Mayors discuss industry’s role in fight against poverty

BY LIZA MAYER

“Most definitely the best news ever!” Mayor Georgina Ollerhead’s excitement was palpable on the other end of the line. As the COVID-19 pandemic continued its relentless spread worldwide, the news that Northern Harvest Sea Farms regained its farming licenses in the Fortune Bay region of Newfoundland and Labrador was much-needed good news for Ollerhead and her hometown.

Ollerhead is the mayor of Harbour Breton, a small fishing community of 1,600 people. The town, situated near the mouth of Fortune Bay, is home to Northern Harvest Sea Farms owned by Mowi Canada East, and the Barry Group fish processing plant.

continued on page 24

There’s more work for processors as restaurant lockdowns force seafood producers to change course

BY MATT JONES

he COVID-19 pandemic has affected aquaculture like any other but there’s one industry sector that’s seeing business go up: seafood processing.

Tech giant uses expertise to bring immediate and far-reaching change in fish farming

BY LALOU RAMOS

It has long been conceded that when it comes to funding and attention, the ocean always gets the short end of the stick.

Look no further than the disparity between the budgets allocated for space exploration and oceanic research to see where the US government’s priority lies. Our love for the outer space has inspired us to map in brilliant high-resolution images nearly 90 percent of the surface of Mars while over 80 percent of our ocean remains unexplored and unmapped.

Billionaire entrepreneurs like Elon Musk and Richard Branson may have the resources to explore the potentials of the deep, but they too would rather look skyward for business opportunities.

That is why is it refreshing and encouraging to hear that X, the innovation lab within Alphabet – the parent company of Google –is actively involved in ocean research.

continued on page 12

In the past, Infectious Hematopoietic Necrosis (IHN) has resulted in devastating economic losses to the Canadian salmon industry.1

The success of APEX-IHN® vaccination programs has meant that the risk of IHN is not often spoken about, and yet the potential threat of infection from wild fish remains ever present.

Don’t let IHN become the ‘elephant in the room’, keep protecting your salmon, and your profits, with APEX-IHN®.

Areport examining the impacts of fluctuating sea surface temperatures on fisheries and aquaculture has a finding that many might find surprising: El Niño, or the warming of sea temperatures, has some positive impact on aquaculture after all.

The warming of the sea surface has always been seen as bad news because it affects marine life in the Pacific Ocean and causes weather anomalies, such as severe storms, flooding and drought.

But a new study from the Food and Agriculture Organization said “extreme” El Niño is associated with an average increase of 6,000 tonnes of aquaculture yield in North America. “Extreme” El Nino is where temperatures are warmer than average by 0.5 °C or more for at least five months and where precipitation is over 4 mm higher than normal between December and February in the eastern Pacific.

On the other hand, the opposite phenomenon – periods of irregular cooling called La Niña – is associated with an 8,000-tonne decrease in yield in the region.

Chris Harrod, who led the report’s aquaculture component, noted however that fluctuating sea surface temperatures affect different parts of the North American region in different ways. “Conditions that have positive effects on the climate in New England may have the opposite impact in the Gulf of Mexico, and vice versa,” he says.

The report does not look into the specifics of how El Niño or La Niña impact specific species of fish in different regions, but Harrod says such research would be extremely valuable.

“We would need to analyse information for each of the key species at the level of state or even individual producers to get a more subtle idea of the factors driving the patterns we showed. This is an important thing to do, but will take considerable time and effort.”

– Matt Jones

Aquaco Farms’ first harvest in late April was a bittersweet milestone for CEO and founder Joe Cardenas.

While it was the culmination of years of hard work for the banker-turned-fish farmer, the harvest came when most restaurants have shut down due to the COVID-19 pandemic.

Aquaco Farms is a recirculating aquaculture facility in St Lucie, Florida. The farm has been harvesting fish weighing 1-lb on average every Friday since late April.

Wholesalers that sell to restaurants were its intended market, but as the pandemic broke out, Cardenas found himself behind the wheel delivering the fish to retail customers. A few of Aquaco’s investors have also pitched in to help deliver orders and three drivers have been hired.

“Fortunately our production numbers of approximately 2,000 lbs a week (50 mt annually) are absorbable as the hospitality sector creeps back open in Florida,” he says.

Facebook and word of mouth have been the source of most of the demand. “We started with a home delivery service based on people in quarantine wanting our fish, yet not yet dining out. We sell 5-lb boxes of pompano and deliver within a 90-mile radius. The feedback has been amazing.”

Ever the optimist, Cardenas forecasts more sales. In fact, he is hiring his first sales staff.

In the tradition of many start-ups, Joe Cardenas found himself serving both as CEO and delivery truck driver to transport pompano to quarantined consumers Photo: Aquaco Farms

The world’s appetite for fish and fish products shows no sign of slowing, according to the latest report from the Food and Agriculture Organization (FAO) of the United Nations.

fish consumption will rise by 5 percent to 21.5 kg per capita in 2030 as incomes rise and post-harvest methods and distribution channels expand

Both fisheries and aquaculture sector significantly expanded in the past decades and total production, trade and consumption reached an all-time high in 2018, according to “The State of World Fisheries and Aquaculture” report.

Aquaculture accounted for a record 46 percent of global fish production in 2018. That figure is projected to grow to 53 percent in 2030. In volume terms, aquaculture production is projected to grow by 32 percent to 109 million tonnes in 2030.

The report however said growth rate will slow down to 2.3 percent (from 4.6 percent) over the period 2019–2030 as the broader industry adapts and enforces environmental regulations; suitable farming sites become less available; and disease outbreaks related to intensive production practices become more prevalent.

However, the slower growth rate doesn’t mean a decrease in production, the report emphasized. “Expressed in percentage terms, growth rates are usually higher when the calculation starts from a low base, and decline as the size of the base grows.”

It said though: “More needs to be done to ensure fisheries and aquaculture around the world are sustainable. Failure to implement adequate measures threaten the contribution of the sector to food security and livelihoods.”

Salmon farmers have reduced use of antibiotics and medicinal sea-lice solutions by half over the past seven years

Photo: NAIA

The use of antibiotics and chemical delousing methods fell by 50 percent in salmon farming over the last seven years among members of the Global Salmon Initiative (GSI).

This was among the highlights of the latest annual sustainability report from the GSI, an initiative established in 2013 by global farmed salmon producers focused on making the industry sustainable.

The latest report tracked data from 2013-2019 from GSI’s 14 members, which represent more than 50 percent of the global farmed salmon industry.

The annual report attributed the improvements to better antibiotics stewardship, disease control and fish welfare. Sea lice treatments have become more “holistic,” the GSI said, with the farmers’ use of non-medicinal approaches rising by 130 percent over the seven-year period.

The report also showed that almost 65 percent of the total salmon production of GSI members is Aquaculture Stewardship Council (ASC)-certified. ASC certification recognizes aquaculture producers as environmentally and socially responsible.

The National Fisheries Institute (NFI) on 16 June cautioned its members not to be misled by news stories linking imported salmon to COVID-19 that emerged in a Beijing market.

NFI said the news on 13 June in China alleged that a “European strain” of the coronavirus has been discovered in the Xinfadi food market in Beijing and that imported salmon may have brought it into the country. The news led to the cancellation of orders for Norwegian salmon that weekend.

But former FDA commissioner Dr Scott Gottlieb told CNBC’s Squawk Box that the theory is unlikely. “The idea it hitched a ride on fish is highly implausible. I mean it is absurd. I can’t see any plausible scenario where this virus rode in on a salmon,” he said. Other experts echoed those sentiments.

On 17 June, Norway's fisheries and seafood minister announced that Chinese and Norwegian authorities have concluded salmon from Norway was not the source of the coronavirus found at the market, reported The New York Times.

China is still a small — but fast-growing — market for salmon.

Senator Jack Bailey believes the key to curtailing oyster thefts in Maryland is to ease conflicts between farmers and property owners

An aquaculture bill being proposed in Maryland may hold the key to resolving conflicts between oyster farmers and landowners in the state and, in the process, stem oyster thefts.

Thefts continue to be a big problem for US oyster farmers (see ANA Mar/Apr 2020), but in Maryland, they are largely not prosecuted because a 2009 law precluded property owners from having a say in aquaculture operations in the waters near their properties.

