The global agricultural biologicals market is set to grow from $15.12 billion in 2024 to $43.53 billion by 2035, with a CAGR of 10%. This growth is fueled by the rising demand for sustainable farming solutions, including biopesticides, biofertilizers, and biostimulants. Leading companies such as Bayer, Syngenta, Corteva, BASF, and Novozymes are driving innovation in biological crop protection and soil enhancement. North America currently leads the market, but Asia-Pacific is expected to see the highest growth. As farmers shift to eco-friendly agricultural practices, biological solutions offer an effective alternative to conventional agrochemicals.

Agricultural biologicals encompass a diverse array of products (derived from naturally occurring microorganisms, plant extracts, beneficial insects or other organic matter) used for enhancing soil fertility, biological activity, and the growth of plants. These products are environmentally friendly, leave no harmful residues in the ecosystem and mitigate risks to the health of farmers and consumers. Agricultural biologicals are frequently used with the primary objective of reducing the reliance on conventional chemical fertilizers and agrochemicals. For instance, companies like Novozymes, in collaboration with Bayer and other prominent companies in this domain, propose that their microbial products can serve as an effective alternative or supplement for agrochemicals and fertilizers.

This revolution is expected to benefit stakeholders at various levels. In the future, consumers are likely to gain assurance that their food is cultivated in a safe and sustainable manner. Additionally, farmers are anticipated to have access to new tools for regenerative agriculture and can explore additional revenue streams through sustainable services, such as carbon sequestration to combat climate change. Furthermore, driven by the rising demand for organically grown crops, growing focus on sustainable agricultural practices and preservation of natural resources, the agricultural biologicals market is anticipated to witness steady growth in the coming decade.

Presently, over 200 companies claim to offer agricultural biologicals for sustainable farming; close to 105 such players have entered this domain post 2000. 40% of the agricultural biological providers offer all three kinds of products for various types of crops; over 85% of such players provide these products as foliar sprays.

In pursuit of building a competitive edge in this field, stakeholders are actively upgrading their existing capabilities and adding new competencies in order to enhance their respective product portfolios. The growing interest in this domain is evident from the rise in partnership activity; in fact, 43 partnership deals related to agricultural biologicals were inked recently. Since 2019, more than 1,300 patents have been filed / granted by various stakeholders in order to protect the intellectual property generated within this domain. Driven by the increasing pace of innovation and partnership activity, the market for agricultural biologicals is poised to witness steady growth in the foreseeable future.

As a result of the growing demand for organic food products, the agricultural biologicals market is likely to grow at a CAGR of ~10% over the coming years. The agricultural biologicals market is expected to be well distributed across different type of products, source of products, modes of application, type of crops treated and key geographical regions.

International design prize for nextgeneration Case IH Axial-Flow combine

New AF combine wins Red Dot Design Award

Internal redesign takes Axial-Flow concept to the next level in capacity

External restyling creates futuristic new look

The bold new look of the nextgeneration Case IH Axial-Flow combine, set to take the capacity of the Axial-Flow design into a whole new sector and introduce a distinctive new style, has won an internationally-acclaimed prize, taking a Red Dot Design Award for product design.

Judged annually, the Red Dot Design Award is one of the world’s largest design competitions, and its label has become established internationally as one of the most sought-after marks of quality for good design.

Core details of the new Case IH AF series Axial-Flow were revealed at Agritechnica 2023, and the new combine recently made its full global debut in North America. It is designed with a renewed focus on helping users to maximize output per engine hour while minimizing losses and grain damage, retaining the proven Axial-Flow principle of rotary threshing and separation.

Major advances in the new AF include a 775hp engine, an active dynamic cleaning system, 20,000litre grain tank, 210 litres/second unloading rate and headers of up to 15m (50ft). Users benefit from performance-enhancing technology including AFS Harvest Command, to minimize losses, maximize throughput and protect grain quality, helping experienced users get even more from their combine, and inexperienced ones quickly become proficient operators, to assist in tackling labour challenges. The new technology is packaged within a fresh Axial-Flow style that introduced

a new look to the range, designed to show that this is a very different class of combine. The design team from Case IH and its parent CNH will receive the Red Dot Design award for the AF at a special ‘Red Dot: Best of the Best’ ceremony, to be held at the Aalto Theater in Essen, Germany, on June 24.

“The receipt of a Red Dot Design Award is a great honor for the design team behind the new Axial Flow,” says David Wilkie, industrial design director at Case IH parent CNH.

“We wanted to create a look that showed this combine is much more than a refresh of existing ideas in terms of internal engineering, and is something really very different. I’m really pleased the Red Dot jury recognized our efforts to create a style that matches the Axial-Flow AF’s considerable substance.”

