caseih.co.nz

PO Box 36753

Merivale, Christchurch 8146

ph 03 329 6555

www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Agrichemical Manual.

© RURAL CONTRACTOR AND LARGE

SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

CONTRIBUTIONS - Editorial and photographic contributions are welcomed and should be sent directly to AgriMedia Ltd. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

EDITOR

Paul Titus

87 Stanbury Avenue, Christchurch mob 021 655 092 email titus@agrimedia.co.nz

ADVERTISING MANAGER

Michael Lightbourne mob 021 403 853 email michael@agrimedia.co.nz

CIRCULATION

email admin@agrimedia.co.nz

PRODUCTION, LAYOUT & DESIGN

Hannah Kincaid

email art@agrimedia.co.nz

CONTRIBUTORS

Joanna Ibell, David Hill, Fiona Calvert, Kathy Davis, Jacqueline Knight, Logan Tasker, Antonia Olszewski.

Printed by Blueprint Ltd

TECHNOLOGY

3

Kiwi inventor’s ‘edible’ netwrap on the menu 4 Successful forage crops with Allen Custom Drills

6 Genetically modified pasture crops have huge potential 8 Healthy soil for a wealthy future

TechnoPack gives Kverneland balers superpowers

Diverse pasture trials preliminary findings

World needs better phosphorus use 16 Anticipation is vital to protect brassica crops 18 Make every pasture dollar go further this spring 20 Donaghys builds on history of innovation and service 21 ‘Blue chip’ inoculant offers real alternative

Nitrogen-fixing maize and cereals now a reality

Food waste could boost animal nutrition

Soil conditioner lifesaver for forage crops

Smart job and invoicing app designed for ag contractors 30 Cooler bales, less spoilage with Biostart preservatives

Interest in hay bale grazing on upswing

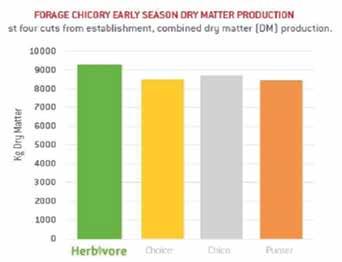

Annual chicory can outperform ryegrass, plantain

Benefits of diverse pastures for soil health and carbon management 38 NIR sensors now in the mix for maize trading

App counts true cost of pasture weeds

Peecon mixer wagon an investment in innovation and quality

Vantage NZ gives mixed fleets guidance, precision and more

New tool to protect wholecrop barley

Kuhn grass gear sweeping up awards 48 Mid-sized Fendt rake offers ISOBUS bells & whistles 49 When does maize need nutrients? 50 Agpac’s charitable journey with TrioWorld

Belt mergers can boost triple mower performance 52 Weed and pest control in maize

54 2024 roundup of forage cultivars for Quality Silage, Hay and Grazing

68 Busy couple have eyes on the prize

Loyalty driving force behind experienced contractor 76 Across The Ditch: For the love of the game

KIA ORA. IN A BIG WAY MY ROLE AS EDITOR OF THIS PUBLICATION IS AN EASY ONE. MY JOB IS TO GATHER STORIES ABOUT NEW AND INTERESTING THINGS HAPPENING IN AGRICULTURE, BUT THAT REALLY MEANS REPORTING ON THE HARD YAKKA OF OTHERS.

Out there in the hinterland contractors and farmers are putting their energy and money on the line running dynamic businesses. At the same time, engineers and researchers in factories, labs and test farms are beavering away to come up with new technology and plant breeds that our primary producers can use.

This Green to Gold special edition of the magazine is a testament to this. It is chocker with stories about some of the latest gizmos, chemistry and genetic technology that is coming down the track.

For example, we talk with Feilding-based H&T Agronomics. They have been working with partners in the United States, who have isolated and deployed microbes that give maize and cereals the same capability as clover and other legumes to fix their own nitrogen.

The microbes are delivered to the plant via the ‘N-Fix’ seed coating. It is commercially available this season, and H&T says it could reduce synthetic urea input in maize by up to 25 percent.

Another of our stories tells the tale of a clever Kiwi invention – Econet biodegradable netwrap. Like many people, Southland farmer Grant Lightfoot was fed up with plastic netwrap, which cannot be recycled but can end up in the guts of livestock or in the gears of power harrows and other implements.

Grant knew that round bale netwrap used to be made from the natural fibre sisal. So, he and his partner literally hand-knitted 50m of net wrap from jute, another natural fibre, to see if they could make it work. It did, and Grant is now collaborating with a factory to produce commercial netwrap that is not only biodegradable but also edible for sheep, cows and deer.

As the new government moves to end the ban on genetically engineered and modified organisms outside of laboratories in Aotearoa, you might wonder how that will work.

But it turns out AgResearch is already going down that track. It has been working with its partners in Australia to do trials on genetically modified plants outside the lab. In another article in this issue, they report on an

PAUL TITUS, EDITOR

endophyte and two pasture species with GE features they have developed.

Oh look! There is still some room for a few dad jokes. Stop me if you have heard them before…

As I get older, I remember all of the people who I have lost along the way. Maybe a career as a tour guide wasn’t the right choice.

***

I went to the doctor to see what he thought about a suspicious-looking mole. He said they all look like that and I should have left him in the garden.

***

Did you hear about the new restaurant on the moon? Great food, no atmosphere.

***

A man asked his waiter, “Does your piano player take requests?”

The waiter said, “Yes he does, sir.” The man replied “Then please ask him to play solitaire until I’ve finished my meal.”

RC

EARTHWORM eDNA IN SOIL TESTING

● Our new eDNA test enhances soil health monitoring, providing valuable measures on the biological health of your soil

● A simpler, less labour-intensive way to measure earthworm presence

● A New Zealand first, this development reflects our commitment to supporting farmers and producers on their sustainability journeys

FARMER GRANT LIGHTFOOT IS LEAPING FORWARD, BY LOOKING TO THE PAST.

Bales used to be wrapped in a natural fibre – sisal. Sisal breaks down eventually and that was considered to be a problem.

It was replaced with twisted polypropylene, a plastic-based fibre. It lasts forever, hoorah!

Today, having a plastic that lasts forever is no longer a source of delight. It does not decompose and it can spread as micro plastics. And, while the outer, air-tight wraps of silage film can be recycled, there is no recycling option for the inner net.

This is the problem Grant is solving – how to wrap biodegradable net around a round bale.

His solution is a return to a natural fibre. Instead of sisal, he has focused on jute, an annual crop that mostly grows in India and Pakistan.

Grant says cows can eat jute, which makes it easier when placing bales in a paddock.

“You see dairy farmers taking a week’s worth of plastic off silage bales, and then there is the net. By the time the ring feeder is on a lot is wasted. With my bales, you leave the netwrap on and there is no wastage.”

Grant has a deer farm in Orepuki, by Te Waewae Bay in Southland. He has been trialling the bales on his stags, cows and other animals for two to three years. He says all animals can eat it.

“There are no worries. It is just going back to the old days and how we used to bale hay or straw.”

He started working on the problem while working as a commercial diver on oil rigs.

“I used to live in a decompression chamber for months on end. There is lots of time to think. I wanted to invent something and came up with this.”

Initial thoughts were towards hemp, but even a low level of THC prevents access to an American market.

He settled on jute, and he is now pleased that is the direction he took.

“It took about eight months. The novelty wore off and it was painful. But when we tried it in a baler, I knew I was onto something.”

It took five years to develop the product Kiwi Econet. Balers do not have to be modified to use the biodegradable net. Grant has trialled it in his own Welger baler and in a contractor’s McHale Fusion.

Econet is made off-shore and Grant now has samples from the factory to put through a baler. If he is satisfied with the product, it will go into full commercial production and it should be available in the New Zealand market this coming season.

Standard rolls of plastic netwrap are 3600m while Econet will be about 1000m. The smaller size decreases the weight, but it does mean that rolls need to be changed more often.

“It is not as bad as it sounds though, because you don’t have to put so many wraps on with Econet. You can apply one-and-a halflayers, not three.”

Grant has a patent pending, and is working on a distribution network. He says the price could be a little more than the comparable plastic, but if it is, it will not be by much. “Plus it has the advantage that animals can eat it.”

Already Kiwi Econet is making not so much waves, as tsunamis. At the Southern Field

KIWI ECONET IS MADE OF JUTE, WHICH IS EDIBLE TO COWS, SHEEP AND DEER.

Days at Waimumu in February he won the Farm Innovation Awards. Grant won $500 for the award, which he donated to the local Westpac Rescue Helicopter.

He was then invited to National Fieldays at Mystery Creek and placed in the top five for

The beginning shows great tenacity. He and his partner Coleen Quirk hand-knitted 50m of jute net.

