The global agricultural tires market size was valued at USD 8.39 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 12.6 Billion by 2033, exhibiting a CAGR of 4.15% during 2025-2033. North America currently dominates the market, holding a significant market share of over 37.1% in 2024. The rising food demand, the emerging technological advancements in tire technology, and the implementation of favorable government policies to promote modernization and mechanization in the agriculture sector are some of the major factors propelling the market across the North American region.

The migration of people from rural to urban regions, rising labor costs, and lack of skilled labor in most developing countries fuel tractor sales. Farm labor shortage and rising costs are among the main reasons for the increasing Market CAGR of the farming industry. The increasing need for operational efficiency and the rise in labor costs are expected to boost the agricultural tires market revenue over the forecast period. The market for agricultural tractors will be driven by limited labor availability. Considering simple demand-supply economics and the transfer of labor from urban to rural areas, farm labor costs are directly linked to the percentage of a country's entire population employed in agriculture. Hence, farm owners invest in farm equipment to reduce dependency on human labor, reducing the time and effort taken for farming.Farmers increasingly invest in less workforce equipment to work at optimum capacity. Although these equipment types come with a high initial investment, they help improve overall crop quality and quantity. Many farmers are scaling down their agricultural operations and leasing out a portion of their farms to offset rising labor costs.As more farmers reduce their dependency on labor, tractor sales are expected to witness healthy growth in the coming years, thereby driving the demand for tractor tires over the forecast period.

The demand for tractor tire replacements in Europe is significantly rising, influenced by key market dynamics. Agricultural growth is driven by increasing food requirements and sustainable practices, necessitating reliable machinery and, thus, more frequent tire replacements. Additionally, technological advancements in tire design enhance performance and durability, prompting farmers to upgrade their tires for better efficiency. Lastly, environmental regulations are pushing for machinery upgrades to meet stricter standards, further driving the replacement market. Stakeholders must adapt to these evolving trends to effectively capitalize on this growing segment.

Technological advancements in tire manufacturing are markedly shaping the demand for tractor tires in the Europe tractor tires industry, driven by innovations that enhance performance and sustainability. Intelligent automation and Industry 4.0 principles are streamlining production through robotics and AI, improving efficiency and safety. Additionally, additive manufacturing techniques like 3D printing enable rapid prototyping and innovative designs, exemplified by Michelin's eco-friendly 3D-printed tires. The focus on sustainable materials, such as Bridgestone's Guayule rubber, reflects a commitment to reducing environmental impact while meeting performance standards. Finally, integrating the Internet of Things (IoT) allows real-time tire monitoring, enabling proactive maintenance and enhancing operational efficiency. As agricultural practices evolve, these advancements drive significant growth in the market.

