WHAT'S IN THE PROPOSED LCD AND DRAFT POLICY ARTICLE FOR KNEE ORTHOSES? 20

AOPA NAMES EXECUTIVE DIRECTOR 16

AUTOMATING KEY STEPS OF THE CUSTOM-MADE ORTHOSIS DESIGN PROCESS 46

WHAT'S IN THE PROPOSED LCD AND DRAFT POLICY ARTICLE FOR KNEE ORTHOSES? 20

AOPA NAMES EXECUTIVE DIRECTOR 16

AUTOMATING KEY STEPS OF THE CUSTOM-MADE ORTHOSIS DESIGN PROCESS 46

3D printing and digital workflows are transforming O&P—and the practitioners who use them P.24

THE PREMIER MEETING FOR ORTHOTIC, PROSTHETIC, AND PEDORTHIC

September 3–6, 2025, for an ideal combination of top-notch education and entertainment at the 108th AOPA National Assembly in Orlando, FL, at the Orange County Convention Center (OCCC).

EXHIBITS EDUCATION NETWORKING

CX™, the #1 small hand. The TASKA CX, available in small and medium, has a legacy of proven performance and trust. While others chase trends, the CX consistently delivers what matters most - unmatched durability, reliability, and aesthetic excellence. It’s the benchmark for quality, engineered to endure and chosen by users and prosthetists who demand more. In a crowded market, the CX doesn’t just stand out - it sets the standard. To discover more, visit fillauer.com or taskaprosthetics.com

3D printing is reshaping everything from manufacturing workflows to patient-care delivery. Practitioners who once relied on traditional hand skills are now embracing additive manufacturing, AI-assisted design, and new materials. From remote brace repairs to prosthetics that could intelligently fail to protect users in accidents, the technology is reshaping not just how devices are made, but practitioners' relationship with technology of all kinds.

By JOSEPHINE ROSSI

After leading the organization as interim executive director for six months, Teri Kuffel, JD has been appointed by the AOPA Board of Directors as full-time executive director.

Access tips for navigating recent changes to the Medicare program.

to earn CE

by taking the online quiz.

Find out how Louis-Philippe Broze, co-founder and chief executive officer of Spentys, is elevating the design process for custom-made orthoses.

Meet Alex Miller, CPO, MSPO, and learn about his collaboration with an active patient to design a custom cycling foot for

Learn what the Assembly sponsoring organizations will showcase at their booths in Orlando.

See the full list of companies exhibiting at AOPA's 2025 National Assembly.

Dear AOPA Members,

As I reflect on the past seven months serving as your interim and now executive director, I’m filled with gratitude, momentum, and a deep sense of responsibility. It is my honor and privilege to work alongside AOPA’s Board of Directors, our dedicated staff, valued members, and O&P partners to advance our shared mission: improving access to high-quality care and elevating the O&P profession.

Leadership transitions present a unique opportunity—a natural moment to pause, assess, and explore the organization through a fresh lens. That’s exactly what we’ve been doing. Together, the Board, staff, and I have been asking important questions, listening with intention, and identifying new ways to amplify AOPA’s impact.

As the first person in some time to lead AOPA with direct industry experience, I bring with me an understanding of the challenges and opportunities you face every day. That perspective has helped shape our priorities, ensuring they’re firmly grounded in the needs of our members, the profession, and, most importantly, the individuals we serve.

One theme has remained front and center: Collaboration is essential. Over the past seven months, we’ve doubled down on the power of working together—because real progress happens when our community moves as one.

Three powerful examples:

• The Medicare O&P Patient-Centered Care Act: Together with the O&P Alliance, our peer organizations, and our members across the country, we’re aligning our advocacy efforts to speak with a unified voice in Washington and beyond. The reintroduction of these bills in the House and Senate is a true testament to collaboration and grassroots advocacy at its finest. We look forward to working together to move this legislation across the finish line this session. (Read more on page 10.)

• Proposed LCD Revision to Expand Coverage of Knee Braces Used to Treat OA: After nearly two years of persistent engagement from AOPA staff and Coding and Reimbursement Committee following our formal LCD reconsideration request, the DME

MACs have released a draft revision to the Knee Orthoses Local Coverage Determination (LCD) and its corresponding Policy Article. This proposed update represents a major step forward in correcting one of the most significant omissions in Medicare coverage, orthotic treatment for osteoarthritis (OA) of the knee. AOPA will continue to use its expertise to participate in the public hearing and submit formal comments to ensure this becomes policy.

• So Every BODY Can Move (SEBCM): Together with our peer organizations, we’re working on this transformative, state-by-state initiative to expand access to activity-specific orthoses and prostheses and increase access to O&P care. With legislation already enacted in 12 states and momentum growing nationwide, we’re showing up and showing how united advocacy can drive real, life-changing results.

These efforts go beyond policy—they reflect our commitment to advancing the O&P profession, supporting your work, and improving lives across the limb loss and limb difference community. With the year halfway through, I want to share a few highlights of how we’re translating our strategic vision into meaningful results:

Communicating the power of O&P: We're continually working to amplify the voice of the profession with communications that show how O&P care transforms lives. Communicating the power of O&P is integrated into all strategic priorities, focus areas, and goals.

Increasing access to care: As mentioned prior, the AOPA advocacy team is working daily to ensure all patients have access to clinically appropriate, high-quality O&P services and that our members can be compensated fairly for that care.

Helping members navigate a changing healthcare landscape: From regulatory updates to the expansion of AOPAversity’s free and online CE courses, we’re equipping you with tools to thrive amid shifts in the healthcare environment, audits, and clinical demands.

Identifying and influencing trends and learnings that may impact O&P: We’re investing in research through the O&P Foundation for Research and Education and developing education specific to issues our members are facing that will help them in their businesses. AOPA has committed to donating $1 million over five years, demonstrating our unwavering commitment to help advance innovation, education, and research in the O&P profession.

Enhancing AOPA value, engagement, and community: AOPA is making it easier than ever to engage with benefits through the new AOPA Hub. We are improving our committee structure and increasing opportunities through new offerings at the 2025 National Assembly. We are visiting more members in offices and labs, engaging with the O&P schools so that students can acclimate to our profession; and those who aspire to do so can become rising stars.

Driving collaboration by creating strategic relationships: Our work continues beyond the O&P community. We’re working to build bridges—with allied health organizations, policymakers, regulators, and payors—to strengthen O&P’s collective impact.

Bolstering infrastructure, innovation, and staff engagement: Behind the scenes, we’re improving our systems, launching a new website, fostering staff development, and ensuring AOPA remains a nimble, responsive organization.

Each of these endeavors ties back to AOPA’s vision, “A world where orthotic and prosthetic care transforms lives,” and our core goal: supporting you, your business, and your patients. I’m proud of the progress we’ve made, excited about the momentum we’re building, and looking forward to what the future holds.

I’m especially looking forward to connecting with many of you in person at the 2025 National Assembly in Orlando. It will be a powerful opportunity to learn, collaborate, and celebrate the future of O&P—one that has never looked brighter.

As always, I welcome your feedback, questions, and ideas. Please don’t hesitate to reach out to me directly at any time for any reason at tkuffel@AOPAnet.org

Thank you for being part of the AOPA community.

Very Truly

Teri Kuffel, JD AOPA Executive Director

See through design

instructions and

SEBCM

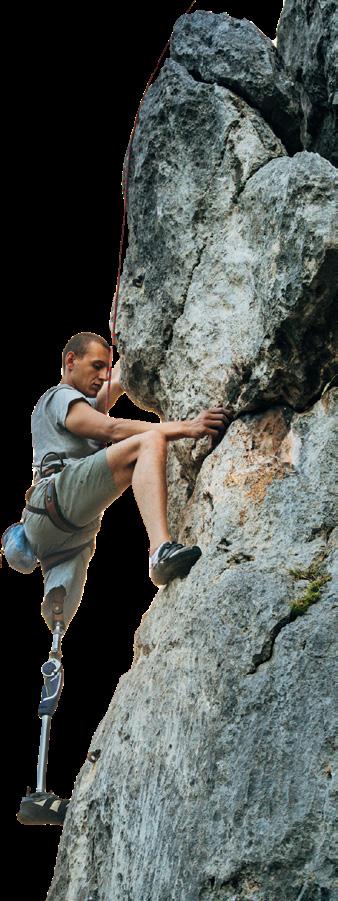

As Paralympic athletes train to compete for gold, AOPA and state advocates are going after the goal of implementing legislation mandating insurance coverage for recreational prosthetic and orthotic care in 28 states by the 2028 Los Angeles Paralympic Games.

