CALIBRATION OF BRE365 SOAKAWAY TESTING

A comprehensive discussion on safety and alternatives

TASK-SPECIFIC SITE SUPERVISION TRAINING

A look at different types of supervisionary training for ground practitioners

AGS BITESITE GUIDE: PILE DESIGN

The series continues: Pile Design Based on Calculation - Ground Model Method

SHARING GROUND MODELS USING AGSI

A history of AGSi, what it is, and how it can be utilised to share ground models

March 2024

Chair’s Foreword

Welcome to the March issue of the AGS Magazine.

I would like to start by congratulating the Early Careers team for their successful delivering the Early Careers Webinar Series – Common Risks of GI’s, Identification and Mitigation. In total, 849 people registered for the event. The event received an overall 4.4 star review and if you missed it, it is now available for replay on the AGS website.

I would also like to thank those of you that took the time to respond to the Sustainability Working Groups questionnaire which was issued with the membership renewal. A series of questions were asked including which of the UN Sustainable Development Goals should be priorities for the AGS. Look out for the results of the survey, which will be used by the AGS to prioritise areas of working.

In this edition we present our bitesize Guide – Pile Design Based on Calculation – Ground Model Method. Our previous bitesize guides were in the top three publications in the last month and I hope you also find this one useful.

Our other main topic explored in this magazine looks at BRE365 Soakaway Testing: Discussion on Safety and Alternatives. The AGS are keen

to hear examples of good practice for safely undertaking the BRE365 methodology and examples where SuDs design has been informed by alternative methods. Please contact the AGS at ags@ags. org.uk with examples or comments.

Also in this edition: Tomasz Daktera takes us on a look inside SoilCloud.

We have several events coming up, in March: BS8574 – A Guide to Data Management Plans and in April we have our Annual Conference, an inperson event which will have a sustainability theme. This year we are also trialling a drinks reception after the event. I hope you will be able to join us.

We are always on the lookout for additional, informative content for the magazine, so if you have a case study or technical article that you think the wider geotechnical and geoenvironmental public would find beneficial, please do get in touch.

We would be interested in your feedback on the magazine and our future plans. Please contact ags@ags.org.uk if you have any comments.

ABOUT THE AGS

The Association of Geotechnical and Geoenvironmental Specialists (AGS) is a not-for-profit trade association established to improve the profile and quality of geotechnical and geoenvironmental engineering. The membership comprises UK organisations and individuals having a common interest in the business of ground investigation, geotechnics, geoenvironmental engineering, engineering geology, geochemistry, hydrogeology, and other related disciplines.

EDITORIAL BOARD

Vivien Dent, AGS Chair

Sally Hudson, Coffey Geotechnics

Caroline Kratz, Forum Court Associates (FCA)

Katie Kennedy, FCA

Julian Lovell, Equipe Group

Calum Spires, Equipe Group

David Entwisle, BGS

Chris Vincett, Retired

Lauren Hunt, Arcadis

Adam Latimer, Ian Farmer Associates

Dimitris Xirouchakis, Structural Soils

Emma Anderson, HaskoningDHV UK

Daniele Fornelli, Geotechnical Observations

EDITORIAL STORY

If you have a news story or event which you’d like to tell our editorial team about, please contact the AGS on 020 8658 8212 or ags@ags.org.uk. Please note that articles should act as opinion pieces and not directly advertise a company. The AGS is under no obligation to feature articles or events received.

CONTACT US

AGS

Forum Court, Office 2FF, Saphir House, 5 Jubilee Way, Faversham, Kent, ME13 8GD

ags@ags.org.uk

020 8658 8212

Vivien Dent AGS Chair

Association of Geotechnical & Geoenvironmental Specialists

@agsgeotech

www.ags.org.uk

2 Magazine

FEATURE PAGE 32

COVER STORY

PAGE 22

Calibration of BRE365 soakaway testing; discussion on safety & alternatives with James Harrison of 4D Geo Ltd.

Site supervision: Shouldn’t we be specific?

Calum Spires and Julian Lovell of geotechnical training specialsits, Equipe Group, discuss the need for supervisionary qualifications to be specific to the task at hand.

AGS BITESITE GUIDE: PILE DESIGN BASED ON CALCULATION - GROUND MODEL METHOD

PAGE 16

The series continues with Chris Raison.

SHARING GROUND MODELS USING AGSI

PAGE 28

A history of AGSi, what it is, and how it can be utilised to share ground models.

INSIDE: SOILCLOUD

PAGE 36

The AGS Magazine conducts a Q & A with, Tomasz Daktera - President at SoilCloud SAS.

MORE INSIDE

PAGE 4

News in Short:

Incl. upcoming AGS Events

PAGE 10

AGS Annual Conference: The Final Details

PAGE 14

AGS Webinar: Early Careers Webinar

March 2024 3

Inside

month’s

this

issue

News and Events

Beale & Co – historic webinars and articles

Beale & Co, who provide the AGS Legal Helpline, are a specialist international construction and insurance law firm. They have several historic webinars, which are on their website for all to view (see here), as are their articles (which are published regularly) (see here).

Beale & Co can also offer seminars, workshops and updates to AGS members on a range of hot topics. If you would like a copy of the seminar

and workshop offering, please email ags@ags. org.uk.

As a reminder, if you’re an AGS Member and are looking for legal advice, please contact Beale & Co and ask quote ‘AGS Helpline’ where the first 15 minutes of legal advice will be free of charge.

LEGAL HELPLINE

Telephone: +44 (0) 20 7469 0400 (Please quote ‘AGS Helpline’) www.beale-law.com

Breaking Ground Podcast: New Episodes Now Live

Breaking Ground, a podcast collaboration between Ground Engineering Magazine and the Ground Forum, have released two new episodes which are available for free listening:

Î Skevi Perdikou from Geofem

Î Social Mobility

Hosted by Steve Hadley, Breaking Ground covers a wide range of ground engineering related topics. Key themes include sustainability, design, commerce, diversity, health and safety, welfare, construction techniques, education, and industry challenges. Episodes also profile industry members' careers within the context of discussing industry issues, construction techniques and case studies.

Breaking Ground is available for free download on channels including Spotify, Apple Podcasts and Google Podcasts. To listen to the podcast, click HERE.

For further information on the podcast or for podcast sponsorship opportunities please email gforum@ground-forum.org.uk.

4 Magazine

AGS Live and Virtual Events 2024

BS8574 – A Guide to Data Management Plans (webinar)

Î Date: 12th March 2024 (11am-13.15pm)

Î Fee: Free for AGS members and £30+VAT for non-members.

Î Speakers:

∙ Jackie Bland (Principal Ground Investigation Data Manager at Structural Soils and AGS Data Format Working Group Leader)

Craig Brown (Senior Data Manager –BAM Ritchies)

∙ Neil Chadwick (Director, Digital Geotechnical)

∙ Simon Miles (Chief Geotechnical Engineer, AtkinsRéalis)

∙ Tony Daly (Managing Director, Amageo Limited)

AGS Annual Conference (live event and networking drinks)

Î Date: 25th April 2024

Î Location: One Great George Street, London

Î Fee: £110 for Members and £180 for nonmembers (Ex VAT). A limited number of delegates per AGS Member company may

attend the Annual Conference free of charge, see details on the AGS website.

Î Speakers:

∙ Mark Hill (The Pension Regulator)

Roseanna Bloxham (RSK)

∙ Jim Webster (Earthworks Materials Solutions)

∙ Tim Rolfe (Yes Environmental)

∙ Alan Thomas (ERM)

∙ Ebenezer Adenmosun (on behalf of the Ground Forum Mentoring Scheme)

Marla Gillow (Ramboll)

AGS Early Careers Webinars - Drilling Techniques and In Situ Testing

Î Date: 5th June 2024

Î Fee: FOC for AGS Members and students, and £50 (plus VAT) for non-Members

Further details will be announced in due course.

CPT webinar (webinar)

Î Date: 25th September 2024

Further details will be announced in due course.

We Need to Talk About Groundwater (live event)

Î Date: 6th November 2024

Î Location: Etc. Venues Manchester

Further details will be announced in due course.

March 2024 5

News and Events

Revision of BS 10175

The Draft for Public Comment (DPC) of a revised version of BS 10175- Investigation of potentially contaminated sites – Code of practice, is scheduled for publication in May. It is not radically different from the current version, but it is a thorough revision with small technical changes throughout and some new material introduced. Amendments 1 & 2 have been consolidated into the text and essential updates to references and names of organisations etc. made.

There will be a two-month comment period on the DPC. It will be possible to comment on-line using BSI’s Standard Development System (DPS) or using a comment template. Please note

AGS Publication Updates

that those submitting comments are asked to make suggestions as to how the draft should be changed to deal with any issues they raise.

The DPS does not provide a copy of whole draft documents to download (it displays text clause by clause) but copies should be available to members via AGS and to members of other organisations represented on BS committee EH/4 Soil quality.

It is a long document, but please remember that even a single suggestion for improvement about something which particularly interests you will be of value.

Mike Smith Chair, BSI committee EH/4 Soil quality

The top three downloaded AGS publications in last month:

1. EC7 Next Gen: Bitesize Guide: Geotechnical Units, Ground Models and Geotechnical Design Models– what are these, what do they cover and who is responsible?

