Weaving the city

A slow time factory

Ana-Maria Zagnat - Flux 3.2

Contents

2.........3.1 recap

4.........site and users

6.........manifesto

7.........design development

11........masterplan

12........ historical context

13........programme

14........vignettes

15........plans

20.......sections& elevations

22........structure& techincal details

25........climate emergency

26........building regulations

27........construction sequence

28........interior views

3.1 Recap

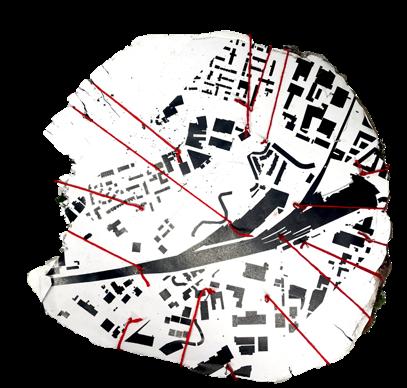

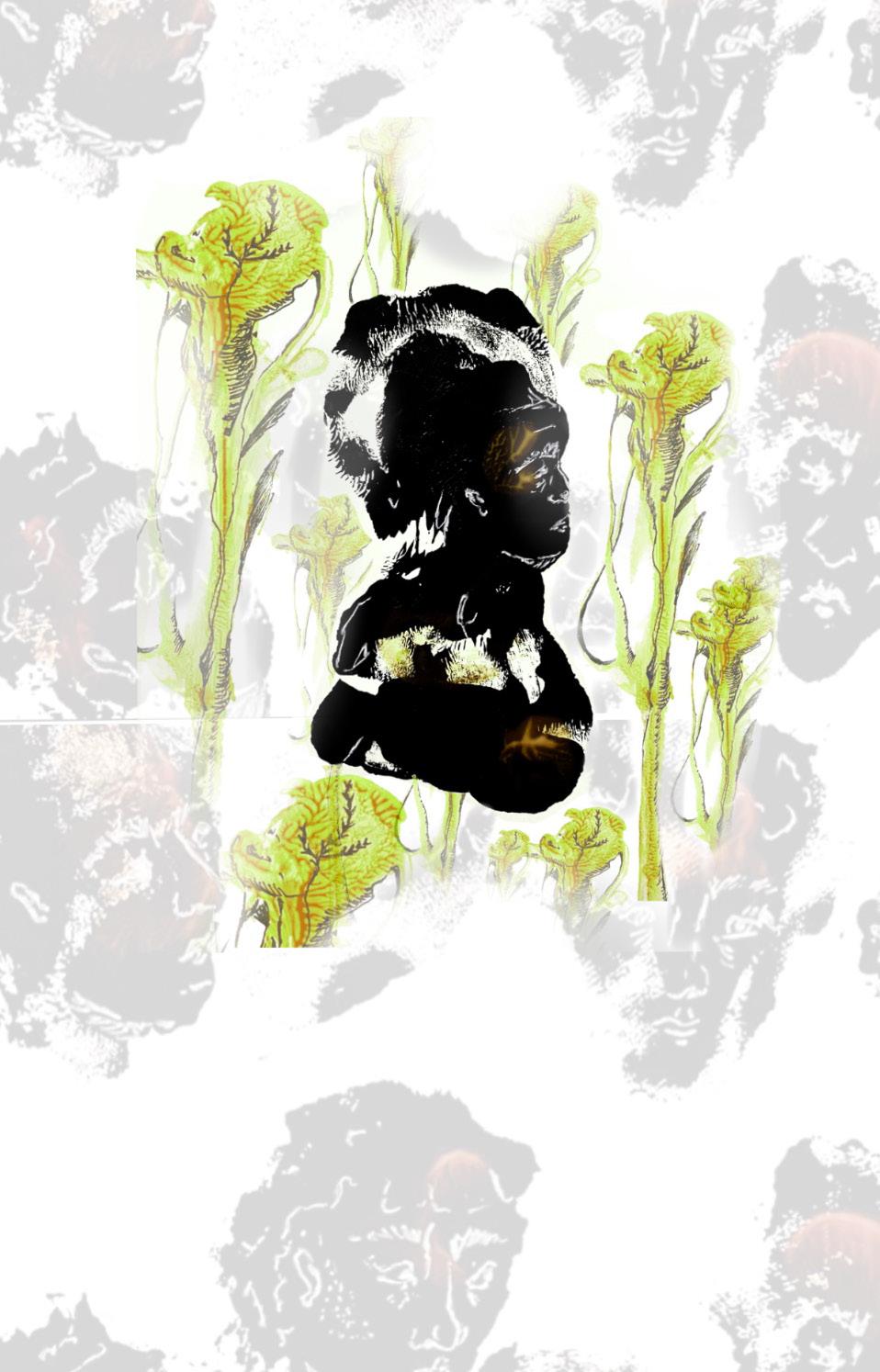

Inverted green archeology

Thee new vegetation of Mayfield has put its own mark on the area as a response of decaying and an inverted green archeology was created.

Our aim is to celebrate it and help it grow as now it is a distinctive characteristic of Mayfield and it defines its uniqueness. We inted to preserve these small sparks of life, and to create a space that everyone can enjoy. We want to explore methods of spreading the exiting ‘greenary’, and to highlight it.

The purpose is to consider first the existing life of Mayfield, and just afterward to ‘integrate‘ other ones; to acknoledge, not to ignore.

We are planning to do so by creating growing areas (community gardens) where people can help spreading the vegetation; also, by building structures that are sensitive to it and have the green archeology as a focal point of their design.

2

3.1 Recap

A self-sustained building

interactive spaces to learn about it growing spaces

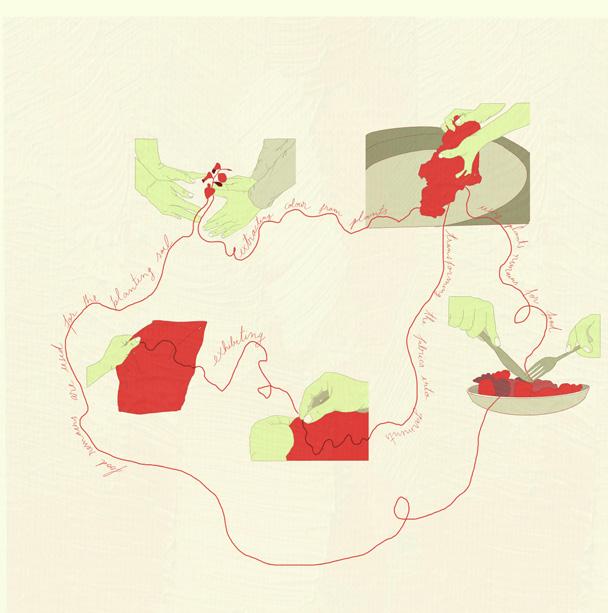

To celebrate the vegetation of Mayfield, I tried to create a building that uses vegetation in its programme and transforms it in something new.

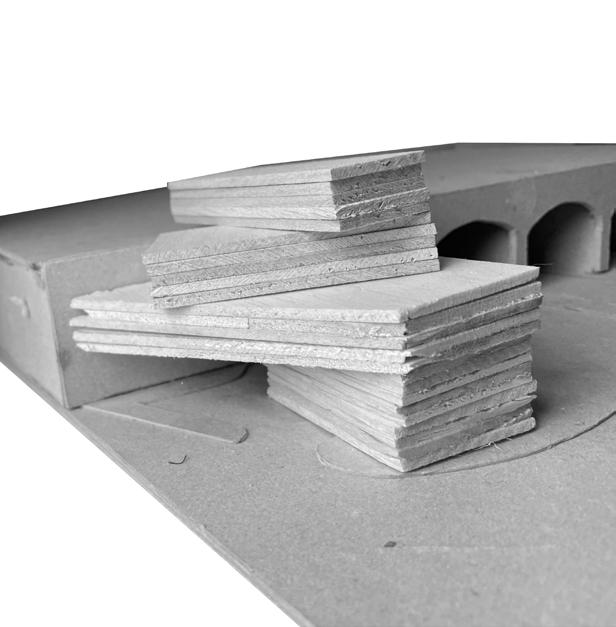

Therefore, it has a cyclic programme that creates minimal waste. Moreover, the cantilevers provides its users with multiple views of Mayfield’s green.

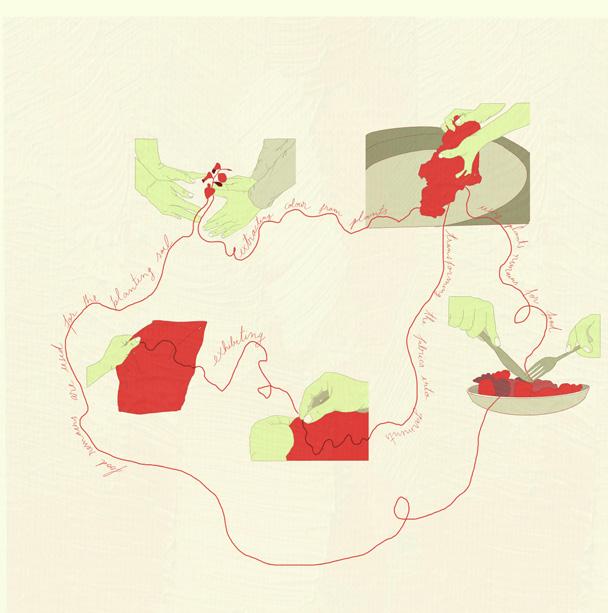

growing plant illustration 100 100

existing greenary

dyeing textiles

food hall

3

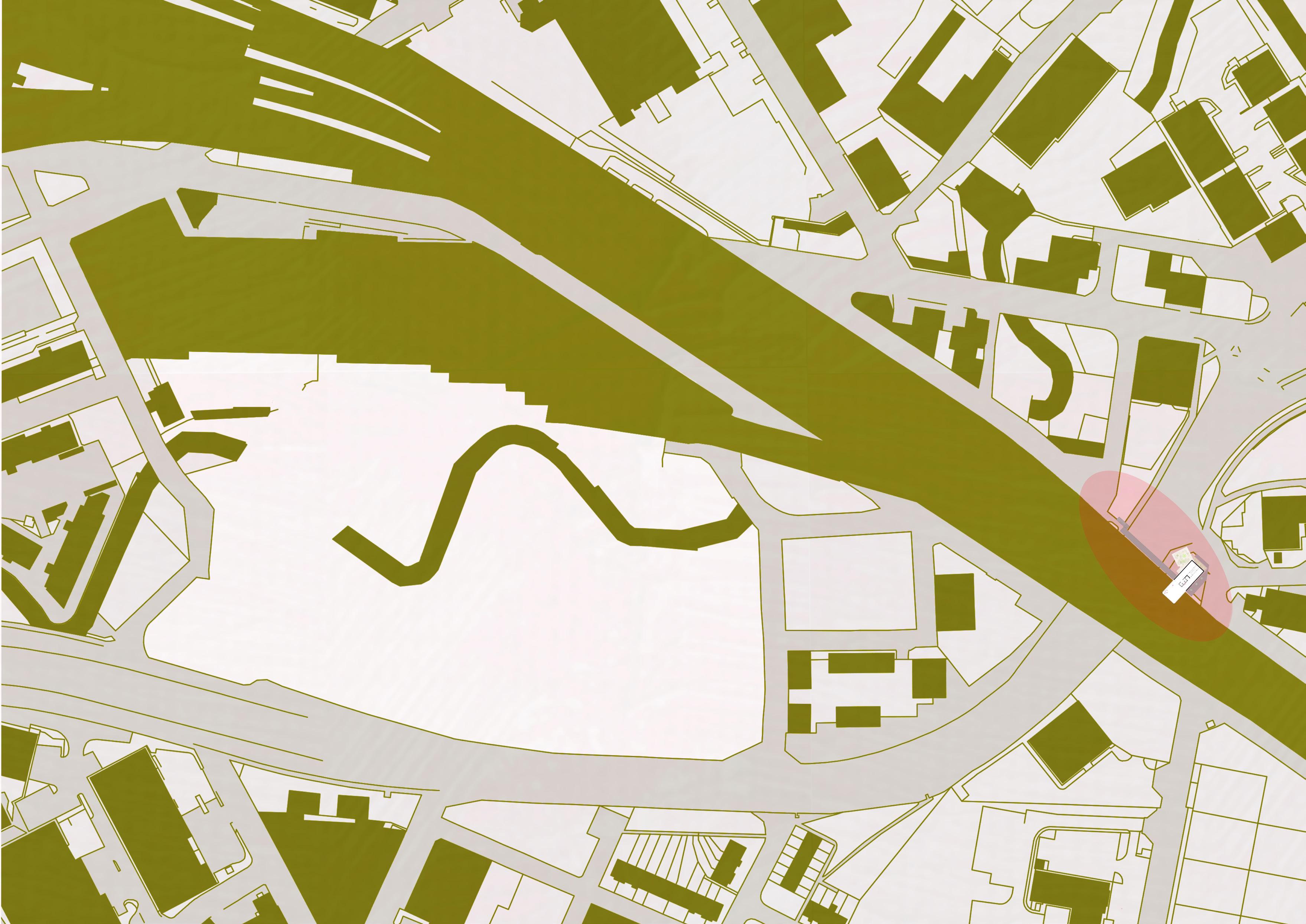

Site context

DEPOT MAYFIELD 100 0

Circulation around mayfield 0 10 20 50 100 200 4

Users engagement

Circulation around mayfield

The mixed programme of the building allows all types of citizens to explore it. It creates a safe, inclusive space that everyone can enjoy.

PROFESSIONALS

they can come to have a relaxing dinner after astressful workday

TRAVELERS

they can discover Mayfield’s textiles history through interactive workshops about natural textiles dyeing

FAMILIES/CHILDREN

they can learn by visiting the textile factory, participating in the workshops, exploring the vegetation

STUDENTS

they can shop clothes or other textile with unique prints and ethically made

SENIORS

they can admire the green views of Mayfield and grab a meal at the restaurant.

5

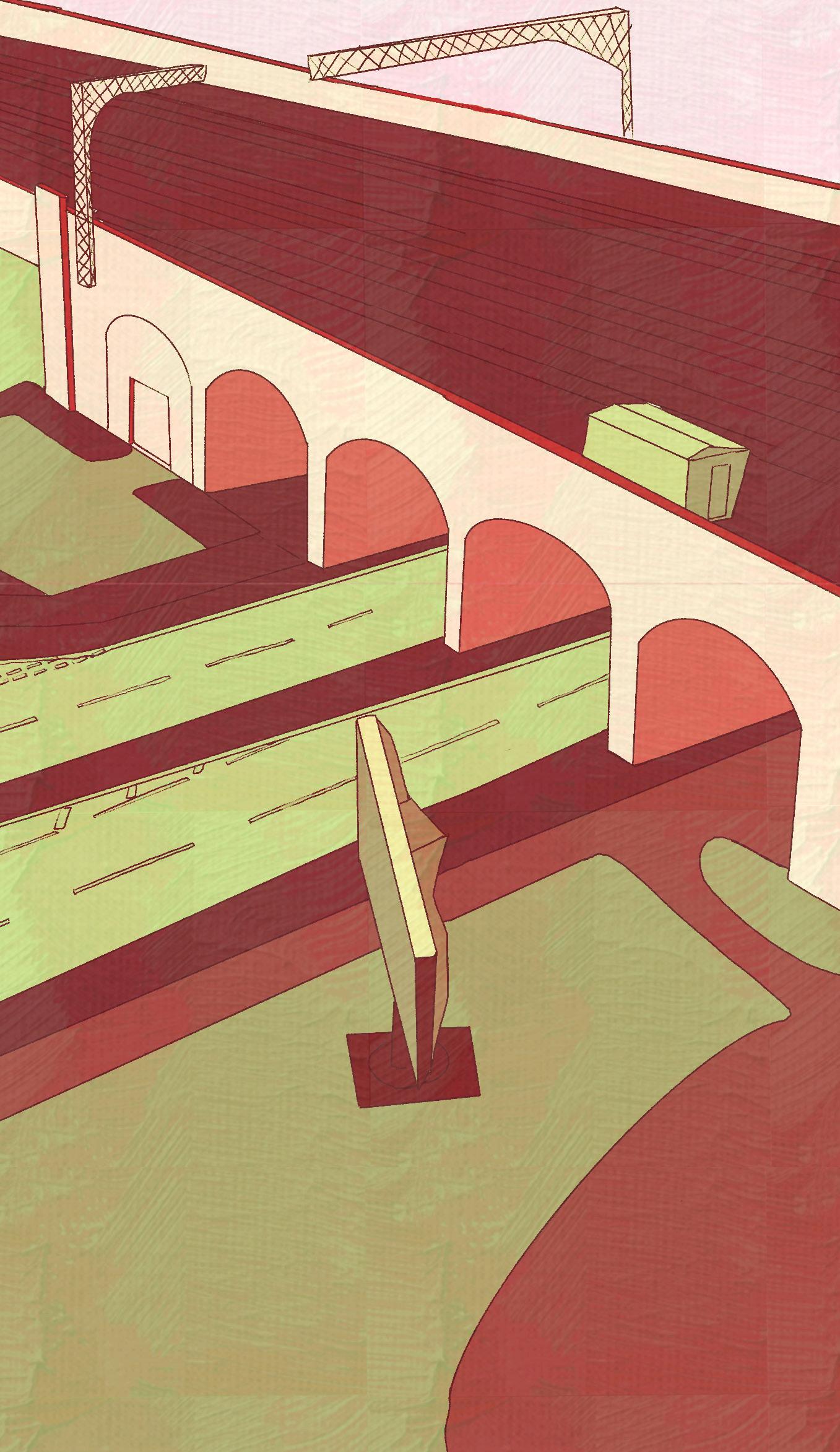

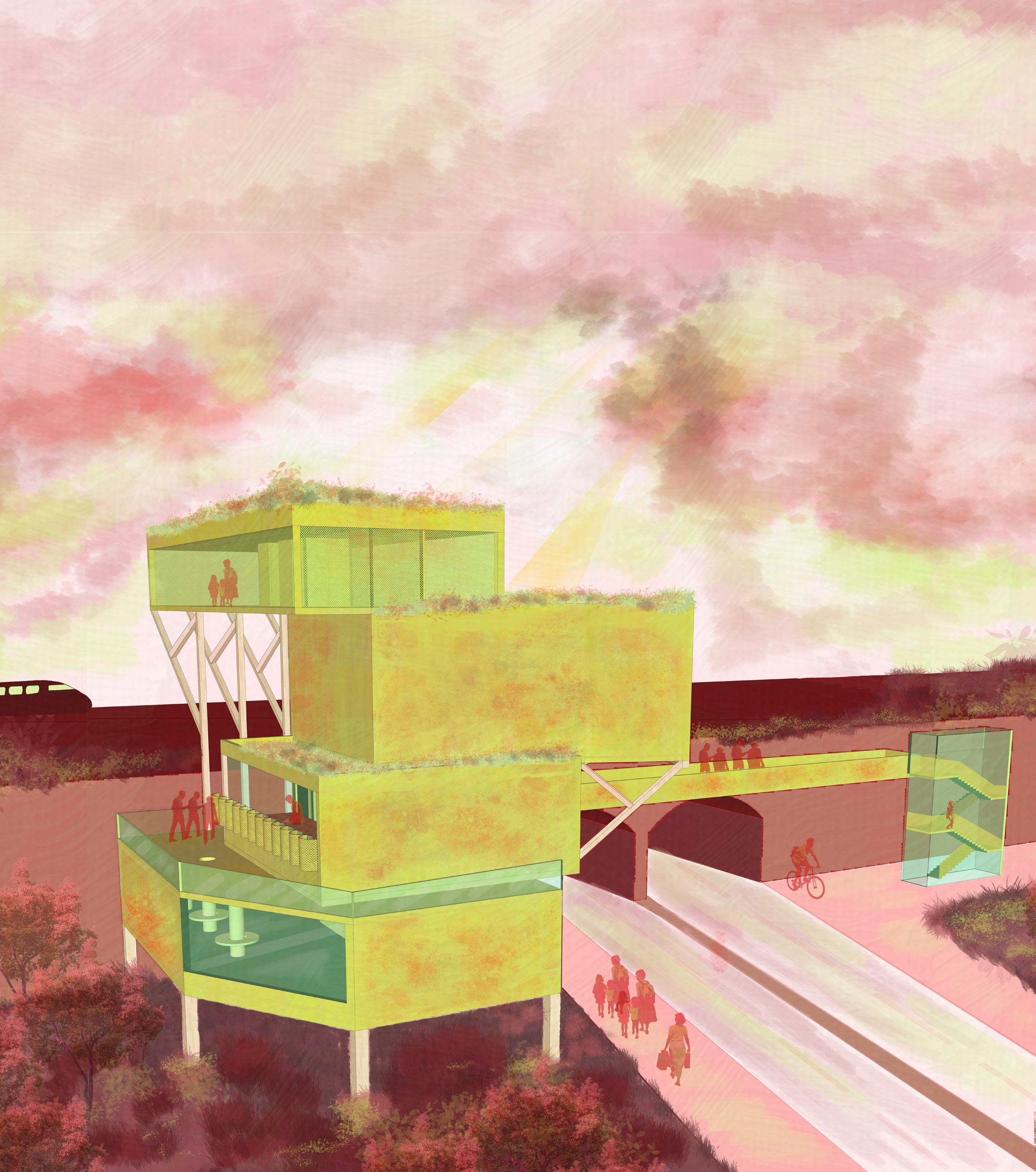

A city of woven ‘green’

Manifesto shades of green and red as texture

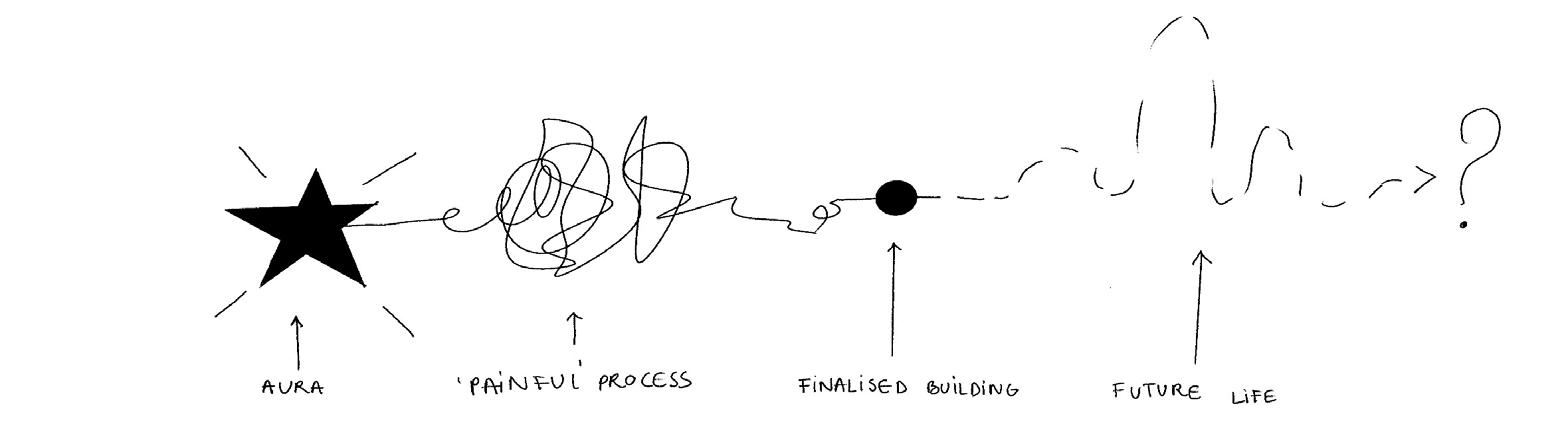

Developing the previous concept of celebrating the existing greenery of Mayfield that Invertd Green Archeology expressed, A City of Woven ‘Green‘ reffers to the development of the existing greenery in Mayfield to create a new object.

