FEATURE

What’s new in Fertiliser Technology and Spreaders

FEATURE

What’s new in Spraying Technology

EQUIPMENT

Kuhn unveils new folding power harrows

What’s new in Fertiliser Technology and Spreaders

FEATURE

What’s new in Spraying Technology

Kuhn unveils new folding power harrows

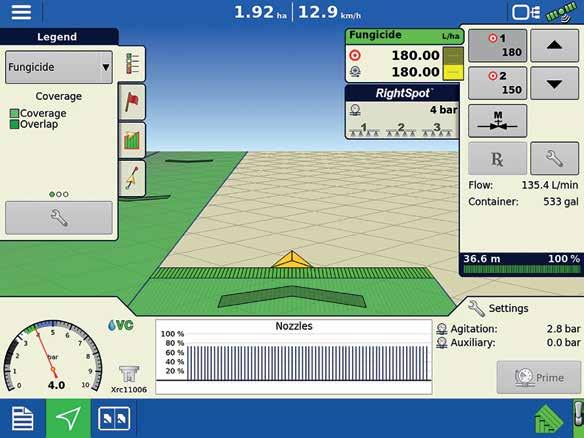

Take your spraying program to the next level of accuracy and performance with RightSpot™ precision technology from Ag Leader. Suitable for retrofitting to most self-propelled or trailed sprayers, RightSpot utilises blended pulse technology to maintain consistent droplet size and coverage at all operating speeds. With independent control of up to 144 nozzles, automatic turn compensation and automatic reticulation, priming and flushing, RightSpot significantly reduces input costs and the potential for spray drift. Contact your local Ag Leader dealer and find out how RightSpot can optimise the efficacy of your spraying program.

02 FROM THE EDITOR: First the bad news

INDUSTRY NEWS

03 Kiwi and Irish researchers take up methane emissions challenge

04 Subsoiler-direct drill combo the next big thing

06 Use layers of deterrence to stop rural crime

08 Trials confirm Pudama spot fertilising potential

09 Award honours top Kiwi agrichemical applicators

10 Bio-stimulants breathe new life into old mill

12 Fertmark extends scope to cover bio stimulants, other new products

14 Compaction, subsoilers and how to use them

16 Norwood welcomes Landini to its stable

17 Contractor sweating the details in lead up to world ploughing champs

18 Tabula links arms with Topcon

18 Another free conference for rural contractors

19 Pilot scheme to recycle 10,000 cow collars

20 Generation soft bait the real deal in rodent control

TECHNOLOGY

22 Freshfilter proves itself to veteran spray contractor

24 Automatic top link adjustment for smarter fert applications

25 Ag Leader upgrade costs fraction of new or second-hand sprayer

27 Electrical weeding could zap dependence on agrichemicals

28 Topcon universal load cells give muck spreader next level a ccuracy

PROFILES

30 New business with a long history

34 Custom-built mulchers do the hard yards

40 Injection of youth takes spray business forward

46 Across the Ditch: Sam monk - an amaizing life

FEATURES

50 What’s new in spray technology

66 What’s new in fertiliser technology and spreaders

EQUIPMENT

84 Meet the Boss – Valtra S6 Series high horsepower tractors born to work

86 Life better with high capacity Pegasus sprayer on the job

89 Contractor’s Veenhuis slurry tanker both faster and smarter

90 Case IH set to launch biggest Axial-Flows yet

91 Kuhn unveils new folding power harrows

92 Cutting-edge Kverneland gear keeps arable farm ticking over

95 Latest Deere S7 combines gobble more grain, less fuel

96 Years of accurate, low-cost drilling with Allen P-D Series

PAUL TITUS, EDITOR

PAUL TITUS, EDITOR

KIA ORA. THE NEWS IN THE AGRICULTURAL WORLD WAS A BIT GRIM AS WE WERE FINALISING THIS ISSUE. FORTUNATELY WE HAVE SOME UPLIFTING STORIES TO GET YOU OVER THE HUMP.

