as many native plants as possible. When you introduce foreign plant material that can technically grow in the planting zone that you’re in, it can struggle to survive in some cases, while native plants thrive. And then, sometimes foreign plants can thrive too much – Staff Vine or Oriental Bittersweet is very invasive and will choke out neighbouring plants.

If you were excavating and found a genie in a bottle, and you were granted some wishes for your business, what would they be?

There is new heavy equipment technology – excavators that have a 360 wrist that can pick things up – I

see us building complex rock-walls effortlessly with that equipment. There’s also a new generation of electric excavators and heavier-duty electric work trucks coming out that look really promising. These electric motors have 100 percent torque access, so you’re able to haul more easily, not waiting for gears to shift and so on. They’d be better for power, size and maintenance. To switch away from diesel would be great – we can show our clients we not only stand for creating these amazing landscapes but protecting them as well by being more green.

We want to expand our company to meet the demand. We have exceptional staff who return every year, and we’ve been incredibly lucky. I need to mention the following people, who were critical in our company winning this award: Quinn Stokes, Tasha Chapman, Calum Foster and Carissa Polonen. Their attention to quality is outstanding in everything they build. We are currently booking a year in advance. The only thing throttling this business is personnel. We currently have three crews with five per crew and we’d like more of that – we could easily keep another full crew busy with all the calls coming in. cc

By Steve Maxwell

Whenit comes to winning jobs, it all comes down to value. The more value you can offer potential clients, the more power you’ll have for winning jobs at higher prices. Decks are low-hanging fruit when it comes to this. Most decks are built with no more attention to longevity that pressure treated lumber and perhaps some joist tape. With that recipe a deck will last 10, 20 or maybe 25 years at the most. But put a handful of little-used deck details into practice and the decks you build can last 50 years at only slightly more cost. That’s super-appealing to some clients, and a huge selling point, as I’ll show you here.

The problem with typical decks is the way wooden frames are put together. Most have way too much wood-to-wood contact area. The larger the area of contact, the longer it takes for the area to dry. And the longer it takes to dry, the more welcoming the area is to rot. Things get even worse when insects such as earwigs move into wood-towood contact zones, depositing droppings into the moist environment, triggering even faster decay because of the nutrients present. Composite beams made from four two-

by-10s spiked together; deck boards meeting and touching end-to-end; a tight fit between deck floor frames and house walls – all these common deck details seem insignificant while building, but they really matter 10 or 15 years down the road. Just because you use pressure-treated lumber or cedar doesn’t eliminate consequences. All wood eventually rots when it stays wet, and pressure treated lumber of the kind meant for above-ground use can turn to compost in 10 years under the wrong conditions. I’ve seen it happen.

Long-life deck framing features include rot-proof drainage spacers between boards of composite beams; periodic double joists so floor boards can be spaced on their ends; rot-proof drainage spacers between the deck frame and house wall.

Sometimes the best thing you can do for a client is save them from their own bad ideas and, when it comes to

decks, this applies to composites in a big way. More and more people are paying higher prices to have new decks built with plastic or composite lumber for the top surface. Even older decks are having wooden boards removed and replaced with composites to reduce ongoing maintenance. One important part of the 50-year deck is a walking surface that doesn’t need to be refinished every two or three years. There’s also a new reason why selling clients on composites is easier than it used to be.

Typically speaking, synthetic deck lumber can be somewhat more expensive than deck wood, but not nearly as much more as in years past. As you’re talking to clients about synthetic deck materials, be sure to mention that in a sense the purchase price of these materials also includes all the finishing products and refinishing labour that would otherwise have to be spent with an ordinary wooden deck. It’s a pay-now-enjoy-later proposition, and costs are more reasonable when looked at this way. Just don’t think that “maintenance-free” deck materials get your clients out of all maintenance chores. Explain that cleaning is still needed and sometimes removal of moss and lichen.

Don’t let your stairs sink

The job of supporting the bottom end of deck stairs might seem simple enough, but looks can be deceiving, especially here in Canada with our seasonal freeze-thaw cycles. That’s because sooner or later things sink into the soil. Even firm soil has a tendency to yield when something is resting on it all the time. This is why a concrete pier foundation is the best option for supporting the bottom end of your deck stairs. Bore down below the frost line with a post hole auger on each side where the bottom of the stairs will sit, put a cardboard form tube into each hole, cut the tubes so they’re the right height to support the bottom end of stairs, then fill the tubes with concrete all the way to the top. A solid, frost-proof support for your stairs is what you’ll get. It’s much better than a patio slab sitting on the soil.