Richard Fritz, state attorney for St Mary’s county where most of the state’s aquaculture leases are concentrated, believes the law infringes on the landowner’s riparian rights so he refuses to prosecute any cases involving theft or damage to oyster farms in front of someone else’s property.

Last year, Senator Jack Bailey introduced Senate Bill 711 to break the impasse.

“I was a natural resource police officer for 30 years, so I am extremely familiar with the conflicts that exist between landowners and watermen. I have negotiated and been involved in quite a few of them,” says Bailey. “So I introduced this bill for aquaculture conflict resolution.”

SB711 is intended to compel the Department of Natural Resources to seek conflict resolution between property owners and farmers. If a property owner objects to a lease that’s 50 feet off their shoreline, could a compromise be reached to move that lease to 100 or 150 feet offshore?

“I believe that is the way to successfully manage this,” adds Bailey. “If we give them some buy-in to be involved in the process, I think they will be the best protectors that you could ever have. They’re going to watch it, to make sure nobody messes with it.”

The bill was unsuccessful in the Maryland General Assembly in March due in part to the assembly adjourning nearly three weeks earlier than planned because of the COVID-19 pandemic. Bailey is planning to reintroduce the bill in the next legislative session in January 2021.

- Matt Jones

Anovel alternative protein derived from wood residues has proven to be nutritionally effective as feed for juvenile Atlantic salmon, trials show. The protein, called Called SylPro, is a result of a technology that converts wood residues into protein for use in fish and other animal feed. North Carolinabased biotech firm Arbiom is behind the product.

Study results showed no statistical difference in body weight gain for SylPro compared to the control diet up to the 20-percent inclusion level, the company said.

Scientists from Norway have sounded the alarm on the welfare of cleanerfish when used as delousing agents for farmed salmon.

The scientists, from the Norwegian University of Science and Technology and the Norwegian Institute of Marine Research, told Norwegian SciTech News about the need for more insight into what measures the industry could take to further improve the wellbeing of cleanerfish, after hearing similar concerns from local fish farmers.

While their deployment reduces the salmon industry’s reliance on chemical delousing agents, more robust data is needed on their effectiveness and mortality rates when they are deployed in salmonid cages, the scientists said in the report released in April.

In May, Mowi’s operations in Atlantic Canada saw more than 28,000 lumpfish (Cyclopterus lumpus) die in two separate occasions during and post-transfer to its farm sites. The company attributed the deaths of the cleanerfish at the Newfoundland site to rough sea conditions immediately post-transfer, while in New Brunswick, the lumpfish died during transport due to an undisclosed “non-disease” issue.

“Fish welfare is very important and taken very seriously,” said Danny Boyce, an academic leading the cleaner-fish initiative in the Canadian province of Newfoundland and Labrador, where Canada’s first commercial hatchery will be built.

“Constant improvements at the farm level to help improve survival, including fish health, feeding stations, hides and placement locations and staff training are being made,” Boyce said in an email to Aquaculture North America (ANA)

Dr Elizabeth Fairchild, who represents the University of New Hampshire in the US Lumpfish Consortium, said the issues highlighted in the Norwegian report are “definitely of concern and an area all cleanerfish researchers are discussing.”

“We do plan to evaluate how effective lumpfish are in delousing the trout as well as how they fare in the cages,” Fairchild told this publication.

Norway has been using cleanerfish as delousing agent over the past five years but in North America, the practice is just beginning.

Editor Liza Mayer

Tel: 778-828-6867

lmayer@annexbusinessmedia.com

Advertising Manager Jeremy Thain

Tel: (250) 474-3982

Fax: (250) 478-3979

Toll free in N.A. 1-877-936-2266 jthain@annexbusinessmedia.com

Media Designer Svetlana Avrutin

Account Manager Morgen Balch mbalch@annexbusinessmedia.com

Audience Development Manager / Subscriptions Urszula Grzyb

Tel: 416-510-5180 ugrzyb@annexbusinessmedia.com Fax: 416-510-6875 or 416-442-2191

Regular Contributors: Ruby Gonzalez, John Nickum, Matt Jones, Lynn Fantom

Annex Privacy Officer

Privacy@annexbusinessmedia.com

Tel: 800-668-2384

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Microplastics and contaminants associated with marine litter have negative effects on marine life and may affect food safety. In one of the world’s most densely populated regions where most are living in coastal areas, marine litter has serious negative effects on fisheries and aquaculture, acknowledged the United Nations.

Enter FRED, a "vacuum cleaner" for the ocean being developed by California nonprofit Clear Blue Sea. Short for Floating Robot for Eliminating Debris, FRED is a solar-powered marine vessel designed to collect trash on open bodies of water.

FRED’s debris collection conveyor belt picks up floating debris sized from about 10mm to 1m long. The vessel is still in development but the team hopes to pilot test a design in Hawaii this year. The team is working on a 50-foot version of the trash collector.

Clear Blue Sea says it is partnering with sustainable recycling organizations to ensure the plastic is repurposed and does not end up back in the ocean. It is seeking funding (www. clearbluesea.org) to fulfill its mission to cleanse the oceans of plastic pollution.

While the challenges posed by marine debris, plastics and microplastics are well known, so too is the fact that no single solution exists to solve them. Another nonprofit, called The Ocean Cleanup, is in a more-advanced stages of development of its garbage collection system for the ocean.

In light of on-going developments related to the COVID-19 global pandemic, Annex Business Media, organizer of the annual RASTECH Conference and Tradeshow, has decided to postpone the event to 3-4 Nov 2021. It will be followed by the RAS Investors’ Workshop on 5 Nov 2021.

The event will remain in the same location at the Westin Hilton Head Island Resort in South Carolina, USA.

Grieg Seafood achieves ASC certification milestone

Grieg Seafood’s five farms in Nootka Sound in British Columbia are now certified according to the standards of the Aquaculture Stewardship Council (ASC). Grieg operates 22 farm sites in BC, and Nootka Sound is the company’s first fully ASC-certified region.

The milestone is even more momentous for the company because it came amidst the COVID-19 pandemic. Grieg’s certification team said it has implemented measures to ensure the wellbeing of independent third-party auditors who visit to evaluate the farms.

All of Grieg’s farms in the province are on track for ASC certification by 2021, the company said.

exas officials released on May 21 the guidelines for oyster farming in the state, paving the way for the birth of a new industry.

Texas is the only coastal state in the US that does not have a farmed shellfish industry, that is, until Governor Greg Abbott signed in May 2019 the bill that allows oyster farming along the Texas Gulf Coast.

The Texas Parks and Wildlife Commission developed the guidelines at the direction of the Texas Legislature. The guidelines, which take effect in September, are meant to ensure the new industry is successful while protecting important coastal habitat such as seagrass meadows and natural oyster reefs. They include:

• Only the native species, Eastern oyster (Crassostrea virginica) can be used; seed or young oysters should originate from close to where they will be cultivated.

• Growing operations cannot be located where they could harm important natural areas, including seagrass, mangroves, and bird nesting sites.

• The Texas Parks and Wildlife Department (TPWD) will inspect each operation site annually.

• Growers must have a plan to secure or remove gear during storms and are responsible for labeling equipment with identification tags and retrieving any lost or abandoned gear.

Oyster farming could enhance coastal environments ad provide economic benefits to coastal communities in Texas, says a non-profit Photo: ©Bart

TPWD Deputy Director Lance Robinson was expecting the application process to begin sometime in June, or roughly two weeks, following the publication of the new rules in the Texas Register.

He acknowledged that individuals interested in growing oysters would have to go through a number of agencies to secure the required permits.

“The length of time for an applicant to obtain all of the necessary clearances from other state and federal agencies is unknown at this time but all are prepared to start the process once contacted by an applicant,” Lance told Aquaculture North America (ANA)

Holly Binns, director of The Pew Charitable Trusts’ ocean and coastal conservation work in the Gulf of Mexico, acknowledged the potential of oyster mariculture in satisfying some of the state’s consumer demand for oysters and provide economic benefits to coastal communities.

“If done right, oyster aquaculture could enhance coastal environments by contributing some of the benefits that wild oysters do, such as filtering pollution from the water and providing habitat for small fish and other marine life,” she said.