THERE IS ALREADY INTEREST AROUND THE WORLD IN ECONET, AND GRANT LIGHTFOOT IS HEADING TO THE UNITED STATES TO DEMONSTRATE IT.

CONTRACTORS AND FARMERS WHO ESTABLISH PASTURE AND FORAGE CROPS HAVE TO SOW DIFFERENT TYPES OF SEED IN A DIVERSE RANGE OF TERRAINS. QUALITY-BUILT ALLEN CUSTOM DRILLS ARE SPECIFICALLY DESIGNED TO DEAL WITH THESE CHALLENGES AND THEY CAN PLAY A CRITICAL ROLE IN SUCCESSFUL FORAGE AND FODDER CROPS.

Often these crops have to be drilled in tight windows at particular times of the year to ensure they establish well and are successful. Accuracy is critical to manage this.

Using a proven, accurate system to get the seed into the ground is the best way to promote even germination of the crop. With their renowned Accord metering system Allen Custom Drills can play a pivotal

role to achieve this.

Around the world agricultural businesses face tough competition to maintain their own footprint in the market. The same is true for agricultural machinery manufacturers and Allen Custom Drills has maintained its advantage by continuing to build their machines from the ground up in Ashburton, Mid Canterbury.

Over their 20 years in business, they have established a solid market for their products and built up strong relationships with their customers, suppliers and dealers.

With their tough frame developed to work efficiently in New Zealand’s rugged terrains, they can handle conditions virtually anywhere in the world.

Craig Allen designs all Allen Custom Drills himself using a state-of-the-art computer aided design (CAD) program. Each drill is designed for high performance, simplicity and low maintenance costs.

The Allen drill range is based

on five base models. Customers can work closely with Craig from the design phase to build what works for them and their farming or contracting operations.

Getting the seed into the ground right from the start is a key for maximising the productivity of your land. Allen Custom Drills’ Accord metering system can be operated using their 7115 drill controller with 7-inch touchscreen. Or you can specify your Allen drill ISOBUS-ready.

Craig says he and his company pride themselves on the quality and durability of their drills.

“We won’t compromise on reliability or strength. Any component incorporated into our product must perform and meet our very high expectations.

“We are confident that we have the highest performing, reliable and efficient drills on the market. We get a lot of positive feedback and good yarns from our customers or operators. That is what continues to drive me if I am honest.”

Allen Custom Drills strives to

continuously improve their products, their business and their people. As a team they use the latest science to learn from the ‘old’ while developing new technology for the future.

They can show people an Allen drill at work, so they can see exactly how it operates and the results it can give.

“I can safely say that many of our customers are happy for us to call in with someone who is thinking about an Allen drill, so they can jump in the cab and see the drill run,” Craig says.

When you invest in an Allen Custom Drill, you get not only a high-quality and high-performance agricultural machine, you also get a relationship with a proud family-owned New Zealand company.

WITH THEIR ROBUST BUILD AND ACCURATE METERING SYSTEM, ALLEN CUSTOM DRILLS ARE THE IDEAL TOOL TO ESTABLISH FORAGE CROPS AND PASTURE IN A WIDE RANGE OF CONDITIONS.

the Innovation Awards there. He was invited to the Royal Highland Show in Edinburgh, but unfortunately could not make it. He is going to Texas to show Econet on large-scale farms

there. He has been invited to the Environmental Southland awards in October.

As an idea of the scale of the plastic problem this could solve, Grant describes a conversation

he had about one Israeli factory. “They make about 15 billion metres of plastic net annually. That is just one factory and you can’t do anything else with that net.

Along with direct and dealer distribution in New Zealand, Allen Custom Drills also exports their air seeder drills to Australia.

For more information on Allen Custom Drills, visit the website allencustomdrills.co.nz or call 03 308 4094. RC

“I can’t wait to get it out there. I'm getting phone calls and emails daily and they are worldwide.”

More information is available on the website kiwieconet.nz. RC

PASTURE IS THE FOUNDATION OF NEW ZEALAND’S LIVESTOCK INDUSTRIES, AND AGRESEARCH IS NOW WORKING WITH PARTNERS TO USE GENE EDITING AND GENETIC MODIFICATION TO IMPROVE THE PERFORMANCE OF MAJOR PASTURE SPECIES.

Gene editing and modification can be used to change the DNA of plants and animals by inserting, replacing or deleting genetic material in their genome.

The technology has the potential to improve farm productivity and animal health. It can also help reduce farming’s environmental impact by reducing greenhouse gas emissions and nitrogen leeching.

Currently AgResearch is working on three pasture programmes. The plants that have been bred with the gene technology are now either under indoor containment in New Zealand or in field trials offshore.

Those three projects are: 1) gene edited endophytes, 2) high metabolisable energy ryegrass, and 3) high condensed tannin white clover.

AgResearch and its partners are seeking permission to operate a contained outdoor growing trial of ryegrass that carries geneedited Epichloë endophytes.

Epichloë endophytes live inside ryegrass and form a mutually beneficial relationship with their host. Natural substances released by the endophytes deter insect pests from eating the ryegrass and improve plant growth and persistence.

The benefit should be reduced use of chemical pesticides and increased efficiencies in milk and meat production.

Endophytes have already been a boon to

TECHNICIAN ASHLEY PRENTICE CHECKS AGRESEARCH’S GENETICALLY MODIFIED HIGH ME RYEGRASS IN A CONTAINMENT GLASSHOUSE.

New Zealand agriculture. An estimated 90 percent of proprietary ryegrass sold in New Zealand contains an endophyte. The economic benefit of just the AR37 endophyte is estimated to have been $3.6 billion over 20 years.

There are drawbacks, however. Some endophytes that protect ryegrass against pests also produce toxins that can be harmful to the livestock that eat the ryegrass. They can cause heat stress or the disease ryegrass staggers.

AgResearch scientists, with support from commercial partners PGG Wrightson Seeds and Grasslanz Technology, have identified ways to change the DNA of selected endophytes via gene editing that improves plant protection or reduces harm to livestock.

There is a very low risk of genetic material from genetically altered endophytes to travel outside of the trial site. AgResearch wants to conduct a contained trial, which means that

any genetic material that can be reproduced is confined to that site. The edited endophytes are contained in the ryegrass seed and do not travel via the ryegrass pollen.

As part of the application process, AgResearch and its partners will engage with interested and affected parties to understand and address any concerns they raise. If approved, the trial would allow scientists to test how resistant the ryegrass with geneedited endophytes is to insect pests and how well they grow in outdoor conditions here. Outdoor trialling of ryegrass containing these gene-edited endophytes is already underway in Victoria and New South Wales, Australia. The Australian trials will run for three years. They will measure persistence, yield, insect damage, chemistry and the level of endophyte presence in the ryegrass.

AgResearch and its partners have developed a genetically modified High Metabolisable Energy (HME) ryegrass that should reduce environmental impacts while boosting animal nutrition and farm productivity. There is some evidence that suggests it could also reduce methane emissions by 10 to 15 percent and trials will be carried out to test this.

Researchers have developed the modified ryegrass by adding and modifying two plant genes to increase fat content in the leaf and

THE GENETICALLY MODIFIED HIGH ME RYEGRASS AGRESEARCH HAS DEVELOPED COULD IMPROVE ANIMAL PERFORMANCE AND REDUCE METHANE EMISSIONS BY AS MUCH AS TO 15 PERCENT.

enhance photosynthesis in the plant. The aim is to improve animal nutrition and thereby reduce urinary nitrogen excretion. The benefit of this is reduced nitrous oxide emissions and nitrate leaching.

AgResearch scientists have had government support for the project and they have worked with their commercial partners –Grasslanz Technology, PGG Wrightson Seeds and DairyNZ – to develop the HME ryegrass.

One genetic modification they made was with the protein oleosin from the sesame plant. It helps to form and stabilise the increased fats in the plant.

When applying to Australia’s Office of the Gene Technology Regulator for permission to conduct trials in Australia, regulators raised concerns about the risk of sesame as a food allergen.

Although AgResearch scientists were confident that sesame oleosin was not expressed in the pollen of HME ryegrass, they made the decision to use an alternative oleosin from rice to provide certainty. Rice oleosins are not considered allergenic, and the change from sesame to rice does not affect the quality or function of the ryegrass.

In Aotearoa, scientists are preparing for a trial that should start later this year, in which lambs will be fed both the HME ryegrass and an unmodified ryegrass. Enough of the HME ryegrass will be grown in contained glasshouses that it can be ensiled and fed to lambs.

This trial will provide insights on methane

emissions and urinary nitrogen excretion. Confirmation in cattle will need to be performed in outdoor trials, probably in Australia.