Don’t skimp on foundation

There are two main ways to support a deck on the ground. You can set the posts to rest on top of the earth on concrete deck blocks, or you can build a below-grade foundation. Deck blocks can work fine on soils that don’t rise and fall with frost, but they’re a risky choice for many Canadian building sites. Concrete piers poured on site into cardboard form tubes are a better option because they create support for your new deck that’s almost completely free from the hazards of freezing soil and the destructive movement this causes. Getting the bottom of your deck foundation piers down below the frost line keeps things solid in all seasons, but there’s more. One little-known trick involves making sure the frost can’t grip the outside of the concrete pier and lift it up by friction. This is called frost jacking and a layer of black poly plastic wrapped on the outside ensures this won’t happen. Staple the plastic on the cardboard form tubes before setting them in the ground, then install a hotdipped galvanized post saddle in the top while the concrete is still wet.

Join a completely Dealer-Owned company today.

Dealers share and participate equally without the influence of any external shareholders. Harness our massive buying power, comprehensive distribution, national brand recognition and marketing support.

Choose a wood finish pragmatically

Wooden decks are big, and even a beautiful deck will turn into a maintenance nightmare if finishing and refinishing of the wood rules your client’s life. That’s why you must never choose a deck finish based on looks alone. Choose a deck finish based on what it will be like to live with. So what makes the right deck finish?

Appearance, quality and a maintenance regime your client can live with. Generally speaking, the more opaque the finish, the longer it lasts. The best clear water repellent treatments have the shortest working life – about 12 to 18 months before refinishing is required. Paint-like deck finishes last as long as five years. The best transparent, coloured deck finishes last somewhere in between. The easiest option involves not finishing your deck at all, or spraying it with a one-time treatment that weathers the deck evenly within hours, and never needs attention again. My favourite is something called Ecowood Treatment.

Have you noticed that sometimes a few minutes of the right kind of talking to clients can trigger more revenues than hours spent using a hammer, saw and nail gun? Sell your deck clients on the superior value of the 50-year deck concept and you’ll enjoy better work and better profits. cc

Today’s pressure-treated lumber contains compounds that reduce rot, but these same compounds also speed the corrosion of metals, much more than the old CCA lumber from the past. Aluminum is particularly prone to rapid disintegration when touching today’s pressure treated wood, but so is steel. Even electroplated steel will corrode badly in five to 10 years of contact with the copper-based preservatives used in modern ACQ lumber.

That’s why stainless steel is your best choice for deck fasteners, followed by hot-dipped galvanized.

What caught our interest

RESISTS DAMAGE

trex.com

Trex’s Transcend line has grown with the new Lineage line for outdoor decks. Trex Transcend Lineage boards feature an elevated esthetic with subtle, elegant graining that delivers a natural appearance. Available in two new colour options –Rainier, an airy mountain grey, and Biscayne, a light coastal

brown – these new offerings expand the collection with nature-inspired tones and texturing that are on-trend with what homeowners look for. The boards are engineered with heat-mitigating technology in the shell to reflect the sun and keep boards nice and cool. They’re made from recycled and reclaimed content and engineered with a durable integrated shell that resists stains, scratches and mould. They won’t rot, warp, crack or splinter like wood and upkeep is hassle-free. No sanding, staining or painting is ever needed, and spills wash off easily with just soap and water. Square-edge boards come in 16- and 20-foot lengths. Grooved boards come in 12-, 16and 20-foot lengths and accommodate the Trex Hideaway fastening system, which allows for a smooth finish free of nails and other fasteners. Coordinating fascia is available in one-by-eight and oneby-12-inch sizes. All are backed by Trex’s 25-year limited residential fade and stain warranties.

ANTI-MOULD PRIMER

rustoleum.com

Zinsser’s Mould Stop Primer is a great water-based coating. Perfect for the outdoors, you can use it to paint over existing stains left by mould, mildew, moss, fungi and any other fungal organisms. The Mould Stop Primer is made with antibiotic agents so that it prevents the growth of mould, mildew and other fungal organisms on the paint film. Use it to cover residual microbiological and fungal stains and to prevent odour-causing bacteria on paint film. It’s also suitable for use under wallcoverings. It can be used on interiors or exterior, and is water-based and tintable. The primer comes in 3.78-litre and 946 milliliter sizes.

