Brett Waggoner

VP - ACME SALES

352.799.1111 ext.225 bwaggoner@ameintl.net

Justin Meyer SOUTH CENTRAL SALES

352.799.1111 ext.301 jmeyer@ameintl.net

NORTH CENTRAL SOUTH CENTRAL

Brandon Trail

SOUTHEAST SALES

352.799.1111 ext.305 btrail@ameintl.net

SOUTHEAST

ACCND - CANADA

Jude DeCastro

The ACME Division of AME International was founded to be a unique supplier to the agriculture and construction equipment industry. The ACME Division is dedicated to working with mechanics, technicians, safety teams, manufacturers, and maintenance departments. On-site demo days with one of our ACME trailers is a great way for your team to experience how our tools can work in your shop and answer technical questions. See the ACME difference and bring us in for a demo day to see how our products will make your shop safer and more efficient.

ACWS - WEST

Casey McGrew

ACNC - NORTH CENTRAL

Justin Meyer

ACSC - SOUTH CENTRAL

Justin Meyer

ACSE - SOUTHEAST

Brandon Trail

ACMA - MID-ATLANTIC

Eric Frantz

ACNE - NORTHEAST

Eric Frantz

Casey McGrew WESTERN SALES

352.799.1111 ext.306 cmcgrew@ameintl.net

WEST

Autumn Glidden INSIDE SALES

352.799.1111 ext.304 aglidden@ameintl.net

Inside Sales INSIDE SALES insidesales@ameintl.net

CANADA

NORTHEAST

MID-ATLANTIC

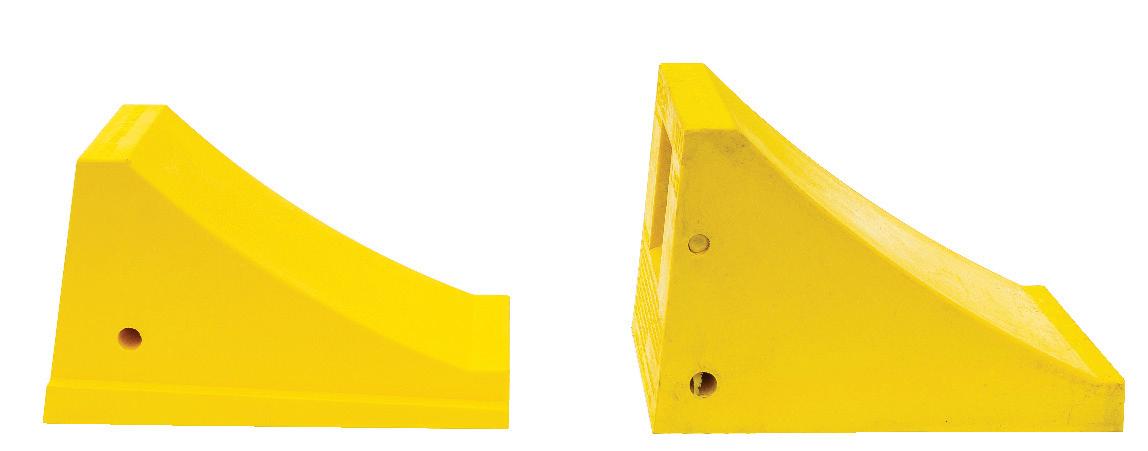

15337 WHEEL CHOCKS SEE PAGE 9

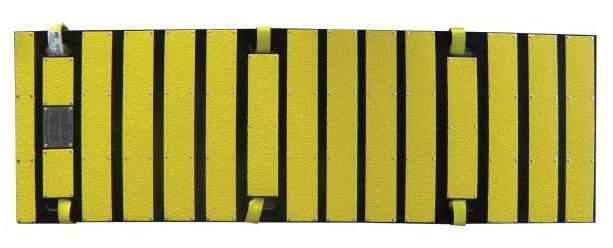

15345 DOZER TRACK MATS SEE PAGE 37

HYDRAULIC RAMS SEE PAGE 42

15355 WHEEL CHOCKS SEE PAGE 10

15348 DOZER MAINTENANCE MATS SEE PAGE 38

67520K TORQIT KIT SEE PAGE 48

15002 STEEL CRIBBING SEE PAGE 17

WT1500NT-B WHEEL TROLLEY SEE PAGE 51

15324 WHEEL CHOCKS SEE PAGE 10

14415 JACK STAND SEE PAGE 33

13141 HYDRAULIC JACK SEE PAGE 31

14441 CRIBBING KIT SEE PAGE 13

15350 RIPPER REST PADS SEE PAGE 38

14225 JACK STAND SEE PAGE 36

65-1H HYDRAULIC JACK SEE PAGE 26

36555 LOTOK KIT SEE PAGE 21

14400 JACK STAND SEE PAGE 34

67510K TORQIT KIT SEE PAGE 48

14415 JACK STAND SEE PAGE 33

13075 HYDRAULIC RAM KIT SEE PAGE 40

67751 BREAK-A-WAY WRENCH SEE PAGE 50

15269PL CRIBBING KIT SEE PAGE 13

14220 JACK STAND SEE PAGE 35

25-1H HYDRAULIC JACK SEE PAGE 25

WT1500NT-B WHEEL TROLLEY SEE PAGE 51

36555 LOTOK KIT SEE PAGE 21

14441 CRIBBING KIT SEE PAGE 13

15002 STEEL CRIBBING SEE PAGE 17

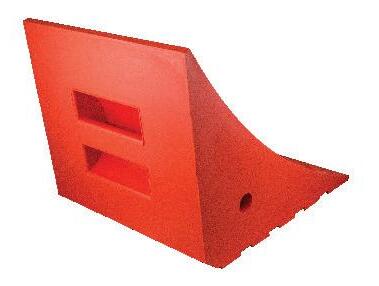

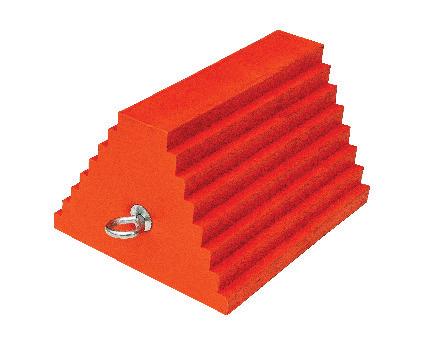

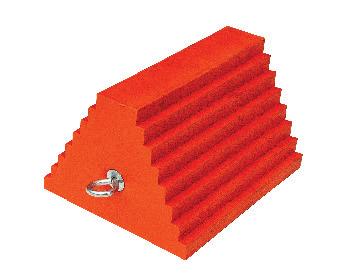

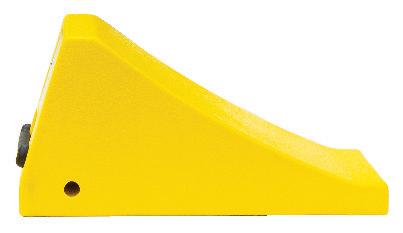

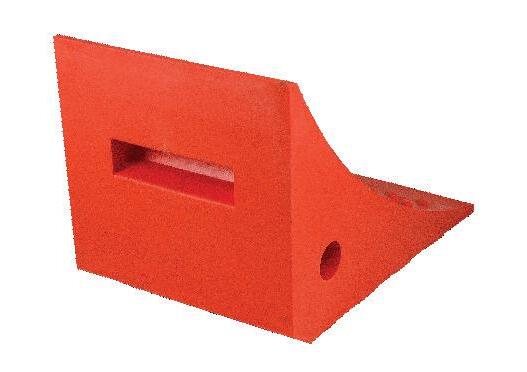

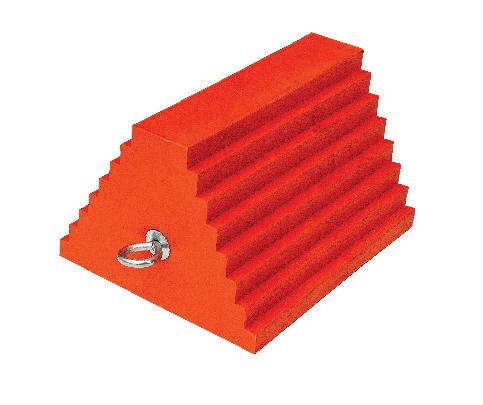

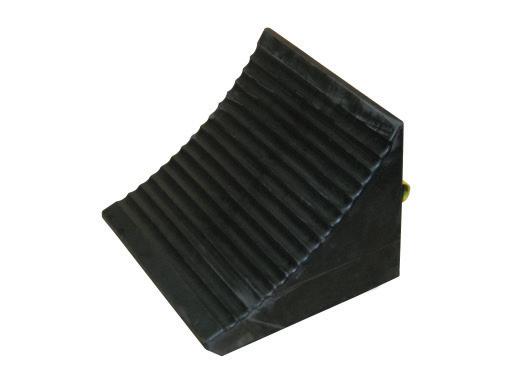

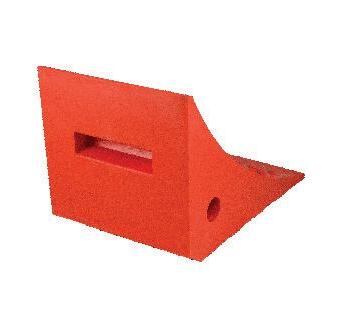

We offer wheel chocks for virtually every application - from over the highway trucks to off-the-road equipment.

• Solid light weight construction, high impact polyurethane material

1910.111(f)(9)

• Non-conductive, no threat to puncture the tire

Durable, light weight, and easy to use - extensively field tested

Impervious to chemicals, salts, rot and resistant to fuel, oils & solvents

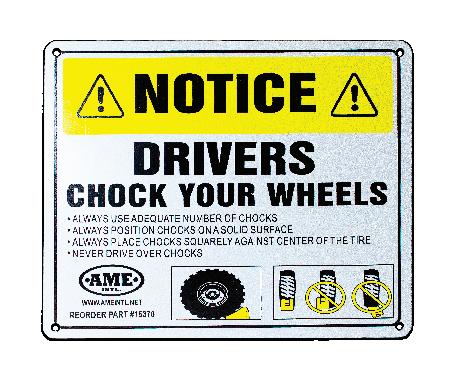

Chock blocks. At least two chock blocks shall be provided. These blocks shall be placed to prevent rolling of the vehicle whenever it is parked during loading and unloading operations.