So Every BODY Can Move (SEBCM) is a policy and advocacy initiative with the mission to create life-changing access to orthotic and prosthetic care necessary for physical activity for individuals with disabilities. As a founding partner and steering committee member of the movement, AOPA has worked since 2022 to encourage states to adopt laws that would require state-regulated insurance plans to cover prosthetic and orthotic devices necessary for activities of daily living, like bathing, or exercise that would improve an individual’s overall health and maximize limb function. Activities such as running, biking, swimming, strength training, skiing, climbing, or surfing should be deemed medically necessary and covered by insurance as they yield both physical and mental health gains, according to SEBCM ’s model legislation.

This summer, New Jersey became the 12th state to enact its own variation of SEBCM legislation, joining Washington, Oregon, Colorado, New Mexico, Minnesota, Illinois, Arkansas, Georgia, Maine, New Hampshire, and Maryland, all of which have laws on the books. Legislation has been introduced in nine other states and advocates have plans to pursue legislation in 16 more.

“In every state, there are hundreds or thousands of bills that get introduced in any session, with a very small percentage actually getting passed, so, advocacy is generally a long game, and we expect it could take several attempts to get one of our bills passed in any state,” says Maggie Baumer, JD, a state lead and state coach for SEBCM. “However, we have also seen rapid success with this initiative, with 12 states passing the bill in just three years—pretty incredible by any standard!”

Baumer leads enterprise patient advocacy at Hanger in addition to serving as a state coach for SEBCM, guiding the process of passing, implementing, and expanding legislation to broader age groups and patient populations.

State coaches like Baumer help state teams avoid pitfalls like filing bills late in the legislative session, limiting the time they have to gain traction and support. They also help develop financial analyses that show legislators and insurance plans how SEBCM laws can reduce costs.

As activism continues to bring more states on board, a new phase of advocacy has ramped up to assist stakeholders in states with new laws in expediting their implementation. “There is often a lag

in translating requirements of new legislation into the practical,” says Morgan Fabber, MPH, AOPA’s manager of state and federal advocacy and an advisor for SEBCM. “So, the goal is to help them understand how to communicate effectively with legislators and policy makers to help it go into effect faster.”

AOPA has created an arsenal of tools to equip state leads and core teams to usher in change smoothly and efficiently:

An Implementation Guide on the SEBCM website provides practical tips for state leads to help them effectively communicate about the new law with the O&P clinics, patients, and the extended O&P community. Suggestions for creating community engagement opportunities and identifying key patients for testing insurance claims processes, and ideas for collaborating with the state insurance commission, are featured in the guide, along with template communications to make outreach simple.

Monthly implementation meetings are held to assist all states that have passed SEBCM legislation in moving it forward. Implementation sessions provide opportunities to share successes, challenges, and ideas across various states.

New orientation sessions will launch soon to brief states immediately after their bills pass. Orientation sessions will highlight the experiences of states further along in the process, where the focus has shifted to making sure patients have full access to adaptive O&P care.

Two new Frequently Asked Questions (FAQs) resources have been published, one with patient-facing information and one with clinician and billing staff-facing information. The FAQs resources answer a variety of questions received from stakeholders and offer guidance for navigating the reimbursement process and understanding the nuances of SEBCM legislation.

AOPA Director of Health Policy and Advocacy Joe McTernan, a national lead for SEBCM, says the resources merge the experience of state leads and coaches to provide actionable guidance to ease the implementation process.

Once a bill has passed, one of the main implementation hurdles is identifying the insurance plans to which the law applies, typically fully insured plans regulated at the state level, public employee plans, and, in some cases, Medicaid, Baumer says.

“The other barrier to putting the law into practice is simply adoption,” she says. “It takes time for clinicians and administrators to get used to the idea of this coverage and implement the steps to carry it forward.”

With AOPA’s implementation resources, coalitions can plan ahead to create educational materials and programs for practitioners, patients, and the limb loss and limb difference communities, greatly expediting the new law’s effective usage.

Jennifer Davis is a contributing freelance writer for O&P Almanac

On July 17, Sens. Mark Warner and Steve Daines and Reps. Glenn “GT” Thompson, Gus Bilirakis, Debbie Dingell, and Mike Thompson introduced the Medicare Orthotics and Prosthetics Patient-Centered Care Act in the Senate (S 2329) and House of Representatives (HR 4475), respectively. This bipartisan legislation represents a significant step forward in improving access, quality, and oversight in O&P care for Medicare beneficiaries.

“AOPA applauds the introduction of this critical legislation and sincerely thanks Sens. Warner and Daines and Reps. Thompson, Bilirakis, Dingell, and Thompson for their leadership,” said Teri Kuffel, JD, executive director of AOPA. “We look forward to working with Congress to advance this patient-centered bill and ensure individuals living with limb loss, limb difference, and musculoskeletal conditions receive the safe, high-quality care they deserve.”

The Medicare O&P Patient-Centered Care Act includes three essential provisions designed to improve clinical outcomes and reduce unnecessary Medicare spending:

• Prohibits drop shipping of custom orthoses and prostheses directly to beneficiaries, ensuring patients receive appropriate in-person care from certified professionals

• Exempts O&P providers from the competitive bidding program, simplifying care delivery by allowing patients to receive comprehensive services from a single provider

The postmastectomy prosthesis market, estimated at $500 million in 2025, is projected to exhibit a compound annual growth rate of 5% over the next eight years, reaching approximately $750 million by 2033.

SOURCE:

• Allows timely access to replacement custom orthoses when a patient’s clinical condition changes—removing outdated barriers that delay medically necessary care.

An independent analysis by Braid-Forbes Health Research estimates that this legislation will result in $60 million in net savings over the first 10 years of enactment, including $73 million in fraud and abuse prevention with an estimated cost of only $13 million to increase care efficiencies.

“This bill isn’t just about improving care—it’s about protecting patients and the integrity of the Medicare program,” said AOPA President Rick Riley. “Medicare beneficiaries deserve access to personalized, clinically appropriate orthotic and prosthetic services—without risk of fraud, delay, or disruption. This legislation brings us closer to that goal, and we urge Congress to act swiftly.”

In a study of individuals with unilateral lower-extremity amputation, University of Colorado researchers found that participants with bone-anchored prostheses experienced mobility advantages compared to the socket prosthesis users.

The researchers leveraged the new Colorado Limb Donning Timed Up-and-Go (COLD-TUG) test—a measurement tool that combines the time required for donning a prosthesis with the time to complete the Timed-Up-and-Go test—in studying a group of individuals with lower-limb amputation. The COLDTUG test measures time required for a series of activities: donning a prosthesis, getting up from a

chair, walking 3 meters, turning around, walking back to the chair, and sitting down again.

Participants who had undergone osseointegration had a significantly shorter mean COLD-TUG time compared to the socket group. The researchers determined that the COLD-TUG test accurately measures prosthesis donning burden in the context of functional mobility. The study was published in May in the Journal of Bone & Joint Surgery

At Hersco we pride ourselves on being at the leading edge of technology. We have mastered the art of seamlessly accepting scans, designing foot orthotics and 3d printing. We deliver industry leading quality in an eco-friendly manner.

Hersco: simplifying orthotics, one scan at a time.

Participants with above-knee amputation who participated in a clinical study at the Massachusetts Institute of Technology (MIT) found that a newly designed “tissue-integrated” prosthetic knee system offered greater stability and control, according to a new study.

The new bionic knee is directly integrated with the user’s muscle and bone tissue, using an agonist-antagonist myoneural interface surgical approach, wherein muscle pairs are reconnected during surgery so that they can dynamically communicate with each other within the residual limb, combined with osseointegration via the e-OPRA system.

The researchers measured the participants’ ability to perform several tasks, including bending the knee to a specified angle, climbing stairs, and stepping over obstacles. The new system offers the user improved control over the movement of the prosthesis, according to the research team, which included Hugh Herr, PhD, Rickard Branemark, MD, MSc, PhD, and others. Study participants reported feeling that the limb felt more like a part of their own body, compared to people who had more traditional above-knee amputations.

