SELECTED WORKS (2020-2025)

.1 UBS Place St. François

Lausanne, CHE

Professional (page 4 - 13)

.2

Casa Ameuroso

Sonora, MEX

Professional (page 14 - 23)

.3 ME Operational Offices

Tamaulipas, MEX

.4

CITY

30 Housing Units

Oulu, FIN

Academic (MCH) (page 30 - 37)

.5 Madrid Norte

Madrid, ESP

Professional (page 24 - 29) (page 38 - 43)

Academic (MCH)

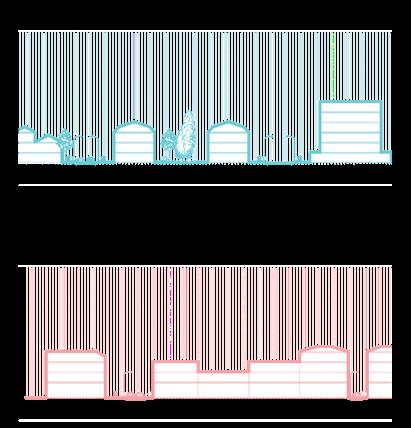

Lausanne, Switzerland

3,053 m 2 G.a.

RDR Architectes Drafting + Schemes Intern

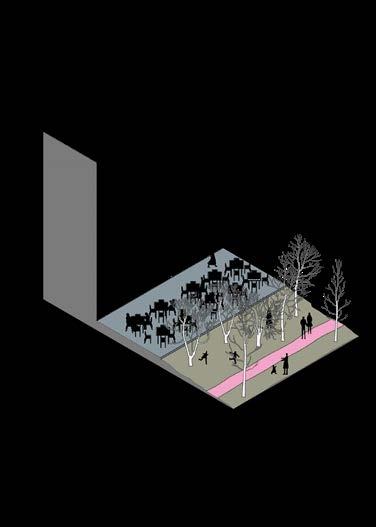

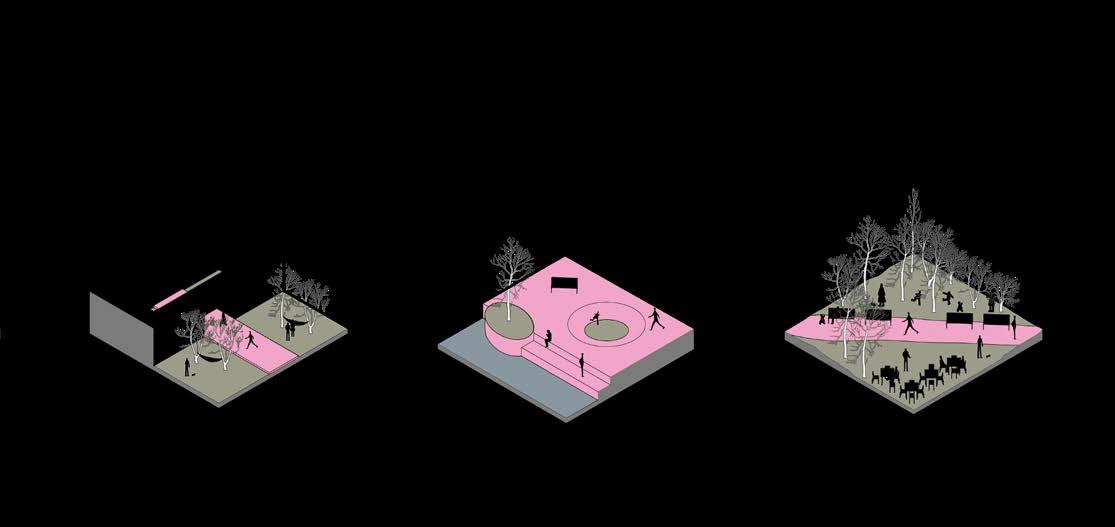

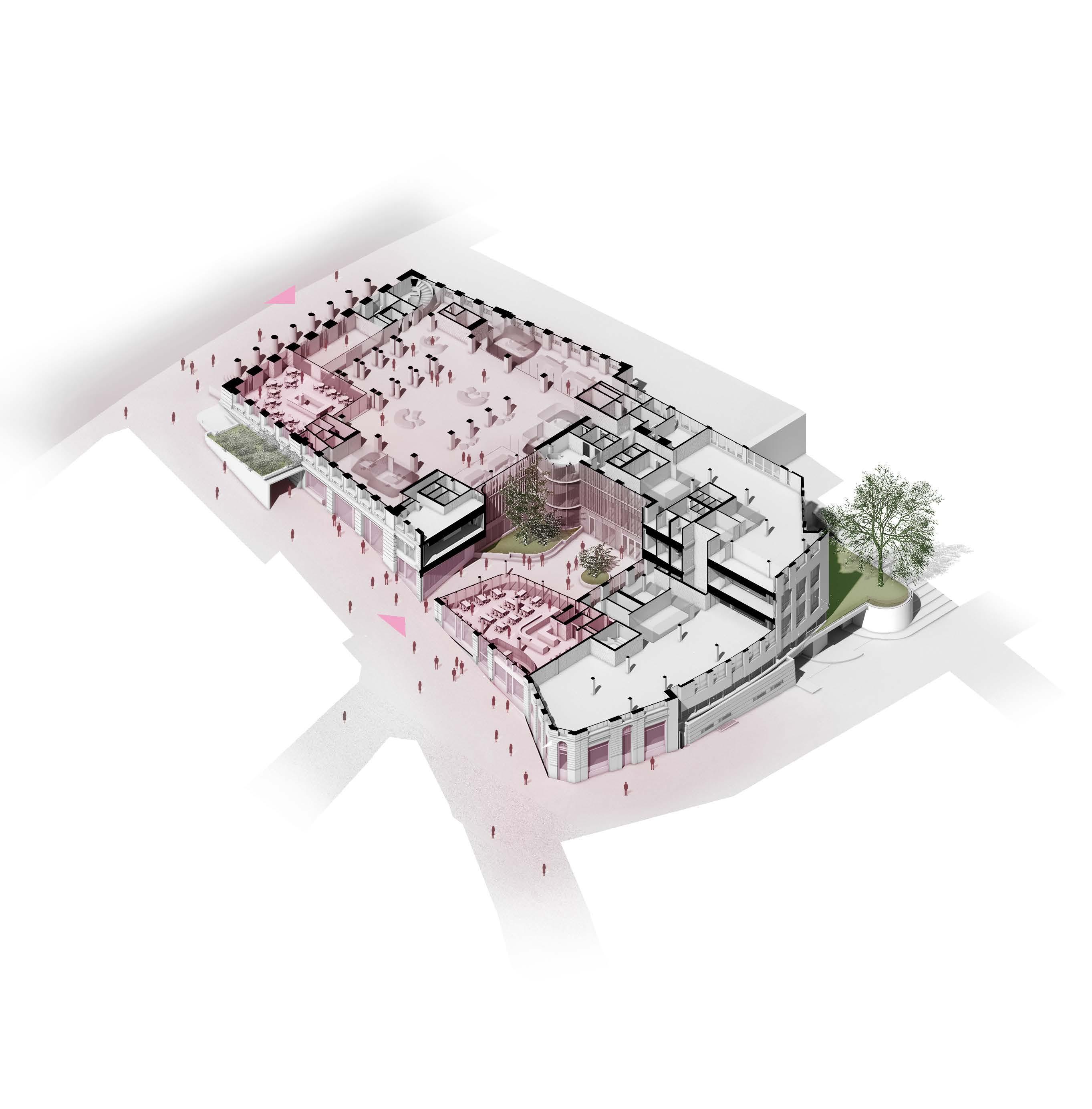

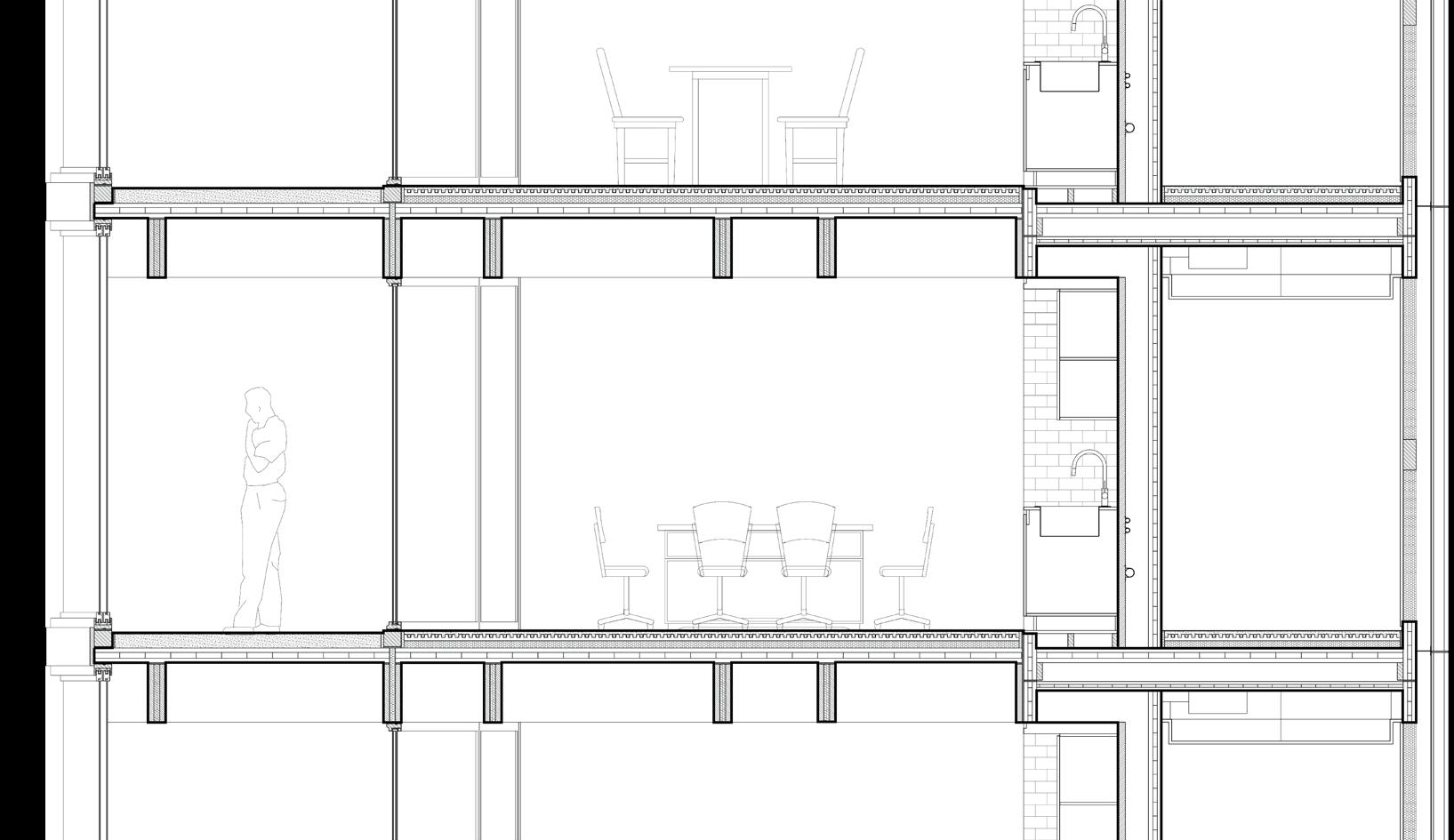

Located in the historic center of Lausanne, this building holds significant historical and contextual importance within the city. UBS launched a competition to refurbish and adapt its Paradeplatz branch in Zurich to meet the current architectural, economic, and environmental needs. Although RDR Architectes placed second behind Herzog & de Meuron’s project, UBS decided to commission RDR Architectes for the renovation of its branch in Place Saint-François.

