NEW HCPCS CODES

TAKE EFFECT P.12

COMPLY WITH THE NEW NONDISCRIMINATION RULE P.16

TECH ADVANCES TRANSFORM PEDIATRIC CARE P.28

TRANSFORMATIONS: RUNNING BLADES EXPAND

POSSIBILITIES P.36

NEW HCPCS CODES

TAKE EFFECT P.12

COMPLY WITH THE NEW NONDISCRIMINATION RULE P.16

TECH ADVANCES TRANSFORM PEDIATRIC CARE P.28

TRANSFORMATIONS: RUNNING BLADES EXPAND

POSSIBILITIES P.36

What you need to know about recent federal changes and how they impact O&P P.18

THE PREMIER MEETING FOR ORTHOTIC, PROSTHETIC, AND PEDORTHIC

September 3–6, 2025, for an ideal combination of top-notch education and entertainment at the 108th AOPA National Assembly in Orlando, FL, at the Orange County Convention Center (OCCC).

EXHIBITS EDUCATION NETWORKING

Recent executive orders, federal agency workforce reductions, cutbacks in research and grant funding, potential Medicaid cuts, and tariffs are shaking things up. In this exclusive roundtable discussion, O&P Almanac Editor Josephine Rossi speaks with key AOPA leaders to investigate how these changes impact O&P clinicians, manufacturers, and patients.

O&P facilities that focus on pediatric patients are embracing new tools, measurement techniques, and sensor technologies to optimize care for infants and children who require cranial remolding orthoses, scoliosis braces, ankle-foot orthoses, and more.

By Jennifer Davis

Learn about 13 new L codes, six new A codes, several descriptor changes, and more that went into effect April 1. Opportunity to earn CE credits by taking the online quiz.

Find out what your facility must do to comply with provisions in the recently published nondiscrimination rule, which clarifies various accessibility and technical standards for web content, mobile applications, patient kiosks, and more.

Baylor College of Medicine’s Sally Kenworthy, PhD, CPO, discusses the future of evidence-based care, clinical care pathways, and the next generation of O&P.

An Illinois clinician fit a young patient with congenital bilateral limb loss with running blades—just in time for the holidays.

President

Rick Riley

O&P Boost, Bakersfield, CA

President-Elect

Kimberly Hanson, CPRH Ottobock, Austin, TX

Vice President

Matt Swiggum Proteor, Tempe, AZ

Treasurer

Chris Nolan

Immediate Past President

Mitchell Dobson, CPO Hanger Clinic, Austin, TX

Interim Executive Director

Teri Kuffel, JD

Arise Orthotics & Prosthetics, Spring Lake Park, MN

DIRECTORS

Jeff Erenstone, CPO

Mountain Orthotic and Prosthetic Services, Lake Placid, NY

Deanna Fish, MS, CPO Orthomerica Products Inc., Orlando, FL

Arlene Gillis, MEd, CP, LPO International Institute of Orthotics and Prosthetics, Tampa, FL

Adrienne Hill, MHA, CPO, LPO, FAAOP Kennesaw State University, Kennesaw, GA

Shane Kelly

Thuasne North America, Bakersfield, CA

Jim Kingsley

Hanger Clinic, Oak Brook Terrace, IL

Andrew L. Steele, MBA, CPO, LPO Clark & Associates Prosthetics and Orthotics, Waterloo, IA

Shane Wurdeman, PhD, CP, FAAOP(D) Research Chair

Hanger Clinic, Houston Medical Center, Houston, TX

AMERICAN ORTHOTIC & PROSTHETIC ASSOCIATION (AOPA)

330 John Carlyle St., Ste. 200 Alexandria, VA 22314 Office: 571-431-0876 Fax: 571-431-0899 AOPAnet.org

EXECUTIVE OFFICES

Teri Kuffel, JD, interim executive director, 571-431-0876, executivedirector@AOPAnet.org

Akilah Williams, MBA, SHRM-CP, director of finance and strategic operations, 571-431-0819, awilliams@AOPAnet.org

HEALTH POLICY AND ADVOCACY

Joe McTernan, director of health policy and advocacy, 571-431-0811, jmcternan@AOPAnet.org

Devon Bernard, assistant director of coding and reimbursement services, education, and programming, 571-431-0854, dbernard@AOPAnet.org

Morgan Fabber, MPH, manager of state and federal advocacy, 571-431-0814, mfabber@AOPAnet.org

MEETINGS & EDUCATION

Ashley Vande Bunte, CMP, director, meetings and education, 571/431-0860, avandebunte@AOPAnet.org

Kelly O’Neill, CEM, assistant director, meetings and exhibitions, 571-431-0852, kelly.oneill@AOPAnet.org

Jules Gohng, meetings and education coordinator, 571-431-0843, jgohng@AOPAnet.org

MEMBERSHIP & COMMUNICATIONS

Joy Klapp, director of communications and membership, 571-431-0817, jklapp@AOPAnet.org

Betty Leppin, senior manager of member services, 571-431-0810, bleppin@AOPAnet.org

Madison McTernan, coordinator of membership and communications, 571-431-0852, mmcternan@AOPAnet.org

AOPA Bookstore: 571-431-0876

Reimbursement/Coding: 571-431-0833, LCodeSearch.com

O&P ALMANAC

AOPA, publisher

Josephine Rossi, editor, 703-662-5828, jrossi@contentcommunicators.com

Catherine Marinoff, art director, 786-252-1667, catherine@marinoffdesign.com

Bob Heiman, director of sales, 856-520-9632, bob.rhmedia@comcast.net

PUBLISHER AOPA

EDITORIAL MANAGEMENT CONTENT

COMMUNICATORS LLC

ADVERTISING SALES RH MEDIA LLC

DESIGN & PRODUCTION MARINOFF DESIGN LLC

PRINTING SHERIDAN

O&P Almanac (ISSN: 1061-4621) is published bimonthly by the American Orthotic & Prosthetic Association, 330 John Carlyle St., Ste. 200, Alexandria, VA 22314. To subscribe, contact 571-431-0876, fax 571-431-0899, or email info@ aopanet.org. Yearly subscription rates: $59 domestic, $99 foreign. All foreign subscriptions must be prepaid in U.S. currency, and payment should come from a U.S. affiliate bank. A $35 processing fee must be added for non-affiliate bank checks. O&P Almanac does not issue refunds. Periodical postage paid at Alexandria, VA, and additional mailing offices.

Postmaster: Send address changes to: O&P Almanac 330 John Carlyle St., Ste. 200, Alexandria, VA 22314.

Copyright © 2025 American Orthotic and Prosthetic Association. All rights reserved. This publication may not be copied in part or in whole without written permission from the publisher. The opinions expressed by authors do not necessarily reflect the official views of AOPA, nor does the association necessarily endorse products shown in the O&P Almanac. The O&P Almanac is not responsible for returning any unsolicited materials. All letters, press releases, announcements, and articles submitted to the O&P Almanac may be edited for space and content. The magazine is meant to provide accurate, authoritative information about the subject matter covered. It is provided and disseminated with the understanding that the publisher is not engaged in rendering legal or other professional services. If legal advice and/or expert assistance is required, a competent professional should be consulted.

Share your message with AOPA membership— approximately 9,000 orthotic and prosthetic professionals, facility owners, and industry personnel. Contact Bob Heiman at 856-520-9632 or email bob.rhmedia@comcast.net. Learn more at bit.ly/AlmanacMediaKit25.

PDE™ braces adapt as kids grow, providing modular, adjustable support that keeps up with every stage of their journey. With dynamic PDE™ springs, they can move freely, explore, and take flight toward their dreams.

Scan to learn more or visit fabtechsystems.com

A PERFECT SOLUTION FOR:

Smaller patients like kids and youths.

Supports moderate muscle weakness & nerve impairments affecting dorsiflexion/plantarflexion.

Beneficial for various conditions, including Guillain-Barre Syndrome, Spina Bifida, Cerebral Palsy, and more - With options for stability, control, and energy return.

Get the PDE FITTING KIT - An in-house tool with spring categories (1-5) and assembly components for initial brace setup and fine-tuning during fitting and delivery.

PDE KIDS™ FEATURES

• 175mm & 225mm Sizes

• 7 Flex Spring Choices

• Modular, Reusable Design

• Low profile

• Adjustable Alignment

An international team of researchers examined the test-retest reliability of the 10-meter walk test (10MWT) to assess walking function among individuals with lower-limb amputation.