More economic analyses are needed to encourage the type of investment in fish breeding innovations, says a geneticist

The aquaculture industry is sorely behind other types of farming when it comes to innovations that enhance animal breeding, but support for academic research in this area could help it catch up, says author and professor of Aquaculture at Louisiana State University, Dr Greg Lutz.

Speaking at the Aquaculture Genetics webinar organized by Auburn University in May, Lutz said the investment needed to apply the modern molecular methods required to help the industry advance remains largely in the purview of sectors that are big enough to attract them, such as salmon — and to a lesser extent — shrimp and tilapia.

“In some countries, there is a modest level of government support for such activities, but many researchers in many countries are forced to focus their efforts wherever the funding leads them. Perhaps the first research work that should be supported would involve more economic analyses in order to help build the confidence to encourage the type of investment these industries require,” he said. He suggested that economic studies will assist policy makers and researchers in deciding which interventions are most beneficial.

Webinar host Dr David Cline, an extension aquaculturist at Auburn University, said producers and policymakers often perceive genetics as a complicated and intimidating topic. “As a result, they may be reluctant to delve into the subject in spite of its increasing relevance,” he said.

Aquaculture has made massive improvements in terms of production systems, but those can only go so far, said Lutz. He said there’s also been huge progress in the field of nutrition but there is more room to grow.

He sees “tremendous gains” being made over the next 20 years in breeding innovations via genetic editing, which improve yields in animal protein production and industry sustainability.

“There are still a lot of things that mom-and-pops can do on their farms in terms of how they manage their breeding stock, how they do their selection, or if they want to cross distinct lines,” but innovations of this scale (genetic editing) will come from breeding companies, he said. “All the good fish are going to trickle down from these breeding companies.”

The Aquaculture Genetics live broadcast on Zoom attracted 300 participants worldwide and has been the most popular so far, said Cline. The next one currently on the calendar is scheduled for July 10th at 1pm central time. Kim Thompson, director of the Seafood for the Future Program at the Aquarium of the Pacific, will discuss aquaculture perceptions and sustainable aquaculture.

With the restaurant and catering markets mostly closed, aquaculture producers have shifted some products that were destined for those markets toward retail, which requires additional processing.

“Retail sales are stable and, in some cases, actually increasing as families are looking for healthy meals to cook at home and new meal ideas,” says Shawn Hall, spokesperson for the British Columbia Salmon Farmers Association (BCSFA). “That doesn’t make up for the decline in restaurant sales, but it helps.”

British Columbia-based processor Brown’s Bay Packing is somewhat isolated from much of the market impact because its role is in the very early part of the supply chain of Cermaq and Grieg Seafood. What weighs on the company’s operations and bottom line are the costs involved in implementing new safety measures and in expanding its workforce so it could schedule shifts further apart.

“We’re two months in, we haven’t had enough month-ends and profit/loss analysis. It will impact our bottom line but I can’t tell you yet if it is 20 percent or 10 percent,” says co-owner and managing director David Stover.

MONUMENTAL SHIFT

In this crowded market, Pacific Seafood is educating its sales team to provide more value and support to customers when businesses resume.

“This is one of those events in history that we’ll never forget and we’ll mark time by because things will be different after this. It won’t ever go back to the way it was.

For Oregon-based processor Pacific Seafood, 95 percent of the restaurant market disappeared with the closures of catering services, casinos, cruise lines and schools.

“There was a pickup in retail, but people in some cases weren’t even comfortable going to a retail location. They were looking for options,” says Bill Heuffner, vice-president of marketing and development.

The business-to-business distributor had to switch gears if it was to continue paying its fishermen and keep its aquaculture operations running. It established its own e-commerce platform and started selling fresh and frozen product directly to US consumers.

“We built the capability, we got our operations up and our distribution locations ready to fulfill these types of orders and did that in a matter of weeks,” says Heuffner. “It was pretty monumental – something we’d considered for years – but we were able to marshal the resources and make it happen relatively overnight. And we’re improving on that day to day.”

In grocery stores, while retail sales increased, so did competition as other seafood distributors also redirected toward the retail market the products that would have gone to restaurants.

“The competitive landscape is greater now than I’ve experienced in my career in this business,” says Tyson Yeck, Pacific Seafood vice-president of sales. “But this is really an opportunity to separate ourselves as leaders and true partners for our best customers around the country. Our food service and restaurant customers need our help now more than ever and the retail partners around the country are receiving offers (of support) from producers and farmers around the country.”

The companies have to be ready to be nimble, agile and change for that new norm,” says Hueffner.

“As restaurants start to reopen, [our sales team] can be more than just the fish peddler, but actual consultants to help the restaurateurs and our partners in that segment of the business come out of this,” he continues. “It’s not going to be easy and they’re going to need real true partners, not just sales people pitching their products.”

Such moves show the seafood industry’s forward-thinking and resilience, says Hall of BCSFA. “We’re going to be here to feed people and safely maintain jobs through the crisis. And when the time is right, we’re going to be here to support the recovery.”

For Brown’s Bay Packing, the new working conditions, such as shorter shifts, have actually been beneficial.

“When we ran four or five days a week, 10-12 hour shifts, we didn’t get a response from female job applicants. We’re getting good response now,” says Stover.

He hopes the new measures will lessen the impact of seasonal cold and flu on the workforce. The workplace changes at Brown’s Bay Packing will likely stay even after the pandemic because of the benefits.

Hall says that is also likely going to be the case for the other association members who have implemented similar measures.

Meanwhile, Canada’s federal government has allocated $62.5 million for aid to seafood processors. Prime Minister Justin Trudeau said that funding could be used to buy equipment, such as freezers or storage space, to help them adapt to the changing market.

Hall expects some of the BCSFA’s membership to apply for aid.

Stover was initially disinclined to apply for the aid because there are companies that are suffering much more than Brown’s Bay Packing. However, there is one potential avenue that interests him: automation.

“There are pieces of equipment that we could acquire that would allow more physical distancing. It would make the work less rigorous, safer. That will appeal to not just the young workers, but also to mature workers,” he says.

COVID-19 is upending all types of companies. Dismal first quarter results virtually across the board have given us a glimpse into the devastation the pandemic has wrought. But despite this volatility, lenders are still supporting the aquaculture industry because of its critical place in the food sector. A tight credit market however means management teams have to be on point. It is against this dire backdrop that lenders are being forced to pick the winners from the losers.

As a critical food sector, aquaculture has a leg up with lenders since cash flows haven’t completely evaporated compared to hospitality, restaurants, and other sectors shut down by the coronavirus. We’ve been working closely with banks and institutional investors to help them understand who’s well placed to survive the pandemic. Here are the key questions that they have been asking aquaculture and seafood executives when lending into this crisis.

Operationally, how have you prepared for COVID-19?

In sum

COVID-19 outbreaks at Smithfield, JBS, and Tyson facilities demonstrated how poorly prepared the meat processing industry was to implement the social distancing needed to protect its line workers. These outbreaks have led to closures, sickened employees, and likely, future lawsuits.

Fish processing has reportedly had some incidence too (think Pacific Seafood, Highline, and Bornstein Seafood) although not as severe, and lenders will want it to stay that way. Thankfully, aquaculture sites can be relatively remote and crowding poses a limited risk unlike processing, so farming is less of a concern in a COVID-19 world. Still, there should be a comprehensive plan to allow any staff that can work from home to do so; cybersecurity and communication protocols for remote work; and proper guidelines and personal protective equipment (PPE) for frontline workers who can’t be isolated. Lenders want to understand how you’re adapting your work environment to the current health crisis and that your operations can still operate effectively without putting your employees in danger.

How has the business pivoted to continue to generate revenues?

With hospitality and the food service sectors on hiatus, seafood companies are driving value-add products to retail and ecommerce channels. Chinese seafood demand is starting to rebound for those businesses with the scale and access to deliver to that part of the world. Lenders are looking to understand the depth of your relationships in these functioning markets and how effectively you can service them. Retail customers, for instance, are focusing on core products such as salmon, cod, and shrimp where supply chains are developed and deliveries reliable. Grocers also want products with longer shelf life such as fillet and frozen. Companies with this market depth are definitely being supported by lenders.

That’s not saying that only these producers and processors will have any luck receiving capital support. The key takeaway is for companies to demonstrate how their market niche is keeping the cash flow coming and the lights running.

