According to the Market Statsville Group (MSG), the Global Agriculture Tire Market size was valued at USD 7,089.6 million in 2024 and is expected to grow from USD 7,415.7 million by 2025 to USD 10,626.9 million by 2033, at a CAGR of 4.6% during the forecast period (2025 – 2033).

Agriculture tires represent an essential component of the world's tire market. Increased mechanization in farm operations, and also increasing food production requirements, make agriculture a growing demand sector for these types of specialized tires designed for tractors, harvesters, sprayers, and other machinery for agriculture purposes with higher traction, durability, and soil protection. The market is driven by factors such as technology in tire material, rising usage of radial tires, and policies promoted by the government to encourage high technology in farming. North America, Europe, and Asia-Pacific are the regions; the Asia-Pacific region is growing, mainly because of developing activities in agriculture sectors in countries like India and China. Sustainable trends in the industry are biodegradable tires and fuelefficient designs. Fluctuating raw material costs and supply chain disruption present some challenge, but major market players will be seen trying to focus more on product innovation and strategic partnership. The global agriculture tire market will thus face a steady increase as more areas become mechanized with agriculture operations around the globe.

Agriculture tires are specific tires for farmlay machines such as tractors, harvesters, sprayers, and other equipment used on farm. The agriculture tires have better traction, durability, and load-carrying capacity with minimal soil compaction to increase crop yields. These tires have two options, namely, bias and radial, for varying farming conditions. There are advanced agriculture tires, which have reinforced sidewalls and a new tread pattern, leading to higher efficiency and performance across terrains.

Fluctuations in the raw material prices often have a challenging nature on the agriculture tire market. Some of these raw materials involved include natural rubber, synthetic rubber, carbon black, and steel. Political tension, trade policy, and the interference of the supply chain oftentimes changes the availability and hence the prices for these raw materials, thereby affecting the increased costs of production in the tire manufacturing companies. Environmental issues and government regulations over the rubber plantations also affect the supply and, therefore, unstable prices. As raw material costs increase, the manufacturers are compelled to raise the price of the tires, thus making it difficult for farmers in developing regions to afford them. Changes in currency and the economic situation also impact the changes in prices and strategies of procurement. The companies responded to the situation by investing in alternative materials, recycling, and improving efficiency. However, the persistent volatility of the raw material's price continued to squeeze both profitability and affordability and, therefore, was a continuous challenge for the agriculture tire market.

9to 15 November 2025 in Hanover, Germany- Guiding theme “Touch Smart Efficiency” – Seizing opportunities of digitalization – Agritechnica 2025: Platform for the international agricultural machinery tradeagritechnica.com

Digitalization is advancing steadily on farms. This development requires agricultural machinery dealers to be ready with equipment and knowledge that will meet the challenges of the future. A wide range of new developments at Agritechnica 2025, which takes place in Hanover, Germany from November 9 to 15, offer opportunities for agricultural machinery dealers. Relevant features at Agritechnica in hall 2 include "Business Matchmaking", which enables targeted contacts between dealers and exhibitors, and the International Dealer Center. Registered dealers will benefit from being listed at www.agritechnica.com and in the trade fair app since they can be found quickly by customers and exhibitors.

The agricultural machinery industry is contending with a host of challenges. Geopolitical crises are driving price volatility, while high interest rates and unclear policy directions add to economic uncertainty.

At the same time, extreme weather is affecting both yields and product quality, creating further strain on farming operations. The impact on farm income varies depending on business orientation, but across the board, these factors are shaping investment decisions and dampening confidence in long-term

planning. Agricultural equipment dealers have limited ability to respond to external pressures such as deferred purchasing by farms, extreme weather events, and political uncertainty—though some are countering with attractive sales or financing offers.

When it comes to digitalization, which poses a direct and internal challenge for the trade, the situation looks different: Success increasingly depends on the expertise, technical know-how, and the quality of digital solutions and services offered by machinery dealers.

„Agricultural equipment dealers are expected to integrate digital technologies into their portfolios and provide tailored solutions to farmers. But this is often easier said than done. The technologies involved are complex and require extensive consultation, while rapid innovation cycles in systems, machines, and software demand constant upskilling,“ says Ralph Königs, Business Segment Dealer Manager, Agritechnica.

Adding to the pressure, sales and workshop staff increasingly face customers who are highly techsavvy and well-versed in digital tools such as sensors and software. “To remain credible partners, dealership staff must be thoroughly trained in integrated digital solutions and capable of presenting them convincingly. When strong product performance is paired with seamless system interfaces, successful sales

become far more achievable,” adds Königs.

There are signs of cautious optimism in the agricultural sector. Many dealers are hopeful that German farmers will show a greater willing-

ness to invest in 2025. According to the latest agricultural barometer from Landwirtschaftliche Rentenbank, the business climate in the sector has improved compared to autumn 2024. The survey indicates that 64 percent of farmers are planning investments this year, suggesting a moderate upward trend in market activity.

Agritechnica 2025 provides farmers with a valuable opportunity to explore the latest technologies together with their machinery dealers. As the world’s leading trade fair for agricultural machinery, it brings together manufacturers, dealers, farmers, and industry experts from around the globe, fostering international exchange and networking.

This year’s edition introduces new formats aimed at enhancing visibility and connections within the sector. Registered dealers can be listed on the official website and in the trade fair app, making them easily accessible to both customers and exhibitors.

The International Dealer Center (IDC) will again serve as the central meeting point for the international agricultural machinery trade at Agritechnica 2025. Trade visitors can access an exclusive lounge for dealers, business partners, customers, and employees. Daily “Pop-up Talk Dealer” sessions at 5 p.m. will feature international speakers, followed by informal networking opportunities. An on-site information counter will also be available to address questions on training and professional development in the sector.

New at this year’s event is the “Business Matchmaking” format, designed to connect dealers and exhibitors directly, supporting targeted business contacts. The established “Workshop Live” returns in an updated version 2.0,

forming part of the Agribusiness Days, which will spotlight key service topics such as robotics, artificial intelligence, and precision farming. The program also aims to attract young professionals and highlight career opportunities in agricultural and construction machinery technology. Registered dealers can select from four participation packages, including access to discounted admission tickets.

JCB unveiled an unprecedented number of new machines for on-farm materials handling at the LAMMA Show, at the NEC Birmingham.

In addition to featuring the JCB Fastrac iCON high-speed tractors, the exhibit underscored JCB’s leading role in efficient materials handling, with innovative British-built solutions that included the Loadall telescopic handler range and wheeled loaders purpose-built for agriculture from ultra-compact machines to the biggest and most powerful loading shovels.

New to the Loadall telehandler lineup are top-spec AGRI Pro versions of the 538-60 and 560-80, the former bringing the 50kph DualTech VT hydro-mechanical transmission to the 6m class for the first time,

providing hydrostatic drive for precision low-speed control and auto powershift direct drive for efficient field and road travel.