“A prosthesis that’s tissue-integrated—anchored to the bone and directly controlled by the nervous system—is not merely a lifeless, separate device, but rather a system that is carefully integrated into

human physiology, offering a greater level of prosthetic embodiment,” said Herr, co-director of the K. Lisa Yang Center for Bionics at MIT. “It’s not simply a tool that the human employs, but rather an integral part of self.” The study was published in July in Science

Researchers are examining how the study of axolotls can aid in the development of human limb regeneration. Axolotls are a species of salamander that are expert at regeneration. After losing a limb, adult axolotls can grow the limb back fresh and new—and they can also regrow tissue in the heart, lungs, and brain.

A team of Boston researchers studied axolotls that had been genetically engineered to glow in the dark to understand the molecular underpinnings of their ability to regenerate limbs. James Monaghan, MA, from Northeastern University’s Department of Biology, led the investigation, tracing the ability of the axolotl to regenerate to a molecule known as retinoic acid, which is responsible for telling the animal’s cells which body part to grow back.

Monaghan and his team discovered that axolotls have a gradient of retinoic acid signaling. In the arm, for example, this means axolotls have more retinoic acid in their shoulders and less retinoic acid in their hands. The retinoic acid acts as a cue to the regenerative cells, called fibroblasts, telling them what and how much to grow back, according to the researchers.

Understanding the signal for regeneration is a step toward applying these lessons to humans, Monaghan said. Further study “could help with scar-free wound healing but also something even more ambitious, like growing back an entire finger,” Monaghan said. “It’s not out of the realm [of possibility] to think that something larger could grow back like a hand.” The study was published in June in Nature

A majority (63%) of healthcare consumers trust the health information shared on social media by influencers, and 82% are likely to follow health advice given by healthcare influencers.

In a single-center study, one hospital partnered with an independent prosthesis care program to determine whether such a partnership would result in better patient outcomes for individuals who undergo transfemoral and transtibial amputation.

Over a four-year period, the researchers found that 59% of patients who participated in the prosthesis care program received prostheses within 12 months, compared with only 25% among those not in the program. Forty-seven percent of prosthesis care program participants achieved ambulation within a year, compared with 13% of nonparticipants.

“Participating in a prosthesis care program significantly improved rates of prosthesis receipt and ambulation after major amputation in this at-risk population,” reported the researchers. The study was published in June in Journal of Vascular Surgery

BY THE NUMBERS

The So Every BODY Can Move (SEBCM) program, launched in pursuit of creating equitable and life-changing access to O&P care and devices for physical activity, made Forbes’ inaugural “Accessibility 100” list. The list highlights the biggest innovators and impact makers in the field of accessibility for people with disabilities.

SEBCM, which is supported by AOPA, the Amputee Coalition, the American Academy of Orthotists and Prosthetists, and the National Association for the Advancement of Orthotics and Prosthetics, was recognized within the Law & Government category, which honors those working to protect and expand the civil rights of people with disabilities.

“This recognition is a tremendous honor for our collective movement,” said Nicole Ver Kuilen, who leads the program at the Amputee Coalition. “It belongs to all of our dedicated advocates and legislative champions—individuals who show up every day to demand change, collaborate across divides to shape policy, and prove that physical activity is a fundamental right, not a privilege.”

The Limb Loss and Preservation Registry (LLPR) is the first national registry designed to improve care for individuals with limb loss and limb difference. The LLPR collects data on limb preservation, amputation, and nerve surgical hospital procedures from hospitals, providers, and patients.

>466,000 Unique Patients

Tina Culbreth, CHC, CCEP, CHPC, CDME, has been appointed director of compliance by the Board of Certification/Accreditation (BOC). In this leadership role, Culbreth will provide strategic oversight of business activities such as accreditation eligibility reviews, corrective action processes, and surveyor communications. She also will collaborate with internal teams and stakeholders to enhance process efficiency and ensure alignment with CMS requirements and BOC’s rigorous standards. Culbreth brings more than a decade of experience in compliance leadership, most recently serving in compliance roles at Illumina and Ortho Virginia. “Tina brings a combination of strategic insight, operational excellence, and industry-specific compliance knowledge,” said Judi Knott, MA, MBA, CAE, president chief executive officer of BOC. “Her leadership and experience will further our commitment to excellence in accreditation and certification.”

Brian Hafner, PhD, and his team at the University of Washington (UW) Center on Outcomes Research in Rehabilitation, were awarded the Bryan and Joyce Blatchford Team Prize for Innovation at the International Society for Prosthetics and Orthotics World Congress in June. The prize recognizes achievements related to O&P hardware or scientifically based new techniques resulting in improved devices.

Elizabeth Halsne, PhD, MSE, CPO, LPO, has joined the faculty of the UW Prosthetics-Orthotics Division as assistant professor. This is a joint appointment between the Puget Sound VA Center for Limb Loss and Mobility and the UW Department of Rehabilitation Medicine. She also serves as program manager for the Orthotics and Prosthetics Foundation for Education and Research’s Early Career Research Grant Program.

Teri Kuffel, JD, executive director of AOPA, was honored with a Leadership Award from the National Association for the Advancement of Orthotics & Prosthetics (NAAOP) in recognition of her outstanding leadership in the O&P profession and at AOPA. NAAOP Executive Director George Breece presented the award to Kuffel in July.

Ashlie White has joined AOPA as senior director of external affairs, effective Aug. 18. White most recently served as chief strategy and programs officer at the Amputee Coalition. Previously, she served as AOPA's director of health policy and strategic alliances.

In her new role, White will direct federal and state policy initiatives, facilitate research collaborations, and lead AOPA's strategic external alliances.

Embla Medical, parent company of Össur, Fior & Gentz, and College Park, was named to Forbes’ “Accessibility 100” list in the Sports & Recreation category. “We are honored to have received this recognition as a purpose-driven company that is passionately committed to improving the quality of life for people experiencing chronic mobility challenges,” said Sveinn Sölvason, Embla Medical’s president and chief executive officer.

Hanger Clinic has been awarded a national group purchasing agreement for O&P care with Premier Inc. Under this agreement, members of Premier—a technology-driven healthcare improvement company—can access Hanger Clinic’s comprehensive services to support care delivery for patients requiring orthotic and prosthetic interventions, including orthopedic trauma, spinal trauma, stroke rehabilitation, and amputee care.

Hanger Inc. has entered into an agreement to acquire Point Designs, a Colorado-based firm offering upper-limb prostheses, including partial hand prostheses, with expertise in additive manufacturing and mechanical design. “Point Designs is the perfect partner to bring on board as part of our focus on creating the most comprehensive offering of products, services, and care for patients with upper limb loss or difference,” shared Pete Stoy, Hanger’s chief executive officer (CEO). “We are excited about the experience and knowledge the Point Designs team can bring to our ecosystem of upper-limb prosthetic innovation and patient care.”

“We are very excited about the opportunity to join the Hanger family and to expand our ability to positively impact the lives of those with upper-limb loss or limb difference,” said Levin Sliker, PhD, CEO and co-founder of Point Designs. The transaction is expected to close in Q3 of 2025.

Kuffel will lead the organization’s efforts to advance public policy, education, and member engagement

Teri Kuffel, JD, has been appointed by the AOPA Board of Directors to serve as the organization’s executive director.

Kuffel, who served as interim executive director from January through July of this year, received unanimous support from the Board. She has proven her ability to provide strong and passionate leadership that is built on her nearly three decades of experience in the O&P profession.

During her eight years of service on the AOPA Board, including her role as president from 2022 to 2023, she consistently and passionately demonstrated her commitment to AOPA’s vision,

mission, and strategic priorities, always striving to bring more value to its members. She is recognized as an effective legislative advocate and collaborator who has nurtured relationships with the leaderships of O&P associations and businesses, as well as state and national legislators.

“These past six months, Teri has continuously demonstrated her innate ability to engage with sister organizations and AOPA members. Her leadership during this transition has been steady, strategic, and forward-looking,” said Rick Riley, president of AOPA. “Teri is a business leader who has real-world experience in the daily operations of an O&P clinic. I am confident our decision to choose Teri to guide AOPA through its next chapter of growth and impact will be widely supported by O&P providers and suppliers, as well as our sister organizations, including those that comprise the O&P Alliance.”

Kuffel earned her juris doctorate from Mitchell Hamline School of Law in St. Paul, Minnesota. She co-founded and has served as vice president of Arise Orthotics & Prosthetics, a longtime AOPA member in Minnesota. She also has served on the boards of the Minnesota Society of Orthotists, Prosthetists, and Pedorthists as well as Wiggle Your Toes, an amputee nonprofit. Kuffel has led grassroots advocacy initiatives that helped achieve legislative wins benefiting patients and O&P providers in her home state.