John Deere has announced the introduction of the all new T5 and T6 walker combines with eight new models

Featuring a range of engine power options, from the robust 6.8-litre engine with a maximum power of 305 HP in the T5 400 to the powerful JD9X 9-litre engine delivering 466 HP in the flagship T6 800 model, these combines deliver outstanding harvesting performance John Deere claim the new T5 and T6 combines offer the ultimate operator experience, with the cabin from the X9 which brings first class operator comfort and functionality. This luxurious workspace features ActiveSeatTM II, LED lights, a new corner post display and an electronic dust-sealing door. The CommandPROTM joystick provides the operator with intuitive and personalised control of all main combine functions.

Further enhancing the operator experience, John Deere integrated its state-of-the-art precision ag technology packages, featuring the StarFireTM 7500 receiver, G5Plus CommandCenter™ display, JDLinkTM connectivity for operational efficiency and straightforward data management.

“The introduction of our new T5 and T6 combines represents a significant step forward in harvesting technology in the walker combines industry,” says Jonathan Edwards, John Deere Product Marketing Manager for Europe. “They will provide farmers with the tools they need to enhance productivity and efficiency in the field.”

The eight new models* of the T5 and T6 combines come with an impressive range of engine power options, starting from the 305 HP (max power) 6.8-litre engine in the T5 400 and the powerful new JD9X 9-litre engine starting with 348 HP in the 5-walker T5 500 and delivering impressive 466 HP in the flagship 6-

walker model T6 800. All JD9X engine models offer intelligent engine speed management which improves fuel efficiency by reducing engine rpm during road transport and when stationary at junctions or traffic lights. All engine variants meet the stringent Stage V emissions standards.

The feeder house, engineered to the same width as the rest of the crop channel (1.67 m for the 6walker models), eliminates flow restrictions throughout the combine. Together with the large threshing and separation area of the T5 and T6 combines, this delivers outstanding harvesting performance.

The model year 2025 combines also come with new options for grain handling, new grain tank options of up to 13,500 l for T6 (+23%) and 11,500 l for T5 (+15%). Additionally, operators can benefit from the adjustable spout, enabling more control over the unloading no matter what trailer you have.

The unloading speed at peak performance reaches up to 150 l/ sec, allowing for fast unloading of 10 t of grain in just 90 sec. Moreover, side-hill compensation options are available, with base compensation of up to 7% incline and the optional side-hill package (compensation of up to 14% incline) and HillMasterTM technology with a compensation of up to 22% incline.

With respect to smart farming, the all-new T5 and T6 combines are fitted with advanced John Deere Precision Ag Technology, including the StarFireTM 7500 integrated receiver and the G5Plus CommandCenterTM display.

The G5Plus CommandCenterTM provides operators with a large,

high-definition 12.8? display featuring intuitive menu functionalities, offering ultimate control and visibility during harvesting. Additionally, operators have the option to equip the combine with the G5Plus extended monitor. This allows operators to control more functions simulta-

neously, such as viewing vehicle control functions on the primary display and precision farming applications like AutoPathTM, Machine Sync or Grain Sensing on the extended monitor.

Machine Sync enables the combine driver to control the tractor speed,

Farming, ranching and agribusiness industries are plentiful in Canada. Your future opportunities and quality of life await! Invest in a dynamic and vibrant country that offers successful export, technology, resources, mineral, infrastucture and educational advantages.

Let our partnerships do the hard work for you! Our partnership with Interfarms.nl connects our Canadian and European farm markets in addition to providing helpful resources and advice to our clients looking to immigrate. We also work closely with MNP accountants to obtain international tax advice direct from the experts. We are available to communicate in english, german and dutch languages.