Do you have liquidity for an extended downturn?

We are back to a “cash is king” environment and, naturally, lenders will be trying to understand your balance sheet and where you can draw additional support if needed. The company’s cash position and revolver availability is always the starting point on this question, but are there any unencumbered assets such as real estate, processing equipment, or vessels that can be used to raise money in a pinch?

There will also be concerns on your counterparties where liquidity can be caught. Lenders know that deliveries are taking longer as a global supply chain works its way through COVID-19 related delays. On the receivables side, weak customers may be pushing their payments out or could be facing their own credit issues.

Working capital is going to be the blind spot for many companies since so many assumptions must be made in such a volatile environment. Even long-standing relationships are getting stress tested and lenders will want to know if additional liquidity will be needed to fill any gaps.

Over the next 6-months, what is your current rate of cash burn?

Cash burn goes hand-in-hand with liquidity, so lenders have been diving deep into aquaculture companies’ burn rates, and management teams should be ready with projections for at least the next six months.

By Howard Tang

These details should tackle not only operational needs such as working capital and staff, but maturing debt, priority maintenance and other near-term liabilities. If the company is eligible for various government stimulus programs, these projections will be a good time to showcase them.

Expectations are for a slow recovery from COVID-19 so lenders are testing bearish scenarios and figuring out how much product needs to be sold to break even. Operating flexibility will also be important to demonstrate in your cash burn models.

What parts of the business can be shut down; maintenance put off for the future; or negotiations conducted to preserve cash? And what are the long-term implications to the business? Your projections should address these questions and give lenders an honest sense of these options.

It’s great to have long term visions of expansion and what the business will be like after COVID-19 passes, but lenders need to deal with the here and now. So discussions should surround the key concerns raised by these questions, otherwise you may find little interest from lenders for those grand plans.

BY LYNN FANTOM

During the Great Depression, “Aunt Sammy,” a radio character invented by the USDA as Uncle Sam’s matronly counterpart, helped homemakers stretch budgets with new recipes for casseroles, loaves, and croquettes — still popular comfort food today. For the first time, government food guides imparted nutritional advice, foreshadowing the food pyramid and labeling practices to come decades later.

In addition to changing how people ate, the economic tragedy of the 1930s led to US legislation that created a better transportation system. According to “A Square Meal” by Jane Ziegelman and Andrew Coes, New Deal infrastructure allowed farmers to deliver harvests to regional centers for national distribution.

Legacies of the Great Depression still linger. Will the COVID-19 crisis also alter future consumer preferences and the food supply chain? Will some changes even be for the better?

DIRECT TO CONSUMER

waterfront communities. In fact, only about five percent stays local, according to Ben Martens, executive director of Maine Coast Fishermen’s Association.

That may change for good.

For example, Hoopers Island Oyster Co on Maryland’s Eastern shore traditionally has sold to wholesalers serving hotels and restaurants in Baltimore and Washington DC, as well as other cities in the Northeast and Southeast.

“We had planned to roll out a new direct-to-consumer sales effort in the fall, but when the coronavirus hit, we decided to speed up that initiative,” said managing partner Ricky Fitzhugh. The Chesapeake Bay grower began selling at local farmers’ markets and produce stores, which “moved nice quantities of oysters.” They trialed phone orders and online ordering, with parking-lot pickups around Maryland.

“It’s been extremely successful,” Fitzhugh said. “We plan to continue these activities year-round in addition to wholesale sales for restaurants and hotels when that market reopens.”

At the largest producer of farmed shellfish in the United States, Taylor Shellfish Farms, the volume of e-commerce sales are up nine times from last year, said Bill Dewey, director of public affairs. He acknowledged however that the growth in online sales don’t come close to making up for lost restaurant sales.

“That is for all our products collectively not just raw oysters and clams. That is partly due to the pandemic and more home consumption and partly due to a focused effort by the company over the past couple of years to build our e-commerce,” he said.

When food is grown close to where people live, that’s a benefit “not to be underestimated,” Hollander, the mussel farmer, noted. The pandemic accentuated that consumer sensitivity.

“I think that in the aftermath of the coronavirus, there will be increased skepticism not only about how people move freely between countries, but also about how products move,” Johan Andreassen, chief executive of Atlantic Sapphire, tells this publication. He has frequently linked the potential of his giant RAS operation in Florida to a belief that consumers want to buy local, even if it is from an indoor farm.

Looking to the future, Andreassen added, “Will it be as desirable to import a lot of seafood product that has gone for further processing in China? I don’t think so.”

With an eye toward traceability, John Ng built his steelhead trout farm in New York’s Hudson Valley with a strong brand association to the local farm-to-table community. In fact, many chefs have listed his RAS operation on their menus alongside fruit, vegetable, and cheese purveyors.

Like Fitzhugh, Ng had been thinking of adding a new distribution channel: e-commerce. Already established at New York area restaurants and with retailers like Fresh Direct, he had sourced no-Styrofoam packaging from a Canadian supplier and tested shipping options. “We shipped fish to ourselves to confirm quality,” he said.

The COVID-19 crisis moved the expansion to e-commerce into high gear.

Online ordering launched in May, along with an updated website. Initially, customers can choose among three different sizes of whole fillets. Later in the year, Ng plans to offer portion-size (four to size ounces) twin fillet packs.

“In this current time, it’s valuable to highlight local production with a crop that is isolated from the external environment. I see a bright future for us with online sales.”

He may be right. According to market research firm Mintel, 41 percent of US consumers say that they are shopping online more often than they were last year — and that was before the pandemic.

FROZEN SEAFOOD: UNSUNG HERO

When consumers did go to supermarkets during the shutdown, trips were less frequent and better planned. In surgical masks and gloves, they ventured into aisles almost foreign to them: the unglamorous shelves of canned goods and uncomfortably frigid cases of frozen food.

Those traffic patterns were among the challenges for Love the Wild, Jacqueline Claudia’s pioneering line of frozen, farm-raised fish. Launched in 2014, it attracted investors like the actor and environmentalist Leonardo DiCaprio, but ceased retail operations April 1.

“Had we been in full distribution and firing on all cylinders, this really could have been our moment,” said Claudia.

Data suggest she can rightfully lay claim to starting a company “ahead of its time.” Between mid-March and April, US sales of canned and frozen seafood shot up 37 percent compared to a year earlier, according to IRI, a market research company that specializes in retail intelligence.

“People’s expectations for frozen — and frozen seafood in particular — are low,” Claudia said. But trying it at home during the pandemic could have begun to chip away at those preconceptions.

Blind taste tests have validated that eating is believing. In fact, Gabe Watkins of steelhead farm Riverence said that last year the James Beard Foundation brought together a group of around 75 people for such a tasting to compare flash-frozen and fresh fish. By a large majority, flash-frozen was preferred.

The James Beard Foundation explained why: “The advent of modern freezing methods allows for seafood to be frozen at its peak freshness, capturing its flavor, preserving its texture, and maintaining its high nutritive value.”

“At Riverence, we flash freeze within an hour of harvest,” Watkins said.

Like other farmers, Riverence was hit hard by the pandemic, resulting in a lay-off of 162 employees and a 25-percent pay cut for salaried staff. But the acquisitive, vertically integrated organization has invested in flash freezing technology and clearly believes in it.

“Frozen is where seafood is going to win or lose,”

Jacqueline Claudia has predicted. “I really believe this when I look at people’s budget, especially going into a recession.”

its website to offer recipes like Oyster Rockefeller Dip and Oyster Pot Pie, comforting southern dishes for the home-bound.

When wholesale markets closed, the situation to move inventory became so dire that collaboration ensued to get consumers to eat more fish at home.

For example, the Seafood Nutrition Partnership brought together 35 organizations to form the group called Seafood4Health Action Coalition and sponsor a 12-week social media campaign to encourage seafood consumption. Called “Eat Seafood, America,” the campaign encouraged consumers and the industry to post photos of seafood meals. (The health-oriented campaign would have pleased Aunt Sammy.)

Maine Aquaculture Association took another tack: a series of recipes and short instructional videos in a series called “Sea Farm to Table.” With each recipe, it included where to buy the local Atlantic salmon, mussels, oysters and kelp.