2. EC7 Next Gen: Bitesize Guide: EN 1997:202X – Introduction

3. Safety Guidance - Welfare

Recent AGS publications available on the AGS website:

• EC7 Next Gen: Bitesize Guide: EN 1997:202X – Introduction

• EC7 Next Gen: Bitesize Guide: Geotechnical Units, Ground Models and Geotechnical Design Models– what are these, what do they cover and who is responsible?

• EC7 Next Gen: Bitesize Guide – Pile Design Based on Calculation – Ground Model Method

• Bitesize Guide – Introduction to BRE Digest SD1

Safety Guidance – Noise

• Safety Guidance – Competence

Safety Guidance – Mental Health (Work Related Stress)

• Safety Guidance – Asbestos in Soils

To download the publications for free; click here

March 2024 7

Register for the SiLC Annual Forum 2024!

The SiLC Annual Forum 2024 takes place virtually on Wednesday 20th March (9.3013.30) and registration is now open for those wishing to attend.

Chaired by Dr. Tom Henman (Director at RSK and Chair of SiLC PTP), the event will bring together industry professionals for a stellar programme of presentations and discussions divided into two sessions; Current Developments in the Land Condition Sector and Looking into the Future.

Confirmed speakers include Emma Tattersdill (Partner (Environmental Law), Bexley Beaumont) who will present on the Levelling Up and Regeneration Act, Freddie Kennedy (Associate Director at AtkinsRéalis) presenting on The Future of Land Condition and Sustainable Development, Lucy Bethell (Senior Associate (Contaminated Land Specialist) at Mott MacDonald) presenting on Antimicrobial Resistance in the Environment: A Systems Thinking Approach, and Rae Watney (Senior Land Quality Officer at Sheffield City Council) presenting on NCLOG Guidance. There will also be presentations by Louise Beale (Technical Director SLR Consulting, Deputy Chair SiLC PTP) who will discuss Future Policy and Regulation of Excavated Soils, Paul Nathanail (Director, Land Quality Management) who will discuss Digital Data and AI, and Claire Dickinson (Director at, Geo-environmental Matters) who will explore Changing Weather and Approaches

to Land Remediation.

In addition to these presentations, there will also be an early careers segment hosted by Carrie Rose (Associated Technical Director at Atkins), as well as a video on ‘Healthy Soils as Part of a Sustainable Future’ presented by Bruce Lascelles (UK Director – Sustainable Land Management at Arcadis).

The event will feature a panel discussion on ‘What regulators expect to see on the incorporation of climate change into land condition assessments’, Chaired by Mark Hill (Climate & Sustainability – Lead at The Pensions, Regulator), with Katy Baker (Senior Technical Director, Arcadis), Robert Tyler (Senior Contaminated Land Officer, Royal Borough of Kensington and Chelsea), Mark Field (Bid Director, VertaseFLI), Heidi Bignell (Technical Advisor, Land and Contamination Management, Environment Agency) and James Bryan (Climate Change Advisor, Environment Agency) announced as panel speakers.

TICKETS

Tickets are £72 for SiLC Members, £32.40 for Retired SiLC Members, and £111.60 for Non SiLCs. For Affiliate Schemes the rate is £70 per ticket, with Local Authority & Other Public Sectors, Jobseeking/Graduates and Students welcome to register free of charge. All prices include VAT.

To register, visit: https://www.silc.org.uk/ event/silc-annual-forum-2024/

All bookings must be paid in full by Friday 15th March to be accepted.

8 Magazine

SPONSORED BY

3RD & 4TH JULY 2024

EXHIBITION REGISTRATION NOW OPEN GOLD

65% SOLD OUT! GET IN TOUCH NOW TO BOOK YOUR EXHIBITION SPACE

Places are selling out fast!

If you want to join our growing list of exhibitors and sponsors, visit our website to book your place.

www.geotechnica.co.uk

Want to see the current list of exhibitors?

Scan this

March 2024 9

SPONSORS

SPONSORS

SPONSORS

SILVER

BRONZE

News and Events

The AGS Annual Conference 2024 will be taking place on Thursday 25th April at One Great George Street in Westminster, London.

Hosted by AGS Chair, Vivien Dent, this full day, CPD event will feature a number of expert speakers from across the geotechnical and geoenvironmental sector, each presenting with

In aid of

an overarching theme of sustainability. The conference will also include reports from each of the AGS’ Working Group Leaders, providing an overview of their activities over the past 12 months. The day will conclude with a drinks reception in the Great Hall – a first for the Annual Conference.

Our speaker programme includes:

Î Sustainable Earthworks Practice on Major Civil Engineering Projects

Jim Webster, Director at Earthworks and Materials Solutions

10 Magazine

Î The Role of Quantitative Risk Assessment in Reducing Soil Disposal and Importation at Contaminated Sites

Tim Rolfe, Director at YES Environmental

Î NHBC NF93 Building Foundation Solutions: Future-proofing Against Climate Change

Roseanna Bloxham, Principal GeoEnvironmental Engineer at RSK Environment

Î Sustainable Finance, Pensions and Climate Disclosures

Mark Hill, Climate and Sustainability Lead at The Pensions Regulator

Î GFUMP – Making a big difference in the Ground Engineering Industry

Ebenezer Adenmosun, Director at Geofirma and Co-Founder of the Ground Forum Undergraduate Mentoring Scheme

Î Case Study: Measuring Carbon From Design to Construction at 2-3 Finsbury Avenue

Marla Gillow, Senior Geotechnical Engineer at Ramboll

Î Insights from the Sustainable Remediation of an Agrochemical Manufacturing Facility

Alan Thomas, Technical Partner at ERM

Full details on their presentations can be found on the AGS website.

The event will showcase all entries for the AGS Early Career Professional Poster Competition, which will show how industry professionals are applying sustainable practices in the workplace. For full details on how to enter click HERE. Entry closes on Friday 6th April.

The AGS is proud to announce that they will be donating a percentage of profits generated from the Annual Conference to Projects for Nature, an initiative which aims to restore nature recovery in the UK.

TICKETS

AGS Member companies are entitled to a limited number of complimentary tickets, for details, please visit the AGS website. Additional tickets are priced at £110 for AGS Members, and £180 for Non-Members (ex VAT). To register click HERE.

Students and retired AGS Members may attend the conference for £25 (ex VAT). To secure a ticket at this rate, please email ags@ags.org.uk.

Registration strictly closes on Monday 15th April.

SPONSORED BY

March 2024 11

EARLY CAREER PROFESSIONALS

CALL FOR POSTERS

The AGS is holding a sustainability-themed poster competition at this year’s Annual Conference, and we’d like to see how Early Career Professionals are applying sustainable practices in the workplace.

Whether it’s applying SuRF UK’s sustainable management practices, using mobile data capture, using ethically sourced PPE, we’d like to see your ideas and practices for how you’re improving sustainability.

The poster should be colourful, eye-catching and aim to inspire businesses to become more sustainable. Submissions can cover any of the 17 UN Sustainable Development Goals:

https://sdgs.un.org/goals

The winner will receive a Selfridges hamper worth £85, free entry to this year’s Annual Conference on 25th April in London, plus have their poster printed in AGS Magazine which reaches over 6,000 industry professionals 6 times a year. All posters submitted will be displayed at the Annual Conference.

To enter, email your A4 poster alongside your full name and company to ags@ags.org.uk. Entry closes on Friday 5th April at 9pm.

For full details visit www.ags.org.uk/2023/12/early-career-professionals-call-for-posters

12 Magazine

News and Events

Geoprofessionals from across North America will gather at GBA’s 2024 Annual Conference, April 18-20, 2024, at the JW Marriott, Anaheim Resort in Anaheim, California. With a theme of “Champion Excellence,” conference participants will gain the skills and knowledge to actively promote and support the pursuit of exceptional performance, quality, and success in all aspects of their firm.

Keynote speakers include New York Times best-selling author and innovation consultant Diana Kander and famed one-handed Major League Baseball pitcher Jim Abbott.

The event offers opportunities for development of highly sought-after skills such as communication, innovation, and overcoming adversity, as well as Business Round Table Sessions – the unique chance to discuss problem-solving, best practices, and strategies

with geoprofessional peers about the issues impacting the industry.

Those who are newer to the geoprofessions can engage with executive-level industry leaders, connect with new mentors, and boost their professional profiles. Mid-level geoprofessionals can unlock new leadership opportunities, exchange best practices for risk management, and network with hundreds of like-minded professionals. Seasoned geoprofessionals can share strategic insights as they address industry challenges and contribute to the elevation of the profession with their invaluable experiences.

The GBA Annual Conference offers up to 6.5 professional development hours.

Registration is open now.

Learn more and register here.

March 2024 13

NEWS, REPLAYS & UPCOMING EVENTS AGS WEBINAR

On 24th January 2024, the AGS held an Early Careers webinar entitled Common Risks of GIs, Identification and Mitigation.

The webinar was chaired by Harry McAllister (Senior Consultant, TRC Companies) and included presentations from Lauren Hunt (Geoenvironmental Consultant, Arcadis), Vicki Morten (Associate Technical Director, Arcadis), Will Capps (Technical Manager, Delta-Simons), Amy Juden (Head of Geoenvironmental at The Environmental Protection Group), Leo Phillips

(Environmental Monitoring Manager at The Environmental Protection Group) and Jon Rayner (SH&E Director, AECOM).