The AGRI Pro spec also features an uprated driveline with heavier-duty axles, wider tyres and a dual-axle power braking system to further raise the productivity potential of these machines.

For high-lift operations – particularly stacking and retrieving bales – the new JCB Loadall 542-100 combines 4.2 tonne lift capacity and 9.8m lift height with the 40kph or 50kph DualTech VT transmission.

Yet despite these all-round gains –including the heavier duty driveline on the 50kph version – the newcomer is no bigger than the continuing 536-95, so it has the

manoeuvrability needed for everyday work in and around farm buildings. Two new wheeled loaders are at opposite ends of the performance spectrum – the 403E Full Cab is a battery-electric ultracompact machine with special control features to keep the operator warm and comfortable with least possible impact on work time.

Meanwhile, the latest JCB 435S heavy-duty silage and muck loader gains significantly increased power and torque throughout the engine’s operating speed range, and new six-speed powershift control features that lift performance efficiency on the clamp and on the road.

The 435S also has a new load weighing option available that can

also be factory-installed on other top-end JCB wheeled loaders, as well as all full-size JCB Loadall telescopic handlers.

JCB’s market leading telescopic wheeled loader range gets two allnew mid-range machines – the TM280 with 109hp and hydrostatic drive, and the TM280S with 130hp and DualTech VT hydro-mechanical drive – in a package barely 2m wide and 2.6m tall.

This compact size has been achieved by a new chassis design that houses the powertrain as low as possible while still delivering 2.75m lift capacity and 4.8m lift height.

JCB also unveiled the new TM110 telescopic wheeled loader (pictured) to further expand the already comprehensive range.

Mitas has launched its its latest range: Agriterra ULTRA, designed to set new standards in durability and performance.

Developed for a wide range of applications, including trailers, loading and transport vehicles, spreaders, and slurry tankers, Agriterra ULTRA is engineered to establish new industry benchmarks in performance and durability.

Leveraging engineering expertise, Agriterra ULTRA features a newly designed structure that enhances strength and durability. This new reinforced construction minimizes stress and heat buildup, ensuring greater efficiency and stability both in the field and on the road. Rigorously tested under the most demanding conditions, Agriterra ULTRA not only delivers superior durability and stability but also consistently outperforms comparable competitor products, reinforcing its position as the top choice for modern agricultural needs.

“Agriterra ULTRA represents a significant milestone in our commitment to providing high-performing solutions for the agricultural sector. Its redesigned ULTRA construction and advanced compounds ensure exceptional durability

and reliability, making Agriterra ULTRA the ultimate trailer tire solution on the market,” said Roberta D’Agnano, Global Brand Director Mitas at Yokohama TWS.

Agriterra ULTRA will be available in a range of key sizes, during the course of the year, starting from size 560/60R22.5TL IMP 165D.

A specialized version featuring VF (Very High Flexion) technology, will also be available under the name Agriterra ULTRA Soil Protector. Thanks to advanced technology, Agriterra ULTRA Soil Protector increases load capacity by up to 40% while enabling lower inflation pressure, which expands the tire’s footprint. The result is enhanced ground protection and optimized crop yields, providing farmers with a more efficient and reliable option for their equipment.

Additionally, Agriterra ULTRA Soil Protector ensures excellent grassland protection and superior performance in wet terrain, thanks to its rounded shoulder design.

Farming, ranching and agribusiness industries are plentiful in Canada. Your future opportunities and quality of life await! Invest in a dynamic and vibrant country that offers successful export, technology, resources, mineral, infrastucture and educational advantages.

Let our partnerships do the hard work for you! Our partnership with Interfarms.nl connects our Canadian and European farm markets in addition to providing helpful resources and advice to our clients looking to immigrate. We also work closely with MNP accountants to obtain international tax advice direct from the experts. We are available to communicate in english, german and dutch languages.

*Used* Deutz 6180,16 reg, FL, front pto .................................£55,000

*Used* Deutz 7250,16 reg, FL, front pto, 3500hrs £75,000

*Used* Deutz 62 15TTV 18 reg, 3000hrs, full spec POA

*Used* Deutz8280, full spec, 60k, front linkage, 710/70/42 80% tyres

*Used* John Deere 6170R 14 reg, 50k, 6,000 hrs

*Used* John Deere 6155R, 1150 hrs, full spec, 21 reg

*Used* John Deere 6900 40k, R reg £16750

*Used* John Deere 6330 07 reg, 40k, air con

*Used* John Deere 6330 10 reg, 40k, air con, 6500hrs

*Used* John Deere 6330 10 reg, 40k, loader, air con, 6250hrs

4x 580/60/22.5 wheel and tyre assemblies, ex Bateman sprayer

*Used* Claas Variant round baler, nice condition £13,300 *Used* John

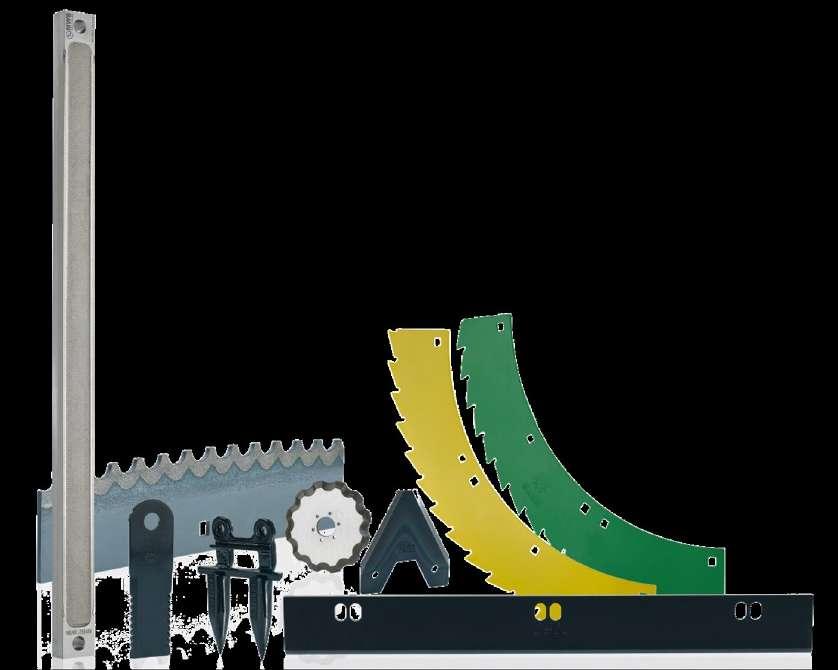

MWS is the largest specialist in the production of cutting tools for agricultural, forestry & municipal technology

QUALITY «MADE IN GERMANY» FROM MWS –PRODUCER OF ORIGINAL CUTTING TOOLS FOR WORLD BRANDS

OUR STRENGTHS:

• assortment of over 5000 items,

• quality Made in Germany,

• production of cutting tools according to individual requirements,

• increase of service life up to 4 times due to wear-resistant coating

Specially designed for tractors with Central Tyre Inflation Systems, the Michelin EvoBib is suited for both road and field work.