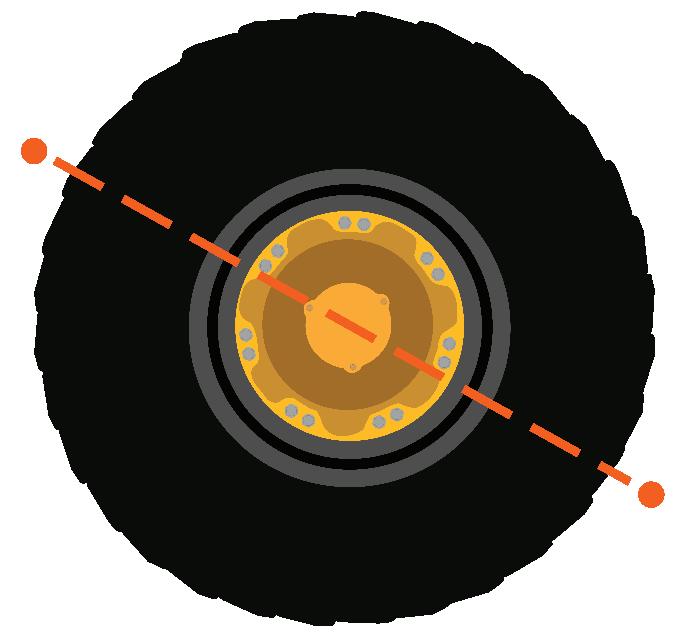

To find the size of your tire's diameter, measure from tread to tread. Starting from one side tread, going straight across the wheel face to the opposing side tread. Measurements must be 180 degrees apart. Use a stiff tape measurer to calculate the wheel diameter. Looser tape measures may not provide as accurate of a diameter calculation because they can bend or tilt.

Smaller tire diameters require smaller chocks, while larger ones require larger chocks. RULE OF THUMB: Use chocks ¼ the height of your tires.

Your wheels must be chocked before loading or unloading. Consider your environment and the condition of the ground surface when selecting a wheel chock. Always use adequate number of chocks. Always ensure your parking brake is set. Never drive over chocks.

POSITION CHOCK SNUGLY BEHIND THE TIRE. KICK/TAP CHOCK INTO PLACE.

CHOCK BOTH SIDES OF WHEEL WHEN WORKING ON LEVEL SURFACE OR FOR ADDED SECURITY

ALWAYS POSITION CHOCKS DOWNHILL & BELOW VEHICLE'S CENTER OF GRAVITY.

PLACE CHOCK SQUARE WITH TIRE. CHOCK SHOULD ALWAYS BE CENTERED WITH THE TIRE.

FOR AUTOMOTIVE TRUCK, CAR & SUV TIRES

FOR SERVICE TRUCK, CRANE TRUCK, & FREIGHT TRUCK TIRES

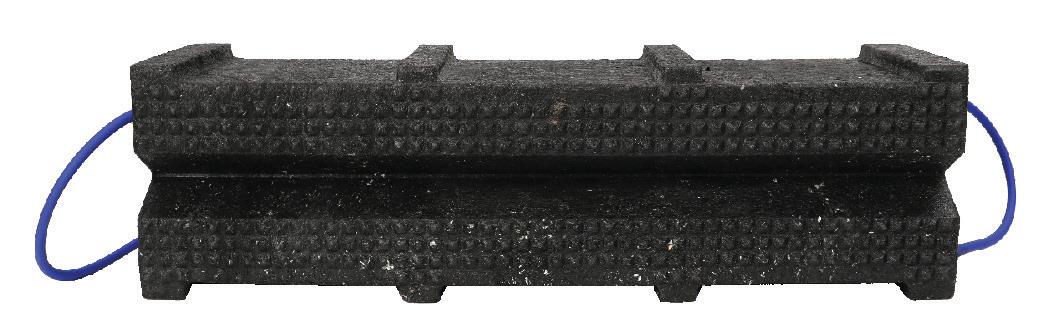

• 100% recycled plastic

• Unmatched strength – stronger than wood

• Resistant to gas, oil, and chemicals

• Certified and tested

• 50 year warranty against splitting, rot, fluid absorption, termites, or mold caused by the environment

• Made in the USA

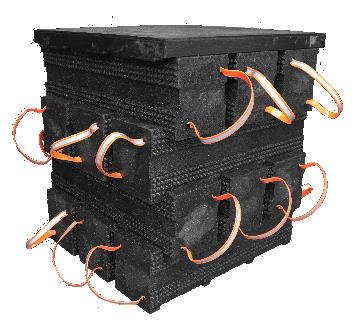

• Color-coded lanyards are durable and help identify blocks working load limit at a glance

• Pyramid surface ensures working load limits are optimized

Colored-coded lanyards depict each cribbing block’s working-load limit, at a glance.

Pyramid surface does not rot or splinter, is resistant to pests, fungus, oils, as well as other harmful materials, and also allows for a variety of secure stacking methods.

For over a decade, AME International has partnered with Turtle Plastics, providing industry leading solutions for cribbing needs. Designed to give you the ability to configure the components to fit your application, Turtle Plastics' cribbing is made from 100% recycled plastic and provides superior safety and reliability compared to wooden cribbing and alternative blocks.

Before using cribbing products, read the owner’s guide and familiarize yourself with best practices and commonly used symbols. Work on an even surface and ensure that the weight of the load is evenly distributed across the cribbing stack. Workloads are measured at 77°F/25°C.

Please contact us with questions or for the

limit guide.

• 100% recycled plastic

• Unmatched strength – stronger than wood

• Resistant to gas, oil, and chemicals

• Certified & tested

• 50 year warranty against splitting, rot, fluid absorption, termites, or mold caused by the environment

• Made in the USA

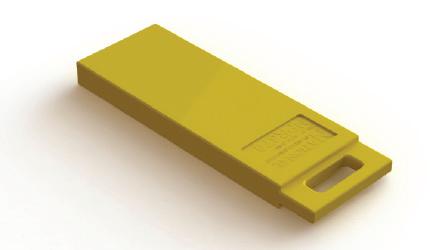

• Compatible with #14500-#14503 and #14468LT Jack Plates

1926.305(d)(1)(i):

After the load has been raised, it shall be cribbed, blocked, or otherwise secured at once.

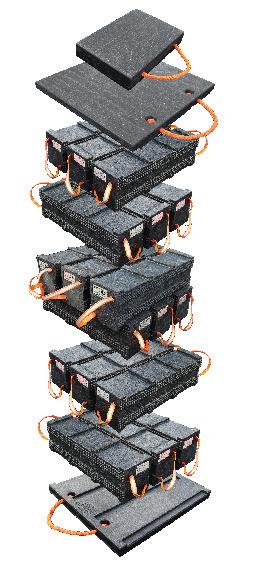

∙ Heavy-duty construction

∙ Orange lanyard dictating high working load limit

∙ Best option for the largest jobs

∙ Available in The Slab® (15231) or Half Slab® (15232)

∙ Can be paired with the 14501 Titan Jack Plate for 15231 & 14500 Titan Jack Plate for 15232

∙ Perfect cribbing for mining and construction equipment use

∙ The Slab® and Half Slab® can be stacked to a maximum height of 3’ high in a single row configuration

∙ The Slab® can be stacked to a maximum height of 6’ high in two row configuration

15231 The Slab® 6” x 12” x 24” 55 lbs (25 kg)

15232 Half Slab® 6” x 12” x 12” 26.5 lbs (12 kg)

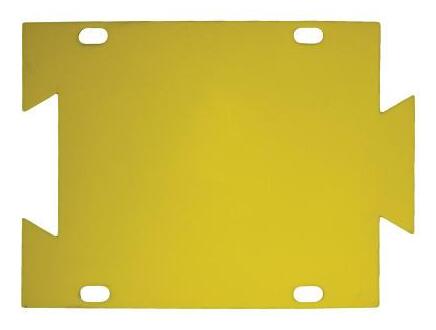

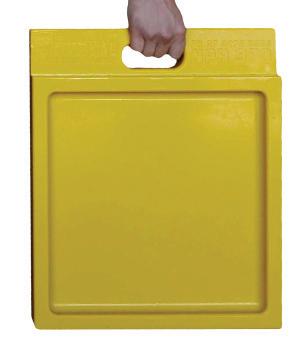

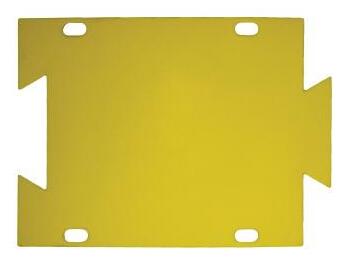

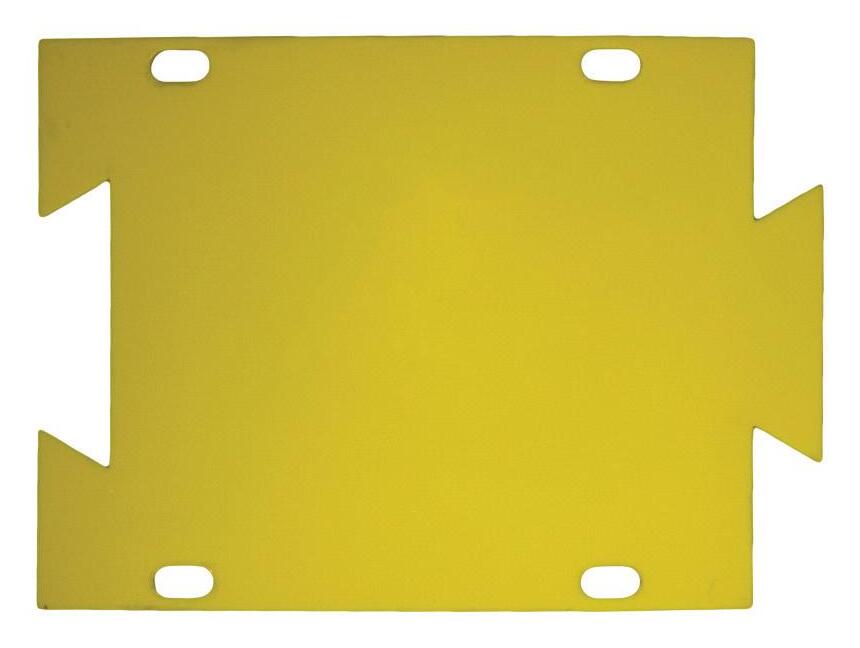

Jack plates provide greater stability to bottle jacks, hydraulic rams, jack stands and cribbing