The researchers sought to determine the reliability of preferred walking speed, maximal walking speed, and walking speed reserve (the difference between maximal and preferred walking speeds) by conducting a test-retest study with a 48-hour to 120-hour interval between testing days. They found that preferred walking speed showed “excellent” reliability between day 1 (familiarization day) and day 2, and a significant speed increase from day 2 to day 3. Maximal walking speed showed “excellent” reliability between day 1 and day 2 and between day 2 and day 3. However, they noted that walking speed reserve was “poorly reliable” between day 1 and day 2 and between day 2 and day 3.

“Preferred walking speed obtained from a single 10MWT and maximal walking speed obtained after a

10MWT familiarization day are reliable walking speed measures for persons with lower-limb amputation with similar characteristics to those of our sample,” reported the researchers in an article in Prosthetics and Orthotics International in January. “Nonetheless, it is critical that both preferred walking speed and maximal walking speed are obtained after a 10MWT familiarization to obtain a reliable walking speed reserve.”

Approximately 24.2 million people signed up for Affordable Care Act plans during the open enrollment period for 2025—an all-time high. This number breaks last year’s record of 21.3 million.

SOURCE:

German researchers recently studied the use of a transcutaneous osseointegrated prosthesis system (TOPS) for patients with short transfemoral residual limbs. Some transfemoral patients with short residual limbs benefit from implants because they face challenges in achieving independent walking ability using conventional socket technology due to mechanically inadequate socket contact surface.

The researchers examined the results of 14 TOPS procedures performed at Rostock University Medical Center in Germany between 2022 and 2024, including nine among patients with short residual limbs. While they found that patients with short residual limbs who had undergone TOPS endured a prolonged rehabilitation phase compared to those with more “standard” TOPS procedures, “a significant gain in quality of life is evident.” The study was published in Orthopedics and Traumatology in January.

Learning to control a myoelectric arm prosthesis after amputation can be facilitated by training in a virtual reality environment (VRE), according to researchers from the University of Groningen in the Netherlands. The research team examined skill transfer of VRE training to assess its effectiveness.

Twenty participants without amputation were divided into two groups: a virtual reality training group and a prosthesis simulator training group. The VRE group leveraged a newly developed VRE with game-like elements specifically designed for upper-limb prosthesis training. Both groups performed five training sessions in a pre-test/post-test design, with researchers measuring functional control, motivation, and perceived workload.

The researchers found that skill transfer was established among both groups. “VRE training is an effective training method for arm prosthesis control and has valuable potential for implementation in a rehabilitation setting,” they reported. The study was published in January in Technology and Disability

The key factors driving patient engagement and loyalty toward healthcare providers are access, ease of doing business, digital engagement, and trust, according to a survey from Accenture. Consumers are seeking convenient locations and office hours, the ability to schedule an appointment quickly, telehealth and virtual care offerings, and excellent customer service, according to the research.

Nine in 10 respondents (89%) cited “ease of navigation” as a reason why they had switched or stopped seeing their previous

BY THE NUMBERS

healthcare provider. This category included respondents who had switched providers after visiting facilities that were difficult to do business with, enduring bad experiences with front desk or administrative staff, or experiencing inferior digital or online service and support solutions.

Forty-four percent of respondents reported they switched providers due to subpar clinical experiences, and 13% cited inconvenient office hours/ appointment times or distance to facility as a reason for switching providers. Another 10% said they weren’t getting “good value” for their money.

John McFall, the first astronaut with a physical disability cleared for a long-duration mission to the International Space Station (ISS), is being called the European Space Agency’s first “parastronaut.”

McFall, who lost the lower part of his right leg in a motorcycle accident at age 19, is a former Paralympian and was a trauma and orthopedic specialist registrar working in the south of England before he joined the ISS team. He completed ESA’s Fly! Feasibility Study in 2024, which examined the technical difficulties of sending an astronaut with a disability to ISS. The study included a rigorous medical evaluation, along with training in spacecraft operations, ISS operations, and crew support. McFall successfully completed all aspects of the study, demonstrating that it’s technically possible for an individual with an amputation like McFall’s to fly on a long-duration mission.

McFall is now in the “mission ready” phase, also known as “astronaut reserves training,” as he awaits a mission assignment.

AOPA has partnered with Hanger Inc. to establish the Dr. James H. Campbell Commitment to Outcomes Award, recognizing individuals who have made outstanding contributions to improving clinical outcomes in O&P. Funded by Hanger Inc. in honor of James H. Campbell, PhD, CO, FAAOP, the award celebrates those dedicated to advancing evidence-based practice, implementing clinical outcomes programs, publishing peer-reviewed research, and driving innovation in patient care. It will be given annually beginning in 2025.

• Implementing clinical outcomes programs as a standard of care

• Publishing peer-reviewed research on clinical outcomes

• Driving outcomes-based product development to improve patient quality of life

• Successfully integrating validated clinical outcomes processes in a clinical setting.

Nominations are being accepted through April 30. Nominations should be submitted to aopa.wufoo.com/forms/x2me2380qi12z2/

The recipient must have demonstrated exceptional commitment to clinical outcomes excellence through at least one of the following:

• Advancing evidence-based O&P practice

The final selection will be made by the AOPA Board of Directors. The inaugural award will be presented at AOPA’s 2025 National Assembly, Sept. 3-6 in Orlando, during the Annual Business Meeting and Awards Ceremony. The recipient will receive a $3,000 honorarium; two nights at the National Assembly headquarters hotel; complimentary registration to the National Assembly; coach airfare to the National Assembly; and recognition in the O&P Almanac, AOPA social media, and a national press release. Contact Joy Klapp, AOPA’s director of communications and membership, with questions at jklapp@aopnet.org

This year, the AOPA Policy Forum will be virtual and will feature an education session May 6, followed by congressional meetings conducted by Zoom May 7–8 and May 12–15. See page 43 for details.

Tom DiBello, CO, LO, FAAOP, Hanger Clinic’s director of clinical and scientific affairs, was honored with the Titus Ferguson Lifetime Achievement Award by the American Academy of Orthotists and Prosthetists during its annual meeting in Atlanta in February. The award recognizes an outstanding academician whose accomplishments and contributions have made a significant impact on the growth and development of the O&P profession.

DiBello has been actively practicing for more than 40 years in the O&P field. His primary interest is in the management of patients with lower-limb disability and weakness. He also is a clinical assistant professor at the Baylor College of Medicine (BCM), honorary adjunct faculty at Texas Women’s University, and chairman of the Advisory Committee of BCM’s Master of Science Program in Orthotics and Prosthetics.

“Throughout his remarkable career, Tom’s unwavering commitment to excellence and passion for orthotics and prosthetics has inspired countless individuals around the world,” said Shane Wurdeman, PhD, CP, FAAOP(D), Hanger Clinic’s chief clinical officer. “He has been a leader through the power of example, always carrying himself with grace and humility. Tom’s legacy is not only found in his achievements but in the countless lives he has touched and uplifted along the way.”

Joshua Mullins has joined the Board of Certification/Accreditation (BOC) as director of business development. Mullins will oversee BOC’s business development and sales functions, aiding the organization in expansion and supporting its continued growth.

Mullins joins BOC with more than 15 years of experience in the durable medical equipment, prosthetics, orthotics, and supplies (DMEPOS) field and offers focused expertise in business and strategic sales management. He most recently served as vice president of business development for iFIT Prosthetics and is a recognized industry expert in adjustable socket technology

“We are delighted to welcome Josh to the BOC team,” said Judi Knott, MA, MBA, CAE, president and chief executive officer of BOC. “With his extensive experience in DMEPOS, Josh brings invaluable industry knowledge and a passion for fostering strong partnerships. His leadership will be instrumental in advancing our mission and also growing the BOC community.”

Becky Piper; Meaghan Cusack, PsyD; and Akeem Kearse have joined the Dralla Foundation as the newest members of its Review Board. The Review Board plays a crucial role in determining the grants that Dralla awards each year.

Piper has spent more than a decade empowering others with disabilities. A survivor of a life-changing attack that left her paralyzed on her right side, Piper has turned her challenges into inspiration, helping others embrace their abilities.

Cusack brings a wealth of expertise as an above-knee amputee and adaptive sports enthusiast. Diagnosed with osteosarcoma at age 10, Cusack became a competitive adaptive climber and a passionate advocate for mental health and physical empowerment

Kearse, who has bilateral lower-limb amputation, is an accomplished hand cyclist and rock climber. He also serves as a case coordinator, helping others navigate complex challenges.

Don E. Hardin Jr., a former AOPA president, passed away April 6 at age 89 after a battle with cancer.

Hardin played an important role in the O&P profession beginning in 1967; worked for several O&P companies, including Ottobock; and most recently served as principal of Don Hardin Associates, an O&P consultancy.