The tyre offers optimised longevity, reduced soil compaction, reduced fuel consumption, improved and sustainable traction.

Michelin has launched a new version of its ‘2-in-1’ EvoBib tyre – the first agricultural tyre on the market specifically designed to be used with Central Tyre Inflation Systems (CTIS), which makes it possible to obtain performance both on the road and in the field due to its adaptive design.

In field use, the footprint is maximized due to the tread design, and its very low-pressure structure –utilising Michelin Ultraflex Technology – which reduces soil compaction and improves the tractor’s traction capabilities.

In road use, the reduced footprint and the central rib of the tread

pattern cut rolling resistance, while longevity is improved and fuel consumption is reduced.

The new tread design has also been adapted to optimise longevity and offer excellent traction capabilities until the end of the tyre’s life. In the new EvoBib, the tyre casing is now PFO (Pressure Field Operation) rated, a standard that allows manufacturers to increase the load capacity of their tyres for field use.

The new EvoBib has a footprint variation of 47 per cent* between road and field, double that of a VF tyre such as the Michelin AxioBib 2 (24 per cent) that would have usually been used with a CTIS. The new EvoBib increases in traction by 15 per cent** compared to a competitor’s VF tyre with a hybrid tread pattern, and the same traction capability as a VF tyre with a lug tread pattern (under normal field conditions).

Fuel consumption is also improved, close to that obtained using a standard road profile tyre. While

there’s a reduction in consumption of 2 litres per hour*** compared to a competitor’s hybrid VF tyre, and a reduction of 1 litre per hour compared to MICHELIN AxioBib 2 with CTIS.

Two sizes of MICHELIN EvoBib – VF 710/70 R 42 and VF 600/70 R 30 –are now available, which can be used on tractors between 200 and 300 hp, equipped with CTIS. The range will be expanded in 2023 with the addition of new sizes for larger tractors of more than 300 hp.

With this new addition, Michelin now has a complete range of solutions for powerful tractors.

To help customers make the correct tyre choice, Michelin has published the following recommendations:

If more than 80 per cent of usage is in fields and/or difficult working conditions, MICHELIN AxioBib 2 is preferred because of the traction capabilities offered by its lugs. Between 20 and 80 per cent field use, MICHELIN EvoBib with CTIS

makes it possible to optimise all performance characteristics on the road and in the field, for users looking for a return on investment. If the field usage is less than 20 per cent (mostly road use), and the tractor is not required to work in extreme conditions, MICHELIN RoadBib will be the most suitable option due to its increased longevity and the fuel savings it offers.

VF TractorMaster VF900/60R42 tractor tyres now available worldwide

Continental launches its largest agricultural tyre to improve the efficiency of larger agricultural machines.

Continental has launched its largest tractor tyre to date, the VF TractorMaster VF900/60R42. With a diameter of 2,147 millimetres, the tyre weighs 450 kilogrammes and has a load index of 189 (10,300 kg). The tyre size is specifically designed to manage the weight, improve the grip, and reduce the impact of agricultural machinery with over 300 horsepower.

Rising costs and the pressure to transport increasingly larger loads in a shorter time mean that the demand for powerful agricultural machinery is growing. Benjamin Hübner, product line manager for agricultural tyres at Continental: “This development not only demands top performance from machines, but also from their tyres. That is why we develop and test our agricultural tyres in close consultation with our customers.”

The trend toward large machines is the primary goal of working even more efficiently and cost-effectively. In 2022, Continental therefore launched five new tyre sizes of its VF TractorMaster (650/60 R 34; 650/65 R 42; 710/75 R42; 650/65 R 34; 710/60 R 34).

Thanks to VF technology, the tyre can be driven with 40 percent more load at the same tyre pressure as a standard tyre or 40 percent less tyre pressure at the same load. In addition, tyres with VF technology operate more fuelefficiently than conventional tractor tyres. Hübner commented: “The VF TractorMaster combines efficiency and soil preservation. The VF technology allows for a smooth transition from field to road without having to adjust the tyre pressure. At the same time, the impact of heavy machinery on the soil is minimised by a wider tread surface when working in the field.”

Continental is striving to continuously expand its agricultural tyre business as part of its Vision 2030 strategy. The expansion of the portfolio and the realignment of the Agricultural Tyres business field, headed by Ivonne Bierwirth, underscore the company’s growth strategy.

Following the launch of the Michelin SprayBib CFO (Cyclical Field Operation*) in 2022, a new dimension has now been added to the range – the Michelin SprayBib CFO VF 710/60 R46

Designed for self-propelled sprayers, it is the first very-low-pressure flotation tyre in the Michelin SprayBib CFO range.

This 2.05m diameter tyre is said to offer high productivity levels, help protect the soil, and provide very good stability to sprayers with largecapacity tanks.

Commenting, Gordon Brookes, Michelin’s Customer Engineering Support Manager, says: “This is the first flotation tyre in the new SprayBib CFO range. It was developed to meet the requirements of equipment users and manufacturers. Their desire was especially warranted as some constructors had already tested prototypes of these tyres on their machines with a view to homologating these as OEM fittings.”

The SprayBib CFO range increases load capacity by up to 14%** during cyclic operations in the fields, at speeds reaching up to 30 kph. The development of a new casing allows the load per axle to be increased to 1.3 metric tonnes (depending on the tyre dimension).

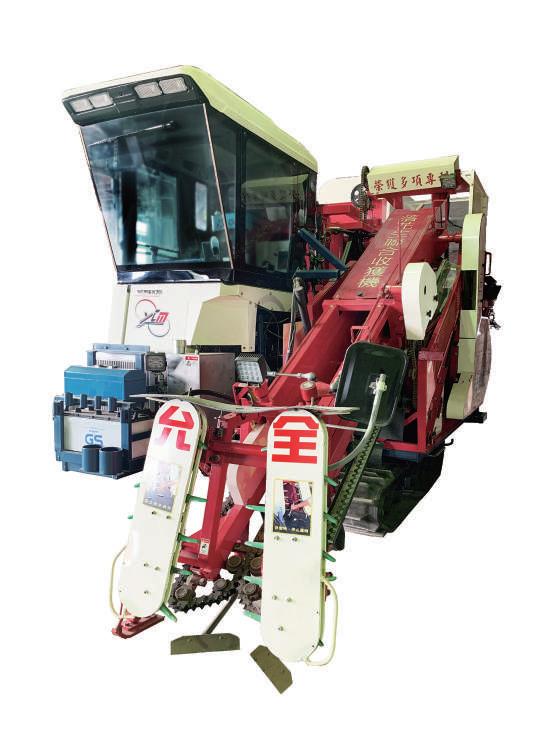

The new APS SYNFLOW system takes threshing technology to another level in the new 5000-6000 range. Together with new drive systems, intelligent operator assistance systems – CEMOS AUTOMATIC, greater comfort in a larger cab and the new field scanner for precision guidance, efficiency is unrivalled in the new LEXION straw walker range. The proof is in the performance.

