Ana ZagnaT

BA(Hons) Architecture graduate

Weaving the city

A slow time factory

3rd year project

Ana ZagnaT

BA(Hons) Architecture graduate

Weaving the city

A slow time factory

3rd year project

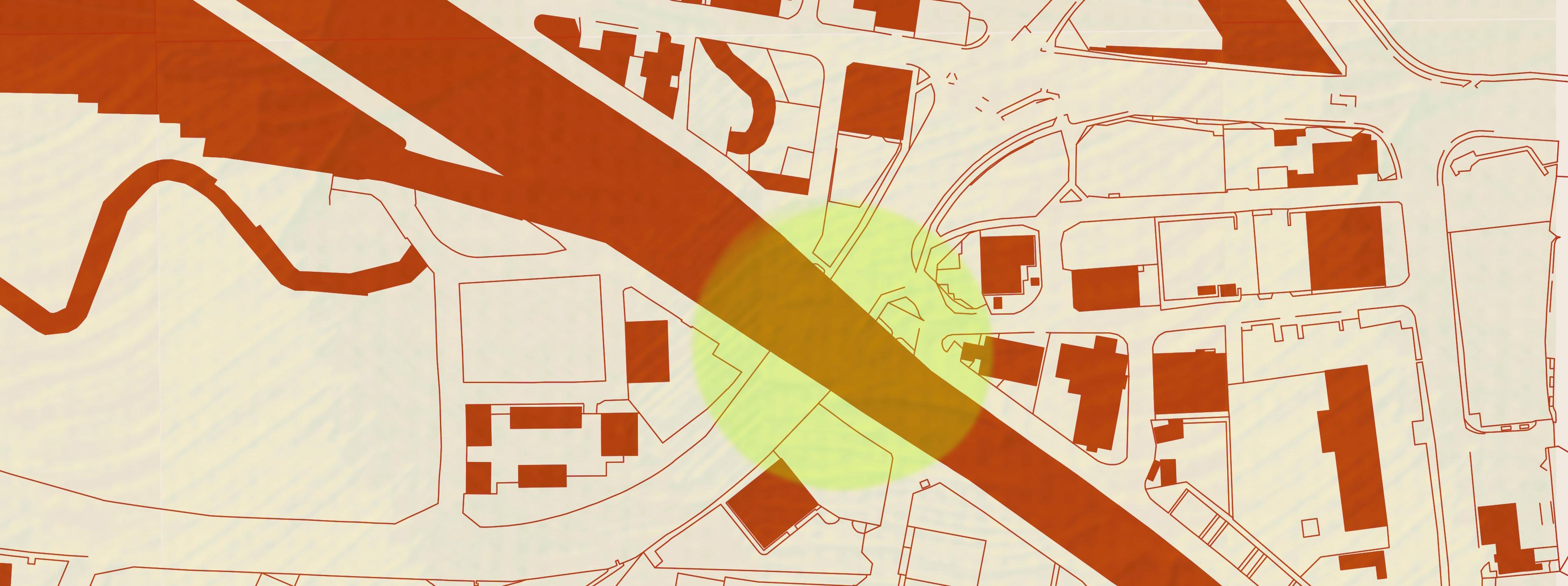

Manchester is known to be the first industrial city, being the epicentre of the country’s cotton industry. ‘Cottonpolis‘ was built on the back of slavery. The recognition of the industrial impact Manchester had is rarely associated with the heavy truth behind it.

I am designing a building with a programme that involves textiles in Mayfield to commemorate the slaves that worked on the mancunian cotton fields and brought the city its famous nickname, Cottonpolis.

The purpose is to create buildings that can constantly change their concept to adappt similar to the vegetation used in the programme of the building that changes its initial state until it reaches an optimal form.

My building does not act like a typical factory, but rather celebrates a slow time, and therefore, creates inclusive, safe spaces for everyone.