The project aims to improve the flow from the street through the building, achieved by demolishing and reconfiguring the interior architecture to create more green spaces and enhance the circulation on the public levels. These new public spaces will be complemented by the addition of new shops and cafés.

Moreover, the renovation also includes updating the office areas to meet current architectural standards, ensuring a modern and comfortable environment for UBS employees.

Even though the project is in its final stages, UBS has decided to hold an exhibition in Lausanne to showcase the work of RDR Architectes behind the future renovation. This is the stage where I was involved.

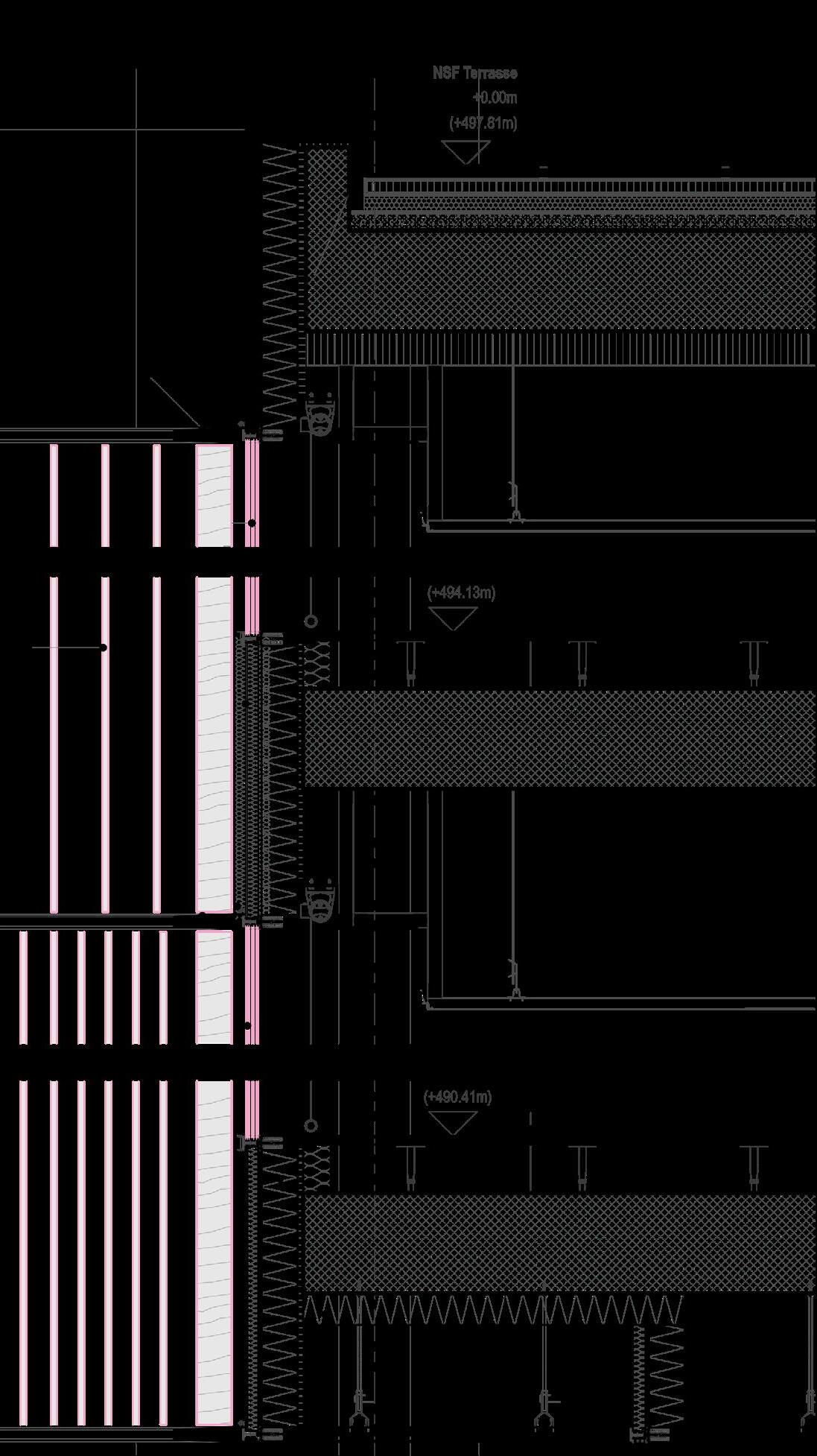

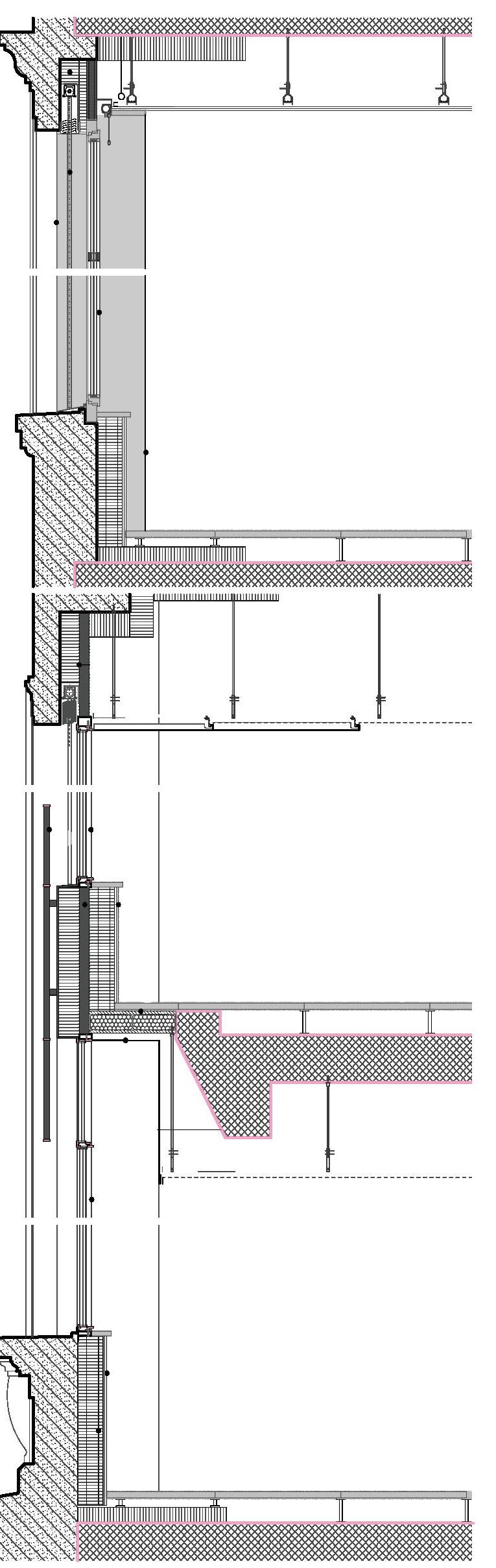

Poteau-traverse façade with a satin white RAL 9016 powder-coated finish and triple glazing. Fire resistance EI30. Load-bearing profile of 50x125mm.