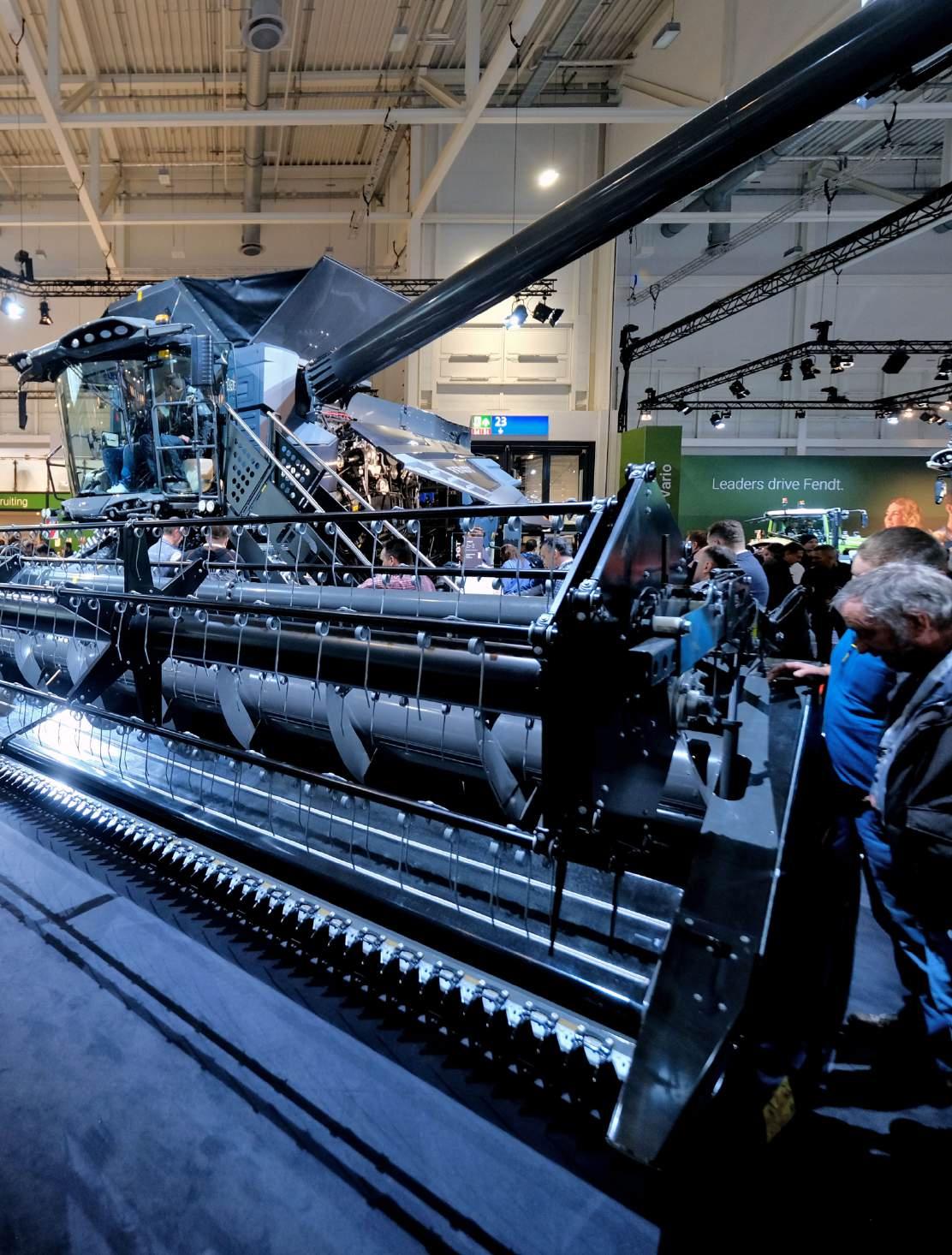

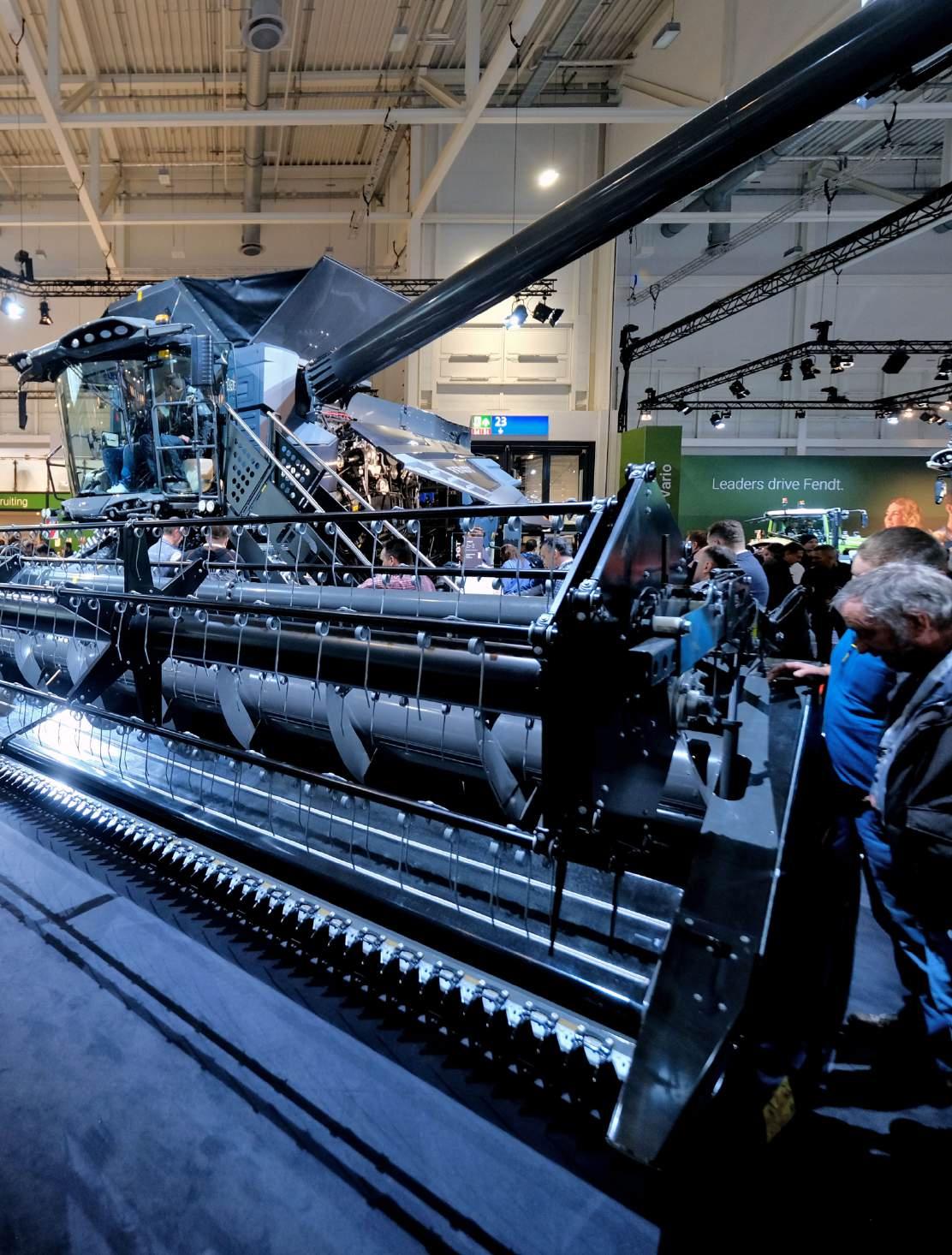

Claas has unveiled their Lexion 8900 Terra Trac for the first time on North American soil at the Ag in Motion farm show in Saskatchewan, Canada.

“More than a machine,” the top model in the Lexion lineup offers the most available horsepower in their largest combine range, delivering 779 max horsepower (SAE) from a highly efficient 16.2L MAN engine with Dynamic Power – an increase of 89 hp over the Lexion 8800 model.

The Lexion 8900 Terra Trac class-10+ combine is particularly well suited for the large-scale small grain operations common in western Canada and other key growing regions in the US. While the Lexion 8900 Terra Trac is new to North America, it’s been offered in elect regions around the world since 2019.

The machine displayed at the Ag in Motion show is special for a couple of reasons: It’s the first Lexion 8900 Terra Trac combine available in North America, and it features a unique paint scheme and graphics

commemorating the production of more than 500,000 combines since Claas – the undisputed European market leader for decades – started producing them in the 1930’s.

For 25 years, the Lexion combine has delivered unparalleled performance and efficiency for growers across the globe,” said Combine Product Manager Greg Frenzel at Claas of America. “The Lexion 8900 Terra Trac offers farmers throughout North America more power and productivity than ever before with all of the familiar performance accessories farmers have come to expect from Claas.”

The latest edition to the Claas combine offering is steeped in Lexion DNA, featuring leading fuel efficiency, superior grain retention, massive throughput, and the most advanced track system – Terra Trac –in the industry, all hallmarks of the Lexion 8000 series.

Threshing and separation is handled through the field-proven APS Synflow hybrid system featuring an accelerated pre-separation system

that threshes up to 30% of the grain before the crop reaches twin rotors that gently finish the separation process. Unlike with other combines in its class, the threshing and separation speeds are controlled independently, giving the machine the ability to harvest quickly without compromising grain quality.

Coupled with the Claas-exclusive Cemos Automatic combine automation system, the Lexion 8900 Terra Trac makes autonomous and automatic real-time in-field adjustments as field conditions change with more precision and speed than a seasoned operator.

The grain handling system on the Lexion 8900 Terra Trac is sized to match its incredible throughput. The machine features a 510-bushel grain tank and a lightning-quick 5.1 bushel-per-second unloading speed for large, high-yielding fields.

Adding to the efficiency of the machine, is another Claas-exclusive feature: The Dynamic IC Cooling System on the Lexion combine is found on the top of the machine,

where the air is cooler and cleaner. The system senses the workload of the combine and directs more power to the cooling fan when the load is high and less when it isn’t; pulling just the right amount of power to keep the engine cool with an eye on fuel efficiency. Coupled with its AUTO LUBE system (standard on the Lexion 8900 Terra Trac), the performance of the Dynamic Cooling System also helps reduce daily maintenance.

The Lexion 8900 is exclusively offered with the Terra Trac undercarriage, for a smooth ride, superior traction, minimal compaction, and excellent header stability for the biggest farming operations.

Claas offers a wide range of headers designed to maximize the performance of the high-capacity Lexion 8900 Terra Trac, including the Convio Flex 1530 with a 50 ft./15.3 m working width and 9 in / 225 mm flex range. This advanced flex draper features Auto Belt Speed as well as Active Float operator assistance systems for fast and efficient crop gathering.

A harrow that can do more than just spread straw Also suitable for modern

The harrow is commonly used to spread the straw after threshing with the combine at an angle of 20° to 30° to the sowing/threshing direction. Several passes with the harrow, ideally at intervals of 8 to 10 days apart, will give the best results.

The characteristics of the harrow are the large area output due to the large working width, the high speed of up to 25 km/h and, above all, the low diesel consumption of 1.5 to 3 l/ha.

The harrow cultivates the soil superficially, with the tines scraping the surface. The stalk bends and the straw collected between the harrow tines is pulled behind it. Due to the arrangement of the tines, the straw is released at the headlands where there is little or no straw, distributing the crop evenly.

3Check valves on double-locking hydraulic cylinders as standard.

3Teeth guard for use on public roads.

3Hydraulic tooth angle adjustment - from simple sliding to deep plunging.

3Load centre close to tractor, strong square frame.

3The harrow sections are flanged to the main frame, not welded.

3The teeth are made of 16 mm spring steel with a total tooth length of 84 cm.

3Protective bushes on bolted connections.

3Grease nipples on pins and joints.

Hauptstraße 8–10, D-94439 Roßbach / Münchsdorf Tel.: +49 (0) 8723 / 91 01 34, E-Mail: wallner.export@gmail.com www.wallner-maschinen.de

Case IH AF series takes Axial-Flow principle into new capacity class

Trelleborg Tires’ award-winning ProgressiveTraction® technology enhances the tread of its iconic TM800 line, boosting traction, fuel efficiency, and overall performance for greater productivity in agricultural operations

Bigger feederhouse with more lift capacity for wider headers

Longest single rotor and largest grain tank capacity in the sector

The Pöttinger Novacat V 9200 CF is now available with Cross Flow ROSS FLOW auger which can be used very effectively on grassland as well as with whole plant silage.

Powerful engines producing up to 775hp

Two sizes for mid- to high-horsepower tractors (540/65R28 and 650/65R38) have been released, with four more rolling out progressively in the upcoming weeks.

The Austrian agricultural machinery manufacturer Pöttinger launched a revolution in mowing technology some years ago, making it possible to merge swaths without using conditioners.

Double cleaning shoe with automatic cross-distribution maximizes grain quality

AThe TM800 ProgressiveTraction® delivers up to 17% more traction on soft soil and 10% on hard soil, ensuring superior grip and enhanced field performance under varying conditions

new capacity class is being added to the Case IH Axial-Flow range for 2024, with the European launch of the new AF9 and AF10 combines. They share a ground-up new design providing significant capacity advances from front to rear, while maintaining the simple yet effective Axial-Flow principles of single-rotor threshing and separation.

Cross Flow is the name of this cost effective system. A cross flow auger is integrated into the mower to deposit the forage either merged into a swath, or spread over the working width of the rear mower, or as a wide swath to one side.

Trelleborg Tires has announcesd a range extension for its TM800 ProgressiveTraction®, with two sizes (540/65R28 and 650/65R38) already released for mid- to high-horsepower tractors, and four more set to roll out progressively in the upcoming weeks.

Cross Flow is now also available for the Novacat V 9200. This mower combination features impressively low weight and a low power requirement.