*Used* Deutz 6180,16 reg, FL, front pto .................................£55,000

*Used* Deutz 7250,16 reg, FL, front pto, 3500hrs £75,000

*Used* Deutz 62 15TTV 18 reg, 3000hrs, full spec POA

*Used* Deutz8280, full spec, 60k, front linkage, 710/70/42 80% tyres

*Used* John Deere 6170R 14 reg, 50k, 6,000 hrs

*Used* John Deere 6155R, 1150 hrs, full spec, 21 reg

*Used* John Deere 6900 40k, R reg £16750

*Used* John Deere 6330 07 reg, 40k, air con

*Used* John Deere 6330 10 reg, 40k, air con, 6500hrs

*Used* John Deere 6330 10 reg, 40k, loader, air con, 6250hrs

4x 580/60/22.5 wheel and tyre assemblies, ex Bateman sprayer

*Used* Claas Variant round baler, nice condition £13,300 *Used* John

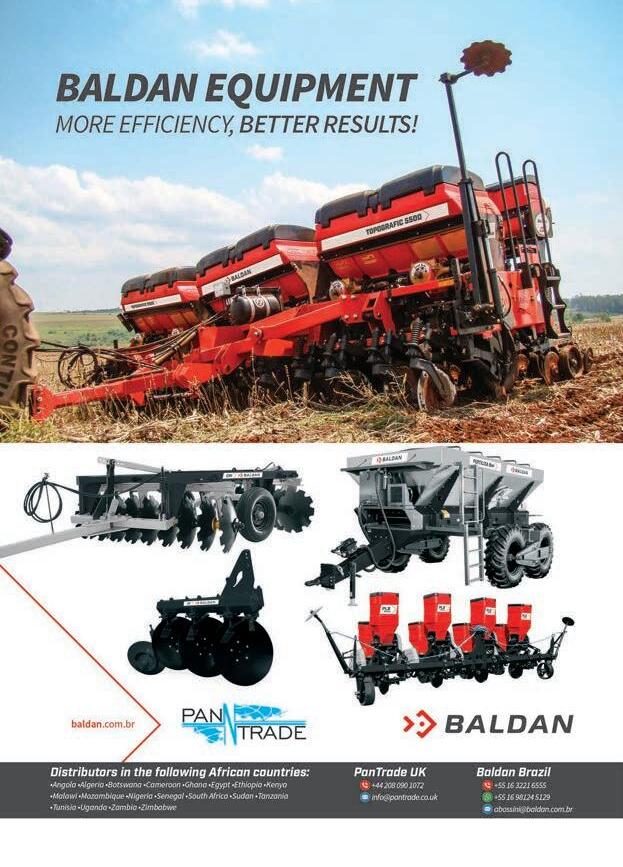

MWS is the largest specialist in the production of cutting tools for agricultural, forestry & municipal technology

QUALITY «MADE IN GERMANY» FROM MWS –PRODUCER OF ORIGINAL CUTTING TOOLS FOR WORLD BRANDS

OUR STRENGTHS:

• assortment of over 5000 items,

• quality Made in Germany,

• production of cutting tools according to individual requirements,

• increase of service life up to 4 times due to wear-resistant coating

The new range from New Holland is inspiredbytheStraddleTractor Conceptcreatedincollaboration withItaliandesignfirmPininfarina

It’s a multifunction tractor designed fornarrowvineyards,withanelegant and compact design, great comfort andmanoeuvrability

Createdtoworkwithmultiple implements combinations, keeping themattachedwithoutleavingthe cab, activated at a flick of a switch

It features the best innovations available on New Holland’s tractors, including efficient hydraulic system Intelliflow™and MyPLM Connect to maximize productivity through technology.

New Holland introduces the new Straddle Tractor TE6 Range –TE6.120N and TE6.150N – multifunction tractors specifically designed for narrow vineyards that require machines with an extreme manoeuvrability and compact dimensions, and that will be available starting from the end of 2023.

The new Straddle Tractor range’s design is inspired by the Straddle Tractor Concept, created by New

Holland in collaboration with Italian design firm Pininfarina and winner of the Good Design Award and of the German Design Award in 2022. The Concept tractor featured a futuristic and stylish look inspired by the shape of a glass of Champagne as a homage to premium wine growers of regions such as Champagne, Médoc and Burgundy.

The new TE6.120N and TE6.150N are in fact specifically designed for some of the most prestigious wineproducing regions, adapting to the narrow French vineyards and to any terrain that has similar characteristics.

The new tractor range is highly multifunctional: it features three independent tool zones for multiple possible implement combinations. They are also designed to grant an extra quick hitch – less than 10 minutes for the sprayer – and to allow the operator to keep the tools attached without leaving the cab, saving time and maximizing efficiency.

Maximum manoeuvrability is granted by the Superlight new steering system.

Thierry Le Briquer, Grape, Olive and Coffee Harvester Global Product and

Platform Manager at New Holland says “Multifunctionality, maneuverability, compact design and power: these are the key elements of the new Straddle Tractor range that is completely revolutionizing our offering in Straddle tractors. The best quality is ensured by our engineering and manufacturing at the Centre of Excellence in Coëx, France, where these tractors are produced and that is specialized in grape, olive harvesters and straddle tractors, serving customers worldwide.”