Hardin graduated from Bradley University with a business degree, majoring in marketing. He soon took a job in O&P and became a tireless advocate for the profession. He spent years building trusted relationships with Medicare contractors, insurance companies, and policy makers.

He volunteered for the AOPA National Assembly Committee in the 1970s and 1980s and served as AOPA president in 1991-1992. He also spent time on AOPA’s Government Relations Committee. In 2003, Hardin was honored with the AOPA Lifetime Achievement Award.

Hardin was always ready to offer small pieces of wisdom, usually with a wry smile and a subtle wink, and his charm and positive energy will be deeply missed. AOPA’s thoughts are with his family, friends, and the entire O&P profession.

Fillauer TRS is moving its operations to Fillauer’s Chattanooga, Tennessee, location. The move will allow Fillauer to streamline its upper-body power product line, giving customers a single point of contact for orders and logistics. “Having all body power products in one location will allow us to continually improve our offerings and focus on the devices that best meet our users’ needs,” said Sam Hale, vice president of research and development.

Hanger Inc. has entered into an agreement to acquire Coapt, a Chicago-based firm that uses myoelectric technology to provide intuitive and personal control for upper-limb prosthesis wearers. Coapt works with product manufacturers to incorporate its pattern recognition technology into myoelectric protheses, giving users more natural functional control to fit their lifestyles.

“At Hanger, we’re constantly looking for ways to return independence and control to those with limb loss or limb difference,” said Pete Stoy, Hanger’s chief executive officer (CEO). “I’m thrilled to work with the Coapt team, and their technology is a natural complement to our focus on bringing innovation to patient care. Together we will provide more access and better outcomes to upper-limb prosthesis users.”

“I’m excited about the potential of this partnership,” said Blair Lock, CEO of Coapt. “Hanger’s focus on clinical outcomes, combined with its manufacturing capability and clinic footprint, will help strengthen our products and broaden their use.”

Hanger Clinic celebrated the opening of its new Integrated Care Center (ICC) in Schaumburg, Illinois, in March. The 19,000-squarefoot facility features a collaborative environment designed for an integrated, outcomes-based care model. Patients at the ICC will have the opportunity to trial different technologies to determine the best fit based on their individual needs and lifestyle, and to test those devices out in a real-world setting, including a large gym, rock

climbing wall, golf simulator, running track, full kitchen, and demo apartment, according to Hanger.

The on-site fabrication lab provides direct patient access to technicians. The ICC also offers advanced technologies that provide the ability to track progress, including performance-based measures in addition to patient-reported measures to improve care. The collaborative environment facilitates integrative care with external healthcare partners and creates opportunities for peer support programs and community events, according to Hanger.

ARCH Medical Solutions Corp. has acquired KISS Technologies LLC of Owings Mills, Maryland.

KISS is a provider of high-performance prosthetic suspension systems. The acquisition aligns with ARCH’s strategic growth in the prosthetics market and further strengthens its position as a contract manufacturer of medical devices. With this transition, KISS Technologies will join the ARCH—American Prosthetic Components business.

“We are excited to welcome KISS to the ARCH Medical Solutions family, expanding our capabilities and product offering in prosthetic technology,” said Paul Barck, divisional president of ARCH Medical Solutions.

“We are thrilled to join ARCH Medical Solutions and American Prosthetic Components, a company that shares our passion for innovation and excellence in prosthetic component manufacturing,” said Lee and Ann Mantelmacher from KISS Technologies LLC. “This partnership will provide the support and resources necessary to continue advancing prosthetic suspension technology, ensuring we meet the evolving needs of patients and prosthetists alike.”

L0720

L1933

L1952

L5827

L6028

L6029

L6030

L6031

L6032

L6033

L6037

L6700

L7406

A6515

A6516

A6517

A6518

A6519

A6611

Cervical-thoracolumbosacral orthosis, anterior-posterior-lateral control, prefabricated item that has been trimmed, bent, molded, assembled, or otherwise customized to fit a specific patient by an individual with expertise

Ankle-foot orthosis, rigid anterior tibial section, total carbon-fiber or equal material, prefabricated, off-the-shelf

Ankle-foot orthosis, spiral (Institute of Rehabilitative Medicine type), plastic or other material, prefabricated, off-the-shelf

Endoskeletal knee-shin system, single-axis, electromechanical swingand stance-phase control, with or without shock absorption and stance extension damping

Partial hand including fingers, flexible or nonflexible interface, endoskeletal system, molded to patient model, for use without external power, not including inserts described by L6692

Upper-extremity addition, test socket/interface, partial hand including fingers

Upper-extremity addition, external frame, partial hand including fingers

Replacement socket/interface, partial hand including fingers, molded to patient model, for use with or without external power

Addition to upper-extremity prosthesis, partial hand including fingers, ultralight material (titanium, carbon fiber or equal)

Addition to upper-extremity prosthesis, partial hand including fingers, acrylic material

Immediate postsurgical or early fitting, application of initial rigid dressing, including fitting alignment and suspension of components, and one cast change, partial hand including fingers

Upper-extremity addition, external powered feature, myoelectronic control module, additional EMG inputs, pattern-recognition, decoding intent movement

Addition to upper-extremity, user-adjustable, mechanical, residual-limb volume management system

Gradient compression wrap with adjustable straps, full leg, each, custom

Gradient compression wrap with adjustable straps, foot, each, custom

Gradient compression wrap with adjustable straps, below-knee, each, custom

Gradient compression wrap with adjustable straps, arm, each, custom

Gradient compression garment, not otherwise specified, for nighttime use, each

Gradient compression wrap with adjustable straps, above knee, each, custom

The final determinations also resulted in one HCPCS code being deleted: Code L8010, “breast prosthesis, mastectomy sleeve,” will no longer

be active for claims with dates of service on or after April 1, 2025. Alternate codes that may be used include A6576, A6577, or A6578.

When reviewing the code descriptor changes, it’s evident that CMS is moving away from the more generic

L1951

“prefabricated, includes fitting and adjustment” language and toward clear differentiation between custom-fitted and off-the-shelf (OTS) versions of orthoses.

Ankle-foot orthosis, spiral (Institute of Rehabilitative Medicine type), plastic or other material, prefabricated, includes fitting and adjustment

L1932

L1971

Ankle-foot orthosis, rigid anterior tibial section, total carbon-fiber or equal material, prefabricated, includes fitting and adjustment

This intent was made clear several years ago when the DME MACs and the Pricing, Data Analysis, and Coding contractor released coding guidance

L6692

Ankle-foot orthosis, plastic or other material with ankle joint, prefabricated, includes fitting and adjustment

Upper-extremity addition, silicone gel insert or equal, each

L6698 Addition to upper-extremity prosthesis, below-elbow/ above-elbow, lock mechanism, excludes socket insert

A6549

A6583

A6585

A6586

Ankle-foot orthosis, spiral (Institute of Rehabilitative Medicine type), plastic or other material, prefabricated item that has been trimmed, bent, molded, assembled, or otherwise customized to fit a specific patient by an individual with expertise

Ankle-foot orthosis, rigid anterior tibial section, total carbon-fiber or equal material, prefabricated item that has been trimmed, bent, molded, assembled, or otherwise customized to fit a specific patient by an individual with expertise

Ankle-foot orthosis, plastic or other material with ankle joint, with or without dorsiflexion assist, prefabricated, includes fitting and adjustment

Upper-extremity addition, silicone gel insert or equal, with or without locking mechanism, each

Addition to upper-extremity prosthesis, lock mechanism, excludes socket insert

Gradient compression garment, not otherwise specified Gradient compression garment, not otherwise specified, for daytime use, each

Gradient compression wrap with adjustable straps, below-knee, 30–50 mmhg, each

Gradient pressure wrap with adjustable straps, above-knee, each

Gradient pressure wrap with adjustable straps, full leg, each

A6587 Gradient pressure wrap with adjustable straps, foot, each

A6588

Gradient pressure wrap with adjustable straps, arm, each

Gradient compression wrap with adjustable straps, below-knee, each

Gradient compression wrap with adjustable straps, above-knee, each

Gradient compression wrap with adjustable straps, full leg, each

Gradient compression wrap with adjustable straps, foot, each

Gradient compression wrap with adjustable straps, arm, each

BY DEVON BERNARD

New rule outlines requirements for ensuring all patients can access your facility’s kiosks, content, and equipment

The Office of Civil Rights recently published a final rule titled “Nondiscrimination on the Basis of Disability in Programs or Activities Receiving Federal Financial Assistance,” which is an update to Section 504 of the Rehabilitation Act of 1973. Two main provisions in this rule may directly impact your operations. These provisions, among other things, clarify accessibility and technical standards for web content, mobile applications, and patient kiosks, and establish standards for accessible medical diagnostic equipment.