Advancing from its iconic TM800 tire line, this latest evolution sets a new benchmark in agricultural performance. This tire line features Trelleborg Tires’ proprietary ProgressiveTraction® technology, an award-winning innovation celebrated for its proven results in modern farming applications. The TM800 ProgressiveTraction® is designed to deliver outstanding results across diverse agricultural terrains, from soft to hard soils. By enhancing operational

Feedback from the field was the basis for this development, following demand for a cost-effective and straightforward system for merging swaths. Cross Flow works without a conditioner and is characterised by its low weight compared to conventional swath merging systems. This technology ensures optimum conservation of the forage and soil, as well as the running costs, thanks to the fuel savings.

The AF9 and AF10 launch completes the Case IH ‘Year of the Combine’ that began with the Axial-Flow 160 and 260 series release. Case IH now offers the industry’s largest line of single-rotor combines, staying true to a system it pioneered in 1977. The new models feature key components designed to minimize total cost of harvesting for the largest farming and contracting operations. The AF10 is powered by a 775hp FPT Cursor 16 engine, while the AF9 features an FPT Cursor 13 producing 635hp. Both units are mounted lengthways for simplicity of drive and efficiency of power transmission, with engine rpm when harvesting lowered from 2,100 to 1,900rpm, boosting fuel efficiency. Service intervals have been extended from 600hrs/one year to

750 hrs/two years, with additional operating cost benefits. AF10 grain tank capacity is 20,000 litres – the joint largest in the industry for reduced unloading downtime –with a 210 l/sec unloading rate, while comparable figures for the AF9

are 16,000 litres and 159 l/sec. There are four unloading auger length options to match different header widths, while a pivoting spout aids even unloading, and cross-auger shutoff ensures the unloading auger is emptied if part-unloading the tank.

And, without a conditioner, the forage is handled extremely gently. Thanks to the closed trough shape, the forage is transported directly from the sward to the swath. This prevents forage losses, minimises dirt ingress and avoids disintegration losses.

efficiency, it reduces working time per hectare, improves fuel economy, and extends tread life, ensuring more productive and cost-effective farming operations.

Morecompactdesign,reduced turningradiusmeansgreater manoeuvrability

Loweroverallheighteases building access

More lift height aids tasks such as bale stacking

Case IH is strengthening its Farmlift telescopic loader range by launching a new particularly compact Farmlift 626 that offers increases in manoeuvrability, accessibility and capability compared to its predecessor.

These include higher lift height for greater productivity, a reduced turning radius to make yard work easier, and a lower overall height for better access to low doorways and buildings. This means the Farmlift 626 suits a wide range of applications across livestock businesses and many other enterprises.

The Farmlift 626 is powered by a

74hp (54.6kW) four-cylinder engine driving through a single-range 30km/ hr hydrostatic transmission. A mechanical electro-proportional hydraulic system is powered by a gear pump providing 80 l/min of oil flow at 210 bar pressure. Maximum lift capacity is 2,600kg, while the new model offers 0.22m more maximum lift height than its predecessor, at 5.9m. Headstock rotation on the Farmlift 626 is 155°, for faster unloading.

At just over 4m, the new machine is shorter than its predecessor, yet its 2.525m wheelbase is slightly longer, a combination which helps ensure good stability when handling heavy loads or working at speed. With a reduced outside turn radius of 3.25m, the Farmlift 626 is easier to manoeuvre where yard and building space are restricted. Access to buildings, doorways and gateways is also enhanced by a lower overall height of 1.93m and a 1.89m overall width. Despite the narrow breadth of the Farmlift 626, its 960mm-wide

cab is broader than the one on the model it replaces, providing greater operator comfort.

For the first time on a Case IH compact telehandler, the specification can include TMR homologation. If road registration is required, this simplifies the process, and with TMR approval the Farmlift 626 can be factory-fitted with a trailer hitch and hydraulic or pneumatic trailer braking. The optional telematics provides instant identification of location, plus automated monitoring and recording of operating and performance data. Via the Case IH FieldOps™ app, data from the Farmlift 626 and all connected machines in a fleet can be monitored via any online smart device or PC. Further options include carbon filters for the cab ventilation system to protect operator health in particularly dusty conditions.

AMAZONE is expanding its range of precision seeders with the new trailed models, Precea 9000-TCC and 12000-TCC, in working widths of 9 and 12 m respectively.

This variant, which has been developed specially for large-scale farms and contractors, stands out with its high-performance overpressure singling, large tank capacities and innovative Central Seed Supply seed delivery system. The highprecision seed placement ensures optimum field emergence, even at increased working speeds of up to 15 km/h.

For exceptionally high work rates and reduced fill times, the new Precea-TCC models feature a central seed hopper with a capacity of 2,000 l for up to two big bags. The new Central Seed Supply seed delivery system carries the seed from the central hopper to the singling units via an air stream. There, the seed for each row is temporarily stored in a small reception unit. Once this reception unit reaches the maximum fill level, the air stream is automatically cut off by the stored seed, shutting off any further supply. When the fill level decreases again, the air stream restarts automatically

and conveys new seed from the main hopper to the individual rows. Thanks to the intelligent air stream system of the Central Seed Supply, every singling unit is independently supplied with seed, without the need for complex sensor systems or electronic controls.

For seed singling, AMAZONE uses its high-precision PreTeC singling units, which function based on the overpressure principle. This means the seed is pressed against the singling disc by air pressure. The seal rotates along with the singling disc, which considerably reduces the power consumption of the electric drives for the individual rows. The remotely controlled, automatic SmartControl stripper finger adjustment is coupled with the optical sensors and effectively prevents any misses or doubles. Meanwhile, the electrically-driven singling disc turns in relation to the forward speed and desired seed rate; conveying the seed towards the propulsion channel. At this point, the contact pressure is broken, and the seed is shot precisely into the seed furrow, caught by the catcher roller, and securely embedded. The furrow formers ensure the precise seed placement. Two carrying rollers and

the high, hydraulically adjustable coulter pressure ensure uniform depth control. For even greater convenience, AMAZONE offers SmartForce automatic coulter pressure regulation. This ensures that the set contact force remains constant for a consistently uniform seed placement, especially in variable soil conditions The ElectricDrive electric metering drive allows the desired seed rate to be conveniently set via the ISOBUS terminal and serves as the basis for precise, part-area, site-specific rate control using GPS and field zone maps. In addition, the GPS SectionControl actively saves seed row-by-row in wedge-shaped fields and on headlands, especially at these larger working widths, and provides optimal conditions for mechanical weed control with a hoe.

The electric drive for the individual rows also make it possible to maintain evenly spaced placement across the entire working width. A yaw sensor is used to calculate the difference between the forward speed on the inside and outside of

the bend. The innovative CurveControl then adjusts the speed of the each singling disc accordingly, ensuring that the seed spacing remains uniform, even around bends. The even spacing allows the plants to be adequately supplied with nutrients. This results in homogeneous crops and ensures even ripening. For the simultaneous application of fertiliser, the PreceaTCC is equipped with an easily accessible twin-chamber hopper with a total filling volume of 6,000 l. Each hopper has its own electric metering unit that is connected to a distributor head, meaning that halfside shut-off is available as standard. Fertiliser is placed via the FerTeC twin HD fertiliser coulter. The relationship between the placement depth of the fertiliser and the sowing depth is set only once. If the sowing depth is subsequently changed, the fertiliser automatically adjusts the fertiliser placement depth accordingly. The Precea-TCC is offered with 12 or 16 rows for row widths of 70, 75 and 80 cm. A telescopic axle is available for the running gear of the Precea. During field operation, this allows the position of over-sized tyres to be adjusted so that the wheels run between the seed rows, preventing compaction directly beneath the seed rows.

Farming, ranching and agribusiness industries are plentiful in Canada. Your future opportunities and quality of life await! Invest in a dynamic and vibrant country that offers successful export, technology, resources, mineral, infrastucture and educational advantages.

Let our partnerships do the hard work for you! Our partnership with Interfarms.nl connects our Canadian and European farm markets in addition to providing helpful resources and advice to our clients looking to immigrate. We also work closely with MNP accountants to obtain international tax advice direct from the experts. We are available to communicate in english, german and dutch languages.