Lauren Hunt and Vicki Morten began the webinar with their insights on Site Supervision and Regulations, highlighting the role of the Site Supervisor and Construction Design and Management (CDM) Regulations.

This was followed by a presentation from Will Capps on Buried Utilities Do’s and Don’ts, where Will provided an overview of methods available to avoid striking underground utilities during Site Investigation. Amy Juden followed with a presentation on Asbestos in Soil: Exposure, Risk and Mitigation, focusing on exposure risk from asbestos in soil and how to effectively manage it when planning and undertaking site works.

Leo Phillips then spoke about Ground Gas Risks: Key Considerations When Completing Field Work, before Jon Rayner’s final presentation on Safety Culture, Putting Your Right Foot Forwards. The webinar ended with a group Q&A.

If you missed the webinar, the recording is now live on the AGS website and is free for AGS members and non-members.

14 Magazine

SPONSORED BY

The AGS are pleased to announce a new webinar entitled ‘BS8574 – A Guide to Data Management Plans’, taking place on Tuesday 12th March (11am-1pm).

Following on from the AGS Data Conference in 2022, it was highlighted there were many questions in relation to data management plans and BS8574.

This webinar will, therefore, aim to explain the key areas of content from BS8574 that should be included. Presentations will cover what a data management plan is, what it is used for and why, with consideration for the difference between strategy, policy, and plan.

Speakers will also discuss the pitfalls faced with not having an adequate data management plan and the benefits of a good data management plan, with practical examples of best practice throughout from varying industry viewpoints. There will also be a Q&A session at the end, where attendees will have the opportunity to ask questions.

Speakers for this event include Jackie Bland (Principal Ground Investigation Data Manager at Structural Soils and AGS Data Format Working Group Leader), Craig Brown (Senior Data Manager – BAM Ritchies), Neil Chadwick (Director, Digital Geotechnical), Simon Miles (Chief Geotechnical Engineer, AtkinsRéalis) and Tony Daly (Managing Director at Amageo Limited).

Sponsored by SoilCloud, this webinar is free to attend for Members and £36 including VAT for Non-Members. To register, please click here

15 March 2024

Image Credit: On-site data capture - Equipe Group

Pile Design Based on Calculation – Ground Model Method

Guide produced by Chris Raison, Raison Foster Associates

The guide can be downloaded from the AGS website here.

The current published version of BS EN 1997-1:2004 + A1:2013 includes pile design based on calculation using ground parameters, but refers to this as the ‘alternative procedure’ [see the note to 7.6.2.3 (8)]. This was always anomalous, as in the UK, pile design using ground parameters has for many years been the predominant method of design.

The proposed draft of prEN 1997-3:2023 Clause

6 has corrected this situation by introducing pile design for the axial resistance of a single pile by calculation as the primary method [see 6.5.3.1] with two options:

• The Ground Model Method; or

• The Model Pile Method.

The Ground Model Method is based on using ground properties determined from field and laboratory tests for a single Geotechnical Design Model [see FprEN 1997:2024 3.1.6.4, 4.2.3 and Annex B.4.2] either covering the whole extent or just a localised part of the project site area.

The Model Pile Method is based on individual pile resistance profiles determined from field test results or ground properties from field or laboratory tests [for example from a series

16 Magazine

Image Credit: Debbie Darling

of CPT or borehole profiles] which are then combined using correlation factors.

Note that the Eurocodes appear to use the terms ground property and ground parameter as interchangeable and do not clearly differentiate. However, it is perhaps more accurate to define a ground property as a fundamental attribute or quality of ground. Examples would include weight density, strength or stiffness. A parameter is a much looser term for a numerical or measurable factor that characterises behaviour and can include properties, but also other variable attributes such as water content, liquid and plastic limits, adhesion factors or bearing capacity factors.

This note provides some commentary and presents the Ground Model Method as implemented in prEN 1997-3:2023, including the recommended default values for partial load factors, resistance factors and model factors. This is essentially a factual description focussing just on the Ground Model Method of calculation particularly relevant to UK pile design.

new UK NA will be the subject of some future discussion notes.

Verification of Ultimate Limit States

BS EN 1990:2023 subclause 8.3.1 (1) requires the following inequality to be verified when checking ultimate limit states:

Ed ≤ Rd

Ed is the design value of the effect of actions and Rd is the design value of the corresponding resistance.

Actions

When applying partial factors to actions, the design value of the effect of actions E, is calculated from BS EN 1990:2023 Formula (8.4) given in 8.3.2.2 (1). This formula is reproduced as follows:

“ This note provides some commentary and presents the Ground Model Method as implemented in prEN 1997-3:2023, including the recommended default values for partial load factors, resistance factors and model factors.

Note that there is currently no UK National Annex [NA] for prEN 1997-3:2023 covering Clause 6 piled foundations. There may be changes to the requirements for pile design and the UK values for the various partial factors, model factors and resistance factors given below, which are all Nationally Determined Parameters [NDP]. Precise details and values for NDPs to be used for pile design in the UK will be given in the relevant UK NA. Specific aspects and discussion of the new proposals together with some suggestions for determining values of the NDPs in the

Ed = E { ∑ (γF.ψ.Fk ) ; ad ;XRd } Fk denotes the characteristic value of an action [such as the permanent action Gk or the variable action Qk]; ad denotes values of geometrical properties; XRd denotes the values of material properties; γF are partial factors on actions and ψ is a combination factors applied to actions.

Combination factors, ψ, are given in BS EN 1990:2023 Table A.1.7 for buildings. Other factor sets are relevant for different types of structure.

Partial factors on actions are given in BS EN 1990:2023 Table A.1.8 for verification cases VC1 to VC4 for buildings, and in Table A.2.10 for VC1 to VC4 for bridges and associated geotechnical structures. VC1 is appropriate for structural and geotechnical design where the main uncertainty relates to actions, VC2 for static equilibrium and uplift, VC3 for various

March 2024 17

geotechnical structures where the main uncertainty relates to the ground strength, and VC4 for situations where the effects of actions are to be factored.

Based on these broad definitions, it is not clear whether VC1 or VC3 would be more relevant for pile design particularly as the main uncertainty with pile resistance is the ground strength. In the event, prEN 1997-3:2023 has adopted VC1, but reasons for this choice have not been adequately presented or justified.

prEN 1997-3:2023 subclause 6.2.4.4 (2) requires that the effect of downdrag should be classified as a permanent action. 6.6.4.1 (2) requires that the drag force due to settling ground acting on a pile shaft shall be multiplied by the partial load factor for permanent actions.

Note that the partial factors on actions for verification case VC1 are similar to those for Design Approach 1 Combination 1 [DA1-C1] given in the current published version of BS EN 1997-1:2004 + A1:2013 in Table A.3 [Factor Set A1], but these now include a consequence factor kF.

These additional consequence factors kF are defined by BS EN 1990:2023 Table A.1.9 as 0.9 for a low, 1.0 for a normal and 1.1 for a high consequence respectively.

Values for the partial factors on actions for verification case VC3 are similar to those given for Design Approach 1 Combination 2 [DA1-C2] in the current published BS EN 1997-1:2004 +

A1:2013 in Table A.3 [Factor Set A2].

Axial Compressive and Tensile Resistances

prEN 1997-3:2023 subclause 6.5.3.1 (4) states that the axial compressive resistance Rc of a single pile should be determined from the following formula:

Rc= Rb+Rs

Rb is the pile base resistance and Rs is the pile shaft resistance.

Subclauses 6.5.3.1 (8) to (10) give the following formulae for the base resistance Rb and shaft compression and tensile resistances Rs and Rst respectively:

qb is the unit base resistance; Ab is the area of the pile base; qs,i and qst,i are the unit shaft resistances in compression and tension, and As,i is the area of the pile shaft in geotechnical unit i.

These formulae are recognisable from any text

18 Magazine

Type Group Symbol Effect VC1 Permanent action Gk All γG Unfavourable 1.35kF Water γGw 1.2kF All γG,fav Favourable 1.0 Variable action Qk All γQ Unfavourable 1.5kF Water γQw 1.35kF All γQ,fav Favourable 0.0 Drag force Drep γG 1.35kF

Extracts from Table A.1.8

Factors for VC1 given in Table 6.9

book dealing with pile design and are similar to those given in BS EN 1997-1:2004 + A1:2013.

Design Axial Compressive and Tensile Resistances

prEN 1997-3:2023 subclause 6.6.2.1 (2) and 6.6.2.2 (2) give the following formulae for the design axial compressive and tensile resistances Rcd and Rtd:

Rc,rep, Rb,rep, Rs,rep and Rt,rep are the representative pile resistances, γRd is a model factor and γRc, γRb, γRs and γRst are resistance factors.

For design by calculation using the Ground Model Method, subclause 6.6.2.4.1 (1) confirms that the representative value of resistance of a single pile, Rrep, is to be taken equal to the calculated pile resistance Rcalc This is a change from the current definition of the representative [characteristic] value of resistance given in the UK NA to BS EN 1997-1:2004 + A1:2013, which requires a model factor to be applied to the calculated shaft and base resistances to derive the characteristic resistance.

