CANADIAN CONTRACTOR TURNS YEARS

YEARS

A very happy birthday! 05 We’re celebrating this milestone for Canadian Contractor in style.

Technologies that changed the game 08 Steve Maxwell looks at 20 years of innovation that made our lives easier and more profitable.

Who needs the internet? 11 In 2001, the internet still needed some explanation.

Message from a founder 13 Steve Payne remembers Canadian Contractor’s early days.

Gamechangers The

In Case You Missed It

Here are some selections from our huge video archive, still available at canadiancontractor.ca.

MOTIVATING YOUR STAFF WITHOUT MONEY

- NOV. 3, 2011

Author Daniel Pink explains research that shows people don’t respond to stimulus in a straight-line way. Reward doesn’t always encourage good behaviour and punishment doesn’t always reduce bad.

THE MAKING OF A CONTRACTOR -

MAY 28, 2018

Rob Koci’s interview with John McLellan of John McLellan Contracting, in which McLellan talks about the accident that left his father a quadriplegic and launched him into the accessibility contracting business.

THE MARCH TO NET ZERO -

MARCH

26, 2018

Gary Meine of Nudura explains the upcoming changes to building codes that will drive the construction business toward ever-more efficient designs. This is a three-part series.

THE 90-DAY PROFITABILITY CHALLENGE -

SEPT. 11, 2015

Steve Payne talks to Mike Draper, the contractor coach, about how to assess your company’s profitability. it’s not as easy as you think.

ISSN 1498-8941 (Print)

ISSN 1929-6495 (Online)

Editor Patrick Flannery PFlannery@annexbusinessmedia.com

Associate Editor Sukanya Ray Ghosh SRayGhosh@annexbusinessmedia.com

National Account Manager Amanda McCracken 226-931-5095 AMcCracken@annexbusinessmedia.com

Media Designer Graham Jeffrey

Publisher Danielle Labrie 226-931-0375 DLabrie@annexbusinessmedia.com

Account Coordinator Barb Vowles bvowles@annexbusinessmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-510-5182

Martin McAnulty, Vice President Sales mmcanulty@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Circulation email:bolechnowicz@annexbusinessmedia.com Tel: 416-510-5187

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

HAPPY BIRTHDAY, CANADIAN CONTRACTOR!

It seemed a bit odd for me to be commenting on the 20th birthday of this magazine given I’ve only been working on it since June. So we’ve brought back co-founder and long-time publisher/editor Steve Payne to have a word about Canadian’s Contractor’s origins and his memories from the early days. You can find his guest column on the back page. Thanks, Steve!

As you’ll see from Steve’s piece, Contractor has always been about telling it like it is from the perspective of you, the contractor, without letting anyone else’s agenda get in the way. That’s one of the reasons I’m happy to have the chance to edit this magazine. Truth and trust are important in any communication and I can see that great trust has been built up over the long life of this title. I hope to be worthy of it and please let me know if I stray.

True to form, our cover story idea came directly from one of our readers. Andy McCracken owns The Right Angle in Simcoe, Ont., and he’s married to our national sales manager, Amanda. When Amanda mentioned the magazine’s anniversary to him, he thought it would be a good idea to look back at some of the tool technology innovations in the last 20 years that have changed the way contractors work. I couldn’t have agreed more. So Andy provided a list of gamechanging tools he could think of and we commissioned the famous Steve Maxwell to write all about them.

We needed more so I went back to a trick I’ve used in other magazine anniversary issues: reprint the old stuff. One of the great things about trade magazines is how they create a record of an industry. Each issue represents a snapshot in time that becomes more and more interesting history as the years go by. Just think of how future generations will look at media from 2020, completely obsessed with some virus. They’ll get a sense of the level of disruption and concern the pandemic caused, even if they have never known one themselves.