For the past 10 years, Kuffel also has dedicated time to educating the next generation of clinicians as a business and legal ethics instructor for the Master of Science in O&P Program at Concordia University in St. Paul.

As executive director, Kuffel will lead AOPA’s efforts in advancing public policy, education, and member engagement—ensuring the association remains the leading voice for the O&P profession across the United States.

“It is my honor and privilege to serve this profession that has given me so much,” said Kuffel. “I am grateful for the trust of the Board and excited to continue working alongside our members, partners, and staff to strengthen the future of O&P.”

The only manufacturer offering a oneband guarantee, providing confidence and reliability.

Our team includes 4 experienced clinical orthotists and prosthetists who have fitted thousands of Starbands.

Access top cranial educational resources and gain CEUs to enhance your clinical expertise.

Orthomerica’s SmartSoc® and Starscanner® deliver fast, reliable, and comprehensive Star Reports®, featuring the StarScale™, multi-plane 3D data visualization, and secure patient data storage.

Navigate insurance and compliance with our support.

Over 600,000+ infants treated with Orthomerica’s cranial solutions worldwide.

Tailored for pediatricians and healthcare professionals to help grow your business.

Orthomerica offers the most FDA-cleared CROs for all types of patient-specific cranial deformities.

For those of us who live and breathe orthotics and prosthetics, the transformative power of our work is undeniable. We see it every day—in the confident stride of a veteran with a new prosthesis, the steady balance of a child with cerebral palsy in a custom orthosis, or the return to independence for a stroke survivor learning to walk again.

These are not small victories. They are life-changing moments made possible through evidence-based practice and innovative care. And yet, despite its profound impact, the orthotic, prosthetic, and pedorthic (OP&P) profession remains drastically underfunded and under-researched compared to other healthcare disciplines.

The Orthotics and Prosthetics Foundation for Education and Research is here to change that.

Founded by the OP&P community, for the OP&P community, the O&P Foundation is the only independent, 501c3 dedicated solely to advancing our field through funding programs in research, education, and professional practice. As we near the close of a historic $1 million matching opportunity from the American Board for Certification in Orthotics, Prosthetics, and Pedorthics (ABC)— which ends Nov. 30, 2025—now is the moment for the OP&P community to come together and invest in our shared vision to improve the quality of orthotic and prosthetic care.

The O&P Foundation’s mission is straightforward: to advance the art and science of orthotic and prosthetic rehabilitation. It does this by enhancing clinical practice through professional training awards, promoting education and training access via academic scholarships, strengthening the knowledge base through research grants, and inspiring excellence through recognition of scholarly achievements.

From its inception, the O&P Foundation has focused on empowering OP&P professionals at every stage—from students just entering the field, to seasoned clinicians managing unbelievable patient loads. “We exist to seed sustainability and progress in the profession,” says Fanny Schultea, MS, MSEd, CPO, LP, FAAOP(D), executive director of the O&P Foundation. “Every scholarship, every grant, every professional training award is an investment in the long-term quality and accessibility of O&P care for our patients.”

The O&P Foundation’s strategic plan for the next three years is built around five guiding priorities:

Engaging Broader and Deeper Networks: Mapping and connecting with every segment of the OP&P field—from academic programs to clinical practices and industry partners

Achieving Financial Sustainability: Maintaining strong program-to-operations ratios and driving efficient fundraising to maximize donor impact

Strategic Partnerships: Launching cross-sector collaborations that increase program reach, attract new funding sources, and elevate the profession as a whole

Demonstrating Impact Through Metrics and Storytelling: Collecting and sharing the outcomes of funded programs to show the real-world impacts of the investments in research, education, and professional practice

Building a Strong Volunteer Pipeline: Ensuring a committed, skilled, and diverse pool of volunteers and future leaders to carry forward the mission of the O&P Foundation.

Every initiative launched under this plan is designed with the future of patient care in mind—and all of the professionals who deliver it. 1 2 3 4 5

Too often, OP&P research funding lags behind other medical fields, limiting the scope and scale of studies needed to demonstrate clinical efficacy and value. The O&P Foundation is directly addressing this gap through its targeted research priorities. These include studies that improve clinical outcomes, enhance patient experience, and reduce healthcare costs—aligned with valuebased care principles and key domains of quality such as safety, equity, effectiveness, and patient-centeredness.

Importantly, the O&P Foundation’s funding structure encourages early-career researchers, clinicians, and innovators to enter the research ecosystem, often launching careers that grow into larger, federally funded projects. O&P Foundation Immediate Past Chair Shane Wurdeman, PhD, CPO, FAAOP(D), says: “The fellowship award was a springboard for my career. It helped me establish a research lab and eventually secure over $30 million in federal grants.”

With populations of the patients we serve projected to grow rapidly, the demand for OP&P care and providers is increasing parallel to the rates of diabetes, vascular disease, and aging. The O&P Foundation is working proactively to support access to clinical education and training by ensuring that funding is not a barrier to a well-trained and motivated workforce ready to meet these growing demands. Through its scholarship programs, professional training, and continuing education funding opportunities, the O&P Foundation has already helped close to 60 future clinicians complete their training and grow into their clinical and professional roles. One of those

clinicians, Janet Trujillo, CPO, says, “Without the O&P Foundation’s scholarship, I wouldn’t have completed my master’s program or participated in global service trips that deepened my commitment to equitable care.”

Similarly, Denise Hull, CPO, says, “The funding allowed me to attend conferences, explore career pathways, and accelerate my professional growth.”

The opportunity to shape the future of the profession has never been greater. Thanks to ABC’s $1 million matching challenge, every dollar donated to the O&P Foundation through Nov. 30, 2025, will be matched—doubling its impact.

Whether you’re an individual clinician, a practice owner, a manufacturer, or a researcher, you have a role to play. Your contribution will fund research that drives better outcomes, education that supports tomorrow’s workforce, and programs that advance quality and equity in patient care.

The Orthotics and Prosthetics Foundation for Education and Research isn’t just another nonprofit. It is the backbone of our collective future—built by and for the OP&P community. It exists so that every patient receives the highest quality care, and every professional is empowered to provide it.

As we count down to the close of the ABC match challenge, there’s never been a more urgent time to give and support. Together, we can create a more sustainable future, one of growth, for the O&P profession and the care we provide. Let’s move it forward—together.

Consider taking one or more of the following actions to support the O&P Foundation.

Donate: Make a one-time or recurring gift. Every dollar donated will be matched through Nov. 30, 2025.

Sponsor: Fund an existing or new scholarship, training award, or research grant aligned with shared values.

Partner: Join our industry consortium to build the evidence base and support infrastructure needed for sustainable, high-quality OP&P care.

Advocate: Share our mission and impact stories with your networks to elevate awareness and support us across the OP&P field and beyond.

Volunteer: Come share your energy, time, and talent—join the O&P Foundation as a volunteer and help drive our mission as a committee chair, committee member, reviewer, ambassador, or board member.

Connect With Us: Stay connected with O&P Foundation news and updates by signing up for our mailing list, or reach out directly to Fanny Schultea at executivedirector @oandpfoundation. org

BY JOE MCTERNAN

Change is inevitable. Whether we like it or not, whether it is comfortable or challenging, everything changes. When I look back at my 30 years in the O&P profession, the amount of change I have seen is almost incomprehensible. From changes to functional level classifications, to the advent of programs like competitive bidding and prior authorization, to regular updates to O&P coverage policies, changes have impacted the overall landscape of O&P care. Often, the difference between operational success and failure is a direct result of a company’s ability to understand change and react to it accordingly.

The year 2025 has seen a significant number of Medicare program changes that will have a direct impact on O&P care and the patients you serve. This month’s Reimbursement Page examines some of the more significant recent and proposed changes and discusses how they may impact your O&P business. Understanding these changes will help you adjust to them in a way that positively impacts your business.

On April 28, 2025, CMS announced that Cotiviti Government Services had been awarded the contract to serve as the

Region 5 Recovery Audit Contractor (RAC), responsible for all RAC audits for claims for durable medical equipment, prosthetics, orthotics, and supplies (DMEPOS) nationwide. Cotiviti replaces Performant Recovery, which will remain an administrative subcontractor to Cotiviti but will no longer be the main point of contact for RAC audits. While an official transition date from Performant to Cotiviti has not yet been released, Cotiviti is expected to begin performing active DMEPOS RAC audits soon. Cotiviti currently serves as the RAC contractor for several other Medicare product categories so it is already familiar with RAC operations. In addition, the DMEPOS

RAC contractor prior to Performant Recovery was Connolly Healthcare, a company that was later acquired by Cotiviti. This should help facilitate a fairly seamless RAC transition from Performant to Cotiviti.