Outdoor field trials are now being conducted in Australia on white clover that has been modified to reduce the environmental impact of livestock and improve animal health and production. Recent research in the lab in New Zealand has confirmed its benefits.

Scientists have modified white clover to boost the level of condensed tannins in its leaves. Condensed tannins occur naturally in the flowers of white clover and in other species such as grapes, tea and other human foods.

AgResearch scientists are working with partners PGG Wrightson Seeds and Grasslanz Technology to genetically modify the white clover with a gene taken from another species of clover.

The results in laboratory containment trials in New Zealand suggest the high condensed tannin (HiCT) white clover could reduce methane emissions by more than 15 percent.

Researchers now have permission to grow the HiCT white clover outdoors under a bee exclusion tent for field trials in Australia.

A potential benefit of the HiCT white clover is reduced bloat, which can be fatal for sheep and cattle. Research at AgResearch’s facilities has shown HiCT white clover can reduce frothy foam and biofilm, which are indicators of bloat.

Further phases of research will include feeding the HiCT white clover to animals to consider the potential for commercialisation. RC

By Fiona Calvert, Hill Labs

CROP SOILS HAVE A HEAVY DEMAND

PLACED ON THEM AND NEED PARTICULAR CARE TO MAINTAIN THEIR HEALTH AND LONG-TERM PRODUCTIVITY.

Cropping rotations can result in a high requirement for nutrient supply. Additionally, cultivation and harvest machinery can degrade soil structure and reduce organic matter. Depending on management practices, there may be reduced earthworm populations as well as lowered microbial activity.

Various definitions exist for soil health but the general consensus is that a healthy soil will have a continued capacity to sustain plant, animal and human ecosystems.

Soil health is a dynamic quality that is affected by land-use, management practices and climactic effects. A healthy soil will have good tilth (it is crumbly, well-structured, dark with organic matter), extensive rooting, optimal pH, sufficient nutrients and be free of contaminants. That is, it must be fertile for growing both plants and soil biological organisms.

For agricultural and horticultural production systems, soil health is a combination of physical properties such as soil texture, chemical

FIGURE 1: SOIL HEALTH IS DETERMINED BY PHYSICAL, CHEMICAL AND BIOLOGICAL PROPERTIES.

properties such as pH and mineral nutrient content, and biological properties including living biomass and mineralisable N.

All of these properties are profoundly influenced by soil organic matter and soil type. (See Figure 1.)

The quantity and nature of organic matter is highly dependent on farming practices and climatic conditions. Some of the factors known to affect the build-up or depletion of soil organic matter are listed in Figure 2.

Regular soil fertility monitoring for pasture and crop rotations is an important practice to inform the optimal lime, nitrogen and fertiliser application to meet your production targets and maintain fertility. When doing soil testing for fertility insights, soil health indicators can be added.

Hill Labs has a package of soil tests that help evaluate overall soil health. The Soil Health Package includes basic soil tests (pH, Olsen P, exchangeable cations, CEC and percent base saturation), extractable sulphur tests (sulphate and organic S), anion storage capacity (ASC), organic matter (from total carbon), total nitrogen, potentially available (mineralisable) nitrogen, carbon-nitrogen ratio and also hot water extractable carbon (HWEC).

The HWEC test has been shown to be a good indicator of soil health, as it is highly correlated with microbial biomass carbon and aggregate stability.

Monitoring soils with this group of tests over time provides data to support your management practices. This can provide confidence that the soil will continue to support a thriving ecosystem.

A complementary test that provides an estimation of earthworm abundance in soil has recently been released. Earthworms are an important component of soil biology, and abundant earthworm populations are recognised as an indicator of healthy soil.

Previously, methods for identifying earthworm populations were labour-intensive and required going out to a field to take a spadesquare down to the depth of the spade, break-

OR DEPLETE SOIL ORGANIC MATTER.

CONSISTENT SAMPLING (AT THE SAME LOCATION AND TIME OF YEAR) AND DELIVERING THE SAMPLES TO THE LAB QUICKLY ARE VITAL FOR USEFUL SOIL ANALYSIS.

ing it up and counting the earthworms.

Hill Labs’ new earthworm eDNA test can help build a holistic understanding of soil health. Molecular technology, in the form of quantitative real-time PCR (qPCR) is used to identify the presence of Aporrectodea caliginosa, New Zealand’s most prominent earthworm species.

The test is carried out on the same sample submitted for soil fertility and organic matter tests. It needs to be received at the lab as soon after sample collection as possible to minimise eDNA degradation.

Additional tests such as soil texture (percent sand, percent silt and percent clay) might be useful where little information is available about a soil. Soil texture tests can aid with irrigation, agrichemical application or other land-use decisions.

Completing the laboratory-based soil health monitoring programme is occasional testing for potential contaminants e.g. cadmium, copper or spray residues.

Organic Matter Accumulation

Grass/clover/mixed pasture

Moist summer growing conditions

Direct drill/low or no tillage

Incorporation of crop residue

Controlled grazing

Friable soil structure, good root density

Moderate N fertiliser application

Green manure/cover crops

Organic Matter Depletion

Bare soil/fallow

Summer drought

Intensive cultivation

Removal or burning crop residue

Overgrazing

Compacted soil, shallow root zone

Excessive N fertiliser application

Erosion

Visual assessment of soil has an important role in soil monitoring and is complementary to soil tests. Grading for rooting depth, colour, porosity and soil structure make up a Visual Soil Assessment (Landcare Research) protocol that many advisors are proficient in using. A complete soil monitoring programme enables best practice management to achieve healthy soils and a wealthy productive future.

Vital to any monitoring program is a correct sampling technique in which samples are taken from the same spatial location and at a similar time of year. This minimises variation in space (including sample depth) and time when comparing measurements.

There is significant benefit to engaging experienced advisors to guide sampling for soil fertility and soil health testing.

Further information on the lab tests described in this article can be found on the Hill Labs website hill-labs.co.nz. RC

The Fusion 4 Plus is a fully automatic integrated baler wrapper which can apply film or net wrap to the barrel of the bale, delivering optimum bale density.

• Maximum output whilst keeping the machine short and compact at 5.8 metres in length

• 25 knife-chopping unit

• Patented unique bale transfer technique

• ISOBUS ready

The McHale V6750 variable chamber round baler has been designed with the demands of today’s farmer and contractor in mind.

• High-Intake 2.1m pick-up

• 15 knife heavy-duty chopper unit and feed rotor

• Double drive system with auto greasing

• Net and bale density can be adjusted from the cab through the console

VARIO PLUS

The Fusion Vario Plus is a fully automatic integrated baler wrapper that applies film or net wrap to the barrel of the bale, delivering optimum bale density.

• Hay and straw bales from 0.6m to 1.68m

• Haylage or silage bales from 1m to 1.45m to allow for wrapping

WHEN KVERNELAND ROUND BALERS ARE FITTED WITH THE TECHNOPACK PACKAGE, THEY GET TWO ADVANCED FEATURES – CROP HUMIDITY SENSING AND BALE EJECTION CONTROL. THEY ALSO GAIN THE ABILITY TO USE TRACTOR IMPLEMENT MANAGEMENT (OR TIM).

The TechnoPack can be fitted to new balers at the Kubota-Kverneland baler factory in Ravenna, Italy. Or it can be retrofitted to some existing round baler models.

With this technology, baler operators can track the moisture levels in their bales and they can easily monitor the status of bale ejection at the back of the baler.

If they have a compatible tractor, they can also use TIM to enable the implement to take control of certain tractor functions.

Kverneland offers two levels of TIM. The first level allows the baler to adjust the tractor's speed during baling. The baler can also control the engine’s rpm to match the baling conditions for optimal crop intake, and it stops the tractor so the tailgate can open and eject the bale at exactly the right time.

An even more advanced version is TIM Pack 2.0. In addition to all the capabilities of standard TIM, with TIM 2.0 the baler also has Auto Blockage Control (ABC) and Auto Feed Control (AFC).

With ABC, the baler automatically detects and remedies crop blockages faster than the driver

can. With AFC, the baler uses a swingable drawbar to automatically adjust the baler’s position in the sward to maximise bale shape and density without the driver making steering adjustments.

Adrian Ploscar is bale equipment product manager at Kubota’s baler factory. He says the TechnoPack can be fitted to all Kverneland variable chamber round balers.

“The TechnoPack’s real-time moisture detection system uses two electrodes in the bale chamber to measure the electrical conductivity of the crop. This allows the operator to keep track of the crop's humidity, so they always know that they are baling in the right conditions,” Adrian says.

“Crop humidity sensing also displays the average moisture level for the entire bale while it is being bound. This ensures all bales meet quality targets and it reduces the risk of mould.