Aluminum profile with a satin white RAL 9016 powder-coated finish of 50mm x 30mm.

Aluminum profile plated with oak wood of 20 x 120 x 3700mm.

Mineral wool panel with a thermal conductivity of U=0.16 W/(m²·K).

Triple-glazed panel with enamel on the inside and mineral wool insulation. White glass RAL 9016. Laminated glass guardrail.

U-profile for glass guardrail.

Brushed anodized aluminum finish RAL 9007.

Cladding of aluminum composite panels.

White satin powder-coated finish RAL 9016 with LED at 45-degree beam angle. Triple glass with an opaque interior surface.

Fachada Poteau-traverse, acabado satinado blanco RAL 9016, recubrimiento en polvo, triple acristalamiento. Resistencia al fuego EI30. Perfil portante de 50x125 mm.

Perfil de aluminio con acabado satinado blanco RAL 9016 con recubrimiento en polvo de 50mm x 30mm.

Perfil de aluminio revestido con madera de roble de 20 x 120 x 3700 mm.

Panel de lana mineral con una conductividad térmica de U=0,16 W/(m²·K).

Panel de triple acristalamiento con esmalte en el interior y aislamiento de lana mine -

ral. Vidrio blanco RAL 9016. Barandilla de vidrio laminado.

Perfil en U para barandilla de vidrio.

Acabado de aluminio anodizado cepillado RAL 9007.

Revestimiento de paneles compuestos de aluminio.

Acabado satinado blanco RAL 9016 con recubrimiento en polvo y LED con un ángu -

lo de haz de 45 grados.

Vidrio triple con superficie interior opaca.

Double glazing type ISO PYRAN G8 (8 mm PYRAN G8 / 16 mm steel spacer / 66.2 laminated) with argon and low emissivity. (Ug value: 1.1) Slab extension (new slab limit).

Support wall for the curtain wall with FW60 Schüco profile.

Horizontal support of the curtain wall with FW60 Schüco profile.

Aluminum profile with a satin white finish RAL 9016 and powder coating, 50mm x 30mm. Curtain wall retaining wall.

Vidrio doble tipo ISO PYRAN G8 (8 mm PYRAN G8 / 16 mm espaciador de acero / 66.2 laminado) con argón y baja emisividad. (valor Ug: 1.1)

Extension de losa (nuevo limite de losa).

Muro de apoyo del muro cortina con Perfil FW60 Schüco. Apoyo horizontal del muro conrtina con Perfil FW60 Schüco.

Perfil de aluminio con acabado satinado blanco RAL 9016 con recubrimiento en polvo de 50mm x 30mm.

Murete de contención de muro cortina.

Solid stained oak window with triple glazing.

Exterior frames in powder-coated aluminum IGP, color of your choice. Louvered blinds type Lamisol Griesser.

130 mm thick glass wool.

Steel frame with RAL 9007 powder-coated finish. Triple glazing, ultra-slim window from the MHB range.

Perforated metal plate. 40 x 8 mm, spaced every 30 mm / 60 mm / 120 mm.

Isolated metal frame.

Interior frames in solid stained oak. EI60 acoustic and non-combustible closure.

5 mm folded sheet metal frame with satin white RAL 9016 powder-coated finish. Plasterboard 25 mm - Glass wool 30 mm -

-

mm.

Ventana de roble macizo teñido con triple acristalamiento.

Marcos exteriores de aluminio termo-lacado IGP, color a elegir.

Persiana de lamas tipo Lamisol Griesser.

Lana de vidrio de 130 mm de espesor.

Marco de acero con acabado termolacado RAL 9007. Triple acristalamiento, ventana

ultra delgada de la gama MHB.

Placa metálica perforada. 40 x 8 mm, separada cada 30 mm / 60 mm / 120 mm.

Marco de metal aislado.

Marcos interiores de roble macizo teñido.

Cierre EI60 acústico e incombustible.

Marco de chapa plegada de 5 mm con acabado termolacado satinado blanco RAL 9016.

Cartón yeso de 25 mm - Lana de vidrio de 30 mm - Lana de vidrio de 80 mmLana de vidrio de 60 mm - Mampostería de 400 mm.

.2 (page 12 - 19)

Sonora, Mexico

1,400 m 2

Independent Work

Schematic Design + Construction

Documents

Lead Architect & Executive

Project Director

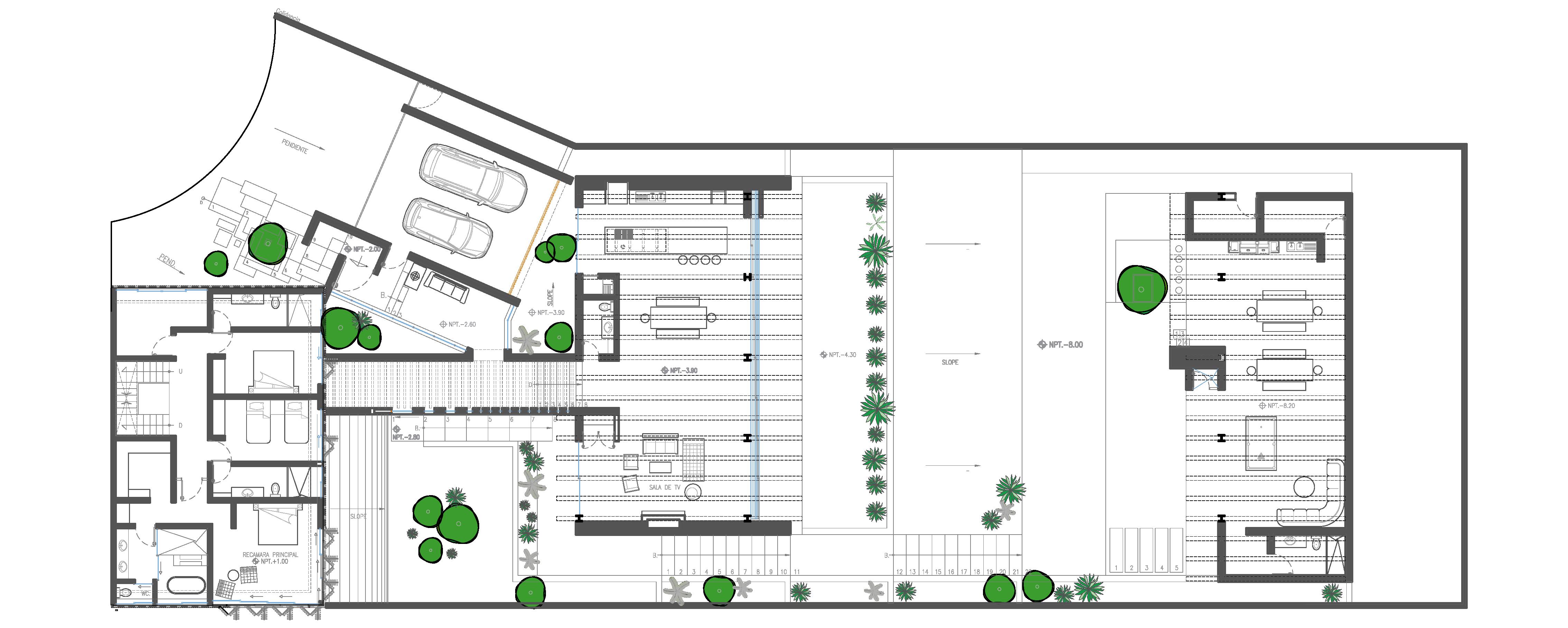

The Ameuroso House is a commission located on the Sonoran Desert, just on the peripheries of the city of Hermosillo. The commission was given by Mr. Alessio Ameuroso, an Italian businessman and investor.

The plot is found on top of a hill which results in a challenging topography with a difference of 11 meters of elevation.

The clients’ characteristics resulted in 3 main volumes, public, semi-public and private. Lastly, due to the aggressive topography of the plot, and the contrasting program of the project, it became essential to create transitional spaces that could harmonize the different personalities within the project.

It was essential to uncover and discover the house within the beautiful landscapes of the dessert while protecting it from its extreme weather conditions, giving as a result a handful of climatic strategies that would allow the possibility of being protected while being on the rawness of the outside.

The Project is developed with local materials, reinforcing the sensibility towards the land and its environment.