APS SYNFLOW

New larger threshing system with wider drums and an additional separator drum for increased separation performance.

NEW PIVOTING CONCAVE

Can be operated via CEBIS, for a rapid response to change in crop type or conditions in the field.

Call your local CLAAS dealer today for a demonstration and for our Early Action Finance Terms.

JET STREAM CLEANING SYSTEM

Comes as standard on all new straw walker machines.

Before 30.11.20

claas.co.uk/products/combines/ lexion-6900-5300

CR development introduced across Europe and worldwide in 2001?

Milestone marked as latest CR10 and CR11 combines enter production New Holland is marking the 50th?year since introducing the first combines featuring the brand’s Twin Rotor threshing and separation technology, a product line which has grown from a single model in 1975 to a complete range today, led by the new CR10 and CR11.

The milestone will be celebrated globally with special displays at shows and exhibitions.

Over 70,000 TR and CR Twin Rotor combines have been produced globally to date. New Holland’s Centre of Harvesting Excellence in Zedelgem, Belgium, has recently undergone significant investment and upgrading for production of the latest CR10 and CR11 models.

Well-known for its expertise in grassland farming products such as balers and forage harvesting equipment, New Holland, then primarily a US-based manufacturer, entered the combine market in 1964 when it acquired Belgian company Claeys, which had introduced its first self-propelled combine in 1952. Over the decade that followed the acquisition, New Holland continued to develop the conventional strawwalker combine line it had acquired, but during the 1960s began to investigate new ways of threshing

and separating grain to boost output, increase cleanliness and reduce losses.

To do this, New Holland engineers studied centrifugal force and its potential for separating grain from plant matter, an innovative concept distinctly different from the drum/ concave and straw-walker traditional method of threshing and separation. The first development machine, adapted from a 985 straw-walker model from the Claeys factory in Belgium, was trialled in corn in 1968, and wheat the following year. The trials showed benefits from splitting the incoming crop flow from the elevator/feeder house into two streams, feeding it into two counterrotating longitudinal rotors working against longitudinal concaves that consisted of threshing sections followed by separation sections. The high speed of the rotors meant centrifugal force ejected much of the grain through the concaves, minimising grain damage when compared to conventional drum and concave threshing, and minimising losses when set against straw-walker separation.

By 1969, a totally new combine design with these internal elements was under test, and in 1975 the first production model, the TR70 with a 145hp engine and 5,550-litre/158bushel grain tank, was launched –the first New Holland combine built in the USA. For 1979 it was replaced by the upgraded TR75, and joined by a larger companion, the TR85.

Over the next two decades the range evolved, with the 25,000th?TR combine produced in 1997.?

European high-capacity combine development had taken a separate path with the development of the

Twin-Flow combines introduced in 1983. These used a conventional drum and concave followed by a large beater and rotary separator and then a lateral Twin Flow rotor that split the crop into two streams to separate the final grains. However,

by the late 1990s New Holland engineers in Europe and North America began work on a totally new Twin Rotor design that would meet the needs of farmers around the world in all types of combinable crop. Introduced in 2002 and blending key features from the TR and TF machines with new developments and styling, the new 333hp CR960 and 428hp CR980 were initially built in the USA, before production was transferred in 2005 to the Zedelgem plant in Belgium.?

The CR960 featured twin rotors of 432mm/17in diameter, with larger 560mm/ 22in diameter units on the CR980, which had a 12,500-litre/355-bushel grain tank. Operators benefited from a completely new cab design.?The range was gradually expanded,?and introduced features including IntelliSense combine automation, Dynamic Flow Control remotely-adjustable rotor vanes, Dynamic Feed Roll technology and Opti-Spread Plus residue management. Development of the Elevation models in 2007 introduced

IntelliCruise feed rate control for maximum output, and Opti-Clean cleaning technology to further enhance grain cleanliness. These and other innovations have earned the TR and CR combines multiple industry awards throughout the world.? The next development was the CR7.90, CR8.90, CR9.90 and CR10.90 models, with the latter machine in 2014 taking the Guinness World Record for the most wheat harvested in eight hours, at 797.656 tonnes (29,308 bushels). The record still stands today.

The New Holland CR combine range is now topped by the recentlyintroduced CR11 (775hp, 20,000-litre/567-bushel tank capacity) and CR10 (634hp, 16,000-litre/454-bushel grain tank) models. Like their forebears, they continue to incorporate proven Twin Rotor technology, but have more capacity than ever, with greater power and tank volume matched by rotors with a diameter of 600mm/24in and a length of 3,600mm/142in, to maximize crop handling capacity, ensure thorough threshing and separation, and protect grain quality.

Develon dealer ATLAS von der Wehl GmbH recommended DL250-7 wheel loader for its high power reserve

With the trend towards alternative energy production, working methods in agriculture are also changing. For example, whole crop silage is playing an increasingly important role in the operation of biogas plants. This involves chopping up entire grain plants and using them as a fermentation substrate. This also results in biogas plant operators being less dependent on weather conditions and crop yields.

Particularly powerful machines are required to handle the biomass. A new DEVELON DL250-7 wheel loader recently passed its baptism

of fire in this respect when it was successfully deployed for the first time at the biogas plant of Bioenergie Gut Lauenbrück GmbH located between Bremen and Hamburg in Germany.

When purchasing the 14-tonne machine, Bioenergie Gut Lauenbrück GmbH placed its trust in the local company and Develon dealer, ATLAS von der Wehl GmbH. The Develon dealer recommended the DL250-7, which delivers 128 kW at 2100 rpm thanks to its Develon DL06 Stage V engine, not least because of its high power reserve. This ensures that the wheel loader works efficiently even in demanding conditions and achieves a fast travelling speed in road traffic. With

its impressive breakout force and high traction, the DL250-7 is ideally suited for various types of silo applications. At Bioenergie Gut Lauenbrück GmbH, it has proved its worth particularly when pushing the silage material, which is unloaded from the bottom of the silo by the trailer, onto the steep silo mountain. Its high operating weight makes the DL250-7 ideal for compacting the silage. It can also be optionally equipped with a high-tipping bucket and used to fill the biogas plant with the silage.