In this case, I opened one of our early issues (OK, Amanda opened it for me over a Zoom call – she has all our back issues) and found historical gold. There it was, a Robert Gerlsbeck article from 2001 trying to explain the internet to contractors and discuss whether they might be able to get some use out of this newfangled gadgetry. It’s full of the sort of puzzled skepticism that was so common at the time as people who never had the slightest interest in computers were being dragged kicking and screaming into daily contact with them. Sometimes the internet is just called “the net.” People were spending a lot of time “surfing the web.” Your business was doing just fine without a “URL.” It seemed possible that someday people would get comfortable with buying things online. Even the photo is a historical gem, depicting two ends not of an ethernet cable (which would have been a bit outdated itself) but of regular telephone cable. Ah, dial-up. Those were the days. You can find Gerlsbeck’s article on page 12 in all of its tech-grumpy glory.

We’ve come a long way in 20 years. cc

By Patrick Flannery Editor ”

” Each issue represents a snapshot in time that becomes more and more interesting history as the years go by.

What keeps you up at night?

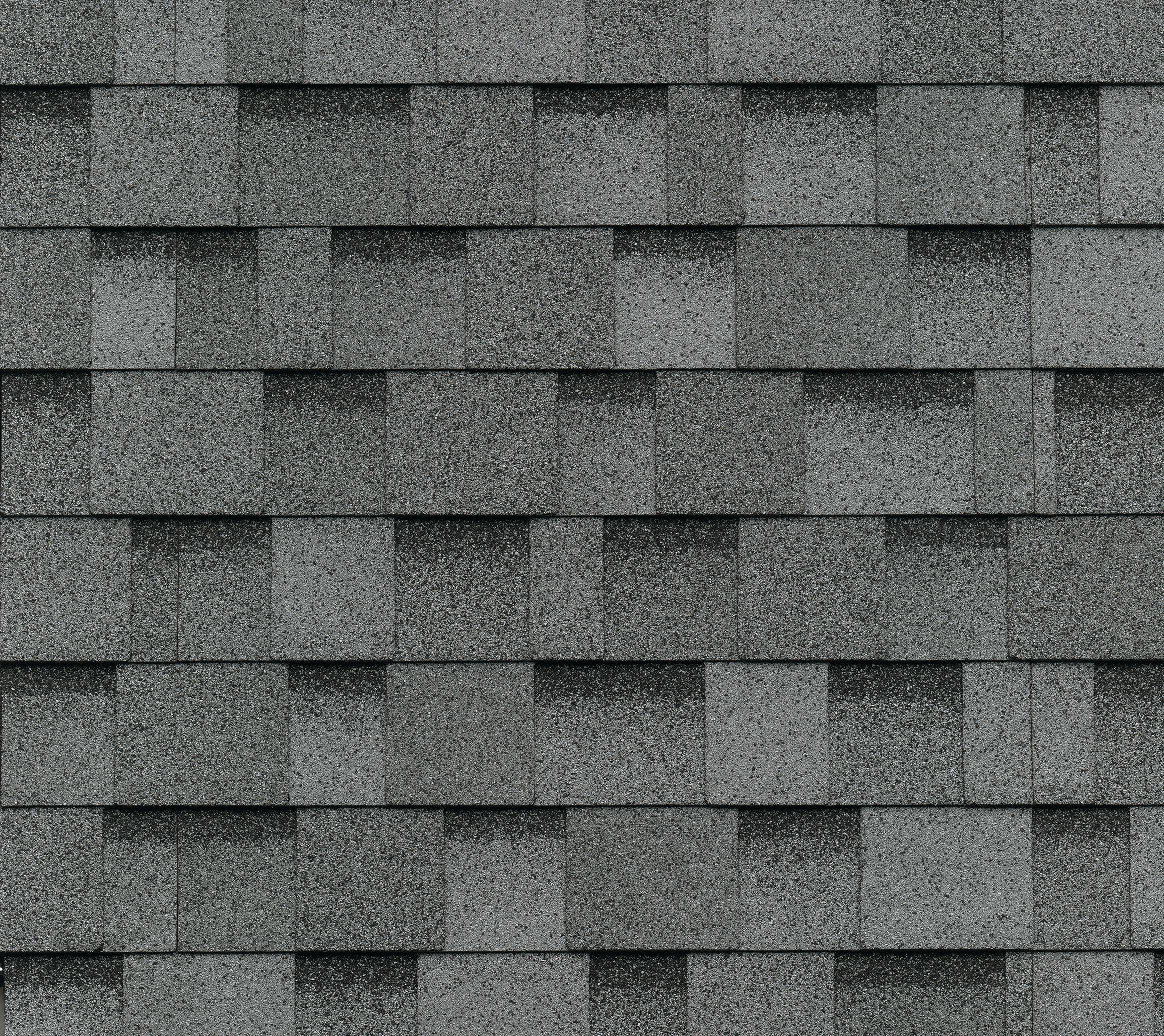

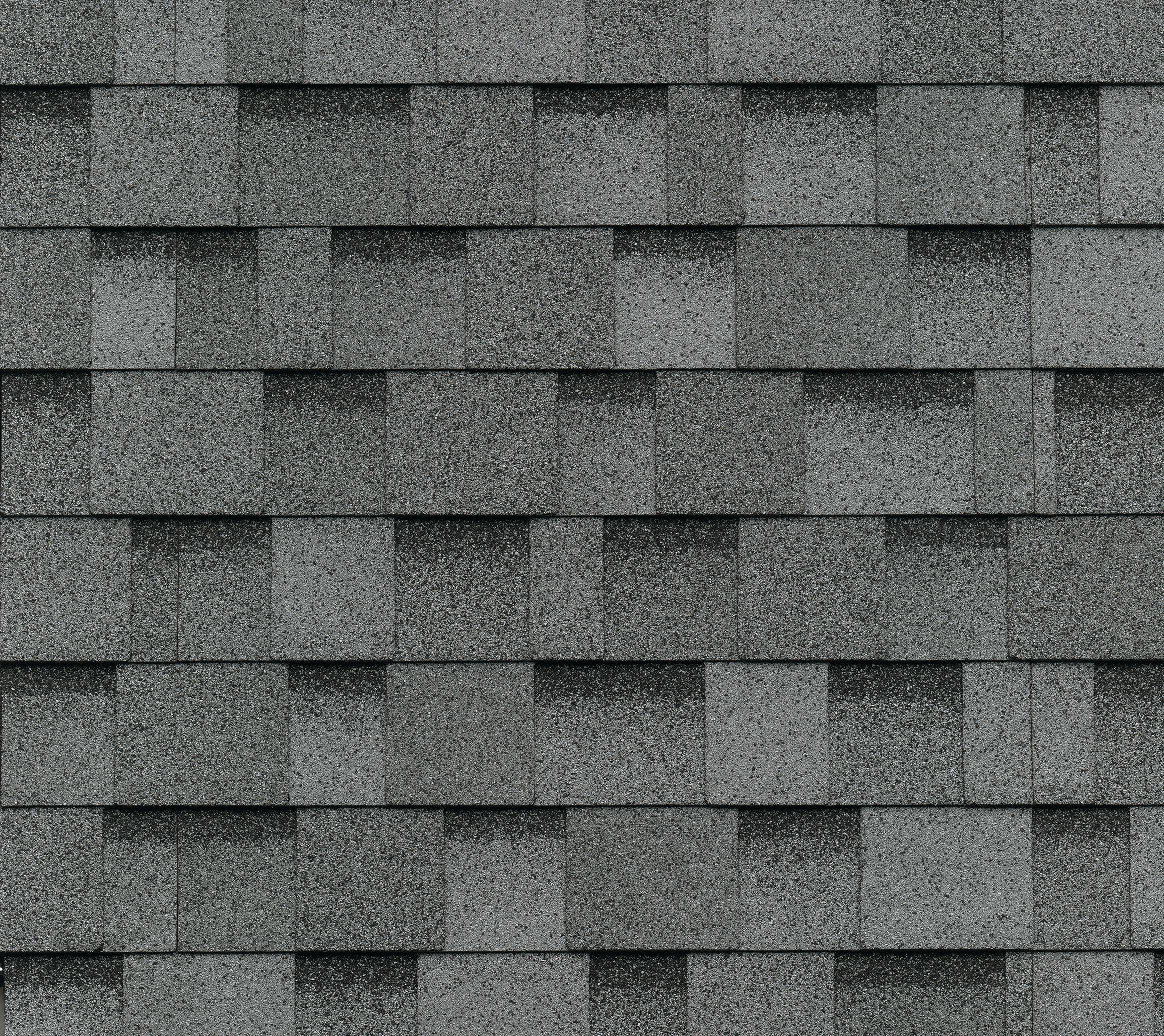

Is it the howling wind, or worry over what it might be doing to your reputation? Find peace of mind with IKO’s Performance Shingles with ArmourZone ® . The ArmourZone is an oversized 1-1/4” wide nailing area reinforced by a tear-resistant, woven band inserted into and extending beyond the common bond. It makes nail placement easy and helps prevent pull through in high winds. They’re covered by a 210 km/h (130 mph) Limited Wind Warranty. 1