First the bad news: Sluggish international demand and Australia’s high red meat export levels were putting real pressure on Kiwi farmers while dry weather was wreaking havoc in several places around the country.

If you live in Canterbury, like I do, the atmosphere was even sadder with the Crusaders off to their worst start in Super Rugby history. If you look further afield it is always possible to find much grimmer news, such as the brutal wars afflicting Gaza and Ukraine. As ever, we thank our lucky stars that we live in Aotearoa.

Now the good news: I am always pleased to get away from my desk to visit with farmers and contractors, especially those who think outside the box. In March I had the chance to visit with Arthur Grigg at Surrey Hills Station, in the foothills of the Canterbury high country.

Arthur and his father Paul are using no-till to develop their hill country paddocks. Always looking for an edge, they direct drill their paddocks with a mix of oat-ryegrass as well as kale and fodder beet.

The Griggs recently upgraded their direct drill and tractor. To get a return on that investment, they came up with the idea of using them to do a better version of strip tillage.

Rather than pair their direct drill with a strip tiller, which does what it says on the box – cultivates strips out of pasture or ex-cropped ground – they run it in tandem with a subsoiler. The subsoiler removes compaction and leaves friable soil for the drill to work in without break-

ing up the soil surface.

Now Arthur is going contracting with their ‘strip no-till’ set up. They reckon it is the ideal way to restore and reseed winter grazed paddocks in a single pass.

We also have a story on Agrihub Solutions, which is converting the old paper mill in Mataura to produce soil bio-stimulants from fish and seaweed. And we catch up with Mark Dillon, who is heading off to the World Ploughing Champs in Estonia.

So as the 2023-2024 season winds down, here are a few jokes to relax with.

A cheese factory exploded in France. Da brie was everywhere.

***

What do you call a hippie's wife? Mississippi.

***

What did the full glass say to the empty glass? You look drunk.

***

A teenager brought her new boyfriend home to meet her parents. Unfortunately they were taken aback by his haircut, his tattoos and his piercings.

Later, the girl’s mum said to her daughter, “Dear, he doesn’t seem to be a very nice boy.”

“Oh, please, Mum!” daughter retorted. “If he wasn’t nice, would he be doing 500 hours of community service?”

***

A man finally got the courage to speak his mind to his wife. “Your mother has been living with us for five years. Isn’t it time she got a place of her own?” he asked.

“My mother?” replied his wife. “I thought she was your mother.”

AgriMedia Ltd, Ashcroft House Tancreds Road PO Box 37151, Halswell, Christchurch 8245 ph 03 329 6555 fax 03 329 6550 www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Agrichemical Manual.

© RURAL CONTRACTOR AND LARGE

SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

CONTRIBUTIONS - Editorial and photographic contributions are welcomed and should be sent directly to AgriMedia Ltd. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

EDITOR

Paul Titus

87 Stanbury Avenue, Christchurch ph (03) 381 6912 mob 021 655 092

email titus@agrimedia.co.nz

ADVERTISING MANAGER

Paula Forde

mob 027 229 0362

email paula@agrimedia.co.nz

CIRCULATION

email admin@agrimedia.co.nz

PRODUCTION, LAYOUT & DESIGN

Hannah Kincaid email art@agrimedia.co.nz

CONTRIBUTORS

Joanna Ibell, David Hill, Jim Lindsay, Brendon Burns, Bill Ritchie, Paul Collins, Mark Hamilton-Manns, Andrew Sing.

Printed by Blueprint Ltd

RESEARCHERS IN NEW ZEALAND AND IRELAND ARE WORKING TOGETHER TO BETTER UNDERSTAND METHANE EMISSIONS FROM PASTURE-BASED FARM SYSTEMS.

The four-year programme will see researchers, students, professors and database experts from DairyNZ and several Irish institutes and universities attempt to quantify methane emissions from dairy cows.