ATLAS von der Wehl recently delivered a 15 tonne Develon DL280-7 wheel loader to another customer. This machine, which is powered by a Develon DL06 Stage

V engine, is also used for silage maize harvesting. For this purpose, the DL280-7 was additionally equipped with a Bekamax central lubrication system optimized for agricultural and construction machinery, a loading shovel, green forks and a high-tipping bucket. Thanks to the hydraulic quick hitch, these attachments can be fitted particularly quickly and easily. In addition to the larger wheel loaders such as the DL250-7 and DL280-7, Develon offers a diverse range of different smaller wheel loaders for demanding agricultural applications. For example, attachments such as agricultural buckets with grapples and bale clamps are available for the Develon range of compact wheel loaders such as the DL60-7 model, with an operating weight of 3.8 tonne or the DL85-7 with an operating weight of 5.1 tonne.

JCB secured Silver in the prestigious “Machine of the Year” award at the LAMMA agricultural machinery show – the largest event of its kind in Britain – at NEC Birmingham last week (15/16 January, 2025)

The all-new JCB Telemaster TM280S telescopic wheeled loader was recognised for its productivity, operator comfort and innovative engineering ahead of a host of other new farming machines launched at the show.

JCB Agriculture Managing Director, John Smith, said: “No stone has been left unturned in developing the new TM280S as a highly capable, operator-friendly materials handling machine for farming and related industries, so we’re delighted this

has been recognised by the LAMMA show organisers with this award.

“It’s testament to everyone’s work carried out at factories across the JCB group that we now have a very competitive addition to our marketleading range of telescopic wheeled loaders with appeal to new farming customers at home and overseas.”

JCB’s Telemaster machines are the only ones of this type engineered and built in Britain –manufactured at JCB’s Earthmovers factory in Cheadle, Staffordshire, the TM280S features an innovative chassis design, and a unique transmission engineered and manufactured at JCB Transmissions, Wrexham and a 130hp DieselMAX engine designed

and built at JCB Power Systems, Derby. Together with a spacious cabin from JCB Cab Systems at Uttoxeter, the newcomer offers farmers a powerful and highly productive machine in a mid-size package that will be perfect for daily chores on dairy, beef and other livestock farms.

Its telescopic boom lifts 2.75 tonnes to 4.8 metres and the unique DualTech VT transmission provides flexible and highly controllable hydrostatic drive when working at low speed before switching to direct mechanical drive at travel speeds for maximum power-efficiency and fuel economy.

Standing just 2.6 metres tall – a key objective to ensure the machine can enter traditional farm buildings with low doorways – the new model provides great all-round visibility from its central driving position so that operators can work with confidence in and around farm buildings to get jobs completed quickly during a busy farming day.

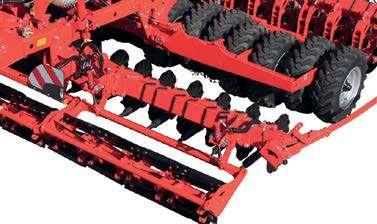

Sprinter is the drill you can depend on in all conditions. For use after the plough, minimum cultivation and direct sowing. 3000 to 8000 litre hopper and Duett coulters to micro-loosen underneath the seed horizon.

Avatar SD is a high performance direct drill with single disc coulter. Available in 3m to 12m working widths, it features a 2-bar design for high harvest residues and single, double or triple hopper for seed, fertiliser and microgranules.

Visit horsch.com, your local HORSCH dealer or call 01733 667895.

Flach & Le-Roy Ltd is an industry leader in designing and delivering high performance drying, ventilation & storage systems.

• Destroy cover crops

• Adjust ground pressure from the cab

AUROCK FEATURES & OPTIONS SUPPLEMENTARY

Some direct dril ls from around the world may have been a good idea when they were invented. But times have changed–so keep up with the future. With a Novag drill you’re not only investing in the world’s mostinnovativeno-tillagedrill,butyou’ll alsoreceivehealthy soils that will make the next generat ion’s farming a success. Cut your costs and working hours and let the worms, fungi and bac teria do the job for you. Enjoy increasing carbon sequestration, water storage and nutritional quality–all while increasing yields and revenues! It even helps you to restore thriving ecosys tems. This may sound like a fairytale, but it works.

Novag \ www.novagsas.com

To find out more, contact your local Fendt Dealer today.

Creating innovation from ideas requires experience and passion, but above all, persistence and courage. Our products have been revolutionising agricultural technology for over 80 years, and that will always remain the case. It's Fendt. Because we understand agriculture.

The modern precision agricultural equipment is strongly driven by technical innovation through electrification and cross brand digitalization. Critical advancements in agricultural equipment have made it possible for farms to track crop production with great precision. Electronically integrated equipment is used to optimize crop potential by ensuring that the correct amount of water, seed, pesticide, and fertilizer are applied to the crops via GPS. This new way of farming is accomplished with the help of monitors, sensors, and cross brand computerized systems.

Powell Ag Solutions circular connectors:

• Feature high-temperature silicone to act as a barrier from hydraulic fluids, fossil fuels, and lubricating oils.

• Environmentally sealed to IP67/IP69K protection in mated condition.

• Offers excellent protection from ingress of dust, water, fertilizer, pesticides, and mud.

• Operational in temperatures ranging from -55 °C to 125 °C, functioning well in exposed cold weather environments, and withstand the high temperatures seen in most agricultural equipment applications.

• Designed with a rapid and secure mating system that is also highly vibration resistant.

Morecompactdesign,reduced turningradiusmeansgreater manoeuvrability

Loweroverallheighteases building access

More lift height aids tasks such as bale stacking

Case IH is strengthening its Farmlift telescopic loader range by launching a new particularly compact Farmlift 626 that offers increases in manoeuvrability, accessibility and capability compared to its predecessor.

These include higher lift height for greater productivity, a reduced turning radius to make yard work easier, and a lower overall height for better access to low doorways and buildings. This means the Farmlift 626 suits a wide range of applications across livestock businesses and many other enterprises.

The Farmlift 626 is powered by a

74hp (54.6kW) four-cylinder engine driving through a single-range 30km/ hr hydrostatic transmission. A mechanical electro-proportional hydraulic system is powered by a gear pump providing 80 l/min of oil flow at 210 bar pressure. Maximum lift capacity is 2,600kg, while the new model offers 0.22m more maximum lift height than its predecessor, at 5.9m. Headstock rotation on the Farmlift 626 is 155°, for faster unloading.

At just over 4m, the new machine is shorter than its predecessor, yet its 2.525m wheelbase is slightly longer, a combination which helps ensure good stability when handling heavy loads or working at speed. With a reduced outside turn radius of 3.25m, the Farmlift 626 is easier to manoeuvre where yard and building space are restricted. Access to buildings, doorways and gateways is also enhanced by a lower overall height of 1.93m and a 1.89m overall width. Despite the narrow breadth of the Farmlift 626, its 960mm-wide

cab is broader than the one on the model it replaces, providing greater operator comfort.