The Dekton exterior worktop makes strong and durable surfaces for outdoor use. Mixing style and utility, the innovative surfaces are transformed into functional and esthetic worktops. The worktops have a high UV resistance and use a low coefficient of thermal expansion to endure sudden temperature changes in Canadian climates. The slabs feature high scratchresistance, stain-resistance, abrasion-resistance and impact resistance. The slabs are made large in a 3,200-by-1,440-millimetre design, so less joints are required for big projects. Dekton carries two lines of exterior worktops: the natural series which features natural-stone colours like Portum, inspired by the natural stone of Porto Bello and the Urban Style line that features colours like radium and other metallic looks. All of Dekton’s slabs are available in five thicknesses ranging from four to 30 millimetres.

Unilock natural-stone slabs are perfect for a new landscape. Use them for pool decks, patios, entrances, or as an overlay to a wooden deck or existing concrete. They also carry pillar caps, steps and coping. Unilock’s Indian Limestone is an esthetically beautiful design and has been selected based on its low waterabsorption, freeze-thaw durability and flexible strength so it prevents splitting. The slabs come in a variety of sizes including 12-by-24, 24-by-36 and 24-by-24 inches. The natural stone comes from Kurnool, India, in natural charcoal greys and blacks. The finish is naturally split, edge dressed and calibrated. It has a wet slip resistance of 65 with a 0.1-percent absorbency. Solar reflectance is 0.08, absorbance is 0.92 and thermal emission is 0.9.

Vince is a Red Seal journeyman carpenter and proud of it. He was raised to respect the time and education that goes into an apprenticeship and feels it is the best way for tradespeople to turn their job into a real vocation. He worked hard to get his ticket and feels it sets him apart from others who haven’t gone to the trouble to have their experience and knowledge officially acknowledged.

Now that Vince has a business of his own, he’d like to continue promoting apprenticeship and certification in his workforce. But it is proving to be almost more problematic than it is worth. Finding enough journeypersons to meet the ratios for apprentices seems impossible and restricts the size of his workforce. Getting the apprentices to keep up with their reporting and classroom time is a constant effort – provided they even stay with the industry long enough to qualify for their tickets. And there’s no doubt that once they get their tickets, it isn’t long before they are looking for greener pastures where they can be paid more than Vince can afford or are going into business for themselves...sometimes as competitors.

Vince can see the benefit of his investments in his workforce in the form of better quality, less wasted time and a more professional approach that pleases his clients. But the hassles in the system are giving him heartburn.

Nathan was having trouble figuring out the environmentally friendly thing to do given the conflicts that can arise between energy efficiency and embodied carbon. Jax Bailey of J. Bailey and Sons New Homes and Renovations in Prince George, B.C., recommends hard work, innovation and education to stay ahead of the trends.

Nathan is proud of his environmentally conscious initiatives to the point of involving his staff and seeking clients that share that view. He needs to work harder and become more aware, educated and informed. Nathan can search out local restore opportunities for both purchasing and repurposing retrofit materials he removes. Nathan can also reach out to universities and colleges who have young, keen minds that are looking into these types of projects to find out if they can help him find other alternative solutions as part of their “green initiatives.” Nathan needs to grow his business in the way that the energy efficiency standards are moving, he needs to stay on par or ahead of that trend instead of ignoring them because if he does not, he could end up being pushed out of business by builders who are following the rules. In summary, find out the standards, meet or better them, seek out resources and materials to keep on track and find ways to be innovative, creative and stand out while following the energy efficiency rules imposed by the province. Congratulations, Jax, you take home the DeWalt driver and cutoff tool!

1. Forget this whole apprenticeship thing. It’s a broken, antiquated system.

2. Suck it up and stick with it. He’s doing the right thing for his workers and those who stay will make a great crew.

3. Hire unskilled workers and pair them with his journeymen even if the ratios are off. Let the ones who are keen pursue their apprenticeships.

4. Look at foreign workers who might have the skills he needs but aren’t recognized by his province’s system.

5. Something else?

If you have a solution to Nathan’s dilemma, email your entry to pflannery@annexbusinessmedia.com and put “Vince dilemma” in the subject line. Please don’t post your response to the Dilemma post on our website. Entries close Sept. 30. The winner will be announced in the November issue.

A S I M P L E , F O O D S A F E S E A L F O R Y O U R

T I L E , S T O N E & M A S O N R Y S U R F A C E S