Lightweight and easy to handle

Non-skid surface to prevent jacks from sliding under wet or oily conditions

Durable high density polymer resists the elements

All AME International Jack Plates are proudly manufactured in the USA

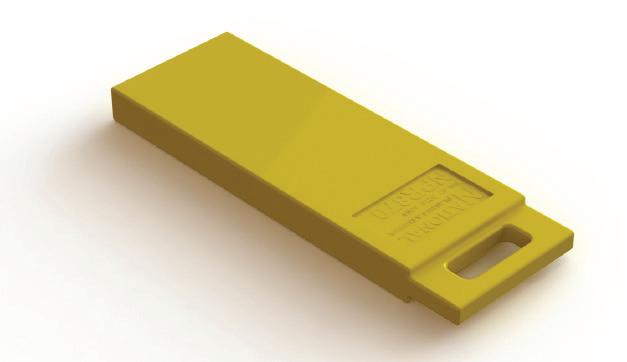

∙ Locky Top Jack plates provide greater stability to bottle jacks, hydraulic rams, jack stands and cribbing

∙ Lightweight and easy to handle

∙ Non-skid surface to prevent jacks from sliding under wet or oily conditions

∙ Durable high density polymer resists the elements

∙ #14503 Bottom Locky-Top Jackplate designed to secure base of cribbing block stack

∙ Capacity: 100 Tons

∙ New pyramid surface on one side is designed to mate with Stacker Cribbing Blocks pyramid surface for secure, exact fit, as well as provide better grip onto uneven terrain in the field

∙ Provides increased stability and gripping-surface

∙ Complies with OSHA regulation 29 CFR 1926.305

∙ Capacity: 100 Tons

∙ Steel cribbing is durable - will not bend or warp

∙ Model #15002 is a complete set - includes: 3”, 6” and 9” stands

∙ Units can be stacked together for 18” total lift

∙ Recessed area on cribbing fits 7” square plate on 55-ton cylinders

∙ Built in carrying handle

∙ Tested/Certified up to 100 tons

∙ Use with AME Jack Plates to secure load and reduce hazardous energy

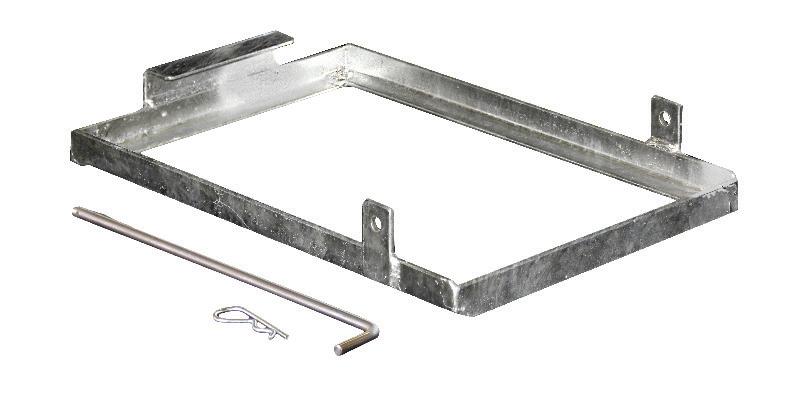

∙ Kits contain both the basic Composite Cribbing and Wheel Chocks components

∙ A convenient carrying bag is provided for smaller parts

∙ Keeps forklift and service truck stable during repairs

∙ Creates a safer repair environment for technicians

Kit Includes:

(2) 15302 Wheel Chocks

(2) 14303 Bessy Clamp

(2) R2-17-1-10 Stockpicker Rizer

(2) 15236 Little Black Diamond Crib®

(2) F55 4”x4”x48” Stacker (2) F55 4”x4”x22” EverBlock

(1) 15237 Carrying Bag

∙ Ideal for forklift trucks

∙ Sturdy, welded, heavy gauge steel constructionprevents distortion

∙ Capacity: 4.5 tons per stand, sold in pairs

∙ Minimum height: 9.5” (24.1 cm)

∙ Maximum height: 16.5” (41.9 cm)

∙ Weight: 10 lbs (4.5 kg)

∙ Designed specifically for use on forklifts Features specially designed seals

Strong steel construction with low pickup height Capacity: 4 Tons

Minimum Height / Low Clearance: 2.25” (5.7 cm)

Maximum height / Max Lifting Height: 16” (40.64 cm)

∙ Weight: 69 lbs (31 kg)

∙ Capacity: 7.5 tons

∙ Minimum Height / Low Clearance: 2.25” (5.7 cm)

∙ Maximum Height / Max Lifting Height: 16.6” (41 cm)

∙ Weight: 99 lbs (45 kg)

∙ Jack for forklifts and low clearance vehicles

∙ Also suitable for agriculture and industry

∙ Extremely low minimum height of only 2.17 in

∙ With 2 lifting heights (scissors 2.17-17.91 in, cylinder 16.14-28.74 in)

∙ Scissor capacity: 8800 lb

∙ Cylinder capacity: 11000 lb

∙ Fold-able, convenient for service trucks

∙ Precise and safe control by lowering

∙ Built-in safety overload valve

∙ All Shure-Steps® are heavy-duty, rated for 500 pounds

∙ Some Shure-Steps® are stackable, so if the 10 inch height isn’t quite enough for your mechanic, just throw another Shure-Step® on top and “Presto!” ... now your mechanic is 16 inches off the ground on a safe and sturdy step

∙ The Shure-Steps® have 6 large rubber pads on the bottom to keep them from sliding on slick wet floors

∙ All the Shure-Step® models come in high-vis yellow

∙ The super rough top surface (Nobby Top) makes the step safe to use even after spilling oil or hydraulic fluid on them

#95010 Tailgate Warning Flag

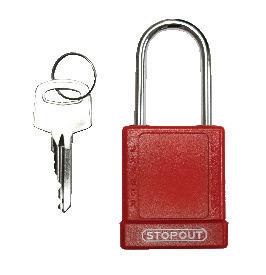

#95030 Aluminum Padlock

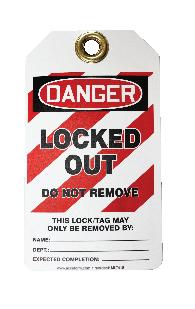

#95035-1 Equipment Tag (1-pack)

#95025 Wheel Cover

#95045 6' Adjustable Cable Lockout

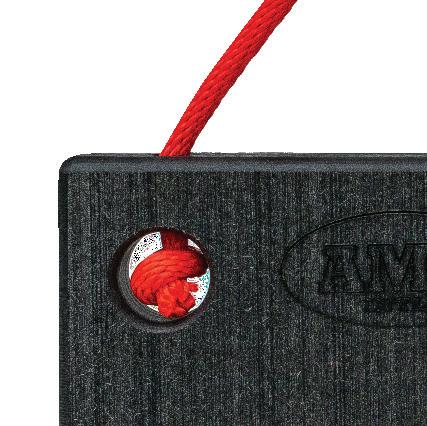

# 36555 Basic Lock-Out Tag-Out Kit:

∙ (1) # 95010 Tailgate Warning Flag

∙ (1) # 95025 “Do Not Start or Move Vehicle” Wheel Cover

∙ (1) # 95030 Plastic Body Aluminum Padlock

∙ (1) # 95035-1 “Do Not Operate Equipment” Tag (1-pack)

∙ (1) # 95045 Adjustable 6' Cable Lockout

∙ (1) # BL8 8” Black Zip Ties (Bundle of 100)

#36400 Earthmover Lock-Out Tag-Out Kit:

∙ (1) # 95010 Tailgate Warning Flag

∙ (1) # 95025 “Do Not Start or Move Vehicle” Wheel Cover

∙ (1) # 95030 Plastic Body Aluminum Padlock

∙ (1) # 95035-1 “Do Not Operate Equipment” Tag

∙ (1) # BL8 8” Black Zip Ties (Bundle of 100)

∙ (2) # 15301 Black Urethane Wheel Chocks

∙ (1) #95040 Standard Steel Hasp, 1.5”

#15367 Wheel Chocks

#95040 Standard Steel Hasp

#BL8 8" Black Zip Ties

#15301 Wheel Chocks

#36300 Commercial Truck Lock-Out Tag-Out Kit:

∙ (1) # 95010 Tailgate Warning Flag

∙ (1) # 95025 “Do Not Start or Move Vehicle” Wheel Cover

∙ (1) # 95030 Plastic Body Aluminum Padlock

∙ (1) # 95035-1 “Do Not Operate Equipment” Tag

∙ (1) # BL8 8” Black Zip Ties (Bundle of 100)

∙ (2) # 15367 Orange Urethane Wheel Chocks

∙ Air operated & easy to maneuver (operates with only 80 psi of air pressure)

∙ Single piece handle - will not break

∙ Extension saddles include: 1 of each, 1”, 2”, and 4”

∙ Min. Height: 9” (18.5 cm)

∙ Stroke Length: 6” (15 cm)

∙ Weight: 90 lbs (41 kg)

∙ Chromed ram and aluminum air motor for long life

∙ Heavy-duty return springs

∙ Each unit factory tested at 150% overload

∙ Capacity: 20-ton

∙ Maximum Height: 18.5”

∙ Minimum Height: 9.7”

∙ Flexilla® whip hose for longer life and maximum durability in all climate conditions

∙ In-line regulator limits inlet pressure to 94 PSI to prevent air bypass

∙ 10”x10” 50-ton Jack Plate 14453 included for optimal weight displacement on uneven or non-compacted surfaces

∙ Cylinder is welded to the base, assuring strength and eliminating leaks

∙ Chromed pump piston and ram for added rust resistance

∙ Extension screw gives added height when necessary

∙ Meets ANS/ASME PALD & CE/GS standards

∙ Super low minimum height for easy access

∙ Capacity: 20 tons

∙ Dimensions: Height: 6” (15.3 cm), Length: 13” (33 cm) Width: 5” (12.7 cm

∙ Minimum Height: 5.8” (14.8 cm)

∙ Maximum Height: 10” (25.6 cm)

∙ Weight: 21 lbs (9.5 kg)

AME International presents AC HydraulicA/S Hydraulic Jacks, available in several models designed for passenger cars, low clearance cars, vans, and SUVs.