The purpose is to create buildings that can constantly change their concept to adappt similar to the vegetation used in the programme of the building that changes its initial state until it reaches an optimal form. I want to express the idea of change in a way that is easy to perceive by everybody, by associating diferent colors to textures, sounds etc. I intend to emphasise the idea of evolution by using materials that react viisibbly to the weather but also remind the users of nature, such as corten steel, copper, timber etc.

6

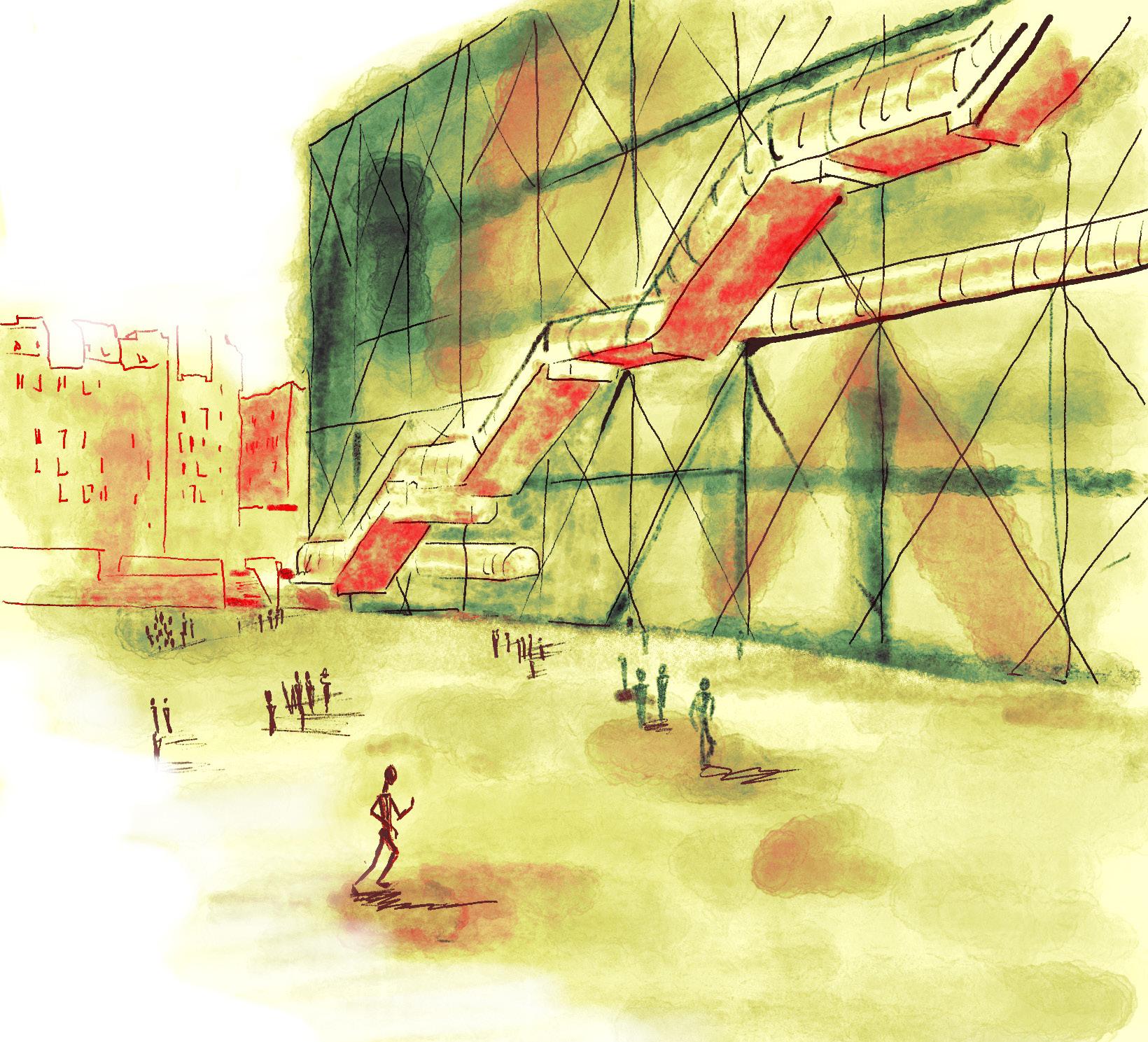

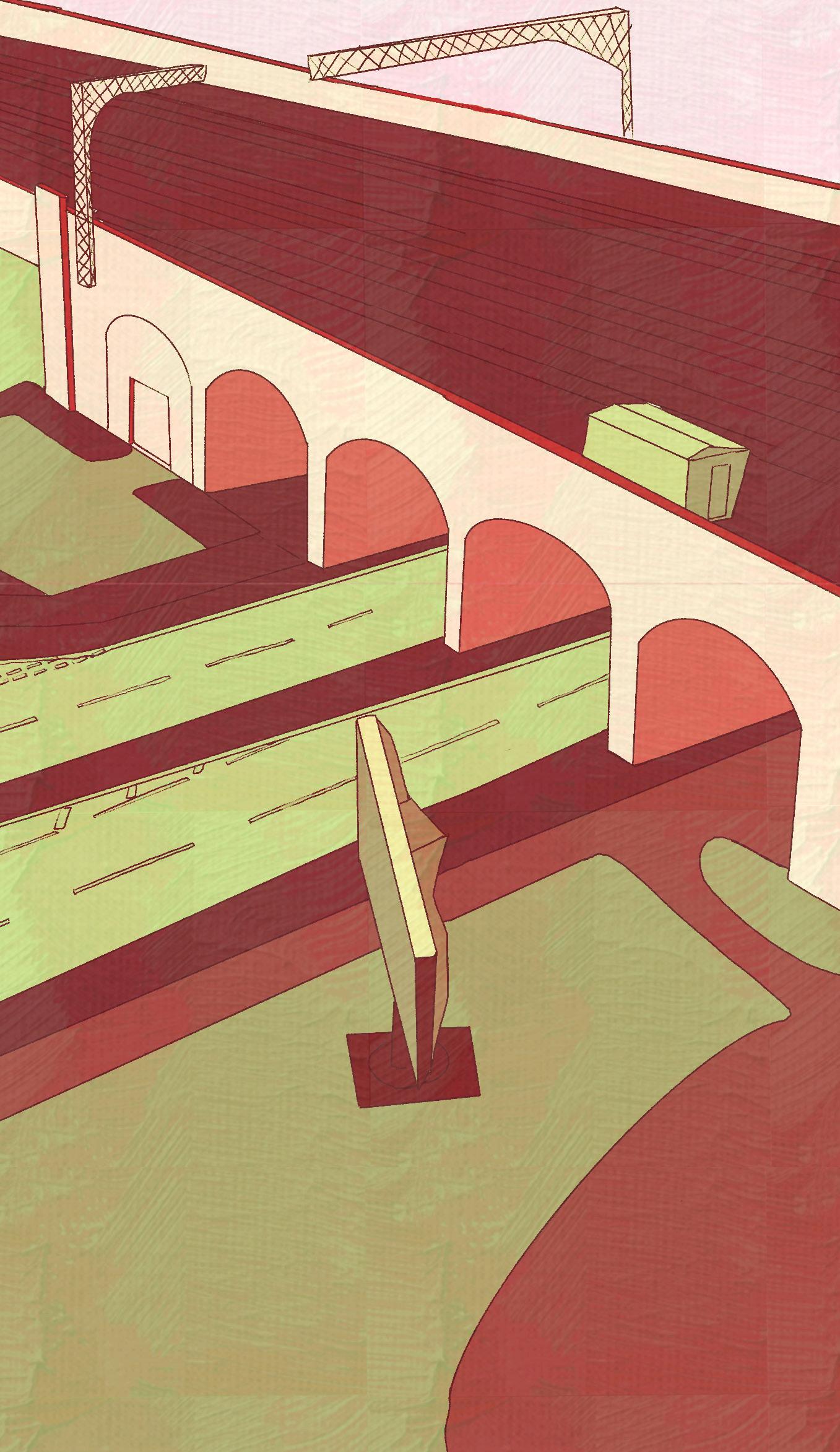

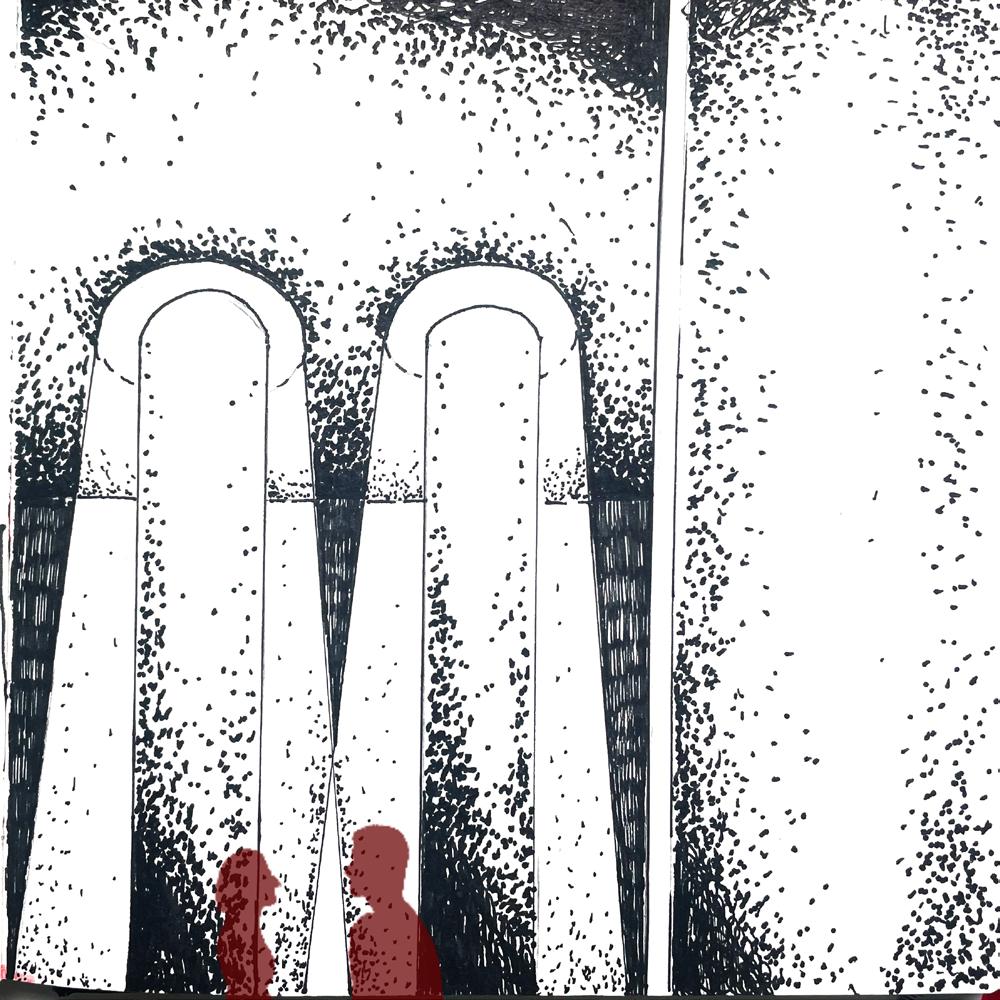

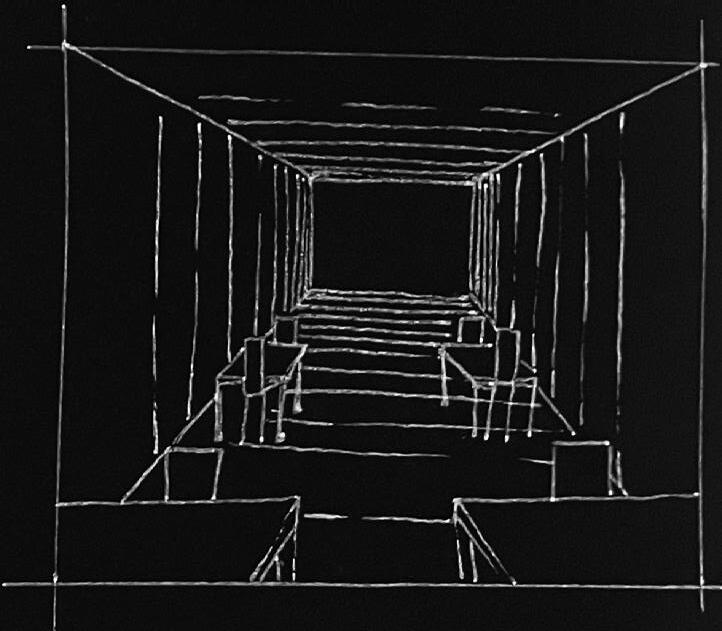

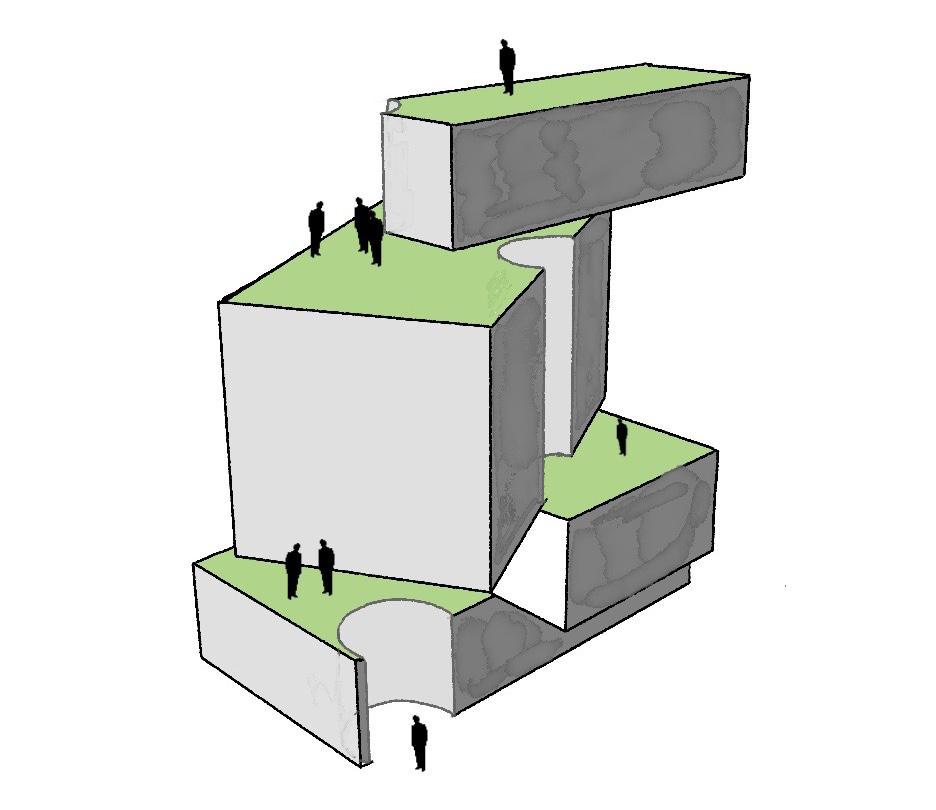

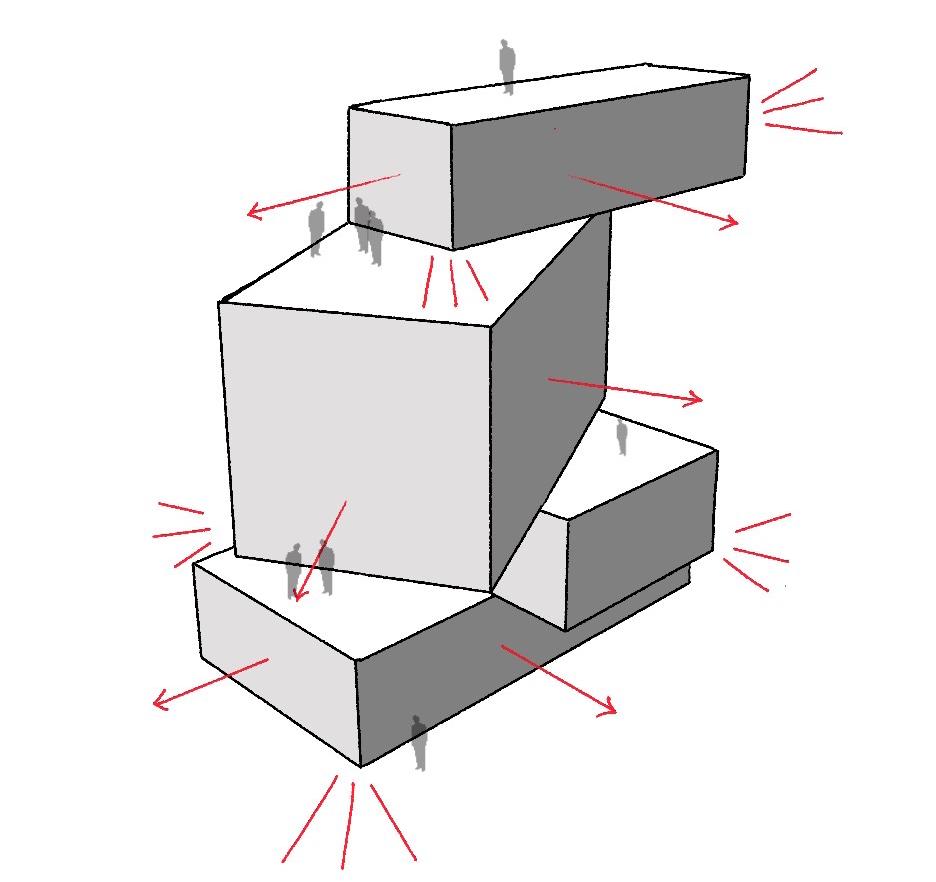

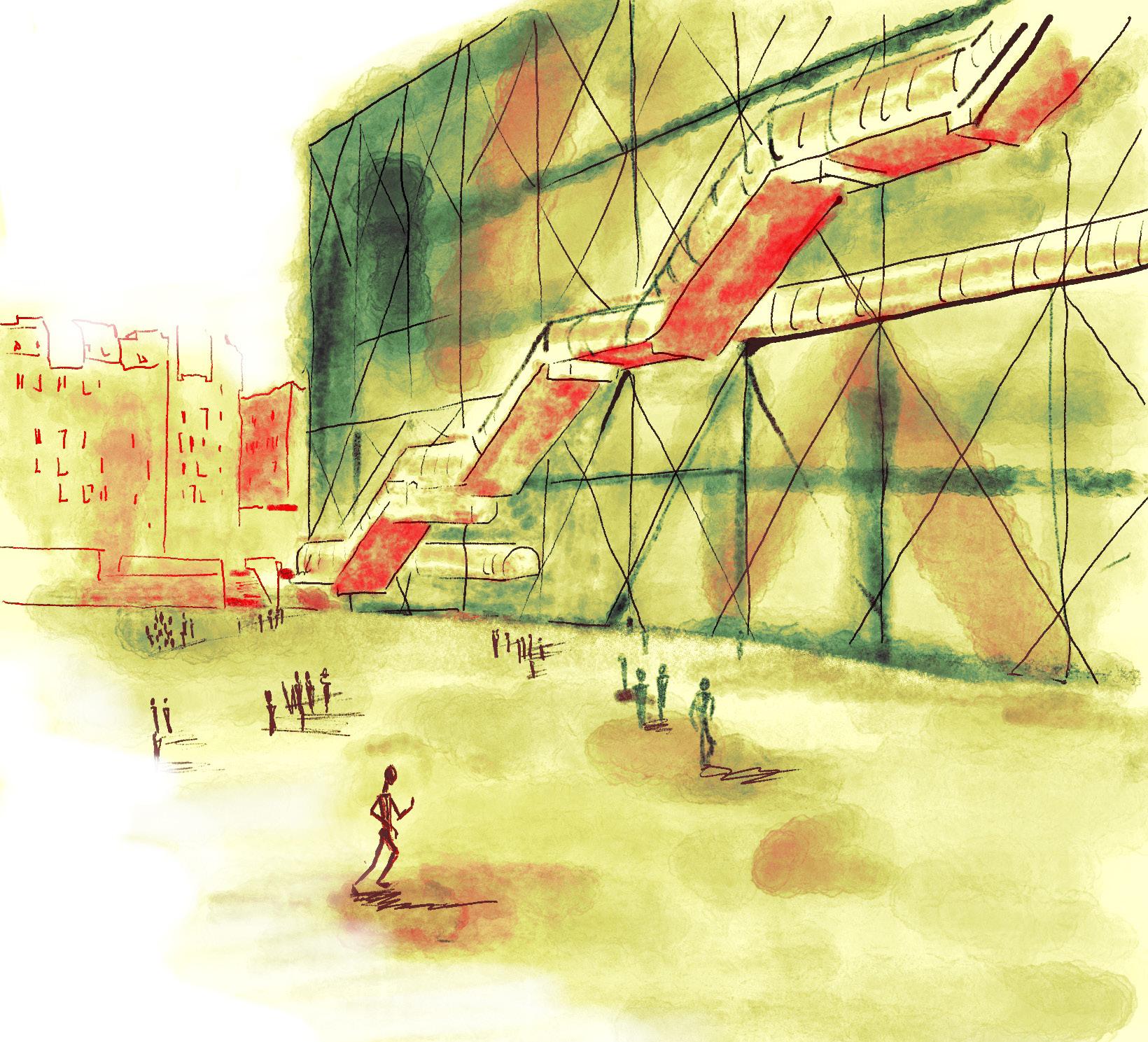

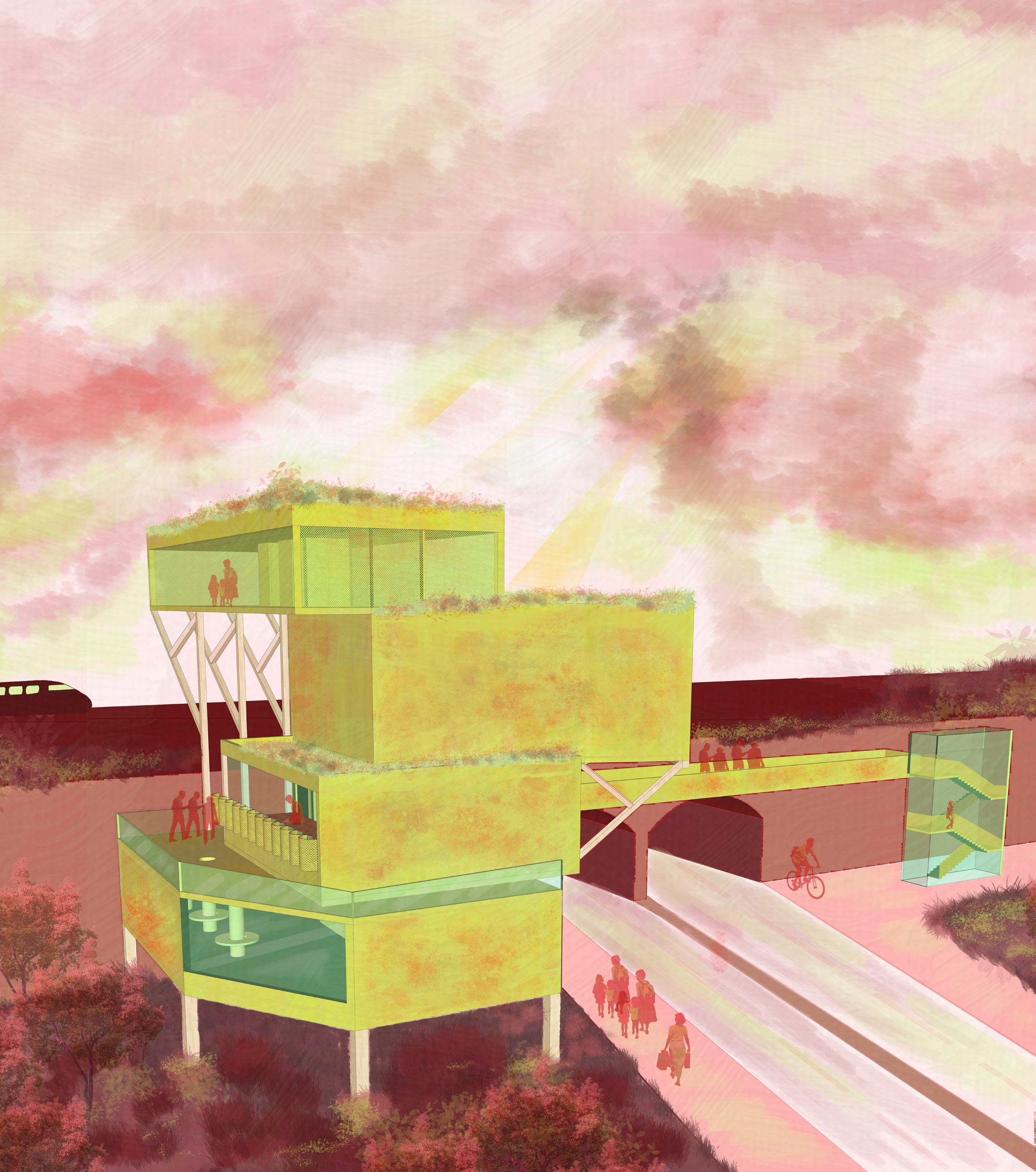

Merging concept development & users experience

One of the main purposes of the building is to merge different groups of people together and create safe inclusive spaces.