For the first time on a Case IH compact telehandler, the specification can include TMR homologation. If road registration is required, this simplifies the process, and with TMR approval the Farmlift 626 can be factory-fitted with a trailer hitch and hydraulic or pneumatic trailer braking. The optional telematics provides instant identification of location, plus automated monitoring and recording of operating and performance data. Via the Case IH FieldOps™ app, data from the Farmlift 626 and all connected machines in a fleet can be monitored via any online smart device or PC. Further options include carbon filters for the cab ventilation system to protect operator health in particularly dusty conditions.

Titan Europe is celebrating securing record-breaking sales for its innovative and exclusive agricultural Waffle Wheel® in 2022.

The Waffle Wheel® has been designed to provide farmers with the ability to adjust the wheels on their tractor to eight different track width positions, depending on crop row widths.

More than 100,000 Waffle Wheels were sold during last year, the first time annual sales had exceeded six figures.

The growth is the result of significant business gains in the OEM sector due to the product’s superior performance and dynamic aesthetic.

This helps to reduce crop damage and improve productivity, while its trademarked pin technology ensures accurate concentricity at every setting.

Chris Akers, CEO for Titan Europe Wheels, said: “We are thrilled to see the Waffle Wheel being selected as the fitment of choice for so many of our OEM customers.

“We are very proud of the design and engineering excellence behind the development and production of the Waffle Wheel and of its proven performance in the field.”

The unique product enhances stability and reduces vibration of tractors, allowing even the largest vehicles to run safely and comfortably at high speed after every track adjustment.

Chris added: “The fact that sales of this product continue to grow demonstrates that our OEM customers are experiencing the value of selecting this unique product for their machines and, ultimately, that end users are feeling the benefits and requesting tractors be fitted with the Waffle Wheels.”

Already large tyre range further extended with addition of two new sizes in 70 and 95 series

High appreciation across all markets

Customers value prolonged traction due to evolving footprint

True star on the fields for farming and contracting businesses due to excellent quality price ratio

Yokohama Off-Highway Tires has announced the launch of yet two more sizes of its much sought-after radial tractor tyre Alliance Agri Star II.

With immediate effect, sizes 800/70R38 and 210/95R18 are now available, bringing the total number of SKUs in this tyre range to 89.

“It is with enormous pride that we see customers’ appreciation across different markets such as Germany, France, Spain, Italy or the Netherlands. We receive highly positive feedback via our field engineers and distribution partners in particular to prolonged traction, low wear, and the resulting excellent quality price ratio”, highlights Angelo Noronha, President Europe at ?Yokohama Off-Highway Tyres.

Following about eight months of mastering everyday challenges with the Alliance Agri Star II, French contractor Olivier Gayet is more than satisfied. “We have done 1000 hours of work with them, a lot of transport, and we have been able to see that with these Agri Star II tyres, we have never had any traction problems in terms of grip on the road and in the fields.” For him, it is particularly important and remarkable that “thanks to these Agri Star II tyres, we have been able to optimise the working time.”

Practical experience in the last four years have given solid evidence that –whatever the circumstances are in terms of soils, tasks or tractors – the construction of this tyre pays off, thanks to the unique Stratified Layer Technology (SLT) developed by Alliance, the footprint of this radial tractor tyre evolves throughout its lifetime, thus ensuring prolonged traction.

“Comments of end-customers often refer to the good balance between grip and preservation of the soil, efficiency and quality, the level of performance and comfort that is reported to match that of more expensive brands”, says Angelo Noronha.

BENINGTON 01438 869251

BRAINTREE 01376 321144

COLCHESTER 01206 871881

FULBOURN 01223 880676

LITTLEPORT 01353 860761

MARLESFORD 01728 746437

NORTH WALSHAM 01692 405121

ALBOURNE 01273 834689 DARTFORD 01322 863285 FAKENHAM 01328 855611

When developing the Tiger 6S – one of the largest and most productive sugar beet harvesters – manufacturer ROPA turned to its long-time engine partner to develop exactly the kind of reliable, immensely powerful and high-torque/low RPM power source it could depend upon When familyowned German manufacturer ROPA Fahrzeug- und Maschinenbau GmbH was designing one of the world’s largest and most advanced sugar beet harvesters, it collaborated with Volvo Penta to ensure its Tiger 6S would have the power and torque to support a daily haul of around 2000 tonnes, while working as reliably and efficiently as possible.

Beets are the source of around 20% of the 176 million tonnes of sugar consumed annually around the world. Germany is one of the world’s top five growers of sugar beets, producing over 4 million tonnes of the sugar that is used and consumed each year.

Every moment of suitable weather in the short timeframe between late September or early October is crucial for harvesting beets before the soil freezes in Europe – a concern not faced by sugar cane producers in warmer, tropical climates. Beets must therefore be extracted as swiftly and efficiently as possible with the most reliable equipment.

Volvo Penta adopts a partnership approach, intensively collaborating with customers throughout a machine’s pre-production stages to optimize powering, positioning,

fitment and performance of an engine. The company also comprehensively trains an OEM’s field service technicians. This approach tailors the power solution for machine operation and application, as Michael Gruber, Head of Technology, ROPA, proudly reveals:

“It was important that we had an industrial engine that is durable, robust and reliable, so we informed Volvo Penta of our desires and requirements for Stage V very early on. The result was the Volvo Penta D16 TWD1683VE, which provides immense power [796hp/585kW] from its six inline cylinders and dual turbochargers while delivering very high torque at the very low RPM that is necessary for harvesting beet.”

In the 1000-1100 RPM range, the 16.12-liter diesel engine generates a huge 3,550 Nm (just 100 Nm below maximum torque), enabling it to work for longer in the low speed range. This results in valuable fuel efficiency while supporting more stable, sympathetic vehicle operation in pursuit of that allimportant maximum uptime.

Its common-rail injection, SCR catalytic converter and AdBlue combine for even cleaner, more efficient, power generation, while enabling compliance with the most stringent off-highway exhaust emission standards without the need for exhaust gas recirculation or a diesel particulate filter.

Regardless of weather conditions, operators can confidently run the ROPA Tiger 6S – a huge 15m-long,

approximately 33,400 kg harvester that can quickly fill its 43 m³ / 30 tonne-capacity bunker and empty it in under a minute. Even at low engine speeds, it makes quick work of the job at hand, hitting ground speeds of 17.5 km/h in the field at 1240 RPM. Its maximum 40 km/h

road speed is achievable at 1200 RPM, facilitated by its stepless CVR (constant variable ROPA) gearbox for optimal power traction without gear changes.

“The reaction time and response qualities of this engine are far

superior to the previous Stage IV engine,” explains ROPA operator Werner Hofbauer. “The two serially connected turbochargers ensure a very agile behaviour, which suits this machine really well.”