If you use kiosks or a similar type of automated check-in/check-out system at your facility, you must ensure that individuals

with any type of disability are not excluded from using the kiosks, and that the kiosks are available to everyone. If a kiosk cannot be used by an individual, that individual must be able to access the features of the kiosk in a different manner.

For example, if an individual is not able to hear audio prompts from the kiosk or cannot manually use the touchscreens, they should be able to proceed to the personnel at your main desk to check in, schedule a follow-up appointment, or pay.

To ensure that all web and mobile applications are accessible and usable for individuals with disabilities, the new law requires compliance with the technical standards found in the Content Accessibility Guidelines (WCAG) 2.1 AA. These guidelines cover such things as ensuring sufficient color contrast on pages,

keyboard navigation, clear headings, alternative text for images or captions for videos, and adjustable text size. All of your web-based or app-based content must meet these guidelines by May 11, 2026, if your company has 15 or more employees, or May 10, 2027, if you company has fewer than 15 employees.

There are five circumstances under which you may not be required to ensure that your web and app content is in compliance with WCAG 2.1 AA guidelines.

The first exemption applies to archived content. To be part of this exemption, the content must meet all of the following conditions:

• It only includes content that was created before May 11, 2026, or May 10, 2027,

Devon Bernard has worked for AOPA since 2007 and is currently serving as the assistant director of coding and reimbursement services, education, and programming. He is a routine contributor to the O&P Almanac ; and conducts several seminars regarding coding, billing, compliance, and other Medicare issues. Bernard holds a bachelor’s degree from the University of Florida.

Teri Kuffel, JD, is AOPA’s interim executive director and immediate past president. She also is vice president and founding co-owner at Arise Orthotics & Prosthetics Inc., where she manages all business operations. Kuffel has worked in the O&P industry with contract, human resource, compliance, and organizational management since 1999 and has been an AOPA state representative for more than a decade.

Joe McTernan is director of health policy and advocacy for AOPA and previously served as AOPA’s manager of reimbursement. From 1998 until 2005, he was director of regulatory affairs for Hanger Prosthetics and Orthotics in Bethesda, Maryland. In addition to participating in frequent AOPA seminars regarding coding, billing, compliance, and other Medicare issues, McTernan authors articles for the O&P Almanac and the AOPA In Advance SmartBrief newsletter.

AOPA President Rick Riley has devoted his entire 41-year career to the healthcare sector, including 30 years on the supplier side of O&P. He was a senior executive at brace manufacturer Townsend Design for 25 years, including 17 years as the company’s CEO. Riley founded O&P Boost in 2020 and currently provides management, marketing, and sales consulting services to O&P suppliers.

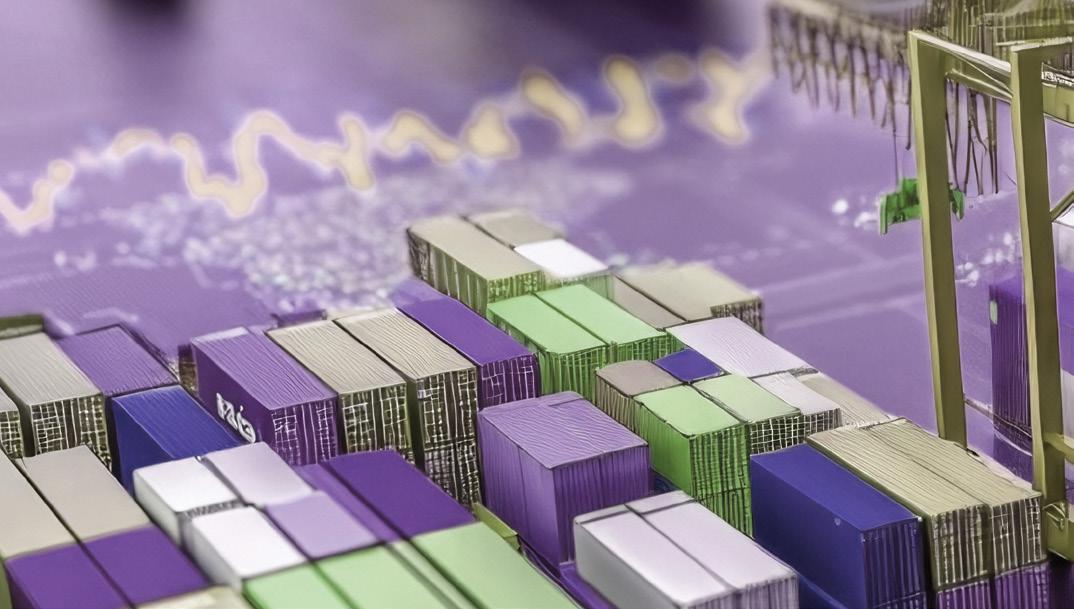

Josephine Rossi: What are you hearing from members about how tariffs could affect manufacturers and supply chains?

Rick Riley: There’s certainly angst about the potential impact. Without an exemption for medical devices, there’ll be consequences. Some manufacturers producing goods outside the U.S.—whether in Mexico, Canada, Asia, or Europe—have been preparing by stockpiling, like car manufacturers trying to get vehicles across the border before tariffs take effect. Major distributors have likely added to existing inventories as a hedge.

If tariffs go into effect, they’re determined by country of origin. For example, with a 20% tariff on a $100 product, that becomes $120 when received by the distributor or purchaser. Someone must bear that cost—they might try to work with manufacturers to adjust the front-end price, but ultimately, someone must absorb it.

Rossi: Are you hearing anything about materials pricing?

Riley: It’s not just finished goods, but also raw materials. If raw materials are part of goods made outside the U.S., it’s all incorporated into the price. Plastics, metals, and other materials can be impacted.

Joe McTernan: There was a recent story about aluminum tariffs. One big concern is the proposed tariff on aluminum, and the U.S. simply doesn’t have the capability to manufacture aluminum in high volume. Canada is a major producer and exporter. The story I saw involved a small craft brewery in North Carolina whose aluminum can costs were potentially increasing. They were seeking workarounds to avoid raising prices. It affects metals, plastics, and all kinds of materials, potentially impacting both our manufacturer members and patient-care members who don’t know the downstream effects.

CUSTOM: FOOT ORTHOTICS • AFO’S • RICHIES

At Hersco, our first priority is to fabricate custom orthotics accurately and precisely. We have mastered the art of accepting scans and 3D printing to deliver better orthotics for your patients and the environment. 3D printing is not only environmentally friendly, but allows us to specify modifications that were not possible before.

Riley: Consider the thousands of foot orthoses manufactured daily in the United States. Many foam materials aren’t manufactured domestically. Labs making foot orthoses might have a two- or three-month inventory, maybe boosted slightly, but eventually, if tariffs remain in effect, even those types of raw goods will be impacted.

Teri Kuffel, JD: Regarding industry preparation, some members have expressed concern. We want to ensure medical devices are exempt from tariffs. When we visited Sen. Tammy Duckworth last month, this was a topic we discussed. As a device wearer and bilateral amputee, she said O&P-related issues are among her top three priorities. We’ve communicated with other legislators, and we will address the topic of tariffs, among many other important matters, during our Policy Forum on May 6.

McTernan: One challenge is that there are two ways to address tariffs. You can do it legislatively, when possible, but now you must also lobby the administration directly because many tariffs are being created through executive orders not subject to legislation. Our audience isn’t just the Hill, but also the executive branch. In 2012, we had the medical device excise tax—a 2.3% tax on medical equipment. AOPA secured an exemption, but that was strictly legislative as part of the Affordable Care Act. We leveraged exemptions in the legislation to ensure we were included. That tax ultimately went away and was a huge legislative win, but it’s more complicated this time since it’s not just a legislative approach but also administrative.

Kuffel: We’ve requested this be discussed on the O&P Alliance agenda, bringing in our sister organizations. The situation changes daily. We’re watching closely and communicating with appropriate legislators, which will extend to the administration.

Riley: One final point: This could appear as a separate line item on an invoice that an O&P clinic receives, not necessarily a general price change. The challenge for clinics is that L codes and reimbursements remain the same regardless. There’s really no way for clinics to pass that cost to end users or insurance carriers due to Medicare and other payor rules.

Devon Bernard: To be somewhat optimistic, there’s precedent from President Trump’s first term, when tariffs last emerged and medical devices received an exemption. So, there’s hope we’ll have that exemption again.