I tried to explore the idea of connectivity through a series of four images that show 2 hands meeting and getting closer and cloer to one another, merging into one object.

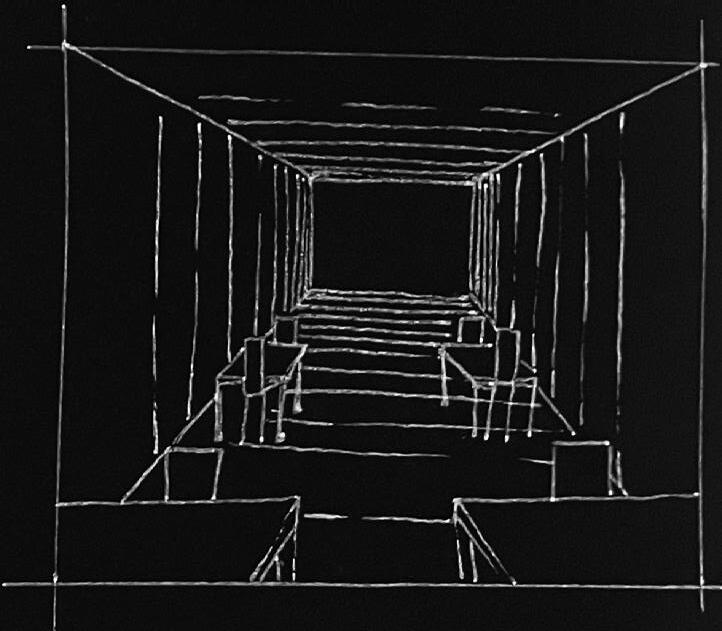

attempted illustrating the concept into my design through a series of vignettes. I questioned the idea of connectivity for each floor and tried to understand tthe importance of tresholds between them.

7

1st floor

4th

3rd floor

2nd floor

floor

Design Process

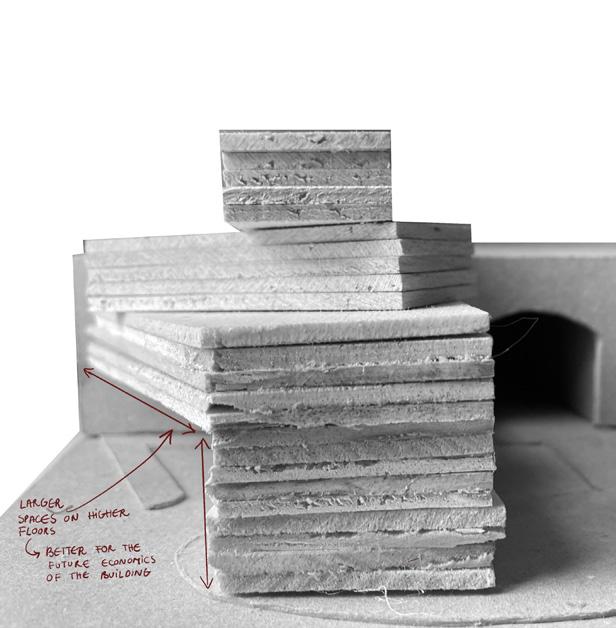

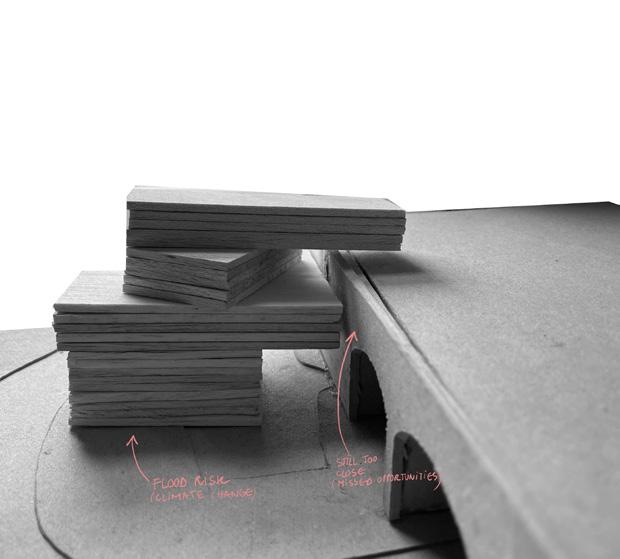

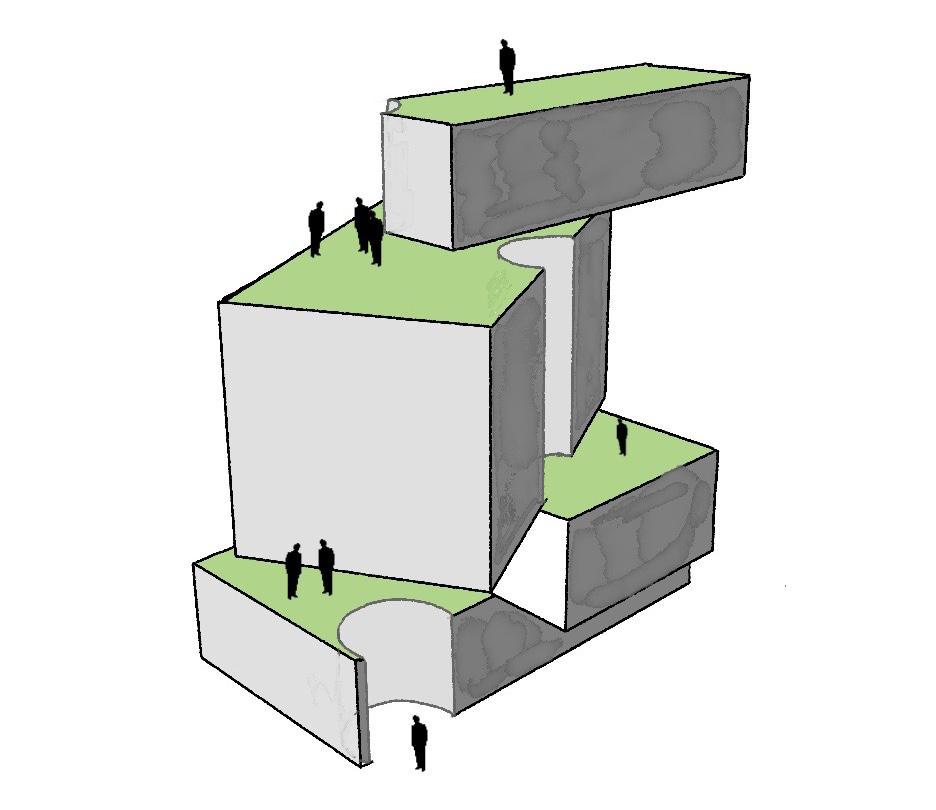

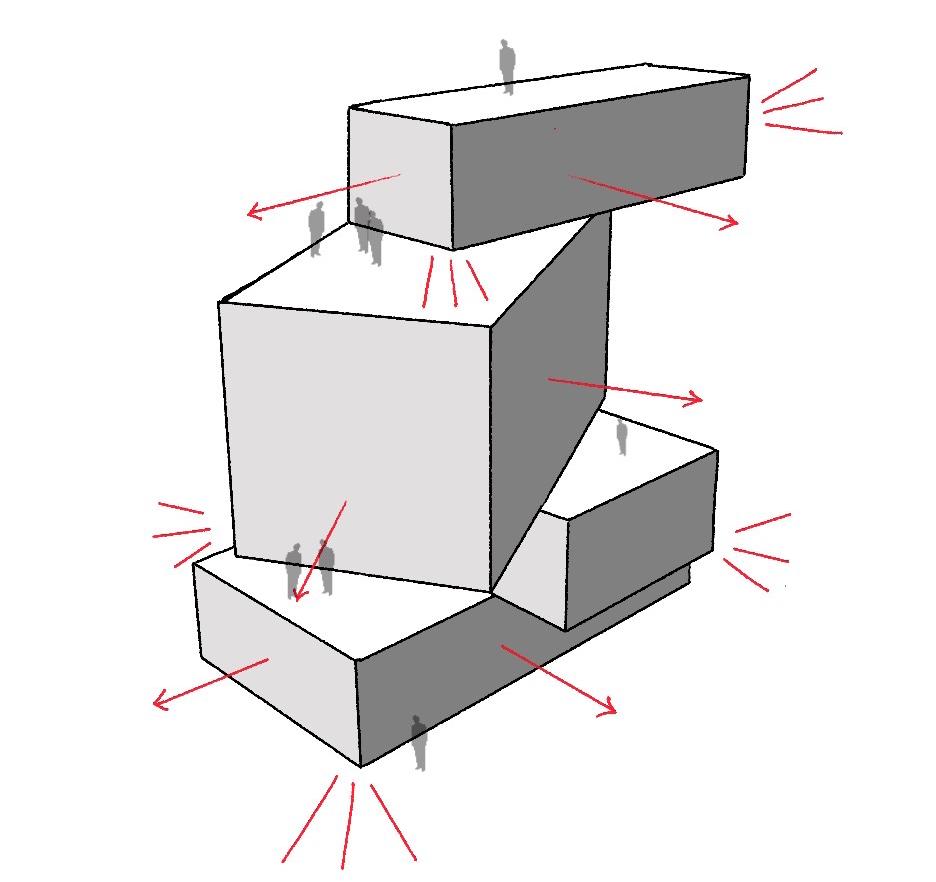

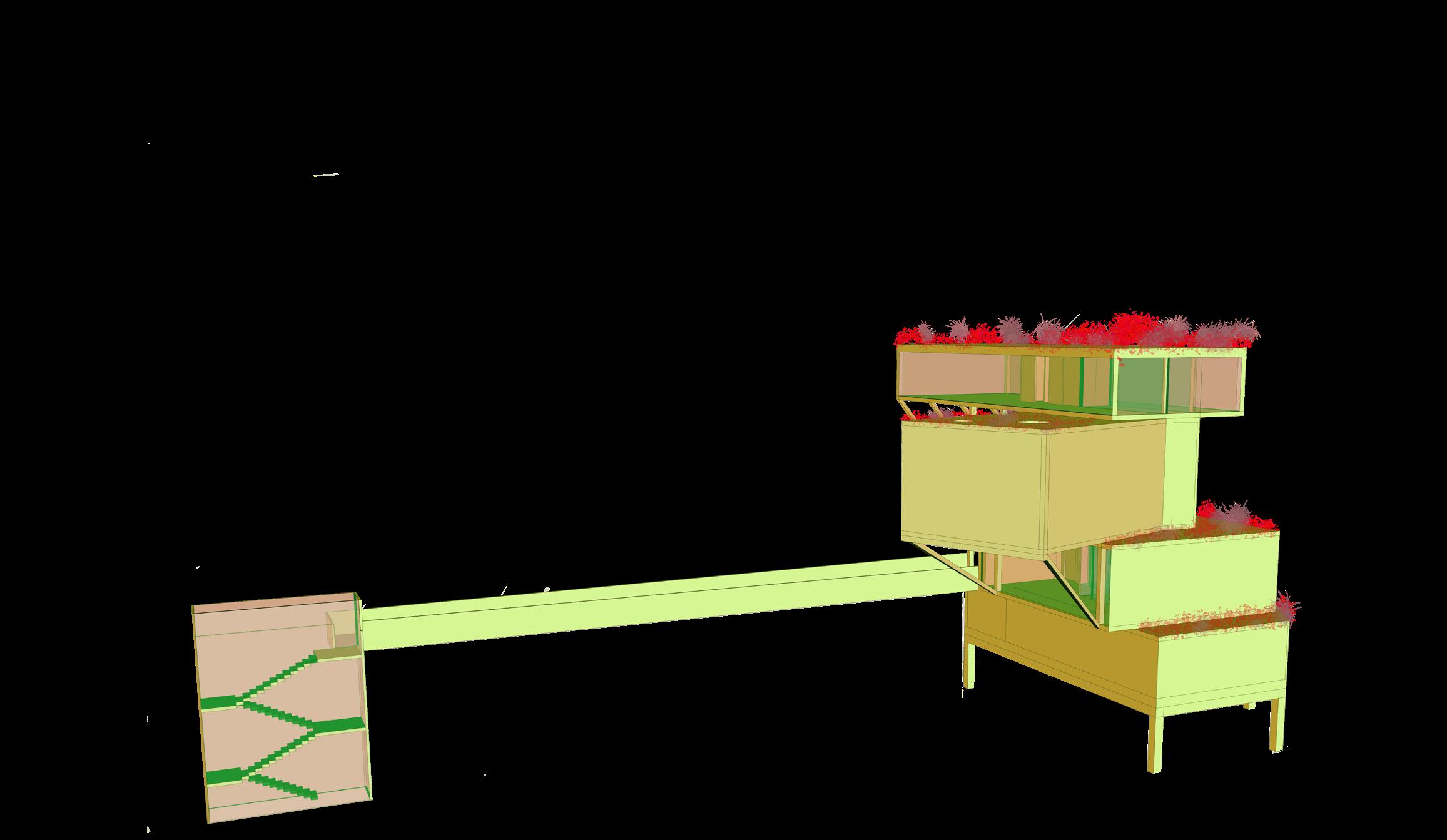

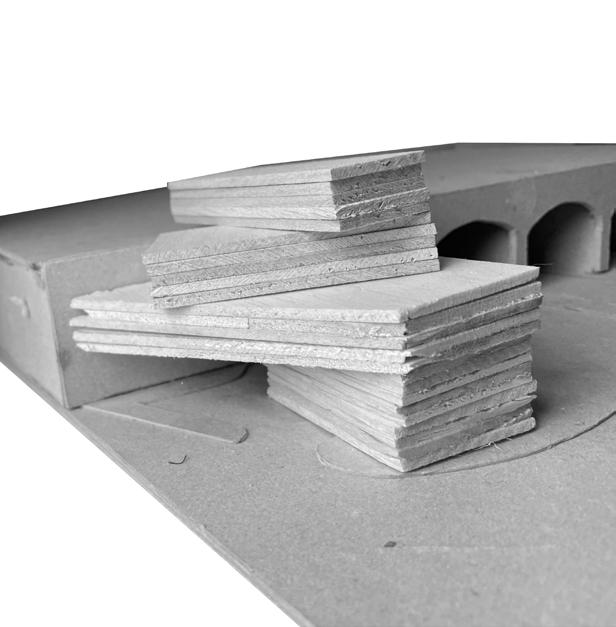

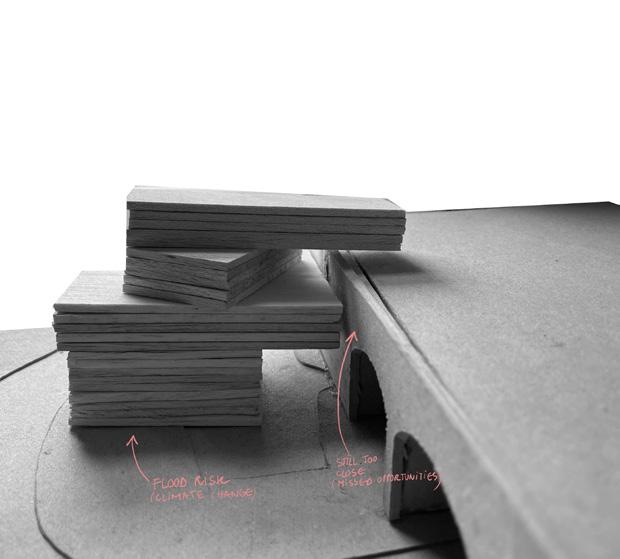

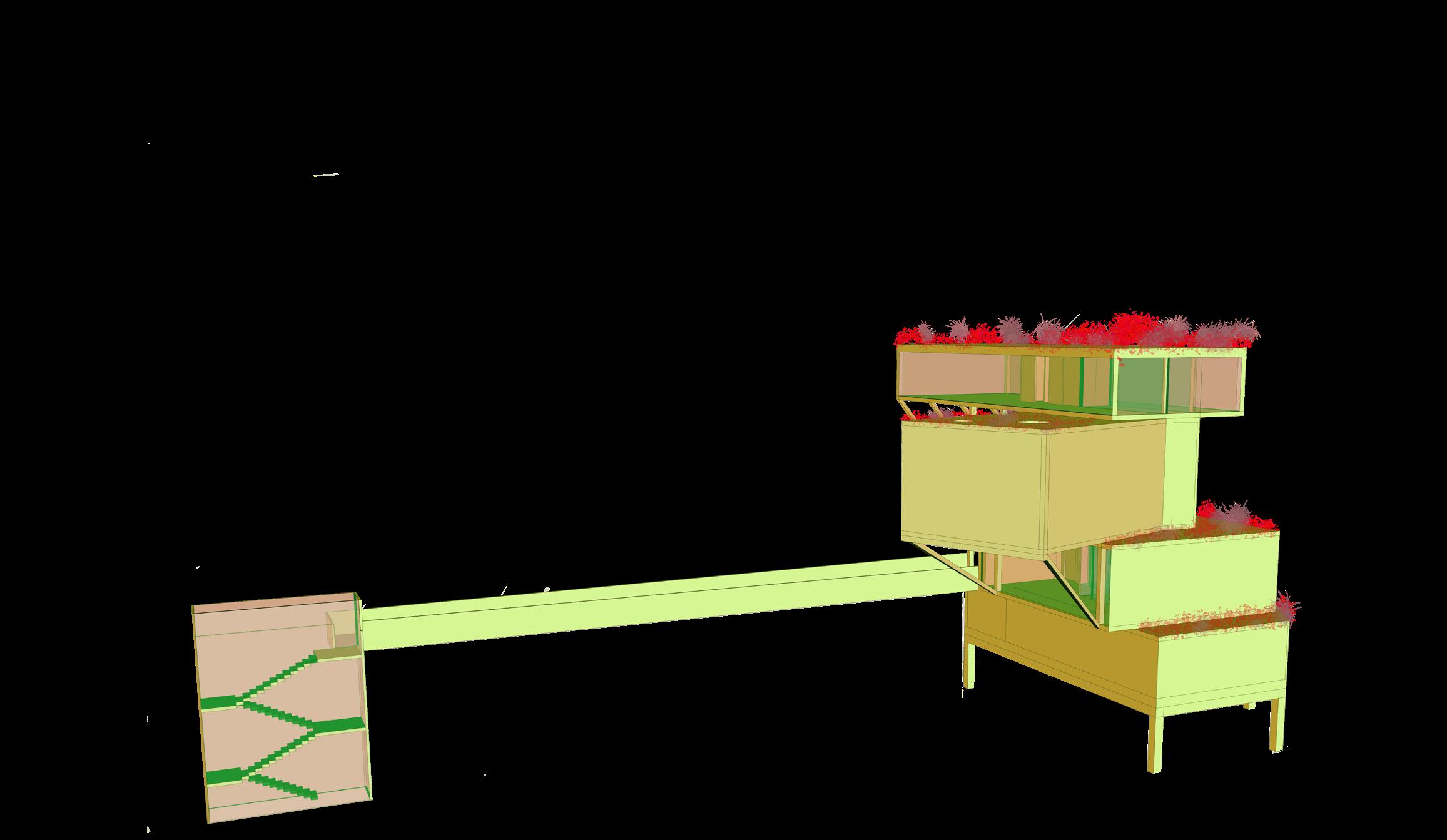

volumetric iterations - exploring connection with the viaduct

I tried to move around the cubes to create a clear connection between the floors and accentuate the cyclic programme of the building.