The effect of this does not alter the design axial

compressive and tensile resistances, but just changes how the model factor is applied within the computation.

Resistance Factors

One of the more significant differences between pile design requirements given in the current published version of BS EN 1997-1:2004 + A1:2013 and that described by prEN 19973:2023 is the proposal to adopt verification case VC1 for pile design.

prEN 1997-3:2023 Table 6.9 gives values for the resistance factors γRb, γRs, γRc and γRst for verification case VC1 for pile axial resistances determined by the Ground Model Method. As pointed out above, verification case VC1 is similar to the current DA1-C1, which uses partial resistance factor set R1. Note however that the DA1-C1 partial factors given by the UK NA to BS EN 1997-1:2004 + A1:2013 were arbitrarily reduced compared to the recommended default values.

prEN 1997-3:2023 has adopted VC1, but reasons for this choice have not been adequately presented or justified for pile design, particularly as the main design uncertainties relate to ground strength.

Model Factors

BS EN 1990:2023 subclause 8.3.5.1 and FprEN 1997-1:2024 subclause 7.2, require a model factor, γRd, to be used to adjust any significant bias and additional uncertainty in a

March 2024 19

Pile Class

Base Shaft Total Tension γRb γRs γRc γRst Full Displacement 1.2 1.05 1.1 1.2 Partial Displacement 1.3 1.1 1.2 1.25 Replacement 1.4 1.15 1.3 1.3 Unclassified 1.5 1.25 1.4 1.5

Extracts from Table 6.9

calculation model compared with a reference model. Suitable reference models can include comparable experience, a full-scale prototype, a small-scale physical model, or a theoretical model.

prEN 1997-3:2023 Table 6.4 gives values for the model factor γRd for verification of the pile axial resistance for calculation by the Ground Model Method.

Note that comparable experience is defined in Table 6.4 as follows:

Comparable experience assumes documented records (or database) of static pile load test results conducted on similar piles, in similar ground conditions, under similar loading conditions from a certain number of sites n

Extensive comparable experience assumes n ≥ 10

This requirement is quite onerous and it is difficult to see any normal situation where comparable experience could actually be used.

Conclusions

The promotion of pile design by calculation for the axial resistance of a single pile as the primary method is a positive recognition that calculation based on using ground properties determined from field and laboratory tests is widespread across Europe. Use of either the Ground Model Method or the Model Pile Method can be more easily applied particularly for projects with variable ground conditions,

pile lengths or multiple loading cases, or where downdrag needs to be considered. In these cases, verification by pile load testing can be very onerous and much more expensive. However, there are some issues and consequences of the new proposals given by prEN 1997-3:2023 that may significantly impact pile design in the UK. These points together with some suggestions for the new UK NA will be the subject of some future discussion notes.

Note that currently there is no UK NA for prEN 1997-3:2023 or Clause 6 covering piled foundations. There may be changes to the requirements for pile design and the UK values for the various partial factors, model factors and resistance factors given above, which are all NDPs. Precise details and values for the NDPs for use for pile design in the UK will be presented in the relevant UK NA.

This document is, of necessity, generic and is not intended to be a complete or comprehensive statement of the law, nor does it constitute legal or specialist advice. It is intended only to highlight issues that may be of interest to AGS members. Neither the writer, nor AGS, assumes any responsibility for any loss which may arise from accessing, or reliance on the material and all liability is disclaimed accordingly. Professional advice should be taken before applying the content of the document to particular circumstances.

20 Magazine

Verification by Model Factor γRd given in Table 6.4 Ultimate Control Tests 1.15 Extensive comparable experience without site-specific Control Tests 1.30 Serviceability Control Tests 1.35 No pile load tests and limited comparable experience 1.55

from Table 6.4

Extracts

•

March 2024 21

Intelligence Optimized Your Environmental Data Co-Pilot

Expert data at your fingertips

Free layers & Insights data reports

Account and card payment integration

Seamless experience in the

on site

www.groundsure.com/io

•

•

•

•

office or

Leading edge, intuitive & fail-safe drawing tools.

Start your journey now.