Each jack is manufactured with a very low minimum height of only 3.15“ (8 cm), a handle length of 37.4” (95 cm), as well as a wide and robust frame made of high-strength steel. Models with Q suffix are fitted with quick-lift pedal for easy reach of lifting point and operates with precise and safe control while lowering. Manual dead man’s release is also included for optimum safety when lowering, along with a built-in safety overload valve. Noiseless wheels incorporating a polyurethane central o-ring offer maximum surface protection. Ergonomically designed handle also ensures positive and safe operation. BY

For protection of car body

Fits:

DK20 / DK20Q

DK13HLQ / DK20HLQ T3

Lifts the car for change of both wheels at the same time

With telescopic arms, reach from 29.33 – 45.27 in (745 – 1150mm)

Fits:

DK20 / DK20Q

DK13HLQ / DK20HLQ

For easy transport and extra maneuverability – also on uneven floors

Fits:

DK40Q / DK60Q

DK100Q / DK120Q DK50HLQ

Extension for cars with high clearance (3.94 in / 100 mm)

Fits:

DK20 / DK20Q

DK13HLQ / DK20HLQ

Extension for cars with high clearance (4.91 in / 125 mm)

Fits:

DK40Q / DK60Q

DK100Q / DK120Q / DK50HLQ

BY

AME International presents AC Hydraulic A/S Air Hydraulic Jacks, designed for heavy-duty, intensive commercial use.

-Hard chromium plated piston rod for long life

-Built-in safety overload valve

-Hand-operated dead-man’s control for optimum safety while lifting and lowering

-Portable air hydraulic jack also available, ideal for service vans, etc.

-Handy design - no loose tubes, handles, or valves.

-All air hydraulic jacks have an air supply of 130 - 145 psi and an air consumption of 350 l/min (12.4 CFM)

-Air hydraulic jacks have a handle length of 45.67” (116 cm)

40-4

Air/Hydraulic Jack

Extremely low profile minimum height allows jack to easily fit under any vehicle

∙ Air hydraulic jack for heavy-duty/intensive commercial applications with high ground clearance

∙ Hard chromium plated piston rod for long life

∙ Built-in safety overload valve

∙ Hand-operated dead-man’s control for optimum safety while lifting and lowering

∙ Ergonomic handle with push buttons

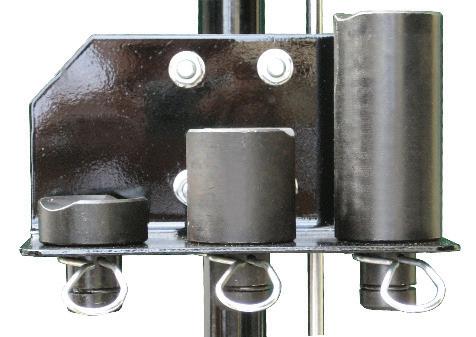

# SBB TRANSPORT

LOCKING DEVICE AND WALL BRACKET FOR B25-2

Safe storage in service vans. Prevents damages in cases of emergency stops. Neat and practical wall mounting in the workshop.

Fits: B25-2

5.71" (145 mm) Diameter

Suitable for lifting under bolts, differential gear etc.

Fits: B25-2

25-1 / 25-1H 25-2 40-4 50-2 50-3

# F250 EXTENSION

Increase the maximum height by 250 mm Cannot be used together with other extensions

Fits: B25-2

25-1 / 25-1H

25-2 50-2 / 50-3

For lifting under different types of axles

#FW1-90 width: 3.54" (90 mm)

#FW1-130 width: 5.12" (130 mm)

Fits: B25-2

25-1 / 25-1H 25-2

40-4

50-2

50-3

AME International presents AC HydraulicA/S heavy-duty jacks for low clearance machinery in mining and construction industries.

- All steel, heavy-duty chassis built to fit harsh environments

- Large rubber tires allow easy positioning on challenging surfaces

- Innovative chassis construction facilitates jack repair and even wheel changing on site

- High ground clearance for clearing rail and rough terrain

- Multiple position handle for easy tilt back and moving

- Handle with dead-man’s release for optimum safety during lifting and lowering.

- Mining jack handle length: 51.2” (130 cm)

- New Air Motor

FHD100 / FHD200

SB65 / SB100 / SB150

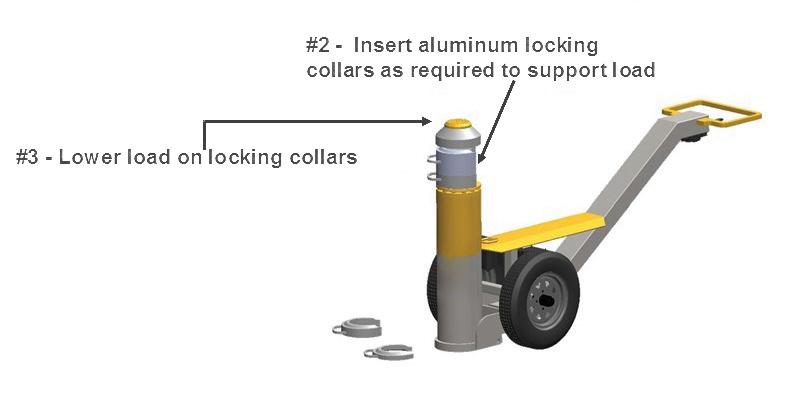

Locking Rings

SB65: 6.5 cm

Fits: All models

SB100: 10 cm

Fits: 100-1 / 150-1, 100-1H / 150-1H

SB150: 15 cm

Fits: 100-1 / 150-1, 100-1H / 150-1H

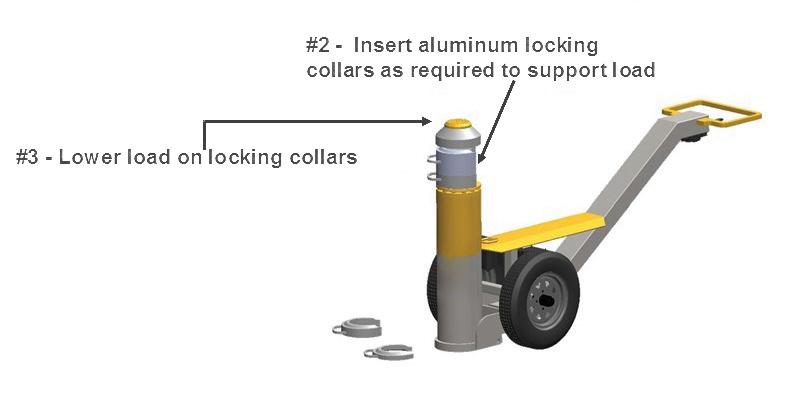

Air/Hydraulic Mining Jacks from 100 – 250 Tons. Each jack comes with custom extensions based on your specific application. Electric power unit available. Power Drive System included on jacks 150-Ton and larger (optional on 150-Ton or smaller). Power Drive System self propels SLJ Jack over terrain with no effort from operator.

7” (178mm) Extensions Suitable for use with:

SLJ 200 Ton to 250 Ton

7” (178mm) Extensions Suitable for use with:

100 Ton SLJ Support Jacks

SLJ 200 Ton to 250 Ton 100 Ton SLJ Support Jacks

8” (203mm) Extensions Suitable for use with:

8” (203mm) Extensions Suitable for use with:

SLJ 300 Ton to 350 Ton

150 Ton SLJ Support Jacks

SLJ 300 Ton to 350 Ton 150 Ton SLJ Support Jacks

Model Description

10” (254mm) Extensions Suitable for use with:

10” (254mm) Extensions Suitable for use with: 200 Ton SLJ Support Jacks

200 Ton SLJ Support Jacks

SLJLC150K Locking Collar Set for SuperLift (100 to 150 Tons). Included are Locking Collars: SLJLC150-1, SLJLC150-2, SLJLC150-3, SLJLC150-6, SLJLC150-AR, SLJLC150-TC SLJLC350K Locking Collar Set for SuperLift (200 to 350 Tons). Included are Locking Collars: SLJLC350-1, SLJLC350-2, SLJLC350-3, SLJLC350-4, SLJLC350-AR, SLJLC350-TC

Model d SLJLC150K Locking Collar Set for SuperLift (100 to 150 Ton). Included are Locking Collars: SLJLC150-1, SLJLC150-2, SLJC150-3, SLJLC150-6, SLJLC150-AR, SLJLC350K Locking Collar Set for SuperLift (200 to 350 Ton). Included are Locking Collars: SLJLC350-1, SLJLC350-2, SLJLC350-3, SLJLC350-4, SLJLC350-AR,

Model description SLJLC150K Locking Collar Set for SuperLift (100 to 150 Ton). Included are Locking Collars: SLJLC150-1, SLJLC150-2, SLJC150-3, SLJLC150-6, SLJLC150-AR, SLJLC350K Locking Collar Set for SuperLift (200 to 350 Ton). Included are Locking Collars: SLJLC350-1, SLJLC350-2, SLJLC350-3, SLJLC350-4, SLJLC350-AR,

∙ Custom heights can be determined upon order to meet the customer’s needs

∙ Saddle and custom extension supplied with each stand

∙ Certificates of conformity supplied for international and domestic requirements

∙ Support weight with engineered

∙ Meets international safety standards

∙ Heavy-duty steel plate to ensure longevity

∙ Transporter allows for easy placement

∙ Includes “Shut-Off Valve” to allow the pump to be removed while ram is extended

∙ 6” (15 cm) stroke

∙ 12” (30.5 cm) retracted height

∙ 18” (48 cm) max. height

∙ Weight: 53 lbs (24 kg)

∙ Includes “Shut-Off Valve” to allow the pump to be removed while ram is extended

∙ Include on 13005 & 13000

∙ Aluminum base plate for stability during field use

∙ Extra thick aluminum cylinder walls measure 0.80” (2 cm) for heavy-duty use

∙ Advanced piston coating resists scarring for longer life

∙ Stroke 6” (15cm)

∙ Retracted height – 12.25” (31.115 cm)

∙ New stop ring design specifically for tire industry

∙ Reduces side load damage

∙ Lightweight aluminum lifting cylinder, easy handling and placing under the vehicle

∙ Includes “Shut-Off Valve” which allows the pump to be removed while the ram is extended

∙ Aluminum base plate included

∙ Recessed base plate allows jacks to nest inside

∙ Low profile saddle ensures precise lifting

∙ Ideal for forklift trucks

∙ Sturdy, welded, heavy gauge steel construction - prevents distortion

∙ Capacity: 4.5 tons per stand (sold in pairs)

∙ Minimum height: 9.5” (24.1 cm)

∙ Maximum height: 16.5” (41.9 cm)

∙ Weight: 10 lbs (4.5 kg)

∙ Always use in pairs

∙ European design accommodates truck axles, forklifts & trailers

∙ 4 pin placements

∙ Capacity: 5 tons per stand (sold in pairs)