8

Exploring circulation

Precedents

Blocks Flexible floors

restaurant dyeing textiles

weaving textiles reception

Turn towards the views

Centre pomppidou

Renzo Piano, Richard Rogers, Gianfranco Franchini

Paris, France

Harbour Experience Centre MVRDV Rotterdam, Netherlands

Terraces

Programme Atrium voids for light Views Public route

9

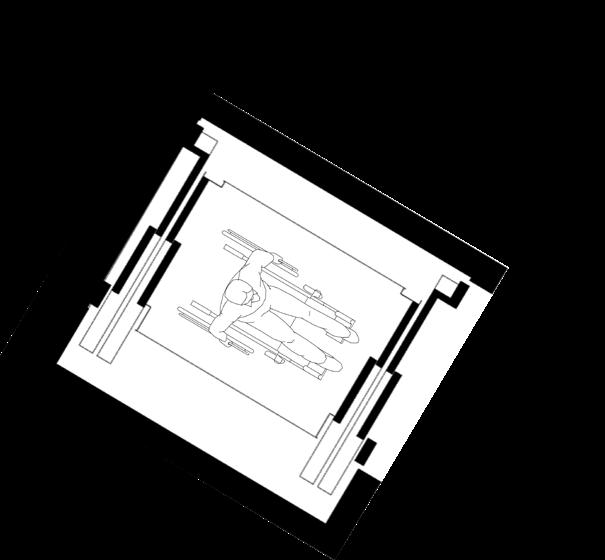

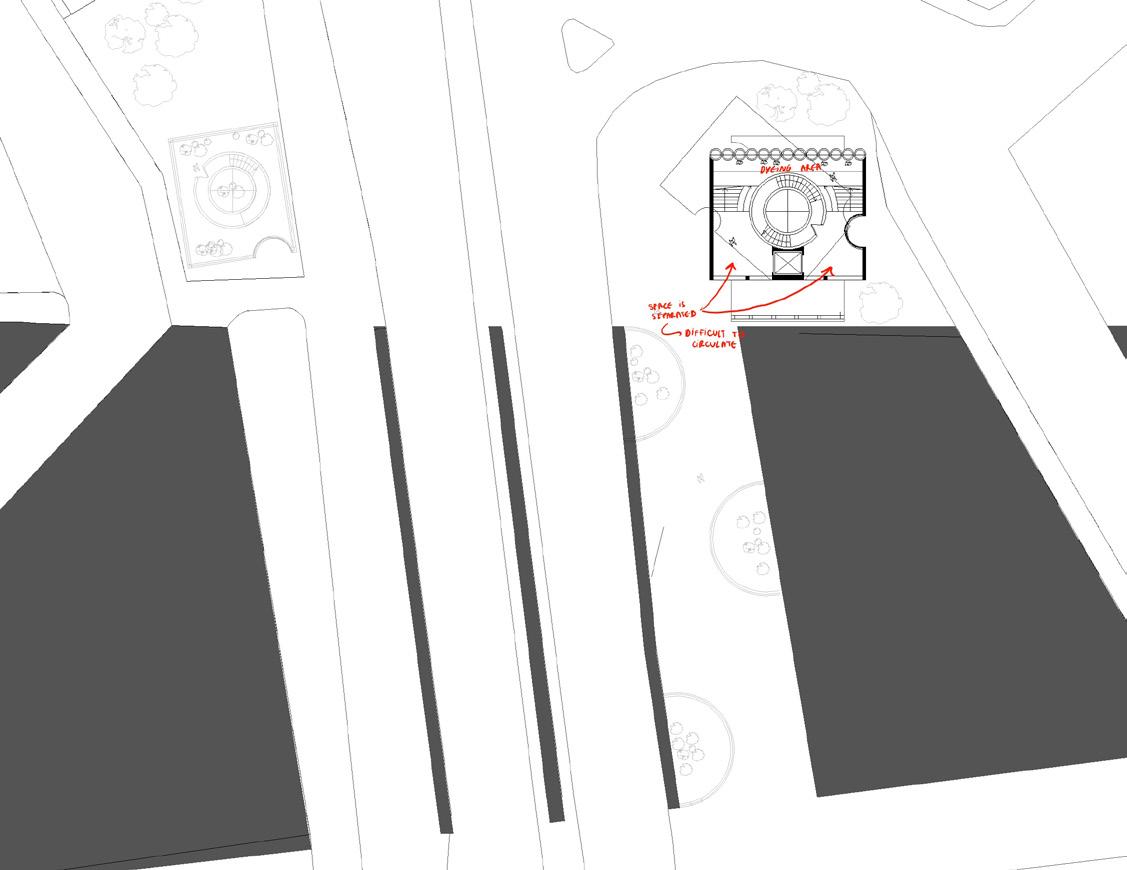

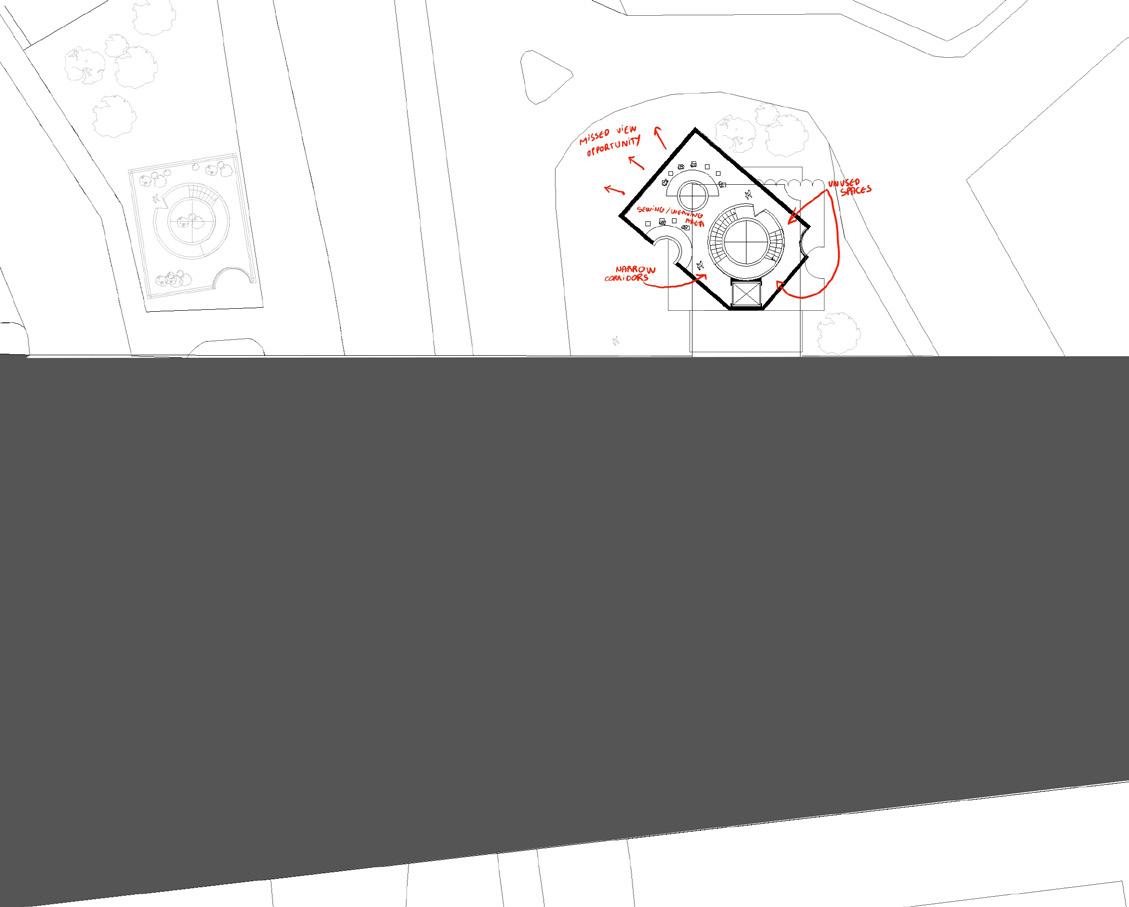

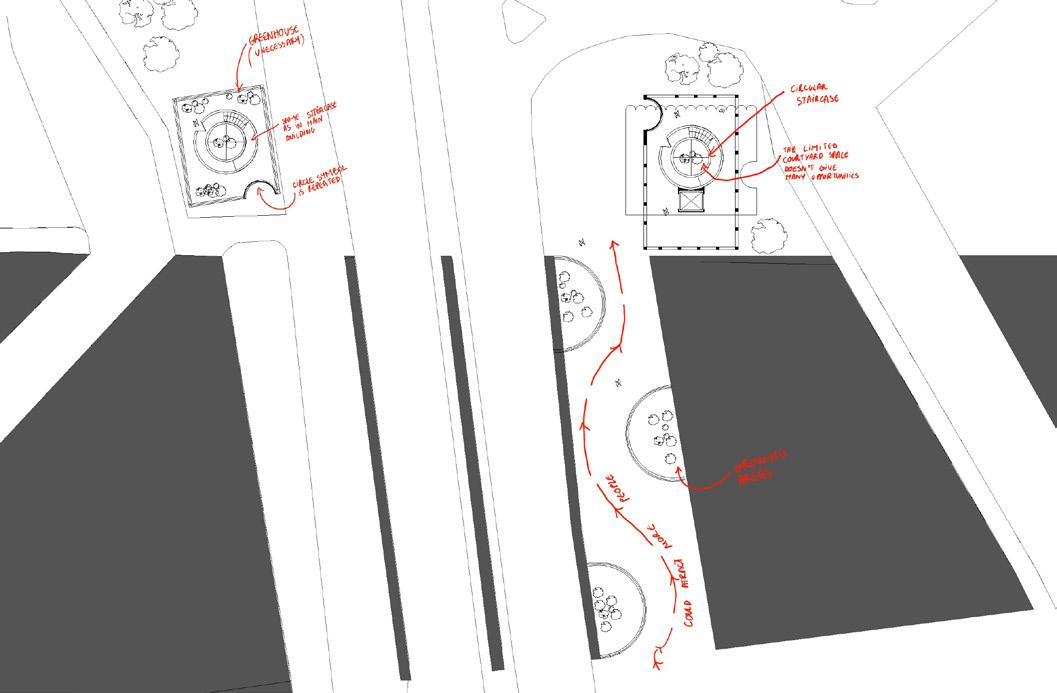

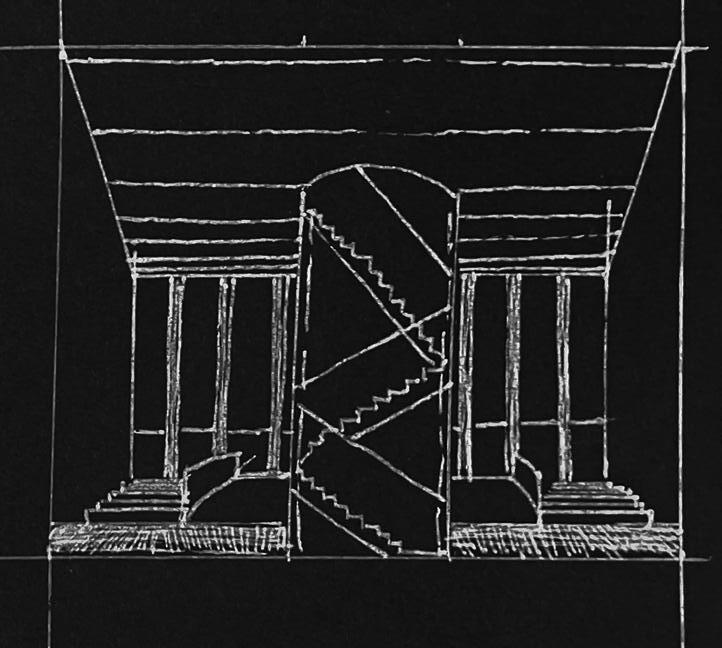

Design Process

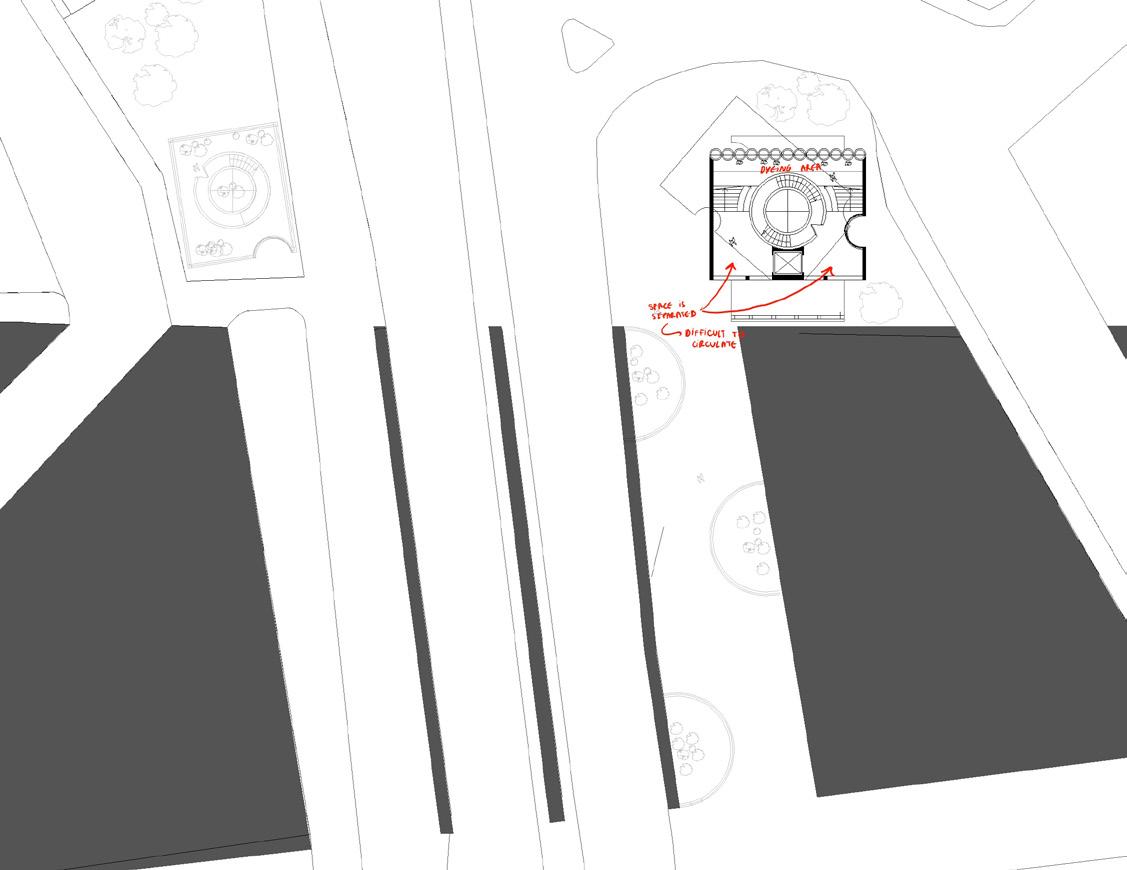

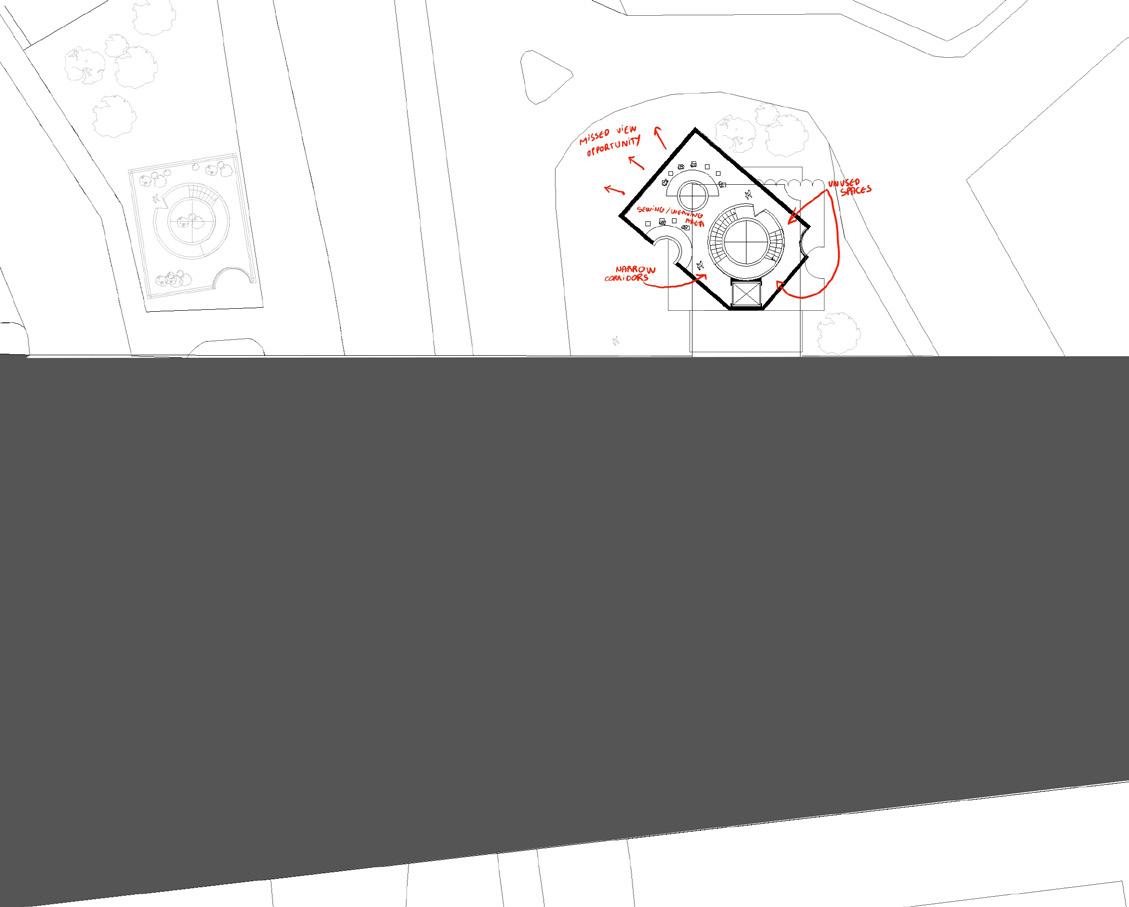

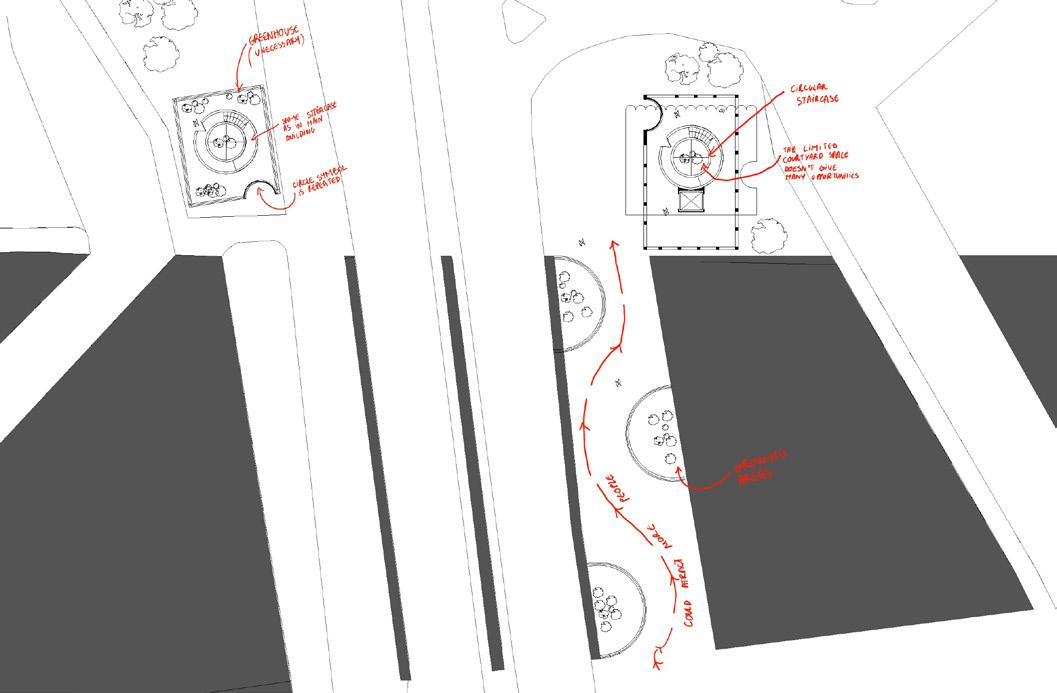

Plans iterations - Circulation as key feature

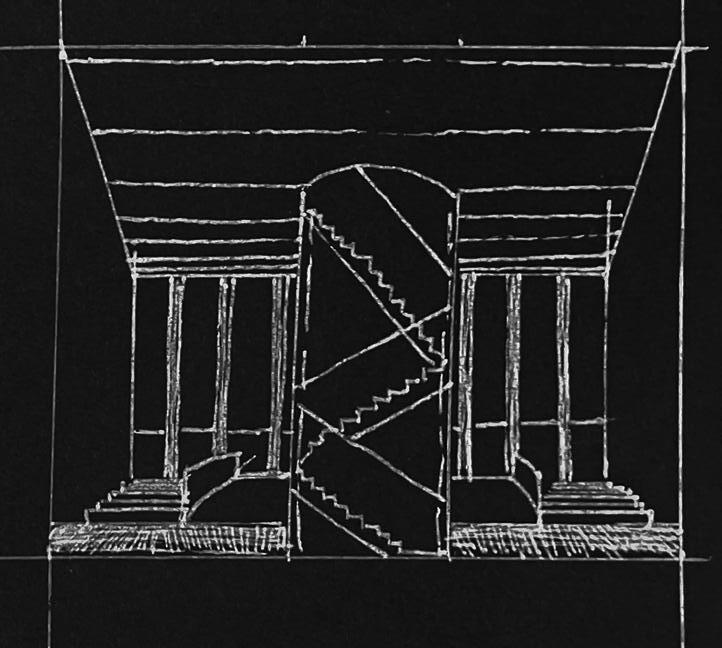

Taking inspiration from the previous precedents, I tried to find a way to highlight the circulation of the building by placing a circular staircase to to conncect the floors. Rather than exposing the circulation, I decided to make it the centre of the building to put the cyclicity of the programme in spotlight.