*Used* Deutz 6180,16 reg, FL, front pto .................................£55,000

*Used* Deutz 7250,16 reg, FL, front pto, 3500hrs £75,000

*Used* Deutz 62 15TTV 18 reg, 3000hrs, full spec POA

*Used* Deutz8280, full spec, 60k, front linkage, 710/70/42 80% tyres

*Used* John Deere 6170R 14 reg, 50k, 6,000 hrs

*Used* John Deere 6155R, 1150 hrs, full spec, 21 reg

*Used* John Deere 6900 40k, R reg £16750

*Used* John Deere 6330 07 reg, 40k, air con

*Used* John Deere 6330 10 reg, 40k, air con, 6500hrs

*Used* John Deere 6330 10 reg, 40k, loader, air con, 6250hrs

4x 580/60/22.5 wheel and tyre assemblies, ex Bateman sprayer

*Used* Claas Variant round baler, nice condition £13,300 *Used* John

MWS is the largest specialist in the production of cutting tools for agricultural, forestry & municipal technology

QUALITY «MADE IN GERMANY» FROM MWS –PRODUCER OF ORIGINAL CUTTING TOOLS FOR WORLD BRANDS

OUR STRENGTHS:

• assortment of over 5000 items,

• quality Made in Germany,

• production of cutting tools according to individual requirements,

• increase of service life up to 4 times due to wear-resistant coating

OPICO introduced a new version of its HE-VA Combi-Disc cultivator at the Highland Show.

Designed specifically for those running mid-sized tractors, the new model has a 2.45m working width and four deep soil-loosening legs –rather than the five employed on 2.75m versions. These changes put the horsepower requirement for the smallest Combi-Disc at just 155hp, making this versatile one-pass tillage tool much more accessible to a wider range of growers.

The Combi-Disc employs two leading rows of soil-loosening legs followed by two rows of serrated sabre discs to provide a surface chopping and mixing effect. This is all followed up with V-profile roller to produce a corrugated, weatherproof finish. It’s this combination of soil-engaging elements that makes the Combi-Disc such an adaptable tool. In normal circumstances the

tines, discs and press are used in partnership to turn previously uncultivated ground into a seedbed in one pass. When conditions require it, the discs can be lifted completely out of work, enabling the unit to be used as a straightforward subsoil loosener/pan-buster.

Likewise, with the legs lifted out of contention, the machine can be put to work as a straightforward shallow disc cultivator. The recent addition of new ‘Stealth’ soil-loosening legs adds further to the Combi-Disc’s versatility, making it a true low disturbance subsoiler with the added ability of providing some surface tilth creation at the same time.

If it’s lift capacity that is the tractor’s limiting factor rather than power, there is also the option to specify the Combi-Disc with a cage roller rather than the standard V-profile ring-press. This brings the 2.45m wide unit’s weight down from

3000kg to 3300kg, thus making it suitable for a wider range of tractors.

“With more and more growers looking towards less intensive cultivations practices yet recognising the requirement for remedial sub-surface work when the need arises, demand for the Combi-Disc is on the up,” explains OPICO’s HE-VA product manager Glenn Bootman.

“But until now power requirement has been the limiting factor for those operating smaller tractors. With this smaller four-leg version anyone running a mid-sized machine can pull it making full use of the tines, discs and press.”

While this new model answers the needs of growers with less horsepower, it’s narrower 2.5m transport width makes it suitable for those regions where narrow lanes and tight gateways are an issue. It completes the HE-VA Combi-Disc line-up with working widths now ranging from 2.45m to 5.25m in both mounted and trailed formats.

The new APS SYNFLOW system takes threshing technology to another level in the new 5000-6000 range. Together with new drive systems, intelligent operator assistance systems – CEMOS AUTOMATIC, greater comfort in a larger cab and the new field scanner for precision guidance, efficiency is unrivalled in the new LEXION straw walker range. The proof is in the performance.

APS SYNFLOW

New larger threshing system with wider drums and an additional separator drum for increased separation performance.

NEW PIVOTING CONCAVE

Can be operated via CEBIS, for a rapid response to change in crop type or conditions in the field.

Call your local CLAAS dealer today for a demonstration and for our Early Action Finance Terms.

JET STREAM CLEANING SYSTEM

Comes as standard on all new straw walker machines.

Before 30.11.20

claas.co.uk/products/combines/ lexion-6900-5300

New electrical weeding technology and products for broadacre arable and vegetable crop applications

The UK manufacturer of technologically advanced mechanical weed control products, Garford Farm Machinery, and Warwickshire based electrical weed control manufacturer RootWave, have announced a new agreement that will bring next generation weeding technology to UK and international markets.

The new agreement will see the two manufacturers co-develop new weeding technology and products, integrating electrical weeding into precision guided toolbar systems, for high-value and high-intensive crops as well as broadacre arable applications.

The RootWave system uses electricity to boil weeds and their roots. This makes electrical weeding highly effective and, because it is non-chemical and does not disturb the soil, it is compatible with both organic and regenerative farming systems.

RootWave’s patented highfrequency alternating-current is

orders of magnitude safer than direct-current, typically used in electrical weed control.

With over 20 years of hoeing experience, and having brought many innovations to market, from the Robocrop Vision Guidance System to the compact hydraulic side shift mechanism, Garford is recognised as the industry leader in precision mechanical weed control.

The Robocrop Guidance System allows for accurate and efficient hoeing for both in row and interrow weed management and prevention control. The system uses video cameras and image analysis computers to locate crop position and then guides the hoes quickly and accurately.

The new eWeeding technology is set to provide a cost-effective and high-performance solution, creating financial and environmental benefits, while supporting better quality crops that are not competing against weeds.

Garford has calculated that by using the eWeeding technology, across a variety of different systems,

estimated costs would come in between £55 to £120 per hectare, significantly lower than chemical herbicide costs.*

When combined with potential other savings from grants, such as the Farming Equipment and Technology Fund (FETF) or Sustainable Farming Incentive (SFI), available to farmers in England, it would further reduce these cost estimates and make the solution attractive to smaller farming enterprises.

RootWave CEO Andrew Diprose said, “Combining forces with Garford allows us to create a formidable solution for the industry, combining best-inclass power electronics, imaging and artificial intelligence to create an unrivalled weed control solution for vegetables, cereals and row-crops.”

“It will alleviate the worries of farmers who are faced with an uncertain future where they don’t know if herbicides will be available, or will even be effective due to safety and resistance issues.”

Garford Managing Director Jonathan Henry said, “We are incredibly excited to pair Garford’s vast experience in precision guided hoes, with RootWave’s world leading expertise in power electronics.

“With the increasingly stringent controls over the use of chemical weed management, alongside resistance issues, we can support UK and global agriculture as it embraces its environmental responsibilities.

“Combining our technologically advanced precision guided weed control solutions, with the benefits of RootWave’s high frequency alternating current electrical weeding technology, we can create commercially viable and effective solutions to growers, as a key part of a sustainable, integrated weed management system.”

* based on operating for 20 hours a day. Includes depreciation, interest, 5year ownership, fuel and wearing parts. Does not include cost of tractor or operator labour

The new flagship New Holland CR11 combine previewed at Agritechnica 2023 has been joined by a CR10 companion model at the official harvest 2024 launch of the new Next Generation design, with both harvesters – built at New Holland’s combine Centre of Excellence in Zedelgem, Belgium –featuring innovative new technology designed to help the largest farming enterprises maximize output, minimize losses and reduce total cost of harvesting.

The primary difference between the two models is in power and grain tank size, to ensure the new combines match the needs of a broad range of large farm enterprises. The CR11 features a 20,000litre grain tank and a 15.9-litre FPT

Cursor 16 engine producing 775hp. The CR10 engine is a 12.9-litre FPT

Cursor 13 generating 635hp, while its grain tank holds 16,000 litres. Beyond additional power and grain capacity, the key features that take these combines into a new league in terms of output, sample quality

and loss minimization include longer twin rotors and the new Twin-Clean cleaning system.

From the front, these new flagship CR combines are designed to handle greater volumes of crop.

Cutterbar widths of 10.6-15.0m (3550ft) are available in fixed, flexible knife, movable knife and draper formats. Corn/maize heads of 12-16 rows are also available, and unloading auger lengths can be specified to match all header widths. There are three driveline options to meet all header requirements – standard with fixed drive, standard with variable drive, and a variable heavy-duty system. On the variable driveline, a CVT drive unit on the engine gearbox allows header/ feeder speed to be varied depending on crop and field conditions. Feeder/header reversing is achieved via with a hydraulic motor on the fixed speed driveline, and with the CVT drive on the variable speed driveline.

The elevator is equipped as

standard with front face adjustment and lateral tilt remote controlled from the cab. From here the crop is fed to New Holland’s proven Dynamic Feed Roll system, which can now be reversed – simultaneously with the elevator and the rotors – in the event of a blockage.