Calibration of BRE365

Soakaway Testing; Discussion on

Safety and Alternatives

Article contributed by James Harrison, 4D Geo Limited

22 Magazine

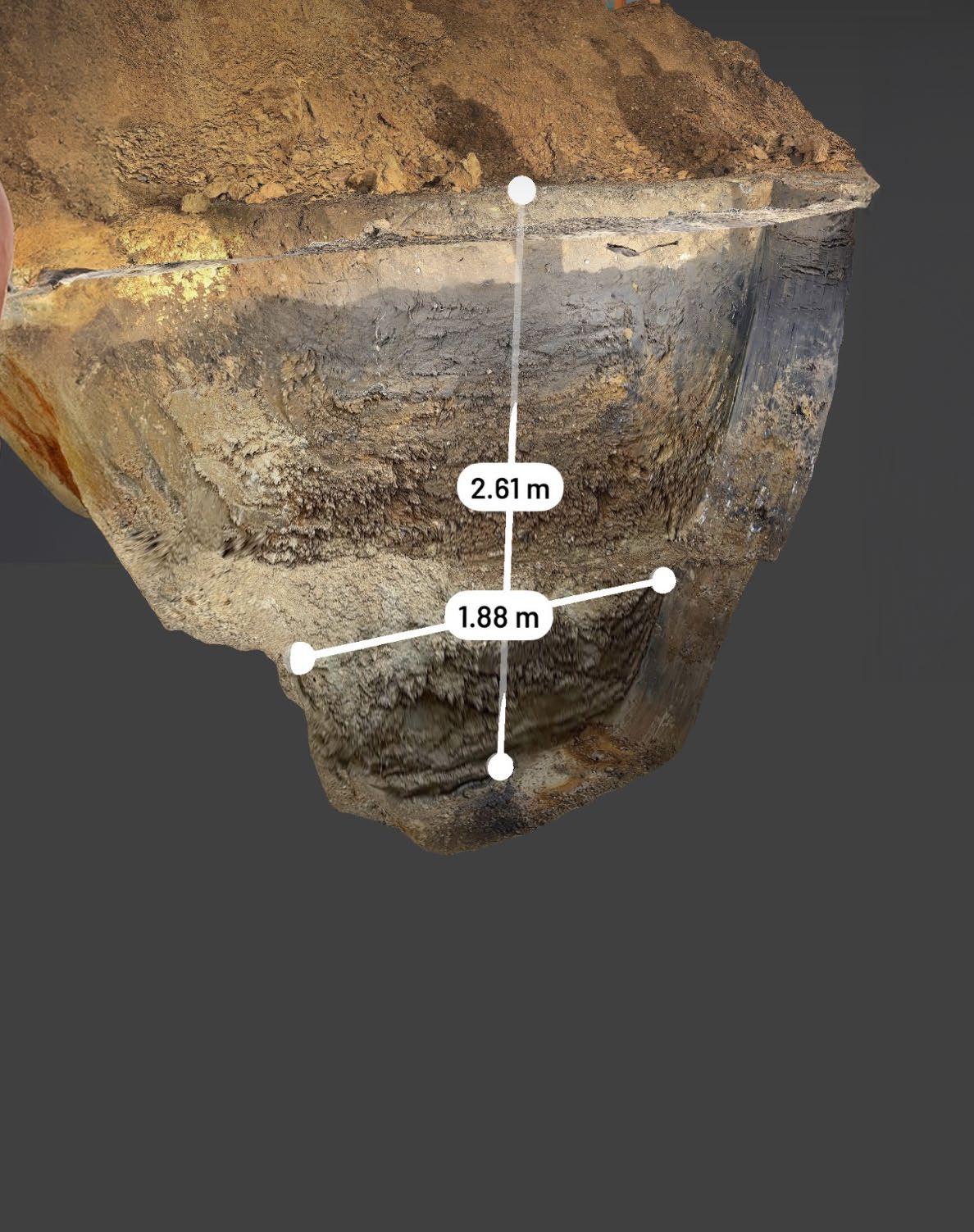

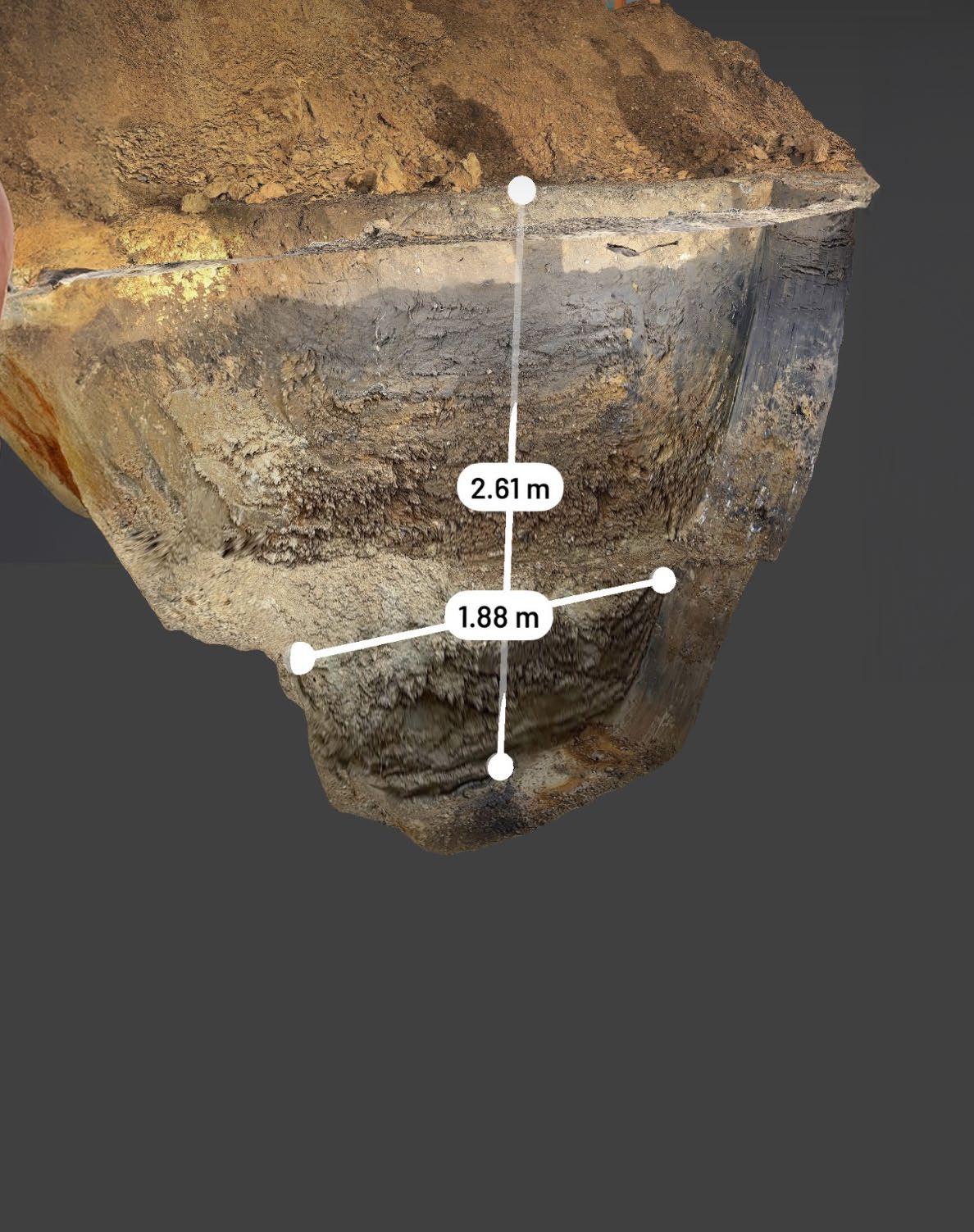

Image Credit: 4D Geo Limited

Since 2007 when the first sustainable urban drainage system (SuDS) manual was published, AGS members have increasingly been asked to provide services to support design of SuDS. The author of this article has been working with the BRE365 test since the 1990s and is still supervising, designing and reporting infiltration rate results to designers from trial pit and borehole methods.

AGS has recently been investigating how our industry manages undertaking and reporting infiltration rates for design of devices for discharge of surface water into land including; soakaways, basins, swales and permeable paving. Amongst members, the almost exclusive method requested by clients is to follow the BRE DG365 procedure as discussed in the AGS article (ref AGS magazine Oct 2021).

BRE DG365 is an empirical methodology for the design of soakaways, which includes the test procedure to provide observational data on infiltration rates. It was not intended for either basins or permeable paving. Because of the sparse nature of the test instructions, how it

1973 BRE151 Soakaways –(also NHBC 5.3.11)

1991 SR 271 The Hydraulic Design of Soakaways Report

1991 (latest revision 2016)

BRE365 Soakaway Design

1996 R156 Infiltration drainage – Manual of good practice

2007 (Version

6 including 2016, 2018, 2019)

C753 The SuDS Manual

is carried out and reported can vary between practitioners. Concerns were first raised in the AGS safety working group at the same time as general trial pitting methods came under renewed scrutiny. The geotechnical working group was also requested to look at data quality in context, which resulted in the previous article. It is recognised that AGS members’ risk assessments and method statements on trial pitting may have been extended to cover BRE365 by written procedures to keep inexperienced staff safe in conducting these in-situ tests. Innovations and modifications may also have been made to the BRE365 method, to standardise in-house practice and to avoid taking up excessive resources during what can be a logistical challenge of labour, plant and materials.

This article is intended to build on the previous article, briefly cover the test origins and discuss what alternatives might be possible.

The development of technology of infiltration testing can be traced through publications. The following list shows an incomplete chronology.

BRE 151 & NHBC 5.3.11 involves recording the

Soakaways BRE Digest 151, Watford. Building Research Establishment (Digest 151 is presented currently as a method in NHBC Standards https:// nhbc-standards.co.uk/5-substructure-ground-floors-drainage-andbasements/5-3-drainage-below-ground/5-3-11-surface-watersoakaways/ )

The Hydraulic Design of Soakaways Report SR271 1991 by DC Watkins published by HR Wallingford is available as a free resource here https:// eprints.hrwallingford.com/311/ and describes the modelled water flow processes in a soakaway.

Empirical method of soakaway design including test for infiltration rate.

CIRIA report Report 156 1996 Infiltration drainage – Manual of good practice Roger Bettess BSc PhD MCIWEM. Provides an infiltration test procedure similar to BRE365 but with some variations and extra information.

The current reference for Suds Approval Boards/Lead Local Flood Authorities (SAB/LLFA) in the UK is the The SuDS Manual (C753) https:// www.ciria.org/ItemDetail?iProductCode=C753&Category=BOOK&WebsiteK ey=3f18c87a-d62b-4eca-8ef4-9b09309c1c91.

March 2024 23

time for a fixed height of water to drain in a small trial hole. The time, t, is graphically translated to a soakaway size using correlations that have uncertain/unknown justification.

SR271 indicates that flow in unsaturated ground is different to saturated ground in four main respects (head in the fluid is due to suction, storage coefficient and conductivity are variables, and gravity induces vertical flow), and compares in-situ test results with those obtained from numerical modelling using Richards modified equation. By relying on testing at the proposed location of the device and use of bulk factors of safety the design philosophy is confirmed to be experimental. Uncertainties do not include the possibility of significant variations in ground type at the location of the test (and by implication the soakaway). This may be a point of contention with some practitioners used to UK shallow geology.

The work in R156 was carried out by HR Wallingford under contract to CIRIA between October 1991 to March 1995 inclusive. R156 cites many other sources of information (BRE were part of the steering group represented by Dr John Powell). The extra information in R156 does help to confirm the experimental nature of the test specific to the location of the proposed infiltration device and the intrinsic adoption of bulk safety factors. This requires that the location of the device (test site) must be chosen by a designer.

C753 probably deserves an AGS article on its own. In Chapter 01 - The philosophy of SuDs, the 3-D conceptual model in Figure 1.2 models the underlying geology as a grey monoblock rather than layers of strata, for example, which is a shame. In nearly 1000 pages of C753 the word geology occurs 16 times, frequently associated with land stability; ecology is listed 42 times and archaeology once. Possibly geology is not that important to the delivery of SuDs, but is regarded as a constraint. AGS

24 Magazine

Image Credit: 4D Geo Limited

members are probably most interested in SuDs Section 25 Infiltration design methods, and specifically 25.3 Infiltration Testing Methods and Appendix B.4 Infiltration Assessment. Appendix B.4 includes a checklist (Table B6) intended for use by the approving bodies (and the designers) which assumes competence in ground assessments, which may not be available in all design teams. There are plenty of apparently excellent SuDS case studies, but they don’t generally include details of the geology or infiltration tests and how infiltration challenges were overcome. Competent ground assessors, such as engineering geologists, would surely benefit designers.

Discussion

The SUDS manual is probably the most important document for members and designers to understand. Unfortunately, members may only be requested to perform the BRE365 test and nothing else.

In my experience, over-winter (worstcase) water level monitoring has been more frequently requested by designers indicating a more favourable approach to ground modelling. It seems the current SuDS manual was written with Eurocodes in mind, but apparently not integrated, possibly due to the embedded modelling from SR271 between test, device design and bulk safety factors. Mention of 14688 & 14689 in the B6 checklist are assumed to enable initial permeability assessments to be made by designers from descriptions correlated to published permeability values. In such cases, ground practitioners might note subtle fines content descriptors in coarse soils that could lead to significantly different engineering properties in tests. Designers and regulators might just see either SAND or CLAY and get a wrong outcome.

It is tempting to assume that permeability and infiltration approximate to the same value but that may not be accurate. Scale &

March 2024 25

geology variations mean that measurements of permeability in small laboratory samples cannot be representative unless part of a fully developed ground characterisation. In any event permeability cannot be used in exactly the same way as infiltration rate due to the modelling/empirical link between test and the device design. It is the device (soakaway/ basin) that has a characteristic design value of infiltration (usually the tested soil worstcase), and potentially too conservative if water will find preferential pathways and bulk safety factors are deployed. Whilst the SuDS manual includes falling head tests in ISO 22282-2:2012 as acceptable in principle, there are conditions and limitations. There may be parallels here with the recent AGS presentation on sample disturbance where taking a few high quality and well-selected data sets might be considered “better” than many more data of variable/unknown control.