Cotiviti has not yet activated its RAC resources for Region 5 DMEPOS services, but these resources will eventually be added to its website at cotiviti.com/markets/ cms-rac

AOPA will closely monitor O&P RAC activity as Cotiviti begins its work and will work with the entity to ensure that O&P providers are treated fairly and that any issues are addressed quickly and efficiently.

CMS on June 30 released its 2026 Home Health Prospective Payment System Proposed Rule, which annually includes proposed changes that CMS intends to

implement in the DMEPOS space. This year’s proposed rule contains several proposals that will significantly impact O&P operations, including changes to DMEPOS competitive bidding, facility accreditation requirements, provider enrollment processes, and Medicare prior authorization.

The proposed rule would increase the frequency of Medicare DMEPOS facility accreditation renewal form the current three-year cycle to an annual requirement. The stated purpose of this proposal is to improve efforts to combat Medicare fraud and abuse in the DMEPOS space. The proposed rule would require CMS-approved accreditation organizations (AOs) to re-accredit Medicare DMEPOS suppliers annually. While AOPA and its O&P Alliance partners fully support efforts to eliminate fraud and abuse in the Medicare program,

an annual re-accreditation requirement will result in exponentially higher administrative costs to both AOs and the providers they accredit and also will result in significantly more time that will have to be dedicated to performing accreditation review and preparing for the re-accreditation process. This may prove challenging to both AOs and accredited facilities alike.

The proposed rule also includes requirements for more frequent unannounced provider enrollment audits performed by CMS and its contractors. While this is also intended to reduce Medicare fraud and abuse, the current provider enrollment audit process is already facing significant process challenges. Simply increasing the number and frequency of enrollment audits will likely highlight and increase these challenges rather than improve them.

MT. EMEYS 9705

SIZE: 7, 7.5 - 11.5, 12-17

WIDTH: D, 4E, 6E, 9E

BREATHABILITY

Another section of the proposed rule addresses the expected return of DMEPOS competitive bidding. The original round of Medicare competitive bidding that initially impacted O&P involved 23 off-theshelf (OTS) orthosis codes and ended in December 2023. The proposed rule indicates that CMS intends to announce a new round of competitive bidding in the near future. While it is unlikely that CMS will include codes from the last competitive bidding round in future rounds, as it is unlikely that additional savings will be achieved, the remaining 22 OTS Healthcare Common Procedure Coding System (HCPCS) codes that were eligible for competitive bidding but not selected for previous inclusion are likely to be included.

AOPA has long advocated for expansion of the competitive bidding exemption currently in place for physicians and therapists to include certified and licensed orthotists and prosthetists. This would allow for O&P practitioners to provide OTS orthoses to their patient population without requiring a DMEPOS competitive bidding process. This is in the interest of holistic patient care and is one of the three main provisions of the recently reintroduced Medicare O&P Patient-Centered

Care Act in both the House of Representatives and Senate (see page 10). AOPA will continue to advocate for this legislation while also communicating why DMEPOS competitive bidding should not be expanded to additional O&P HCPCS codes.

The proposed rule also includes a pathway for providers that achieve high success rates on claims subject to Medicare prior authorization to be exempt from further prior authorization for a predetermined time. While this seems to be a positive proposal, Medicare prior authorization has been an extremely successful program, and if it continues to operate in a fair and efficient manner, providers may want to consider continuing to file for prior authorization even if an exemption is available.

AOPA will work with its O&P Alliance partners to develop and communicate relevant comments to the proposed rule in advance of the Aug. 29 deadline.

An example of a positive change for the O&P profession and its patients in 2025 involves the recently published proposed Local Coverage of Determination (LCD)

and affiliated draft Policy Article for Knee Orthoses. This was published by the durable medical equipment Medicare administrative contractors (DME MACs) July 24, and would expand Medicare coverage for certain custom-fitted and custom-fabricated knee orthoses used to treat osteoarthritis without requiring documentation of a recent injury to or surgery on the knee or objective documentation of ligamentous joint laxity.

This is a policy challenge that has existed for many years. In August 2023, AOPA and its Coding & Reimbursement Committee submitted a formal LCD reconsideration request to the DME MACs asking that they revise their policy to include coverage for osteoarthritis braces to manage pain and improve ambulation.

The proposed LCD released July 24 expands this coverage and incorporates much of the policy language suggested by AOPA; it appears to be very beneficial to Medicare beneficiaries seeking orthotic intervention to manage osteoarthritis.

CMS will hold a public hearing on the proposed LCD Aug. 27. AOPA will attend the hearing and provide relevant comments. The proposed LCD and draft Policy Article may be accessed on the CMS website.

Because this entire column was built around discussing change, I can’t think of a better way to end it than with a word of congratulations and welcome to Teri Kuffel, JD, AOPA’s new full-time executive director.

Kuffel has been a long-time member of the AOPA Board of Directors and served as president in 2022-2023, and she brings her lifetime of experience to the executive leadership role at AOPA. This is a new challenge, and we look forward to her tenure and leadership as she takes over the role of executive director. Welcome, Teri!

Joe McTernan is director of health policy and advocacy at AOPA. Reach him at jmcternan@AOPAnet.org

Coapt’s new HCPCS Level II code means more access to modern pattern recognition myo control for upper limb prosthesis users L6700

Prosthetic devices are only as good as how they are controlled. Coapt’s convenient and highly compatible system applies the remarkable power of myoelectric pattern recognition – adding personalized, modern control – to arm and hand prostheses. Scan and connect with us to find out more. www.coaptengineering.com

BY JOSEPHINE ROSSI

3D printing and digital workflows are transforming O&P—and the practitioners who use them

It’s Tuesday in a college dorm room where a student texts a photo of her broken orthosis to her orthotist six hours away. Within hours, a 3D printer is creating her replacement brace based on a digital file; it arrives by Friday without significant disruption to her schedule. This scenario, now routine for some practitioners, illustrates how additive manufacturing is transforming a hands-on field.

For the uninitiated, the 3D printing (also called additive manufacturing) workflow involves scanning a patient’s limb to create a digital model, customizing the design using specialized software, and then printing the device layer-by-layer before final finishing and delivery to the patient. What was once associated with oversized, clunky, expensive machines making toys and knickknacks has now become an efficient, commercially viable manufacturing technique used across many industries, including the fabrication of prostheses, orthoses, and their components.

Through conversations with practitioners, educators, and manufacturers, a picture emerges of a profession facing both unprecedented opportunities and fundamental challenges.

Brent Wright, CP, BOCO, vice president of EastPoint Prosthetics and Orthotics, who has been working in O&P since he was 16, says he initially dismissed digital methods. The turning point came in 2014 after an

f 3D printing has evolved from creating novelty items to efficient manufacturing for prostheses and orthotics, with some practitioners converting nearly all work to digital methods.

f Implementation varies by application and economics— complex, high-value devices like adjustable sockets benefit most, while simpler applications face reimbursement barriers.

intensive clinic in Guatemala where a large patient load left his hands “just shot” from physical demands. A colleague encouraged him to try digital work.

“That moved the needle for me to start looking as this is an alternative for clinicians to the high labor intensity work,” he says. “If you're not even looking at this technology, you are doing your patients a disservice.”

Today, nearly all of Wright’s prosthetic work involves 3D printing, though the economic realities vary significantly by application. Digital works well for complex, high-value devices requiring extensive technical work, such as adjustable sockets, upperextremity sockets, or ankle-foot orthoses (AFOs) that use struts. Simpler applications face barriers: “For what you get reimbursed, it's not worth doing,” explains Wright, who also is co-founder of Advanced 3D, which offers additive manufacturing, digitization, and reverse engineering services.

This selective implementation pattern appears across different practice settings. At Gillette Children’s Specialty Healthcare, Corey Baum CO, LO, and John Sytniak, CPO, describe a hybrid approach developed over more than a decade. Their facility uses in-house 3D printing for specialty wheelchair seating components while outsourcing printing of other applications. “One hundred percent of our cranial remolding helmets, 20% of our FOs [foot orthoses], SMOs [supramalleolar orthoses], and AFOs are 3D printed.”

f Digital workflows enable quantified, evidence-based practice by providing concrete data points that help clinicians track patient changes and reduce material waste, fitting times, and physical storage needs.

f Future materials will combine flexibility and rigidity in specific zones, with advances in multimaterial printing and "tunable" properties, while AI serves as a design tool rather than replacement for clinical judgment.

f Related emerging technologies include embedded monitoring sensors in devices, virtual reality modifications, and open-source manufacturing platforms, though practitioners emphasize patient safety must remain paramount.