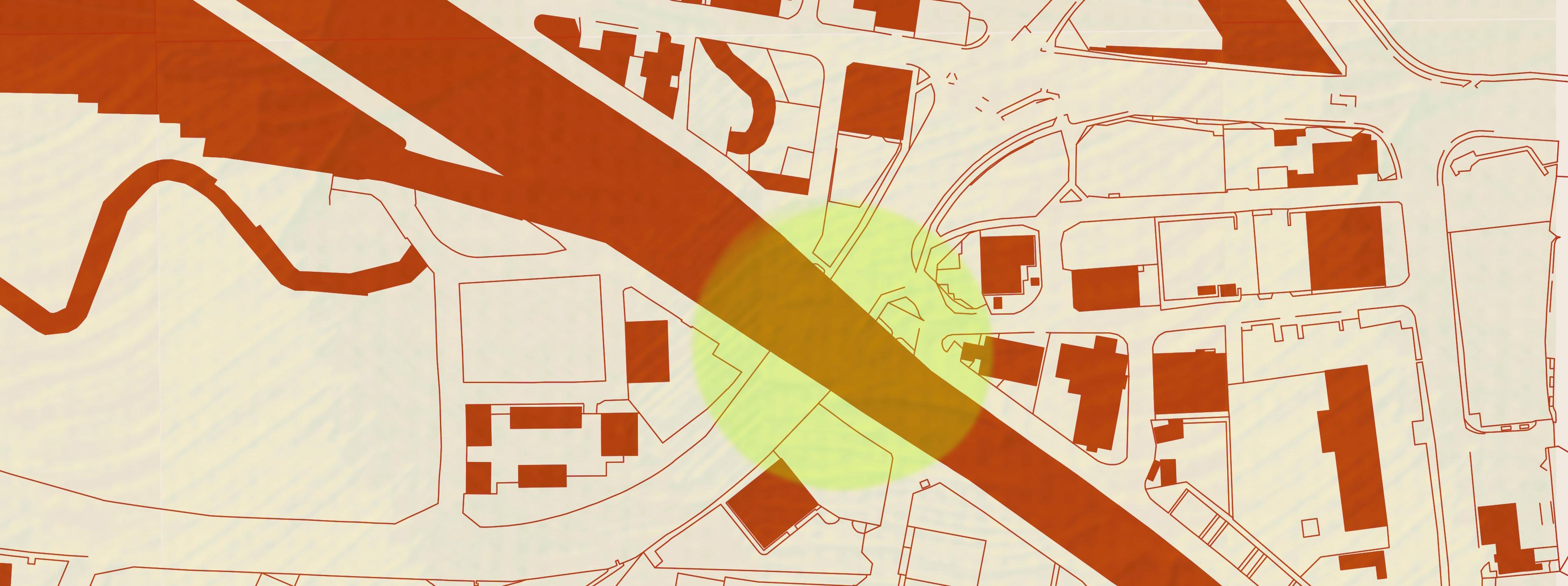

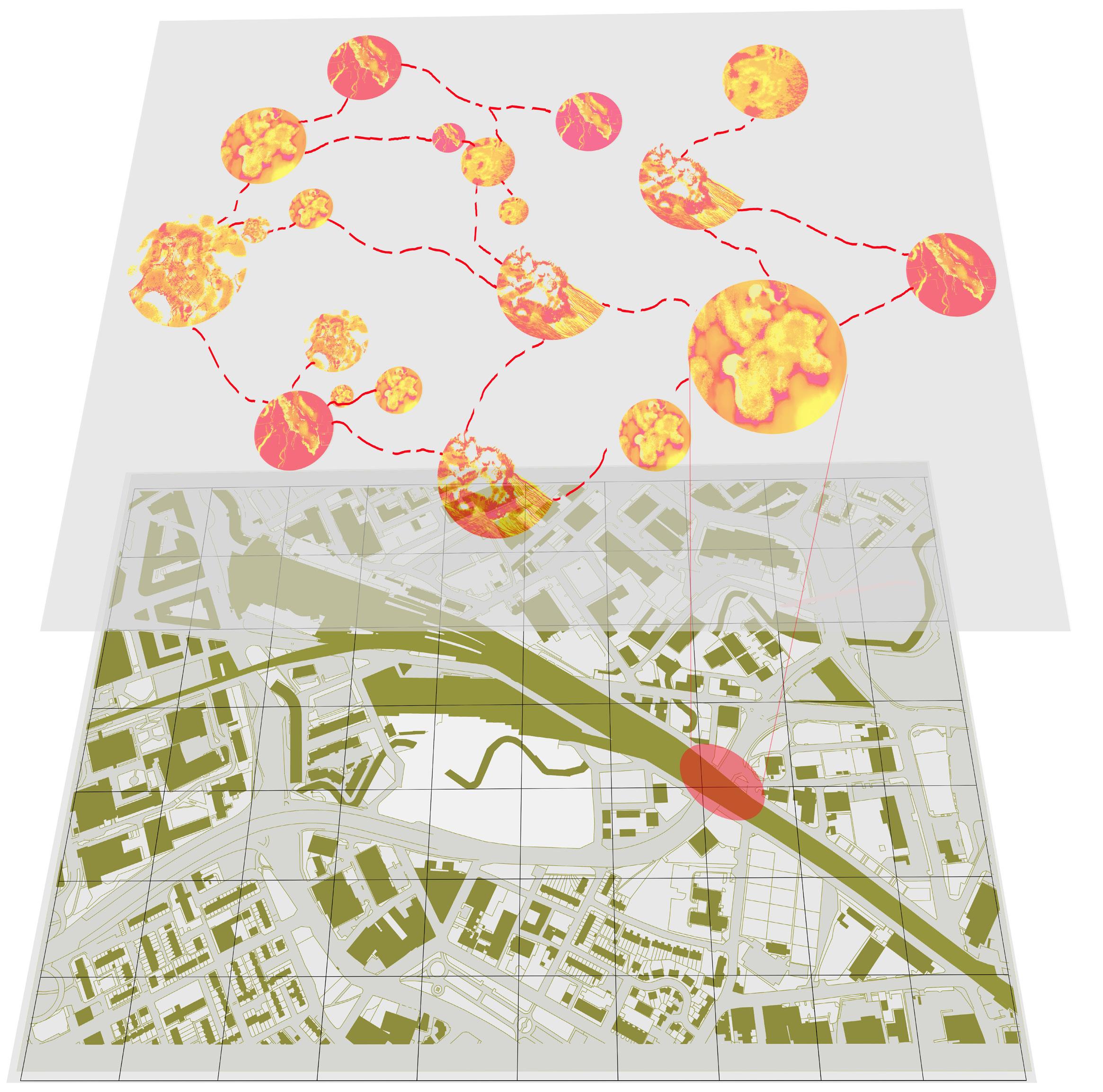

vegetation map of Myfield and its surroundings

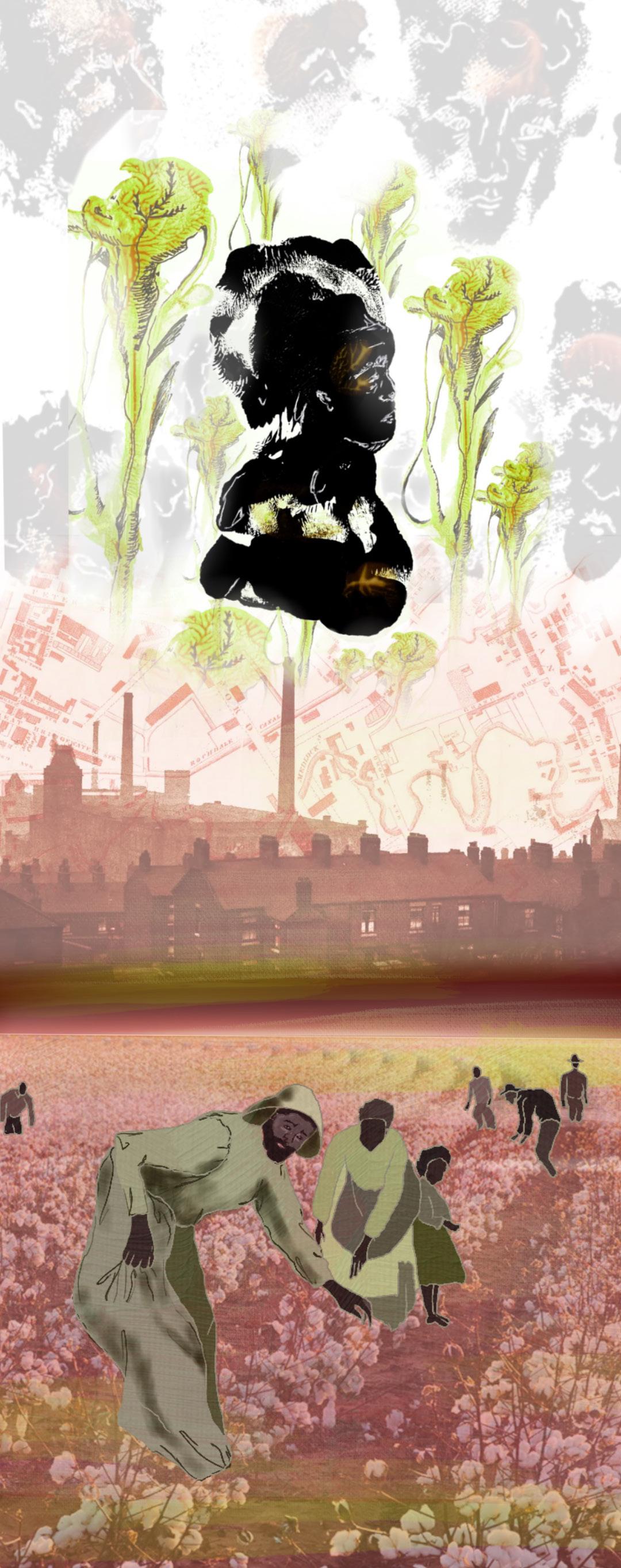

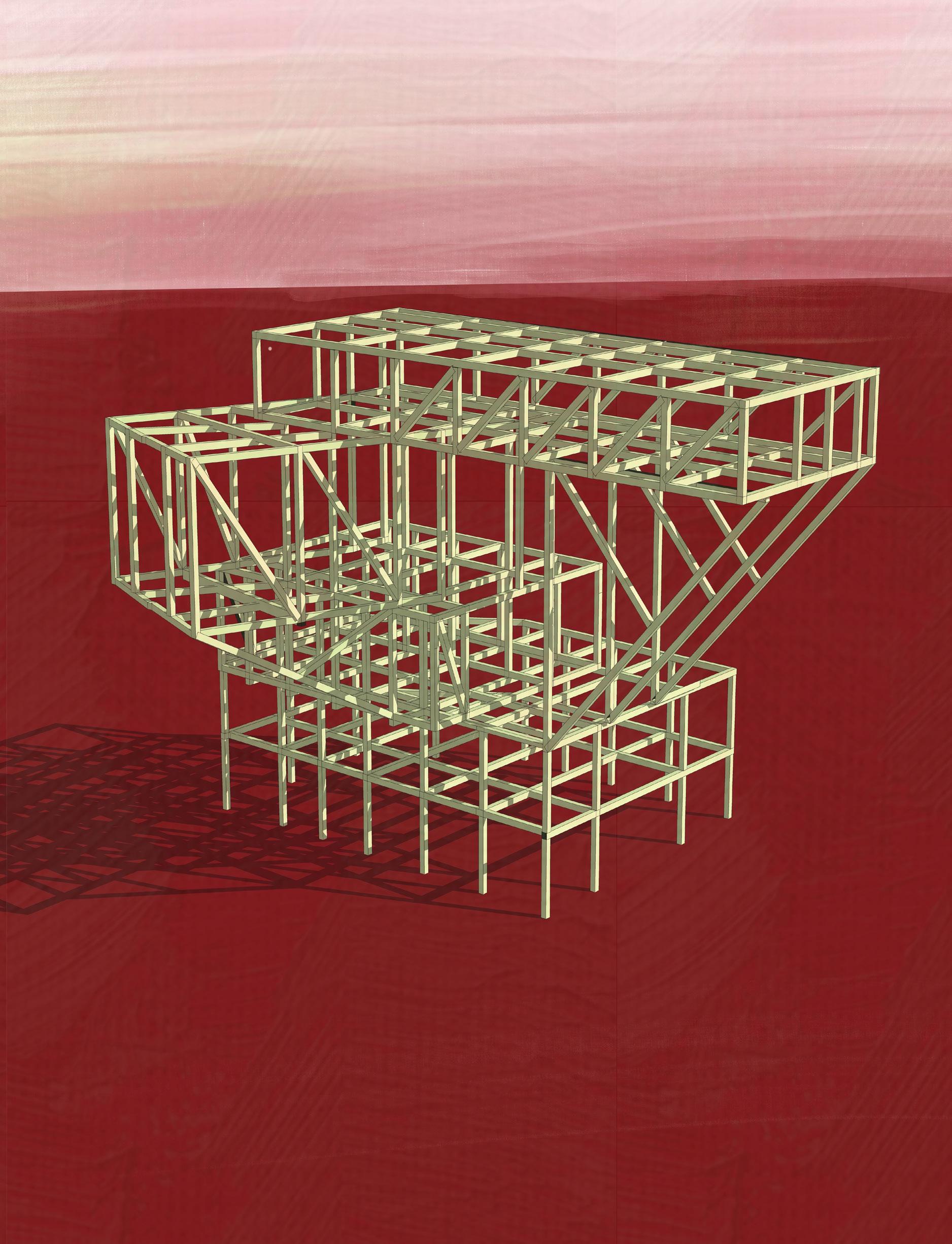

initial volumetric models exploring form

As the climate emergency became reality in the past years, with temperatures constantly rising, the risk of flooding increased. Therefore, I chose to rise my building on stilts to create spaces that would resist the test of time.

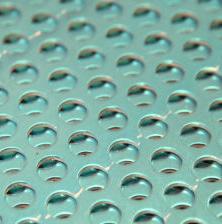

Materials

I chose materials that could represent the programme (sustainable textile dyeing) and atmosphere of the building best, therefor I looked to be highly sustainable (CLT) and to react visibly to external elements, such as rain, sunlight (coppper changes its colour).