0 25 50 100

10

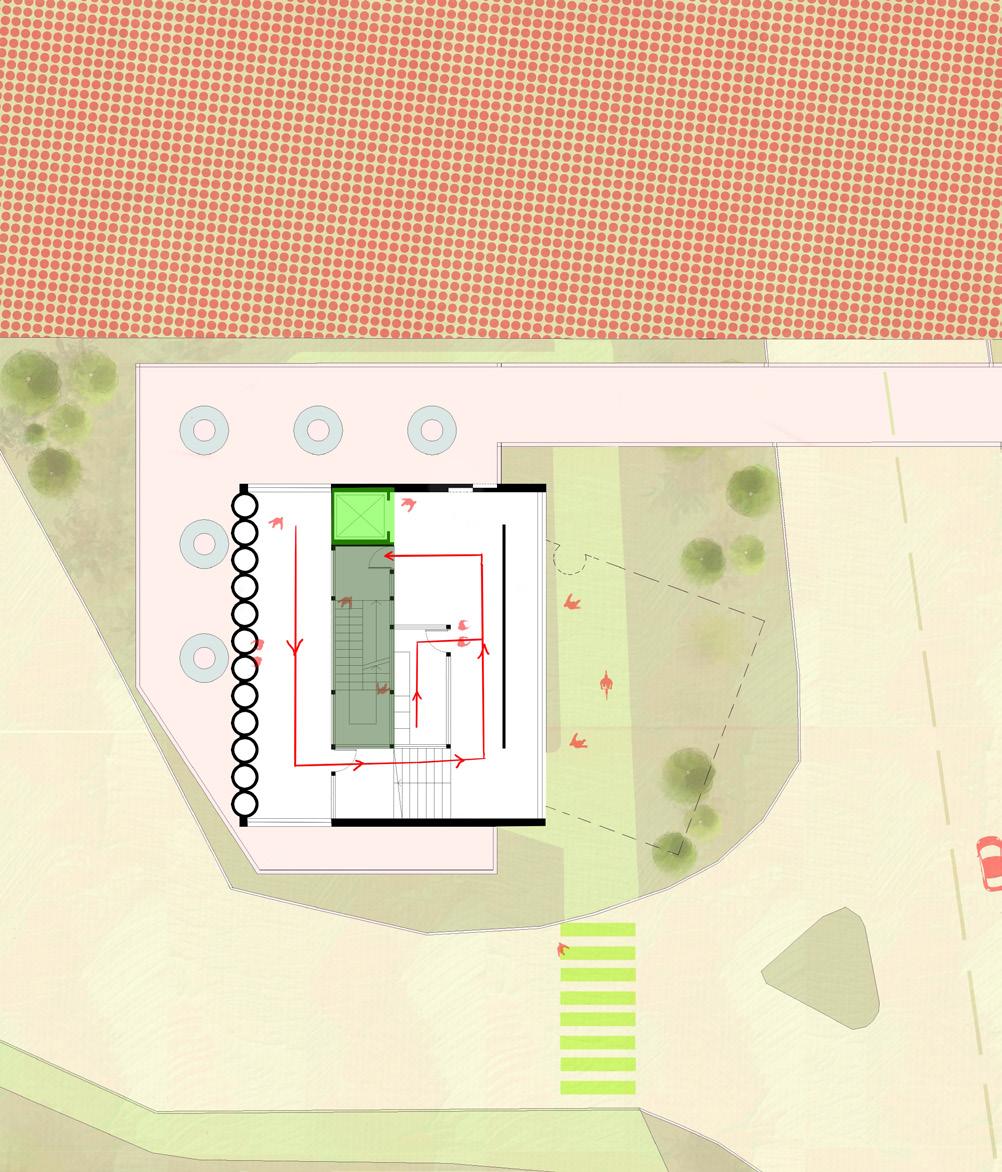

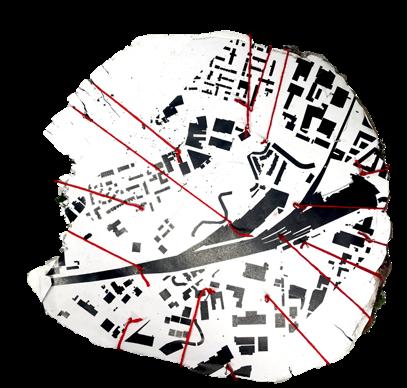

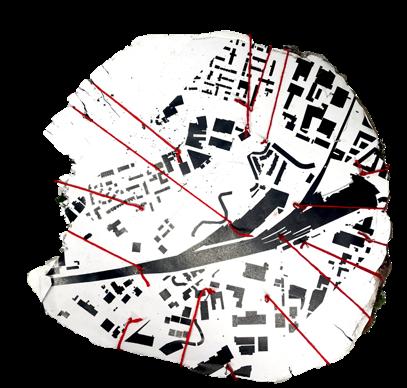

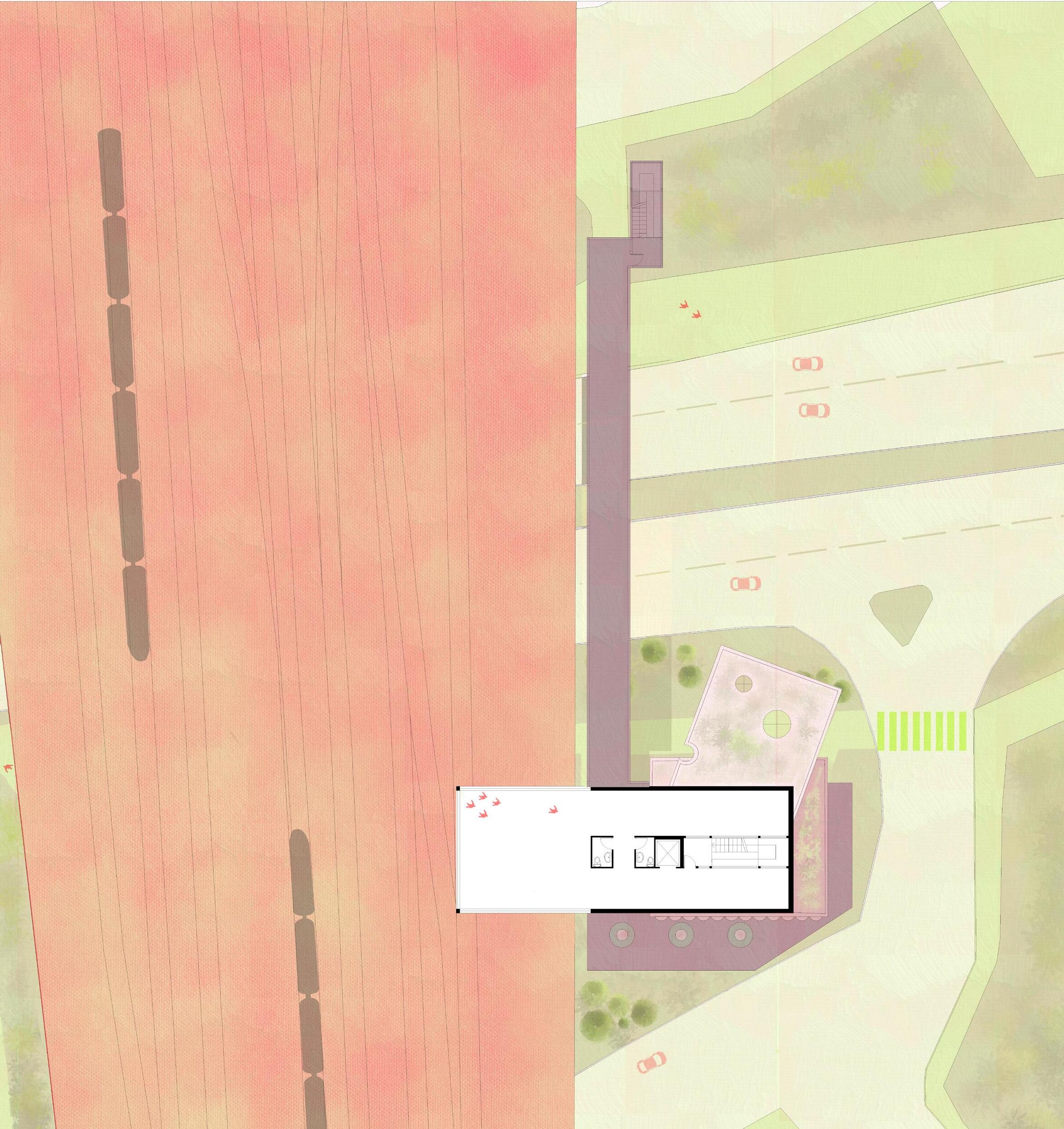

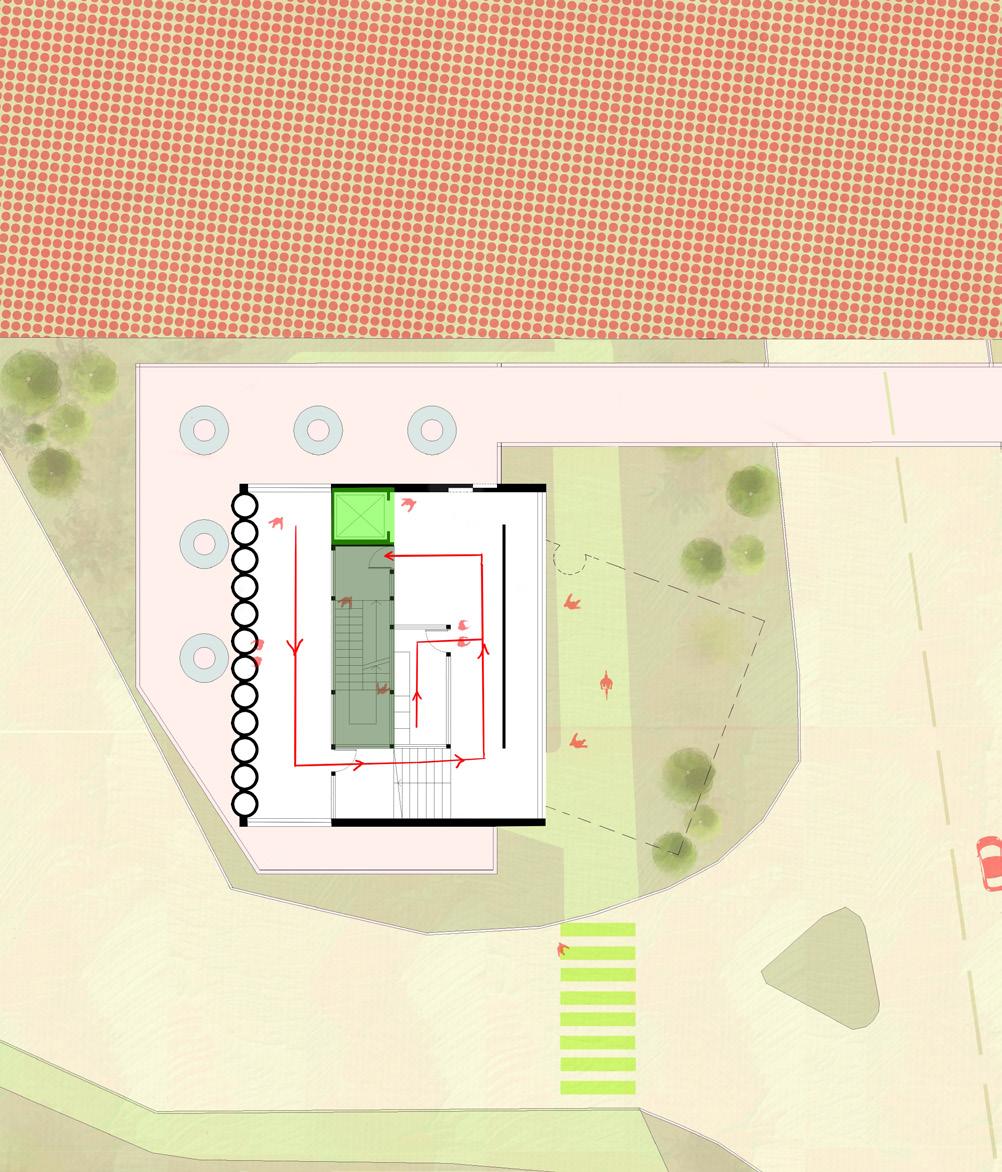

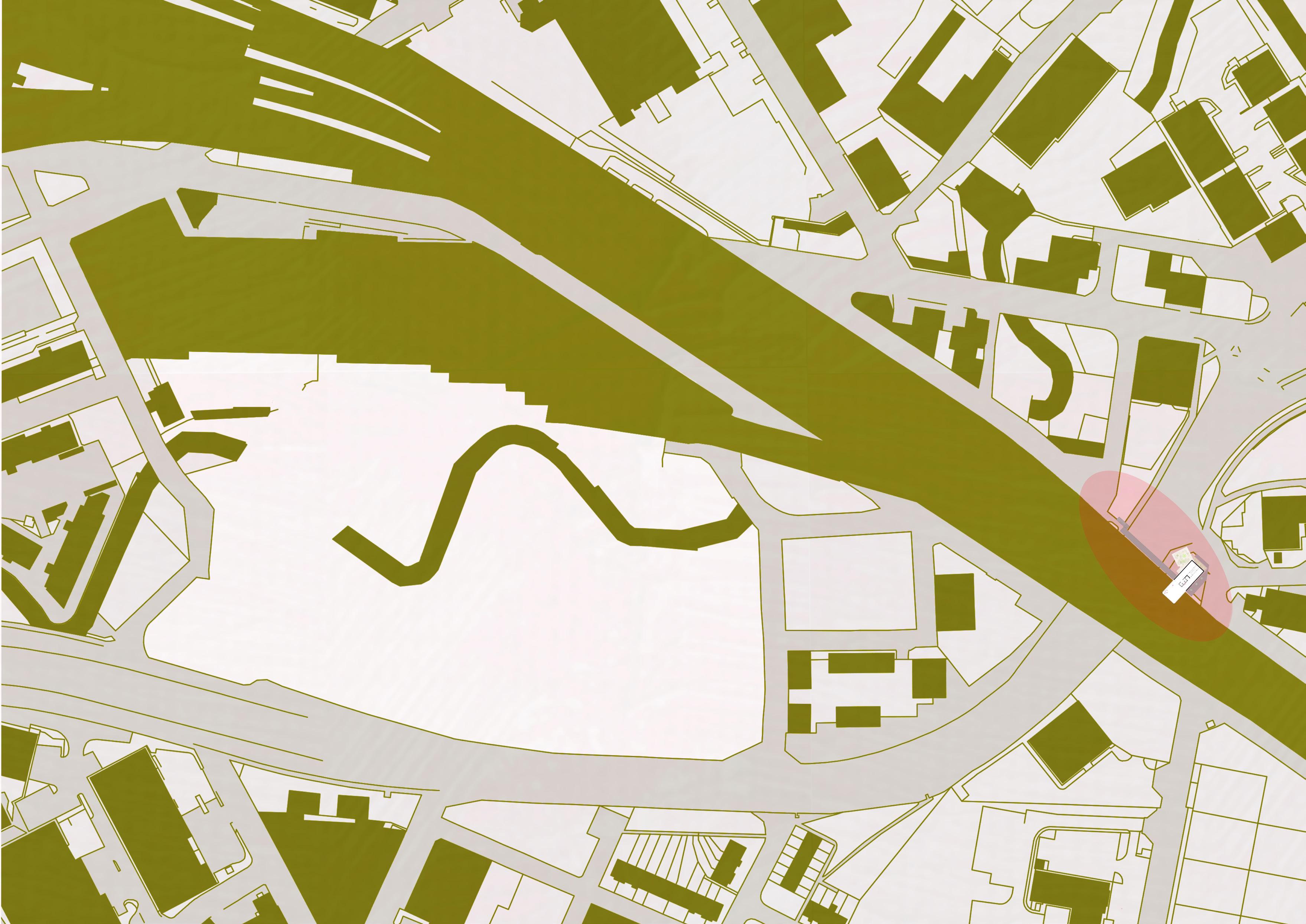

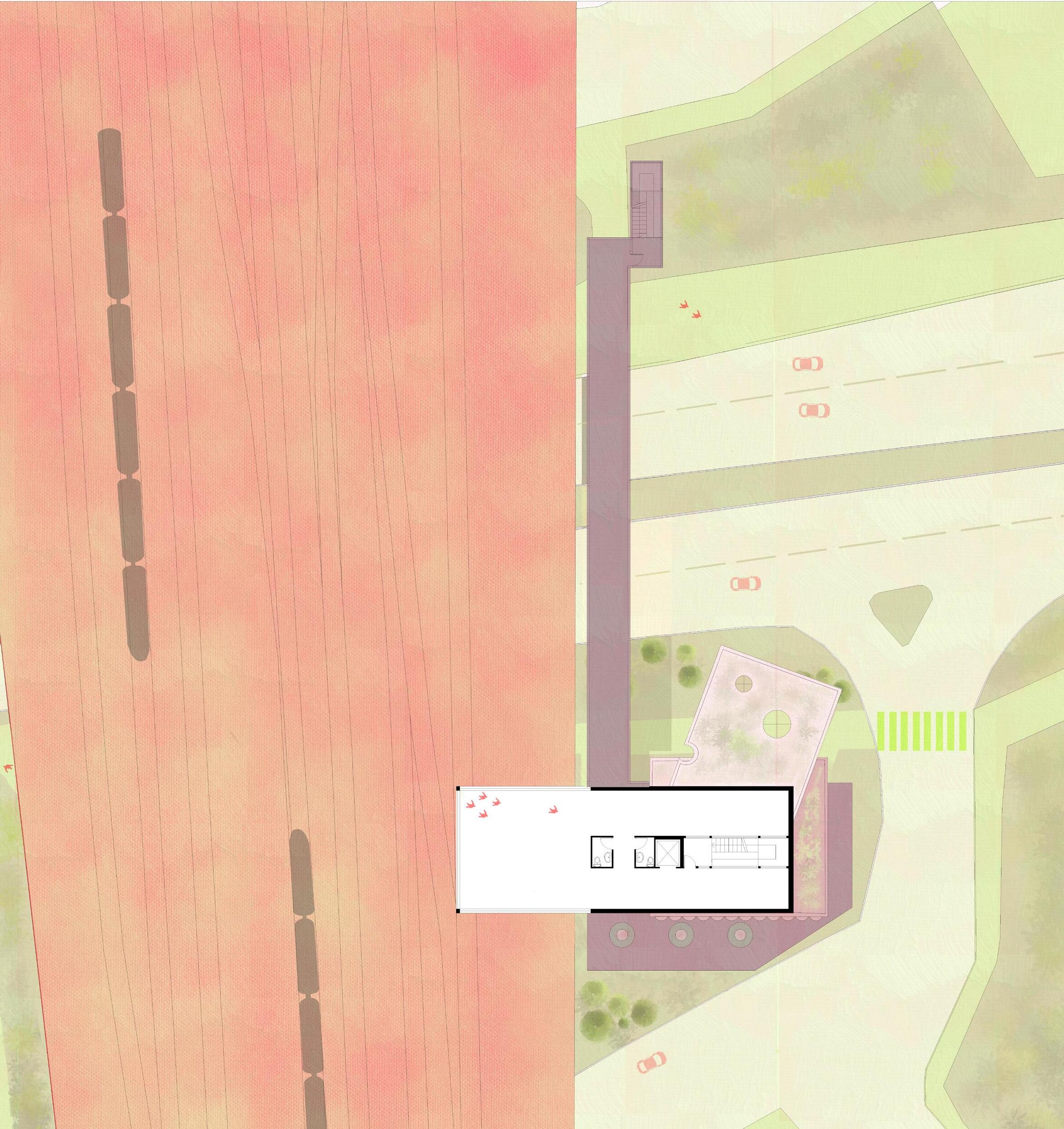

Masterplan Chosen design - Vegetation center 0 10 20 50 100 200 11

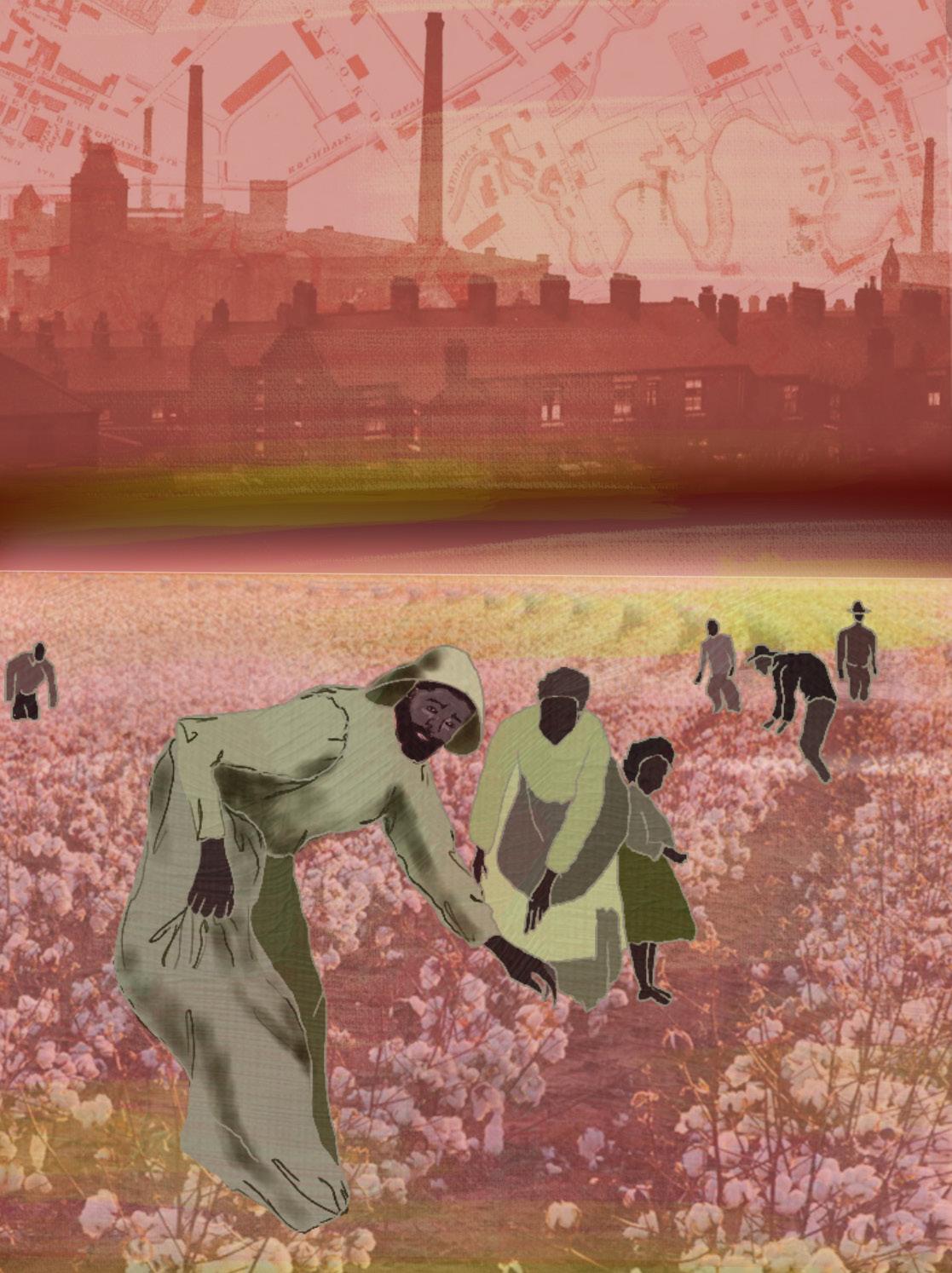

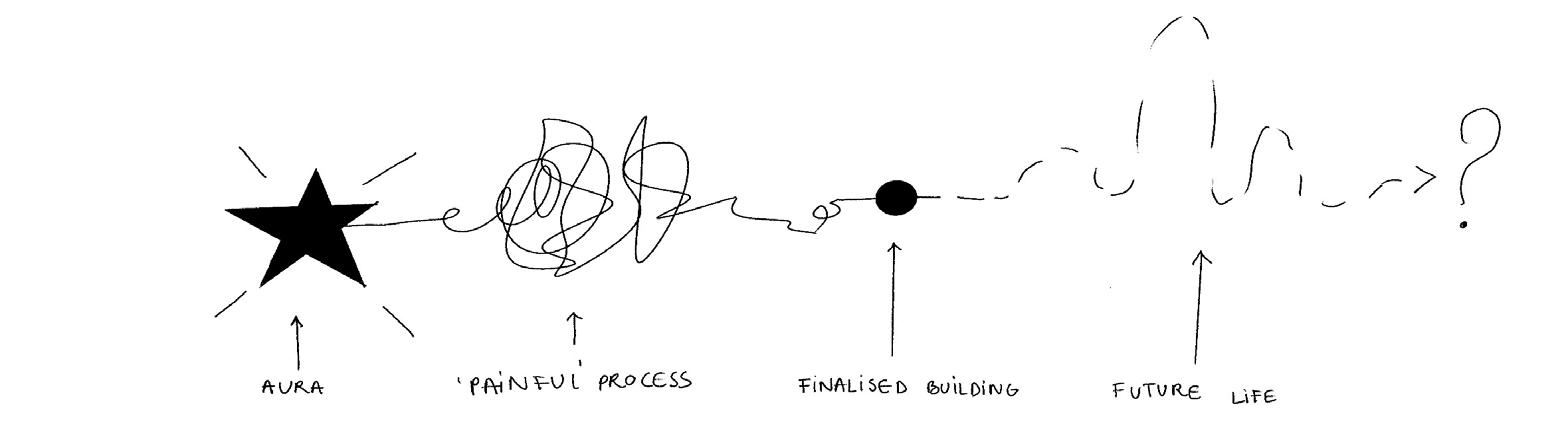

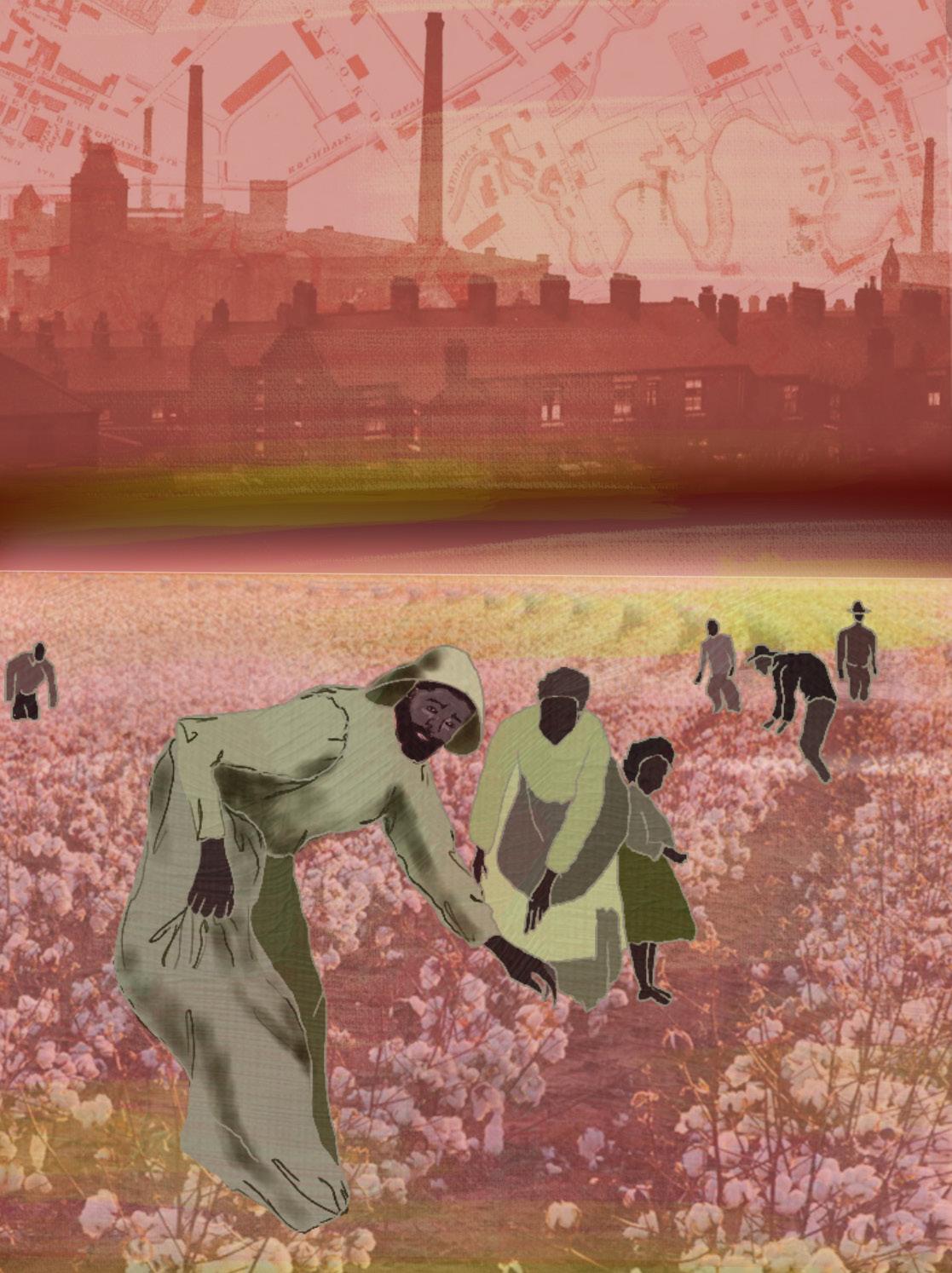

Time is irreverssible

Absorbing the past to build for the future

Manchester is known to be the first industrial city, being the epicentre of the country’s cotton industry. ‘Cottonpolis‘ was built on the back of slavery. The recognition of the industrial impact Manchester had is rarely associated with the heavy truth behind it.

I am designing a building with a programme that involves textiles in Mayfield to commemorate the slaves that worked on the mancunian cotton fields and brought