The DFR accelerates the crop and splits it into two even streams to feed the two longitudinal threshing and separating rotors that follow. A large stone trap in front of the DFR can be emptied either manually or, optionally, remotely via hydraulic activation from the cab.

New Holland was the first to launch a combine featuring two longitudinal rotors at its heart, pioneering its Twin Rotor threshing and separation technology almost 50 years ago, in 1975. Over time, its design has evolved to ensure it meets similarly evolving demands for throughput, grain protection, grain retention and straw quality.

In the new CR10 and CR11, the two

600mm (24in) rotors are of increased diameter and length, providing greater capacity for the crop to circulate and the grain be be threshed and separated. Each rotor features 40 standard rasp bars, eight HX raspbars and 12 spiked raspbars. The HX units combine the height of spiked raspbars with the profile of the standard units, with a greater sidewall angle helping accelerate crop flow in the transition zone of the stepped rotor cage, between the threshing zone and the separation zone. Vane angle can be remotely controlled from the cab, and the new vane design aids crop ejection should the rotors need to be reversed.

New rotor cages feature a stepped design with a broader cage and higher vanes in the separation area, to allow greater crop mat movement, improved separation and enhanced power efficiency. The concave area comprises two sets of three lightweight threshing concaves and separation grates, and two sets of six lightweight grates.

NewBRAUD7.50M,7.30Land8.50L replaceBRAUD7030M,7030Land 8030L

Power increase and new transmission on all models boosts productivity

Morehoppercapacityforless emptyingdowntime

Harvestingheadupdatesfor enhancedharvestperformance

New Holland is renewing its compact self-propelled grape harvester offering with the release of an updated range for 2024. Characterized by new styling, the BRAUD 7.50M, 7.30L and 8.50L models supersede the BRAUD 7030M, 7030L and 8030L, and offer enhanced comfort, capacity, power and productivity thanks to new and updated features in multiple areas.

All machines incorporate FPT fourcylinder engines without exhaust gas recirculation, but while the BRAUD 7.30L retains the same 128hp power and 3,100- litre hopper capacity figures as the BRAUD 7030L it replaces, the BRAUD 7.50M and BRAUD 8.50L both feature a 16hp power increase, to 144hp, for faster workrates in challenging conditions. These two machines also benefit from a 500-litre hopper volume

boost, to 2,800 litres on the BRAUD 7.50M/1,600 litres on Opti-Grape™ versions, and 3,600 litres on the 8.50L/2,400 litres on Opti-Grape™ II versions. All models feature the latest IntelliView™ IV Plus touchscreen operating terminal, upgraded seat options and LED lighting, and on IV PLUS all apart from the BRAUD 7.30L, locking of the machine’s levelling system is automated when moving from field to road mode.

The SDC Shaking system features a new pinch adjustment arrangement on all machines that ensures consistent vine shaking whatever the thickness of the vegetation, with a jack-free locking system for simple pinch adjustment from the cab that also eases cleaning procedures. Optimized shaker plates, standard on the BRAUD 7.50M and optional on the BRAUD 8.50L, are turned on automatically at the fruiting zone, and can be individually removed in less than two minutes by removing one bolt per shaker.

Optional features include OptiGrape™ II cleaning and cane removal systems. Available on 24” or 28” wheels, with optional front axle suspension, the BRAUD 8.50L is now also compatible with the

SupAir high-capacity sprayer from Berthoud. Further options include a static weighing system and 3.05 m unloading height on augerconfigured machines, allowing discharge of a full 3,600-litres load onto trucks or trailers with a 3.0m net height. A destemmer is optional on all models except those with a 3m unload height, while OptiGrape™ II can be specified on the BRAUD 7.50M and BRAUD 8.50L, offering a potential capacity boost of up to 30%.

All models feature a revised, more efficient hydrostatic transmission to provide operators with full confidence on slopes. An automatic height/lateral tilt correction (CDHA) system on the BRAUD 8.50L provides up to 30% slope correction, while machine height can be raised by up to 600mm on the BRAUD 8.50L and 500mm on BRAUD 7.50M and BRAUD 7.30L models, with three levels of adjustment. Machine height and headland height are both recordable.

A front axle suspension option enhances comfort particularly on the road, while also ensuring the wheels are kept in contact with the ground when climbing slopes,

supplemented by a traction control system. Suspension is activated automatically at road speeds, or via a button on the IntelliView™ IV Plus display when in the field. While it utilises the same software as IntelliView™ IV, the latest IntelliView™ IV Plus features a new main screen, with hardware derived from the large IntelliView™ 12 unit used on other New Holland machines. An inductive type of touchscreen rather than the previously-used capacitive type, it has a better display quality and touchscreen ‘feel’, with faster reactivity. Among other views, it can display the feed from one standard base camera, plus a new rear view monitor, with a total of up to four camera feeds possible.

Operator vision is enhanced through a new front top cab worklight package, with power per light raised from 1,200 to 2,000 lumens, providing a total of 12,000 lumens –2.5 times more than previously. A new external mirror package aids rearward vision, combining standard and high-angle mirrors in a single unit. Comfort is further enhanced by a new operator’s seat, with full leather upholstery, heating and ventilation, lumbar support and sliding backrest extension.

While the company has a full line-up of trailed and mounted machines, it was the Tempo Ultra Isotronic that took centre stage at the event in Nottinghamshire in June.

While there are options for more basic levels of specification, as the flagship mounted mode,l it is fully loaded with every feature you’d expect from a top line machine.

This includes ISObus controls which mean it can be connected directly to the tractor terminal or alternatively to a separate compatible control box. Having this on-board technology as standard means it’s also possible to have GPS-managed section control (down to individual nozzles), variable rate control and an automated boom recirculation system that avoids delays in spray line purging to maintain even coverage when coming into work.

The control computer also manages all the Tempo Ultra’s hydraulic functions. A single tractor spoolvalve supplies oil to the sprayer’s

centralised electro-hydraulic valve block which handles everything including boom fold, variable geometry tilt control as well as the pendulum frame’s height. Electronic boom height control is an option with up to four ultrasonic sensors providing automatic management of crop-to-nozzle clearance and boom tilt.

Boom widths of 15m to 30m are available all with a steel lattice construction and larger versions with aluminium outside sections.

Two sizes of tank are available for the Temp Ultra Isotronic rated at 1600-litres and 2000-litres (1820litres and 2180-litres actual) with an additional 300-litre clean water tank and 30-litre induction hopper.

For those that require additional volume there is the option of 1100litre or 1500-litre front tanks, potentially taking total capacity in excess of 3500-litres. Equipped with independent twin pumps and recirculation systems, these can be set to empty at the same rate as the

rear unit to ensure even weight distribution across front and rear axles.

While the standard main spray pump is rated at 199-liltres/min, higher output 249-litres/min and 277-litres/min versions are available, all of which operate at 20bar.

Two different options are available for the main sprayer fill/washout control panel – one with manual valves, the other with an electronic terminal that provides control the filling cycle with automatic shutoff when the preset volume is reached. It also oversees automated rinsing and washout cycles as well as spray mix agitation.

Although they’re making their UK debut this year, sprayers are nothing new to Maschio Gaspardo. In fact, the company has been building agrochemical application equipment since its acquisition of two leading Italian sprayer manufacturers in 2012.

Sprinter is the drill you can depend on in all conditions. For use after the plough, minimum cultivation and direct sowing. 3000 to 8000 litre hopper and Duett coulters to micro-loosen underneath the seed horizon.

Avatar SD is a high performance direct drill with single disc coulter. Available in 3m to 12m working widths, it features a 2-bar design for high harvest residues and single, double or triple hopper for seed, fertiliser and microgranules.

Visit horsch.com, your local HORSCH dealer or call 01733 667895.

Flach & Le-Roy Ltd is an industry leader in designing and delivering high performance drying, ventilation & storage systems.

• Destroy cover crops

• Adjust ground pressure from the cab

AUROCK FEATURES & OPTIONS SUPPLEMENTARY

Some direct dril ls from around the world may have been a good idea when they were invented. But times have changed–so keep up with the future. With a Novag drill you’re not only investing in the world’s mostinnovativeno-tillagedrill,butyou’ll alsoreceivehealthy soils that will make the next generat ion’s farming a success. Cut your costs and working hours and let the worms, fungi and bac teria do the job for you. Enjoy increasing carbon sequestration, water storage and nutritional quality–all while increasing yields and revenues! It even helps you to restore thriving ecosys tems. This may sound like a fairytale, but it works.