GAMECHANGERS

How the last two decades have brought game-changing improvements to the trades.

By Steve Maxwell

It’s easy to take tool progress for granted because no matter how good a new kind of tool is, it quickly becomes your new normal. The last 20 years have brought big improvements in a bunch of tool categories, with lots to be thankful for. Have you noticed many from the list of gamechangers here?

Multi-tools

The first versions of multi-tools weren’t very multi at all. Appearing in a big way in the 1990s, these cute little toys were made exclusively for detail sanding. That’s a pretty underwhelming breakthrough for most contractors, but multi-tools today are anything but underwhelming. They’ve evolved into excellent precision cutting tools. You don’t need precise cutting you say? Maybe you do. Put a good saw-tooth cutting blade into a multi-tool and it’s unmatched for intricate cutting in close quarters. I’ve used multi-tools for cutting two-by rafters in an existing roof for skylight installation, for instance. Multi-tools are also unmatched for under-cutting door trim to make room for retrofit flooring and anywhere else where starting and stopping plunge cuts is necessary. Got to lift some sealed asphalt shingles to work flashing into an existing roof? Take an old multi-tool saw blade, grind off the remaining teeth, then use the smooth sharp edge to slice through the tar that holds one course of shingles to the one below. I can’t count all the ways a good multi-tool has helped me out