We might assume that falling head test data should be presented as a part of a full Eurocode characterisation of the ground to be compliant. Simply replacing isolated infiltration data from a trial pit with more falling head tests in a borehole is likely inadequate, although potentially safer for operatives and might use less resources.

soakaways for overflow situations might be good design but is not necessarily supported by case study.

There is also Geotechnical investigation and testing - Geohydraulic testing - Part 5: Infiltrometer tests (ISO 22282-5:2012), which exclusively describes the various types of ring infiltrometer test; single or double ring, open and closed. In these tests, flow through the side is not included, therefore, not compatible with the SR271 modelling. However, the ring infiltrometer would logically be more appropriate for plane devices such as permeable pavements if the modelling is different. Again in my experience, It seems shallow depth BRE365s is preferred by designers for permeable paving.

Closing

“ Use of boreholes as a device for obtaining infiltration data is a natural ambition for AGS members seeking compliance with standards and health and safety.

Use of boreholes as a device for obtaining infiltration data is a natural ambition for AGS members seeking compliance with standards and health and safety. However, if the depth of infiltration is limited, for example, by the Environment Agency through planning to less than 2m depth (as been the experience of the author), then the preference for using trial pits is understandable. A daisy-chain or in series hierarchy approach from initial water harvesting to bulk basin attenuation with limited shallow infiltration finally to deep

From this discussion, there are no obvious “off the shelf” replacement alternatives to the BRE365 test to recommend to members. Noting the fundamental link in the digest between the design output and the in-situ test. However, practitioners might note that although BRE365 was most recently updated in 2016, Bettes 1996 (R156) is the primary reference in the SUDs manual.

The alternatives to BRE365 should be ISO 22282-2 or ISO 22282-5 neither is wholly recommendable (or likely to be accepted nationwide) as a direct replacement.

To support a sustainable agenda wider use of understanding ground models at the initial stage is recommended and not to rely on limited study & a small data set of BRE365 tests. A site where there is a 3m thick layer of clay over 10m of unsaturated permeable sands; three 2m deep tests would indicate

26 Magazine

infiltration is not possible resulting in the design of an attenuation basin occupying potentially unnecessary space and wasting other resources. A conceptual model, initial investigation and targeted deeper BRE365 tests may result in a much more sustainable scheme.

BRE365 and the SuDS manual could be updated to include the modern context such as health and safety including the gravel filling of test pits, responsible use of resources/logistics and adoption of dataloggers. Guidance could be provided on the benefits of a good geological characterisation and what benefits could be gained from having representative/ characteristic high quality data rather than the adoption of worst-case values because

“ Guidance could be provided on the benefits of a good geological characterisation and what benefits could be gained from having representative/ characteristic high quality data...

of limited data. More case studies might be expanded to include problem solving where poor draining geology has been overcome by engineering for example using linear features which can intercept preferential pathways in variable soil/rock. Or combined systems featuring infiltration devices of limited/known capacity linked to bulk attenuation and final overspill into deep borehole soakaways.

The AGS is keen to hear examples of good practice for safely undertaking the BRE365 methodology and examples where SuDs design has been informed by alternatives to the conventional BRE365 method. Please contact the AGS at ags@ags.org.uk with examples or comments.

Sharing ground models using AGSi

One of the biggest success stories for our industry over the last few decades has been our very own AGS data transfer format, which is used by geotechnical and geoenvironmental professionals to share factual data from ground investigations. It is highly regarded around the world and by other sectors of the construction industry, and is probably the world’s most successful ground data transfer format.

The idea of extending the AGS format to cover interpreted as well as factual data has been around for many years. After a few false starts, work on what is now known as AGSi – the “i” stands for interpretative or information –

began in 2018. This led to a beta publication to industry in 2020. Following consultation and feedback, the first full version, AGSi v1.0.0, was released in December 2022 at the AGS Geotechnical Data Conference.

Originally intended as an extension to the AGS format, AGSi morphed into a standalone but complementary format during development. The main drivers for this were the desire to support the transfer of digital ground models in response to emerging industry demand, and recognition that it needed to be strongly aligned with building information modelling (BIM) and geographic information system (GIS) workflows.

28 Magazine

One of the main objectives of AGSi is to facilitate and encourage the sharing of data rich ground models. However, it is hoped that AGSi will also play a key role in the development of improved automated workflows covering the full investigationinterpretation-design process.

What is AGSi?

AGSi is best described as a high level schema that seeks to bind together the geometry, data and metadata required to form a coherent ground model, bringing order to what may otherwise be chaos.

Perhaps the main thing that surprises new users about AGSi is that it does not include schema for complex geometry, for example, volumes, surfaces or lines. This was considered in the early days of development, but there seemed little sense in creating yet another file format for geometry to add to the many already in use. Instead, it was decided that users should be allowed to use existing external file/transfer formats for geometry, with AGSi simply providing a means of organising and linking to that data. The outcome is a relatively simple schema that can be used alongside existing software. One area where AGSi adds value is the ability to assign data to the geometric elements within a model. This can, typically, be used to provide parameters for geotechnical design, or perhaps summaries of measured properties. However, AGSi is not intended to carry the full data from ground investigations, for which the main AGS (factual) data format should still be used.

What is a ground model?

AGSi consider that ground models may take many different forms, and there may be many different ground models in use on a project, each with a specific role to play.

For many, the ground model will comprise surfaces or volumes representing a best interpretation at the extent of geological units based on interpolation between boreholes. The boreholes themselves may also be shown. Such a model can be described as an observational model.

“ One of the main objectives of AGSi is to facilitate and encourage the sharing of data rich ground models.

However, other types of models may exist in parallel. For example, it would be unusual to use such a model directly in analysis and design. It is more common to derive a different ground model, which is often simplified but considers uncertainty and the requirements of design codes and analysis methods. Such a model is known as an analytical or design model.

AGSi is designed to cater for any type of ground model, with users encouraged to provide information on its nature, permitted usage, limitations and uncertainty, using the specific metadata attributes provided.

Models may also take on different geometric forms. 3D models are the most obvious application, but 2D section models are still commonly used, especially for linear infrastructure projects. Simple 1D stratigraphic profiles also have their place, for example for pile design. All of these different forms can be accommodated by AGSi.

Use cases

The term ground model is routinely used by many of us, but it is often misunderstood and sometimes used carelessly. The author(s) of

The most obvious use case for AGSi is transfer of observational ground models in a software neutral form. This may not be routine at present, but there has been increasing demand for this over the last few years. By providing

March 2024 29

a common transfer format we are removing a technical barrier to sharing. The hope is that this will encourage the industry to confront the legal and contractual concerns about sharing that often arise. The rest of the construction industry is embracing BIM and digital twins, so sharing of ground data and information should become the new normal.

But this is far from the only potential use case of AGSi. Ingestion of AGSi ground models by geotechnical design and analysis software hash huge potential. There are opportunities to transform workflows for the better by streamlining the assembly of model information for use in analysis, replacing what is typically a manual process.

Getting started

AGSi is also looking to push the envelope by using a fully fledged website for its documentation. This is divided up into two

parts: the standard, which formally defines AGSi, and guidance. Both parts can be accessed by anyone, free of charge, from the main AGS website at: https://www.ags.org.uk/dataformat/.

The guidance includes an introduction to AGSi targeted at newcomers and suitable for both non-specialists and developers alike.

It is fair to say that the full potential of AGSi may only be leveraged as software implementations are developed. However, AGSi has been designed with scripting languages, such as Python or R, in mind. It uses JavaScript Object Notation (JSON) as its underlying output format, which the likes of Python can work with easily. This means that it should be relatively easy to develop scripts or tools that can create, read or manipulate AGSi, leading to workflows powered by scripting but making use of spreadsheets and existing modelling or analysis software.

30 Magazine

Below: A 3D model that contains borehole information from British Geological Survey materials and topography from composite digital terrain

On the High Speed 2 project, AGSi files based on real project data have been created and subsequently manipulated to provide input to Oasys ALP(Laterally-Loaded Piles Analysis Software) for pile lateral load design. This was based on Python with Excel used for assembly of input data.

“ Industry feedback and participation is encouraged via the AGSi Early Adopters Group...

Independently, an automated Python based workflow for pile design has been created that uses both AGSi and AGS Piling data as input (AGS Piling is a draft schema for piling data). This work is currently only a proof of concept, but it has already shown what can be achieved with relatively modest resources.

AGSi community

The development of AGSi is managed by

a specialist group within the AGS Data Management Working Group. Industry feedback and participation is encouraged via the AGSi Early Adopters Group, which is open to allcomers. Contact AGS if you wish to join this. We are also looking to develop tools that users may find helpful, with work already well progressed on an AGSi file validation tool. The current thinking is for this work to be taken forward as an open source project, similar to that for the (main) AGS format validation tool.

Publication of AGSi is just the start of the journey. With the help of the Early Adopters Group, the emphasis is now on implementation and adoption, i.e. what can we do to facilitate its use in the real world to encourage new and improved methods of working?

March 2024 31

Site supervision: Shouldn’t we be specific?