Novag \ www.novagsas.com

To find out more, contact your local Fendt Dealer today.

Creating innovation from ideas requires experience and passion, but above all, persistence and courage. Our products have been revolutionising agricultural technology for over 80 years, and that will always remain the case. It's Fendt. Because we understand agriculture.

The modern precision agricultural equipment is strongly driven by technical innovation through electrification and cross brand digitalization. Critical advancements in agricultural equipment have made it possible for farms to track crop production with great precision. Electronically integrated equipment is used to optimize crop potential by ensuring that the correct amount of water, seed, pesticide, and fertilizer are applied to the crops via GPS. This new way of farming is accomplished with the help of monitors, sensors, and cross brand computerized systems.

Powell Ag Solutions circular connectors:

• Feature high-temperature silicone to act as a barrier from hydraulic fluids, fossil fuels, and lubricating oils.

• Environmentally sealed to IP67/IP69K protection in mated condition.

• Offers excellent protection from ingress of dust, water, fertilizer, pesticides, and mud.

• Operational in temperatures ranging from -55 °C to 125 °C, functioning well in exposed cold weather environments, and withstand the high temperatures seen in most agricultural equipment applications.

• Designed with a rapid and secure mating system that is also highly vibration resistant.

Kubota (UK) Ltd has launched two models of batterypowered RT compact wheeled loader.

Badged as the RT210-2e and RT2202e, the new models offer a zeroemission, near-silent solution for those needing a clean-fuel alternative for working indoors; around livestock; or in environments where ultra-low noise levels are required.

Power for the RT ‘e’ versions is supplied by a 48-volt DC electrical system that is equipped as standard with a 260Ah lithium-ion battery pack. As an option, buyers can choose from two larger battery packs offering 390Ah and 520Ah capacities, offering longer run-times

between charging. Typically, run times can be from two to eight hours, depending on the size of battery pack and the application. On-board charging affords a 230volt/40-amp capability and a fivehour charge time, with a more powerful 60-amp unit available as an option, reducing the charge time for the standard 260Ah battery to just four hours.

For those able to make the most of a three-phase electricity supply, there are two models of 400-volt Super Charger available to further shorten the charging times – the most powerful 300-amp version can fully charge the largest 520Ah battery pack in just 90 minutes. An adaptor is also available to enable the RT ‘e’ models to be recharged via an

electric car charging point. Both Kubota RT ‘e’ models are equipped with an integral energy recovery system that automatically puts power back into the battery pack when the loader decelerates, or travels downhill, contributing to energy conservation.

The drive motor, which is fitted to the rear axle to transmit power to all four wheels is a 135-amp electric motor packing a 6.5kW punch. Travel speeds can be 0-5km/h; 0-12 km/h and 0-20km/h. A more powerful 250-amp electric motor is used to operate the hydraulic system with a power rating of 12kW. Both electric motors are certified IP54, offering protection from dust and water, with in-built protection against over-heating. Operating

weights are 2,200kg and 2,350kg respectively for the RT210-2e and RT220-2e when equipped with the standard 260Ah battery pack.

Models differ only in their front-end configurations, and as a result, tipping loads in the straight-ahead position are 1,480kg for the RT2102e, and 2,054kg for the RT220-2e.

Compact in size, the RT series offers a low overall height of 2.3m, a minimum overall width of 1.04m (RT210-2e), and a maximum hinge pin height of 2.82m (RT210-2e). Either model can be specified in a cab or canopy configuration. Kubota’s batterypowered RT210-2e compact loader, with canopy, is priced at £56,000.

In a major development in highcapacity harvesting, New Holland Agriculture is previewing the new CR11 at Agritechnica show incorporating new cutting-edge technologies that will help drive down the total cost of harvesting for large grain farmers, and increase their bottom-line profitability

The new combine was designed –and will be produced – at New Holland’s centre of Harvesting Excellence in Zedelgem, Belgium. Thanks to the most advanced automation features it will offer new levels of productivity, drive grain loss down close to zero, with best grain quality and perfect residue management.

The new CR11 builds upon the success of the current New Holland flagship combine range, which is topped by the CR10.90, which has held the world record for the most wheat harvested in eight hours –797.656 tons – for almost a decade, since August 15, 2014.

While we approach the 50th anniversary of the New Holland Twin Rotor™ technology in 2025, the new CR11 will also highlight the

advantage of the Twin rotor concept that revolutionized the way farmers harvested and that is now part of New Holland’s DNA. It’s still thanks to the Twin Rotor technology that the new CR can offer the highest productivity at lowest grain crackage on the market.

New Holland has designed the new CR in anticipation of the way in which harvesting demands will continue to evolve, and in response to feedback from customers seeking greater capacity, lower loss and maximum protection of grain quality. Recognizing how higheryielding crops and unpredictable weather can affect both one season’s crop and

the next, New Holland engineers aimed to design a machine that can play its full part in delivering maximum productivity, and clear fields quickly to ensure quality is protected and the following year’s crop establishment can take place in good time and in good conditions.

More productivity, close to zero losses, better and more efficient residue management and a

significant reduction in downtime are the four pillars the CR11 was projected on, with the overall higher objective to reduce the Total Cost of Harvesting to improve the farmer’s bottom line profitability.

Thanks to its 775hp C16 engine, 2x24inch rotors, a graintank of 20.000 liters and a 210l/second unload rate, the CR11 significantly increases productivity to levels that have not been achieved before.

Some features of the new combine will be evident from the machine on display at Agritechnica. The new combine benefits from a completely new design, that combines premium aesthetics with form and functionality. Multiple cab upgrades provide additional benefits in comfort and control.

Also visible, the new 15m (50ft) draper header manufactured by MacDon for New Holland, adds to the overall productivity and field efficiency gains.

Recognizing the trends for reduced ground compaction in combination with transport width regulations, the

CR11 offers a range of wider tracks and bigger tyres.

Lars Sorensen, Head of Combines and Headers at New Holland Agriculture said: “Farm consolidation, increased yields and short harvesting windows are driving the need to continue the evolution of combine capacity, with less grain loss and at the best grain quality.

This new combine is a market gamechanger designed to offer the next level of productivity, with no comparison to anything available on the market today. This was recognized by the DLG when they assigned to our new CR the most important award for innovations in our industry, the Agritechnica Innovation Gold Medal. In the established range of CR models we already had a design proven in these respects, topped by a model in the CR10.90 that offered the ultimate proof of its claim to provide the highest productivity in the world. We have made further strides in technology and automation, and the strong feedback from the first farmer tests mean we are very excited for the launch of these new machines.”

BENINGTON 01438 869251

BRAINTREE 01376 321144

COLCHESTER 01206 871881

FULBOURN 01223 880676

LITTLEPORT 01353 860761

MARLESFORD 01728 746437

NORTH WALSHAM 01692 405121

602982 ALBOURNE 01273 834689 DARTFORD 01322 863285 FAKENHAM 01328 855611

The CNH Design team continues to elevate Ag equipment through creativity that challenges the traditional norms of the industry.

Their efforts were recognized by the 2024 German Design Awards, presented by the German Design Council (est. 1953). The STEYR brand’s Plus tractor series was selected for Excellent Product Design in the Utility Vehicles category for its impressive synergy of function, design, quality and sustainability.

STEYR Plus tractors are the first to feature a dramatic new design language developed for the brand’s products. This sharp and crisp language

emphasizes modernity, strength, power, and technology through features such as striking new hood styling with integrated road and work lighting.

Inside the cab, additional comfort and better visibility complement the latest in telematics, which ease the operator’s task through instant data transfer from the machine to the cloud and auto guidance with automated steering.

“We are honoured to see our efforts to enhance the tech aesthetics of STEYR recognized by the German Design Council,” said David Wilkie, Design Director at CNH. “It underlines the importance of good design in delivering our customers a world class experience when they use our machines.”

New E-series reel irrigators from Bauer have several improved features to make operation and maintenance easier while maintaining the product’s outstanding reputation for strength, performance and durability An example of the improved range will be exhibited at the LAMMA show, January 17/18 at NEC Birmingham in Hall 7, Stand 730..

Adrian Tindall, Bauer UK & Ireland sales manager, said: “Bauer has put in a lot of R&D investment over recent years to equip the marketleading Rainstar E-series for new digital technologies, including the Smart Rain remote monitoring and control app.