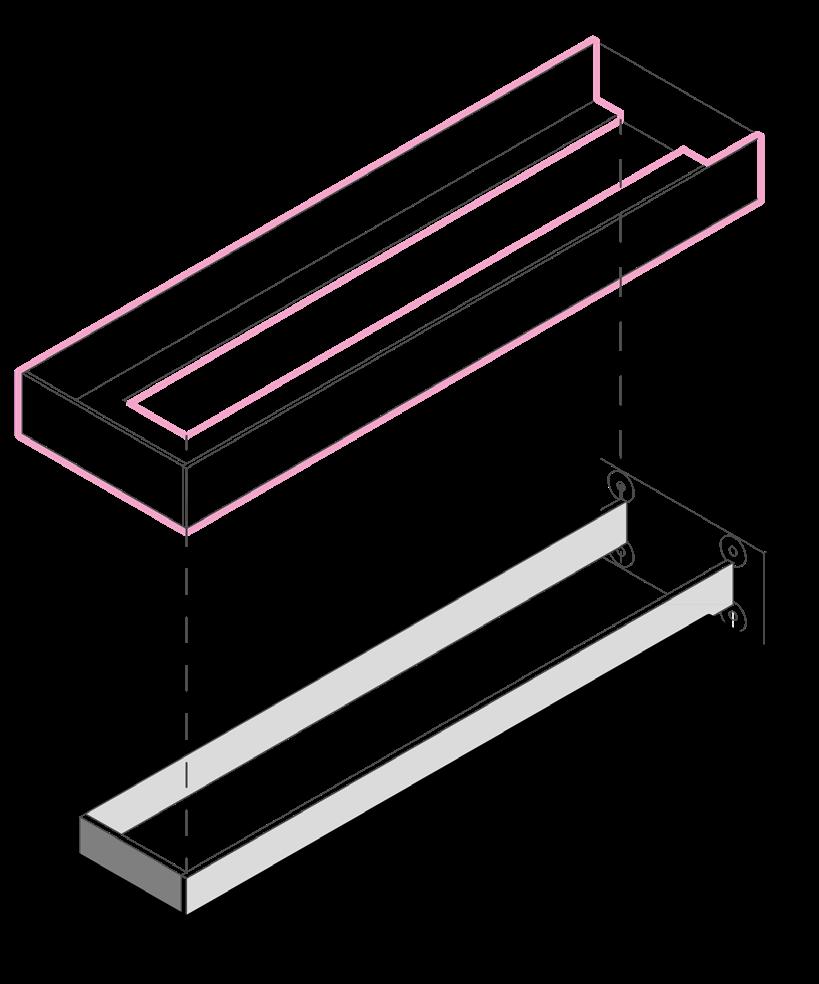

Galvanized RHS profile of 2 x 2”, matte black finish

Galvanized RHS profile of 2 x 2” placed vertically every 60 cm, matte black finish

Screen made with rectangular wooden profiles of 2”x1” @ 2” each

Steel plate of 5/16” for roof garden

Planting soil and fertilizer

Steel plate on both sides of 1/4”

UB Beam of 203 x 133 x 30 mm

Thermal Insulation of 50 mm

Steel plate on both sides of 1/4”

Steel plate join on both sides of beam of 1/4”

4 steel anchors of 5/18”

Ribbed slab, beams made with rods of 3/8” and stirrup of 2/8” @ 15cm

Finish made with laminated wood around each rib.

Triple glazed window

Ceramic tile, Rainforest Ivory 20 x 60 cm

Steel plate join on both sides of beam of 1/4”

Suspended ceiling made with plaster

Reinforced concrete column with rods of 3/8” and stirrups of 2/8” @ 15 cm

PTR de acero galvanizado de 2 x 2”, acabado mate negro

PTR de acero galvanizado de 2 x 2” en vertical @ 60 cm, acabado mate negro

Celosita con polín de madera de primera de 2” x 1” @ 2” c/u

Placa de acero de 5/16” para jardinera en techo

Tierra y fertilizante para jardinera

Placa de 1/4” ambos lados

Trabe universal tipo de 203 x 133 x 30 mm

Aislante térmico de 50 mm

Placa de acero 1/4” ambos lados

Atiesador ambos lados de placa de 6 (1/4”)

4 anclas de 5/8” Acero A36

Losa nervada con armado de 3/8”, nervaduras con var. de 3/8”,es. 2/8” @ 15 cm

Acabado con lamina de acabado de madera en cada nervadura

Ventana de triple hoja

Piso cerámico tipo Rainforest Ivory 20 x 60 cm.

Placa de 1/4” ambos lados de trabe

Plafón de Durock

Columna de concreto reforzado con var. de 3/8” y estribos de 2/8” @ 15 cm

Wood block of 100 x 300 x 1000 mm with a “U” slot to allow for placement over steel plate

Steel plate of 3/8” x 2 2/1” with full penetration weld

Steel plate of 1/2” x 150 x 300 mm to weld wall anchors and steel plates

Two steel bars “U” type with a diameter of 1/2”, bended to fit the wall rods of 3/8”

Vertical rods of 3/8” @ 15 cm and horizontal rods of 3/8” @ 20 cm

Wood type finish made with wood formwork on concrete wall

Reinforced concrete wall of 16 mm of thickness

Bloque de madera de 100 x 300 x 1000 con ranura en “U” para alojar soleras de apoyo.

Solera de 10 (3/8”) x 64 (2 2/1”) soldada con una penetracion completa.

Placa de 13 (1/2”) x 150 x 300 para soldar anclas y soleras

Dos barras tipo “U” lisa de 1/2” Diamentro, doblada a diametro de varilla de 3/8”

Varillas verticales de 3/8” @ 15 cm y varillas horizontales de 3/8” @ 20 cm

Acabado tipo madera, hecho con cimbrado en muro de concreto aparente

Muro de concreto reforzado de 16 cm de espesor

Reinforced concrete column of 16 x 16 cm with 4 rods of 3/8” and stirrups of 2/8” @ 15 cm

Column of 12 x 12 cm with 4 rods of 3/8” and stirrups of 2/8” @ 15 cm

Reinforced concrete column of 40 to 17 cm of width with 5 rods of 3/8” and stirrups of 2/8” @ 15 cm

Concrete column with 2 rods of 3/8” and stirrups of 2/8” @ 15 cm

Double glazed window of 6 mm over an aluminum frame colour matte black

Double brick wall with thermal insulation panel of 5 mm in between

Double glazed door with 6 mm of security glass with aluminum frame colour matte black

Double glazed window of 4 mm with aluminum frame colour matte black

1. 2. 3. 4. 5. 6. 7. 8.

Columna de 16 x 16 cm con 4 varillas de 3/8” y estribos de 2/8” @ 15 cm

Castillo de 12 x 12 cm con 4 varillas de 3/8 “ y estribos de 2/8” @ 15 cm

Columna de 40 a 17 cm con 5 varillas de 3/8” y estribos de 2/8” @ 15 cm

Castillo de concreto con 2 varillas de 3/8” y estrivos de 2/8” @ 15 cm

Ventana de doble acristalamiento de 6 mm de espesor sobre marco de aluminio negro mate.

Muro con doble hilada de ladrillo y panel aislante de 5 mm de espesor entre hiladas

Ventana de cristal corrediza de doble acristalamiento de 6 mm, cristal de seguridad, sobre marco de aluminio color negro mate

Ventana fija de doble acristalamiento de 4 mm de espesor sobre marco de aluminio negro mate.

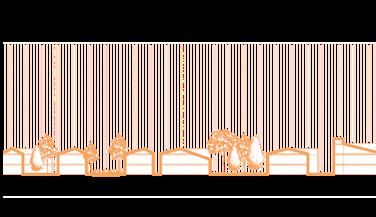

.3

Tamaulipas, Mexico

850 m 2

Independent Work

Schematic Design In progress...