CLT floor slab and walls

CLT support columns and beams

CLT pillars

CLT floor slab and walls

CLT floor slab and walls

CLT floor slab and walls

CLT support columns and beams

CLT Glazing Perforated copper corten steel

CLT floor slab and walls

CLT support columns and beams

CLT pillars

CLT floor slab and walls

CLT floor slab and walls

CLT floor slab and walls

CLT support columns and beams

CLT Glazing Perforated copper corten steel

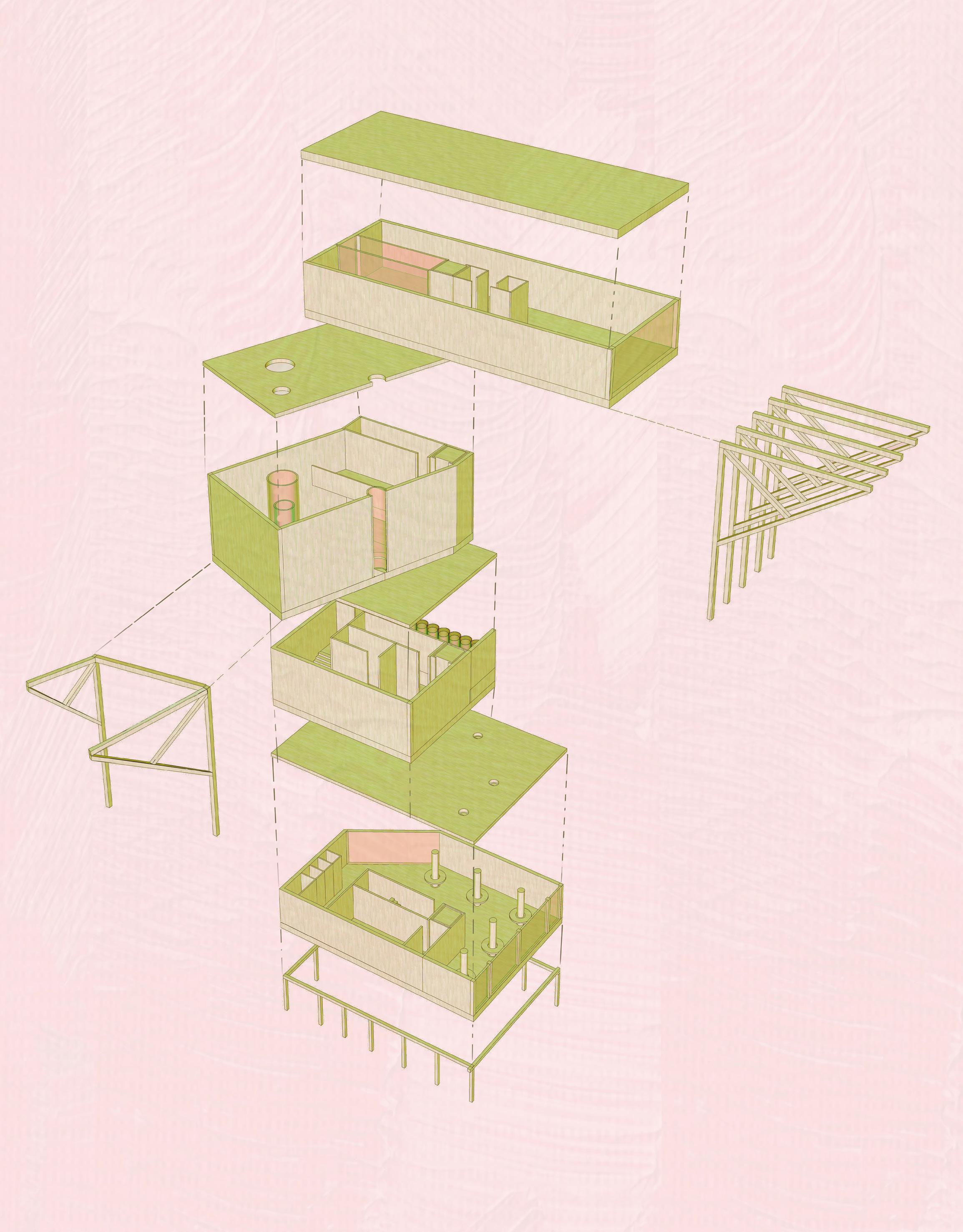

THe programme is thought to be ciclic and displayed vertically in the building. Its purpose is to use the resources in a way that generates minimal waste.

I experimented with oil paint on canvas some of the tresholds of the building to understand light. I produced a triptych where light is the creator of space.

Plans & sections 1:200

Plans & sections 1:200

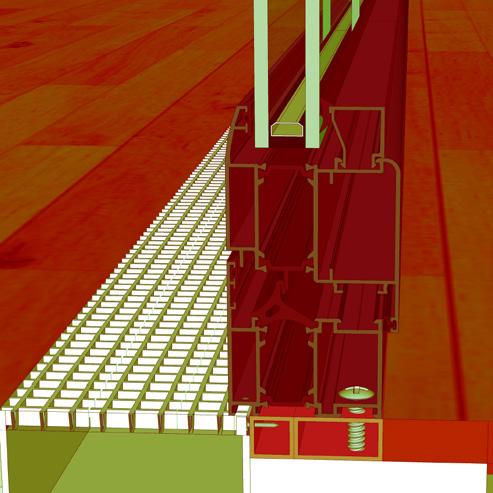

parapet cappin sheet metal clip bitumen waterproofing, 2-ply

130mm thick plywood engineered soil with planting loose gravel moisture-retention layer/drainage layer protection mat waterproof membrane

50 mm plywood deck corten steel envelope

Wall

200 mm thick fiberglass insulation wirh perimeter insulation upstand to prevent thermal bridging

vapour control layer

90 mm thick screed timber beam 40mmx40mm corten steel envelope steel window frame double glazed glass

Floor steel window frame wooden floorboard waterproof building paper screed 60mm thick DPM layer

CLT beam 200mmx200mm fiberglass inulation 70mm thick wirh perimeter insulation upstand to prevent thermal bridging damp proof membrane corten steel envelope layer