∙ Min. Height: 10.5” (26.7 cm)

∙ Max. Height 16.5” (41.9 cm)

∙ Weight (per stand): 16.5 lbs (7.5 kg)

∙ Always use in pairs

∙ Flat top rubber pad grips the lifting point

∙ Ideal for low-profile vehicles or custom cars

∙ Triangular base for stability

∙ Powder coat finish on the base

∙ Minimum Height: 13.8”

∙ Maximum Height: 21.81”

∙ Capacity: 4 tons per stand (sold in pairs)

∙ Always use in pairs

∙ Ideal for light aircraft, flat top rubber pad grips the lifting point

∙ Powder coat finish on base, zinc plated post to prevent rust

∙ Capacity: 3 tons per stand (sold in pairs)

∙ Minimum Height: 19” (48.3 cm), maximum height: 31.5” (80 cm)

∙ Weight: 36.5 lbs (16.6 kg)

∙ Always use in pairs

∙ Screw style stand easily holds load at desired height and secures it with locking collar

∙ Adjustable screw for height extension and retraction

∙ Quick adjustment to desired heights

∙ Capacity: 20 tons per stand (sold individually)

∙ Pin-style stand makes it easy to hold the

∙ Heavy-duty OTR pin-style jack stand

∙ Quick adjustment to the desired heights

∙ Capacity: 25 tons per stand (sold individually)

at

and secure with locking collar

JACK STANDS

∙ Sturdy steel construction for superior safety and strength

∙ Heavy gauge, steel frame helps prevent distortion or twisting

∙ Capacity: 22 tons per stand (sold in pairs)

∙ Min. Height: 9.5” (24.1 cm), Max. Height: 19.9” (50.5 cm)

∙ Weight: 68 lbs (30.8 kg) (Pair)

∙ Always use in pairs

JACK STANDS

∙ 3 lock pin settings for adjustable heights

∙ Adjustable Swivel allows for 2” of variance at locked settings

∙ Capacity: 22 tons per stand (sold in pairs)

∙ Min. Height: 12.5 in (31.75 cm), Max. Height: 21.9” (55.63 cm)

∙ Weight: 76 lbs (34.4 kg) (Pair)

∙ Always use in pairs

JACK STANDS

∙ Sturdy steel construction for superior safety and strength

∙ Heavy gauge, steel frame helps prevent distortion or twisting

∙ Capacity: 12 tons per stand (sold in pairs)

∙ Min. Height: 11.81” (30 cm), Max. Height: 18.11” (46 cm)

∙ Weight: 46 lbs (20.8 kg) (Pair)

∙ Always use in pairs

∙ Used to support (block) track-type or rubber tired vehicles

∙ Height Range: 23.55” - 34.05” (Standard) ; 34.05”-44.55” (with optional Medium Tube 14220-002)

∙ Can be used with separate lifting devices or hydraulic jacks

∙ Capacity: 20 Tons per stand (sold individually)

∙ Rugged heavy-duty design with welded, all steel construction

∙ Dual lock-pin design provides 2 load-bearing surfaces

∙ Adjustable height in 19mm (0.75 in) increments

∙ Features retractable spring-loaded casters

Standard Height Range: 23.5” - 34”

*Accessories available but not included

∙ Used to support (block) track-type or rubber tired vehicles

∙ Height Range: 31.85”-42.35” (with included Short Tube) ; 42.35”-52.85” (with optional 14220-002 Medium Tube) ; 49.50”-69.00” (with optional 14225-001 Long Tube) ; 65.25”-84.75” (with optional 14225-002 Extra Long Tube)

∙ Capacity: 25 Tons per stand (sold individually)

∙ Can be used with separate lifting devices or hydraulic jacks

∙ Rugged heavy-duty design with welded, all steel construction

∙ Dual lock-pin design provides 2 load-bearing surfaces

∙ Adjustable height in 19mm (0.75 in) increments

∙ Features retractable spring-loaded casters

25-Ton Jack Stand Parts / Accessories: Standard Height Range: 31.8” - 42.3” *Accessories available but not included **25-ton use

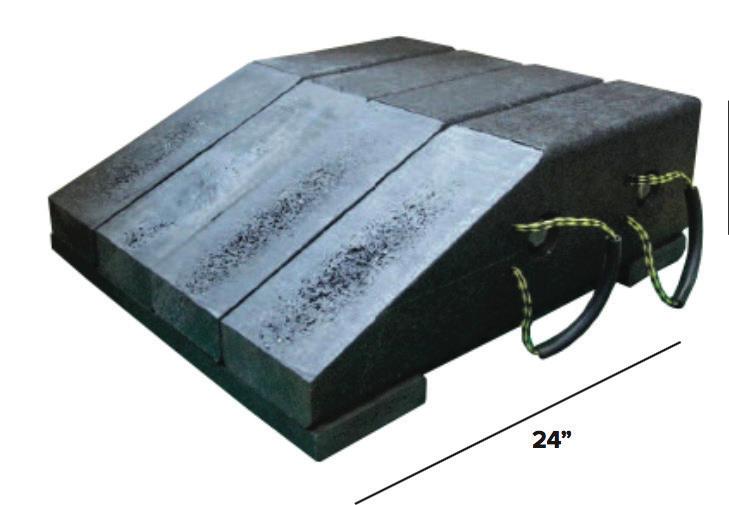

∙ These floor protection mats are an ideal replacement for old conveyor belt, which in the past has been a back breaking exercise moving the belt about the workshop

∙ They provide the protection needed against the potential damage caused by heavy dozers & excavators driving onto concrete floors while entering & exiting workshops

∙ Dimensions: 39 in. (1000 mm) long, 31 in. (800 mm) wide, 0.71 in. (18 mm) thick

∙ Weight: 39 lbs (18 kg)

SCAN HERE TO WATCH VIDEO DEMO

∙ Holds 12 dozer track floor protection pads (#15345 ) at a time

∙ Can also be maneuvered safely & packed away neatly when not in use

∙ Makes low-boy loading your track vehicle a snap

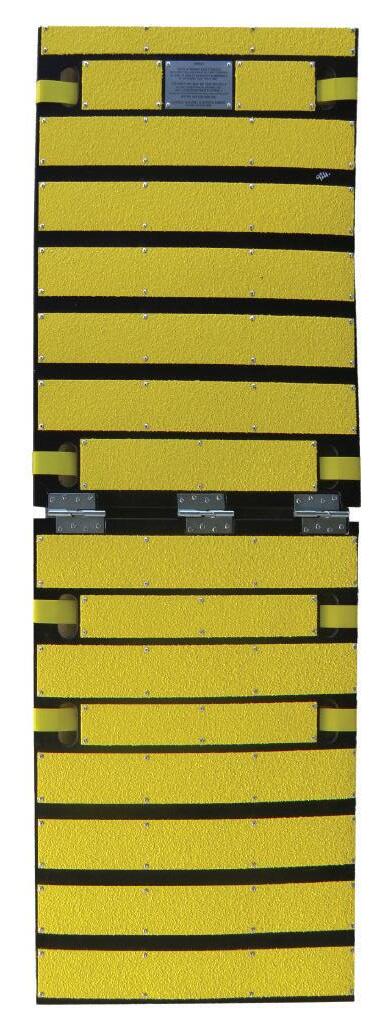

∙ Heavy-duty construction with a 45° angle grade and three sizes to choose from

∙ Made in the U.S.A of 100% recycled plastic

Model Description Weight

∙ These polyurethane Blade Rest Pads assist in protecting the concrete surface of workshop floors as well as entry & exit areas when equipment is parked up ready for maintenance

∙ To be used in sets between the blade and the floor

∙ Rest pads are available in two different sizes (each with molded handle):

∙ Ripper Pads protect workshop floors while removing the problem of lifting heavy steel pads into place

∙ Each pad features raised edges for the ripper types without the boot

∙ Designed to strap on to dozer tracks and eliminate slip/ trip hazards associated with maintenance activities when walking on dozer tracks

∙ Available in two designs: A one piece ridged mat (#15360) for the workshop or in a two pieced hinged mat (#15347 / #15348) suitable for the workshop or field maintenance

∙ Single-acting

Removable plunger adapter allows the use of a variety of threaded attachments Must have for heavy equipment service

TOOL TIP : Avoid pinch points or crush points that can be created by the load or parts of the cylinder. To help prevent material fatigue if the cylinder is to be used in a continuous application, the load should not exceed 85% of the rated capacity or stroke.

TOOL TIP : Avoid maximum extension of rams. 80% stroke ensures longer life.

∙ Versatile ram kit allows you to select your ram length from 3.5” (9 cm) up to 11.5” (29.21 cm)

∙ Steel extensions are durable enough for heavy equipment applications

∙ Comes with 3 extensions: 1” (2.5 cm), 2” (5 cm), 3” (7.5 cm)

∙ 3” extension includes a screw-in saddle that extends another 2”

∙ Extensions can be used individually or together

∙ Ships in carrying case

∙ 10-Ton 1.5” (3.8 cm) stroke

∙ Weight: 11 lbs (5 kg)

∙ Soft face helps prevent marring

∙ Uni-Cast construction of non-ferrous materials eliminates sparking and won’t absorb liquids

∙ No exposed metal on face, head or shaft, urethane covering helps reduce noise

∙ Dead blow function eliminates bounce-back when striking hardened surfaces

∙ Steel reinforced handle provides strength and resists breaking on over-strike

∙ Flat area on head allows upright storage

∙ Made in America

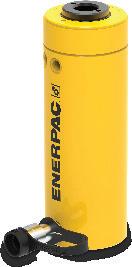

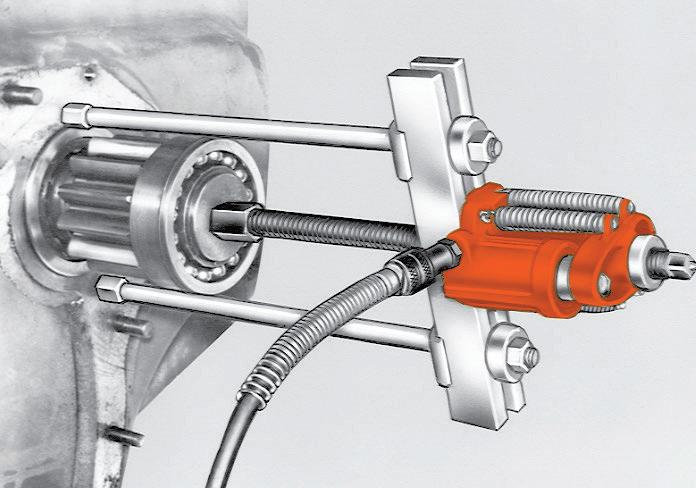

• Cylinders withstand full “dead-end” loads

• Compact design is ideal for applications in which space is limited

• Basic head can be changed from a tapped hole to plain hole by simply changing the insert

• Pistons have “Power-Tech” treatment for corrosion and abrasion resistance

• Complies with ANSI / ASME B30.1 Safety Standards

• RT Series pullers are equipped with a through hole design for additional applications and uses for pulling requiring high force

• RT Series center hole cylinder is versatile for strand or pull applications

NOTE: Each cylinder complete with threaded cylinder head insert, cylinder half coupler and cylinder attaching screws

*The RT1004 has a bypass when full stroke is reached, preventing over-pressurization of the cylinder.