Rossi: We continue to see workforce reductions across multiple federal agencies. Any sense of how this will affect O&P?

McTernan: The direct impact on CMS is estimated at 300 jobs from the 10,000 announced. It’s hitting agencies like NIH [and] FDA, and our friends at the Amputee Coalition are feeling the impact of eliminating the Administration for Community Living, which funds the

National Limb Loss Center. That agency is gone, with responsibilities redistributed across other HHS agencies. Assuming it’s related, delayed Fee Schedule publication isn’t the biggest concern, but it does show impact.

Kuffel: Regarding the VA, we’ve heard about considerable cuts affecting O&P clinics specifically. Every VISN [Veterans Integrated Service Network] office is different, so we don’t know how it affects each one. From what we’re hearing, O&P assistants were the first cuts, with technicians targeted next. Some practitioners and administrators are concerned about their future employment as well, given the recent announcement of thousands of cuts in VA programs.

Many O&P patient-care facilities have VA contracts. This potentially means more work for those contracted or vendor-authorized through the VA system. It’s important that AOPA members that are VA-contracted or vendor-authorized remain good partners, because it potentially will create more work order opportunities.

Kuffel: We’ve sent out a call to action to our members—an email campaign so members can quickly tell legislators why it’s important to keep Medicaid funding intact. As of October 2024, 72.1 million Americans—more than 20% of the U.S. population—are enrolled in Medicaid.

Keeping Medicaid intact helps families and jobs stay intact, benefiting our broader community while ensuring we can serve populations needing our services with continued access to care.

The Amputee Coalition is another concern. Beyond issues with the Administration for Community Living and their Limb Loss Center, there’s significant concern about their government funding being frozen or cut, creating uncertainty about their future. This will affect all our sister organizations and everyone in our industry.

McTernan: On March 14, we had the continuing resolution (CR) that kicked the can down the road until the fiscal year end on September 30. I’d like to say it was a clean CR without impact, but one major consequence was reduced funding to the CDMRP [Congressionally Directed Medical Research Program].

The House Energy and Finance Committee has been tasked with finding $880 billion in savings over 10 years. The CR just delays this, but the goal is to pass an omnibus bill creating a new budget structure. Medicare is off the table per campaign pledges, so if you’re cutting $880 billion in federal healthcare funding, it mainly comes from Medicaid. It’s really the only target left. This means cutting benefit programs and implementing new caps—it’s not surgical but a hack. Our profession has a very skewed portion of our patient population impacted by this.

The new Odyssey ® iQ is a hydraulically dampened microprocessor foot that is lightweight and incredibly low-profile. With an IP67 rating, long-lasting battery, and fast responses, it accommodates a wide range of users and activities. It also features simple setup and a unique method of springassisted dorsiflexion. The Odyssey iQ was created to be user-friendly for patients and clinicians—providing access to valuable functions in College Park’s Stride Studio app.

CROSS™ is intended for mild to moderate knee hyperextension due to neuromuscular diseases or other injuries. The brace can also be used together with Allard AFOs when knee hyperextension is present together with foot drop.

ҋ One-hand donning and doffing.

ҋ Easy adjustment of hyperextension resistance, both through ROM stops and popliteal cross.

ҋ Smooth, low friction liner for comfort and easy application.

head is furthest removed from normal values and target treatment to those values,” Stevens explains.

A study, published in February, applied the indices to perioperative and post-CRO optical surface scanning (OSS) images of the 25 sagittal synostosis cases seen at the Hanger Clinic in Nashville, Tennessee. This study found that through their course of postoperative cranial remolding, the patients realized statistically significant improvements in all indices. These indices have since been incorporated into Hanger’s craniometrics reporting tool, a digital reporting software system that converts 3D shape files into the desired two-dimensional measurements. Hanger Clinic clinicians across the U.S. can input baseline scans, and the tool will flag abnormal variances to create highly specific patient treatment plans. The tool also tracks differences over time to measure CRO transformation—or modify treatment plans—with new levels of accuracy.

While the study aimed to improve care for sagittal synostosis, two of the metrics developed are especially relevant to cases of positional brachycephaly, according to Jason Ramsey, MSPO, CPO, a certified prosthetist/orthotist for Hanger Clinic in Nashville. He says the metrics are particularly useful for clinicians who are still gaining experience diagnosing cranial deformities

FITec 6507/6508

Genuine leather

Slip resistant Rubber outsole

OSHA tested Composite toe box (with or without)

PDAC approved under A5500

Size: 7, 7.5-11.5, 12-17

Width: D, 4E, 6E, 9E

and can help catch cases of sagittal synostosis misdiagnosed as deformational plagiocephaly.

“Some clinicians may have blinders to certain aspects of deformity and if we apply numbers, it can help with that,” Ramsey says. “Now with these measurements, a newer clinician can walk in and raise a red flag.”

Advances in newborn screening and gene therapy for children with spinal muscular atrophy (SMA) have radically changed the treatment approach for that population. SMA—a disease involving the loss of nerve cells in the spinal cord and subsequent loss of voluntary muscle movement—is the most common genetic cause of mortality in infants.

All 50 states recently approved screening for SMA for all hospital births, helping clinicians and families achieve a diagnosis within days rather than waiting for infants to become symptomatic, according to Sara Beyler, CO/LO, an orthotist at Ann & Robert H. Lurie Children’s Hospital of Chicago. Early intervention gives children the opportunity to benefit from gene therapies replacing missing or nonworking genes with working gene copies that help kids grow and make functional gains.

In a few cases, Shriners Children’s identified scoliosis patients who were wearing their braces upside down, making all subsequent instructions inconsequential, according to JoAnne L. Kanas, DPT, CPO, corporate director of orthotics and prosthetics. “Our patients sometimes travel a great distance—sometimes across state lines,” she says. “We also acknowledge that these appointments can be very overwhelming. The helmets are with parents of infants who are usually not happy with their helmet initially. They can be hungry, tired, or just being babies. Scoliosis bracing is hard. No teen or preteen wants to be wearing a brace.”

Telehealth visits occur 24 to 48 hours after initial cranial remolding helmet fitting and two to three days following brace fitting. For both patients with scoliosis and those who wear CROs, these appointments focus on determining how the device feels, how many hours they are able to wear the device daily, and whether there are signs of redness or skin irritation. These visits provide patients and parents with the opportunity to ask questions and review the instructions from the initial appointment. During the appointments, parents are asked to put on their infant’s CRO, and teens with scoliosis illustrate how they put on their orthoses.

The program resolves patient-care issues quickly so children can receive the maximum benefit from their orthotic device. “We look at how tight the straps are being pulled; ask how it’s going for sleep, or

gym class, or sports; answer any questions about undershirts and offer clothing tips,” Kanas says. “And we reinforce the importance of wearing it as prescribed by their physician.”

Shriners also instituted telehealth sessions two weeks prior to prosthetic clinic appointments so families know what to expect at their in-person visit and come prepared. Clinicians can see the patient walk, assess growth, and determine whether a new socket or prosthesis may be needed at the in-person visit. Preliminary data collected during the telehealth appointments indicates they have decreased no-show rates for clinic appointments. Shriners Children’s plans to solicit additional feedback to see if parents think the calls add value to the treatment experience.

O&P professionals are revolutionizing treatment plans and outcomes across multiple pediatric conditions. These advancements aren’t just technical achievements; they represent real quality-of-life improvements for children and their families, reducing treatment times, increasing comfort, and opening new possibilities for those who previously faced limited options. As patient-care professionals continue to merge clinical expertise with technological innovation, the landscape of pediatric O&P care is being redrawn, with promising implications for thousands of children nationwide.

Jennifer Davis is a contributing freelance writer for O&P Almanac

O&P educator discusses evidence-based care, clinical care pathways, and the next generation of O&P professionals

The Fresh Faces column introduces readers to prominent O&P professionals who are making an impact with their contributions to the orthotics and prosthetics profession. This month, we speak with Sally Kenworthy, PhD, CPO.

Sally Kenworthy, PhD, CPO, shares her journey from a first-generation college student to a well-respected O&P clinician, researcher, and educator. After graduating from Texas A&M University with a degree in kinesiology-motor behavior in 2010, she earned a master’s degree in prosthetics and orthotics in 2011 from University of Texas Southwestern Medical Center at Dallas and a doctorate in kinesiology–motor behavior from University of Houston in 2024.

Today, Kenworthy is an assistant professor at Baylor College of Medicine; a researcher who has published on topics including anklefoot orthoses and lower-limb orthoses; and an ardent volunteer for the O&P profession.

O&P Almanac: What brought you to a career in O&P?