DairyNZ principal scientist Dr Jane Kay says they aim to determine the effect that different variables have on cows’ response to methane-reducing technologies. These variables include stages of lactation, pasture species, animal management and seasonal growth.

Jane says the joint programme

strengthens DairyNZ’s connection with Ireland. Scientists will work with Kiwi farmers, research organisations and commercial companies to develop viable tools to reduce on-farm emissions.

DairyNZ was awarded funding in 2023 for this work, as part of a pilot joint research initiative between New Zealand and Ireland.

The programme will develop a methane database for pasturebased systems to ensure emissions and mitigations are accurately accounted for at a farm and national level in both countries. Aotearoa and Ireland face national and market targets to reduce methane.

DairyNZ says Kiwi farmers are among the world’s most emissions-efficient. Consumer and dairy suppliers are pushing dairy farmers to continue reducing emissions, which will help

the New Zealand dairy industry remain competitive.

Jane says a priority of the research is to help farmers reduce emissions and remain profitable.

Strategies to reduce emissions from cows include early life intervention, which involves feeding a natural product to young calves to reduce methane emissions over its lifetime.

“This is an attractive mechanism because it is cost-effective and occurs well before milk harvesting,” Jane says.

Research on methane mitigation technologies will be done at Lye Farm, one of DairyNZ’s two Waikato research farms. The farm provides a setting where scientists can do trials under relevant conditions.

Farmers involved in the project will provide their thoughts and advice on how the strategies can be used on-farm.

DAIRYNZ’S JANE KAY SAYS A PRIORITY OF THE RESEARCH IS TO HELP FARMERS REDUCE EMISSIONS BUT ALSO REMAIN PROFITABLE.

The Irish institutes taking part in the research are the Agriculture and Food Development Authority (Teagasc), University College Cork, and the Irish Cattle Breeding Federation.

A CANTERBURY FARMERCONTRACTOR’S EFFORTS TO ACHIEVE MORE EFFECTIVE NO TILLAGE ON HIS FAMILY’S PROPERTY HAS LED HIM TO DEVELOP WHAT HE ARGUES IS AN IMPROVED VERSION OF STRIP TILLAGE.

Last year Arthur Grigg upgraded to a new 4.5m Novag direct drill. At the same time he took on a new 460-hp Fendt 1046 Vario to pull the power hungry Novag on his hill country paddocks.

Once he could see what the drill and tractor could achieve, Arthur wanted to get the machines working outside the farm gate to bring in some extra income contracting.

Noting the growing interest in strip till, he was curious to see whether he could create the same concept less the ‘tillage’ by using his direct drill in tandem with a set of low disturbance subsoilers.

Because it has 10 ripper legs on 500 mm spacings, his subsoiler provides the benefits of strip tillage – loosening the soil and alleviating compaction in front of the drill – without the moisture loss and removal of organic matter that strip till causes.

But first some background. Surrey Hills Station has been in the Grigg family for more than 90 years. Today the third generation of the family (Paul Grigg and his wife Sara) and the fourth generation (Arthur and his wife Kirsten) run the farm.

The 1240-ha property sits just south of Mt Somers and consists of 300 ha on the flats, 500 ha of developed hill country and 400 ha of native grasses. Today the farm carries 3300 ewes and 400 breeding cows. All of the capital stocks’ progeny are finished on the property and the Griggs also buy in store lambs and finish additional R2 cattle off winter crop.

Arthur says 30 years ago Paul started on a process of improving the hill country blocks. Once he subdivided them, he began the process of cultivating and regrassing about 40 ha each year.

While turning the soil over was a necessary step to start developing these native blocks,

the problems associated with stirring up what was essentially virgin ground was a challenge. Thistle pressures and also the potential for erosion given the high winds the Canterbury foothills are prone to limited the speed of development.