“Now, attention has been turned to some aspects of the mechanical components, mainly to improve access for servicing, maintenance and setting-up to further improve the operator experience.”

The most obvious visual change is to the side guard that covers the reel-drive turbine and gearbox – but less obvious is that instead of being held in place by 10 bolts, the new version has catches that when released allow the cover to swing away. That makes it quicker and easier to access components such as the belt that transfers drive from Bauer’s highly-efficient water turbine to the pulley on the chain and sprocket that slowly rotates the drum to pull in the hose and either a rain gun or boom.

Opening the new cover also reveals a larger battery to power the Ecostar 6000 controller with its 4.3in LED touch-screen, which is supplemented by membrane buttons for the most frequently used functions.

Adrian Tindall explained: “Users can store up to 12 different irrigation programmes that define retraction speed, pre-irrigation, post-irrigation

and speed zones, and then retrieve them at any time to save having to enter individual parameters for every irrigation session.”

Remote access via SMS on a mobile telephone enables irrigation managers to not only stop and start the Rainstar irrigator remotely but also adjust retraction speed, check on the status of the machine and receive error messages. A ‘run finished’ message can be activated, and thanks to a digital input on the irrigator’s water meter, the Ecostar 6000 controller also records the

session and running total of water used.

The battery itself is now kept charged by a more efficient solar panel; it is still fitted flush to the cover but can now be propped at an angle to harvest energy from the sun more effectively.

Other changes include more easily accessible pipe drum bearings should they need attention and retrospective installation of brakes if needed is a new feature of the twoand four-wheel chassis.

AMAZONE is now offering the Tyrok 400 semi-mounted reversible plough for on land ploughing

The Tyrok Onland provides a high level of flexibility as a result of the quick and easy change between either on land or in-furrow operation. The new models are offered with a choice of 7, 8 or 9 furrows for tractors of up to 400 hp.

The tractor size and the size of the tyres determine, amongst other things, its operation in the furrow or on and beside the furrow. Specifically, its use with tracks, dual wheels or extra wide tyres larger than 710 mm does not permit driving in the furrow without compaction damage on soil which has already been partly ploughed.

A major advantage of on land ploughing is the reduced soil pressure as a result of the large contact area of the wide tractor tyres and the possibility of being able to work with a lower tyre pressure. This means that considerably less compaction damage is caused and the formation of any plough pan is prevented. Furthermore, on land

operation provides an improved pull line as a result of the reduced lateral pull and more efficient power transmission. GPS guidance systems can also be used for maximum working comfort and precise match-up to the next furrow. Constant depth control is provided via the front guide wheel, which runs permanently on the unworked soil.

Other factors, such as the soil conditions, have a critical impact on the method of ploughing. A quicker and easier change between on land and in-furrow operation is therefore extremely important. If the soil surface in the field does not allow for optimum traction as a result of rain or wet conditions, quick conversion to in-furrow operation is possible at any time. A throw of the hydraulic lever on the turnover arm is all that is required for this.

The Tyrok Onland has a substantial, high-tensile steel rectangular beam with dimensions of 200x150x10 mm. This gives the Tyrok Onland an extremely high level of rigidity. A decisive advantage over a square beam is that the beam does not

bend, even under hard ground conditions. This ensures a uniform working depth over the entire length and working width, which is crucial, especially at the larger working widths. The Tyrok Onland also scores points with the SmartTurn system. On the headland, the fast turning procedure is hydraulically slowed down two-fold just before the end. This results in a damping effect which reduces stress on the plough structure when the cylinder is retracted. There is no need to compromise on speed as in the Onland variant, the “beam” is automatically retracted before the turnover process via the Onland cylinder, so that the turnover centre of gravity is as low as possible and so the forces acting on the tractor and plough are kept to a minimum.

The SpeedBlade plough body, with its patented extra-large front shin on the mouldboard, makes for minimal wear on the shin. The main wear point automatically shifts further and further back towards the centre of the plough body by increasing the working speed from say 6 km/h up to 8 km/h. As a result, the main wear point is kept on this enlarged front

shin of the mouldboard and away from the main mouldboard, even at high forward speeds; various slatted and solid mouldboard profiles are available depending on the application and objective. Another detail with great effect: the point covers the blade, meaning that the joint is protected by the point. Thanks to this clever join up, no plant residues or baler twine can get entangled.

AMAZONE sets the highest standards in the manufacture of plough wearing parts with its unique ©plus hardening process. The additional introduction of carbon makes Tyrok wearing parts far harder and more durable.

The Tyrok Onland is equipped with mechanical furrow width adjustment as standard. As an option, the working width can be infinitely adjusted hydraulically from the comfort of the tractor cab to suit the conditions. The front furrow adjustment can also be provided mechanically or hydraulically. An advantage here is the direct linkage of the front furrow cylinder at the front of the plough for precise matching to the last furrow.

The John Deere plant in Mannheim is celebrating the production of its 2 millionth tractor

About 3,300 employees help produce 40,000 tractors a year at the site, before the machines are exported all over the world. The factory is one of the most important employers in the city.

Mannheim is the city of inventors. The car, the bicycle and the tractor were invented there, and while no cars or bikes are produced in the city today, tractors continue to roll off the line in the Lindenhof district. The Heinrich Lanz company laid the foundation stone for one of the most successful tractor factories 102 years ago with the Bulldog. John Deere tractors have been produced there since 1956.

Due to the sharp increase in production, the factory is now the largest John Deere production facility outside North America. It is also the largest tractor production facility in Germany, as two-thirds of all tractors manufactured in Germany are produced in Mannheim. The factory benefits from its convenient location on the Rhine, via which about 250 tractors are shipped twice a week to Rotterdam or Antwerp, and then overseas –including the UK and Ireland.

However, the plant is not only a production site. It is also a development site for all medium tractors from John Deere. More than 250 engineers work on the tractors of tomorrow and beyond. The main focus is on performance, comfort and efficiency.

Today’s tractor cabs offer the luxuries of a car with automatic air conditioning, AppleCar Play, comfortable seats, GPS steering and much more. Developers also put a lot of effort into clean fuel combustion; the same strict exhaust emission standards apply to tractors as they do for other vehicles. At the same time, engineers are working on alternative concepts, such as the use of biofuels. Electric drives are also being developed, albeit only for smaller tractors, as the battery capacity for larger machines is not yet sufficient. In 2026, the first fully autonomous and battery-driven tractor delivering approximately 100hp will be presented.

The development department led the way with the introduction of the frame design on the Mannheim tractors. The sturdy bridge steel frame gives the tractors enormous stability when using heavy implements. In addition, the other components of the tractor can be built lighter. For example, the gearbox housings are made of aluminium. After the introduction of

the frame design in the 1990s, production figures went steadily upwards. For more than 20 years, John Deere has been the market leader for tractors in all major Western European countries. The current success is due, among other things, to the flagship of Mannheim production, the 6R 250. With a maximum output of 300 hp, it is the largest tractor ever built in Mannheim. Overall, Mannheim tractors cover the range from 90 to 250 hp rated power in the ‘luxury’ class.

The two millionth tractor will also be a 6R 250. As a thank you to the production team, the tractor is wrapped in portrait photos of more than 300 employees. The tractor will be unveiled at the Mannheim plant on 22 March in the presence of John Deere CEO John C. May. In the following weeks, the tractor will be on display at the John Deere Forum. In the long term, it will be given a place of honour in the factory museum next to its little brother, the 1 millionth tractor, a JD 6400. It took 70 years from the start of production for one million John Deeres to be prodced, but the second million have rolled off the line in about 30 years.

With the handover of the anniversary tractor, the company is not only looking back, but also looking forward. The ceremony will take

place in the building of the new paint shop. More than $80 million USD is currently being invested in the future of the plant and in securing the location. Thanks to state-of-the-art environmental technology, energy consumption is significantly lower and emissions can be reduced to a minimum. Waste water and waste are avoided and the noise level is much lower than in the previous plants.

The training workshop at the Mannheim plant is also looking back and forward. It celebrates its 100th anniversary this summer. In times of a shortage of skilled workers, it is becoming increasingly important for the company to train qualified young people. Currently, the training workshop offers 160 young people qualifications as mechatronics technicians, automotive mechatronics technicians, industrial mechanics, electronics technicians for industrial engineering and construction mechanics with a focus on welding technology.