“Bale ejection control increases the comfort of the tractor driver and makes baling more efficient. A sensor checks if the bale is fully clear of the ramp before the tailgate closes.

KUBOTA-KVERNELAND ENGINEERS HAVE DEVELOPED AN ADVANCED TIM SYSTEM BECAUSE THEY HAVE APPROACHED THE TECHNOLOGY FROM THE PERSPECTIVE OF BOTH THE TRACTOR AND THE IMPLEMENT.

“If the bale isn’t clear from the ramp, the system alerts the driver, which prevents damage to the bale and the machine. This improves efficiency, safety, and convenience by eliminating the need to manually check the ramp.”

It is not necessary to use TIM to get the advantages of moisture sensing and bale ejection control, but if your aim is to maximise baling efficiency by using TIM, then the TechnoPack makes this readily available.

When using TIM, the implement can control the tractor’s three point hitch, its front and rear PTO, and its speed and rpm.

Adrian says Kubota has an advantage in developing TIM because they can work at the technology from the perspective

KVERNELAND BALERS WITH TECHNOPACK HAVE CROP HUMIDITY SENSORS, BALE EJECTION CONTROL AND THE ABILITY TO USE TRACTOR IMPLEMENT MANAGEMENT (TIM).

of both the tractor and baler.

“Kubota is the first to offer a tractor and baler combination that meets AEF TIM certification standards.”

Because TIM is an extension of ISOBUS, it allows tractors and implements from different manufacturers to communicate. This means, a Kverneland baler with the TechnoPack can operate with any TIM capable tractor, not just Kubota.

Among the benefits of TIM is less stressful work for the tractor driver. They will be less fatigued because they do not have to monitor all of the baler’s actions and they do not have to carry out as many manual tasks.

TIM on Kverneland balers also improves safety through such features as a slope sensor that prevents bales from being ejected on steep terrain. Auto Blockage Control (ABC) also helps prevent damage to the baler from crop blockages.

Bale quality is higher because the automatic features help prevent damage to crops and help make better, more consistent bales, which adds up to better forage.

TIM’s automated work also speeds up baling and lowers fuel consumption by adjusting engine speed when needed, which means more profitable operations.

Kverneland’s TIM system represents a major advancement in agricultural technology, offering a smarter and more efficient way to handle hay and silage baling. RC

ADEPIDYN ® technology

The NEW SUPERPOWER has arrived to control Ramularia and Scald in barley.

A flexible solo fungicide that actively protects for longer!

Scan for more information, visit www.syngenta.co.nz or talk to your local distributor.

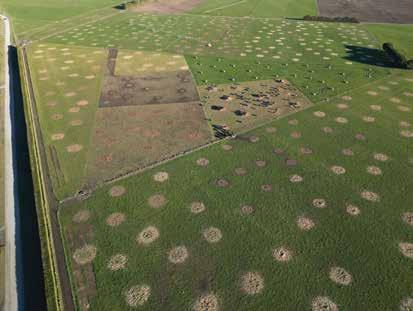

THE FIRST RESULTS FROM A SET OF TRIALS COMPARING DIVERSE PASTURE MIXES TO TRADITIONAL RYEGRASS-CLOVER AND PLANTAIN-CLOVER MIXES SHOW LITTLE DIFFERENCE BETWEEN THEM IN SOIL ORGANIC MATTER, EARTHWORM NUMBERS, MICROBIAL ACTIVITY AND WATER INFILTRATION.

Hawke's Bay applied research company On-Farm Research has now completed two years of an extended series of trials aimed at evaluating what role some aspects of regenerative agriculture could have in dryland farming systems.

On-Farm Research managing director Dr Paul Muir says the company is conducting plot trials and farmlet trials in response

to a 2020 call from the Ministry for Primary Industries to scientifically evaluate the principles of regenerative agriculture.

Regenerative agriculture practices such as keeping soils covered with good pasture covers and encouraging species diversity are said to have environmental benefits such as increased soil

carbon and improved microbial activity.

The first set of plot trials got underway in 2022. They focused on the potential benefits of diverse species in a sward and the role of different grazing heights. The trials looked at two different mowing heights – 20 cm and 8 cm.

THE TRIALS HAVE SHOWN THAT THE NUMBER OF SPECIES IN DIVERSE SPECIES PASTURE DECLINED OVER TIME. AFTER TWO YEARS ONLY SEVEN OF THE 31 SPECIES IN THE DIVERSE MIX REMAINED.

WEIGHT DISTRIBUTION

Unique design allows the spreader to sit closer to the tractor.

• Improves weight distribution for larger payloads with less front weight stress.

DURABILITY

• One-piece stainless steel body integrated with the frame. Eliminates corrosion risk and extends the spreader’s lifespan.

VERSATILE SPREADING

• Conveyor system delivers product to spinners. Bin shape prevents bridging, allowing smooth spreading of various materials, from urea to lime.

ISOBUS COMPATIBILITY

• Plug-and-play control system compatible with all ISOBUS-compliant terminals. Variable rate ready, facilitating easy transfer between machines.

L5 CAPACITY

Loading Height: 2,150 mm

• Urea Capacity: 3,750 kg

• Lime Capacity: 6,000 kg

The aim was to determine the effect of different grazing intensities on production levels among ryegrass, plantain and diverse species and whether different grazing routines affected the mix of species in the diverse pasture.

A diverse pasture mix which had been promoted locally was used for the mowing height trial. This contained 31 different grasses, legumes, brassicas and other species. The mix was sown into plots at rates that ranged from 45 kg/ha to 180 kg/ha.

Paul says this very high level of seed had been used locally by a regenerative farmer but in this study the high seeding rates did not contribute to any extra dry matter.

The ryegrass-clover mix contained four species and was sown at 32 kg/ha. The plantain mix contained six species, of which five were clovers.

Paul says one of the most significant findings of the trial was that the number of species in the diverse pasture declined over time. At 18 months from sowing, only 13-14 of the original 31 species were present and after two years, this had declined to seven species.

“Some species never emerged, probably due to competition from other species in the mix. Some, such as squash, were taken out by frost, and others were annuals that did not persist after the first season. Under both mowing heights the diverse pasture plots became cocksfoot dominant.” Initially the diverse mixtures tended to outperform the other mixtures, with annual ryegrass, cereal and brassica seed contributing an extra 1500 kg DM/ha in the first winter. However, once the annual species had died out, the diverse mixtures became heavily cocksfoot dominant.

Plots mowed to a height of 8 cm generated significantly more dry matter than those mowed at 20 cm. This was partly due to the higher volume of unharvested,

ON-FARM RESEARCH CONDUCTED MOWING AND GRAZING TRIALS COMPARING YIELD AND ENVIRONMENTAL BENEFITS AMONG 1) A DIVERSE SPECIES MIX, 2) RYEGRASS AND CLOVER, AND 3) PLANTAIN AND CLOVER.

OF INFILTRATION RATES SHOWED NO DIFFERENCE BETWEEN RYEGRASS OR PLANTAIN PASTURE AND DIVERSE SPECIES PASTURE.

dead material in the plots mowed at 20 cm, but also because the 8 cm mowing height stimulated more growth from some plants such as plantain.

At a cutting height of 8 cm, the plantain/clover swards were the highest yielding (27.6 tonnes DM over two years) and ryegrass swards were the lowest yielding (25.2 tonnes DM over the same period).

At the 20 cm cutting height, the diverse mixtures had the highest yields. This is probably because the high cutting height better suits Italian ryegrass, cereals and brassicas within the diverse mixtures.

Both the plantain and ryegrass swards performed poorly under the 20 cm cutting regime (15.4 tonnes DM and 12.8 tonnes DM, respectively).

Sowing mixture and mowing height had no effect on earthworm numbers, microbial activity, water infiltration rates or soil carbon.

Earthworm numbers averaged 44 per 20x20x20 cm cube with no significant differences in numbers between species mixtures or mowing height.

To test microbial activity the On-Farm Research field technicians placed an identical square of dried and weighed cotton cloth in the ground under each species mix and left it for six weeks. Then it was dug up, washed and re-weighed. This allowed them

to measure how much of the material has disappeared which was an indicator of the level of microbial activity. There was no difference in the amount of the cloth remained among all the different species mixes and mowing heights.

Water infiltration rates were also measured because faster infiltration is believed to indicate a healthier soil. There was no difference among water infiltration rates among the different species mixes or mowing heights.

An adjacent trial compared infiltration rates in the same diverse and ryegrass mixtures under grazing. Whilst there was no difference between the diverse and ryegrass mixtures, the grazed plots had markedly slower infiltration rates.

This suggests that grazing, treading and compacting the soil have a much bigger impact on infiltration rates than the species mix that has been sown.