In 2012 Arthur returned home to work on the farm and this started a new phase. Paul was keen to go down the path of no tillage so in 2013 they purchased a 3m Cross-Slot direct drill to speed up the development of the farm.

He says while the engine room of the farm is in the flats, they have put a lot of effort in developing the hill country because the returns on investment there are greater in terms of increasing carrying capacity.

That work is paying off, and after years of notill, the rolling hill country paddocks are more productive. They have more friable topsoil as the native turfs have been removed, so they hold on better in dry conditions.

“The Cross-Slot was a great tool and it did its job very well,” Arthur says. “We increased the carrying capacity of our stock by 50 percent.

“We believe that by further lifting the productivity of our hill country we can increase this by another 30 percent. We are also reducing the number of ewes we run and increasing

A HILL COUNTRY CROP OF OATS AND RYEGRASS DIRECT DRILLED TOGETHER IN AUTUMN TO PROVIDE FORAGE OATS OVER WINTER AND RYEGRASS IN SPRING.

the trading component of the business.”

To achieve this, Arthur and Paul decided to upgrade the drill to a 4.5m Novag direct drill, which features similar openers and coulters as the Cross-Slot. At the same time, they replaced their articulated John Deere 9R tractor with the rigid-frame Fendt 1046.

“The 9R was a straight draft tractor. The attachments we could use with it were limited because it had no front and rear linkages. Also an articulated tractor is not ideal on the hills.

ARTHUR GRIGG BELIEVES THAT PAIRING HIS HIGH-PERFORMANCE NOVAG DIRECT DRILL WITH A SUBSOILER IS THE IDEAL WAY TO RESTORE AND REPLANT WINTER GRAZING PADDOCKS IN ONE PASS.

“So we decided to take advantage of a very strong second hand market and move the pivot on to provide ourselves with more options going forward,” Arthur says.

“The Fendt has a lot of weight in the rear end and the Vario transmission is great. On the flats VarioDrive automatically directs the torque to the tyres where it is needed, so there is limited slipping and it puts incredible power to the ground. In the hills, we lock it into four-wheel drive.

“It is comfortable and quiet to drive and it is 30 percent more fuel efficient than our previous tractor. Another reason we got the Fendt is that a good tractor attracts a good operator when it comes to taking on staff.”

Arthur says all of the big tractor’s power is needed to work the Novag drill in the hills. The drill is built heavy to provide the downforce needed to penetrate hard soils, and its coulters are set perpendicular to the ground (whereas they are set at a slight angle on most other competitor direct drills).

It takes more power to drive the Novag’s vertical coulters into the soil, but they create a better tilth for seed and have no issue with trash flow in paddocks with high residues.

“The French company that builds Novag drills has taken on feedback from its customers, and our new drill gives us some real advantages,” he says.

“It is user friendly. The monitor is very intuitive and all traditional monitors are integrated into one unit. Metering, calibration, downforce adjustment, and blockage monitoring are all accessible in the same place.

“It has the same Accord metering system as the Cross-Slot, and it is easy to use the hoppers in different combinations. It has big bins for fert and seed and two auxiliary bins for small seeds or slug bait. You can broadcast the small seeds or granules or put them down the shoot with the seed.”

Paul and Arthur use the Novag drill to sow all of their forage crops – ryegrass, oats, kale, and fodder beet.

It has 24 coulters in two rows of 12. To drill fodder beet they simply swap out the seed rollers on the two auxiliary bins to a specific beet roller. These bins have 12 outlets feeding the back toolbar of 12 coulters, which are on 375 mm row spacings.

Whilst it is definitely not a precision planter, Arthur says it would be fair to categorise this metering as ‘semi precision’. Arthur says fodder beet is a great compensator and despite the fact that the plant placement is not perfectly uniform, it does a great job in growing into space.

Their aim is to achieve low cost production as they use no-till to build up the health of their soil.