“All machines have different requirements,” continues Anna Maria Ullnert, Product Manager Industrial at Volvo Penta. “That’s why we work closely with our customers to secure the best configuration for their specific needs. Through cooperation with operators, designers, and OEMs, we support our customers with everything from performance predictions and application integration to verification and rigorous field testing.”

This comes as no surprise to ROPA, whose three-decade-long partnership with Volvo Penta has helped the company build and maintain its favorable reputation. “We have been using Volvo Penta’s combustion engines for over 30 years – many of them are still running today with 15,000 hours and more

on the clock, but they are no trouble,” concludes Michael. “That’s why we have a lot of trust in Volvo Penta and believe their engines help make one of the best powertrains of any beet harvester on the market. The D16 is a great fit for the Tiger 6S and will be instrumental in helping us keep – and increase – our market-leading position.”

Case IH AF series takes AxialFlow principle into new capacity class

Bigger feederhouse with more lift capacity for wider headers Longest single rotor and largest grain tank capacity in the sector Powerful engines producing up to 775hp.

Double cleaning shoe with automatic cross-distribution maximizes grain quality

A new capacity class is being added to the Case IH Axial-Flow range for 2024, with the European launch of the new AF9 and AF10 combines. They share a ground-up new design providing significant capacity advances from front to rear, while maintaining the simple yet effective Axial-Flow principles of single-rotor threshing and separation.

The AF9 and AF10 launch completes the Case IH ‘Year of the Combine’ that began with the Axial-Flow 160 and 260 series release. Case IH now

offers the industry’s largest line of single-rotor combines, staying true to a system it pioneered in 1977. The new models feature key components designed to minimize total cost of harvesting for the largest farming and contracting operations. The AF10 is powered by a 775hp FPT Cursor 16 engine, while the AF9 features an FPT Cursor 13 producing 635hp. Both units are mounted lengthways for simplicity of drive and efficiency of power transmission, with engine rpm when harvesting lowered from 2,100 to 1,900rpm, boosting fuel efficiency. Service intervals have been extended from 600hrs/one year to 750 hrs/two years, with additional operating cost benefits.

AF10 grain tank capacity is 20,000 litres – the joint largest in the industry for reduced unloading downtime –with a 210 l/sec unloading rate, while comparable figures for the AF9 are 16,000 litres and 159 l/sec. There are four unloading auger length options to match different header widths, while a pivoting spout aids

even unloading, and cross-auger shutoff ensures the unloading auger is emptied if part-unloading the tank. A half-rate unloading shut-off feature on the AF10 enables easy toppingoff of loads. Up front, the AF9 can be fitted with draper headers up to 15.2m (50ft). To match the additional capacity of the AF10, units up to 18.6m (61ft) are possible. These wider widths not only allow operators to exploit the full capacity of these combines, but also mean every field is harvested in fewer passes, boosting productivity.

Beyond their power, cutting capacity and grain holding ability, multiple other advances ensure the new models make their mark at the very top of the combine sector. The feeder house, which has a lift capacity of up to 6,800kg to accommodate the wider headers, is also significantly wider to match the greater crop intake. Standard lateral tilt and front face adjustment aid precise contour-following and assist with header attachment. The feeder chains are powered by a fixed or

optional PowerPlus CVT drive, while a patented Synchronized Feed System (SFS) 450mm lateral feeding rotor smooths crop transfer to the threshing element that leads the Axial-Flow rotor.

The new 762mm-diameter AFXL rotor is the longest in the industry, at 3.67m, boosting crop flow, fuel efficiency and straw quality, while minimising grain damage and maximising separation. Total threshing and separation area is up to 5.1m2. The AFXL rotor features six modules rather than four, fitted with 40 standard raspbars, 12 spiked raspbars and eight HX raspbars. HX units work in a stepped area of the rotor cage and blend the spiked raspbars’ height with the standard units’ profile, with a steeper sidewall angle that speeds crop flow between the threshing and separation zones. Remote vane adjustment allows for instant response to changing conditions. Driven by PowerPlus CVT, in the event of a blockage the rotor can –simultaneously with the SFS – be

easily reversed from the cab.

The new Cross-Flow Cleaning Plus system has the capacity to match the crop volume that comes into these new combines at their full capability. At 8.76m2, the twin-element system offers a total cleaning area that is the largest in the industry, supported by a larger Cross-Flow fan.

The new cleaning shoe features two automatic cross-distribution control mechanisms, one on the grainpan and one on the upper sieves, guaranteeing an even cleaning shoe load in all conditions and allowing side-slope compensation of up to 28%.

Chopper options include a MagnaCut integrated unit for corn/maize, beans and dry wheat straw, with spreading capability up to 13.5m/45ft. A MagnaChop option suits users working with higher straw volumes and seeking a finer chop. Spreading at up to 18m/61ft, it includes remote speed selection, remote chop/drop selection and remote engagement of counterknives, with radar-equipped hydraulically-powered spreaders.

The revised cab interior features a comprehensive suite of precision technologies, including dual Pro 1200 displays to simplify machine manage-

ment and enable easy monitoring and operation of multiple functions through customisable displays, plus Harvest Command™ combine automation and Row Guide Pro™. In addition, the introduction of Connectivity Included* enables seamless transmission of yield and machine data directly to the new Case IH FieldOps™ app, offering farmers a complete data management solution for their operations.

There are also more in-cab control features for full from-the-seat operation of less commonly-used functions, including remote feeder and rotor reverse procedures, rotor gear selection, chopper speed selection, unloading speed choice and chopper knife engage/disengagement. Elsewhere, proven Case IH technology features include Harvest Command automation that continuously adjusts settings according to the operator’s desired focus on grain saving, grain quality or throughput. Comfort-wise, upgraded seating includes swivelling, air conditioning, heating and massage features.

*Connectivity Included will be active for the useful life of the PCM/PCMF modem. If the modem is no longer capable of receiving current cellular services, any modem hardware upgrades are not the responsibility of Case IH. Acceptance of End User License Agreement (EULA) is required.

Michelin is launching two new CerexBib 2 tyre sizes which have been specially designed for the New Holland CR11 combine harvester

Its dimensions and weight represented a unique development challenge – how to minimise soil compaction given the exceptional width of the machine and its tyres.

The addition of two new sizes, VF900/65 R46 CFO and VF 800/70 R46 CFO, expands the dimensions offered in the Michelin CerexBib 2 range.

These two new sizes are designed to meet two significant technical challenges: the load capacity of the new machine, with its much larger hopper (20,000 litres) and much wider header (15 metres) coupled with the constraints concerning the diameter and width of the vehicles, in order to comply with the various European regulations for road transport.