And some growers took on the challenge alone. During the pandemic, Hoopers Island turned to social media and

“I believe that as people are introduced to oysters and the many ways they can be eaten and prepared, the more overall sales our industry will see in the future,” said the company’s managing partner.

But, as marketing gurus are quick to say, the job of building awareness and changing behavior is one that requires sustained effort. And companies alone may not have the resources to do that.

Reflecting on her experience with Love the Wild, founder Claudia said, “Look at the Pork Board, the Peanut Board, the Avocado Board. They’ve come together as an industry to do category-level marketing. That wasn’t work that, as a tiny start-up, we could do ourselves for everybody. The industry needs to start acting together because the world needs us to.”

And that kind of collaboration, along with other recent innovations, may persist long after the time of coronavirus.

Wenger innovative extrusion solutions deliver clean, durable, nutritional feeds specifically designed for the most e cient RAS operations. Feeds produced on Wenger systems maintain their integrity better and longer, for clean and clear water. So you feed the fish, not the filter.

Learn more about the Wenger RAS advantage. Email us at aquafeed@wenger.com today.

X is behind Project Foghorn, which successfully produced carbon-neutral fuel from seawater. The project had to be retired unfortunately as the company realized it would not be feasible to bring down the cost of such fuel to that of gasoline even 10 years down the line. This makes the project an economically risky proposition.

More promising is X’s recent announcement on Tidal, a project geared at developing high-power underwater camera and machine-learning platform to gain better insights into the health and sustainability of the ocean.

Alphabet’s X calls itself a “moonshot factory” and its works, “moonshots.” The term is a playful jab at their seemingly lofty goals and science-fiction-like approaches to developing tech solutions. The purpose behind every moonshot, however, is sensible and practical, explains X’s general manager, Neil Davé. “We focus on real-world problems which, if solved, would improve the lives of millions of people. We look for radical solutions that can deliver 10X improvement on the way things are today. Finally, we develop breakthrough technologies that could make the solution a reality,” Davé says.

Since its creation in 2010, X, previously an R&D arm of Google, has hatched many groundbreaking technologies that are now stand-alone companies within Alphabet including: Waymo driverless cars, Wing delivery drones, and loon balloon-powered Internet connectivity. The difference between those nascent technologies and Tidal is that the latter addresses humanity’s basic and most pressing needs.

“Tidal is working on a moonshot to protect the ocean and preserve its ability to support life and help sustainably feed humanity,” explains Davé.

“Nearly half of the world relies on fish for food. And, with the kind of population growth expected to hit 10 billion people by 2050, it’s really crucial for us to find sustainable ways to feed people while also protecting our environment,” he adds.

Alphabet, the parent company of Google, is actively involved in ocean research. It aims to find 'radical solutions that can deliver 10X improvement on the way things are today.'

fixture for over 30 years in the industry, Morenot Canada Ltd (formerly Campbell River Netloft) has seen a lot of changes. Fully owned by an industry pioneer in Morenot Aquaculture of Norway since 1996, the company only just last year finally changed the name to reflect its inclusion in the Morenot Group of companies operating around the world.

This close connection allows Morenot Canada to offer all of the services available within the group globally, to their customers locally – from nets of all shapes and sizes to design and engineering services as well as mooring analysis, mooring supply and assembly and complete turnkey project management. One such project was the first large offshore rig built for Salmar Norway in 2016-17, where some of the crew from Morenot Canada provided assistance as well. Morenot oversaw this project from start to finish and still maintains the servicing requirements.

In addition to this, Morenot also offers “Aquacom®”, a web-based asset management and maintenance tracking software adapted to aquaculture and the whole production chain from hatchery, sea sites, vessels and processing plants, which helps more customers be more efficient in their daily operations. Aquacom also integrates with Netlog® for up-to-the-minute tracking and compilation of all net statistics and locations in a customer’s inventory.

The innovative minds at Morenot also came up with The FlexiLink® Mooring System. This proprietary Mooring System is the result of years of R&D in collaboration with the research organization Sintef and Norwegian fish farming companies. The system meets all the requirements of NS 9415 with tested and certified components.

This system consists of ropes combined with flexible fibre straps of 50–490-ton breaking load. This provides greater security and reduces the number of components in the mooring. The fibre straps exclude mechanical abrasion and reduces necessary inspection of the grid,

which offers lower maintenance and lifetime costs. The pre-fabricated grid makes the installation simpler and quicker, typically down to a few hours compared to several days when using traditional steel hardware and components. Several of these systems are already in use in British Columbia.

Aside from this, Morenot Canada can also offer traditional mooring components from anchors and heavy chain through to heavy mooring ropes as well as shackles and thimbles and large buoys if required.

”With the 2019 acquisition of Hvalpsund, Morenot now offers the full range of moorings, nets and circular pens. The range of Hvalpsund pens is the perfect fit for Morenot’s patented Flexilink mooring system. The Hvalpsund pen does not only have the widest walking/ working area of any two-pipe circle, it is also metal/corrosion-free and therefore fits perfectly together with the Flexilink mooring in being close to maintenance-free. The new HD500NG has unique safety features such as mooring points, weight suspension points and bird pole sockets being integrated into the bracket – which helps eliminate trip hazards. The 500NG was also developed with flexibility in mind and a variety of design features is available. All in all, this makes the Hvalpsund HD500NG pen (suitable for pen sizes ranging from 120m to 200m) one of the most versatile production platforms available in the market today,” the company said.

With all this to offer, Morenot Canada can be your complete supplier for most of your aquaculture equipment needs. They also maintain a ready, trained crew to supply your regular net service needs – from net washing and disinfection to repairs and alterations of your existing nets, to new builds of containment or predator nets, large or small. With a large inventory of new mesh ready to go, they can also quickly supply seines nets, corklines, dipnets and most other specialty nets as required.

R&D labs are notoriously secretive, and rightfully so, as companies seek to protect the valuable concepts and prototypes developed within its walls. Interestingly there were no big mysteries in the development of Tidal. In fact, X has been engaging with fish farmers around the world for many years now and their input find their way in Tidal solutions.

“We started working with fish farmers to understand what life is like on the ocean, and to gain insight into the challenges they face on their farms, especially when it comes to operating more sustainably and more profitably at scale,” Davé says.

It is during those fish farm trips that Davé’s team realized the need for tools that could help farmers dramatically improve essential parts of their operations — from feeding and monitoring fish health to spotting pests and reducing waste.

Some fish farmers today are already using such tools on their farms but not without difficulty. Davé recalls seeing how some farms monitor fish via a live feed from underwater cameras installed in each pen. “I remember walking into a room with a fish farmer who had to watch 10 video monitors simultaneously to observe fish behaviors. They were trying to track things that happen in milliseconds — like a fish eating a feed pellet, or a fish swimming vertically — across multiple screens,” Davé says.

The fact that cameras enable farmers to see only a fraction of what’s really happening underwater, Davé and team see a huge gap in the market. “That’s where we knew we could help,” he says.

SMART UNDERWATER CAM

The Tidal solution comprises an integrated hardware and software tools that can interpret complex oceanic environments, offering a complete picture of what’s happening underwater. The Tidal computer sensor system continuously observes fish and collects environmental data like temperature and salinity to provide farmers with information about the health and wellbeing of fish in real time.

“Our aim is to deliver real-time insights to farmers so they can make important decisions that impact their bottom line and the environment,” Davé says.

The information the camera collects is integrated into a Machine Learning powered software platform that detects patterns from which Tidal extracts insights. “We train our machine learning models at farms in diverse locations, where environmental factors like weather, currents, and temperature vary so it can provide farmers with consistent, accurate insights under a wide range of environmental conditions,” Davé says.

As the mothership of the world’s most powerful and ubiquitous search engine, Alphabet understands data and insights better than anyone else. As early as 2012, the company has been developing Machine-Learning capabilities via another moonshot called Brain, which now powers Google’s newer features, ranging from multi-language translation and imagebased search to voice recognition.

Norway-based Mowi ASA, the world’s largest producer of Atlantic salmon, was one of the companies X collaborated with for the Tidal moonshot.

“We started working with fish farmers to understand what life is like on the ocean, and to gain insight into the challenges they face on their farms — especially when it comes to operating more sustainably and more profitably at scale.”