“We don’t follow the fodder beet bible, which is to fully cultivate to prepare a seedbed, precision plant and then apply six or more sprays. At this stage it costs us around $1700/ha to establish fodder beet, which is about half of the standard cost. Our system conservatively gives us yields of 20-26

THE GRIGGS’ FENDT 1046 VARIO CAN DELIVER 460 HP TO PULL THE 4.5M NOVAG DRILL AND 10-LEG RYETEC SUBSOILER.

tonnes, even on the hills,” Arthur says.

Once they worked out how to get the most of the Novag drill on their own property, Arthur turned his attention to how it could be used to provide services to other farmers.

“We were looking for a gap in the market to do some contracting. There is a big demand from dairy farmers to restore and drill paddocks coming out of winter grazing, and I could see there is a growing appetite for strip tillage.

“I thought that the Novag could offer something better. We talked with Grant Reith and Harry Burgess at New Zealand Tractors and we decided to go with a Ryetec subsoiler to do one pass ripping and drilling.

“The Ryetec’s low disturbance ripper legs can subsoil down to depths of 250-300 mm to address compaction. We run it with a packer roller, which evens out any hoof marks and smearing from the ripper legs.

“It leaves smooth, friable, ripped ground for the drill, so we are effectively getting the benefits of strip till in a genuine no-till pass.”

Arthur says, has taken a bit of trial and error to get the system right. At first he ran it with Ryetec’s roller rings which are designed for cultivated ground but they left ridges on the soil surface. They then switched to Ryetec’s

pasture roller, which does exactly what he wants it to do.

With the Fendt 1046 Arthur can work the ripper-direct drill combination even in heavy clay soils. A pass with the Novag and Ryetec subsoiler in tandem has huge power requirements. When the soil is not overly compacted the subsoiler can be left off.

But it means he can direct drill winter forage crops in spring or summer and then restore the compacted paddocks post winter grazing and plant a crop in a single pass.

Arthur says the concept is primarily to conserve and look after soil structure, with soil health front of mind.

“In a simple forage cropping scenario, I see no logic in full tillage as a precursor to intensive winter grazing. Nowadays we are seeing a huge push towards achieving more sustainable farming practices and soil health must be farmers' primary concern.”

At this point Arthur is doing all of the work with the Novag and Ryetec subsoiler himself as a side hustle to farming, but when the contracting business is well established he intends to take on an employee to do some of that work.

For more information on Surrey Hills Contracting and its unique subsoiling and direct drilling service, call Arthur Grigg on 027 320 8336.

THE GRIGG FAMILY USES THEIR FENDT 1046 VARIO AND 4.5M NOVAG DIRECT DRILL TO SOW RYEGRASS, OATS, KALE, AND FODDER BEET IN THEIR HILL COUNTRY PADDOCKS.

PEOPLE WHO LIVE IN RURAL AREAS AND WORK IN AGRICULTURE FACE A UNIQUE SET OF CHALLENGES, FROM THE WEATHER TO GLOBAL MARKET CONDITIONS TO ON-FARM SAFETY. AT TIMES RURAL PROPERTY OWNERS – MOST RECENTLY IN NORTHLAND, AUCKLAND AND HAWKE’S BAY – ALSO HAVE TO DEAL WITH THE EFFECTS OF ISOLATION DUE TO EXTREME WEATHER EVENTS OR EARTHQUAKES.

Rural security company Farmgate Security Limited says another growing threat is rural crime.

While rural crime has long been an issue that farmers and rural property owners have had to deal with, a recent survey sponsored by Federated Farmers finds that 67 percent of those surveyed had been or suspected they had been a victim of rural crime in the last two years. This is up 16 percent on two years ago.

Farmgate staff talk to hundreds of rural property owners every month and they say many communities are facing an epidemic of rural crime. This includes the theft of diesel, stock and tools. Farm bikes are the biggest items lost, but also alarming is the fact that many people think they had lost something but are not sure.