of construction jams over the years. When you’ve got wood to cut with a multi-tool, power matters. Corded models are generally more powerful than cordless, but the DeWalt 20 volt multi-tool is currently my favourite because it’s almost as powerful as corded multi-tools but handier.

Metal-tolerant carbide blades

My first commercial carpentry job was a cold, wet, muddy project forming concrete during the winter of 1989. We were pouring around five-foot diameter steel pipes at the bottom of 30-foot deep trenches cut through Toronto subdivisions for water main construction. I was using a big worm drive saw at the time and even the best carbide blades back then lost teeth instantly if I hit even one old nail. Fast-forward and today’s best carbide blades can chew through nailembedded, screw-embedded wood all day long without missing a beat. The best of these blades have gotten even better during the last 10 years. In tests I’ve conducted, you can slice through half a dozen deck screws driven into the end of a two-by-six multiple times, then turn around and rip cut two-by lumber like the blade was new. Diablo was the first company to take this kind of things seriously, but secrets don’t stay that way for long in the tool business. Today, all the major blade companies offer metal-tough carbide blades in all typical sizes for hand-held circular saws. Got steel studs to cut? A metal-cutting chopsaw with a dedicated ferrous metal blade can make hundreds of cuts in steel and still work perfectly. I even use toothed carbide blades to cut heavy steel angle iron, channel and shaft up to one inch in diameter for metal fabrication projects.