Freshwater Basin

Reliable supply of fresh water

Restingplace and hideaway for cleanerfish

Protects your fish against lice and algae

High-quality tarpaulin with proven technical solutions

“As one of the most sustainable animal proteins and one of the world’s most popular fish, salmon was a natural choice for Tidal to study.”

– Neil Davé

“Mowi has a long history of testing new solutions to make the industry more effective and sustainable and we’re open to innovation and experimentation,” says Mowi Chief Sustainability and Technology Officer, Catarina Martins.

Martins says Mowi and Tidal share a mission and belief that technology can help unlock the potential of the ocean to increase ocean-based food production.

Always open to innovation, Mowi had tested other sensor and camera systems but found that Tidal’s technology has the biggest potential.

“Tidal’s system gives us far more advanced data about the welfare and health of the fish than we have today. It is able to collect large amounts of data in a short amount of time, and we see the potential for Tidal to be able to quickly build more capabilities on their platform given their development speed,” Martins said.

Davé said Tidal’s partnership with Atlantic salmon farmers like Mowi have been successful as the industry itself is already quite sophisticated.

“As one of the most sustainable animal proteins and one of the world’s most popular fish, salmon was a natural choice for Tidal to study. Salmon farmer’s openness to new technology has helped our team prototype and iterate our system quickly to ensure it addresses the challenges farmers face every day,” Davé said.

Davé is aware that diseases and parasite, nutrients, pollution and escapes remain a big challenge for salmon producers.

“There’s a clear opportunity to help while also validating that the technology we’re building is solving real challenges. These challenges also affect other finfish, so it’s a great starting point to build a technology solution that could be useful for other farmers,” he concludes.

Andfjord Salmon of Norway is investing in a new concept: a closed shore-based system of flowthrough pools made of glass fiber reinforced polyester composite from HighComp AS. Shown here is one of the 17.5-by-5-meter panels that will form the pool

BY LYNN FANTOM

ike deep-water waves, news reports about offshore aquaculture around the world have been breaking hard and fast in recent months, including both technology and personnel announcements. But perhaps the greatest momentum to move farming offshore has surfaced in Washington, DC.

LIt’s been a long time coming, especially when viewed from what’s happening in Europe. In May, the Trump Administration issued an Executive Order designed to develop more effective permitting related to offshore aquaculture. Among its edicts are to limit to two years any environmental decisions and for the National Oceanic and Atmospheric Administration (NOAA) to take the lead when two or more agencies are involved.

“This is a big moment for aquaculture in this country,” said Jeanne McKnight, Executive Director, Northwest Aquaculture Alliance. “The United States currently ranks 17th in global production of aquaculture yet imports 85 percent of the seafood we consume — largely from aquaculture. We are glad our government recognizes that the time has come to produce this high-quality protein right here at home.”

Neil Sims, the chief executive of Ocean Era, formerly Kampachi Farms, is a passionate proponent of ocean farming. “When I talk to my colleagues in the Gulf of Mexico region, they’d just throw their hands up in the air and say, ‘The process is open-ended.’ But now, this EO removes a lot of the risks for a permit applicant.” His company’s permit for Velella Epsilon, a small-scale yet innovative submersible net-pen trial planned for offshore of Florida, is now in its third year of regulatory review.

The Executive Order has also introduced “aquaculture opportunity areas,” directing the Secretary of Commerce to identify locations suitable for commercial aquaculture for which the federal government will complete a programmatic environmental impact statement (EIS). The EIS may also identify suitable species and gear, as well as reporting requirements for owners and operators.

“That is going to be phenomenal in terms of allowing both commercial development, but also innovation,” Sims said. “If Congress also supports it with the legislation that had been proposed by Senator Wicker, together they will herald a new day for offshore aquaculture in the US.”

Wicker’s proposed legislation in 2018, known as the AQUAA Act (Advancing the Quality and Understanding of American Aquaculture Act) died in 2019, but it was re-introduced early this year in the US House of Representatives as HR 6191. It aims to establish a regulatory system for sustainable offshore aquaculture in exclusive economic zones.

News on regulatory progress in the US comes at a time when the world is increasingly aware of the ocean’s vast potential to help feed the planet.

Food security has also come into sharper focus during the COVID-19 crisis as both Canadians and Americans have seen what happens when one country is dependent on another for manufacturing and supply chains. Remember Trump’s directive for American firm 3M to stop exporting N95 masks to Canada? It’s not a big leap to imagine how export freezes could create food shortages.

So, the time is now to address seafood trade deficits.

“The inventory and identification of regulatory development initiatives and tools for offshore aquaculture in the US will provide the opportunity for Canada to examine the US framework and enable future alignment of Canada’s framework for offshore aquaculture to that of the US.”

NORWAY: GOVERNMENT SUPPORT SPURS INVESTMENTS

The regulatory certainty and support in Norway have given Atlantic salmon producers the confidence to make large, sustained investments in new technologies.

Gustav Witzoe, chief executive of SalMar, recognized that SalMar’s “huge” investments in offshore aquaculture technologies “would not have been possible if the government and a united Norwegian parliament had not introduced the development license scheme.”

When appropriately sited, commercially scaled offshore aquaculture installations have the potential to operate in a way that produces a relatively small pollution footprint, says a University of Miami study

In May, the company announced that good results from Ocean Farm 1 – SalMar’s and the world’s first offshore salmon farm – have prompted it to apply to convert those development licenses into permanent permits. SalMar will pay much less than buying licenses during commercial auctions. And the industry as a whole advances in its sophistication, thanks to this Norwegian Directorate of Fisheries program. It’s a win-win.

SalMar is also building on the success of Ocean Farm 1 trial with Smart Fish Farm, a more technologically advanced system that can withstand exposure better and provide twice the capacity. The system, now in its final stages of design, will be located in open water 20 to 30 nautical miles off the coast.

Certitude about the governmental framework also inspired Andfjord Salmon to invest in a newly announced patented concept: a closed shore-based system of flowthrough pools made of glass fiber reinforced polyester composite materials, instead of the traditional steel, aluminum and concrete.

The tank contractor, HighComp AS of Norway, is tapping into its offshore experience in the oil and gas industry and constructed the large pool panels off-site. This plan yielded shorter installation time, plus high-quality finish and durability, the company said.

Similar to land-based RAS farms, the design limits escapes, sea lice, and poisonous algae and isolates waste. And like the open net pens of neighboring farms in northern Norway, it utilizes fresh Arctic seawater and promises none of the off-flavors associated with RAS.

On 1 April, Martin Rasmussen stepped into the CEO spot at Andfjord, which has a government concession to farm 10,000 metric tons of Atlantic salmon. He anticipates the site will be ready this year in late summer and says his focus is on proof of concept.

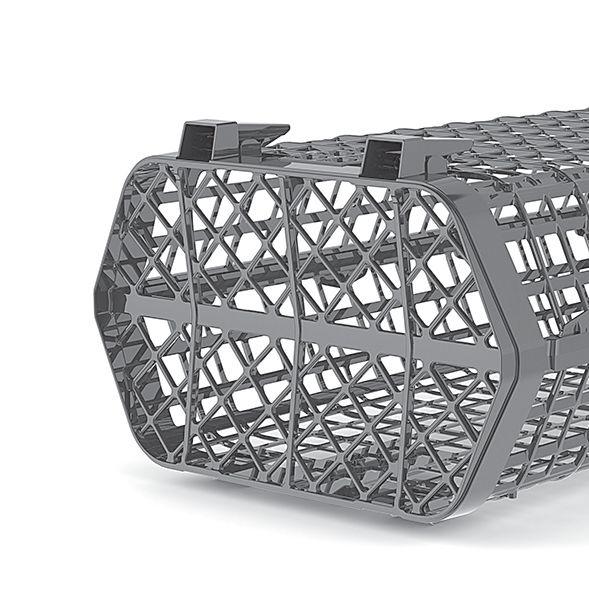

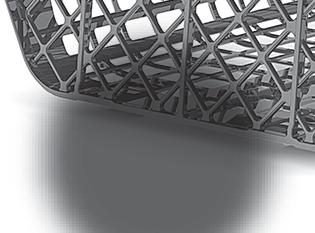

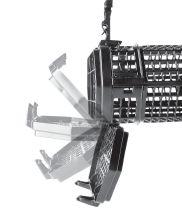

October 2019, Poseidon Ocean Systems delivered the first Trident Hybrid steel cage system to Cermaq Canada on the west coast of Vancouver Island. At first glance, the 40m x 40m square cages look a lot like other steel cage systems that dot the rugged coastlines of Canada, Chile and Scotland. But if you look closer, you’ll see the similarities are only skin deep.