Some property owners are dealing with home invasions, threatening behaviour from neighbours, dogs poisoned while stock is loaded into trucks at night, trespassing vehicles, and even gang activity.

This, says Farmgate managing

director Andrew Sing, highlights the need for rural properties to have cameras at their entrances to track all people and vehicles entering and leaving. It is also good to have cameras overlooking any key assets elsewhere on the property.

But the problem is bigger than individual property owners. Because the police presence in many rural communities has dropped, rural people and their communities feel increasingly vulnerable, and they are looking for help.

“We are now working with whole rural communities who are joining together to deal with lawlessness and antisocial behaviour. This includes havoc caused by boy racers on the outskirts of many towns and cities,” Andrew says.

“After Cyclone Gabrielle there was looting and strangers entering properties around the rural Hawke’s Bay community of Puketapu. Later boy racers used some of these rural roads and intersections as places to gather and do burnouts.

“Some residents contacted Farmgate and we worked with them to install an observation camera and a high quality license plate recognition camera at entry points and exit points to the community and at various intersections.

“We installed the cameras where the residents of Puketapu wanted them. Recently the cameras were intentionally damaged but we have now mounted them higher to prevent further tampering. We sent the police images of the cars and their license plates that were there on the night the damage took place.”

Andrew says Farmgate is a purpose-driven company. They are partnering with Puketapu and other communities to install cameras because they know they work and because they care.

THEFTS OR WORSE ON RURAL PROPERTIES IS A GROWING PROBLEM, BUT WORKING WITH NEIGHBOURS AND DEPLOYING TECHNOLOGY SUCH AS REMOTE CAMERAS CAN HELP COMBAT CRIME.

FARMGATE SECURITY CAN EQUIP ITS CAMERAS AND OTHER SECURITY DEVICES WITH SOLAR PANELS, SO THEY CAN BE DEPLOYED ANYWHERE.

Farmgate has security products that others may not supply, and it has the capability to supply all of them with solar panels, so they can be deployed anywhere.

This is particularly important for farmers and rural property owners because often their valuable equipment, tools or diesel tanks are located where mains power is not readily available.

The message from Farmgate is to put up as many deterrents to enter your property as you can. If you stop unwanted visitors, it could reduce the statistics.

“Along with cameras, this should include basic steps such as shutting gates and having good communication with your neighbours. A sign stating that cameras are recording may be enough to deter people from entering a property. Where possible installing barrier arms and, of course, cameras should also help,” Andrew says.

“We suggest a two-fold approach. The first is FarmCam cameras that can be set up at entry ways and other key places around the property. These can