Cordless caulking guns

If you use construction adhesive as part of subfloor installation (and we’re all supposed to, right?), then a cordless caulking gun may be the most welcome tool advancement going. Rinky-dink “attachments” for coupling a cordless drill with a caulking dispenser have been around for a while. Ask me why I hate them. Today’s cordless caulking guns are much different. Available for regular caulking tubes

and the big contractor size, these are not just easier on your hands. A cordless caulking gun will pay for itself on the first job because it saves so much time. Just be sure to warm the caulking tubes before dispensing in winter. Forget this step and your caulking gun plunger will probably get covered in goop that sneaks past as the failed diaphragm blows out from excess pressure. Milwaukee makes some of my favourite high-end cordless caulkers. Ryobi makes one, too, and it’s a lot cheaper – just the economical brand to hand to a worker who isn’t the most careful person on the team. Both the Milwaukee and Ryobi guns back off on plunger pressure a bit when you release the trigger, minimizing ooze-out from the tip between applications.

Battery nailers

No one uses a finishing nailer because finishing nails are difficult or tiring to drive. The advantage of a finishing nailer is speed. When battery-powered versions came out they added convenience to the virtues of speed because they got rid of the air hose of traditional pneumatic nailers. Granted, a battery-powered finishing nailer isn’t quite as fast as an air-nailer in rapid-fire situations, but do you really need to fire finishing nails like Rambo? I consider the reduction in speed a small price to pay for not tripping or having an air compressor startle me every time it fires up. Battery nailer technology has gotten so good that you can even get a framing nailer that runs on standard cordless tool batteries. DeWalt’s cordless framing nailer drives 2 1/2-inch with ease and 3 1/2-inch all the way home in most framing situations. In my experience you’ll get a surprising number of shots from a single charge, too.

Cordless impact wrenches

Technically speaking, these are supposed to be mechanic’s tools and they are. But cordless impact wrenches are also useful for any carpenter driving lag bolts or even long construction screws. Looking like an impact driver but beefier, cordless impact wrenches deliver more torque than drivers made for screws. All impact wrenches also have either a 3/8- or 1/2-inch square drive output made to take sockets. If you need to drive anything larger than 1/4-inch diameter lags, go for a 1/2-inch model. Some manufacturers make right-angle impact wrenches for work in close quarters, but in my experience these right angle tools are not yet nearly powerful enough for driving lags. If you need power, then get a conventional-design impact wrench. Do you ever work on your own vehicles and heavy equipment? You’ll find cordless impact wrenches unbeatable for breaking loose rusted bolts. The rapid-fire impacts delivered to the threads really work better than torque from a hand-held wrench.

Dump trailers

Last summer I was in Windsor, Ont., working on a century home and I needed to find a dump to get rid of construction waste. In that city the “dump” is actually a massive industrial building. You drive in, unload your construction trash onto a concrete floor and a loader scoops it up and pushes it into a compactor. Everything gets squished into big cubes, then carted off to who-knows-where. Every time I delivered a load of junk to the place, I was lined up with a bunch of dump trailers. Every second vehicle was a pickup truck with a big black dumper. I’m not sure why these

things are almost always black, but it’s no secret why they’re popular. Anything that automates the unloading of tons of construction trash is worth it. And it’s not just roofers using these things, either. Unless all you do is new construction, a dump trailer might well be the best boring investment you can consider. Advances in battery-powered hydraulics and long-stroke hydraulic cylinders is behind the explosion in dump trailer popularity.

Laser layout tools

Laser levels have been around for a while, but innovations in laser layout tools are on the rise. One of my favourite models casts laser lines on the floor, making it easier and more foolproof when setting any kind of tile. Another cool layout laser layout tool projects a spot of laser light directly above the unit, perfectly plumb with a marked location on the bottom of the tool. Sounds simple enough, but this is certainly something of a game-changer in the right situation. I used this “plumb laser” most recently for locating of the top end of floor-to-ceiling posts that meet with an angled cathedral ceiling. Establishing reliable plumb points in a situation like this is difficult without a laser layout tool, but insanely simple with one.