To test soil carbon (as well as nitrogen and bulk density) a corer was used to take soil samples to a depth of 30 cm. Samples were taken across the experimental area at the start and at the end of the trial two years later.

Soil carbon increased over those two years (from 2.1 to 2.5

percent) as the site went from fully cultivated to a fully developed sward. Species mixtures or mowing height made no difference to soil carbon, however.

Paul says in this first mowing trial, the 8 cm cutting height might have suited plantain but it was not low enough to stimulate ryegrass regrowth and tillering. Therefore, a second series of plot trials has been started that will also provide a wider range of cutting heights.

The new trial has cutting heights of 5 cm, 10 cm, and 15 cm, and the mowing is being done on two different intervals, four weeks and eight weeks. The new trial is also using a diverse pasture mix containing 19 of the more perennial species. Any that did not perform in the first trial have been eliminated.

Sponsors and funders for the current project are MPI, Hawke's Bay Regional Council, AGMARDT, Barenbrug Seeds, Poukawa Research Foundation, Ravensdown, Atkins Ranch and The Nature Conservancy.

The research has a four and a half year timeframe, and it is overseen by a governance group and a technical committee who monitor and advise on its various trials. RC

MORE EFFICIENT USE OF PHOSPHORUS

COULD SEE LIMITED STOCKS OF THE IMPORTANT FERTILISER LAST MORE THAN 500 YEARS AND BOOST GLOBAL FOOD PRODUCTION TO FEED GROWING POPULATIONS.

But these benefits will only happen if countries are less wasteful with how they use phosphorus, a recent study shows.

Up to 40 percent of farm soils have overapplications of phosphorus, with farms in Europe and North America over-applying the most.

The global population is due to hit nearly 10 billion by 2050, and it is estimated that to feed this number of people a further 500 million hectares of arable land will be needed unless phosphorus can be more efficiently used to boost and maintain crop yields.

Phosphorus is listed as a critical raw material by the European Union, and globally 20,500 kilotonnes of phosphorus are applied to agricultural soils each year as fertiliser.

Concerns have been raised about its limited supply and loss to freshwater where it can degrade water quality. Phosphorus predominantly comes from mining phosphate rock. There are a relatively small number of sources located in countries like Morocco and Russia.

Previous estimates of how long global phosphorus supplies could last vary from 30 to more than 300 years. These prior estimates were based on current wasteful practices continuing and contained a lot of uncertainty.

Research by scientists at Lancaster University in the UK and AgResearch and Lincoln University in NZ has examined concentrations of phosphorus in farm soils across the globe to determine optimum growth of 28 major food crops – from wheat and maize to rice and apples.

The research revealed soils that do not contain enough phosphorus and soils that contain concentrations higher than plants need for optimal growth.

Their findings shed new light on the amounts of phosphorus available in soils and the amounts needed as fertilisers. They reveal that phosphorus reserves could last for up to 531 years if we use it more efficiently and equitably. That is 77 years longer than if we stick with current practices.

Professor Phil Haygarth of Lancaster University is a co-author of the paper. Phil says phosphorus is an essential fertiliser that drives food production on farms around the world.

“It is the ‘energy’ of agriculture that drives our food systems, but we need to manage our supplies carefully. We need to seek ways

to be more efficient and sustainable with its use.

“Our study shows that there is considerable potential to improve the efficiency of how we use phosphorus fertilisers. We show it is possible to optimise global food production without accelerating the depletion of precious and finite global phosphorus fertiliser reserves.

“We are unlikely to run out of phosphorus in the next 500 years, but only if we apply as much as needed to produce optimal crop yields and stop wasteful over-applications,” Phil says.

The research team calculated 10,556 kilotonnes of phosphorus is wasted each year through over-application with much of that dominated by wheat and grassland in Europe and maize and rice in Asia.

Professor Richard McDowell of Lincoln University is the lead author of the study. He says many farmers over-apply phosphorus to bank it in the soil, but only a fraction of soil phosphorus can be used by plants.

“Adjusting applications to sustain the levels that plants need to produce optimal yields negates the need for phosphorus being wasted. If there are excessive levels in soil that plants can’t use, phosphorus can potentially be lost to water, which risks causing water quality problems like eutrophication,” Richard says.

The researchers involved in the study have calculated that around the world nearly 75 percent of farmed soils are in phosphorus deficit. Phosphorus deficits are most acute in Asian countries such as India.

As a result, the researchers calculate that there should be an application of almost 57,000 kilotonnes of phosphorus to alleviate those soils in deficit to boost crop yields.

They then calculated that 17,500 kilotonnes of phosphorus are needed each year to maintain optimum soil phosphorus con-

RICHARD MCDOWELL SAYS IT IS IMPORTANT NOT TO APPLY MORE PHOSPHOROUS THAN CROPS CAN USE.

TO FEED THE WORLD’S GROWING POPULATION FARMERS NEED TO AVOID OVER OR UNDER USE OF PHOSPHORUS.

centrations. This would result in a global reduction in the demand for phosphorus by around 3000 kilotonnes annually.

Richard says the science is clear, but to use phosphorus efficiently and extend supplies, governments need to collaborate to make policies that promote phosphorus use only where needed.

“That will involve balancing distributions of phosphorus for optimal crop growth and reducing subsidies that sustain overuse of phosphorus and likely cause water quality problems.”

The findings are outlined in the paper ‘Phosphorus Applications Adjusted to Optimal Crop Yields Can Help Sustain Global Phosphorus Reserves’ published by Nature Food.

The paper’s authors are Richard McDowell and Peter Pletnyakov of Lincoln University and AgResearch, and Professor Phil Haygarth of Lancaster University. Richard was funded by New Zealand’s Our Land and Water National Science Challenge. RC

Donaghys Crop a proud New Zealand founded agri-business

We’re your partners in agri-business.

Article

BY COMBINING ACCESS TO A GLOBAL RESEARCH PIPELINE WITH LOCAL KNOWLEDGE OF FORAGE BRASSICA PRODUCTION IN AOTEAROA NEW ZEALAND, CORTEVA AGRISCIENCE CAN PROVIDE A RANGE OF PRODUCTS TO DEAL WITH WEEDS AND PESTS.

Corteva’s forage brassica herbicide and insecticide portfolio includes options that will offer protection against most scenarios typically encountered around NZ.

A heavy weed infestation in a brassica crop will reduce yield and quality and result in a poor crop at grazing. Corteva says to avoid this and reduce competition from weeds for light, water and nutrients, it is necessary to protect the crop from emergence right through to canopy closure.

Good weed control in a brassica crop includes limiting weed competition in the crop and pasture rotation by reducing weed seeds within the soil. It is also important to target perennial and rhizomatous weeds such as Californian thistle, yarrow and dock.

Establishing a dense crop canopy is one of the most effective ways to control weeds in brassica crops. To achieve this it is important to aim for rapid emergence, growth and establishment of the crop.

Some of the elements required for good emergence are pH, fertility, seedbed preparation, high quality seed, accurate planting

depth and seed-to soil-contact. Herbicides can also help to bridge the gap.

Applications of post-emergence herbicides should be based on stage of weed growth, not the stage of the crop. And, of course, any post-emergence herbicides must be safe for the germinating brassica seedlings and cotyledons.

It is also important to look out for opportunities to target both weeds and pests at the same time. In these situations, the principle is to focus on the earliest treatment required. Do not delay and compromise optimal control of one over the other. For example, if weeds are ready to be sprayed, don’t delay an application to target insects, and vice versa.

Corteva Agriscience marketing manager Glen Surgenor says there is an increasing emphasis on optimising crop performance, from day one.

Broadleaf herbicides from Corteva Agriscience such as Milestone, Korvetto and Radiate are proven to be reliable tools to achieve this.

Milestone contains two active ingredients – aminopyralid at 60 gm/litre and clopyralid at 276 gm/litre. Both of these are well-recognised and widely used.

Glen says when Milestone was introduced it was a world-first.

“The formulation is sold overseas, but in

THE TWO ACTIVE INGREDIENTS IN CORTEVA’S MILESTONE ARE EFFECTIVE AGAINST THISTLES, WIREWEED, PLANTAIN AND OTHER WEEDS THAT HAMPER BRASSICA CROPS.

THE BEST WAY TO PROTECT A BRASSICA CROP FROM WEEDS IS TO GET A QUICK CANOPY COVER AND POST-EMERGENCE HERBICIDES CAN HELP ENSURE THIS HAPPENS.

no other country was it used for forage brassicas. It has replaced our T-Max product and offers farmers greater crop safety which was a focus of the R&D team that created Milestone.

“By combining the two active ingredients, aminopyralid and clopyralid, Milestone provides exceptional control of thistles, and its weed spectrum includes wireweed, plantain and most other weeds from the T-Max label,” he says.