Open nets, or closed containment?

Imagine if you could switch from traditional net pen farming to floating closed containment as easily as you change nets. Marine engineer and co-founder of Poseidon Ocean Systems, Matt Clarke, said that with Trident, you can.

“Trident is a generational leap in fish farm structural design,” he said. “Aquaculture has come so far in such a short time and we felt that cage system design needed to evolve with the industry.”

Trident’s cage technology has been in development since 2017 by a team of engineers focused on the aquaculture industry. Clarke explained the new design is still completely compatible with existing farming practices, with costs comparable to conventional designs. “We set out to raise the bar for aquaculture and we’re very proud of what we’ve accomplished.”

Setting the standards

If you’re going to design aquaculture equipment, there are two standards to follow and Poseidon knew where to find them.

“We’d been working with the Norwegian Standard NS:9415 for years and it sets a very high bar,” said Clarke. “We also work with the Scottish Standard and the two standards are aligned on cage design. We know that cage system failures and fish escapes have a negative impact on the global industry, not just the operators directly affected. By designing to the standards, we’re lowering the risk for the entire industry.”

Strength and durability by design

To meet the rigorous design standards, Poseidon completely re-imagined the steel structure itself. “We put a lot of effort into the structural design and ran hundreds of simulations to make sure it will stand up in high energy environments. The result is a steel cage structure that is 50 to 100 percent stronger than existing designs and is more suitable for deployment at higher energy sites than anything that has come before us.”

Clarke explained that Trident has been designed to handle maximum wave heights of more than six meters.

One look at the hinge design on Trident and you can see what he’s referring to. “The hinges are the most critical aspect of steel cage system design, so we went above and beyond on those components to make sure that the system will last.” He explained that the manufacturing tolerances and material quality are unmatched in the industry today.

“Our pins are 50-mm diameter high strength steel, paired with PTFE composite bushings. We expect that most customers won’t need to replace our pins or bushings, ever. The result is a 20-year design service life for the structural components.”

Hybrid structure

“The flotation on Trident is HDPE pipe, the same as we use on circular cage systems. It is much stronger and more durable than conventional billets. As a result, we guarantee the flotation for the life of the cage,” said Clarke.

He goes on: “It isn’t just about better flotation, it’s also about how we use the flotation in Trident. The system is a hybrid design; it is a combination of the best features of steel cage designs, combined with many of the best features of circular cage designs. The pipe is an integrated structural component that is continuous throughout the entire farm. There are no gaps at the hinges or unsupported spans like you have with conventional billets. That translates into vastly improved buoyancy, strength and dynamics. This is really apparent during storms – the Trident system responds to waves with a very calm and subdued motion, almost like a giant shock absorber. The typical heaving and lurching motion of conventional cages is nearly eliminated. It is hard to capture in words just how dramatic the improvements are.”

Closed containment capable

“The advancements we’ve made in the structural design with Trident are so profound that it makes floating closed containment an economically viable option for farmers.”

The strength and the stability of the new design makes it capable of supporting existing floating closed containment technologies, Clarke said. “From the structural advancements, to the flotation and right down to the load distribution system, Trident is ready for closed containment operations right out of the box.”

“We see this is a game-changing capability for our customers going forward. Trident as a closed containment structure is a fraction of the cost of conventional closed containment designs. It allows farmers to integrate floating closed containment much more easily into their existing operations to create hybrid farming models,” said Clarke.

“One scenario for these hybrid operations is to use floating closed containment systems for the juvenile stage of the grow-out period. By raising smolts from 100 grams to around 1.5 kilograms in floating closed containment, farmers can double their production output for a fraction of the cost of expanding a hatchery or even their net-pen operations.”

Integration is key

With Trident, Poseidon looked to integrate modern farming equipment right into the cage. “We’ve been focused on integration since day one,” said Clarke. “When you look at fish farms today, they have more and more equipment on the cages, some of which didn’t exist just 10 years ago and farmers have nowhere to safely put everything. A core design goal was coming up with a solution that would allow us to recess all equipment under the decks, but still make it easily accessible for installation and maintenance. This gives farmers properly integrated systems within the farm itself while improving worker safety and reducing maintenance requirements on all equipment.”

The Trident system uses durable fiberglass reinforced plastic decking that allows farmers to run their feed lines and everything else they need on a modern farm safely under their feet. The removable panels are easily replaced in the event of accidental damage.

“That’s one thing we saw repeatedly with welded steel decks – once you damage those decks, they’re very difficult to repair, so the farmer is often stuck with the damage for the life of the cage. With Trident you can replace a damaged deck panel in seconds and safely get back to work.”

Cermaq’s perspective

Cermaq, one of the world’s premier aquaculture companies, had this to say about the Trident Hybrid Cage System: “For us, the biggest benefits we are realizing from the Trident system is the overall improved stability and safety of the structure. The cages have exceeded our expectations for performance during storms, and the feedback from our employees working on the system has been positive,” said David Kiemele, managing director for Cermaq Canada.

“General safety is improved as the system allows for storage under walkways, reducing piping, ropes and cables on the surface of the walkway, which has reduced tripping hazards. We are happy with the security the system provides for our fish, as it is able to shift and flex with all wave and weather conditions.”

The future is now

With so much promise, what does Clarke see as the next challenge for the patent-pending Trident Hybrid technology? “We’re eager to work closely with customers who are interested in seeing how Trident can transform their farming operations. We believe that innovative customers will be able to use Trident to take a big step into the future for aquaculture. We’re excited to be a part of that transformation going forward.”

SPONSORED CONTENT

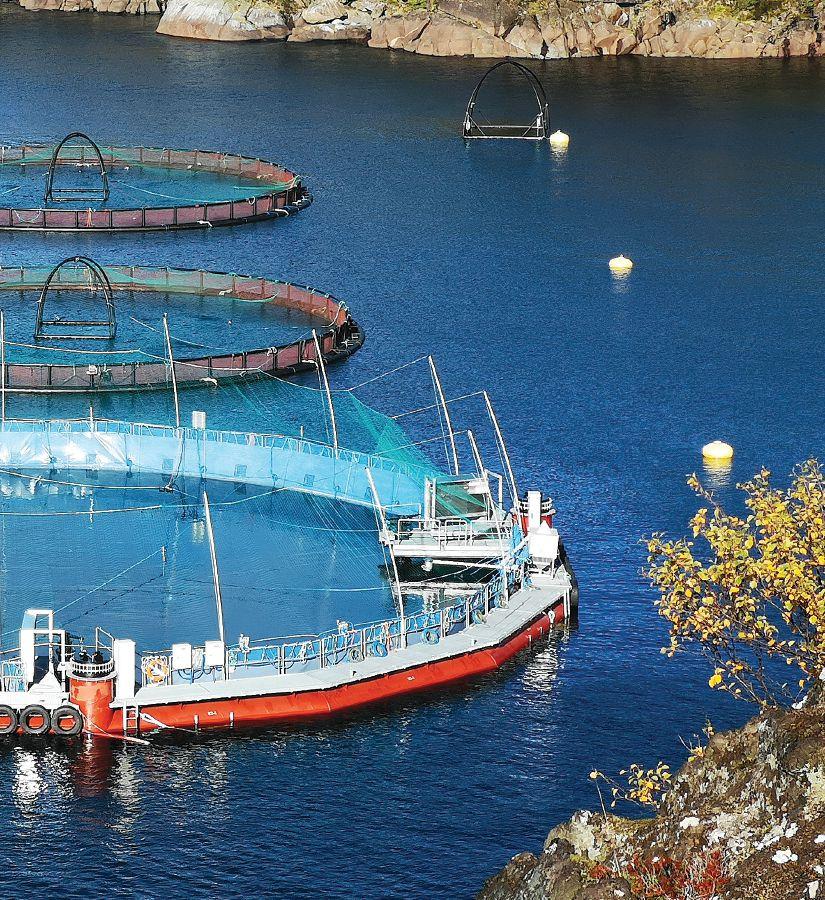

Ocean Farm 1, ‘the world’s first offshore fish farm,’ is now into its second production cycle for SalMar Group. Ocean Farm 1 measures an enormous 110 meters in diameter and 250,000 cubic meters of habitat. The entire design and system integration –from concept and design development, to fabrication and installation in Frohavet, Norway – was conducted by Global Maritime.