Sally Kenworthy, PhD, CPO: I was initially brought into O&P because of my interest in physical therapy. While I was shadowing physical therapists (PTs) for PT school applications, a prosthetist attended an appointment—and I was hooked!

O&P Almanac: What did you enjoy most about your early career as a clinician?

Kenworthy: Although I went to school to become a prosthetist, I had the privilege to learn orthotic management from some of the best clinicians in the world. I initially started out as strictly a pediatric orthotist focused on the lower extremities, but after some

Last year, I had the privilege of serving as a subject matter expert for AOPA’s pilot development of the AFO Care Pathway, and, more recently, I became a board member for the National Commission on Orthotic and Prosthetic Education. I take these contributions very seriously because I know that our decisions can have a long-term positive or negative effect on an industry I care very much about. I also gained a lot from these experiences because of the group contributions and hearing dissenting opinions.

O&P Almanac: You spoke about standardized care pathways at AOPA’s Leadership Conference this year. Why is it important for O&P clinicians to understand and make use of care pathways?

Kenworthy: O&P clinicians need to understand care pathways because they are standard in other professions and define a clinical care process. In other professions, care pathways have helped identify more effective ways to treat stroke in the acute setting and, as a result, have developed processes proven to decrease the risk of a second stroke.

Through care pathways, we—patients, providers, and payors—can start to assess

the clinical journey of the patient and identify unique areas of success and/or areas that need more attention.

On a larger scale, having a care pathway signals to payors and other professions that we are more than a vendor and provide value outside of the device provided to the patient. It’s important that we better define what we do before someone else comes along to do it for us in a way that may not have our profession’s or patients’ best interests in mind. If we use—and refine—care pathways over time, they can ultimately protect our profession and the patients we serve.

O&P Almanac: You are passionate about raising awareness of the value of the contributions of CPOs, as well as orthotics education and research. Why is this so critical?

Kenworthy: I believe that professional awareness, education, and research are the pillars of stability and security for our profession and will always be critical. We have a huge problem related to public awareness of the profession, which is why the WhatIsPOP career awareness initiative from the American Board of Certification in Orthotics, Prosthetics, and Pedorthics is so important.

When we can demonstrate the value and unique contributions of a certified prosthetist/orthotist, it can attract more people to the profession. Better role awareness

from other professions ultimately improves the patient experience because the most qualified person is managing the patient’s orthotic or prosthetic care. This role awareness can even have an impact on our local and federal governments, changing policies and access to care for patients.

Getting an education has opened a world of opportunities that I am incredibly grateful for and believe everyone has a right to. Contributing to high-quality education of future O&P professionals is important for everyone to do, including classroom educators, residency mentors, and professional mentorship from the greats in our field. It creates a cycle of learning that keeps us moving forward, rather than repeating and rediscovering successful clinical approaches over and over again. Research is important because it provides robust evidence to support what we experience to be true in terms of our value and patient outcomes.

O&P Almanac: What are the biggest challenges and opportunities for the future of O&P?

Kenworthy: It seems counterintuitive, but positive—or negative—changes in the profession result from our collective individual behaviors. Because of the behavioral changes of thousands of clinicians who embraced measuring outcomes for their patients, we have incredibly largescale analyses that can be done to show the benefits of microprocessor knees, for example—and look at the policy changes that followed!

In this sense, the everyday clinician has a lot riding on their shoulders, and it seems we are constantly demanding more from them on top of providing excellent care.

I believe the challenge is off-loading the individual CPO enough to prevent burnout and give them the time and energy to focus on other areas that benefit the profession differently. It will require communication from leadership that gets buy-in from their teams and a cultural shift. Our challenges create a massive opportunity for O&P to fully embrace care extenders—again, something that is standard in other health professions.

The Formula foot line provides the ideal balance of flexibility and power, creating a dynamic foot design intended for a wide range of highly active users. Bridging the gap between the Formula Ultra™ and Formula Pediatric™, the new Formula Fit™ is the perfect solution for adolescents and small adults who want to be active.

The Transformations column features the success story of an O&P clinician who has worked with an inspiring or challenging patient. This month, we speak with Chad Knapp, CPO, who fit a young patient with congenital bilateral limb loss with running blades.

It was a very merry Christmas last December for Charles Lowery, a 7-year-old from Illinois. Lowery, who is missing both legs above the knee due to a congenital condition, hopes to one day play football—and he got a head start on fulfilling that goal this past holiday season. Much to his surprise, Lowery was presented with his first pair of running legs directly from “Santa”—with more than a little help from prosthetist Chad Knapp, CPO, clinic manager at the Springfield, Illinois, Hanger Clinic location.

Knapp has found his calling as a prosthetist, providing the most appropriate solutions to patients like Lowery, but he says he became a prosthetist by “stumbling into” the career. After growing up on a farm in Illinois where he enjoyed “working with my hands,” he attended Joliet Junior College. There, he discovered the Orthotics and Prosthetics Technology Program. He liked the satisfaction he felt from fabricating devices, “but I realized I also wanted to do patient care,” Knapp recalls. He transferred to St. Petersburg College for its O&P program, then returned home to Illinois, where he completed his residency at Hanger Clinic—and has been at the company ever since.

Knapp says he is motivated daily by his patients—particularly his pediatric patients. He has been working with Lowery and his family for the past five years, collaborating with his Hanger

team to provide Lowery with mobility solutions appropriate for an active young boy.

“Charles is a bundle of inspiration,” Knapp says. “He never lets anything get him down. He always finds a way.” As a child with bilateral limb absence, “his drive to continue to rise and accomplish any challenge in life is really inspirational for me and for anybody he’s in contact with.”

When Lowery was 2, he was fit with his first prostheses: above-knee carbon sockets with Pelite inner TES belt suspension on both sides, without knee components. When Lowery turned 5, Knapp introduced the Trulife child’s play knees to meet his improved mobility needs. Lowery also worked with a physical therapist to improve his gait as he learned to use knees for the first time and navigate a swing phase. Knapp eventually transitioned Lowery into bilateral above-knee ischial containment carbon sockets with Össur Junior Vari-flex feet, paired with Össur’s Total Knee Junior. While Lowery has done well in all those prostheses, he was never able to run like other children his age.

Then Lowery discovered running blades— and the possibility of running—at a local patient education clinic hosted by Hanger’s Vice President of Lower-Extremity Prosthetics, Kevin Carroll, MS, CP, FAAOP(D). “We met up in June at a local park,” and part of the activities included allowing participants to sample running blades, Knapp recalls. Once Lowery tried on a pair, “he stole the show,” Knapp says. “He did great—you could tell he felt free and that he finally felt just like the rest of the kids. He had a huge smile on his face.”

That test run set the stage for Lowery to dream big. He soon announced he wanted to be able to run on a football team one day soon. But buying his own set of running blades was cost-prohibitive for his family, so Knapp, Carroll, and the local Hanger Clinic team decided to help.

Carroll determined that, despite Lowery’s young age, he had enough strength and ability to successfully wear running legs. Next, Knapp and Carroll connected Lowery’s family to the Timothy J. Piazza Memorial Foundation, an organization that

provides support to those who need prosthetic devices—and children in particular. The Foundation agreed to work with the Lowerys to help get Charles out on the football field.

As luck would have it, the timing of the delivery of the new running blades coincided with the December holiday season, so Knapp collaborated with his Springfield team, including Business Development Manger Paige Topel, along with Lowery’s family, to coordinate the delivery appointment as a Christmas surprise.

Knapp reached out to Michael Tanner, an older patient of his, for assistance. Like Lowery, Tanner has bilateral limb loss, having lost both legs below the knee 12 years ago. More importantly, Tanner is known to dress up and play Santa during the holidays. When Tanner heard Lowery’s story, he knew he wanted to get involved.

On the day of the surprise, Lowery thought he was headed to Hanger Clinic for a regular follow-up visit. Instead, he was

greeted in the lobby by a Christmas tree and “Santa,” who had a very special present for him: his very own running blades, along with customized above-knee sockets decked out in have favorite color, blue. After explaining that “the real Santa” had sent him as a helper, Tanner shared that “I’m a double, just like you—we’re buddies for life.”

Tanner accompanied Lowery to the patient room, where Knapp conducted the fitting and alignment. “It was a whole different set-up” from what Lowery was used to, “but he did well,” says Knapp.

Lowery went home with his new legs and continues to work with Knapp on new sockets and making necessary adjustments to ensure his mobility is improving every day.