the city its famous nickname, Cottonpolis. My building does not act like a typical factory, but rather celebrates a slow time, and therefore, creates inclusive, safe spaces for everyone.

12

Slow time Programme

THe programme is thought to be ciclic and displayed vertically in the building. Its purpose is to use the resources in a way that generates minimal waste.

1. GROW

2. DYE

4. EAT

5. LEARN

3. SEW Programme cycle

1. GROW

2. DYE

4. EAT

5. LEARN

3. SEW Programme cycle

13 1 2 3 4 5

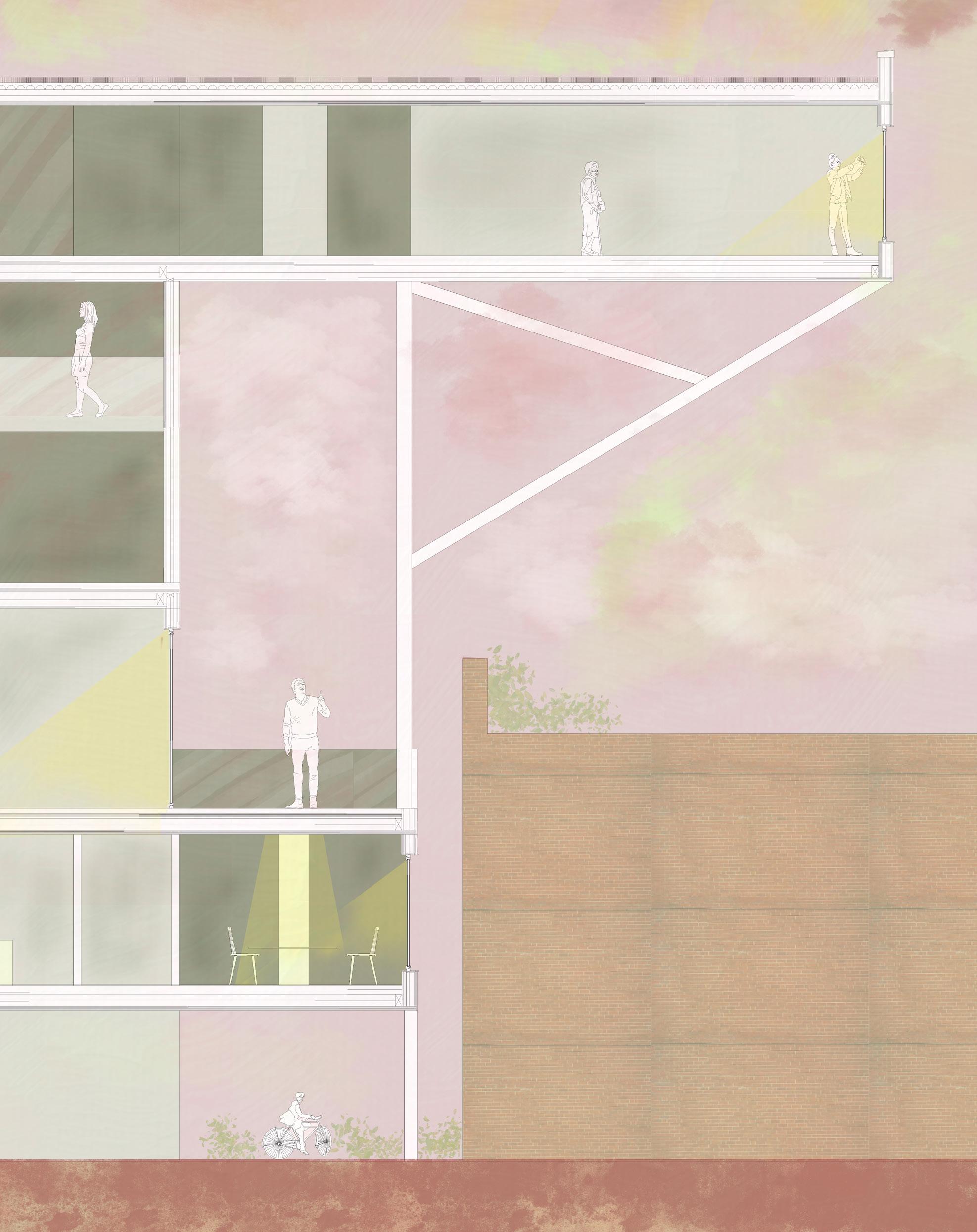

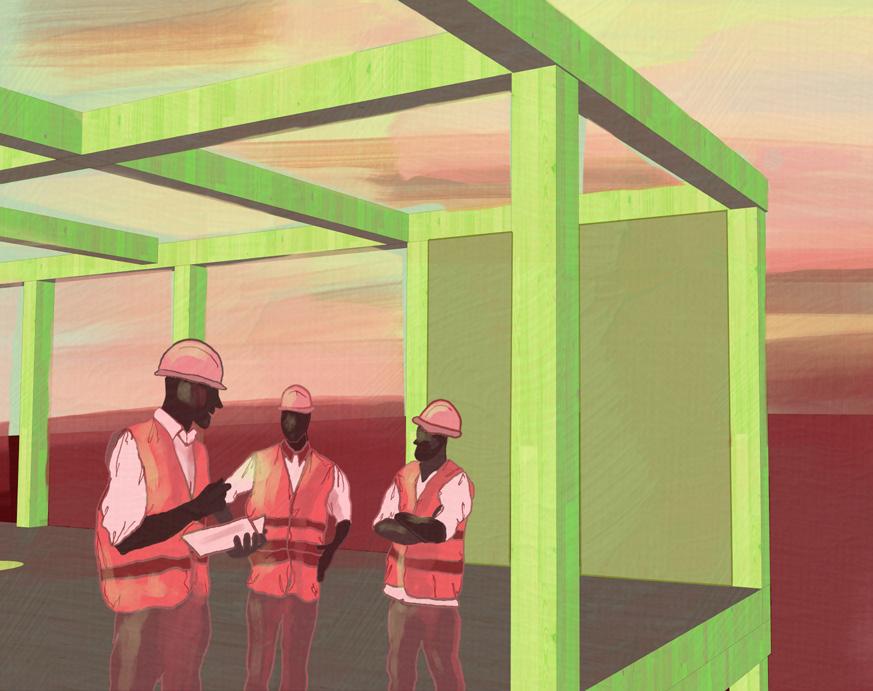

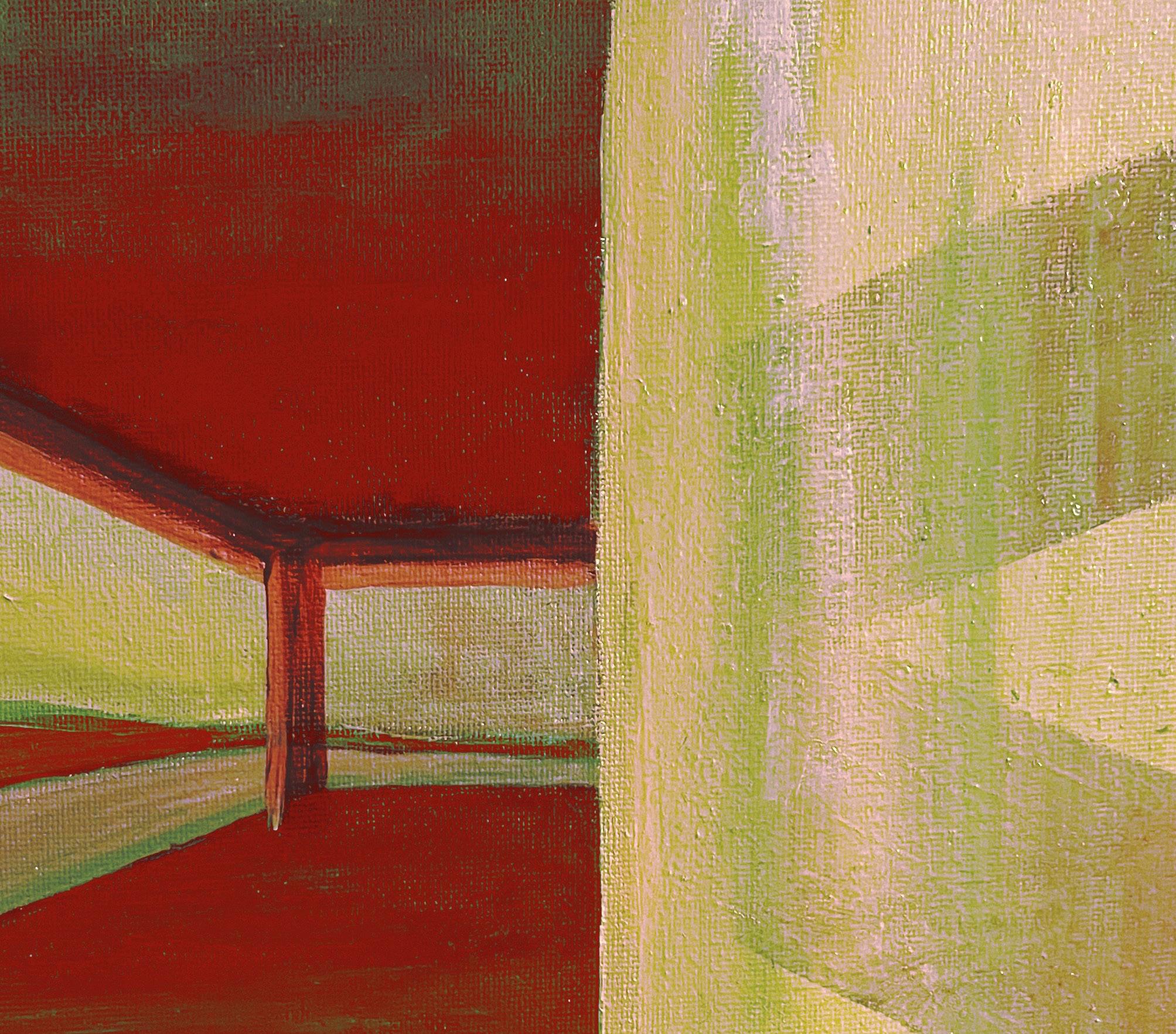

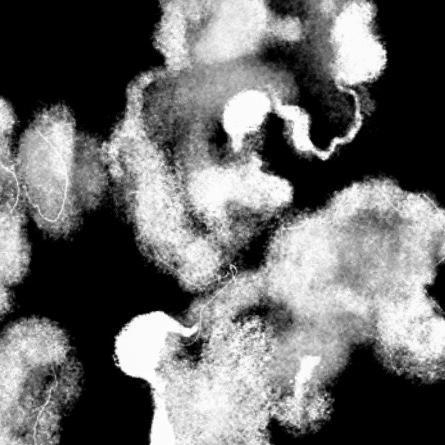

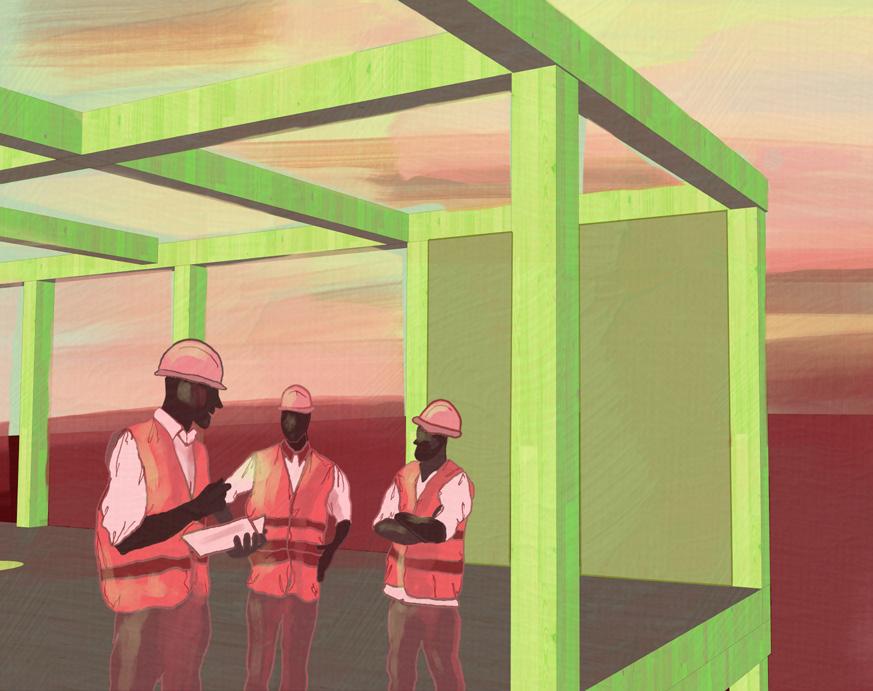

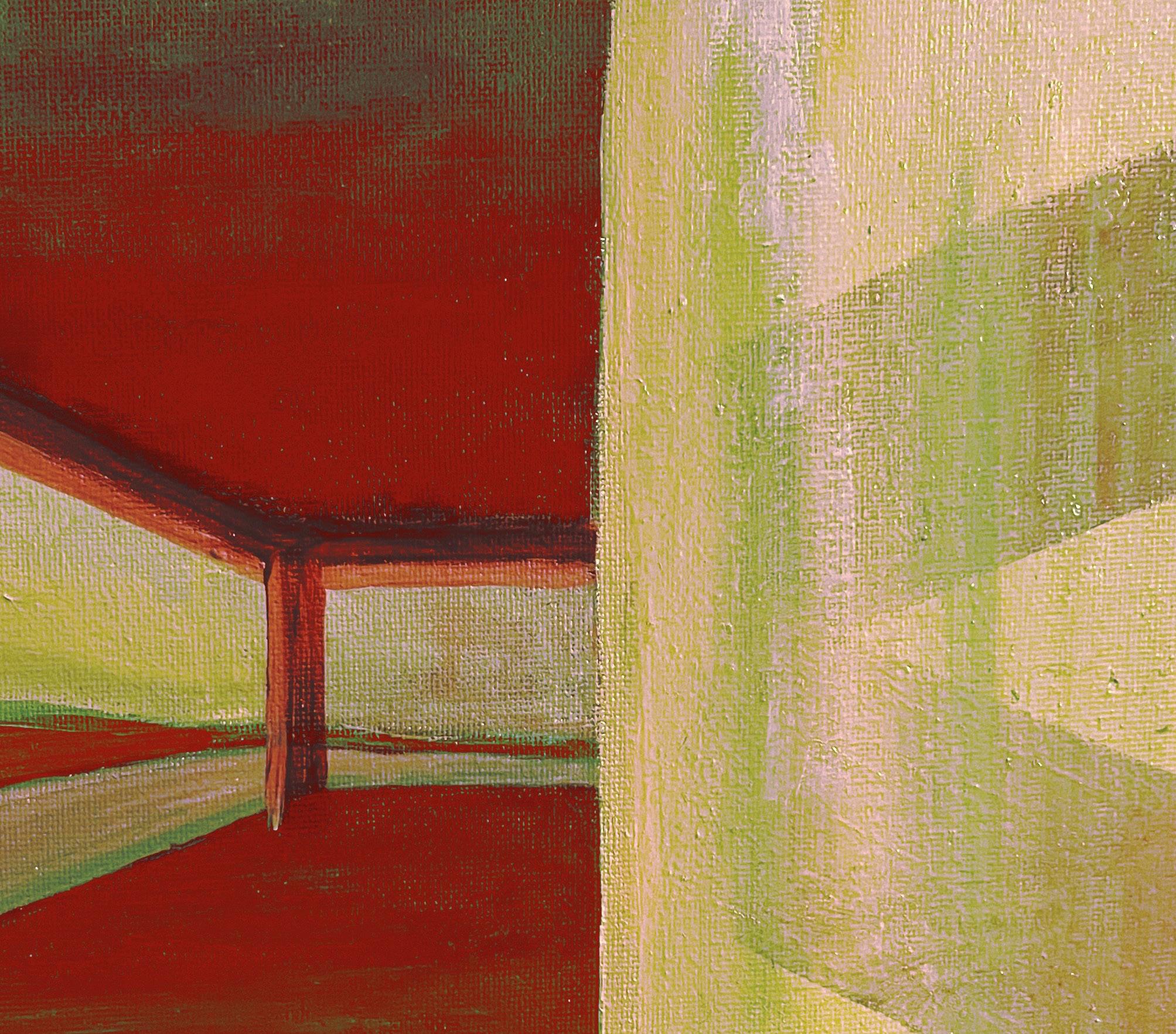

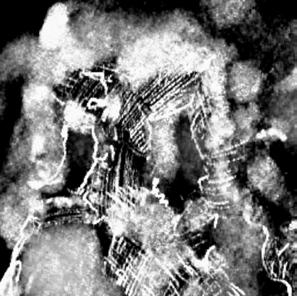

Light the creator

Atmospheric vignettes

I experimented with oil paint on canvas some of the tresholds of the building to understand light. I produced a triptych where light is the creator of space.