Lead Architect

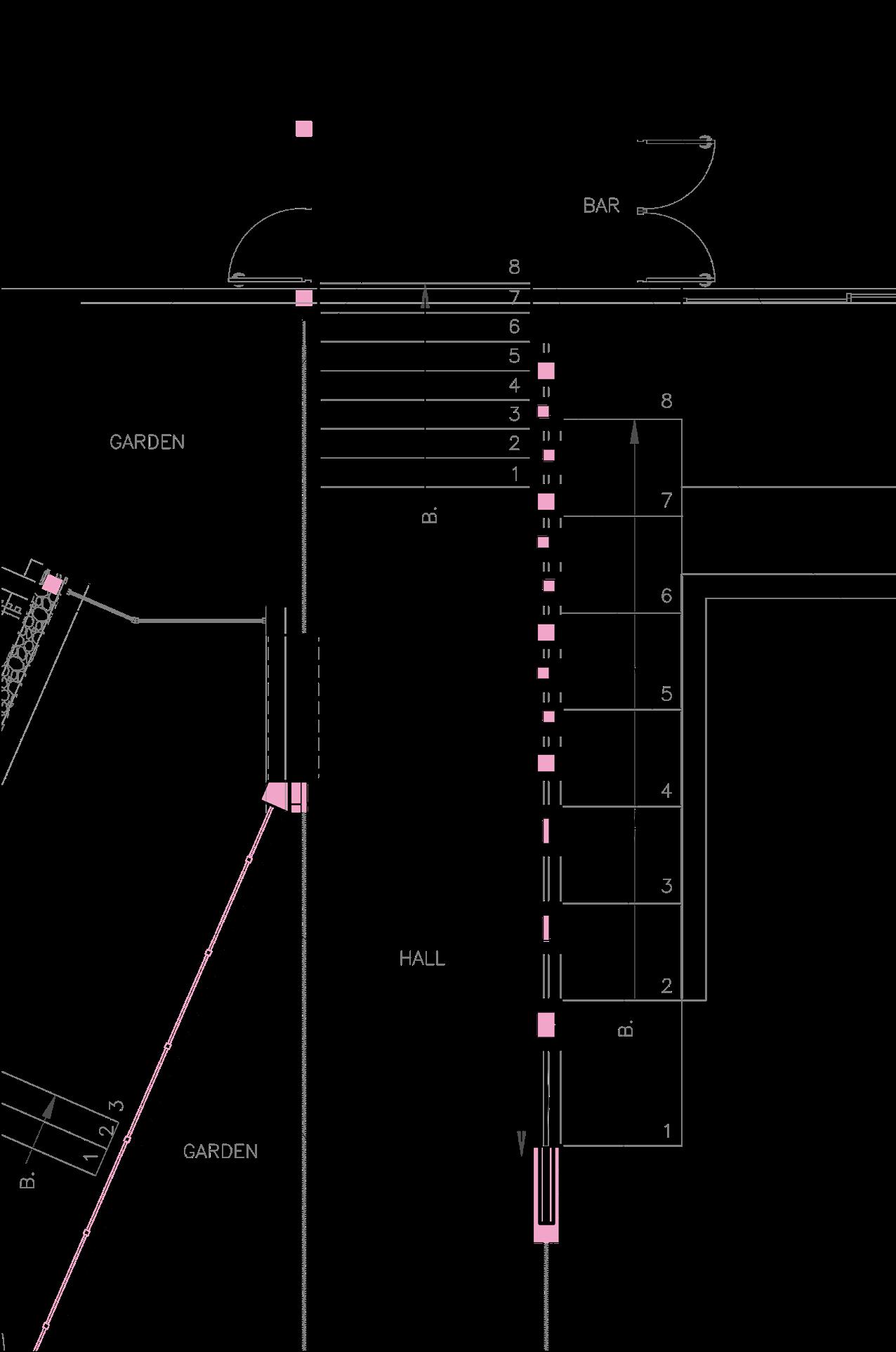

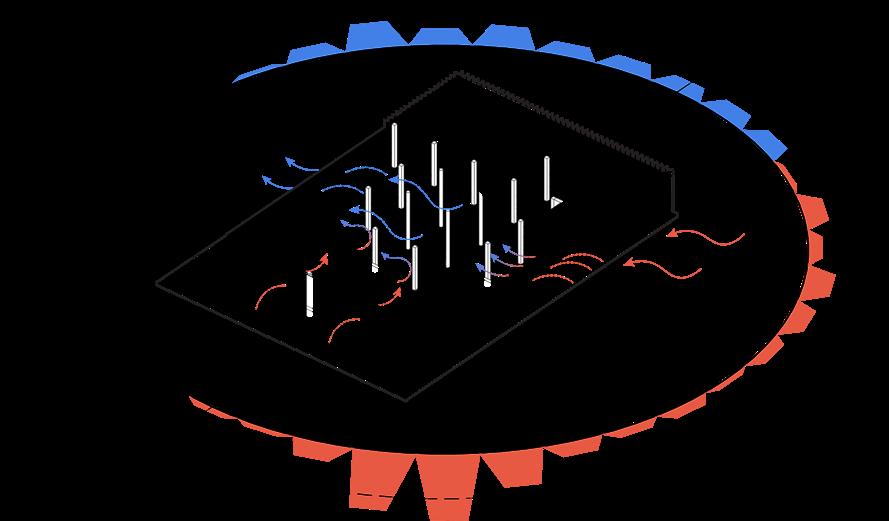

The concept of this project arises from the need to address the extreme climatic conditions of Tamaulipas and the demand for a functional building for the administrative offices of the port in operation. The design seeks to balance efficiency and comfort without sacrificing the quality of the workspace. To achieve this, the structure is conceived as simple yet well thought out, with strategically designed slabs that regulate solar incidence, allowing heat to enter in winter while reducing radiation in summer.

The columns, arranged in a four-meter modular grid, create an efficient structural order, while an aluminum solar protection system wraps the building, providing shade and enhancing natural ventilation by channeling desirable winds inside. This proposal not only responds to the site’s climatic and operational challenges but also dignifies the work environment with a sober, functional design focused on the well-being of its occupants.