Looking to the future, Knapp predicts it won’t be long until Lowery achieves his dream of playing football—flag football, to start. “We’ll do our best to make sure he can comply with the rules” of the local flag football team, “and we’ll get him out there and running,” Knapp says. “I can’t wait to get on the sidelines and watch!”

Beyond football, “the possibilities are endless” for what Lowery can achieve, says Knapp. “Charles has the drive and work ethic to accomplish anything,” he says. “And I’ll be a resource for him going forward” to help him achieve new goals. “Treating Charles makes me want to be better at my job.”

Being able to surprise Lowery at Christmas time is a career highlight that Knapp won’t soon forget. After this experience of ensuring his patient was able to access running blades for physical activity, Knapp plans to get involved with So Every BODY Can Move (SEBCM), a state-based initiative launched by AOPA, the Amputee Coalition, and the Academy focused on ensuring equitable access to prosthetic and orthotic care for

physical activity. Several states have had success in the initiative and have subsequently passed laws that guarantee insurance coverage for activity-specific devices (see State By State on page 48).

Knapp recommends that other clinicians consider getting involved in patient advocacy efforts to ensure individuals with limb loss and limb difference can access the devices they need.

He also has several suggestions for clinicians who are new to the pediatric population. “Be able to listen and truly understand what the patient needs,” he says. “Be able to step outside your comfort zone and be willing to think outside the box. Be dynamic in thinking about what patients may need, in terms of suspension and components. And let your patients know that you’re there to help them—even with new things.”

Knapp also believes it’s important to introduce young patients to peers who may face similar challenges: “It’s very important to get these kids exposure to others who are like them, so they can learn tips and tricks” and be empowered to try new things. Knapp says that although his youngest patients have already faced tremendous adversity head-on; they never back down. “I’m blessed to have them be my patients. Pediatric patients often become more like a family.”

ACCESS YOUR PERSONAL ACCOUNT, VIEW VIDEOS, PRINT CERTIFICATES, OR REVIEW CE CREDIT HISTORY 24/7.

Log in at https://aopahub.aopanet.org. Your username is the email used to create your profile. If you do not currently have an AOPAversity account, visit www.AOPAnet.org/education to create a profile.

FACILITY:

OWNERS:

“We feel like it is important to support the good work that the organization is doing to advance the constantly evolving aspect of our profession. As a business that is constantly looking at ways to improve our care model, it makes sense to offer our support through membership.”

—Noah Nemgar, MSPO, CPO, LPO

LOCATION:

Headquarters in Rochester, Minnesota, with offices in eight other cities

HISTORY: 12 years

Limb Lab, founded in 2013 by Brandon Sampson, CP, and CEO Marty Frana, focuses on creative and innovative solutions to the needs of people experiencing limb loss and limb difference. In addition to its flagship office in Rochester, Minnesota, Limb Lab has locations in Minneapolis and Mankato, Minnesota; Scottsdale, Arizona; La Crosse, Wisconsin; Lincoln and Omaha, Nebraska; and Iowa City and Des Moines, Iowa.

The company prides itself on providing patientcentered, clinician-led care. Limb Lab has developed a reputation for its work with patients who have less common amputations and complex needs. For all of the facility’s patients, Limb Lab practitioners take full advantage of high-tech componentry, collaboration, and creativity.

“Many of our patients have a great deal going on clinically,” says Noah Nemgar, MSPO, CPO, LPO, who serves as market president for Limb Lab in Scottsdale. Patients frequently seek out specialists at the nearby Mayo Clinic, who work closely with clinicians at Limb Lab. This relationship with Mayo Clinic brings a wide range of patients. “It is great to build relationships and bonds with patients from all different walks of life,” says Nemgar.

Sampson adds, “Those different walks include people from around the world and also from all 50 states in the U.S.—and a substantial number from our backyard, in rural Minnesota, Iowa, Nebraska, Wisconsin, and South Dakota.”

Limb Lab clinicians see a lot of sarcoma and cancer patients with very involved amputations, according to Nemgar. “We see patients with hemipelvectomies and hip disarticulations, which is one of my specialties, as well as a high number of forequarter amputations and shoulder disarticulations.” The Rochester location, where the facility first launched, sees high volumes of upper-extremity cases.

“Among the things that differentiate us from our peers is the quality of care and attention to detail we provide,” Nemgar says. “We really thrive on artistry and innovation. We want the devices we create to be beautiful, to be an extension of the patient as we blend the mechanical with the human side of things.

We want our patients to be proud to wear their devices as an extension of their personalities.”

Limb Lab’s commitment to artistry includes the design of its facilities, where much of the furniture is custom made of wood and welded metals. “Our furniture blends an industrial and mechanical look with something organic—the wood,” says Nemgar. “Like our clinical devices, these objects become beautiful works of art that are extremely functional.”

Both technicians and practitioners fabricate devices in-house. “The better you are at fabrication, the better you are as a clinician—I learned that early on,” says Nemgar, who still does casting, modifying, and fabrication by hand. Some offices have adopted 3D printing, and one location houses a seven-axis carving machine. “It is good to continue to keep pushing the boundaries with new and evolving technology. We love creating new devices and components.”

“We have, when appropriate, filed successfully for patents on certain products that we’ve invented,” Sampson adds. “We keep our patent attorneys busy.”

As part of its community presence, the company established the Limb Lab Foundation, which provides low- or no-cost prostheses to those in need. It also donates materials and sponsors individuals to participate in the Range of Motion Project.

One patient made a particular impact on Nemgar: a woman with sarcoma in her mid-60s who underwent hip disarticulation surgery. “She was determined to do everything she could do before the surgery,” he says. “She practices her skills every day trying to improve, and for her amputation level, she is one of the best ambulators I’ve ever worked with.”

Limb Lab clinicians pride themselves on working closely with patients to identify their goals. “Knowing their goals, their dreams, and what they love to do helps steer me in the right direction to design their prosthesis,” Nemgar says. “We want them to be as involved in the process as we are. We use our expertise, but at the end of the day, they are the ones wearing the device.”

Deborah Conn is a contributing writer to O&P Almanac. Reach her at deborahconn@verizon.net

BY DEBORAH CONN

OWNERS:

TWhy Am I an AOPA Member?

“We are a member of AOPA because we want to be a part of this community, which helps us learn how we can improve these devices.”

—Ryan Saavedra

LOCATION: San

HISTORY: Five years

he creation of Alt-Bionics dates back to 2017 when its founder and CEO Ryan Saavedra, nearly lost a finger in a rock-climbing accident. Saavedra, at the time a sophomore engineering student at the University of Texas—San Antonio (UTSA), was worried he might lose a finger from his injured hand, so he experimented with a rudimentary prosthetic finger using cardboard, a straw, and some string. Fortunately, Saavedra managed to keep all of his fingers—but the incident sparked his interest in prosthetic hands.

“As I progressed through college, one finger became four, and that eventually turned into a senior design project where we added artificial intelligence to an open-source design from Open Bionics to enhance the hand’s capabilities,” Saavedra says. The project won UTSA’s technology competition, and news coverage from the event reached the family of Army Ranger Ryan Davis, who lost his arm to an improvised explosive device. “His family approached me, and I took the prosthetic hand to him in the hospital,” Saavedra recalls. After Davis successfully tested the hand, “the room was all smiles and laughter, and then a family member turned to me and asked, ‘What’s next for this technology?’ That was when Alt-Bionics was born.”

Judith Colon, chief financial officer; Samuel Woolfolk, chief technology officer; and Jackson Heinz, director of engineering, joined the company as co-owners within the year, and today the company has eight employees. After five years of development and several fundraising events, Alt-Bionics will launch the Genesis hand in May.

“Our goal was to make the hand as advanced and as affordable as possible,” Saavedra says. “I went to as many clinicians as I could and queried amputees about what problems they faced with currently available prosthetic hands. We got a lot of feedback that helped inform our product.”

The Genesis hand is lightweight at just 1 lb. and costs less than other prosthetic hands, according to Saavedra. The device offers visual feedback from an LED ring on the back of the hand, which, Saavedra

says, is helpful in providing diagnostic independence for both clinicians and users. “You can see the [electromyographic] signal that lets you know how the hand is responding, which really reduces the learning curve,” he says. “We had kids in elementary school figure out how to use the hand in about 5 minutes.”

The prosthesis also features a red light that indicates when the hand is locked, which offers users additional independence from the smartphone app. “We also included a flashlight on the hand as a fun, useful extra,” Saavedra says.

The device’s modular fingers are its most important feature, according to Saavedra. “Fingers break all the time, and they can take months to replace. With our hand, either the clinician or the user can replace a finger in under 5 minutes.” The device includes four extra fingers as part of the package, as well as four extra fingertips to replace those that wear out, he says.