KAITAIA Kaitaia Tractors 09 408 0670

WHANGAREI Piako Tractors Northland 09 438 1319

SILVERDALE Brandt NZ 09 427 9137

PUKEKOHE Brandt NZ 09 237 0043

MORRINSVILLE Piako Tractors 07 889 7055

MATAMATA Matamata Tractors & Machinery (07) 888 6292

HAMILTON Brandt NZ 07 847 0425

CAMBRIDGE Brandt NZ 07 827 5184

ROTORUA Piako Tractors Ltd 07 345 8560

TAUPO Taupo Tractors & Machinery 07 378 4533

STRATFORD FieldTorque Taranaki 06 765 8643

HASTINGS Stevenson and Taylor 0800 4273 2273

WAIPUKURAU Stevenson and Taylor 06 858 6041

DANNEVIRKE Lancaster Tractors 06 374 7731

PALMERSTON NORTH Transag Centre 06 354 7164

MASTERTON Brandt NZ 06 377 3009

NELSON Drummond & Etheridge 03 543 8041

BLENHEIM Drummond & Etheridge 03 579 1111

KAIKOURA Drummond & Etheridge 03 319 7119

GREYMOUTH Drummond & Etheridge 03 768 5116

CHRISTCHURCH Drummond & Etheridge 03 349 4883

ASHBURTON Drummond & Etheridge 03 307 9911

TIMARU Drummond & Etheridge 03 687 4005

OAMARU Drummond & Etheridge 03 437 1111

MOSGIEL JJ Limited 03 489 8199

GORE JJ Limited 03 208 9370

INVERCARGILL JJ Limited 03 211 0013

AT LAST YEAR’S AGRITECHNICA SHOW IN GERMANY, KVERNELAND PRESENTED THE RESULTS OF A SERIES OF TRIALS IT HAS RUN IN COUNTRIES THROUGHOUT EUROPE TO TEST THE EFFECTIVENESS OF ITS PUDAMA SPOT FERTILISER SYSTEM FOR ROW CROPS.

Kverneland says the results of the trials confirm that in many cases Pudama can reduce fertiliser applications by 25 percent without any loss in yield compared to a standard fertiliser application.

Rather than banding fertiliser when precision planting maize beet or other crops, Pudama precisely places a deposit of starter fertiliser below the seed just where it is needed. A targeted deposit of fertiliser gives the maize seedling’s roots better access to the nutrients the growing plant needs.

It also reduces the amount of starter fertiliser placed between maize rows. This significantly reduces nitrate and phosphate discharge into water systems. When a planter places a band of starter fertiliser beneath the row of seed, it cannot all be completely absorbed by the plant so it is prone to leeching or runoff.

Kverneland did a limited release of Pudama in Europe during the Northern Hemisphere spring of 2023. It then conducted several trials across Europe, with different crops, soil conditions and weather patterns.

Those trials aimed to evaluate the advantages Pudama has when growing row crops. The tri-

be bullet cameras, which are ideal for entryways and farm tracks, or observation cameras for the house, shed, diesel tanks, vats or other high value assets.

“Second is license plate cameras that can read and record images of vehicles and their license plate, day or night. These cameras have already successfully identified vehicles of interest to

als were done in collaboration with agronomic institutes, agricultural universities, seed companies, and fertiliser companies.

Even though Europe went on to have a very dry summer, most of the trials showed that Pudama did deliver the positive results Kverneland anticipated.

In half the trials it achieved the same or greater absolute yields, and in a large majority of the trials Pudama’s relative yield per unit of fertiliser was the same or higher than standard planters with continuous application of fert.

In the early stages of the crops’ development (from pre-emergence to 10 leaves), plants sown with the Pudama spot fertiliser system performed better than standard planters that laid out a band of fertiliser.

How does Pudama work? During planting it sends a defined quantity of fertiliser to the fertiliser coulter. From there a burst of air shoots the fertiliser as a deposit into the soil. A sensor connects the fertiliser coulter and seeding unit which synchronises the placement of the seed and fertiliser.

How often the air valve opens and closes to deliver the fertiliser deposit depends on the driv-

KVERNELAND DISTRIBUTORS IN EIGHT EUROPEAN COUNTRIES HAVE CONDUCTED TRIALS ON PUDAMA WITH THE HELP OF LOCAL EXPERTS.

ing speed of the tractor and the programmed distance between seeds in the furrow.

Pudama can work at speeds up to 15 kph when used with Kverneland’s pressurised Optima SX sowing unit. At this rate it can apply up to 25 fertiliser deposits per second.

Using a combination of the Pudama and the Optima TF Profi with SX sowing units, farmers and contractors can save a lot of money by reducing fertiliser, labour and transport costs.

At the moment, this technology already had success during numerous exhibitions in many countries, confirmed by lots of awards.

Pudama has impressed the European agricultural industry.

PUDAMA PRECISELY PLACES A DEPOSIT OF STARTER FERTILISER BELOW THE SEED, JUST WHERE IT IS NEEDED TO SUPPORT THE GROWING SEEDLING.

It has won innovation and environmental awards in the Netherlands, France, England, Belgium and Spain.