Just like the rest of New Holland’s new generation tractor range, the Straddle Tractors are equipped with innovation technology: Intelliview™ IV Plus display and its rearview screens give a total control of the tractor and My PLM Connect® allows operators to manage data in real time, on board or remotely, to maximize efficiency and productivity.

The Blue Power livery reflects New Holland’s new styling lines and balances elegance with comfort. The ergonomics have been completely reshaped with a renovated cab offering comfort and high visibility all around the machine. The FTP Industrial Stage V engine in the row ensures total stability on slopes and inclines, and the IntelliFlow hydraulic system gives a balanced distribution of power all around the tractor.

Carlo Lambro, Brand President of New Holland Agriculture says: “It’s with great pride that we add these Straddle tractors to our already excellent range, featuring a new design that combines our long-lasting identity with the most innovative features and inspired by the collaboration with a great design firm such as Pininfarina. It brings elegance, comfort and performance to our customers specialized in viticulture and I’m excited to see it in action very soon in the most prestigious vineyards.”

CaseIH LB 436 HD large square baler adds new functionalities

Designed for the largest farms and contractors, the LB 436 HD, large square baler receives some important upgrades for 2024, centred around a new load-sensing hydraulic system. This allows operations typically activated from the rear of the baler, to be controlled from the cab via the baler monitor or tractor ISOBUS terminal.

It includes full or partial bale ejection and opening or closing of the bale chute. Tandem axle steering can also be locked from the terminal, with the rear steering axle locking automatically when reversing or when in road mode. For maximum flexibility with different tractor and hydraulic coupler types, flat face hose connectors can now be specified in place of the standard conical types.

Internally, durability enhancements include improved plunger rollers with sealed bearings or heavy-duty units with greaseable bearings, stronger stuffer brake springs, a stronger rotor drive chain, an optional Hardox 400 packer feeder

bottom plate, and a more easily accessed pick-up greasing point. There is also a reinforced cropholding finger shaft, improved optional hydraulic jack with doubleacting safety valve, and additional guides on the front-end hinges of the bale chute to enhance strength.

User interface improvements include a swath feed left/right indicator to aid steering for even feeding, bale length calibration, an offset setting for the moisture sensor, and a new bale automation menu for setting automatic speed control and steering. This includes bale chute open/close, knife engagement and knife drawer opening, auto-levelling, releasing pressure in the bale chamber, tilting the twine box for easy access, and dis/engaging the tandem axle steering lock.

Aimed at farmers and contractors making 7,000 or more silage bales annually, the RB 545 and the wrapper-equipped RB 545 Silage Pack produce bales 1.22m wide and 1.25m high. Both are equipped with a 2.3m double cam-track pickup for handling heavy swaths and a 20-knife chopping unit. They produce high density bales via 18

rollers, which feature a new profile for enhanced bale rotation, and are mounted on automatically greased bearings. These upgrades will positively impact durability and reliability to keep farmers in the field longer.

Beneath refreshed styling that enhances visibility, both balers benefit from main drive, bale chamber, chamber tailgate and rotor drive chains that have all been upgraded to a stronger grade, as have the associated sprockets. Increased chain durability significantly extends chain life.

A redesigned rotor scraper with wider fingers reduces power consumption and provides improved cleaning, reducing the likelihood of wrapping in long crops and improving performance in highyielding, high-moisture grass. New for both models are a 1,000 rpm PTO option available as an alternative to the standard 540 rpm driveline, providing higher inertia for smoother crop flow, reducing blockage potential in heavy grass and matching the demands of chopping with the full set of knives in dense swaths. On Silage Pack models with

either of the two PTO drive specifications, the main gearbox has been tilted upward by 3.5 degrees for better PTO shaft alignment to maximize durability. Silage Pack versions also benefit from the addition of a deflector in the bale transfer area to prevent crop accumulation and any need to spend time on removal.

Key component durability has been further enhanced by new greaseable bushings on the tailgate locks and new bushings for the drop floor pivot arms on both standard and Silage Pack models, plus improved sealing for the conveyor cylinder to prevent water ingress and protect the integral position sensor.

Silage Pack versions now benefit from an improved bale quarter-turn system, with a higher-strength gas strut to decrease the manual handling force required while folding from field to road position. A longer plastic stop helps reduce plastic damage risk while tipping the bale. Tailgate opening time is now 38% faster on both models for quicker operation with reduced damage risk.

Smart, compact and featuring a front cab; the new 300M expands John Deere’s selfpropelled sprayer portfolio in the compact segment.

Featuring the latest Precision Ag technology, a minimum turning radius and two types of boom with or without air sleeve, the 300M is the new specialist sprayer for narrow areas and high-value crops.