Although it was launched six years ago, Korvetto continues to find favour thanks to its unique package of benefits. It offers fast plant-back with control of hard-to-kill weeds like shepherd’s purse. It also provides superb crop safety.

“Plant-back is a standout feature of Korvetto. It is the most flexible post emergence herbicide for brassicas. It has a three month plant-back for clover and six month plantback for fodder beet,” Glen says.

“This gives farmers more flexibility when planning subsequent crop rotations. Some other herbicide options have plant-backs that are 12-24 months, which can be quite limiting.”

Plant-back periods for maize, cereals, ryegrass and forage brassicas are nil; vegetables and legumes other than clover are six months.

Korvetto combines Corteva Agriscience’s new active Arylex (Group 4) with the trusted chemistry of clopyralid (also Group 4), Glen says. This is the only formulation of its type for the forage brassica herbicide market.

As well as controlling key forage brassica weeds like fathen, nightshades and Californian thistles, at 1 litre/ha Korvetto provides best-in-class control of shepherd’s purse and fumitory.

Crop safety is excellent for leafy and bulb turnips, kale, forage rape and swedes. Handling benefits include an in-built methylated seed oil (MSO) adjuvant, so there’s no need

WHILE BENEFICIAL INSECTS ARE THE BEST DEFENCE AGAINST WHITE BUTTERFLY, DIAMONDBACK MOTH CATERPILLARS, APHIDS AND OTHER PESTS THAT TARGET BRASSICAS, CORTEVA SPARTA AND TRANSFORM CAN HELP IF THEIR POPULATION GETS OUT OF CONTROL.

for farmers or contractors to add an oil adjuvant or surfactant to the mix.

Korvetto is safe to use after pre-emergence herbicides and should be applied to actively growing brassica crops when plants have reached the three to four leaf stage.

Radiate is older chemistry, with a narrower weed spectrum, but fills a useful role as a low-cost herbicide when customers need to get rid of fathen in their brassica crops.

Glen says when pests like diamondback moth, white butterfly, looper caterpillars or aphids threaten forage brassica crops, time is critical.

“Caterpillar pests can do significant damage to leaf area within a short space of time. Aphids transmit plant viruses and their feeding points provide entry wounds for diseases that can severely damage plants or even kill large areas of a brassica crop.”

Ideally the first line of defence will be a population of beneficial insects that give natural protection against white butterfly,

diamondback moth caterpillars and aphids.

Species such as brown lacewing, ladybird beetles, hoverfly, parasitic wasps, predatory mites and beetles can play an important role in protecting brassica crops from pest flare ups and damage through until grazing.

Monitor your crop closely for both pests and beneficial insects and if caterpillar and/ or aphid populations do flare up and require treatment, use insecticides with minimal impact on beneficial insects such as Corteva’s Sparta and Transform.

Sparta works by contact and ingestion to control caterpillars in forage brassicas. Translaminar activity ensures good control of insects feeding on the underside of leaves. Transform is a contact and systemic

KUBOTA AND GREAT PLAINS PRODUCT SPECIALISTS ON-SITE

insecticide that provides rapid knockdown and moves within the plant to protect new untreated growth.

Transform’s systemic and translaminar activity resists wash-off and provides aphid control for up to 21 days, which prevents them re-infesting the crop.

Alone or in combination Sparta and Transform are ideal tools for control of key insect pests in forage brassicas. Both products have excellent environmental and toxicology profiles, providing a high level of safety for applicators.

For further information contact your local Corteva Agriscience territory manager and always refer to the product label for further guidelines on timing and use. RC

You’re invited to our Kubota and Great Plains demo day!

Come see and hear about the following products:

- NEW! Great Plains Turbomax Disc Cultivator

- Great Plains Spartan Direct Drill

- Kubota M7-2 Tractors

WEDNESDAY 30TH OCTOBER PANKHURST FARM 658 WARDS ROAD,

IF THERE WAS EVER A SPRING FOR DIGGING INTO THE TRUE VALUE OF DIFFERENT TYPES OF PASTURE SEED, THIS IS IT.

Cost pressures are severe for many red meat farmers, especially those who have had months of minimal grass growth and high supplement bills. Dairy farmers aren’t immune from budgetary restraints either, although their market outlook is brighter.

Pasture has to be sown or resown in spring, so what is the best way to make sure you get the best possible outcome – not just straight away, but in the medium term as well?

First, recognise that a shortterm fix, for whatever reason, will still need to be resolved sooner rather than later. And this will come with all the associated expenses of more seed and other inputs plus more tractor and labour time.

If you sowed annual ryegrass this past autumn as a cost-saving measure, for example, it was only an interim step. When it runs out after six or eight months, those pastures will start going backwards without further renewal. This means spending more money.

Second, it is important to acknowledge that uncertified seed, while cheap, is unlikely to deliver value for red meat

or dairy farmers.

In fact, it might do the opposite. There is no knowing what it contains, or how it will perform.

Of all the potential fixes available to farmers this spring, uncertified seed is the riskiest, for many reasons.

It can introduce new and unwanted weeds, deliver lower yields or bring other issues associated with seed of unknown origin and quality.

At the other end of the spectrum, with least risk and highest lasting value, are certified seeds for top perennial ryegrass like Barenbrug’s Array, Maxsyn and 4front.

There is no question whether

their yield, quality, seasonal growth and performance will give the best return on every dollar spent on pasture renewal this spring.

Quality, germination, purity and endophyte are guaranteed and the long term value inherent in these advanced genetics has been demonstrated time and again.

Some farmers might not be able to afford to sow as many paddocks in these high-value perennials as they would like this spring. For them, value might best be achieved with a hybrid like Shogun or Forge.

They will grow 1.5 tonnes more dry matter per ha through the

RENEWING ONE PADDOCK WELL WITH PROVEN GENETICS GENERATES MORE VALUE THAN SOWING MULTIPLE PADDOCKS IN UNCERTIFIED SEED.

cool season than a perennial for two to five years, with higher palatability for improved animal performance.

They are not perennials and they will need to be replaced. But in the medium term, they can help farmers get through the next few years with reliable, quality, cost-effective feed.

Pasture eaten remains a key driver of profit on farms. When times are tight, pasture is critical to drive production and dilute farmers’ costs per kilogram of milksolids or meat produced.

Even if it means renewing only one paddock really well, with proven pasture genetics, farmers will be better off in terms of value doing this than sowing multiple paddocks with uncertified seed this spring.

If you’d like to talk this through in more detail, contact your local Barenbrug area manager today. Or visit the website barenbrug. co.nz. RC

PASTURE EATEN IS A MAJOR DRIVER OF PROFIT ON FARMS.

THE PROUD NEW ZEALAND BUSINESS DONAGHYS CROP IS CONTINUING TO EXPAND ITS CROP PACKAGING AND HORTICULTURE

RANGE TO SOLIDIFY ITS POSITION AS A LEADER IN THE INDUSTRY.

With origins tracing back to Donaghys Industries Ltd, the company boasts nearly 150 years of experience in the agricultural sector. They began by manufacturing sisal twine, which remains a staple in their current range as Freerun.

With their rich history of innovation and dedication to service, Donaghys has a diverse array of products tailored for New Zealand's agricultural conditions.

They understand the challenges of local conditions and their products are manufactured and sourced to meet the needs of their customers.

Collectively the company’s representatives have more than 100 years of experience in the agricultural industry. They understand the needs of Kiwi farmers and contractors and bring a depth of expertise and commitment to customers to the table.

Their product range offers exceptional value and performance. The line-up of top-tier products covers twines, bale net, bale wrap, silage film and pit covers. All of these products can make forage production easier and more efficient.

Moreover, they take pride in fostering strong relationships with their customers. Donaghys’ Contractors Club offers a fantas-

tic reward scheme that recognises and rewards the loyalty of contractors.

They encourage contractors to check it out and register for the upcoming season to take advantage of the numerous benefits.

As Donaghys Crop continues to grow and innovate, it remains dedicated to supporting New Zealand's agricultural sector with high-quality, reliable products and exceptional service. Their

FOR NEARLY 150 YEARS DONAGHYS HAS SUPPLIED HIGH-QUALITY TWINE AND CROP PACKAGING PRODUCTS TO KIWI FARMERS AND CONTRACTORS.

legacy of innovation, and the expertise and passion of their team ensure that they remain at the forefront of the industry. RC

A GOOD SILAGE INOCULANT SPEEDS UP AND IMPROVES THE FERMENTATION OF GRASS, WHOLECROP OR MAIZE SO THIS IS NOT LEFT UP TO LESS EFFICIENT WILD YEASTS AND BACTERIA. WITH AN EFFECTIVE INOCULANT, SILAGE WILL RETAIN MORE NUTRIENTS, LOSE LESS DRY MATTER AND HAVE BETTER AEROBIC STABILITY.