Vegetarian tablesaws

The inability for a tablesaw to cut any kind of meat is one of those capabilities that should be more widely appreciated than it is. A saw like this simply will not cut meat of any kind, including you and your fingers. I own the Bosch Reaxx portable table saw and what happens when you push a sausage into the blade is amazing. As soon as the blade hits the first few thousandths of an inch of meat, there’s a bang and the blade simply disappears. Look at the sausage and it doesn’t even have a scratch – not even a tiny one. Swap in a new compressed gas cartridge for the spent one after a safety event like this and you’re back in business in minutes and at minimal cost. Bosch had to take the Reaxx off the

U.S. market because of legal action from another company holding a patent, but we Canadians can still buy Reaxx here as well as a handful of similar, safer tablesaws. In a video I shot showing how Reaxx works, I discovered something interesting. This video was shot at 60 frames per second and yet from one frame to the next, the blade disappeared. That’s how fast it happens.

Sub-compact cordless tools

Back in 2005, Milwaukee was the first tool company to offer lithium-ion batteries in power tools. It promised to be a game-changer, and tool manufacturers took this to mean bigger tools without cords. The marketplace disagreed and that first wave of big, expensive lithium-ion models sat largely unbought. Eventually, tool companies decided to try the other end of the tool size spectrum, delivering small tools that are easy to use, easy to store in any tool pouch, and could never be built using yesterday’s old-school nickel-cadmium batteries. This time contractors agreed. It marked the birth of the sub-compact class of power tools and we’re all better off for it. What could be better than having a small but capable impact driver and spare battery in your pouch? Improvements in motor technology and battery storage capacity means that all kinds of sub-compact tools now exist and are on the rise. Funny thing is, while the marketplace did not go for the new kind of big cordless tools that lithium-ion batteries made popular back in 2005, today big lithium-ion tools are popular and getting more popular all the time.

Carbide recip saw blades

Reciprocating saws have been around for decades, but for most of this time they’ve performed much less effectively than they could have. Even back in the 1980s, I wondered when someone would come out with decent recip blades that would resist getting dull quickly. Thankfully, the wait has been over for a few years. We’re right in the middle of a recip saw blade revolution and not one but two kinds of improved recip saw blades are becoming widely available: bi-metal and carbide-tipped. Both last much longer than the old highspeed steel blades, and they cut faster, even compared with brand new high-speed steel blades. In tests I’ve run, cutting 12-inch-long spikes with a bi-metal blade, the carbide teeth still feel sharp to the touch after dozens of cuts through steel. Carbide designs have made recip saws so good that I regularly use them for rough-cutting plate steel that I use for welding projects. cc

THE VIRTUAL CONTRACTOR

The

internet wants you. But do you really need it?

By Robert Gerlsbeck

This article first appeared in the spring issue of Canadian Contractor in 2001, when we were still a bit unsure as to whether this new-fangled internet thing was just a fad. Note our photo on the right of super-high-tech connecting telephone cables.

Ahh, yes. The internet. Everyone keeps telling you that you just have to put your business on it. You hear it from your web-addicted neighbour who surfs all night and gives you a quizzical “What are you nuts?” look when you admit that you are actually running a profitable business without a URL. You hear it from those slick TV commercials, like the one where an impoverishedlooking child in a third world country asks, “Are you ready?”

So, are you ready now? Yet, internet hype aside, the potential for contractors cannot be ignored. The net is, first and foremost, an awesome tool for communicating, and successful contracting businesses are built on communications, right?

Case in point. Rick Simpson, a 25-year construction veteran who builds new homes around Westport, Ont., a cottage community southwest of Ottawa. In January, Canadian Contractor contacted Simpson to ask him if he was getting any new clients from his website (simpsonbuilding. com). Talking on a cell phone from a job site off the beaten track, he related this story.