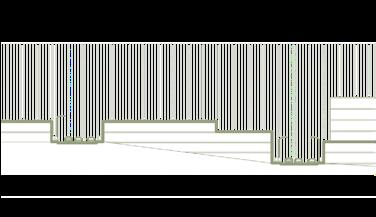

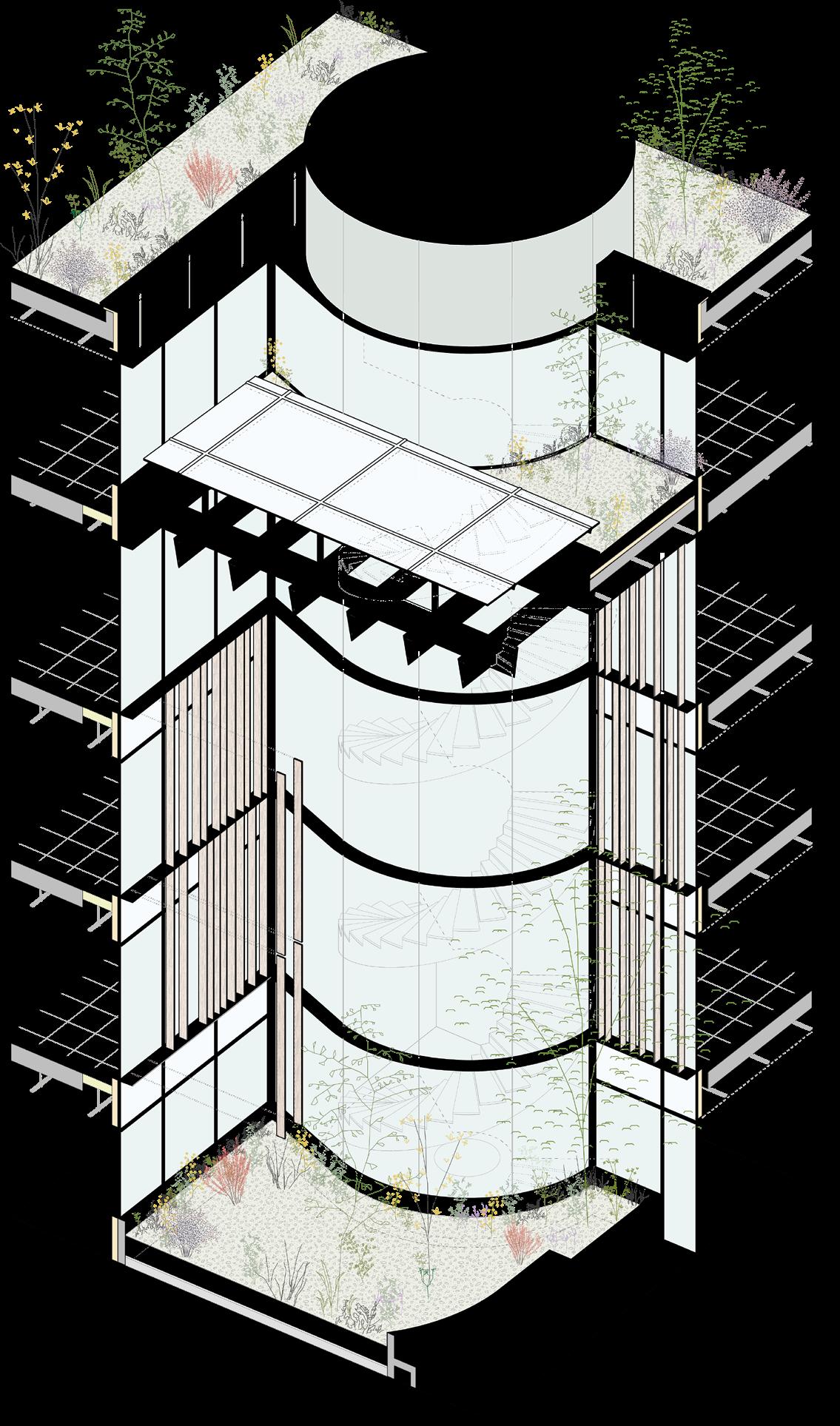

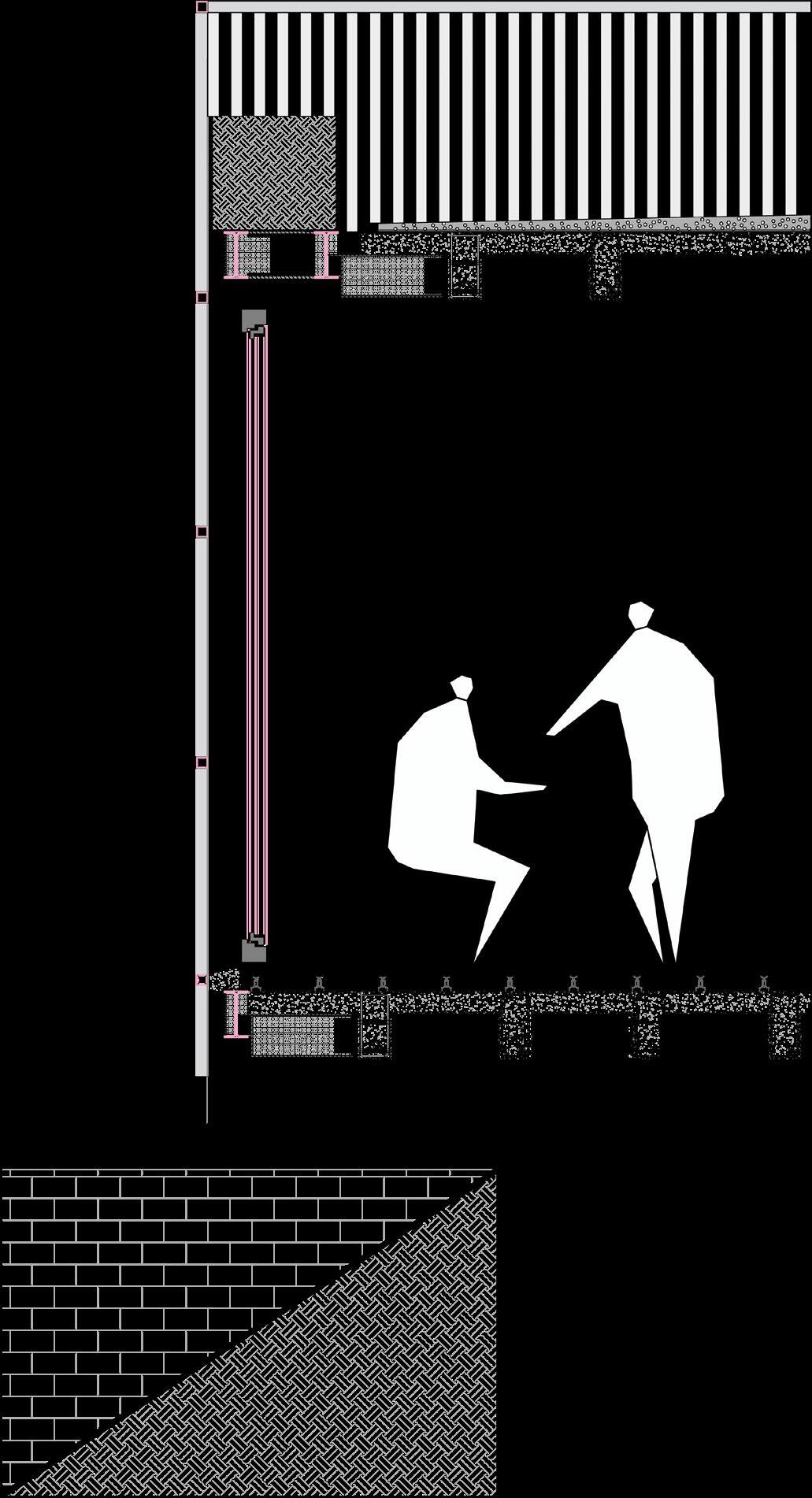

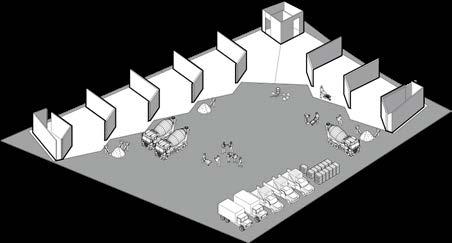

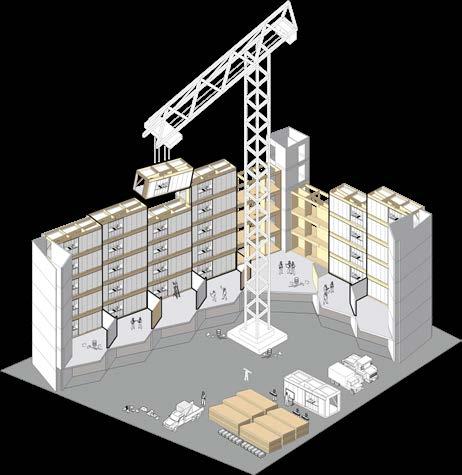

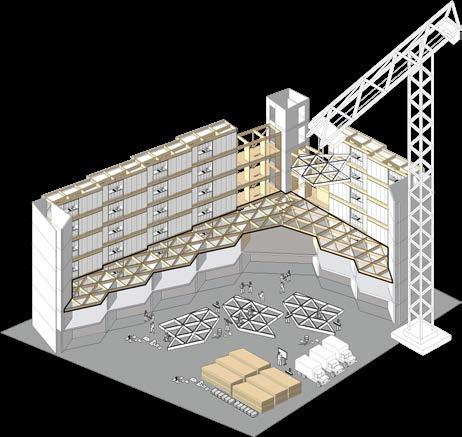

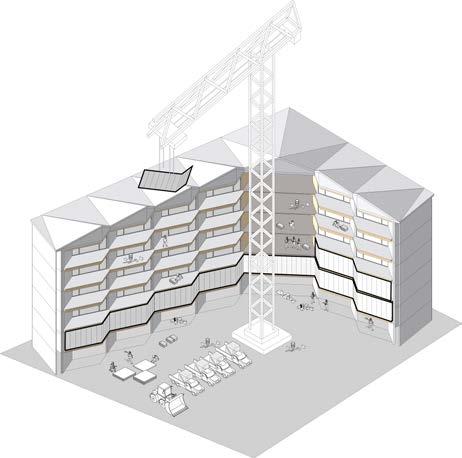

Oulu, Finland

3,750 m 2 MCH (Master Collective Housing) Teamwork

+ Installations + Details

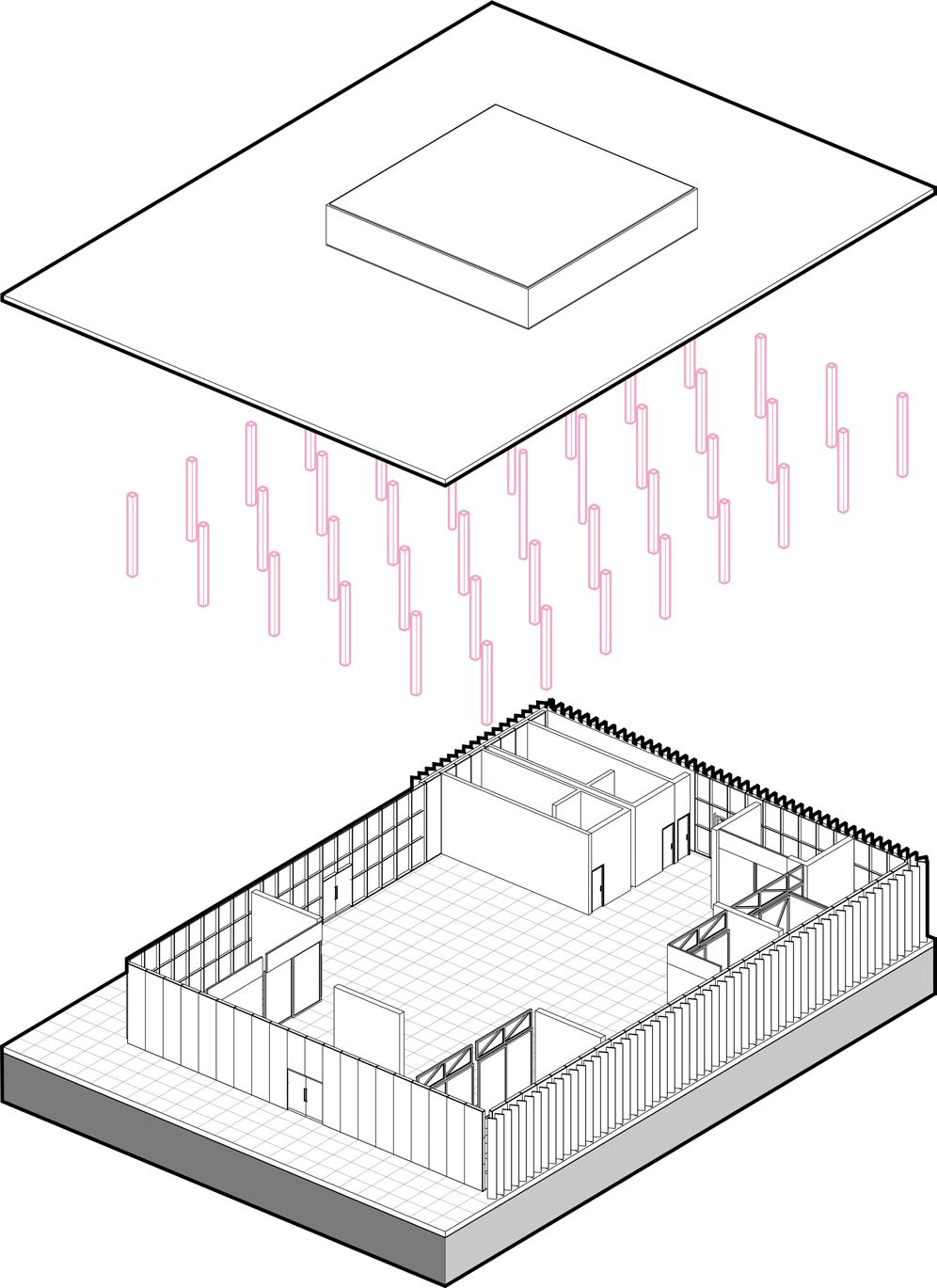

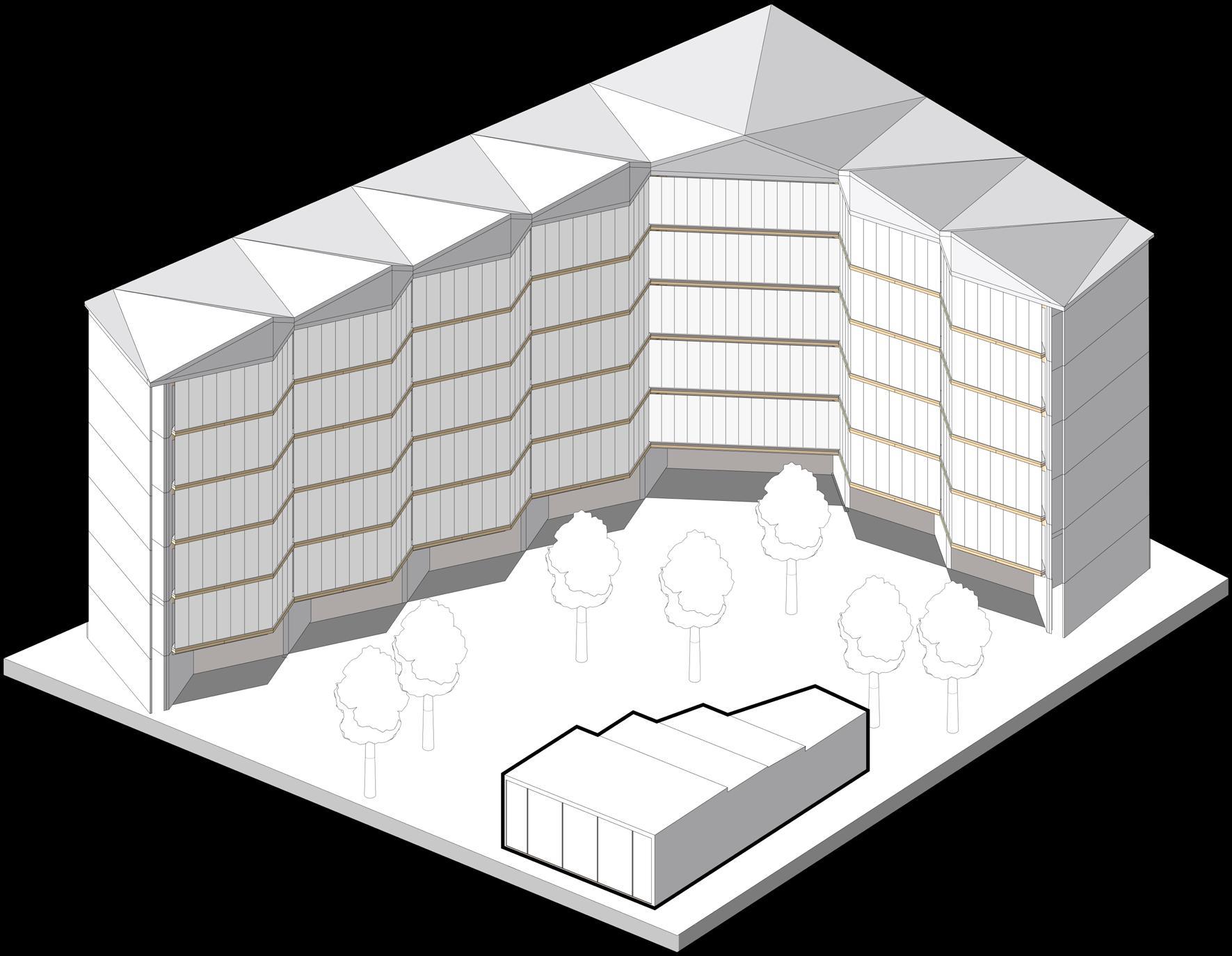

The Project is inspired from the consequences of taking a project from Paris (Rues des Orteaux) to any place with extreme weather conditions on Earth and making the needed adaptations for its success.

Given that, a collective housing project is created at the edge of the river in Oulu, Finland. Moreover, the development of the project goes according to social, cultural, economic and constructive necessities of Finland, considering the most minimal constructive detail of the project.

As an example of the constructive differences, we have from the communal sauna of the building to the apartments design for the scientific and academic community of Oulu, to the CLT-Concrete prefab construction details and the reinforcement of isolation to counteract the extreme weather conditions.

Therefore, it was decided to have a 50 m2 apartment that has the minimum comfortable living conditions, thus, focusing on the communal living of the building, focusing on creating social and interactive spaces between the habitants of the project.

Lastly, the building emphasizes the importance of generating low carbon emissions, creating strategies like, rainwater collection systems, which is used for bathrooms, to then be treated on a local water plant, and then pumped back to create a hydraulic heating system and converting heating into energy for the building.