Global Maritime continues to lead in offshore fish farm design, building on our decades of offshore engineering and operational knowledge to develop new concepts and address the challenges involved with operating these units further offshore and in harsher conditions.

Scottish Sea Farms, which currently operates 42 farms, is also looking offshore, envisioning a full-scale, deep-water operation as an alternative in the ongoing search for coastal sites. That has become an increasing challenge, as competition from local fisheries and tourism mounts.

“For this ambition to be realized, however, we need an engaged, robust, and forwardthinking regulatory framework that enables Scotland’s salmon farms to continue growing in a responsible manner,” said managing director Jim Gallagher. “With this is mind, we’re eager to take the next step by opening the dialogue with Marine Scotland, SEPA (Scottish Environmental Protection Agency), and local authorities.”

Norwegian leaders SalMar and Leroy own Scottish Sea Farms in a 50/50 joint venture. The newly proposed open ocean farm would be Scotland’s first.

In Canada, the agency responsible for regulating the aquaculture industry is watching developments in US offshore aquaculture. “The inventory and identification of regulatory development initiatives and tools for offshore aquaculture in the US will provide the opportunity for Canada to examine the US framework and enable future alignment of Canada’s framework for offshore aquaculture to that of the US,” said the agency, Fisheries and Oceans Canada.

Besides, the cost of new technologies for offshore aquaculture remains prohibitive, although this is true not just in Canada but the rest of the world.

“Investment cost is still very high for offshore cages and there is so far no evidence that going offshore will resolve the lice problem, something that could have balanced the high investments,” acknowledged Alf Reidar Sandstad, CEO of Seafarming Systems of Norway.

Sandstad invented the Aquatraz, a semi-closed salmon “prison” for sheltered areas with a maximum wave height of c. 2.4 meters. The cage, he said, is far cheaper than those designed for offshore environments because designs for sheltered areas can be far lighter that those meant for exposed ones. This cost savings is crucial in strengthening fish farmers’ competitiveness compared to using conventional cages and will open up a large market, he added.

Canada’s salmon farmers remain committed to innovating coastal net pens to get a grip on rising costs related to animal health and ensuring sustainability. They are keen to deploy innovations originating from Norway. For instance, Cermaq Canada is intently watching the company’s pilot of a closed containment system called Certus in northern Norway.

From deep below, at temperatures too cold for lice, this system draws water into a cage with a tarp wall made of strong and flexible composite. In the Norway trial, smolts were grown to two kilograms, then transferred to open cages. Trials have so far shown that the fish are “growing better” than those fish in the company’s traditional net pen structures in the same location, said the company.

David Kiemele, managing director of Cermaq Canada, told this publication in an earlier interview that he sees farming salmon all the way to harvest size in such a system in Canada. He recently repeated his plan, saying to ANA: “I have a desire and focus to trial Certus in Canada. I think there are multiple benefits.”

The large, multinational players based in Norway have taken a leadership role in offshore aquaculture, but smaller entrepreneurs have also emerged, producing niche species in warmer waters.

Open Blue, founded in 2007 by Brian O’Hanlon, farms cobia in 22 prism-shaped, deep-water cages in the Caribbean 13 kilometers (about eight miles) off the coast of Panama. This venture reportedly produces over 1,400 metric tons of fish per year.

The prospects for offshore aquaculture recently lured Andrew Young to Open Blue as chief commercial officer. For more than four years, Young had served as vice president of global sales and marketing at Cooke Seafood and is now based in Panama.

Such confidence in offshore has been fortified by environmental impact studies like the one published last July by University of Miami scientists, who worked with Open Blue. Over five years, researchers collected water and sediment samples in several locations upstream and downstream from submerged fish cages.

The data “demonstrated that when appropriately sited, commercially scaled offshore aquaculture installations have the potential to operate in a way that produces a relatively small pollution footprint,” the university said.

Aaron Welch, Ph.D., who was lead author of the study as a graduate student, today owns a shellfish company in Florida and provides environmental and third-party certification consulting services for finfish farms and hatcheries. “There is a lot of energy and foment in the industry right now,” he agreed. “The economic logic is overpowering.”

But, during the last 15 years, he has observed legislature bubbling up but not necessarily moving forward. Personally, he is in a “wait-and-see mode.”

Similarly optimistic yet pragmatic, Cermaq Canada’s Kiemele scans the horizon with an advisory, “We believe it’s going to take all different kinds of technology. The message is: if there is a shift, it should not be expected to occur quickly. It will take a measured approach and time.”

After all, although big waves signify a lot of energy, only a small amount of water moves forward.

– With additional reporting by Liza Mayer

These days traditional net pen producers are operating farms that are anything but traditional. Although coastal cages may have conventionally defined configurations, an atmosphere of continual improvement pervades the industry, creating cautious optimism among producers and a stream of news from global aquaculture investment accelerators.

One possible reason for the persistent confidence in net pen farming lies in the range of solutions that are constantly being introduced and refined — in nutrition, disease prevention, production hardware, and technology.

Feed, for example, which makes up the largest share of the total cost of production, has been an ongoing focus of innovation, especially as concerns about “fish in/fish out” have grown. One of the newest aquafeed ingredients that’s generating interest is barley.

Co-founded by a chemical engineer and biochemist and part of the HATCH accelerator program for aquaculture start-ups, Montana Microbial Products (MMP) created a patented process to turn barley into barley protein concentrate (BPC), which has proven to be a fully digestible, high-protein ingredient.

“Feed tests done with BPC and Atlantic salmon and trout have shown fish growth and feed conversion ratios equivalent to fish meal-based diets,” noted Bob Kearns, one of the cofounders. “BPC has been used at inclusion rates up to 35 percent of the overall diet with no adverse effects on fish growth, health, flesh color or taste,” he added.

To produce and sell BPC, MMP has recently signed a licensing agreement with the agricultural marketing company Scoular of Nebraska. While Kearns could not comment on the details of Scoular’s plans, he did say that he anticipates this “superior protein” to be in commercial production in 2021 and expects it to be priced competitively with other plant-based proteins. The companies have begun work on Canadian product registration.

The aim of the feeding game is to grow a healthy fish fast at the lowest possible cost, and that purpose is defeated if feed is wasted. “You don’t want to feed pellets to the pollock swimming outside the cages, and you want to transform every kilo of pellets into as much salmon as possible,” said Bendik Søvegjarto, chief executive of Oslo-based technology company CageEye, which is backed by the Dutch investment fund Aqua-Spark.

His company recently announced the fourth generation of its system which gathers data from hydroacoustic sensors, combines it with biological and environmental information, and makes decisions about when and how much to feed fish. Then, it autonomously does the feeding.

It’s better than human feeders with underwater cameras, according to the company, because a camera sees one to three percent of the cage, while this system observes 70 percent. Plus, its machine learning can grapple with millions of patterns an hour, a task impossible for the human mind.

CageEye, which was founded in 2013, expanded into Chile last year. It says there is a waiting list for the product.

Ace Aquatec, based in Dundee, Scotland, is another company harnessing technology to aid fish farming production, including predator control. Recently, it has added to its system thermal cameras that detect the approach of seals and trigger acoustic devices to ward them off.

“This is the latest in a series of innovations aimed at making our deterrents the most environmentally responsible approach to predator control,” said Mike Forbes, head of sales and marketing. For example, enhancements have included low frequencies that cannot be heard by whales, dolphins, and porpoises and modulating sound frequencies to avoid damaging seals’ hearing. In addition, electric deterrents can “train” predators to keep away from farm sites.

Ace Aquatec has also won recognition for its humane in-water electric stunners and last year received an investment from Aqua-Spark. Dr Jenny Bouwsema is director of Ace Aquatec, Canada.

Protection against predators is just one of the boxes the cutting-edge net known as Sapphire Excel ticks off. “The gauge of twine is wound very tight, and it has stainless steel wiring throughout to make the netting bite resistant to predators,” noted Darren Ingersoll of Mowi Canada East, which is adopting it for all of its sites.