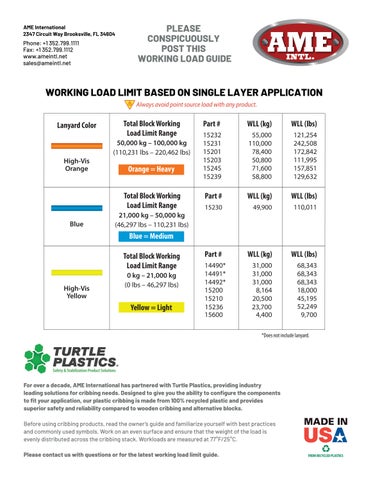

*Does not include lanyard

For over a decade, AME International has partnered with Turtle Plastics, providing industry leading solutions for cribbing needs. Designed to give you the ability to configure the components to fit your application, our plastic cribbing is made from 100% recycled plastic and provides superior safety and reliability compared to wooden cribbing and alternative blocks.

Before using cribbing products, read the owner’s guide and familiarize yourself with best practices and commonly used symbols. Work on an even surface and ensure that the weight of the load is evenly distributed across the cribbing stack. Workloads are measured at 77°F/25°C.

Please contact us with questions or for the latest working load limit guide.

RECOMMENDED BEST PR ACTICE ON BUILDING A CRIBBING STACK

Top plate covering the entir stack ensures maximum displacement and utilization

Required: 14468LT, 14503

and displacement. get close to the lift point. of working load limits.

Additional layers of cribbing as needed to

An assortment of jack plates is ween top plate and load. Often space not allow an additional layer of cribbing. Use our variety of jack plate sizes as shims to reach the load.

14466, 14465, 14489

Bottom jack plate provides maximum footprint

PYR AMID & GRIP-IT CONFIGUR ATION

• The versatility of AME cribbing allows blocks to be used with pyramid sur face. Follow same setup using three by three with crossing additional layers.

• Pyramid surface secures blocks together to prevent slipping.

• Top and bottom plates are used in same fashion, but should incorporate GripIt surface for maximum stability.

14468B, 14503

Essential for non-compacted surfaces. 14468LT, 14503 ALWAYS