The productivity gains extend beyond simple metrics. “I’m able to get my work done during normal business hours,” says Wright. He contrasts this with previous traditional workflows requiring early morning lab work, full patient schedules, and evening nursing home visits extending to 10 p.m.

“Digital workflow and fabrication have cut down on material waste with less plaster and plastic waste compared to traditional fabrication,” say Baum and Sytniak, while offering “the ability to do a wider range of modifications, create modifications macros, leading to greater consistency in modifications.”

Yet implementation isn’t necessarily easy.

One challenge is the learning curve, according to Chad Duncan, CPO, LPO, PhD, CRC, professor and program director of O&P, Salus at Drexel University. Students with backgrounds in “industrial arts, biomedical engineering” or who “tinker” with programs and printers adapt more easily, while those from backgrounds such as psychology or kinesiology, and who haven't been exposed to it, face steeper challenges navigating different software systems. Proficiency isn’t achieved until residency, he says.

“If you're not even looking at this technology, you are doing your patients a disservice.”

—BRENT WRIGHT, CPO, BOCO

As Wright notes, the reimbursement landscape adds another layer of complexity. For orthoses, the challenge is less complex since they don't require endoskeletal/exoskeletal classification, and CMS guidance from February 2024 confirmed that 3D-printed orthoses can use existing custom-fabricated codes if they comply with DMEPOS Quality Standards. However, prostheses will likely require new codes supported by data and research, and both applications face challenges with quality standards that were written 20 years ago before digital models and additive manufacturing existed.

Extensive validation also is required for commercial products, according to Herb Barrack, CPO, co-founder and chief clinical officer of Limber Prosthetics. His company’s development of “the world's first, monolithic, single-printed transtibial adjustable prosthesis” required four years to achieve FDA registration, quality management system implementation, and ISO 10328 standards compliance. “Regulatory is very costly but is a large piece to the puzzle when it comes to safely integrating [additive manufacturing] into your practice,” Barrack notes. “Products must be designed with a particular geometry and load tested in order to keep patient safe and functional while using their prosthesis.”

Beyond manufacturing methods changes, clinical thinking and educational approaches also are progressing. Duncan describes a shift from traditional procedural learning to analytical thinking;

educators want students to understand there is more than one way to address a patient’s needs. “I think that’s the [purpose of] education—[for students] to become more or better problem solvers and process-oriented versus, traditionally, we knew these steps, and we followed these steps.”

“Digital workflow and fabrication have cut down on material waste with less plaster and plastic waste compared to traditional fabrication,” while offering “the ability to do a wider range of modifications, create modifications macros, leading to greater consistency in modifications.”

Perhaps more significantly, digital workflows enable quantified evidence-based practice. Scanning, for example, provides concrete data points helping students better understand pathologies such as diabetes. “If somebody’s having dialysis, the limb changes, and they can actually see that via numbers,” Duncan says. “It could be a very small change, but those small changes do make a difference," he says.

Baum and Sytniak say that digital workflows have cut back on the time they need for fittings and the amount of physical space needed with plaster models. Similarly, Wright explains that when a patient’s traditional carbon-fiber socket breaks, the replacement process requires physical measurements, casting, and fabrication. In contrast, when a digitally designed socket needs to be replaced, “a patient does not have to come in, as long as everything was working before. And we’re able to take those digital files, make adjustments, and reprint and get them in.”

Despite historically limited research focusing specifically on O&P, materials science is advancing. “Specific material properties for O&P are materials that can be flexible in areas where we need movement in the orthosis and rigid in areas that we need support and stability,” say Baum and Sytniak. They also note advancing capabilities: “Materials for 3D printing and printers are advancing daily with capability to print with multiple materials in the same device.”

“We need materials that combine high energy return for optimal patient mobility with the ability to be thermomolded for precise customization—while also being environmentally responsible,” explains Barrack. “Advances in ultralight, high-strength polymers specifically engineered for compatibility with 3D printing will be

For 30 years, The Bremer Group Company has established a reputation for supporting practitioners and patients with quality back braces, and exceptional customer service. The VertAlign® Spinal Support System embraces these 7 Cs.

For more information visit www.bremergroup.com.

game-changing.” These materials must “remain dimensionally stable yet responsive to controlled heating, enabling practitioners to fine-tune fit and function without compromising durability or performance.”

The concept of “tuning” materials through design offers particular promise for future applications. Wright envisions materials that can be precisely calibrated through digital design—adjusted in thickness, flexibility, and structural elements to meet specific patient requirements. He and Duncan both highlight the need for population-specific material development and testing protocols.

Tuning materials through design may eventually help the profession implement controlled failure into devices. Wright advocates engineering devices that “fail safely” rather than catastrophically: He recalls one patient's car accident experience where the absence of his prosthetic leg likely saved his life—doctors said, “You weren’t wearing your prosthesis, were you? Because if you were, you wouldn't be with us right now. It would have split you in half.”

“We have always [said] we don’t want [devices] to fail, we don't want it to break, and I don’t think that’s necessarily the right way to start to look at it,” Wright explains, drawing parallels to automotive crumple zones and modern helmet design. “There’s a chance I won't ever see that in my lifetime, and I’m okay with that, as long as we start the discussion.”

The integration of artificial intelligence (AI) into design and manufacturing represents both potential and limitations. In the case of a socket, the challenge of “fitting a living, breathing, changing body” begins with variables unknown to any algorithm and extends through daily variations in human anatomy and activity. “There’s so much that gets involved with the creation of a socket, and it starts with the surgeon,” Wright explains. “Did they actually do a good job with the surgery? And we don’t know. And so this is where AI starts to fail”—and why human intelligence will always be needed.

AI could also “make us lazy,” warns Duncan. He views AI pragmatically as “just a tool” that is “not always correct.” As AI becomes more prevalent in clinical practice, he expresses concern about technological dependence and knowledge retention, citing research showing that students using AI for writing had significantly lower retention levels compared to those using traditional writing processes.

On the other hand, Wright raises an intriguing possibility about AI’s creative potential in exploratory design. “What if there was some AI hallucination, and it created a shape and it actually works? Because if you go from clinician to clinician to clinician, you have really happy patients with [very] different styles of sockets.”

Beyond materials and AI, emerging technologies promise to expand the boundaries of what O&P devices can accomplish. Baum and Sytniak describe current capabilities for embedded monitoring within 3D-printed devices: “Channels can be printed into devices to track gait, temperature, [and] pressure or monitor wear time for outcome studies.” This integration of sensing technology directly

into devices enables real-time data collection that could revolutionize both clinical care and research.

Duncan envisions even more immersive technologies, including holograms and “virtual reality (VR) modifications” where practitioners use VR headsets to modify devices in three-dimensional space.

Wright identifies broader industry trends toward technological openness that could accelerate innovation. He points to automotive manufacturers’ movement toward “open materials” platforms allowing custom material specifications rather than closed systems. “There is a trend toward intellectual property, individual ... machines that are ‘open source’ that will run these things, and away from this black box idea.” This democratization of manufacturing capability could enable widespread experimentation and rapid innovation cycles.

“Advances in ultralight, high-strength polymers specifically engineered for compatibility with 3D printing will be game-changing.”

HERB BARRACK, CPO

He also cites SpaceX’s rocket engine development as a model for simplifying complex assemblies through 3D printing: “You go from needing to source literally thousands of components to sourcing maybe tens of components … the output is still what you want, but your whole vertical now is more simplified.”

Practical implementation of 3D printing and related emerging technologies requires balancing innovation with safety and proven effectiveness. Technological capability doesn’t automatically translate to clinical superiority in all applications. “The most critical thing is to never forget that patient safety is most important,” Barrack stresses. “Not everyone can 3D print a device that is safe and functional for patients.”

Indeed, Gillette Children’s will continue with selective adoption “where it makes sense to the benefit of the patient’s outcomes,” but Wright sees particular urgency for independent practices facing competitive pressure: “If you’re an independent practice, it’s game on, and move as fast as you can because the big guys are coming, and they will catch up to you.”