The Mannheim location is well equipped for the future. With the two millionth tractor and further investments in assembly being made, the company is sending an important signal to the more than 3,300 employees and the RhineNeckar metropolitan region that it is moving forward.

The Agtech company and organic food producer AUGA group has officially launched its hybrid tractor, AUGA M1, for professional use from the first batch of production

Developed and assembled in Lithuania, the tractor is powered by biomethane and electric drives and is able to operate continuously for up to 12 hours. Compared to diesel-powered analogues, one such tractor reduces carbon dioxide emissions by up to 100 tonnes a year, AUGA group data shows.

“Agriculture is responsible for 20% of global emissions, and there have been no real solutions for reducing pollution in this sector. AUGA group took the initiative several years ago to develop technologies that could enable a breakthrough in this area and let to farmers work more sustainably and to consumers choose food with no cost to nature. A year ago, we introduced a prototype of a hybrid tractor and undertook a series of technology tests which allowed us to improve that conceptual model. Today, a year later, we have the result that we promised everyone ? the new version of the AUGA M1. The tractors from this first production batch will start their work on farms

already in 2023,” says K?stutis Juš?ius, the CEO of AUGA group. According to the CEO, AUGA group received proposals to manufacture the first batch of tractors not only from Lithuania, but also from foreign manufacturers. But AUGA group was keen to ensure that these technologies developed in Lithuania would be assembled in the country as well. So for this first batch AUGA group chose the Rokiškis Machine Factory, which has many years of experience in the production of agricultural machinery.

During tests, AUGA group engineers found ways to reduce energy losses and boost the overall efficiency of the electric drive. They also managed to lighten the tractor’s construction, resulting in lower energy consumption and less pressure on the soil during operation.

The first production batch consists of three tractors. Each includes different components. Serial production will use a combination of the technological solutions that showed the best results over this year’s production tests. The factory version of the AUGA M1 hybrid tractor incorporates components from world-renowned manufacturers, such as a Ford internal combus-

tion engine and a CLAAS cab. AUGA group also updated the design of the AUGA M1 tractors. According to K?stutis Juš?ius, this version of tractor’s design will be the basis for further production. “In creating the prototype, we focused on developing the technology without paying much attention to the design. Now we are presenting the appearance of the future serial production model. The colour of the new tractor is anthracite brown. Anthracite is the world’s oldest coal, while brown is the colour of naturally fertile earth. With the help of all the technologies we develop, we will be storing carbon in the soil in order to reduce the amount in the atmosphere. And as we work sustainably, the land will become more fertile,” the CEO of AUGA group says.

Developed by Lithuanian engineers, the AUGA M1 hybrid tractor is unique for its solutions to problems that the world’s largest agricultural machinery manufacturers have not managed to solve – achieving long hours of operation and convenient refuelling.

The AUGA M1 tractor uses a hybrid biomethane-electric fuel system. During the operation of the tractor, an internal combustion engine

powered by biomethane generates energy and transmits it directly to electric motors that rotate the wheels.

Under normal conditions which do not require high power, the tractor accumulates the generated energy reserve in its batteries. The system does not waste energy under lowload conditions, uses a relatively small but efficient engine, and is capable of producing enormous power when needed.

According to the AUGA group’s CEO, the aim is for the new tractors to be used not just by Lithuanian farmers but also by farmers around the world. Moreover, it is aimed that the operating costs of the AUGA M1 tractor will be the same as those of diesel-powered tractors.

The total investment to date to develop the conceptual model of the AUGA M1 tractor and to produce the first batch is more than €3 million. Since the launch of the prototype, the company has doubled the size of its engineering team and plans to hire even more engineering personnel. After the technological tests in the fields, AUGA group will aim to start mass production as soon as possible this year.

The new range from New Holland is inspiredbytheStraddleTractor Conceptcreatedincollaboration withItaliandesignfirmPininfarina

It’s a multifunction tractor designed fornarrowvineyards,withanelegant and compact design, great comfort andmanoeuvrability

Createdtoworkwithmultiple implements combinations, keeping themattachedwithoutleavingthe cab, activated at a flick of a switch

It features the best innovations available on New Holland’s tractors, including efficient hydraulic system Intelliflow™and MyPLM Connect to maximize productivity through technology.

New Holland introduces the new Straddle Tractor TE6 Range –TE6.120N and TE6.150N – multifunction tractors specifically designed for narrow vineyards that require machines with an extreme manoeuvrability and compact dimensions, and that will be available starting from the end of 2023.

The new Straddle Tractor range’s design is inspired by the Straddle Tractor Concept, created by New

Holland in collaboration with Italian design firm Pininfarina and winner of the Good Design Award and of the German Design Award in 2022. The Concept tractor featured a futuristic and stylish look inspired by the shape of a glass of Champagne as a homage to premium wine growers of regions such as Champagne, Médoc and Burgundy.

The new TE6.120N and TE6.150N are in fact specifically designed for some of the most prestigious wineproducing regions, adapting to the narrow French vineyards and to any terrain that has similar characteristics.

The new tractor range is highly multifunctional: it features three independent tool zones for multiple possible implement combinations. They are also designed to grant an extra quick hitch – less than 10 minutes for the sprayer – and to allow the operator to keep the tools attached without leaving the cab, saving time and maximizing efficiency.

Maximum manoeuvrability is granted by the Superlight new steering system.

Thierry Le Briquer, Grape, Olive and Coffee Harvester Global Product and

Platform Manager at New Holland says “Multifunctionality, maneuverability, compact design and power: these are the key elements of the new Straddle Tractor range that is completely revolutionizing our offering in Straddle tractors. The best quality is ensured by our engineering and manufacturing at the Centre of Excellence in Coëx, France, where these tractors are produced and that is specialized in grape, olive harvesters and straddle tractors, serving customers worldwide.”

Just like the rest of New Holland’s new generation tractor range, the Straddle Tractors are equipped with innovation technology: Intelliview™ IV Plus display and its rearview screens give a total control of the tractor and My PLM Connect® allows operators to manage data in real time, on board or remotely, to maximize efficiency and productivity.

The Blue Power livery reflects New Holland’s new styling lines and balances elegance with comfort. The ergonomics have been completely reshaped with a renovated cab offering comfort and high visibility all around the machine. The FTP Industrial Stage V engine in the row ensures total stability on slopes and inclines, and the IntelliFlow hydraulic system gives a balanced distribution of power all around the tractor.

Carlo Lambro, Brand President of New Holland Agriculture says: “It’s with great pride that we add these Straddle tractors to our already excellent range, featuring a new design that combines our long-lasting identity with the most innovative features and inspired by the collaboration with a great design firm such as Pininfarina. It brings elegance, comfort and performance to our customers specialized in viticulture and I’m excited to see it in action very soon in the most prestigious vineyards.”

Valtra has launched the sixth generation of the S Series, nicknamed “The Boss” This powerful tractor’s eye-catching design enhances performance whilst creating a strong brand identity and desirability. The specially designed lighting from TYRI is one of the design elements that really makes “The Boss” stand out, combining driving lights, DRLs (Day Running Light), and integrated work lights all within one single unit.

Valtra’s sixth-generation S Series combines form and function using a modern and dynamic design language. The sleek curvature of the bonnet provides exceptionally good forward visibility, and the S Series is the first in the industry to

feature a fully integrated light unit, incorporating state-of-the-art LED main/low beam, with LED daytime running lights and LED front work lights.

In order to develop this integrated front-lighting unit for Valtra, TYRI had to involve the entire company’s lighting expertise. The specification from Valtra was clear, expectations were high, and the result was impressive according to Valtra themselves.

“The result was an unprecedentedly high level of light output, which gives our sixth generation of the S Series a very distinctive look,” says Kimmo Wihinen, Valtra’s Head of Industrial Design and User Experi-

ence. For TYRI, it was a prestigious assignment to develop the lighting for the new S Series from Valtra, and developing an approved driving light according to the existing requirements specification was challenging. The development work took almost two years.

“It was a really exciting challenge where the entire company collaborated to create the best possible lighting without compromising on design and user experience. There were many challenges, including avoiding glare on the hood from the work lights. By crossing the light beams from the lighting on the roof, we succeeded in this, and we are very proud of how the final delivery turned out,” says Anders Wärnman,

Sales Manager at TYRI Sweden.

In the Unlimited version of Valtra’s SSeries, TYRI’s intelligent lighting system INTELLilight is also available as an option.