14

Ground Floor

0 25 50 100

Plan1:200

A. greenhouse

B. bikes parking

A A A B C B 15

C. recycling centre

1st Floor

Plan1:200

A.dinning area

B.storage area

C.kitchen

D.toilets

E.reception

0 25 50 100

C A B D E 16

2nd Floor

Plan1:200

A. dyeing area

B. drying/ exhibition area

C. dyeing lab

D, bridge

0 25 50 100

B C A D 17

0 25 50 100

Plan1:200 A.sewing area B.observation/ visitors space A B 18

3rd Floor

0 25 50 100 4th Floor Plan1:200 A B

workshops/ observatory space B.

19

A.

toiilets

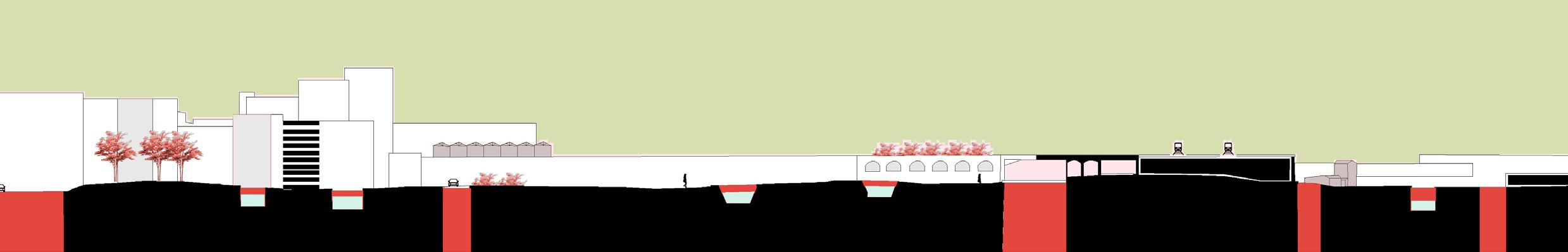

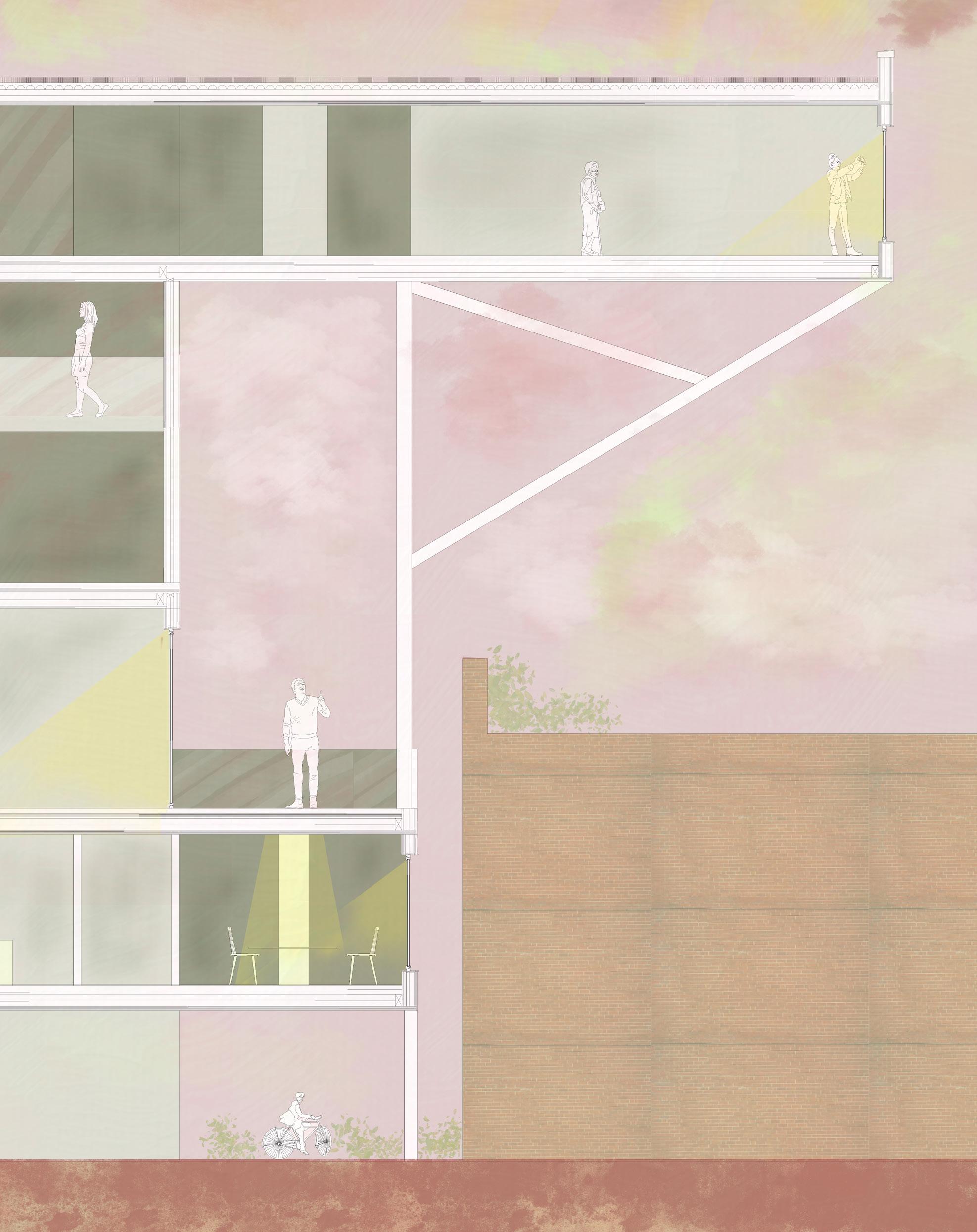

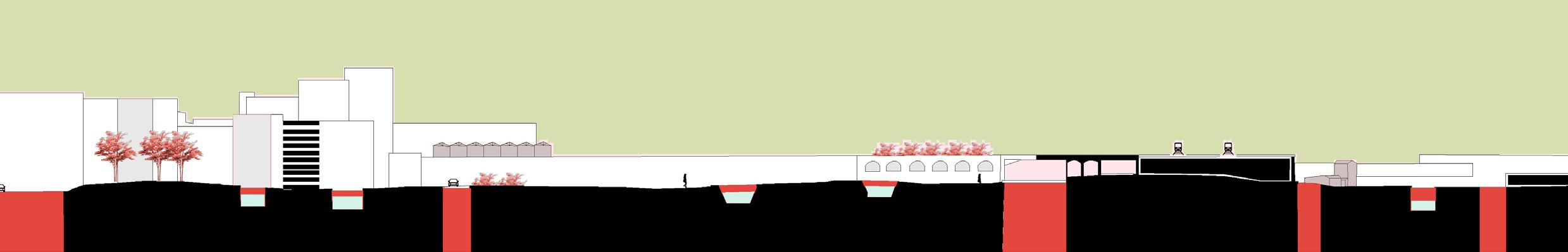

Reaching the viaduct

Section AA’ and BB’ 1:200

100 0 25 50 20

Reaching the viaduct

Section CC’ and Elevation DD’ 1:200 0 25 50 21

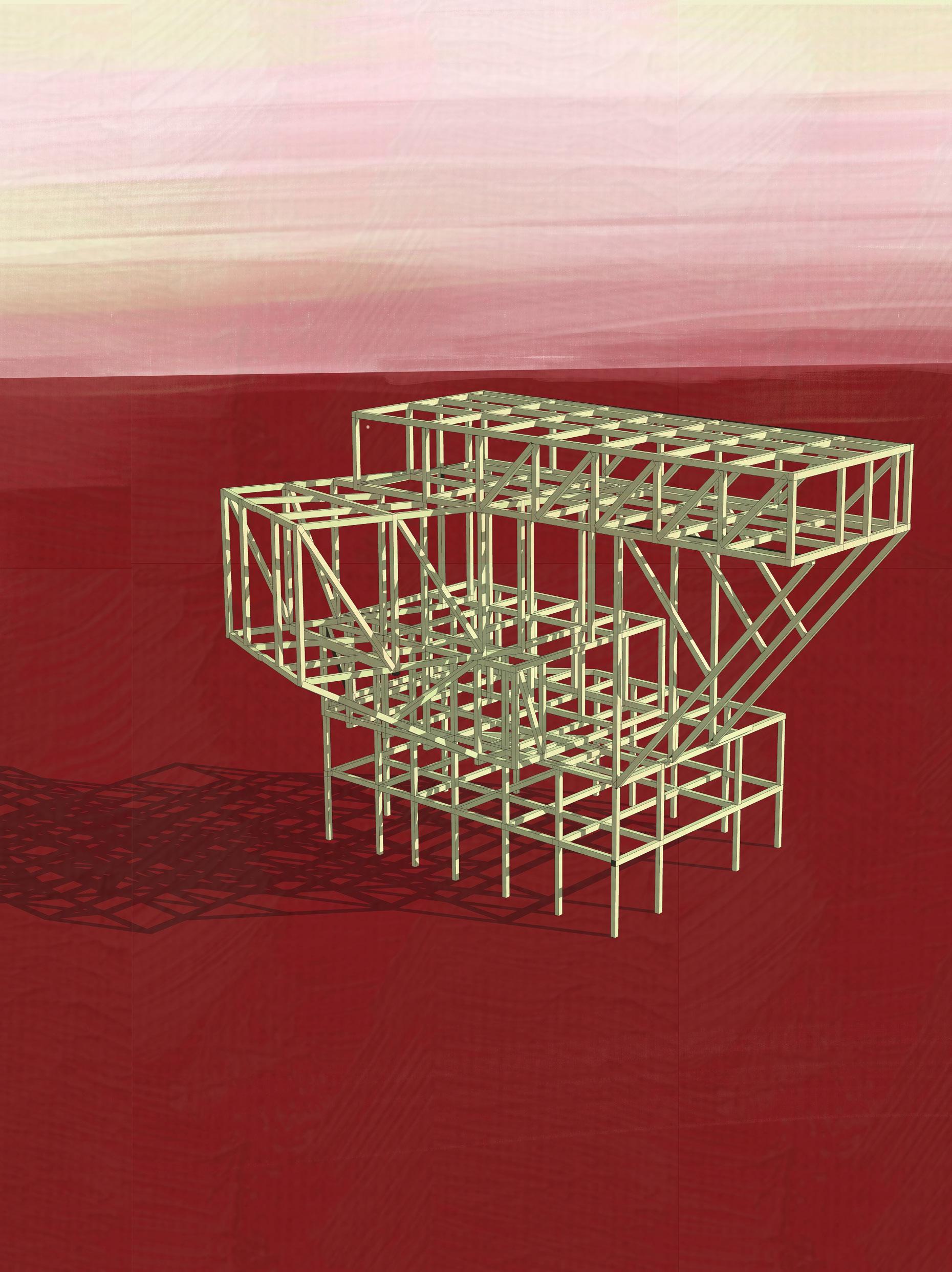

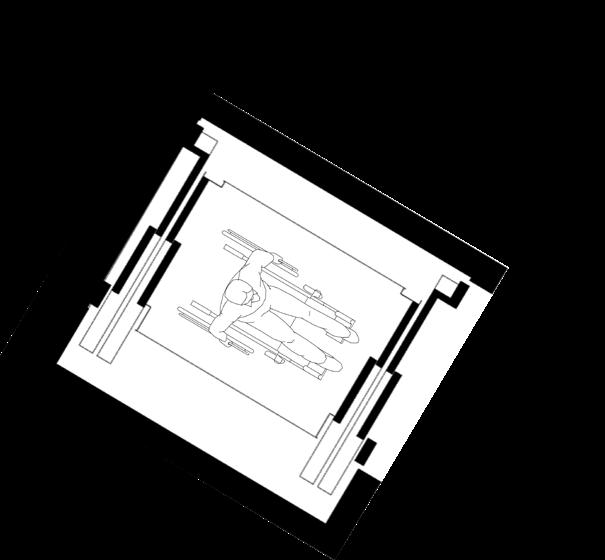

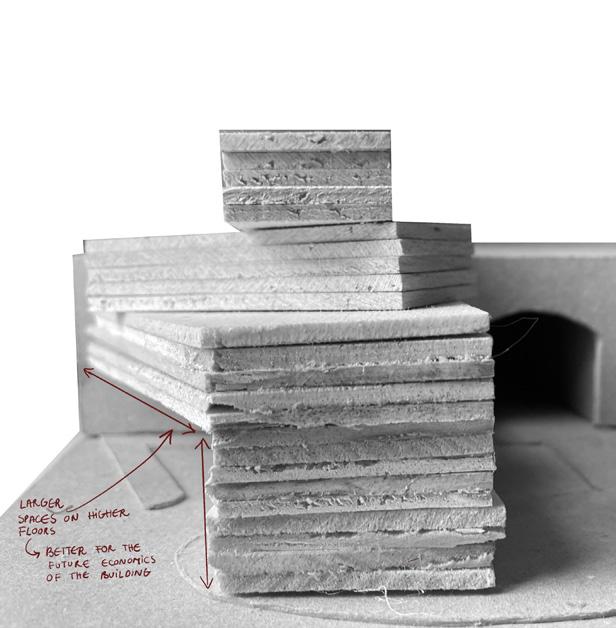

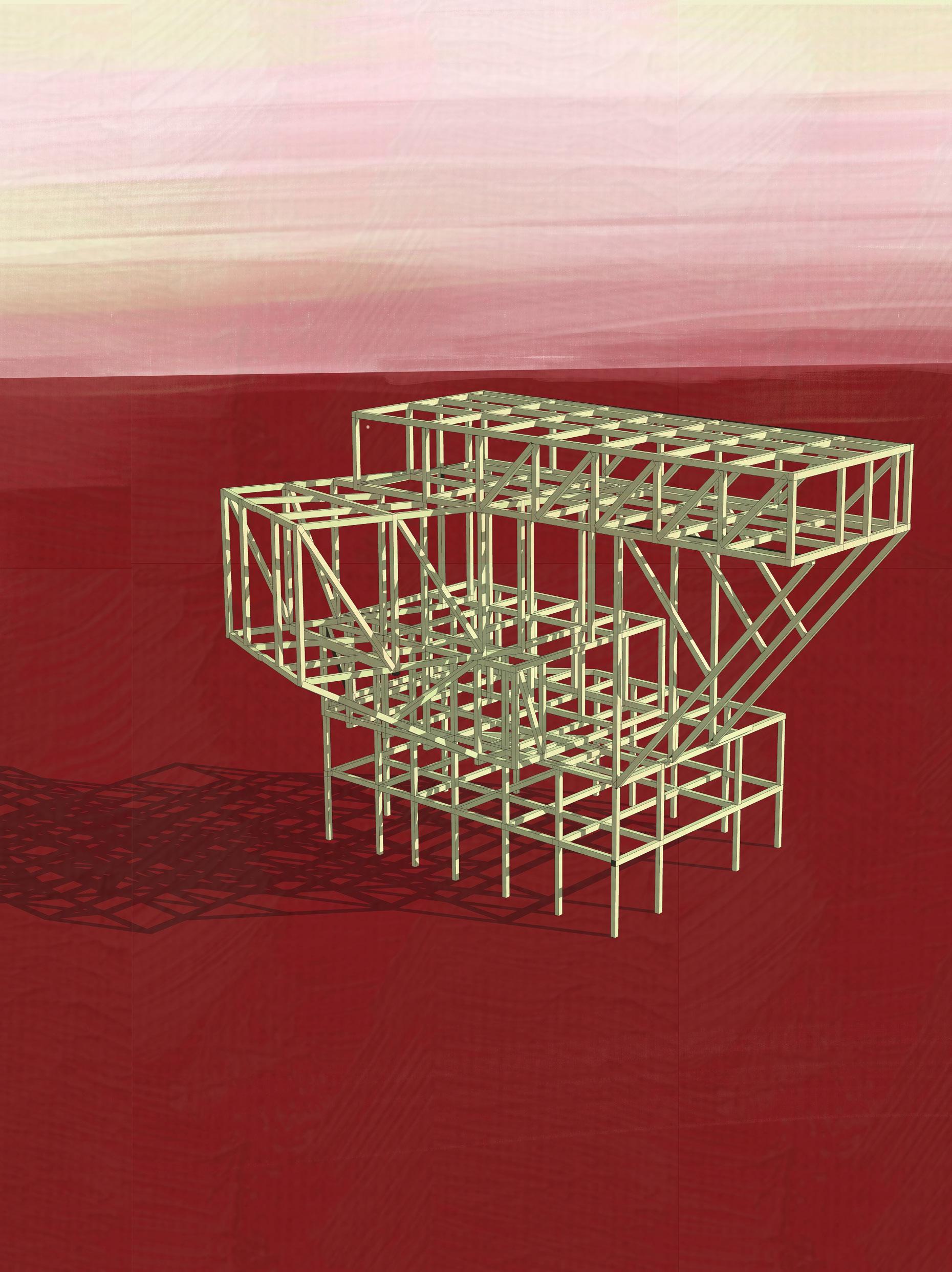

Structural strategy

Structure & Materiality

CLT framing as primary structure

+design flexibility

+high level of thermal performances

+predictability and speed of programme

+improved health and safety

more sustainable

-require a lot of maintainance

-sound travels easier

-shorter spn (can be improved by additional elements)

Materials

I chose materials that could represent the programme (sustainable textile dyeing) and atmosphere of the building best, therefor I looked to be highly sustainable (CLT) and to react visibly to external elements, such as rain, sunlight (coppper changes its colour).