Duncan also has heard the call for rapid adoption, particularly at industry conferences. He believes that while traditional and digital methods will co-exist in the future, clinical practices should be at least learning about integrating 3D printing and AI. “There are still no dumb questions in this arena. There are people way ahead, but at the same time, you can catch up.”

Josephine Rossi is editor of O&P Almanac. She couldn’t resist letting AI contribute to this article, too! Reach her a jrossi@contentcommunicators.com

Expand your network, learn the latest in O&P research and clinical care, and view cutting-edge products and services at AOPA's 2025 National Assembly

Assembly Sponsors………32

Meet the exhibitors that have signed on as title sponsors for AOPA's 2025 National Assembly

Exhibitor Directory………36

Access a complete, alphabetical listing of the exhibitors and their booth numbers

Get ready to catch some rays and shine a light on the latest advances in O&P care when AOPA's 2025 National Assembly convenes in the Sunshine State. Join AOPA Sept. 3-6 in warm and welcoming Orlando, Florida, to learn about the newest innovations in orthotics and prosthetics from the most brilliant researchers and skilled practitioners in the field.

Throughout the event, pop in to the “Ask Me Anything” sessions across from the AOPA Hub #1611 to learn directly from content experts addressing everything from new product development to insurance negotiations in a dynamic, 30-minute “office hours” experience. And enjoy more hands-on programming than ever before with our on-site lab sessions featuring technical and pedorthic demonstrations.

Cap off an exciting first day of sun-drenched programming with the Rolling out the Boardwalk: Welcome to Orlando reception from 5:30 to 7:30 p.m. in West Hall E. Enjoy boardwalk bites, carnival games, and entertainment while you browse the largest O&P exhibit hall in the U.S. and make valuable connections with O&P professionals from around the world.

Savor wine and cheese while perusing the latest research at the Poster Showcase from 5:30 to 6:30 p.m. Sept. 4, or register now to reserve your spot to network for a cause at one of two special receptions that evening. Mingle over a drink and hors d’oeuvres at the research mixer benefiting the O&P Foundation or the So Every BODY Can Move reception, and a portion of your ticket price will benefit those organizations.

Attend the Thranhardt Award Lecture Series at 8 a.m. Sept. 5 to hear the two winners present their best-in-show research. Get inspired and make connections that afternoon at the 10th annual Women in O&P Luncheon from 12 to 1:30 p.m. (Register now for this sell-out event!)

Wrap up the final day of programming with our popular Digital Showcase, which affords unique opportunities to learn about 3D design software tools from exhibitors who will present their prosthetic, orthotic, or pedorthic patient case files and fabricated molds, devices, or 3D prints.

Keep this guide handy as you navigate three sunlit days of research, education, and networking. Remember to follow AOPA’s social channels and share your National Assembly experience with #AOPA2025. See you soon in Orlando!

Wednesday, Sept. 3 | 5:30 - 7:30 p.m.

Rolling Out the Boardwalk: Welcome to Orlando Reception

Thursday, Sept. 4 | 5:30 - 6:30 p.m.

Research Mixer Supporting Poster O&P Foundation Showcase

Thursday, Sept. 4 | 6:30 - 9 p.m.

So Every BODY Can Move Activation Celebration

Wednesday, Sept. 3 5:30 - 7:30 p.m. (Welcome Reception)

Thursday, Sept. 4

9 a.m. - 6:30 p.m.

Friday, Sept. 5

9 a.m. - 4 p.m.

Thursday, Sept. 4 and Friday, Sept. 5 Noon – 2 p.m.

New Product Showcase

Explore the newest O&P innovations in the exhibit hall, then vote for your favorite to help crown this year’s Best in Show!

in the Exhibit Hall*

*For those with lunch tickets/special badges. NEW THIS YEAR

CAN’T MAKE IT TO ORLANDO

That’s OK—if you miss a session you wanted to attend, or if you cannot travel to Orlando for AOPA's 2025 National Assembly, AOPA will bring the education to you—virtually— starting Sept. 25 and ending Nov. 25. Learn on your own

Meet the sponsors of this year’s AOPA National Assembly, and learn about their latest products and services

Booth: 1203

Alps South

Booth: 1003

Area of Specialty: Prosthetic liners & sleeves

St. Petersburg, Florida easyliner.com

ALPS South is excited to connect with clinicians, innovators, and partners at this year’s AOPA National Assembly. Visit our booth to explore the UltraSeal Liner with OptiGel technology, our black reinforced Flex Sleeve, and other high-performance solutions tailored to meet diverse clinical needs. We’ll also highlight our versatile liner portfolio , featuring multiple fabric, gel, and suspension combinations. We look forward to meaningful conversations and opportunities for collaboration that will help us continue improving comfort, mobility, and outcomes for amputees everywhere. Stop by our booth to see what’s new and what’s next!

Area of Specialty: Lower & upper limb prosthetics, bracing & supports, neuro-orthotics Irvine, California ossur.com/en-us

Össur focuses its efforts and expertise on helping people to be confident, safe and mobile, regardless of injuries or conditions that could compromise their quality of life. Visit our booth, 1203, at this year’s conference. Our team looks forward to connecting with all of the clinician-customer attendees, business owners, and the extended health care provider network associated with prosthetic and orthotic patients.

Össur Americas is pleased to share the combined solutions and product offerings from our upper and lower limb Prosthetic, Bracing & Solutions and recently acquired Fior & Gentz (Neuro. Orthotic) business areas. We will be showcasing the newly launched, fully waterproof multiprocessor knee solution - Navii® in our booth along with other key product categories.

A one-of-a-kind seal-in solution.

It’s the only seal-in liner available in gel.

OptiGel has a smooth, soft texture that ensures gentle skin contact and a tailored fit around the residual limb.

*Also available in silicone

It’s made with less constrictive fabric.

Outer knitted fabric combines strength, durability, and differentiated stretch for comfortable elasticity.

It’s available in both locking and cushion.

The locking feature ensures users are provided with a suspension that is secure, firm, and comfortable.

It’s available in 3 ring heights.

American Board for Certification in Prosthetics, Orthotics, and Pedorthics Booth: 1132

Area of Specialty: Credentialing Board Alexandria, Virginia abcop.org

The ABC team looks forward to connecting with current and prospective credential holders and business owners at this year’s National Assembly. We are also thrilled to be helping with a career awareness event for local high school students interested in healthcare careers. Stop by our booth for the latest information about our programs, where we will be highlighting the WhatIsPOP career awareness initiative designed to educate and inspire the next generation of prosthetists, orthotists, and pedorthists. Visit us to learn about the benefits of care extenders, specifically through our assistant certifications, and ask all your questions about ABC credentialing.

BionicM Inc.

Booth: 1632

Area of Specialty: Powered prosthetic knee Ashburn, Virginia & Tokyo, Japan bionicm.com/en

BionicM looks forward meeting with CPOs in booth 1632 at the National Assembly. Come visit with us to discuss the benefits of our powered MPK Bio Leg.

Booth: 1228

Area of Specialty: DMEPOS facility accreditation and credential certification or DMEPOS professionals Owings Mills, Maryland bocusa.org

We look forward to welcoming you at Booth 1228, where you will meet senior Board of Certification/Accreditation (BOC) leaders to learn more about our O&P facility accreditation as well as orthotic and mastectomy fitter certifications. BOC has provided accreditation and certification credentials to professionals and facilities across the country for more than 40 years. We invite BOC-credentialed practitioners to stop by to pick up their certification and accreditation badge ribbons as well as our commemorative anniversary pin. All attendees can also add to their CEU count by attending educational sessions and visiting our booth to help complete your Exhibits Passbook. We will see you soon!

Cailor Fleming now World Insurance

Booth: 1125

Area of Specialty: Professional liability/malpractice and all business insurance Youngstown, Ohio cailorfleming.com

Spinal Technology LLC by Eqwal

Booth: 1501

Area of Specialty: Design and custom fabrication of spinal orthoses West Yarmouth, Massachusetts spinaltechnology.com

Spinal Technology is proud to once again sponsor AOPA’s National Assembly and be exhibiting many custom spinal and scoliosis orthosis samples in Booth 1501, including the Providence Nocturnal Scoliosis® Orthosis. New for 2025, we now fabricate lower-limb prostheses and offer technical guidance to prosthetists.

Spinal Technology is most excited for the Best-in-Show Contest this year and hopes everyone will have a chance to come see our new stWear™ Compliance Monitoring System.