The tyres offer an exceptional load capacity of 19 metric tonnes per tyre, and an impressive diameter of 2.32 metres (for the VF 900/65 R46 CFO size) – representing a major

advance in agricultural tyre technology. Combined with a new rear axle configuration, these high-performance fitments not only increase the vehicle’s footprint by 23%* and reduce ground pressure by 7%**, but also optimise overall fuel consumption. In effect, it is the only range on the market offering a cyclic load bonus of 10 km/h to increase the load or reduce the pressure in the tyres. This speed corresponds to the average speed of the

machines at work.

The new tyres benefit from Michelin Ultraflex Technology, which celebrates its 20th anniversary this year. Launched in 2004 with the introduction of the XeoBib range, the innovative technology provides a larger footprint on the ground, protecting it from compaction and rutting for increased productivity.

A study by England’s Harper Adams University, begun in 2012, proved that tyres with Michelin Ultraflex Technology, inflated at low pressure, could increase yields by up to 4%. This technology was associated with the very first industrial standard – VF (Very High Flexion), followed by IF (Improved Flexion) from 2006. Together, these two norms have redefined the use of low-pressure tyres in farming.

The DLG Test Centre Technology and Farm Inputs, the indepen dent German testing institute, awards the “DLG-APPROVED” quality mark to the BKT tires AGRIMAX VFLECTO VF 650/65 R 42 and VF 540/ 65 R 30.

Reduced soil compaction, less fuel consumption, self-cleaning abilities and user friendliness: these are the winning features for which the DLG Test Centre Technology and Farm Inputs, the independent German testing institute, has awarded the BKT AGRIMAX V-FLECTO tires with the DLG-APPROVED quality mark, as a result of the outstanding performance during field testing.

This prestigious award that recognizes AGRIMAX V-FLECTO’s ability to meet the demanding requirements in both technology and performance for high-power tractors. In particular, the two AGRIMAX VFLECTO tires in sizes VF 650/65 R42 and VF 540/65 R30 have achieved excellent results in the DLG test modules “Resource Protection” and “User friendliness” that were both conducted in the fields.

During the field tests, the AGRIMAX V-FLECTO tires were subject to stringent examinations on Fendt 724

Vario (Gen6) and Fendt Vario 828 tractors. These included the assessment of the tire footprint area and ground pressure values at different depths, ensuring the accurate measurement of the impact on the ground, and soil compaction.

Parallel laboratory tests in depth assessed tire performance in terms of traction, fuel consumption, and self-cleaning properties. This combined approach provided the comprehensive and accurate evaluation of tire performance under various operating conditions.

During field and laboratory tests, the BKT tires were found to have a larger footprint resulting in lower contact pressure, and consequently in less soil compaction. At an inflation pressure of 0.6 bar, AGRIMAX VFLECTO showed ground pressure that was by 16 percent lower than the other tested tires – including premium and budget brands – as well as the lowest footprint depth. This outcome means a significant reduction in soil compaction, which is crucial for sustainable farming practices.

How much fuel can be saved with BKT? In comparison with the least

performing VF tire among the competitors, BKT tires show a reduced fuel consumption by approximately 5%. Considering that ploughing the land takes about two hours per hectare and that an actual working day is 8 hours, it is possible to till up to 15 hectares per day. In other words, AGRIMAX V-FLECTO saves nearly 15 litres of fuel per day per tractor.

If multiplying the daily saving by the number of working days in a year, the economic benefit becomes significant, especially for contractors operating multiple equipment. By way of example, a company that uses 30 pieces of equipment, considering the aforesaid savings of 15 liters per day and per tractor, can achieve overall fuel savings up to 450 litres a day for its entire fleet of 30 tractors. At an average fuel cost of 1.80 euros per litre, this equals a saving of 810 euros per day, and multiplied by the number of working days in a year, the substantial annual saving for a contractor company operating a fleet in the range of 30 tractors fitted with AGRIMAX VFLECTO becomes evident.

When it came to self-cleaning, the AGRIMAX V-FLECTO tires excelled for their remarkable ability to get free

of dirt during operations, resulting in less time spent on maintenance whilst increasing operational efficiency. During the tests, AGRIMAX V-FLECTO took up the least amount of soil compared to competitors, accounting for an 8 percent advantage over the nearest competitor and as much as 126 percent less soil compared to the least performing tire. Not only does this performance feature improve productivity, but it also contributes to keeping roads cleaner when moving equipment from one field to another, in compliance with public road cleaning regulations.

“Our commitment to research and development of cutting-edge solutions is evidenced by the superlative performance of our AGRIMAX V-FLECTO tires, representing the most advanced expression of our vision. Reduced operating costs and a positive impact on the environment are the result of technology that caters for the present and future needs of modern agriculture. We will continue to do our best to make sure that our tires are synonymous with excellence and an unparalleled added value for our customers worldwide.” – Lucia Salmaso, Managing Director of BKT Europe, comments.

OPICO introduced a new version of its HE-VA Combi-Disc cultivator at the Highland Show.

Designed specifically for those running mid-sized tractors, the new model has a 2.45m working width and four deep soil-loosening legs –rather than the five employed on 2.75m versions. These changes put the horsepower requirement for the smallest Combi-Disc at just 155hp, making this versatile one-pass tillage tool much more accessible to a wider range of growers.

The Combi-Disc employs two leading rows of soil-loosening legs followed by two rows of serrated sabre discs to provide a surface chopping and mixing effect. This is all followed up with V-profile roller to produce a corrugated, weatherproof finish. It’s this combination of soil-engaging elements that makes the Combi-Disc such an adaptable tool. In normal circumstances the

tines, discs and press are used in partnership to turn previously uncultivated ground into a seedbed in one pass. When conditions require it, the discs can be lifted completely out of work, enabling the unit to be used as a straightforward subsoil loosener/pan-buster.

Likewise, with the legs lifted out of contention, the machine can be put to work as a straightforward shallow disc cultivator. The recent addition of new ‘Stealth’ soil-loosening legs adds further to the Combi-Disc’s versatility, making it a true low disturbance subsoiler with the added ability of providing some surface tilth creation at the same time.

If it’s lift capacity that is the tractor’s limiting factor rather than power, there is also the option to specify the Combi-Disc with a cage roller rather than the standard V-profile ring-press. This brings the 2.45m wide unit’s weight down from

3000kg to 3300kg, thus making it suitable for a wider range of tractors.

“With more and more growers looking towards less intensive cultivations practices yet recognising the requirement for remedial sub-surface work when the need arises, demand for the Combi-Disc is on the up,” explains OPICO’s HE-VA product manager Glenn Bootman.

“But until now power requirement has been the limiting factor for those operating smaller tractors. With this smaller four-leg version anyone running a mid-sized machine can pull it making full use of the tines, discs and press.”

While this new model answers the needs of growers with less horsepower, it’s narrower 2.5m transport width makes it suitable for those regions where narrow lanes and tight gateways are an issue. It completes the HE-VA Combi-Disc line-up with working widths now ranging from 2.45m to 5.25m in both mounted and trailed formats.