DOUBLE-ACTING

∙ Hollow plunger design allows for both pull and push forces

∙ Single-acting spring return

∙ Material: Steel

∙ Nickel-plated, floating center tube on models over 20 tons increases product life

∙ Baked enamel finish for increased corrosion resistance

∙ Collar threads for easy fixturing

∙ RCH121 includes AR-630 coupler and has 1/4 NPTF port

∙ RCH123 to RCH1003 feature CR-400 Coupler

∙ Relief valves prevent damage in case of over-pressurization

∙ Material: Steel

∙ Baked enamel finish for increased corrosion resistance

∙ Collar threads enable easy fixturing

∙ Double-acting operation for fast retraction

∙ Nickel-plated, floating center tube increases product life

∙ Hollow plunger allows for both pull and push forces

∙ CR-400 couplers and dust caps included on all models

∙ Plunger wiper reduces contamination, extending cylinder life

∙ 10,000 psi (700 bar) working pressure hydraulic hose

∙ Equipped with two 3/8” NPT ends (including one swivel end)

∙ Meets IJ100 jack hose specifications

∙ Made in the USA

*Custom sizes available

∙ Model # 16000 - Complete Set ( # 16050 - Male Half, # 16060 - Female Half)

∙ Interchange with Enerpac C604 and Power Team/OTC 9795

∙ Plastic dust cover available ( Model # CD-411 )

∙ 10,000 PSI (700 bar) quick connect coupling, 3/8” NPT

∙ Parker Series couplings (interchange with IMT couplings)

∙ Model # TC-370 - Complete Set ( # TC-371 - Female Half, # TC-372 - Male Half)

∙ Allows pump to be removed while ram is extended

∙ For use with single acting hydraulic cylinder

∙ Rated at 10,000 PSI (700 BAR)

∙ 45° angled gauge improves visibility

∙ Slim and narrow design

∙ Easy to fit in a broad range of systems

∙ Maximize controlled load movement

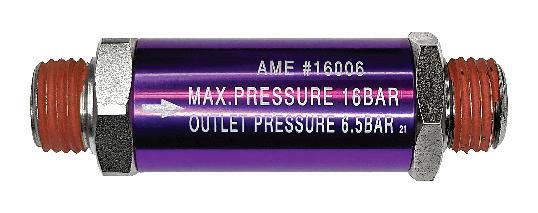

∙ Model # 16005 - Male to Female ¼" NPT Air Reducer

∙ Model # 16006 - Male to Male ¼" NPT Air Reducer

∙ Regulates inlet pressure 94 PSI to prevent air bypass

∙ Max Pressure: 16 Bar

∙ Outlet Pressure: 6.5 Bar

∙ Builds 10,000 PSI of pressure to fit the majority of tools on the market

∙ Operates on 80-120 PSI of inlet air pressure (standard on most compressors and shop air)

∙ Durable metal air motor assemblies

∙ Designed specific to conditions normally associated with OTR sites

∙ Oil capacity: 5 quarts (4.7 liters)

∙ Reservoir type: Steel

∙ Weight: 23 lbs (10.4 kg)

∙ High-performance brush-less motor provides the speed of a ½ HP electric pump, enabling corded productivity with cordless convenience

∙ Lightweight design with integrated handle and carrying strap for portability

∙ Bladder reservoir prevents contamination and allows pump usage in any position

∙ Cordless technology eliminates tripping hazards found in other electric or air powered pumps

∙ Maximum Pressure: 10,000 psi (700 bar)

∙ Valve Type: 3-way, 2-position manual

∙ Oil Flow Rate: 2.6 l/min (160 in3/min) at no load, 0.33l/min (20 in3/min) at full load

∙ Oil Capacity: 2 liters

∙ 2 batteries and charger included

∙ Charger Voltage: 115 V

∙ Weight: 26.3 lbs (12 kg) with batteries

∙ For use with single or double-acting cylinders at operating pressure up to 10,000 psi.

∙ Equipped with 1/2 HP, 3,450 RPM, single-phase, thermal protected induction motor; 10 ft. Remote control cord.

∙ Low amperage draw - small generators and low amperage circuits can be used as power source.

∙ Extremely quiet noise level (67-81 dBA).

∙ Starts under full load for intermittent duty.

∙ Maximum Operating Pressure: 10,000 PSI

∙ Single acting cylinder

∙ Features higher oil flow & bypass pressure

∙ Requires 18% less current draw than comparable pumps

∙ 2.0 gallon usable oil

∙ LCD readout provides pressure and a number of diagnostic and readout capabilities never before offered on a portable electric pump

∙ 2-stage hydraulic electric pumps

∙ Runs cooler and has 18% less current draw than comparable pumps

∙ Maximum Operating Pressure: 10,000 PSI

∙ Single Acting Cylinder

∙ Features higher oil flow & bypass pressure

∙ Requires 18% less current draw than comparable pumps

∙ 2.0 gallon usable oil

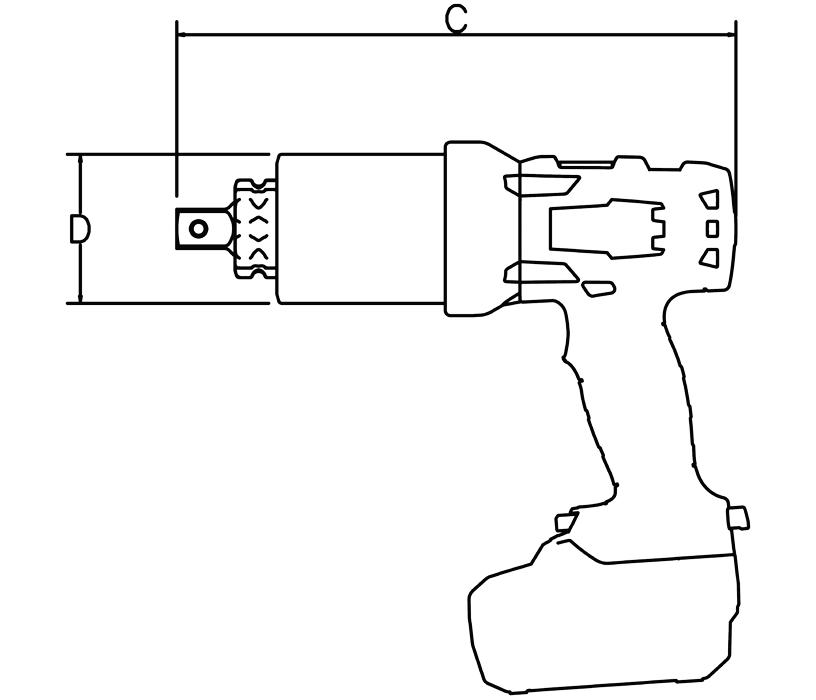

• Hardened alloy steel for durability and long cycle life

• Bearings support the loads experienced at the square drive

• Multi-stage planetary gear systems with optimized tooth design

• Smooth ball bearing rotation of the gearbox housing independent from the motor handle

• High-Efficiency Brush-less Motor

• Ergonomic glass-filled Nylon handle with a durable slip-resistant over mold

• 18V 8.0 Ah LiHD Battery that provides extended run-time

• LCD display for setting and viewing Torque and Units

• Soft-Start Trigger

• Thrust bearing between stages isolates the motor when used in all orientations

• O-Rings seal grease in while keeping dirt and water out

• Gears run on low friction, high strength bearing sleeves

• Tool steel pins in each stage carrier

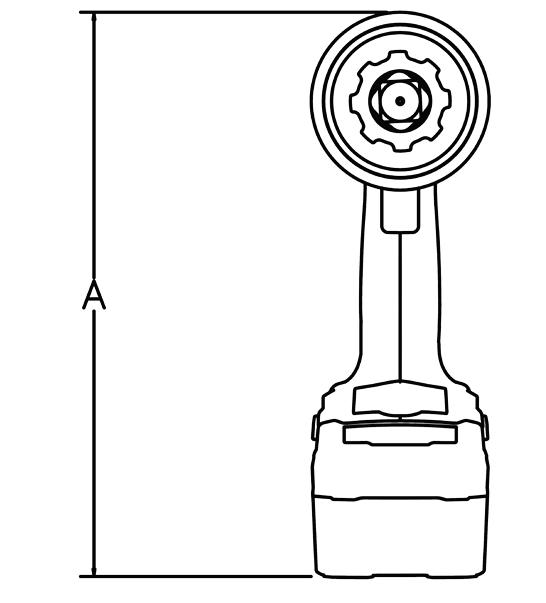

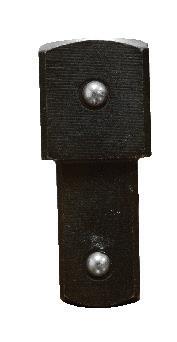

∙ Durable and portable precision torque

∙ Four models from 120 ft/lbs to 3,000 ft/lbs

∙ Lithium ion 8.0 Ah rechargeable battery (full charge in under 60 minutes)

∙ Every unit calibrated in ISO17025 laboratory

∙ 13-Month warranty from date of purchase

67512 LONG EXTENDED REACTION ARM

67518 SOCKET-TO-SOCKET REACTION ARMS

Model Description

67513 STRAIGHT REACTION ARM

67552 ARM FOR CT MODELS

67512 Long Arm for use w/ Deep Well Sockets

67513 Straight Reaction Arm

67514 Sliding Reaction Arm

67516 6" Nose Extension Only

67517 12" Nose Extension Only

67518 Socket to Socket Reaction Arm

67519 18" Nose Extension Only

67552 Standard Reaction Arm

67514 SLIDING STRAIGHT REACTION ARM

67516, 67517, 67519 6", 12", & 18" EXTENSIONS

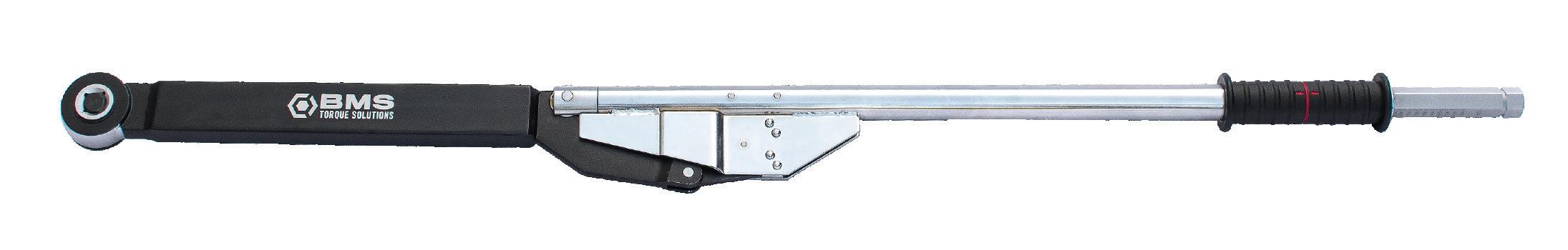

∙ Robust construction gives accurate results to ±4% even in hazardous working conditions

∙ The break-a-way action gives an unmistakable signal in the handle which can be seen & felt

∙ The break angle improves accuracy by reducing the possibility of over-torquing

∙ Dual scale, NM and FT.LB.