Saavedra attributes the low cost of the prosthesis to low overhead and advances in technology. “We have a small, nimble team, and we can take advantage of off-the-shelf hardware and motors that used to be custom made,” he says.

Once the product is launched, Alt-Bionics will provide facilities with trial units and overnight the full package once a facility decides to purchase it. The hand comes with a manual, and Saavedra and his colleagues are available for any needed support. “We made the device as intuitive as possible, with a streamlined app,” he says, “so most clinicians should be able to work easily with patients to set up the hand.”

As technology advances, Saavedra hopes that osseointegration will become more widely available within the next 5 to 10 years. “This would have important implications for both upper- and lowerextremity prostheses, and we are always designing with technological advances in mind,” he says. “No matter how advanced these supporting technologies get, our hands will be ready to integrate.”

Deborah Conn is a contributing writer to O&P Almanac. Reach her at deborahconn@verizon.net

Register today for the 2025 AOPA Policy Forum—we need your voice more than ever!

• Education Session: Tuesday, May 6, 1–5 p.m. ET

• Congressional Meetings Conducted by Zoom: May 7–8 and May 12–15

NOTE: You only need to be prepared to participate in one Senate and one House meeting whenever they are scheduled on these days.

This year’s AOPA Policy Forum will be a virtual event. The decision for a virtual format—this year only—was influenced by several factors, including the impact of a new administration and congressional leadership as well as leadership changes in key committees; the timing of the introduction of the Medicare Orthotic & Prosthetic Patient-Centered Care Act; and the ability to increase participation of O&P professionals, students, and patients in shaping the future of O&P policy.

Virtual education will be recorded for those who aren’t available.

AOPA will continue to facilitate strategic in-person meetings with key members of Congress throughout the year and may call on AOPA members from key states and districts to travel to Washington, DC, to participate in meetings. AOPA is working closely with our O&P sister organizations to ensure maximum advocacy impact for the 2025 Policy Forum and other targeted advocacy strategies this year.

Registration is now open; visit aopanet.org/legislative-regulatory/ 2025-policy-forum. We encourage you to reserve 1–5 p.m. ET on May 6 to join us as we take O&P advocacy to the next level—virtually! Questions? Contact us at info@aopanet.org

Meet up in Orlando in September for the 2025 AOPA National Assembly! Network with O&P stakeholders, take part in educational sessions on the latest hot topics, browse the exhibit hall to see cutting-edge products, and much more.

The 2025 AOPA National Assembly will take place Sept. 3-6 at the Orange County Convention Center. Extend your trip to enjoy all that Orlando has to offer—bring friends or family!

Visit aopaassembly.org today—register by July 19 and save!

Orlando is home to more than 100 lakes. Orlando’s most famous body of water is Lake Eola, originally called Sandy Beach. If you’re a fan of water sports, make plans to visit Lake Jessamine, Lake Virginia, or Lake Tohopekaliga.

Enhance your skills with Allard’s free, ABC/BOC CEU-approved courses!

Access a variety of topics, including Bracing Solutions for Genu-Recurvatum — 24/7 access!

Earn your points today! allard.re/education

Embrace the comfort of custom-fit with Mt Emey®’s Custom Shoe (Medical) Program. Our precise 3D scanning captures your unique foot contours, promising a perfect fit without the wait or waste. From stylish athletics to roomy comfort designs, our handcrafted shoes adapt to your needs. Satisfaction guaranteed before payment. Plus, qualified wholesale accounts receive a free 3D scanner. Step into the Mt Emey difference— where every shoe is made for you. For more information, call 1-888-937-2747 or visit emeys.com

The Icon microprocessor knee was designed to offer a user-friendly experience. Featuring responsive sensors, streamlined setup, and the intuitive Stride Studio app, this knee may enhance user confidence. Clinicians can easily access all adjustments, custom modes, and more in Stride Studio. Our team has developed proprietary technology to put the Icon in a league of its own—providing remarkable accuracy, response time, and weight savings. Equipped with a long-lasting battery and IP68 rating, the Icon is the versatile solution for low to high activity users. Visit college-park.com

Available in multiple fun designs and colors

Helps protect the knee cover Gives a cushioned surface for kneeling

The Coyote® Knee Cover is offered at a great price! The contoured shape was designed to fit the C-Leg 4 and help mimic the natural look of a leg while adding a cosmetically pleasing finish, and extra protection to the surface of the prosthetic knee. Its cushioning also helps stabilize patients when kneeling, enhancing both comfort and functionality. Available in multiple designs and colors, the Knee Cover includes fun and convenient features to suit every style. For more information, contact Coyote at 208-429-0026 or visit www.coyote.us

Designed in partnership with Coapt, Fillauer’s Myo/One™ Electrode System is a streamlined, waterproof system that can reduce hours of trial and error into a couple quick minutes. Designed around one small preamplifier that provides two channels of EMG signal for myoelectric devices, the system replaces cables, fabrication aids, sealing rings, and multiple devices with one simple cable. Myo/One is a convenient, small, versatile, package which is compatible with almost all dual-site myoelectric devices and provides a much simpler system for dual-channel direct EMG control.

Visit our website at fillauer.com to learn more.

Download the Hersco app on your iPhone and connect to the lab anytime. The Hersco app and order portal makes scanning and ordering seamless. Scan patients for foot orthotics, Richie Braces, and ankle gauntlets, and submit at your convenience. Our digital workflow allows you to easily track jobs, re-order devices, and manage your account. Download the app and get your username and password.

Our 3D printers produce accurate and precise orthotics, reducing landfill waste by over 90%!

Email us today at fastorthotics@hersco.com or call 800- 301-8275 to get a free product sample. Visit hersco.com

Contact Bob Heiman at bob.rhmedia@comcast.net

ABC: Application Deadlines, Exams Dates, O&P Conferences, and More! Check out ABC’s Calendar of Events at abcop.org/calendar for the latest dates and event details, so you can plan ahead and be in the know. Questions? Contact us at info@abcop.org or visit abcop.org/contact-us

The Pedorthic Footcare Association: Diabetic Wound Prevention, Management, and Healing Program 10-session online education program series. Approved CEs by ABC and BOC, monthly classes are 1.5 hours each. For more information and to register, visit pedorthics.org/page/diabetic_series_10.

May 6

2025 AOPA Policy Forum Education Session—Virtual. 1–5 p.m. ET. Contact AOPA at info@aopanet.org

May 7–8

2025 AOPA Policy Forum Congressional Meetings— Virtual. Meetings conducted by Zoom. Contact AOPA at info@aopanet.org

May 12–15

2025 AOPA Policy Forum Congressional Meetings—Virtual. Meetings conducted by Zoom. Contact AOPA at info@aopanet.org

June 13–14

27th Annual PrimeFare East—NEW VENUE! Downtown Marriott Hotel and Convention Center, Chattanooga, TN. Contact Cathie Pruitt at 901-359-3936, primecarepruitt@gmail.com, or visit primecareop.com

September 3–6

AOPA National Assembly. Orange County Convention Center, Orlando. For more information, visit aopanet.org

Advertise O&P events for maximum exposure with O&P Almanac Contact Bob Heiman at bob.rhmedia@comcast.net or learn more at bit.ly/ AlmanacMediaKit25. Announcement and payment may also be sent to O&P Almanac, Calendar, P.O. Box 34711, Alexandria, VA 22334-0711, or emailed to jklapp@AOPAnet.org along with VISA or MasterCard number, cardholder name, and expiration date. Make checks payable in U.S. currency to AOPA. Note: AOPA reserves the right to edit calendar listings for space and style considerations.

A large number of O&P Almanac readers view the digital issue— If you’re missing out, visit issuu.com/americanoandp to view your trusted source of everything O&P.

Scan the QR code to start advertising in the O&P Almanac or visit bit.ly/AlmanacMediaKit25

Multiple O&P-related bills are under consideration in Texas. HB 426, a bill that would require Medicaid and the Children’s Health Insurance Program to fully cover cranial remolding orthoses according to clinically accepted guidelines, has passed unanimously in the Committee on Human Services. Now it moves to the next steps in the House. SB 1466/HB 5544 would expand Medicaid coverage of prosthetic devices to adults older than 20 years old; Texas is the only state where Medicaid does not cover necessary O&P devices for adults over 20. Texans can take action and contact legislators through the Texas O&P Advocacy Center at https://p2a.co/f1izYW6

In February, the UHC Community Plan for Indiana Medicaid retired its Upper-Extremity Prosthetic Devices Policy. Although there is no current policy, UHC can still review these claims and choose to approve or deny them.