With the 332M and the 340M, two model variants are introduced. The 332M offers a tank size of 3200 litres and a 175 hp 4-cylinder John Deere engine. A boom width of up to 28 metres and a turning circle of 3.8 metres are ideally suited for work in narrow areas.

The 340M has a tank size of 4000 litres and a working width of up to

36 metres. This width, the 225 hp 6cylinder John Deere engine and a turning circle of 4.2 metres facilitate high performance and compact operation at the same time.

With their compact design and allwheel steering, both variants of the 300M are suited for narrow roads and field work in any situation.

Automatically adjustable track width from 150-180cm, 180-225cm and 225-300cm allow flexible use in all types of crops, including high-value. The 50:50 weight distribution reduces soil compaction and makes work possible even under difficult conditions.

The John Deere 300M is equipped with the latest John Deere Precision Ag essentials, such as the StarFireTM Receiver, the G5Plus Universal Display

and JDLinkTM. The new cab position provides excellent all-round and boom visibility. The suspended and heated seats provide the best comfort, and the new CAT 4 cab is equipped with the latest filter technology.

Both models of the 300M are offered with a steel boom and a stainless-steel boom with air sleeve. Both are available with Individual Nozzle Control. Particularly when used in high-value crops, the airassisted boom of the 300M provides excellent coverage of tall and leafy crops by increased penetration of the crop canopy. The air curtain opens the crop and swirls the spray into the foliage making it ideal for lettuce, vegetables and strawberries.

The PowrSprayTM two-circuit liquid

system design is also a key feature on the 300M. It offers fast filling of up to 600L/min and a highly precise output of 750L/min at three bars. With its unique design and fast response time of only three seconds from minimum to maximum, the centrifugal spray pump with direct rate control offers an accuracy of 98%.

PowrSprayTM technology, already used on the trailed model R700i, offers a variety of advantages such as stress-free filling thanks to ActivePause and the 50-litre PowrFill eductor.

The John Deere 300M will be available in France, Poland, Spain and the UK with the model year 2024.

Other countries will follow in the next few years.

Sprinter is the drill you can depend on in all conditions. For use after the plough, minimum cultivation and direct sowing. 3000 to 8000 litre hopper and Duett coulters to micro-loosen underneath the seed horizon.

Avatar SD is a high performance direct drill with single disc coulter. Available in 3m to 12m working widths, it features a 2-bar design for high harvest residues and single, double or triple hopper for seed, fertiliser and microgranules.

Visit horsch.com, your local HORSCH dealer or call 01733 667895.

Some direct dril ls from around the world may have been a good idea when they were invented. But times have changed–so keep up with the future. With a Novag drill you’re not only investing in the world’s mostinnovativeno-tillagedrill,butyou’ll alsoreceivehealthy soils that will make the next generat ion’s farming a success. Cut your costs and working hours and let the worms, fungi and bac teria do the job for you. Enjoy increasing carbon sequestration, water storage and nutritional quality–all while increasing yields and revenues! It even helps you to restore thriving ecosys tems. This may sound like a fairytale, but it works.

Novag \ www.novagsas.com

The modern precision agricultural equipment is strongly driven by technical innovation through electrification and cross brand digitalization. Critical advancements in agricultural equipment have made it possible for farms to track crop production with great precision. Electronically integrated equipment is used to optimize crop potential by ensuring that the correct amount of water, seed, pesticide, and fertilizer are applied to the crops via GPS. This new way of farming is accomplished with the help of monitors, sensors, and cross brand computerized systems.

Powell Ag Solutions circular connectors:

• Feature high-temperature silicone to act as a barrier from hydraulic fluids, fossil fuels, and lubricating oils.

• Environmentally sealed to IP67/IP69K protection in mated condition.

• Offers excellent protection from ingress of dust, water, fertilizer, pesticides, and mud.

• Operational in temperatures ranging from -55 °C to 125 °C, functioning well in exposed cold weather environments, and withstand the high temperatures seen in most agricultural equipment applications.

• Designed with a rapid and secure mating system that is also highly vibration resistant.

qualities of this engine are far superior to the previous Stage IV engine,” explains ROPA operator Werner Hofbauer. “The two serially connected turbochargers ensure a very agile behaviour, which suits this machine really well.”

“All machines have different requirements,” continues Anna Maria Ullnert, Product Manager Industrial at Volvo Penta. “That’s why we work closely with our customers to secure the best configuration for their specific needs. Through cooperation with operators, designers, and OEMs, we support our customers with everything from performance predictions and application integration to verification and rigorous field testing.”