The cyclic programme of the building is highlighted through strong connections between each floor. The programme shapes the interior spaces and it is clearly illustrated through the integrated furniture

The sewing space (fig 1) has glass columns from which is thread is attached to help weaving. The drying/ exhibition (fig 2 & 3) space has separating walls that act as dryng racks for the fabrics. The coloring area (fig 4) has dyeing tanks that become part of the facade and act as a balustrade,.

The building’s connection with water was explored through 3 key features: brown roof, dyeing tanks, and water colllecting tank. They all use water in 3 different ways: absorbs it to help vegetation flourish, evaporates it to create unique prints on textiles, and it collects it for services use.

1. parapet cappin sheet metal clip bitumen waterproofing, 2-ply

2. 130mm thick plywood

3. engineered soil with planting

4. loose gravel

5. moisture-retention layer/ drainage layer

6. protection mat

7. waterproof membrane

8. 50 mm plywood deck

9. corten steel envelope

10. 200 mm thick fiberglass insulation wirh perimeter insulation upstand to prevent thermal bridging

11. vapour control layer

12. 90 mm thick screed

13. corten steel envelope

14. steel window frame

15 double glazed glass

16. mesh fabric layer

17. plastic cilinder container

900mm diameter

18. timber support boards with wheels 80mm diameter

19. water collecting tank

20. perforated glass lid

21. mesh textile layer anti insects