∙ Carrying case included

∙ Reversible wrench can torque both left and right hand threads

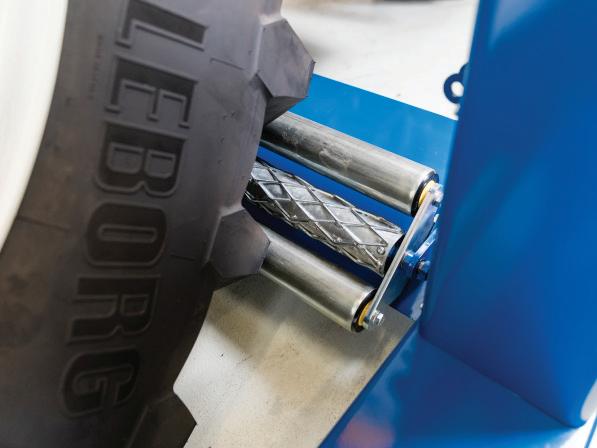

When it comes to aiding the removal and transportation of large wheels, the WT1500NT is in a league of its own. It offers better ergonomics and improvements in both safety and maneuverability compared to other models in the market.

∙ Truly a one-person operation

∙ A waist-high hydraulic pump handle moves the jaws in and out to accept the different size wheels

∙ The handle is also used to raise, lower, and rotate the wheel

∙ A ratchet strap secures the unbolted wheel in place to give maximum safety, this also allows good access to the wheel nuts and more efficient working space

∙ Unique tire handling by one person only

∙ Improved ergonomics, maneuverability, and operator safety

∙ Strongest model in the market

∙ Wheel sizes: min. 39.37 in - max 94.49 in

∙ Wheel width: max 47.24 in

#WTK

Telescopic Crane Arm (sold separately)

∙ Hydraulic wheel trolley for vans, trucks, buses, and removal of wheels and brake drums on aircrafts

∙ Flexible and ergonomic wheel trolley for the easy removal of wheels and brake drums

∙ High lifting height (28.23 in) is ideal for lifting e.g. wheels and brake drums off a transport wagon

∙ Lifting arms with roller bearings for easy rotation of the wheel into correct position

∙ Pedal operated pump leaving both hands free for working

∙ Bracket for easy securing of the wheel while transporting

∙ Hand operated dead man’s release for optimum safety while lowering

∙ Ideal for lifting brake drums, fuel tanks, tool boxes etc.

∙ With 2 pcs. 360º revolving wheels

∙ Model #WTK - Telescopic Crane Arm add on available (sold separately)

∙ Hydraulic workshop crane for auto workshops and service vans

∙ Fold-able within seconds for quick and easy storage

∙ When folded the crane takes up a minimum of space on the workshop floor

∙ Jib arm with large lifting capacity – even in 5th position

∙ Hard chromium plated piston rod and pump piston for long life

∙ Built-in safety overload valve

∙ Fitted with 2 castors and 2 fixed wheels for easy maneuverability even with maximum load

∙ Lifting hook pivots 360º

∙ Hand operated dead man’s release for optimum safety while lowering

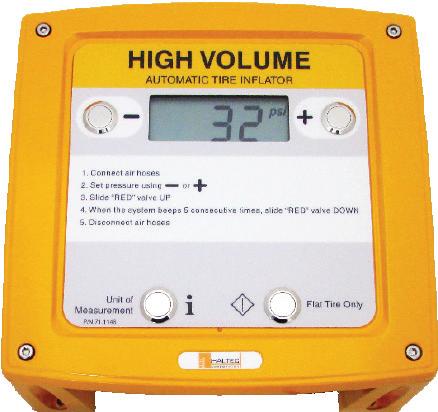

IDEAL FOR MOBILE AIRCRAFT TIRE SERVICING

∙ Two high cylinder nitrogen tanks

∙ Can be used with all Haltec inflators

IDEAL FOR SERVICE CENTERS AND MOUNTING FACILITIES

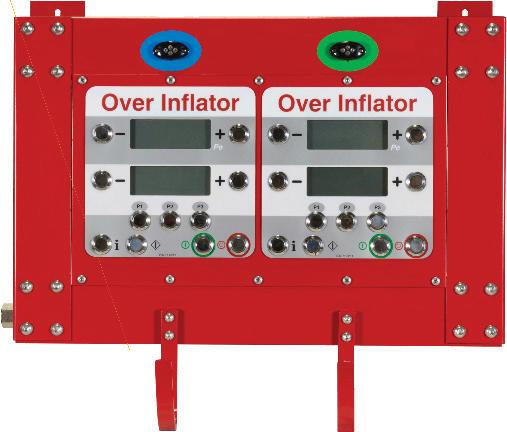

∙ 1/2” inlet/outlet

∙ Operating range: 5-145 PSI

∙ Dual LCD screens indicate gauged and target pressure

IDEAL FOR MULTIPLE TIRE SERVICING

∙ Inflates up to 5 wheels simultaneously at 5-145 psi pressure

∙ Semi pneumatic locking swivel wheel

∙ Color Coded ¼” inflation hose

∙ ½” and ¼” inlet/outlet

∙ Suitable for use with standard or large bore valves and core extraction tools

∙ Inlet pressure gauge

∙ Dual LCD screens indicate gauged & targeted pressure

IDEAL FOR FLEET OPERATIONS, TIRE SERVICE CENTERS AND TIRE MOUNTERS

∙ Designed specifically for inflating large OTR tires

∙ 1/2” inlet/outlet

∙ Operating range: 5-145 PSI

SPECIFICALLY DESIGNED FOR OTR INDUSTRIAL, MINING AND CONTINUOUS OPERATION APPLICATIONS

∙ 1/2” inlet

∙ Weather-proof hardware to withstand high impact, heavy use

∙ Wet and dry tire pressure compensation for normal and liquid filled tires

∙ Easily adjustable base/ambient temperature setting to optimize for any environment

∙ Wireless temperature transmitter

∙ Operating range: 5-145 PSI

∙ Helps prevent accidents, injury & equipment damage

∙ Best for road construction equipment, off-road equipment, warehouse equipment, emergency vehicles, school bus, street sweeper, delivery trucks & oil tankers

∙ Illuminate a safe perimeter around your machinery

∙ Danger area identified giving advance warning to users and pedestrians

∙ Covering 360° hard-wired to vehicle or building

*To select beacon color, please use the following suffixes after the part number: -G (Green), -B (Blue), -R (Red) Example: 94520-R = Red, PerimeterSAFE Short Light

∙ Widely used in numerous OEM applications around the world

∙ 12x lower profile than traditional beacon lights

∙ Solid over-mold construction

∙ No moving parts

94501

∙ IP67 rated

∙ Available in 12V or 24V and White, Amber, Blue, Red or Green colors

MicroBright Beacon. Class 1, 12Volt, Surface Mount/No Base, 8” Jumper cable

MicroBright Beacon. Class 1, 12Volt, Magnetic Base, 12’ straight cord with 12V on/off switch.

MicroBright Beacon. Class 1, 12Volt, Pole Mount, 8” Jumper Cable.

MicroBright Beacon. Class 1, 12Volt, Outer Mount/Screw ln, 8” Jumper Cable

MicroBright Beacon. Class 1, 12Volt, DIN Mount/ Agricultural Machinery Connector

*To select beacon color, please use the following suffixes after the part number: -W (White), -A (Amber), -G (Green), -B (Blue) -R (Red) Example: 94501-A = Amber, Surface Mount/No Base, 8" Jumper Cable

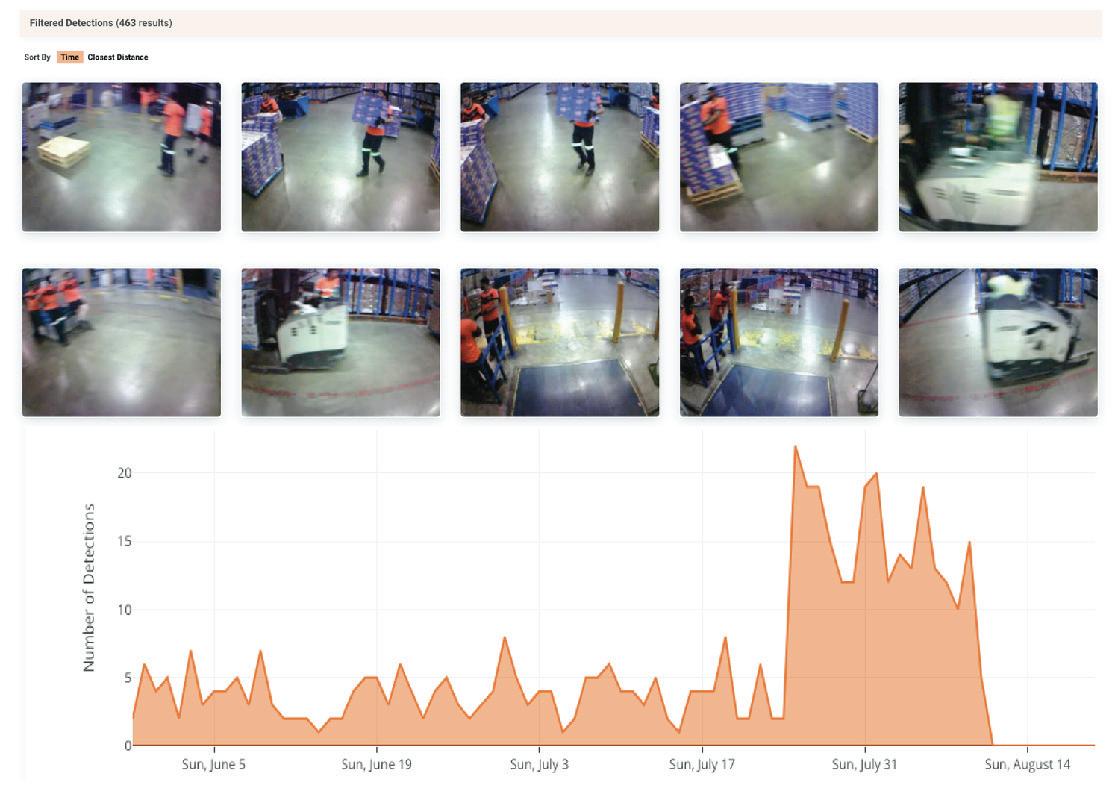

∙ Low upfront cost, quick to install, no IT integration, and no maintenance.