This comes as no surprise to ROPA, whose three-decade-long partnership with Volvo Penta has helped the company build and maintain its favorable reputation. “We have been using Volvo Penta’s combustion engines for over

30 years – many of them are still running today with 15,000 hours and more on the clock, but they are no trouble,” concludes Michael. “That’s why we have a lot of trust in Volvo Penta and believe their engines help make one of the best powertrains of any beet harvester on the market. The D16 is a great fit for the Tiger 6S and will be instrumental in helping us keep – and increase – our market-leading position.”

COLCHESTER

FULBOURN 01223 880676

AMAZONE is expanding its range of precision seeders with the new trailed models, Precea 9000-TCC and 12000-TCC, in working widths of 9 and 12 m respectively.

This variant, which has been developed specially for large-scale farms and contractors, stands out with its high-performance overpressure singling, large tank capacities and innovative Central Seed Supply seed delivery system. The highprecision seed placement ensures optimum field emergence, even at increased working speeds of up to 15 km/h.

For exceptionally high work rates and reduced fill times, the new Precea-TCC models feature a central seed hopper with a capacity of 2,000 l for up to two big bags. The new Central Seed Supply seed delivery system carries the seed from the central hopper to the singling units via an air stream. There, the seed for each row is temporarily stored in a small reception unit. Once this reception unit reaches the maximum fill level, the air stream is automatically cut off by the stored seed, shutting off any further supply. When the fill level decreases again, the air stream restarts automatically

and conveys new seed from the main hopper to the individual rows. Thanks to the intelligent air stream system of the Central Seed Supply, every singling unit is independently supplied with seed, without the need for complex sensor systems or electronic controls.

For seed singling, AMAZONE uses its high-precision PreTeC singling units, which function based on the overpressure principle. This means the seed is pressed against the singling disc by air pressure. The seal rotates along with the singling disc, which considerably reduces the power consumption of the electric drives for the individual rows. The remotely controlled, automatic SmartControl stripper finger adjustment is coupled with the optical sensors and effectively prevents any misses or doubles. Meanwhile, the electrically-driven singling disc turns in relation to the forward speed and desired seed rate; conveying the seed towards the propulsion channel. At this point, the contact pressure is broken, and the seed is shot precisely into the seed furrow, caught by the catcher roller, and securely embedded. The furrow formers ensure the precise seed placement. Two carrying rollers and

the high, hydraulically adjustable coulter pressure ensure uniform depth control. For even greater convenience, AMAZONE offers SmartForce automatic coulter pressure regulation. This ensures that the set contact force remains constant for a consistently uniform seed placement, especially in variable soil conditions The ElectricDrive electric metering drive allows the desired seed rate to be conveniently set via the ISOBUS terminal and serves as the basis for precise, part-area, site-specific rate control using GPS and field zone maps. In addition, the GPS SectionControl actively saves seed row-by-row in wedge-shaped fields and on headlands, especially at these larger working widths, and provides optimal conditions for mechanical weed control with a hoe.

The electric drive for the individual rows also make it possible to maintain evenly spaced placement across the entire working width. A yaw sensor is used to calculate the difference between the forward speed on the inside and outside of

the bend. The innovative CurveControl then adjusts the speed of the each singling disc accordingly, ensuring that the seed spacing remains uniform, even around bends. The even spacing allows the plants to be adequately supplied with nutrients. This results in homogeneous crops and ensures even ripening. For the simultaneous application of fertiliser, the PreceaTCC is equipped with an easily accessible twin-chamber hopper with a total filling volume of 6,000 l. Each hopper has its own electric metering unit that is connected to a distributor head, meaning that halfside shut-off is available as standard. Fertiliser is placed via the FerTeC twin HD fertiliser coulter. The relationship between the placement depth of the fertiliser and the sowing depth is set only once. If the sowing depth is subsequently changed, the fertiliser automatically adjusts the fertiliser placement depth accordingly. The Precea-TCC is offered with 12 or 16 rows for row widths of 70, 75 and 80 cm. A telescopic axle is available for the running gear of the Precea. During field operation, this allows the position of over-sized tyres to be adjusted so that the wheels run between the seed rows, preventing compaction directly beneath the seed rows.

KUHN has launched a new high capacitytrailedsprayer.

The new LEXIS 3800 with a 3800 litre nominal capacity is the largest in the range, with two further models offering 2400 litre and 3000 litre capacities respectively.

The LEXIS is compact and lightweight despite its ability to carry 4000 litres. It has a maximum length of 6.90 metres and an overall width of 2.55 metres. Featuring aluminium booms up to 28 metres, the LEXIS still has an unladen weight of just over 3 tonnes. The latest model also features new Ø1.85m tyres with a

very high flexion (VF) option from 320 to 520mm which will help to reduce compaction and protect soil health.