Article contributed by Calum Spires, Operations Director, Equipe Group and Julian Lovell, Managing Director, Equipe Group

Article contributed by Calum Spires, Operations Director, Equipe Group and Julian Lovell, Managing Director, Equipe Group

In the world of ground engineering (geotechnical or geoenvironmental), technical quality, safety and expertise are vital, especially when it comes to site operations involving ground related activities such as land drilling, piling and ground

32 Magazine

Image Credit: David Wing

investigation. The use of qualified and audited drill crews, machine operators and support staff should ensure the safe operation of the machines, the quality of data and project outcomes. To further support this the AGS has recently published new industry guidance on competence and training for ground

engineering staff..

In all walks of life no matter the level of competence, supervision is still seen to be essential to ensure safety, boost productivity, foster employee development, ensure quality and promote a positive work culture. On ground engineering sites, it is often the ground practitioners such as geotechnical engineers and engineering geologists who are appointed as supervisors. These practitioners are asked to not only make sure the work completed is to specification, but often it is also their responsibility to ensure health, safety and environmental standards are maintained across all of the works. As such, their dayto-day work demands are unique. Skills, knowledge, qualifications and experience (competence) unique in nature to ground engineering, and which cannot be fully met by conventional construction training and qualifications, are required.

Most ground-related degree courses often only touch on health and safety in the workplace. Generic construction supervision training may provide a good overview of construction activities and the associated health and safety risks, but often falls short in catering to the nuanced demands of ground engineering activities. Construction based training such as CITB’s Site Supervision Safety Training Scheme (SSSTS) is often specified by clients, within project specifications, but this is not going to equip a ground practitioner with the knowledge they need to have to ensure a ground related activity is being carried out safely, without impact on the health of those involved or the environment and which is also delivered to specification.

So, is generic construction supervision training pointless? Basic health, safety and environmental principles and the legislation can often be universally applied and background information on general construction accident facts, figures and

March 2024 33

on a training course to supervise an indoor swimming pool? Absolutely not. So why would you send your ground practitioner on a course to supervise a construction site and then expect them to understand the specific health, safety and environmental concerns regarding rotary water flush coring with a Comacchio 205 or the excavation of ten trial pits to 3.5m?

The ability to risk assess (both ahead of site and dynamically in the field), plus the skills to appropriately plan how tasks will be undertaken to ensure safely and quality are crucial to any site being set up and operated in a safe manner – geotechnical or otherwise.

Knowing and understanding the activity, including the machinery being used, personnel requirements, works layout area, support service requirements, welfare provisions, etc, will ensure the creation and implementation of a suitable and sufficient safety system of work, leading to the successful delivery of the scope of works, avoiding potential delays, ensuring efficiency and cost-effective operations.

The Health & Safety Executive (HSE) is clear that organisations must provide an adequate and appropriate level of supervision for their workers and provides guidance relating to the expectations of what those supervisors should know, understand and be able to do. HSE also advises that organisations must recognise that supervisors may need training in the specific hazards of their processes and how

those that could be affected by it.

It is recognised that sites involving ground penetrating activities carry specific safety hazards that demand targeted, specialist knowledge and attention. HSE would, therefore, advocate that ground engineering specific training is required to ensure the competence of those engaged in those work activities and those supervising them. Where a course such as SSSTS may focus on examples of scaffolding and working at height (neither of which are frequently encountered on geotechnical or drilling sites), a more geotechnically orientated training course will focus on ground related activities such as drilling machinery safety (guarding, LOLER, etc.), trial pits and underground and overhead utilities – content which is far more relevant.

The CITB and Build UK recognise the importance of supervisors and that they must have focussed and relevant training. The Build UK Training Standard identifies that whilst SSSTS provides a good baseline for generic construction related training, sector specific supervisor’s courses provide the relevance and focus e.g. for piling the FPS Piling Specialists Supervisor Training course and for the geotechnical sector Equipe’s Safe Supervision of Geotechnical Sites course. These industry specific courses are accredited by CITB and include all of the relevant parts of SSSTS, but apply it to sector specific requirements such

34 Magazine

as movement of drilling machines, safe site set ups and trial pit safety. These courses empower supervisors of ground engineering activities to make informed decisions, and accurately assess risks and the effectiveness of control measures for their projects.

“ These courses empower supervisors of ground engineering activities to make informed decisions, and accurately assess risks and the effectiveness of control measures for their projects.

Supplementary training, such as those following HSG47 Avoiding danger from underground services, GS6 Avoiding danger from overhead power lines, and managing asbestos in soils, will further enable supervisors to better anticipate these specific challenges and proactively address them. However, these courses must also be tailored to the individual’s work environment and activities.

It is a HSE requirement that employers provide

suitable and sufficient instruction and training for their staff. Only through providing relevant and industry specific training to all employees, including supervisors, will it ensure they have a thorough understanding of the intricate health, safety and environmental concerns specific to ground related activities. Attendance of industry specific courses will help foster a culture of safety, promoting seamless project execution, reducing delays, and ensuring workforce wellbeing.

Employers need to look beyond ticking the SSSTS box, even when specified by their clients, and base their plan to ensure competency on learning outcomes. After all, it is learning outcomes that are impactful and beneficial, not merely attendance.

P U S H F U R T H E R , B U I L D B E T T E R Cone penetration testing for onshore, coastal and nearshore projects. www lankelma com info@lankelma co uk +44 (0) 1797 280050

INSIDE SOILCLOUD

Getting to know

SoilCloud SAS with President, Tomasz Daktera.

What does the company do and what areas does it specialise in?

SoilCloud provides a Geotechnical data management web software (AGS compatible). We are leading the digital transition of geotechnical engineering in France (over 60% of all geotechnical data and tests in France are being analysed by our system). We are also present in the UK and 5 other countries around the world.

Where isSoilCloud located?

Our Headquarters are located in France, Paris.

How many people does the company employ?

We are 7 fascinated engineers at SoilCloud. How long have you worked at SoilCloud?

projects as well as product development, global strategy and international sales.

What are the company’s core values?

“ SoilCloud’s software and vision has been recognized as a global change in the whole French geotechnical industry.

Together with Lucas Janodet, we have co-founded SoilCloud in 2018.

What is your career background, and what enticed you to work for SoilCloud?

Together with Lucas Janodet, both geotechnical engineers, we have founded SoilCloud to engage the digital transition in the industry and to make more efficient.

What is your current role within Igne and what does a typical day entail?

As president, I am dealing with medium term and long

Our core values are related to the way we operate. We put our clients and their needs and feedback first. Are there any projects or achievements which Igne is particularly proud to have been a part of?

In 2023, we have won the Solscope Innovation award, which is the most prestigious prize in geotechnical engineering in France (distributed once every two years). SoilCloud’s software and vision has been recognized as a global change in the whole French geotechnical industry.

How does SoilCloud support graduates and early career professionals who are entering the industry?

In our team, one of our IT

36 Magazine

developers is an apprentice still attending school 2 days

Why do you feel the AGS is important to the industry?

As a leader in the digital transition of the geotechnical industry, SoilCloud is strongly promoting the AGS format around the world. The AGS

PRESSUREMETER TESTING

Self

format is something that was ahead of its time in the previous years and the industry is, just now, understanding the great added value of it.

37 March 2024

IN SITU TESTING SPECIALISTS info@insitusii.com +4 4 (0)845 862 0558 8 www.insitusii.com CONE PENETRATION TESTING (CPT)

Shear Vane, Video Cone, Gamma Cone, Magnetometer, MOSTAP Sampling

Seismic,

Boring Pressuremeters

High Pressure Dilatometers

Ménard Pressuremeter tests, Cone

Goodman Jack Borehole Probe

(SBPs),

(HPDs),

Pressuremeter,

Interface

Hydraulic Profiling

INE RAIL RESTRICTED ACCESS TAILINGS STORAGE FACILITIES PETROGRAPHY ANALYSIS SAMPLE AND CORE LOGGING UK & WORLDWIDE Envirolab: over 25 years of expertise Accredited to ISO17025 and MCERTS, we don’t compromise on quality. We use our industry-leading experience to ensure the highest standard is set every time. Contact us on 01613684921 or ask@envlab.co.uk ONLINE WITH LIMS *Details of accredited tests can be found at https:// www.ukas.com/wp-content/ uploads/schedule_ uploads/00002/1247TestingSingle.pdf Envirolab’s UKAS schedule of accreditation. 1247 *

ENVIRONMENTAL Membrane

Probe (MIP),

Tool (HPT), WASTAP, Optical Image Profiler (OIP) MARI

Training Courses

Training: Specialist Geotechnical Courses

Equipe Training's specialist geotechnical training courses are delivered both in person at our dedicated training facility just outside of Banbury, Oxfordshire, and also online via Zoom!