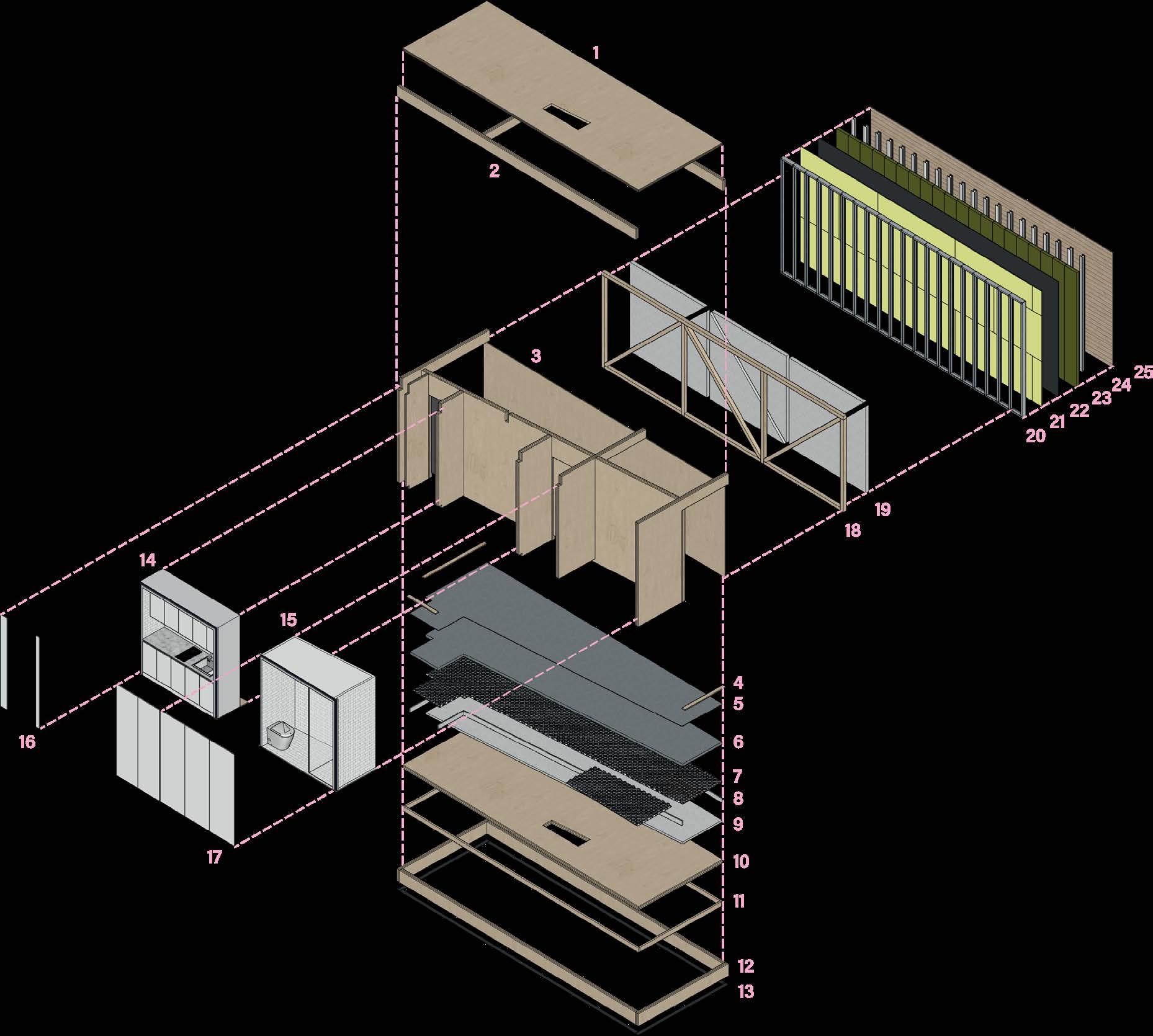

Single Glazing in Aluminum Panel of 4mm with laminated safety glass

Window base of 120 x 120 mm

Triple Glazed window made of 6 mm sheets, finished in wood frame

Cross Laminated Timber beam of 40 mm

Cross Laminated Timber slab of 100 mm

Self-Leveling mortar of 22 mm thickness

Radiant floor with a 3 mm layer of cement placed over a 50 mm insulation panel

CLT beam of 280 mm thickness with a thermal insulation in between sheets.

CLT beam of 400 mm

Expansion joint for prefabricated kitchen module

Thermal insulation of 50 mm of thickness

Radiant floor with 3 mm layer of cement

Cross Laminated Timber wall of 90 mm on prefabricated kitchen module

Kitchen module made with timber structure

Prefabricated facade with steel frame, AWV barrier, 75 mm rainscreen wool, finished with wood cladding

Ventana de acristalamiento sencillo, de cristal de seguridad en panel de aluminio de 4 mm

Base de ventana de 120 x 120 mm

Ventana de triple acristalamiento con hojas de 6 mm, terminado en panel de madera aparente

Trabe de Madera contra laminada (CLT) de 40 mm de espesor

Techo de Madera contra laminada (CLT) de 100 mm de espesor

Hormigón autonivelante de 22 mm de espesor

Calefacción por radiación de piso con 3 mm de cemento sobre un panel aislante de 50 mm

Trabe CLT esp. 280 mm de espesor con aislante térmico al centro

Trabe CLT de 400 mm de espesor

Junta de expansión para unión de modulo prefabricado de cocina

Panel aislante térmico de 500 mm de espesor

Calefacción por radiación de piso con 3 mm de cemento

Muro de madera contra laminada (CLT) de 90 mm de ancho

Cocina prefabricada con estructura de madera

Fachada prefabrica con marco de acero, barrera de aire y agua, panel de lana de 75 mm impermeable, terminado con fachaleta de madera.