The LEXIS can be specified with KUHN’s MANUSET manual rinse operation which only requires two main valves that are controlled from the operator’s control station. Multifunction handwheels reduce handling operations by up to 50 percent and the ergonomic design means valves are easily operated for a simple, trouble-free set-up.

During rinsing, a complete turn with the delivery circuit handwheel ensures that the water drawn in by

the pump is conveyed into all sprayer circuits. The rinsing tank level gauge, visible from the workstation, also enables easy sequencing of the rinsing operations.

The new LEXIS is also available with DILUSET+ which offers operators assisted management of filling and dilution of residual volumes.

Spraying with the LEXIS can be operated using KUHN’s CANBUS control box, a CCI 800 or 1200, or any other ISOBUS terminal.

The LEXIS is stable and manoeuvrable because the shape of its tank has lowered the centre of

gravity. This improves stability, even with a reduced track width of 1.50m or when spraying on gradients. The short tow eye-axle distance of 4.30m coupled with the TRACK ASSIST gyroscopic steering drawbar system also improves tracking in the tractor wheels.

The LEXIS can be fitted with CCE individual nozzle control, AUTOSPRAY PWM technology or the BOOM ASSIST EXTREME contour control system. KUHN’s CCI Connect solutions and MyKUHN portal also provide remote access to the machine and feedback on the tasks performed to harness valuable operational and application data.

Knight Farm Machinery’s latest innovations give operators confidence they can achieve totally accurate spraying while also ensuring they meet all relevant environmental standards. The “Vario Select” system ensures totally even spraying performance even when working on curved routes, around in-field obstructions and on field margins. It uses a combination of four different nozzles at each spray point to offer up to 16 application rates, typically from zero to 800 litres/minute. When the machine turns the gyroscope measures the severity of the turn and adjusts spray levels across the boom. On the inside of the machine, where the boom is travelling slower – application rates get progressively lower while on the outer side, which is going faster, they are progressively raised. It also uses a simple computerised nozzle selector so operators can dial in the target rate, droplet size, minimum and maximum pressures and working speeds: “They can also ask the system to recommend the best choice of nozzles for any particular job”, says Brian Knight. “It enables the machine to ‘spot spray’, with the volume of spray applied being changed according to the severity of the weed, pest or disease problem”. “Active Rinse” supplies fresh water to key parts of the sprayer to ensure totally efficient use of chemicals while minimising the amount of chemical solution in the plumbing. At the end of spraying the system can flush the boom and pipework with clean water and return the washings to the main tank, making moving between fields and on the road much safer. An optional ‘air blow out’ can evacuate all liquid from the pipework and boom to offer an extra level of protection.

The system meets an urgent need says Brian: “The NSTS testing scheme continues to report leaks and drips as the leading fault in sprayers being tested, and unlike other faults, the level of problems is not reducing.

FirstItalianexhibitiondisplayof strikingnew80-117hprange Technology focus to include new FieldOps™app

Standtoalsofeatureflagship313hp 6340 Terrus CVT

Among the highlights of the STEYR® stand at EIMA International 2024 (B/5 in hall 14, Nov 6-10) will be a technology focus including the FieldOps™ multi-brand connected machine app, the 340hp 6340 Terrus CVT –the largest tractor ever offered by STEYR – and the new Plus range of 80-117hp tractors which returns a revered name to the brand’s range, bringing more capacity and fresh look to the utility tractor segment.

The Plus, which is a Tractor of the Year 2025 finalist in the Utility category, has won multiple design awards for its striking styling since its launch late last year, and competes in a sector that is especially

important in Italy and many neighboring countries, with many farms seeking compact mid-size tractors capable of performing both arable and grassland tasks on lowland and on hilly and mountainous grazing ground. With the farmers who run such enterprises increasingly seeking higher levels of technology to help them operate their businesses more efficiently, the STEYR Plus range has been designed with a comprehensive specification and a wide list of options.

The five models all feature fourcylinder FPT Stage V 3.6-litre engines and a 40kph 24F/24R transmission with two-speed powershift, an electro-hydraulic powershuttle and optional creeper. A brake-to-clutch feature allows one-foot drive disengagement and braking, and a full range of STEYR loaders is available, as is the ability to order a tractor complete with loader. The restyled cab can be equipped with

a full array of precision farming technology, including STEYR SGuide steering automation and connectivity, for the first time at this power level.