New Zealand-owned company Independent Wrap is introducing a new range of easy-touse silage inoculants that offer fast, efficient performance at a cost-effective price. The inoculants are supplied by the diversified American multinational food corporation Cargill.

Independent Wrap general manager Richard Howard says after the company trialled two of Cargill’s Forage-Mate silage inoculants last season, they will supply both throughout New Zealand in the coming season.

The two products are Forage-Mate AP, an all-purpose microbial inoculant with three strains of lactic acid producing bacteria, and Forage-Mate BP, a Lactobacillus buchneribased inoculant that promotes aerobic stability during feed-out as well as front-end fermentation.

Richard says Independent Wrap managing direct Lydia Dickinson was searching for an inoculant to add to the company’s range of silage wrap and other consumables for a number of years and the Cargill products are an ideal fit.

“Lydia wanted to find the right products that would expand our offering and add value to our customers. The cornerstone of our business is to provide high-quality, dependable products that we and our team believe in.

“Cargill is a large agricultural company that supplies a range of products and services. Its inoculants have a 10 percent market share in the US, which is a huge amount of business. Their inoculants have some of the highest colony forming units (CFU) on the market and they are easy to store and work with.”

Forage-Mate AP is for contractors and farmers who have good forage management practices and are looking for a high-quality inoculant at an economical price. Its bacteria rapidly increase the lactic acid in the silage

WEST COAST CONTRACTOR HAYDEN HAHN USED FORAGE-MATE INOCULANT LAST YEAR. HE SAYS GRASS WITHOUT IT DOES NOT ENSILE AS WELL AND COWS HOOVER UP THE FEED MADE WITH IT.

and reduce the pH, which reduces dry matter losses.

Richard says the three lactic acid producing bacteria that Forage-Mate AP contains are at their most active at different pH levels, so as one tails off, another kicks in to maintain pH drop and fermentation speed.

“Testing in New Zealand on Forage-Mate AP last season shows that it does exactly what it is supposed to do. It lowered the pH and reduced the activity of yeasts and moulds much faster than leaving silage untreated, which sped up preservation and cut nutrient loss.

“We took samples of treated and untreated silage, and tested both samples at days 0, 3, 7, 14 and 56. Results showed a significantly faster reduction in pH for treated silage at days 3 and 7. At 56 days after ensiling the treated samples showed significantly lower pH, higher lactic acid, and higher crude protein.”

Forage-Mate BP also contains bacteria that speed up the production of lactic acid in silage but it also contains Lactobacillus buchneri which preserves nutrients and protects the silage when it is re-exposed to air during feedout.

It is primarily used for maize silage, which is made in very large volumes and is more susceptible to DM losses due to heating when exposed to oxygen.

“We are in the process of collating data from the trials we ran on Forage-Mate BP during the last maize harvest. When applied at the recommended dose it produces 500,000 CFU/gm of forage, which is significantly more than many other inoculants,” Richard says.

“Forage-Mate BP and AP are very cost competitive compared to other products. Both are also easy to work with. They can be used in most applicators used in New Zealand. And, while the gold standard is to keep them refrigerated, they can safely be stored in a cool, dark place.”

West Coast contractor Hayden Hahn used

WHEN MIXED WITH WATER, FORAGEMATE INOCULANTS TURN A BRIGHT BLUE, WHICH MAKES THEM EASIER TO MONITOR IN THE APPLICATOR.

Forage-Mate AP and BP last season and he was very pleased with the results.

Hayden’s business Coastwide Forage Solutions provides baling, bulk grass and maize silage, precision planting and other services across a big swath of the South Island’s west coast from their base at Dobson, near Greymouth.

He says he already buys his silage wrap from Independent Wrap so he was happy to trial their new silage inoculants.

“The inoculants are price competitive and it was easy to deal with the one supplier for silage wrap and inoculant, so we gave them a try. We did about 300 ha of maize silage and we used Forage-Mate BP on 250 ha of that. The maize stacks have stayed very cool, thanks to the buchneri product. Our customers are very happy with it,” Hayden says.

He also used Forage-Mate AP with his two McHale Fusion combination balers, New Holland forage harvester, and three Krone loader wagons. He is also pleased with its performance.

“We have found that cows really clean up the feed that has the inoculant applied. We used the AP inoculant all of the last season but I did some late cut bales for myself in April and May. They did not ensile as well as the crop that had the inoculant.”

IMAGINE IF MAIZE, RYEGRASS AND CEREALS

HAD THE ABILITY OF CLOVER AND OTHER LEGUMES TO FIX THEIR OWN NITROGEN. AS IN MANY ASPECTS OF LIFE, WHAT WAS ONCE FANCIFUL IS NOW REAL.

Kiwi agronomy and seed enhancement specialists H&T have been working with researchers in the USA, who have developed microbes that can attach themselves to the roots of maize, cereals and forage crops and give them the ability to fix nitrogen from the air.

These bacteria act the same as the rhizobia that give legumes this ability. While they have been identified and multiplied in the USA, they are also native to New Zealand, so they can easily be commercialised.

H&T business manager Duncan Thomas says efforts to find nitrogen fixing bacteria that are compatible with grass species have been going on for decades. Two American companies have made breakthroughs and are developing microbes compatible to particular crops.

The bacteria live naturally in the soil and they have been

identified and tailored to work with particular crops. They are an exciting option because the microbial activity puts nitrogen where the plant needs it and when. It converts nitrogen from the atmosphere into ammoniums directly on the plant’s root system.

“Over the past five or six years, this technology has become very big in the US,” Duncan says. “One company, Pivot Bio, has a million acres of maize under production with their bacteria.

“They supply their product in a two-pack liquid form and it is applied directly into the furrow

Hayden says both Forage-Mate products are easy to mix and he likes the fact that it turns a bright blue when it is mixed.

“With the dye in it I can actually see the inoculant going through the pipes, which you can’t do when it is clear. It is easy to store and mix and it works well with our Ascot Pumps applicators.

“We mix it in 20 litre buckets for the silage harvester and we have two 20-litre containers on each of our balers. Each container will cover 130 bales so we can do 260 bales without refilling, which is a normal day’s work when we are not too busy,” he says.

Richard thanks Canterbury Feed Analysis for testing samples of silage treated with ForageMate AP and BP. Further information and contact details can be found at the website independentwrap.co.nz, or by calling 0800 4 U 2 WRAP. RC

during planting. This requires having a planter with capability to spray the liquid, and their bacteria have a short shelf life.

“Instead, we have been working with another company, BioConsortia, which has developed a microbe that can be applied as a stable seed coating.

“Their product is called N-Fix and it was developed by a group of scientists that includes two New Zealanders. They are developing new generations of these microbes that are more powerful and able to fix more nitrogen.”

H&T brought five different N-fixing microbes to Aotearoa

INTRODUCING MICROBES TO MAIZE SEED TO GIVE PLANTS THE ABILITY TO FIX THEIR OWN NITROGEN IS A GROWING TREND IN THE USA, AND H&T AGRONOMICS IS TRIALLING SEVERAL OPTIONS TO INTRODUCE IT TO AOTEAROA.

and put them through massive replication trials to ensure they would work in local conditions.

Duncan says the results are “very cool”.

Environmental damage from synthetic fertilisers is a concern

INDEPENDENT WRAP IS INTRODUCING TWO NEW INOCULANTS - ALL-PURPOSE FORAGE-MATE AP WHICH HAS THREE STRAINS OF LACTIC ACID PRODUCING BACTERIA, AND FORAGEMATE BP, WHICH HAS LACTOBACILLUS BUCHNERI.

in both the US and NZ, and N-Fix can help reduce it. The amount of nitrogen N-Fix delivers is another selling point. It provides great value for money and it is easy to apply.

In the US, N-Fix can provide the equivalent of 30-50 kg N/ha. With our 190 kg N/ha caps it is typical for maize growers to apply 40 kg of N at planting and then another 150 kg as a sidedressing. With N-Fix they could easily provide some of these nutrients while staying well under the cap.

Another benefit N-Fix offers is consistent uptake of nitrogen even in paddocks that have a lot of variability, Duncan says.

Most paddocks have different zones, some of which have lower nitrogen because of the depth of the topsoil, poorer soil structure or drainage issues. When N-Fix is applied to the seed, every plant has access to it, no matter which part of a paddock it is in.

“We have worked with the world record maize grower David Hula. He highlights fertiliser efficiency as a key driver of high maize yields. N-Fix gives you a tool to do that.”

It has a long shelf life and it is also compatible with H&T’s oth

DIRECTOR PAUL OLIVER WITH A

er seed coatings.