“Where I am right now, I’m miles off the township road, building a cottage. And I got an e-mail from people way

” Consumers are getting used to researching home renovations on the web before they buy. ”

down in the Bahamas who own property that wouldn’t be more than a mile from where I’m standing. It’s an absolute freak coincidence that I would be working back here anyway. And this man (in the Bahamas) starts explaining where this is and that is and where his house is, and all of a sudden I think, ‘Geez, that’s right where I am now.’ ”

Simpson is realistic about the powers of a contractor website. He calls it a “good deal” for what it costs, but points out that it often puts you in touch with people who will never buy anything from you. “I’ll get calls from people in Georgia,” he says, but quickly adds: “But out of that I have gotten people from Georgia looking to buy property up here.” About 40 percent of his overall prospective clients ask him if he has a website.

And yes, to answer our initial question, Simpson has won some jobs via his website. “I think there are a lot of people who work in an office and have access to a computer who will go on their lunch hour and start looking around,” he observes. “And if they spot something, they’ll send you an e-mail.”

It would appear that consumers are quickly getting used to researching big purchases, home renovations, cars, etc., on the web before they buy. They are also comfortable doing business across the net. Robert Case, of Case’s Renovations in Hanwell, N.B., (casesrenovations.com) says his company gets about one or two e-mail requests per week for a quote. “We’re amazed at the number of hits we’ve gotten in the year and-a-half our site has been up,” he says.

Case doesn’t see his website as a selling tool, however. It’s the

simple fact of being on-line and the marketing abilities that he believes are important at this stage. Thus, even contractors who rely on word-of-mouth may find a website to be a handy. “It’s an easy way for customers to learn a bit more about you, see pictures of some of your past jobs and read some references from your customers,” says Chris Van Bargen, who launched Ontariocontractors.com in November. The site is one of several in Canada with a directory feature where consumers can find a specific type of contractor in their area. Other such websites include: EiEiHome. com, ContractorsCanada.com and Homehelpnet.com. Bargen believes contractors should be on the web because consumers today expect to find “legitimate” businesses on-line. “It makes you look professional.”

Website construction 101

But what’s a more professional image going to cost you? Not really that much if you are happy with a basic website. Expect to pay about $350 a year in hosting fees, says Bargen, and between $30 and $100 to have your domain name registered. Website construction can cost as little as a few hundred dollars if you go with the 16-year-old computer whiz next door. Professionals cost a bit more. “A contractor should be able to get a website for between $750 and $1,500,” Bargen says. “The more bells and whistles you want on it, the higher the price.”

Although the standard belief in the internet industry is that a website must be updated constantly to keep viewers coming back, that’s not really true in contracting. Consumers aren’t visiting your site to get a constant

stream of new information. They are doing research on your business. A contractor does not have to spend great sums of money to keep the website fresh, says Bargen. Here, though, are a couple of key elements that a website should have.

▲ Who you are. The introduction on the homepage should explain what you offer. It can be the toughest part of a contractor website, especially if you are a general contractor who does many different things. The introductory paragraph is crucial. Mention how long you’ve been in business, your speciality and the markets you serve. “I like a clean website where I can quickly get the information about what this contractor does,” says Bargen. He suggests you may need to bounce some ideas off other people to get the wording right. “A lot of contractors are creative in the building process, but with a website you also have to be creative in the writing process.” Throw your personality into the site, he advises.

▲ Photos of your work. Not just any photos. Good photos of the jobs you’ve done. It also helps if you have an explanation attached to the photo that outlines what the job entailed and some of the special features you put in.

▲ References. Not all contracting websites have references, but a couple of quotes from satisfied clients will help to legitimize your business. Some sites link the comments to photography of the customer’s renovation. “I like the idea of quotes from customers,” says Bargen. “Something like I loved the workmanship’ or ‘Your guys were great to have around’ adds some personality to a website. I like it better than a Yellow Pages ad, which just has a name and a phone number.”