Stand visitors will be able to investigate the latest CNH precision technology products, visit a Connect Room showing the value of remote monitoring, and investigate what such technology can do for their businesses. A further stand focus will be the new STEYR FieldOps mobile app and web platform, which connects and integrates agronomic insights and machine performance data, creating a complete all-make picture of a farm’s connected machine fleet. Telematics subscriptions on selected new machines can be eliminated with the new Connectivity Included feature.

The STEYR stand will also showcase the 6340 Terrus CVT, the largest

tractor ever to bear the STEYR name. Making its EIMA debut, the 340hp (max) 6340 Terrus CVT tops a range which also includes the 290hp 6290 Terrus CVT and 313hp 6315 Terrus CVT. Producing 340hp maximum power – an unboosted figure available all the time – and maximum torque of 1,398 Nm at 1,400rpm, the 6340 Terrus CVT is built to meet the demands of Italy’s largest farms.

In addition, the stand will feature the latest parts and service innovations from CNH Parts & Service, aimed at helping customers get the maximum from every machine through its lifecycle, for more uptime and productivity, and reduced operating cost. Via mycnhstore.com, the online parts store available in five European countries, customers are guaranteed secure, convenient and personalised parts purchases, with the ability to receive quotes, select a “click&collect” option, share their cart, and more.

KUHN has launched a new high capacitytrailedsprayer.

The new LEXIS 3800 with a 3800 litre nominal capacity is the largest in the range, with two further models offering 2400 litre and 3000 litre capacities respectively.

The LEXIS is compact and lightweight despite its ability to carry 4000 litres. It has a maximum length of 6.90 metres and an overall width of 2.55 metres. Featuring aluminium booms up to 28 metres, the LEXIS still has an unladen weight of just over 3 tonnes. The latest model also features new Ø1.85m tyres with a

very high flexion (VF) option from 320 to 520mm which will help to reduce compaction and protect soil health.

The LEXIS can be specified with KUHN’s MANUSET manual rinse operation which only requires two main valves that are controlled from the operator’s control station. Multifunction handwheels reduce handling operations by up to 50 percent and the ergonomic design means valves are easily operated for a simple, trouble-free set-up.

During rinsing, a complete turn with the delivery circuit handwheel ensures that the water drawn in by

the pump is conveyed into all sprayer circuits. The rinsing tank level gauge, visible from the workstation, also enables easy sequencing of the rinsing operations.

The new LEXIS is also available with DILUSET+ which offers operators assisted management of filling and dilution of residual volumes.

Spraying with the LEXIS can be operated using KUHN’s CANBUS control box, a CCI 800 or 1200, or any other ISOBUS terminal.

The LEXIS is stable and manoeuvrable because the shape of its tank has lowered the centre of

gravity. This improves stability, even with a reduced track width of 1.50m or when spraying on gradients. The short tow eye-axle distance of 4.30m coupled with the TRACK ASSIST gyroscopic steering drawbar system also improves tracking in the tractor wheels.

The LEXIS can be fitted with CCE individual nozzle control, AUTOSPRAY PWM technology or the BOOM ASSIST EXTREME contour control system. KUHN’s CCI Connect solutions and MyKUHN portal also provide remote access to the machine and feedback on the tasks performed to harness valuable operational and application data.

Knight Farm Machinery’s latest innovations give operators confidence they can achieve totally accurate spraying while also ensuring they meet all relevant environmental standards. The “Vario Select” system ensures totally even spraying performance even when working on curved routes, around in-field obstructions and on field margins. It uses a combination of four different nozzles at each spray point to offer up to 16 application rates, typically from zero to 800 litres/minute. When the machine turns the gyroscope measures the severity of the turn and adjusts spray levels across the boom. On the inside of the machine, where the boom is travelling slower – application rates get progressively lower while on the outer side, which is going faster, they are progressively raised. It also uses a simple computerised nozzle selector so operators can dial in the target rate, droplet size, minimum and maximum pressures and working speeds: “They can also ask the system to recommend the best choice of nozzles for any particular job”, says Brian Knight. “It enables the machine to ‘spot spray’, with the volume of spray applied being changed according to the severity of the weed, pest or disease problem”. “Active Rinse” supplies fresh water to key parts of the sprayer to ensure totally efficient use of chemicals while minimising the amount of chemical solution in the plumbing. At the end of spraying the system can flush the boom and pipework with clean water and return the washings to the main tank, making moving between fields and on the road much safer. An optional ‘air blow out’ can evacuate all liquid from the pipework and boom to offer an extra level of protection.

The system meets an urgent need says Brian: “The NSTS testing scheme continues to report leaks and drips as the leading fault in sprayers being tested, and unlike other faults, the level of problems is not reducing.