Booth: 1707

Area of Specialty: O&P news and information Alexandria, Virginia aopanet.org/publications/opalmanac-magazine/

AOPA and O&P Almanac staff look forward to connecting with Assembly attendees and learning what’s top of mind for O&P professionals. The O&P Almanac booth will feature current and past issues of AOPA’s O&P Almanac magazine. Stop by to pick up a copy and learn about earning continuing education credits by reading.

Balance & Symmetry not just bringing the gait back, but bringing the balance back

Safe and Controlled Power brings comfortability and security

Intuitive and Natural Movement brings confidence and higher quality of life

Sunny Xiaojun Sun Founder & CEO

On the following pages is a look at the companies exhibiting at the AOPA's 2025 National Assembly. You’ll find company names, booth numbers, and website information for each exhibitor. Use this guide to get to know this year’s exhibitors and plan your visit to the exhibit hall. Visit aopaassembly.org for full exhibitor details.

n = New Exhibitor for 2025 Bold = Member of AOPA Exhibitors as of Aug. 1, 2025

n A Custom Fit iNMotion LLC Booth: 719 acustomfitinmotion.com

Aether Biomedical Booth: 819 aetherbiomedical.com

Allard USA Booth: 1337 allardusa.com

AllClaim by Ottobock Booth: 1607 shop.ottobock.us

Alps South LLC Booth: 1003 easyliner.com

Alt-Bionics Inc. Booth: 807 altbionics.com

Alternative Prosthetic Services Inc. Booth: 1036 alternativeprosthetics.com

American Academy of Orthotists and Prosthetists Booth: 1338 oandp.org

GOLD SPONSOR

American Board for Certification in Orthotics, Prosthetics, & Pedorthics Booth: 1132 abcop.org

American Central Fabrication Booth: 720 certifiedlimbandbrace.com

American Orthotic & Prosthetic Association (AOPA) Booth: 1611 aopanet.org

American Prosthetic Components Booth: 1430 americanprostheticcomponents.com

n AmerX Health Care Booth: 718 amerxhc.com

n AMPRIA Booth: 1342 ampria.net

Amputee Coalition Booth: 928 amputee-coalition.org

n Anatomic Studios Booth: 714 anatomic-studios.com

Anclote Manufacturing Co. Booth: 809 anclote.net

Anodyne Booth: 1033 anodyneshoes.com

Apis Footwear Company Booth: 906 emeys.com

ARTech Laboratory, Inc. Booth: 701 artechlab-prosthetics.com

Aspen Medical Products Booth: 812 aspenmp.com

n Aurushi Inc. Booth: 1241 aurushi.com

BASINGLEAD Booth: 937 basingtech.com

Becker Orthopedic Appliance Company Booth: 1122 beckerorthopedic.com

BILLY Footwear Booth: 1513 billyfootwear.com

Bionic Power Inc. Booth: 843 bionic-power.com

Bowman Medical International Booth: 1344 bowmanmedicalinternational.com

BionicM Inc. Booth: 1632 bionicm.com/en

Bionic Prosthetics and Orthotics Group Booth: 712 bionicpo.com

BionIT Labs Inc. Booth: 941 bionitlabs.com/us

BioSculptor Corporation Booth: 1614 biosculptor.com

Blatchford Booth: 1010 blatchfordus.com

GOLD SPONSOR

Board of Certification/Accreditation (BOC) Booth: 1228 bocusa.org

BrainRobotics Booth: 804 brainrobotics.com

Breastcare Education Kiosk Booth: 1301 trulife.com

Bulldog Tools, Inc. Booth: 911 BulldogTools.com

GOLD SPONSOR

Cailor Fleming Insurance now World Insurance Booth: 1125 cailorfleming.com/specialty/orthotics-prosthetics-insurance

Cascade Orthopedic Supply, LP Booth: 1319 cascade-usa.com

CBS Medical Billing & Consulting LLC Booth: 1329 cbsmedicalbilling.com

n Certified Orthopedics Inc. Booth: 825 certifiedortho.com

Coapt LLC Booth: 910 coaptengineering.com

College Park Industries Booth: 1103 college-park.com

Comb O&P Booth: 1230 combscan.com

Comfort Products, Inc. Booth: 915 comfortoandp.com

Coretech Orthopedics Booth: 704 coretechortho.com

Cornerstone/Proclaim Billing Services Booth: 1042 Proclaimbillingservice.com

Coyote Booth: 1237 coyote.us

CPO Labs/insoles.ai Booth: 943 insoles.ai

n Crary Shoes Booth: 1340 craryshoes.com

Curbell Plastics Inc. Booth: 1533 curbellplastics.com/materials/industries/ orthotics-and-prosthetics

Cypress Adaptive LLC Booth: 1531 cypressadaptive.com

Danmar Products, Inc. Booth: 1620 danmarproducts.com

DAW Industries Inc. Booth: 1225 daw-usa.com

Dr. Comfort Booth: 805 drcomfort.com

n Drd Kids Footwear Booth: 710 drdfootwear.com

Drew Shoe Corp. Booth: 1619 drewshoe.com

Elevate Movement Booth: 1043 elevatemovement.com

EQWAL Booth: 1501 eqwalgroup.com

Ethnocare Booth: 811 ethnocare.ca

FabCo Prosthetic Designs Booth: 1530 fabcoprostheticdesigns.com

Fillauer Companies Booth: 1109 fillauer.com

n Finger Prosthetics by Paralid Booth: 829 fingerprosthetic.com

FIOR & GENTZ GmbH Booth: 1203

FLO-TECH O&P Systems Inc. Booth: 1706 1800FLO-TECH.com

n Fred’s Legs Booth: 820 fredslegs.com

Friddle’s Orthopedic Appliances Inc. Booth: 1343 friddles.com

Grace Prosthetic Fabrication Inc. Booth: 1014 gpfinc.com

Hanger Clinic Booth: 1029 hangerclinic.com

HiTek Fabrication Booth: 1525 hitekfab.com

HP 3D Printing Booth: 1231 hp.com/us-en/printers/3d-printers.html

IBT Booth: 700 i-biomed.com

Icarus Medical Booth: 1144 icarusmedical.com

Integrum Inc. Booth: 931 integrum.se

Invent Medical USA Booth: 1425 inventmedical.com

Three Decades of Successful Development of Off-The-Shelf to Custom-Fitted to Custom Fabricated and Guidelines to Reduce AFO Insurance Claim Denials

Dynamic Contracture Management in Pediatric Gait: Increasing ROM with LLPS and Multi Motion for Optimal SWASH & AFO Outcomes

n Kanapo Prosthetics and Orthotics Ltd. Booth: 926 kanapo.ca

Kinetic Research Booth: 925 kineticresearch.com

KISS Technologies LLC Booth: 1428 kiss-suspension.com

LaunchPad O&P Booth: 1623 launchpad-op.com

n LEO G. STEIN Booth: 1621 leogstein.com

Levitate Sport Booth: 723 letslevitate.com

Life-Like Laboratory Booth: 1227 lifelikelab.com

Limb Loss and Preservation Registry Booth: 1142 llpr.org

n Limber Prosthetics Inc. Booth: 841 limberprosthetics.com

Lindhe Xtend Inc. Booth: 1325 lindhextend.com

n macu4 AG Booth: 806 macu4.com

Martin Bionics Booth: 800 martinbionics.com

Materialise Booth: 1630 materialisemotion.com

medi USA Booth: 1031 mediusa.com

n Metacarpal Booth: 845 metacarpalprosthetics.com

Mile High Orthotics Lab Booth: 1044 mholabs.com

Mosaic Mfg. 3D Printing Booth: 1243 mosaicmfg.com

MOZN Solutions LLC Booth: 803 moznsolutions.com

Myomo Booth: 922 myomo.com

National Commission on Orthotic and Prosthetic Education Booth: 1130 ncope.org

Neuro Rehab Recovery Booth: 1612 neurorehabrecovery.com

n Neuros Medical Booth: 1040 neurosmedical.com

New Step Orthotic Lab Inc. Booth: 1024 newsteporthotics.com

North Sea Plastics Ltd. Booth: 1045 northseaplastics.com

NuTech Synergies LLC Booth: 1629 nutechsyn.com

Nymbl Systems Booth: 1037 nymblsystems.com

O and P Booth: 1336 oandp.com.mx

SILVER SPONSOR

O&P Almanac Booth: 1707 aopanet.org

n O&P Cloud CAD Booth: 939 oandpcloudcad.com

O&P Insight Booth: 1027 oandpinsight.com

OP Solutions Booth: 1026 opsolutions.us