“We have our own advanced seed coating plant where we can apply pesticides and our Optimised biostimulant. The nitrogen fixing bacteria are not affected by them and in fact it can enhance

It will be commercially available in limited quantities this season and H&T will work closely with selected growers in the North H&T

bination with Optimised, it delivers nitrogen directly to the plant’s roots at the same time the biostimulant helps the plant build bigger roots which are able to access more fertility and water.”

says the feedback from them regarding N-Fix has been very positive.

A LINCOLN UNIVERSITY PHD STUDENT AND HER SUPERVISORS ARE AT WORK ON A PROJECT THAT COULD HELP REDIRECT INDUSTRIAL FOOD SCRAPS AWAY FROM LANDFILL TO SUPPLEMENT THE DIET OF LIVESTOCK. AMONG THE POTENTIAL FEEDS THE RESEARCH IS EXAMINING ARE POTATO OFF-CUTS, APPLES PRESSED FOR JUICING, AND BREWER’S GRAINS FROM MAKING BEER.

Antonia Olszewski is carrying out her research under the supervision of a team of academics from Lincoln University, the University of Canterbury, and Manaaki Whenua Landcare Research. She is exploring how to make use of biowastes left over from food-processing.

Each year New Zealand manufacturers generate millions of tonnes of these industrial food

scraps and they are a cost to the national economy, society, and environment.

Antonia says when biowastes are thrown out, it means less revenue for the companies that create them, lost opportunities for feeding people, and more greenhouse gas emissions as they break down in landfill.

“If biowastes are redirected from landfills, they could be used as a supplement at times of the year when pasture is low

in volume or low in quality. They could also reduce our reliance on imported palm kernel extract. We estimate that if all of New Zealand’s edible biowaste was fed to livestock, we could reduce PKE imports by one third.”

She focused her research on pressed apples, potato scraps and brewer’s grains for several reasons. One is that they are among the country’s top five industrial food scraps in terms of volume that are edible for cows. (The other two are grape marc left over from winemaking and wheat byproducts.)

Availability and the logistics of transporting food waste economically and without spoilage are also issues when dealing with food waste. While apples are more seasonal and only available in parts of the country, potatoes and brewer’s grains are more widely available and they are available at more times during the year.

The research focuses on both the potential feed value of the three different types of food waste and their potential environmental impact. For this reason Antonia is analysing the nitrogen pathways as the food wastes are

DRIED APPLE POMACE SPRINKLED ON TOP OF CUT PASTURE READY TO BE FED TO LAMBS DURING ONE OF THE TRIALS. THE APPLE WASTE INCREASED TOTAL DIET DIGESTIBILITY OF POOR QUALITY PASTURE BY AS MUCH AS 76 PERCENT.

ANTONIA OLSZEWSKI SAMPLING POTATO PEELS FROM A PROCESSING DRUM.

digested and turned into urine and manure.

“My thesis is looking at the whole pathway of carbon and nitrogen – from importing the biowastes on-farm, to what is excreted, to how it helps pasture growth, which in turn feeds the animals again.”

The undigested biowaste has potential value to farms in the form of dung, which adds carbon and nitrogen to the soil. The research includes looking at how the dung from animals fed the different biowastes breaks down in the soil.

In February this year Antonia divided 24 sheep into pens of six and them fed cut pasture with one of the three biowastes as a supplement. A fourth group received only cut pasture.

Replacing poor quality pasture with apple waste increased total diet digestibility from 67 to 76 percent (± 6 percent), but digestibility stayed the same for the pasture with potato group (70 ± 5 percent). The dung from this feeding trial will be used in a soil experiment later this year.

The implications of Antonia’s research to date suggest that if sheep were to be offered food scraps that are rich in easily digestible sugars, such as apple, this could help to improve animal production, particularly during periods where pasture growth is slow or feed quality is poor.

Using apple as a supplement for lactating dairy cows would be useful during early lactation as it will help provide them with the

energy they need during milking.

On the other hand, apple and potato waste are low in protein, which will be useful supplements to reduce nitrogen loss when the protein in the pasture exceeds dairy cows’ requirements.

The groups of sheep that were supplemented with brewer’s grains showed a lower digestibility of 59 percent (± 5 percent) compared to the group eating only pasture.

“We found evidence that the raw potato off-cuts were quickly and almost completely broken down in dairy cow rumen fluid, compared to other biowastes, such as brewers grains and apple waste.

“Potatoes are composed primarily of easily digestible nutrients like starch and very little slow-to-digest-fibre. Brewer’s grains were broken down much more slowly and about 40 percent of the sample remained at the end of the experiment. This is caused by the high proportion of fibre that the rumen microbes need more time to break down,” Antonia says.

The brewer’s grains had a much higher protein content compared to the other biowastes and

the summer pasture.

The higher levels of protein and fibre in brewer's grains may provide a useful supplement with high sugar, low N crops such as fodder beet, particularly to dry stock or dairy cows in late gestation. To reduce nitrate leaching, brewer’s grains should not be fed in autumn when the nitrogen in the pasture is already higher than what the animal requires.

The next stage of the research is a soil experiment. It will involve combining dung from sheep that have been fed biowaste with soil in pots sown with grass seed. Measurements of the grass will be made over three months. The measurements will include the carbon dioxide fluxes of ryegrass on dung-treated soil

under light and dark conditions.

“I am interested to test the nitrogen in the urine from the sheep experiment to see if the biowastes changed the nitrogen partitioning between the urine and dung.”

Antonia will cut the grass to simulate grazing it and let it grow again three times. She will measure how much carbon is removed when the grass is cut. She expects to see the level of carbon in the ecosystem increase over time, despite temporary declines in C each time the grass has been harvested.

This will enable her to determine the carbon and nitrogen pathways among the three different food wastes as well as pasture. For instance, if more of

POTATO WASTE IS LOW IN PROTEIN AND COULD BE USED AS A SUPPLEMENT TO REDUCE NITROGEN LOSS WHEN THE PROTEIN IN THE PASTURE EXCEEDS DAIRY COWS’ REQUIREMENTS.

the consumed N is transferred to dung (instead of urine) when the animals are fed a particular food waste as a supplement. Fecal N is more stable and released more slowly into the environment.

Antonia’s research is funded through The Food Transitions 2050 scholarship program. Her supervisors are Racheal Bryant, Brett Robinson, David Whitehead and Christopher Mangwe. RC

GETTING AND MAINTAINING SOIL MOISTURE CAN BE A BUGBEAR FOR CONTRACTORS AND FARMERS TRYING TO ENSURE GOOD CROP ESTABLISHMENT. ADDED TO THAT CHALLENGE ARE HEIGHTENED CONCERNS AROUND WATER MANAGEMENT AND THE COSTS THAT GO WITH IT.

Budgets are tight, so there is a lot of pressure right now on contractors and farmers but UPL NZ Otago and Southland regional manager Tom McDonald says part of the solution could be simple.

“Zeba soil conditioner is the equivalent of putting moisture down the spout at sowing and retaining it there. Zeba is proven chemistry, but it is not the hard stuff.

“Zeba is one of the all-around good guys. It is easy to apply, safe to handle, and, importantly, there are no residues. It is just very clever science that is good for people, crops, and the environment.”

Corn starch-based and super absorbent, Zeba stores water then releases it when

THE SHANNON FAMILY USED ZEBA TO ESTABLISH A SUCCESSFUL SUMMER FORAGE CROP OF RAPE, SUNFLOWERS AND ITALIAN RYEGRASS ON THEIR CENTRAL OTAGO FARM.

plants need it. Each Zeba granule can hold up to 400 times its own weight in water.

With a high cation exchange capacity, it also interacts positively with soil nutrients and supports soil microbial communities, which promotes resilience. Zeba keeps both water and nutrients at the roots, where the plants need them most. Crop growth is maximised and growth checks minimised.

Tom says Zeba has performed well in very arid areas of countries including Australia, South Africa and India. “Not only that, but in Central Otago, and conditions there can be a real test.”

Sisters Jo and Vicki Shannon farm in the climatically challenging Ida Valley. The area is very dry with hot summers and freezing winters.

The family run Perendales as the main mob, with a terminal mob of Perendale ewes crossed with Hampshire and Texel rams, along with South Devon cattle.

Jo and Vicki took part in a Zeba trial and were won over.

“It is an amazing product,” Jo says. “We would recommend it to anyone. It worked and gave plants a chance to get established. Without it, we just would not have the crops we have now.”

They planted summer crops in October to fatten lambs. Thanks in part to Zeba, the feed lasted to April, and Jo says they will use it again.

Tom says Zeba is a major breakthrough in soil moisture management. “Zeba makes

moisture from irrigation go further and last longer. For dryland systems it is potentially a crop life-saver.