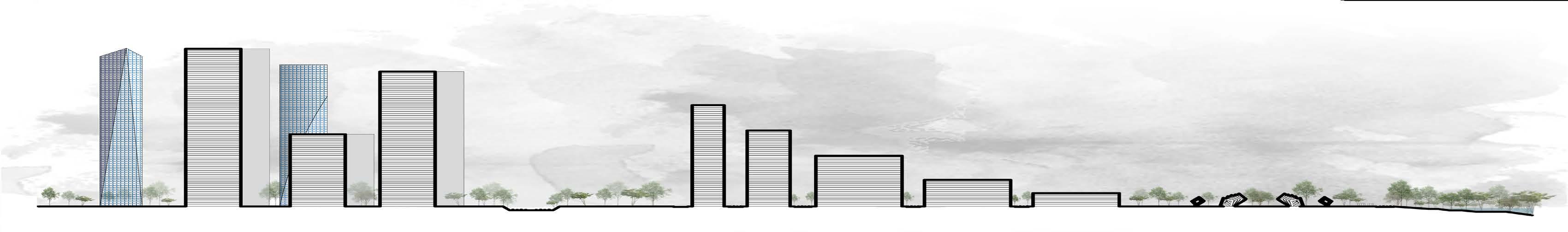

Example of one of many instalations planned for building

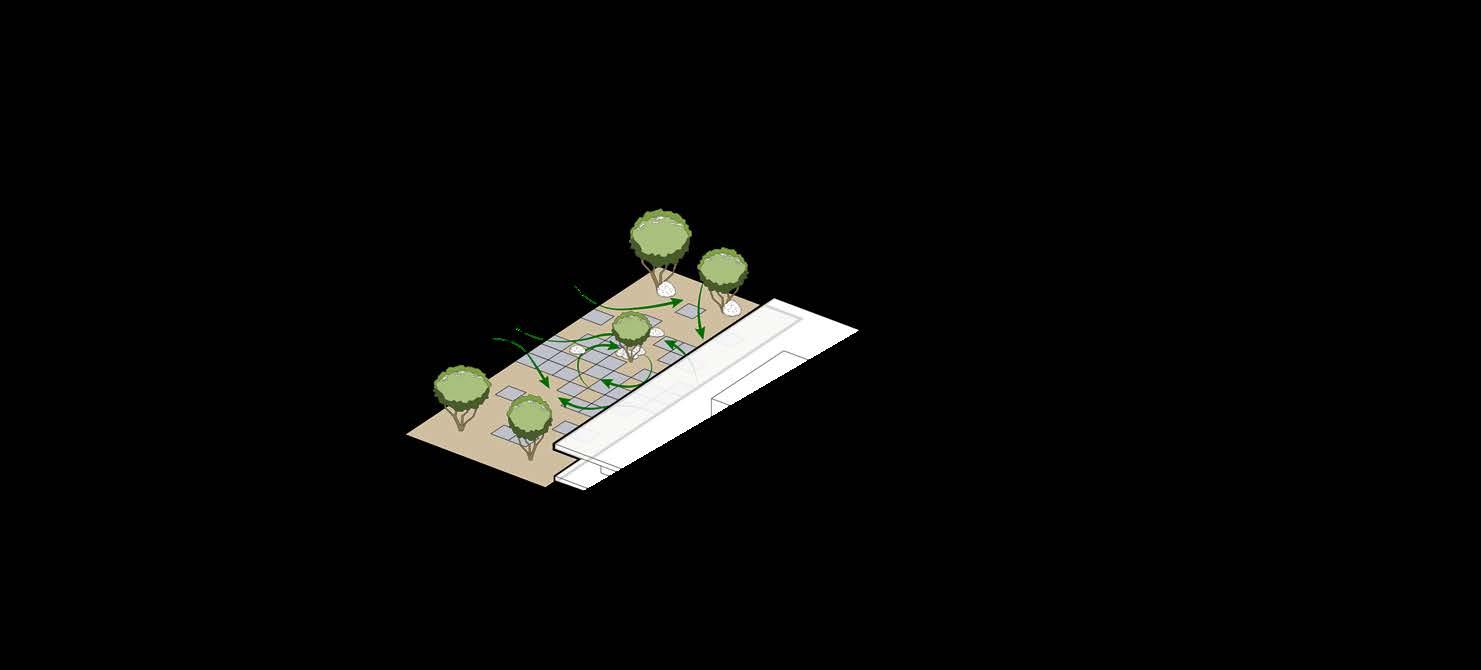

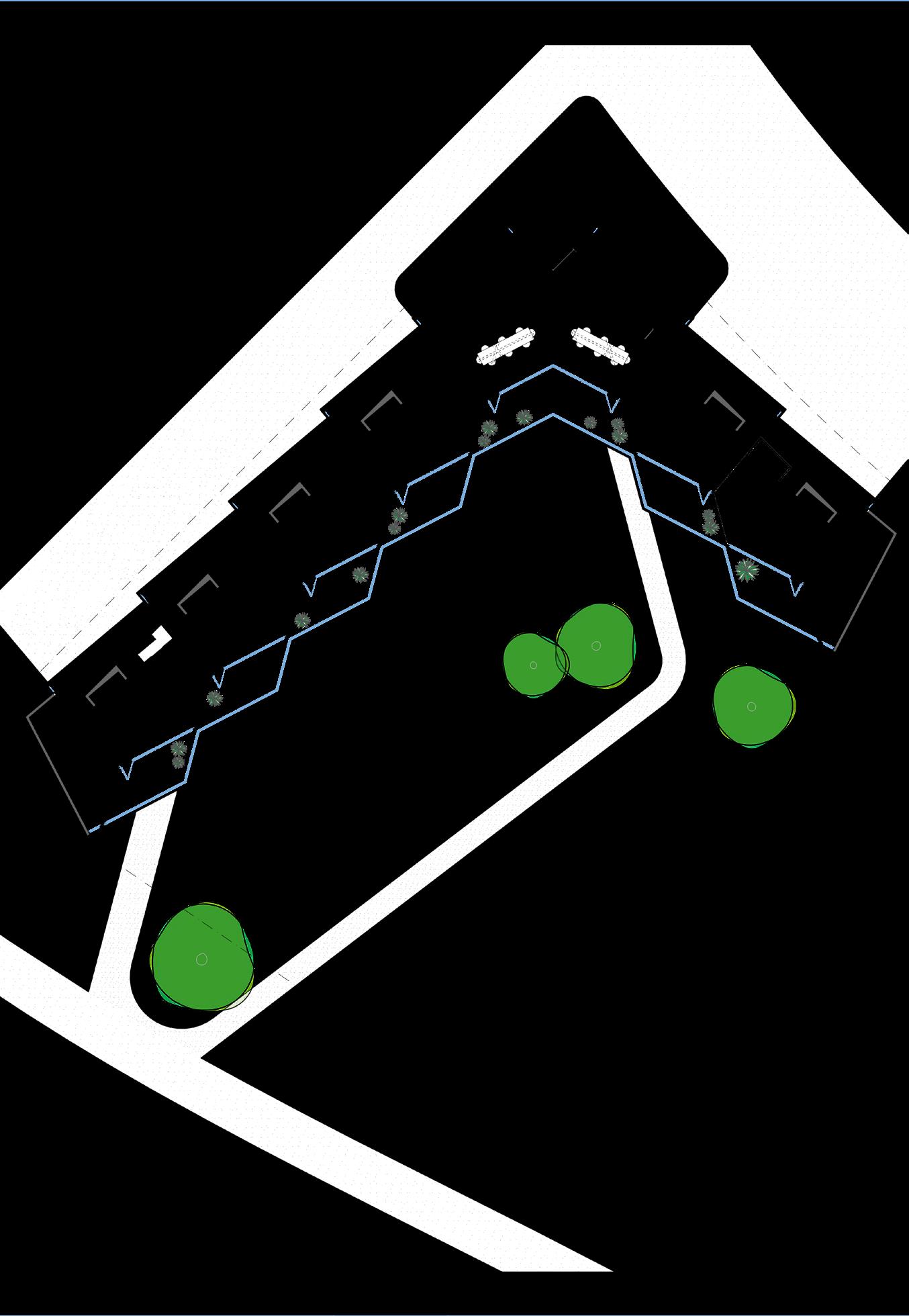

Madrid Norte is located at the north peripheries of Madrid. Its main issues were the segregation caused by the Chamartín Train station and its railways, which caused a harsh edge in between neighborhoods. Moreover, this segregation was accentuated by the historic growth of the city that created different typologies of housing blocks within the district. These variety of block was developed from the 15th Century to the 21st Century, having no relation between each other and no intention of adapting to each other.

Lastly, there is an intention of having a big financial impact in this area due to the placement of the HQ of big corporations around the area and the extension of one of Madrid biggest avenues, Paseo de la Castellana.

Therefore, having in mind that La Castellana did not have a meaningful ending to such prestigious avenue, it was then decided to create a green space, that could give it glorious happy ending to such avenue.

In the same manner, it was decided to densify the district with housing and commerce that would allow through its different heights and streets to weave the existing neighborhoods and create unity within the district, reducing the feeling of insecurity and loneliness that was present in Madrid Norte and creating more human way of living.