Available upcoming dates are provided below:

Î 19th - 20th March 2024 - CPT in Geotechnical Practice (Newcastle University)

Î 26th March 2024 - Understanding and Scheduling Geotechnical Laboratory Tests

Î 10th April 2024 - Slope Stability Design

Î 11th April 2024 - Basic Foundation Design

Î 12th April 2024 - Further Foundation Design

Î 1st May 2024 - Mastering the AGS Data Format

Î 15th May 2024 - Professor David Norbury’s Soil Description Workshop

Î 13th June 2024 - Professor David Norbury’s Rock Description Workshop

Î 19th June 2024 (Online) - Earthworks Design and Construction

Places on these courses can be booked online here, or via contacting Equipe on +44 (0)1295 670990 or info@equipegroup.com

Equipe Training: Specialist Geotechnical Heath and Safety Courses

Equipe Training and their health and safety training partners RPA Safety Services and EB Safety

Solutions are delighted to announce their collection of specialist health and safety courses for the geotechnical market have resumed being delivered in person, as well as being delivered online where required.

These courses are approved and certified by the Institution of Occupational Safety and Health (IOSH) and meet the requirements of UK Health and Safety regulations for working on geotechnical and land drilling sites. Upcoming courses have limited numbers of places available in order to maintain social distancing within the classroom environment. Upcoming dates include:

Î 19th – 21st March 2024 - IOSH Safe Supervision of Geotechnical Sites

Î 23rd May 2024 - IOSH Avoiding Danger from Underground Services

Î TBC - Safe Working on Geotechnical Sites

Places on these courses can be booked online here, or via contacting Equipe on +44 (0)1295 670990 or info@equipegroup.com

38 Magazine

Equipe

NEVER STOP LEARNING

Health and Safety Courses

Delivered in partnership with RPA Safety Services

IOSH Safe Supervision of Geotechnical Sites (3 Days) - £495 + VAT

Learn in detail how to keep yourself and your on-site operatives safe in the field - industry SSSTS equivalent

IOSH Avoiding Danger from Underground Services - £175 + VAT

In accordance with the requirements and guidance set out within HSG47

Other Health and Safety Courses

Delivered in partnership with EB Safety Solutions & RPA Safety Services

MARGI - Managing & working with Asbestos Risk in Ground Investigation - £225 + VAT

Comprehensive guidance to deal with asbestos in a GI environment, including CAR 2012

Geotechnical Courses

Prof. David Norbury’s Soil Description Workshop - £295 + VAT

Providing a detailed approach to soil description practices and techniques

Prof. David Norbury’s Rock Description Workshop - £295 + VAT

Providing a detailed approach to rock description practices and techniques

Understanding and Scheduling Geotechnical Laboratory Tests - £250 + VAT

Detailed overview of processes involved in efficiently scheduling Geotechnical Laboratory Testing

Online and In-Classroom Geotechnical Courses

Delivered in partnership with Plough Geotechnical

Basic Foundation Design - £250 + VAT

Shallow foundation overview for geotechnical practitioners and engineers

Further Foundation Design - £250 + VAT

Complex & deep pile foundations for geotechnical practitioners and engineers

Earthworks Design and Construction - £250 + VAT

A general overview of materials sourcing / selection for design & construction

Slope Stability Design - £250 + VAT

Comprehensive overview for geotechnical practitioners and engineers

March 2024 39

Association of Geotechnical & Geoenvironmental Specialists

WHY BECOME AN AGS MEMBER?

Enhance your status in the industry. Make a statement about quality and good practice. Participate in the AGS Working Groups and help shape the industry and set the standards.

WHAT DO WE STAND FOR?

■ Good practice in geotechnical and geoenvironmental engineering

■ Quality companies providing a quality service

■ Health and Safety

■ AGS Data Format

For

Established in 1988, the Association of Geotechnical and Geoenvironmental Specialists is a not-for-profit trade association which represents over 140 leading companies specialising in site investigation, geotechnics, geoenvironmental engineering, engineering geology, geochemistry, hydrogeology, and other related disciplines.

WHAT DO WE OFFER?

■ Guidance to good practice

■ Listing in the Directory of Members

■ AGS Magazine focused on ground engineering ‘hot topics’

■ Legal helpline

■ Chemical safety helpline

■ AGS Loss Prevention Guidance Document

■ Seminars, meetings, conferences and webinars

■ Collaboration with other bodies

■ Liaison with UKAS

■ Lobbying on matters important to the sector

■ Developing and maintaining the AGS Data Format

MEMBERS CAN CONTRIBUTE BY PRODUCING SUCH DOCUMENTS AS:

■ AGS good practice guidance

■ AGS publications

■ AGS safety guidance

■ AGS client guides

MEMBERS CAN PARTICIPATE IN AGS WORKING GROUPS:

■ Laboratories

■ Contaminated Land

■ Safety

■ Business Practice

■ Loss Prevention

■ Data Management

■ Executive Committee

■ Geotechnical

■ Instrumentation and Monitoring

40 Magazine

on

to become

further information on the AGS and details

how

a member visit www.ags.org.uk

How to become a Member of the AGS

AGS Members all share a commitment to quality in the geotechnical and geoenvironmental industry. This has become widely recognised by clients, governmental bodies and other associations that touch issues to do with the ground.

We welcome both companies and individuals who want to be recognised for their quality of practice to join our growing membership of over 130 Members. We shape our industry, continually improve practice and collaborate on issues that affect us all; from clients, all the way through to the people who use the land and the buildings we help develop.

To become a Member of the AGS, please visit http://www.ags.org.uk/about/become-a-member and submit your application online. Please note that all membership applications are reviewed by the Membership Committee 6 weeks in advance of each quarterly Executive meeting. The deadline for the next round of completed applications is 2nd May 2024.

AGS Chemical and Legal Helplines

All Members of the AGS are entitled to free introductory advice on chemical and legal/contractual matters from AGS Loss Prevention Group members, Marquis & Lord and Beale & Co.

For advice on chemical safety and best practice, Marquis & Lord will provide up to 30 minutes of free advice, for one issue, to any AGS Members.

Additionally, if you’re an AGS Member and are looking for legal advice, please contact Beale & Co and quote ‘AGS Helpline’ where the first 15 minutes of legal advice will be free of charge.

CHEMICAL SAFETY HELPLINE

Marquis & Lord

Tel: +44 (0) 121 288 2386

www.marquisandlord.com

(Please quote ‘AGS Helpline’)

LEGAL HELPLINE

Beale & Co

Tel: +44 (0) 20 7469 0400

www.beale-law.com

Member Reporting Service for Industry Issues

If you have any queries regarding AGS Data Format, there is a discussion forum on the AGS Data Format website, where queries can be posted and answered by the Data Format team.

If a Member has any issues with regard to Safety, Contaminated Land, Geotechnical, Instrumentation & Monitoring or Laboratories which you think the industry should be aware of please email ags@ags.org.uk, we will then forward your email to the relevant AGS Working Group.

Disclaimer

All articles in the AGS Magazine are the opinions of the authors and are not intended to be a complete or comprehensive statement of the law, nor do they constitute legal or specialist advice. They are intended only to highlight current issues from date of publication that may be of interest. Neither the writer(s), nor the AGS, assumes any responsibility for any loss that may arise from accessing, or reliance on the material and all liability is disclaimed accordingly. Professional advice should be taken before applying the content of the articles to particular circumstances.

March 2024 41

Advertising and Rates

An online advertising campaign within the AGS Magazine will help to build and increase industry awareness of your company’s profile, initiatives and offerings.

The AGS can help build a package to suit your needs and budget; whether it’s a series of adverts across multiple issues, a combination of event sponsorship and advertising, or a single advertorial.

How to Advertise in the AGS Magazine

The AGS Magazine is a free email publication that looks at a range of topical issues, insights and concerns, whilst publishing new guidance notes, working group activities and information on upcoming industry seminars.

With 6 issues each year, our subscribers include industry professionals such as practitioners, chartered specialists, senior decision makers and managing directors

To receive a media pack or to discuss advertising rates, please contact Caroline Kratz on 0208 658 8212 or email ags@ags.org.uk

Advert Sizes and Rates

FULL PAGE

W: 210mm

H: 297mm

RATE: £400

HALF PAGE

W: 210mm

H: 145mm

RATE: £250

QUARTER PAGE

W: 105mm

H: 145mm

RATE: £160

DIRECTORY

Company name, address, contact number, email and one logo.

RATE: £50

Advertising Requirements

All adverts should be sent in a PDF, PNG, JPEG, TIFF, PSD (Photoshop) or EPS (Illustrator) format.

All advertising artwork must be supplied in 114 dpi resolution.

Artwork must be delivered to the AGS using the agreed artwork specification size listed left.

Artwork should be emailed to ags@ags.org. uk no later than 10 days prior to publication.

42 Magazine

COMPANY NAME ADDRESS CONTACT NUMBER EMAIL LOGO

Directory

Element

Unit 3 Deeside Point, Zone 3, Deeside Industrial Park, Flintshire, Deeside, CH5 2UA,

+44 (0)1244 833780 contact.us@element.com

Hydrock

Great Suffolk Yard, 127-131 Great Suffolk Street, SE1 1PP

020 3846 8456 London@Hydrock.com

GHD

10th Floor, Nexus 25 Farringdon Street, London, EC4A 4AB

+44 203 077 7900

EMEAcomms@ghd.com

RemedX Ltd

The Old School, Stillhouse Lane, Bedminster, Bristol, BS3 4EB, +44 (0)117 947 1007 remedx@rsk.co.uk

Statom Group

Statom House

795 London Road, West Thurrock

Essex

RM20 3LH

01708 222777