∙ Reliable detection in all conditions. Targeted detection zone minimizes irrelevant alerts.

∙ Works with all Class-2 ANSI Rated high-visibility clothing. Plug ‘n’ play installation. DIY settings updates using SEEN’s free app.

∙ Transforms your existing high-vis into part of an active detection system.

∙ Includes: IRIS 860 Sensor, Insight Camera, InCab Box, Cables, Mounts, & Insight Cloud Access.

Managing the safety of pedestrians working near mobile and/or heavy equipment can be challenging and stressful. IRIS-i lnsight combines active pedestrian detection and video recording to provide detection of reflective tape of high-vis safety vest and accountability for post-event analysis.

lf a pedestrian enters the critical risk zone, they and the driver receive an audible alert and a video recording of the event is available for safety training, post-accident analysis and reconstruction.

∙ Extra tough, sturdy and stable work deck with fully compliant guard and handrails

∙ Room to work and move around on this generously sized deck

∙ Working Load Limit: 551lb (250kg)

∙ Self-closing, full size front gate with keyed security lock

∙ Convenient, solid rear spring-loaded gate

∙ Fits multiple jobs with 6 evenly spaced height increments

∙ Deck Height: 29" - 98"

∙ Extra tough, sturdy and stable work deck with fully compliant guard and handrails

∙ Room to work and move around on this generously sized deck

∙ Working Load Limit: 551lb (250kg)

∙ Self-closing, full size front gate with keyed security lock

∙ Convenient, solid rear spring loaded gate

∙ Fits multiple jobs with 6 evenly spaced height increments

∙ Deck Height: 49" - 148"

Best for jobs if you need to have two workers working side by side. With a working load limit capacity of 440 lbs this deck not only gives more room, but also offers both side gates and individually removable front facing gates.

∙ Effortless climbing with constant grade stairsat any platform height

∙ Anti-sway platform physically locks at every step height

∙ Safely access an elevated work surface from three exit gates on the platform deck - at the end or on either side

∙ Safe and steady height adjustment with hydraulic safety valve + speed controlled descent

∙ Minimal floor footprint remains the same for all platform heights

∙ Easy to move long distances and transport with built-in forklift pockets

∙ Reach over obstacles with a generous 68.5” platform length

∙ Climb or descend spacious, easy gradient stairs effortlessly

∙ Prevent backward falls with a large, compliant safety bar

∙ Deck Height: 63" to 186"

Larger diameter, heavy duty, tow-able wheels along with Jack Stands at each corner allow units with this accessory added to operate off the hard stand. HAMMERHEAD DECK

The slide out deck allows you to reach out up to 114 inches over an obstacle, even with a 330 lb loading. It still features 3 exit gates as does the standard deck and rolls out effortlessly at any height.

When you are faced with tight space the G20 angled deck will save you precious room. With the ability to park your G20 parallel to your work project and “walk the plank” straight out at 90 degrees from the main deck.

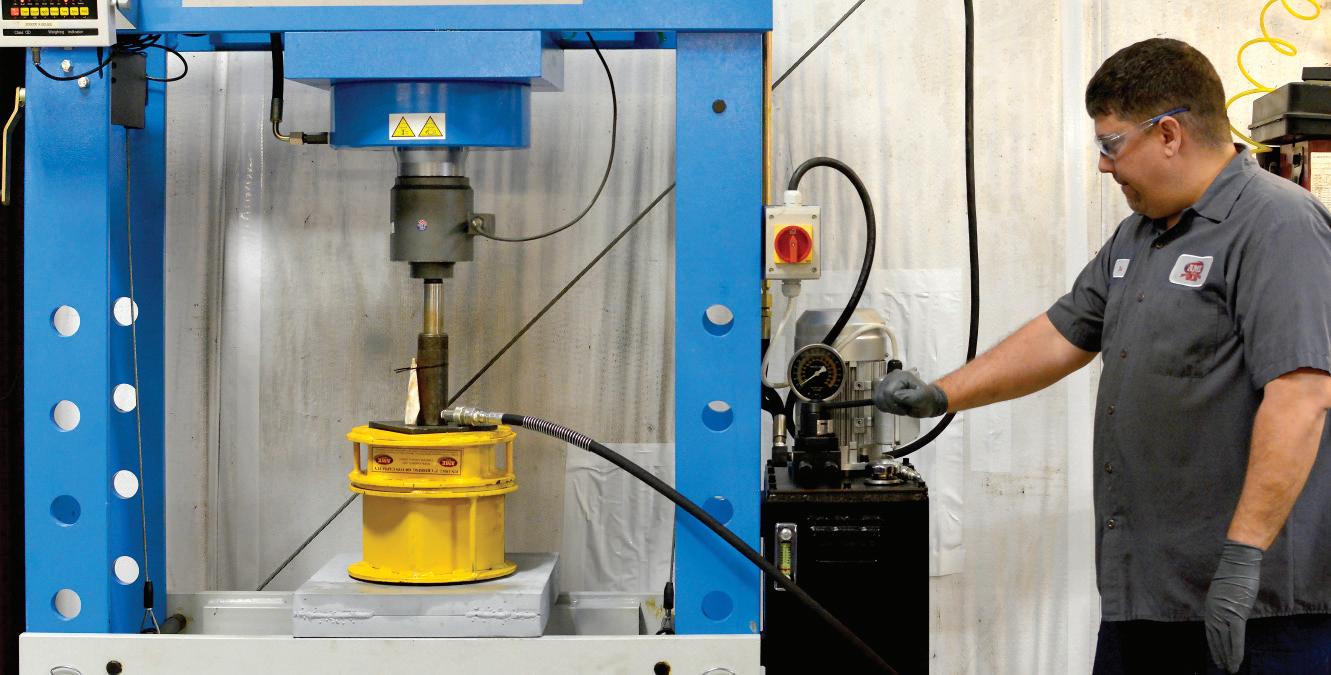

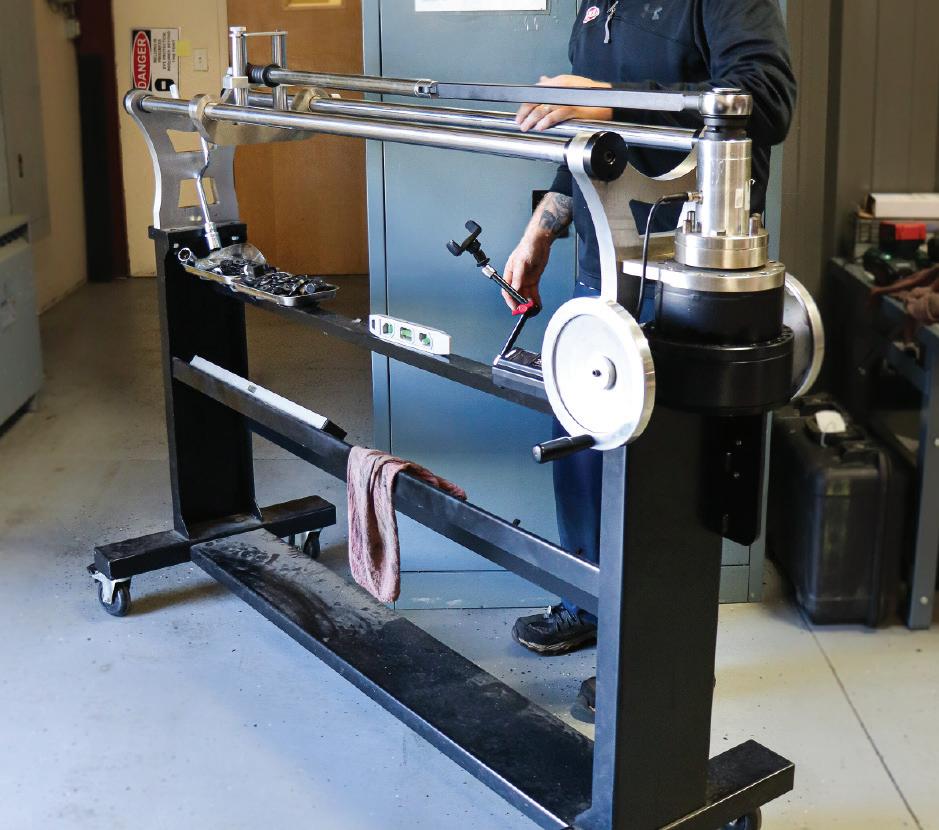

• Repairs are done by Enerpac-certified technicians

• Repairs on ALL makes and brands of tools including OTC, Hydraulic Technologies, Enerpac and more.

• Warranty Center for Enerpac, Hydraulic Technologies, Norco

• 5S certified

• Lengthen the life of your tools

• Rid shops of broken and unwanted tools

• Factory Authorized Service Program

DISCOUNTED

1. Customer will contact AME for RA and UPS prepaid call tag.

2. Once the wrench is received, the unit will be inspected, calibrated and re-certified in 24 hours or less. If the unit needs repair, lead time and cost will depend on the repair needed.

3. AME will ship calibrated unit back to exact location as received.

4. Calibrations and certifications are available for beam, click, or break-away in 1/2” - 1” drives.