▲ Contact info . Make it easy for potential customers to get hold of you. Contact name, address, phone number and e-mail address are all essential components of a good website. cc

WHO TO BLAME FOR CANADIAN CONTRACTOR’S 20TH YEAR

On the 20th anniversary of Canadian Contractor, I’d like to pay particular tribute to the outspoken contractors who have been advising us since our first issue. You know who you are. And to Rob Koci, our founding editor (later publisher) who came up with the idea for this magazine in the first place.

In 1999, a team of three of us at Rogers Media were struggling to publish the perennial money-losing trade book Hardware Merchandising (now defunct). We were at a trade show setting up our booth when Koci first invaded our space, introducing himself as a house framer and renovator who was “attempting to be a freelance writer.” Something about all his joints screaming in pain from repetitive strain injuries and how he needed to get off the tools.Compassionately, we told Koci to go away because we had no freelance funds for him (see previous paragraph).

“Then I’ve got an idea for you,” said Koci, undeterred. “Why don’t you publish a trade magazine for contractors that tells the truth?”

“The truth about what? Again, we don’t have any money for you.”

“The truth about clients that won’t pay you. The truth about how you’re going to be pumping gas for a living unless you figure out how to run a business. And the truth about why you are going to have to work for cash, sometimes, just to get by. Why don’t you publish a magazine about that stuff?”

Back to the office after our trade show, it was budget time. Our boss asked us to submit ideas for “new revenuegenerating projects” for 2000.Unfortunately, we were not flush with inspirational ideas to generate cash for the new millennium. In fact, most of us were looking for other jobs, since we had such a loser on our hands with our hardware mag. Half-heartedly, we threw the idea of a “no-holdsbarred magazine for contractors” into the hopper. I think we suppressed the idea about tax-evasion and “working for cash.” Asked for a full proposal, we threw a few

numbers together and got Koci to start writing stuff for our first of two annual issues (Spring/Summer 2000). Having no job for him, we promised him freelance money only if we could sell any ads. He would later tell us that he wrote the first issue on his laptop from a bench on the boardwalk of The Beaches, because he hated working inside. Prima donna. Koci certainly didn’t fit the image of an “editor” – an ink-stained idealist. Koci looked like the contractor he actually was: squinty-eyed, leather-skinned and wiry as hell. He didn’t want anything to do with offices, The Canadian Press Style Guide, journalistic principles or decorum. “I’m not really a writer. I’m a contractor,” Koci warned us.

By Steve Payne Former Editor/Publisher Canadian Contractor

When he sent us his stories, we found out this was true. Badly-written, semiliterate crap it was. It would all need a rewrite, at first, before Koci got much, much better.

But Koci was giving us something we had never thought of publishing before. A trade magazine that talked about the real problems that its readers were having, not the ones editors from journalism schools thought they should be having. Suddenly, we were flooded with emails and phone calls from contractors who loved the kind of “anti-“ trade magazine we were suddenly publishing. Two issues became four, then six times a year.

Within a few years, Canadian Contractor became a very profitable magazine because advertisers were very interested in putting their messages in a place that was akin to a contractor desk at a lumberyard at six o-clock in the morning. With more than 30,000 renovation contractors and homebuilders participating in the conversation.

To all of the many friends of Canadian Contractor in our industry who helped Rob and me out over the years, as we tried to keep telling the kind of stories that real contractors share between themselves, thank you.

And please make sure you keep in touch with new editor Pat Flannery. He’s one of us. cc

BUILD SMARTER, BUILD STRONGER

Building codes today demand buildings and structures be built with greater energy efficiency by utilizing continuous insulation. Nudura insulated concrete forms (ICFs) allow you to complete the building envelope with one building product for a stronger and more efficient structure.

ICFs give you the opportunity to build residential, commercial, and a variety of other build projects while achieving the demands of todays building codes.

Begin your journey online today to become a trained Nudura ICF Installer by visiting nudura.com/online-course..

NUDURA® INSULATED CONCRETE FORMS COMPLETE THE BUILDING ENVELOPE IN ONE STEP.