CLT floor slab and walls

CLT support columns and beams

CLT pillars

CLT floor slab and walls

CLT floor slab and walls

CLT floor slab and walls

CLT floor slab and walls

CLT support columns and beams

CLT pillars

CLT floor slab and walls

CLT floor slab and walls

CLT floor slab and walls

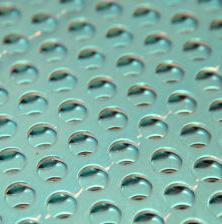

CLT Glazing Perforated copper corten steel

CLT support columns and beams

22

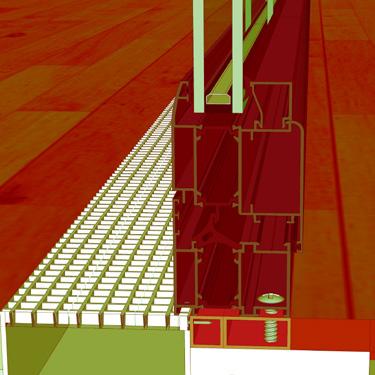

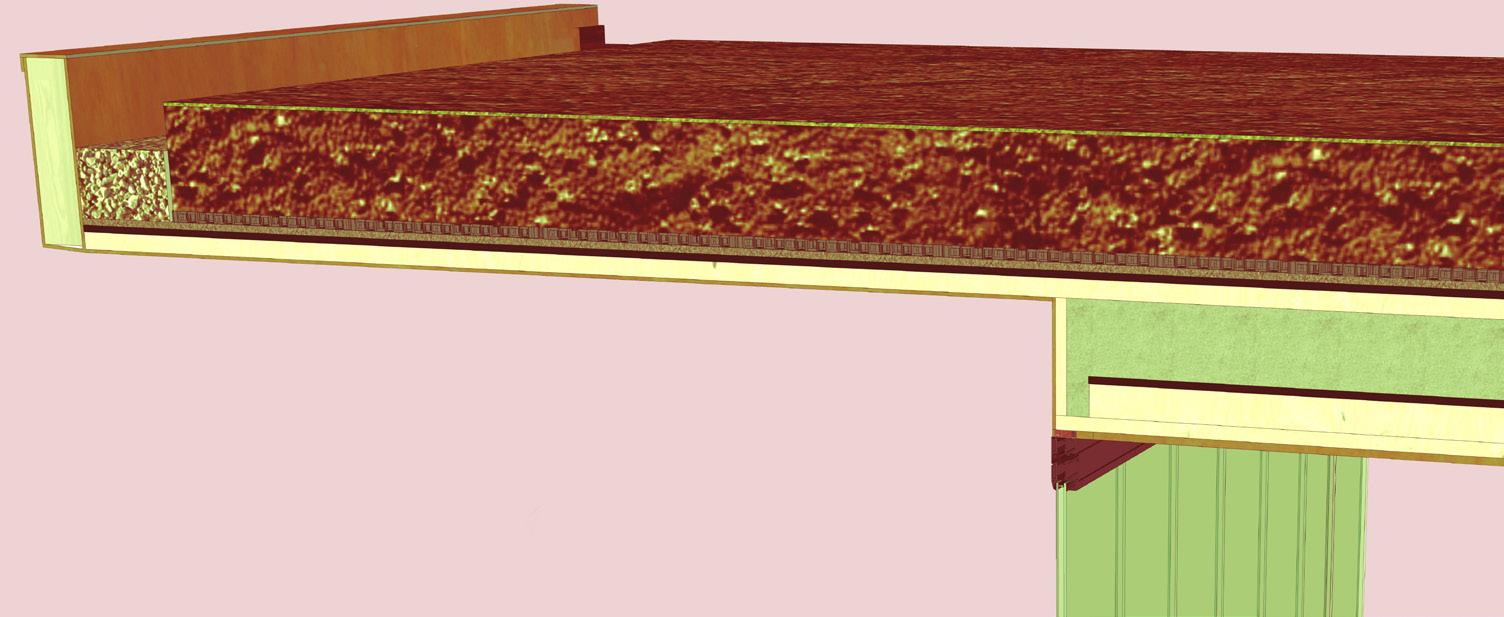

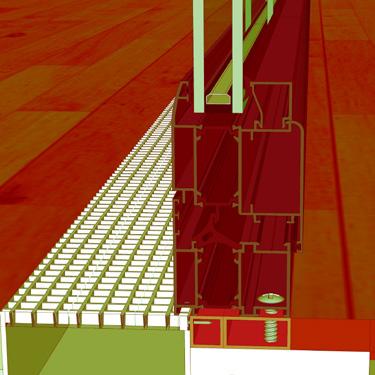

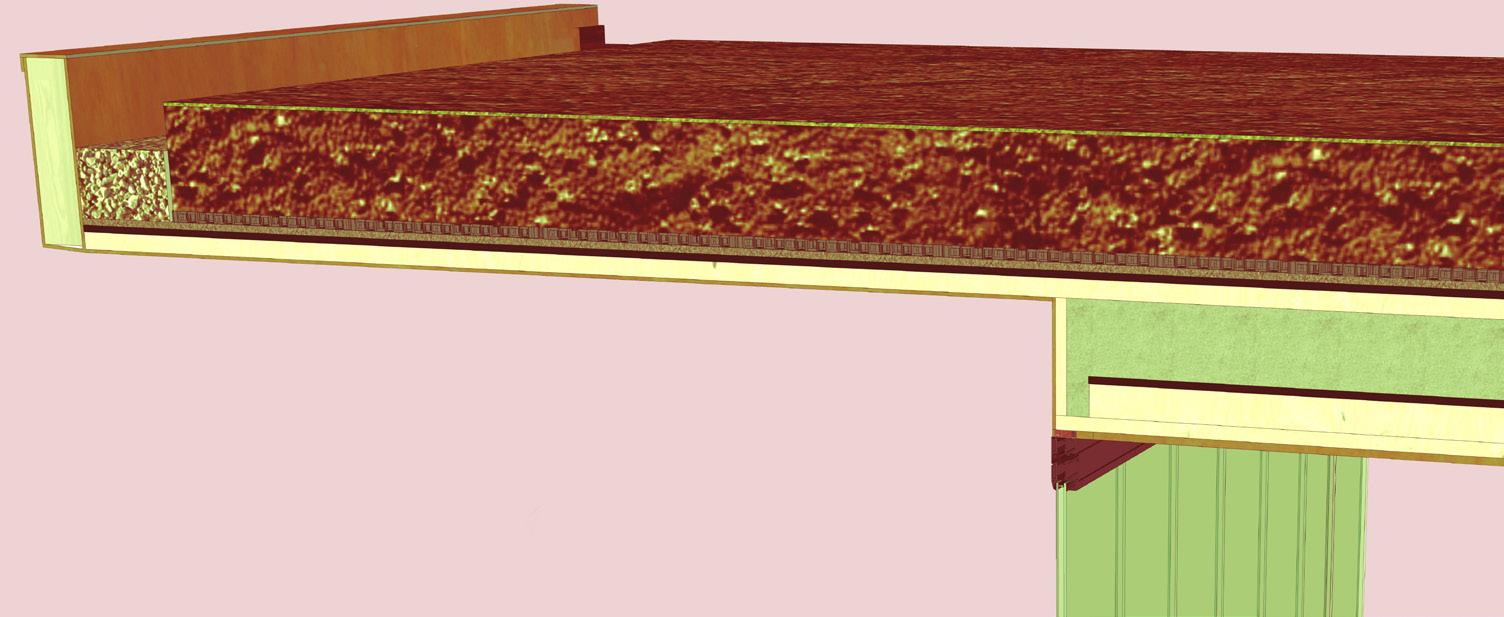

Over the Viaduct

1:20 Section

Brown roof

parapet cappin sheet metal clip bitumen waterproofing, 2-ply 130mm thick plywood

engineered soil with planting loose gravel

moisture-retention layer/drain-

age layer

protection mat

waterproof membrane

50 mm plywood deck

corten steel envelope

Wall

200 mm thick fiberglass insulation wirh perimeter insulation

upstand to prevent thermal bridging

vapour control layer

90 mm thick screed

timber beam 40mmx40mm

corten steel envelope

steel window frame

double glazed glass

Floor

steel window frame

wooden floorboard

waterproof building paper

screed 60mm thick

DPM layer

CLT beam 200mmx200mm

fiberglass inulation 70mm thick

wirh perimeter insulation upstand to prevent thermal bridging

damp proof membrane

corten steel envelope layer

0 1 5 2 10 20 3rd floor plan

23

Connection with water

1:5 Detail

The building’s connection with water was explored through 3 key features: brown roof, dyeing tanks, and water colllecting tank. They all use water in 3 different ways: absorbs it to help vegetation flourish, evaporates it to create unique prints on textiles, and it collects it for services use.

It is similar with Technologies part C, but it is a iteration of that detail as the water collecting tank is added, as the design of th building has slightly changed since.

1. parapet cappin sheet metal clip bitumen waterproofing, 2-ply

2. 130mm thick plywood

3. engineered soil with planting

4. loose gravel

5. moisture-retention layer/drainage layer

6. protection mat

7. waterproof membrane

8. 50 mm plywood deck

9. corten steel envelope

10. 200 mm thick fiberglass insulation wirh perimeter insulation upstand to prevent thermal bridging

11. vapour control layer

12. 90 mm thick screed

13. corten steel envelope

14. steel window frame

15 double glazed glass

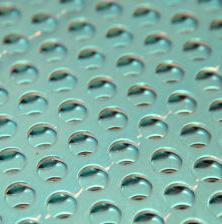

16. mesh fabric layer

17. plastic cilinder container

900mm diameter

18. timber support boards with wheels 80mm diameter

19. water collecting tank

20. perforated glass lid

21. mesh textile layer anti insects

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

21 20 24

Climate emergency

A cyclic programme

Key points

1. strong connections with the outdoors

It improves the users health by letting the greenery take over the building.

2. brown roofs

They absorb the rain water and help developing the biodiversity in Mayfield.

3. natural lighting

The cantilever shape of the building creates plenty of natural lighting opportunitties.

4. mixed and cyclic programme

It creates a safe and inclusive space where everybody is welcomed and can find an activity for their liking. Moreover, the cyclic programme helps achieving minimal waste, as everything iss repurposed constantly.

RIBA Sustainable outcomes

Good Health & wellbeing

- providing spaces with stong visual connection to outside: the balcony facing the ‘mancunian wall‘ and the glass walls have as their main purpose to observe the vegetation formed between the cracks of the bricks

- design spaes with good daylighting & glare control: most big windows are facing south and the overall ‘staircase’ shape of the building helps naturally lighting the building; the mesh metal facade layer is placed on all last floor windows’ to help rduce glare and welcome light inside

Good Health & wellbeing

- secure places for privacy: the whole building is on stilts, above the street level, providing a sense of security

Net zero embodied carbon

- low embodied carbon local materials: timber can be easily sourced from a local supplier in the U.K.

Sustainable connectivity

- high quality pedestrian links: the project provides very accessible link for pedestrins to cross the mancunian way

Sustainable land use & ecology

- creating mixed use development with density appropiate to local context: the building’s programme is diverese and inclusive, tying to engage with the local community

- creating a range of green spaces & landscapes for urban foood production: the project includes plenty of green spaces for people to engage with

2 3 3 4 25

Building regulations

Safe spaces

Fire safety

The building is designed to provide fire escape routes for its users to be able to escape it in case of emergency. Being a factory, the risk of fire could be higher, therefore, additional fire sprinkler systems would be installed.

Facilities

Every toilets cluster assures at least one cubicle accessible for people with dissabilities. The balustrades for the outside areas are 1.2m assuring a sefe space for its users.

The lifts and stairscase core are easy to access for everyone by having the appropriate dimensions.

1500mm

Accessible toilet detail Accessible lift detail 26

2200 mm 2200 mm

fire escape route 1st floor plan 3rd floor plan 2nd floor plan 4th floor plan

lift stairase core

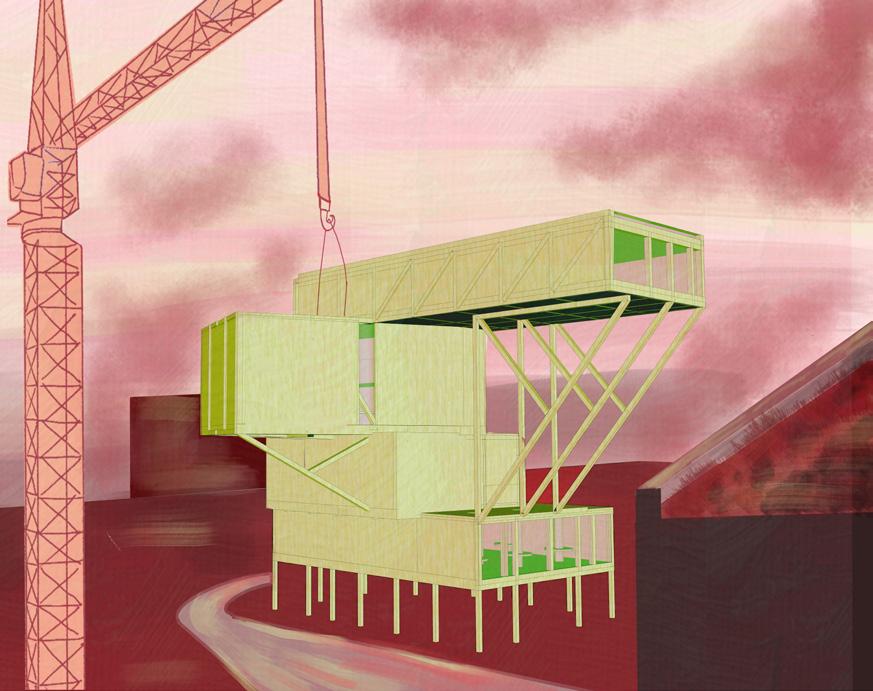

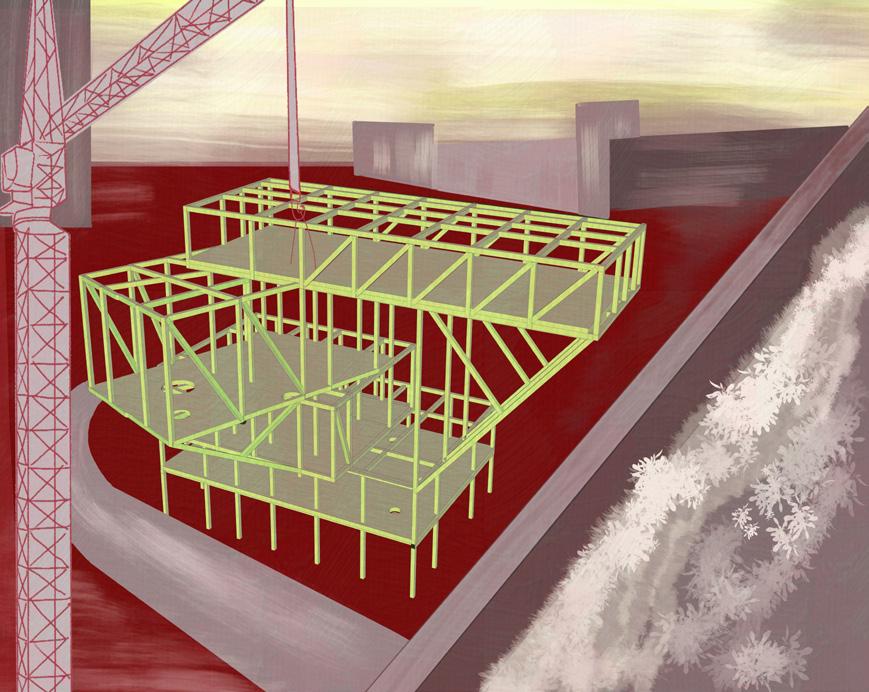

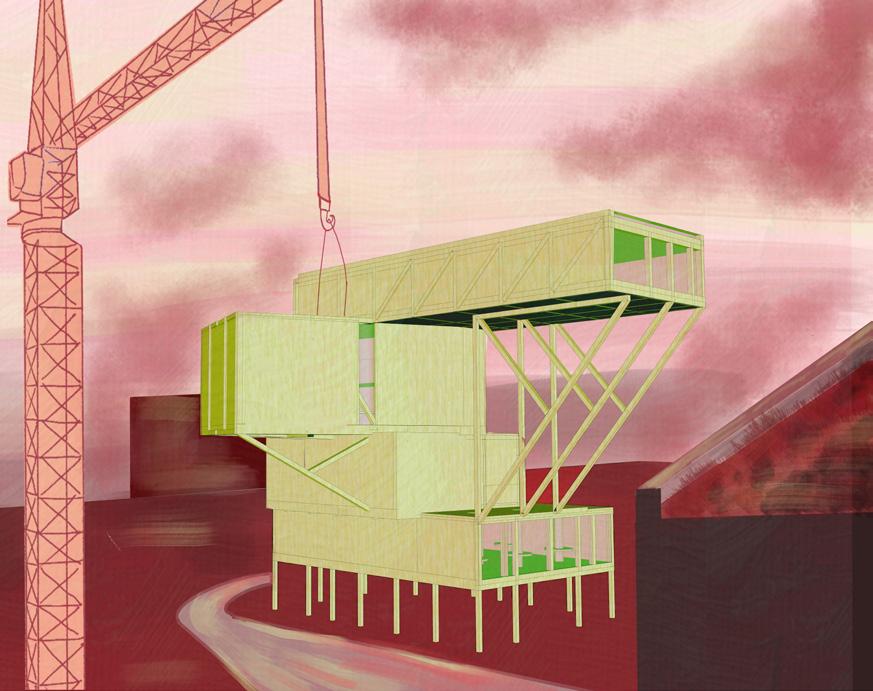

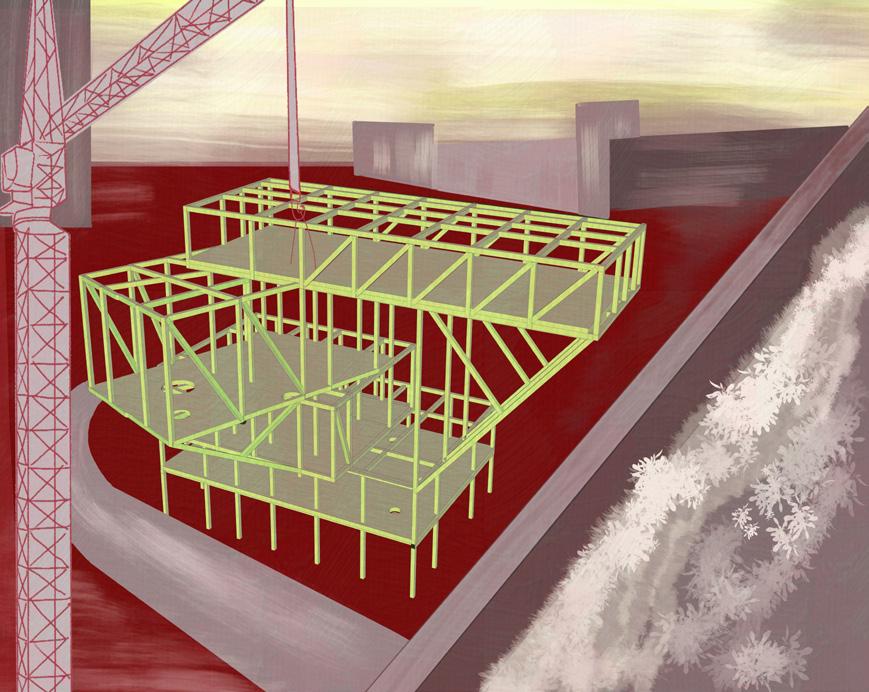

Construction Strategies

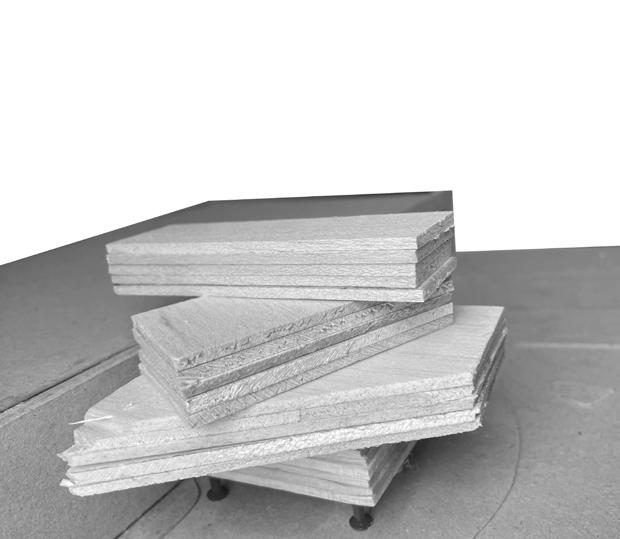

construction sequence

1 2 3 5 6 7

1. concrete is poured for the strip footings foundation

2. the CLT primary structire is built

3. the floors are assembeled with a crane

4. the exterior walls aare installed first, with the help of a crane, and the interior one second by workers

4. rooftops are installed eith a crane, and drainage system for the brown roofs is provided.

5. the services and internal finishes are getting done by workers.

27

6. vegetation is planted for the landscape plan.

4

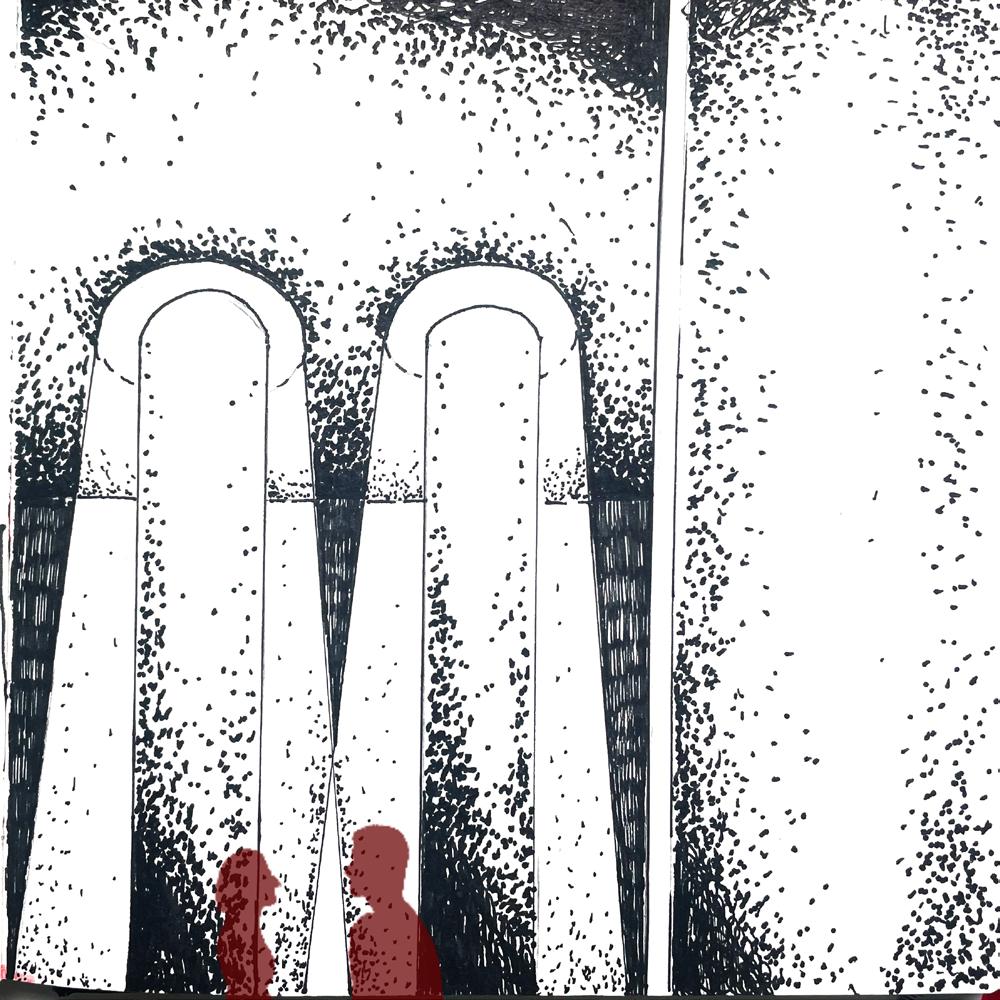

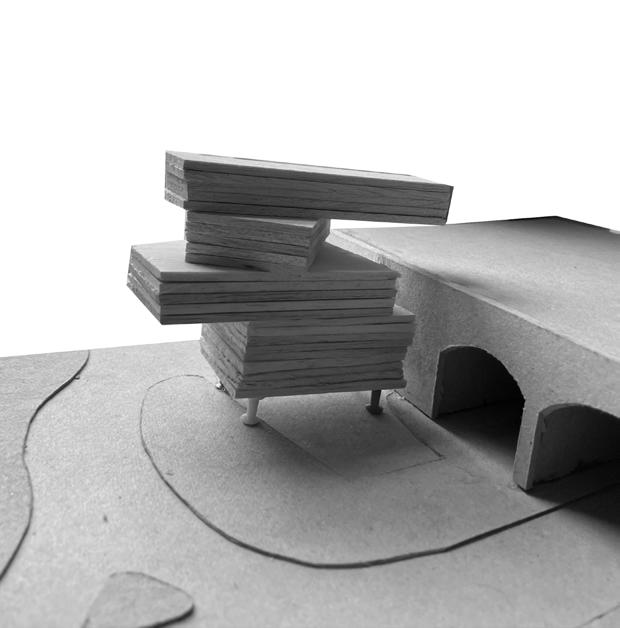

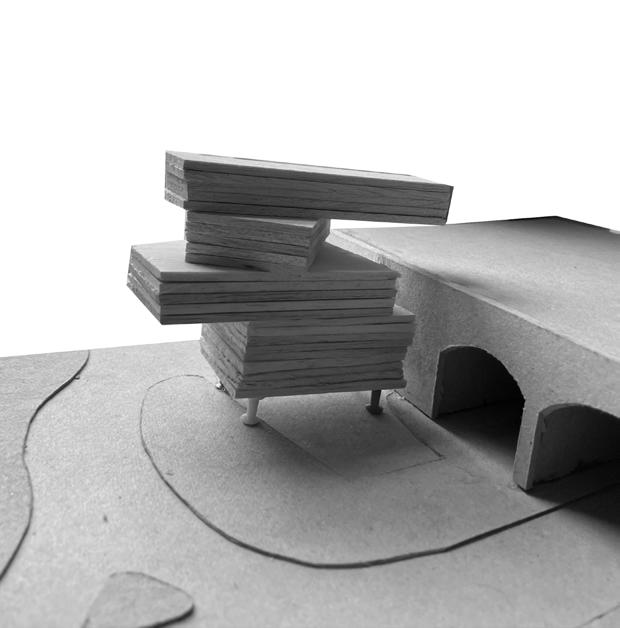

Creating colors

Interior views of the factory

28 physical model views

dyeing area - 2nd floor

weaving colors

Interior views of the factory

29

sewing area - 3rd floor

physical model views

Drying colors

30 drying area/ exhibition space - 2nd floor

drying rack

(internal wall element)

Furniture integrated in the design

1. timber beam

2. steel screw

3. steel hooks

4. timber columns

1 1 2 3 4 5 1 2 2 4 2

5. steel chain (inspired by safety pins)

Interior views of the factory

1. GROW

2. DYE

4. EAT

5. LEARN

3. SEW Programme cycle

1. GROW

2. DYE

4. EAT

5. LEARN

3. SEW Programme cycle

CLT floor slab and walls

CLT support columns and beams

CLT pillars

CLT floor slab and walls

CLT floor slab and walls

CLT floor slab and walls

CLT floor slab and walls

CLT support columns and beams

CLT pillars

CLT floor slab and walls

CLT floor slab and walls

CLT floor slab and walls