Kverneland is now set to release it in more countries, including New Zealand, in spring 2024. It will also make Pudama available on more models.

In addition of the Optima TF Profi (trailed frame), Pudama will be available this year with limited series on Optima F 6m (6m folding unit).

the police and they have followed up on them.

“They also link to the police’s stolen vehicle database. This means, when a Farmgate camera detects a stolen vehicle it provides an immediate notification.”

With its latest technology Farmgate can install cameras hundreds of metres away from the Internet source (us-

ually the house).

“This is an absolute game changer for rural people,”

Andrew says. “What once cost thousands of dollars for equipment, aerials, cabling and installation can be done DIY for a fraction of the price.”

The bottom line is that rural security is now more affordable. Combined with Farmgate’s ability

to deploy solar powered options for its products and 4G cameras for locations where there is no internet, there are rural security tools that can help most rural property owners.

For more information about the options Farmgate provides visit the website farmgate.co.nz or contact the Farmgate team on 07-595-0344.

RURAL CONTRACTORS NZ AND NUFARM HAVE JOINED FORCES TO COME UP WITH A NEW AWARD THAT SHINES A SPOTLIGHT ON THE MOST CONSCIENTIOUS PEOPLE IN THE AGRICHEMICAL SECTOR.

The purpose of the Nufarm RCNZ Agri-Chemical Applicator of the Year award is to recognise an individual who demonstrates excellence in chemical application and innovation.

Nufarm NZ country manager Gavin Kerr says there has never been a better time to promote innovative industry leaders.

“We particularly want to highlight those individuals who promote innovation in the sustainable use of crop protection.

We fully back every product we provide and we are very focused on how our products are applied sustainability. The recent release of our Grassmanship application has been a great example of this.

“We are looking forward to recognising industry leaders within the contractors’ industry in partnership with Rural Contractors NZ.”

Rural Contractors NZ CEO

Andrew Olsen says agrichemicals are the most highly regulated sector of the agricultural industry.

“It gets plenty of attention from government agencies and the public, so it is timely that our partnership with Nufarm has extended to include a robust recognition program. The intent is to give our members the opportunity to put forward their brightest and best. Through a rigorous judging format, we will award the highest

• Multi-functional stubble cultivators, work effectively near the surface and at depth.

• DSD technology automatically changes the angle of the discs as they penetrate the soil.

• Hydraulic weight transfer system ensures uniform tillage.

• Use independently or in combination with other trailing equipment.

level of expertise, compliance and innovation.”

The award winner will receive a trophy and a $5000 development fund to support further education and development related to the crop protection industry.

The award is open to employees of contractors who are full members of Rural Contractors NZ and hold a current Registered Chemical Applicator qualification. Nominated employees must have no more than five years’ experience and must hold a relevant agri-chemical qualification or be working towards one.

An on-line application is used to enter the competition. Applications close Friday 19 April at 5pm.

Shortlisted applicants will be announced Monday 30 April.

Shortlisted applicants will have to meet an experienced judging panel in an on-line meeting format to discuss their application.

The winner will be announced at the RCNZ awards dinner at the conference in Masterton on 19 June.

For more information contact Andrew Olsen on office@ruralcontractors.org.nz or 027 255 2549.

• Contour XL is equipped with bigger, more effective, 610mm discs. Frame is raised to ensure optimum soil flow.

• Available in both trailed and three-point linkage options with working widths from 2.5-8m.

• 5.5m Disc Roller in stock POA

• Efficiently loosens the soil and breaks up hard layers without consolidating or bringing large clods to the surface.

• Varying options of tine type and staggered placement to effectively cultivate even the hardest soil.

• Can be used independently or in combination with other trailing equipment to make optimal use of your tractor and reduce number of passes.

• Use with a Disc Roller to rip and incorporate stubble into a well-drained and structural seedbed, or with a seed drill to cultivate and sow in one pass.

• Two types of stone protection available – hydraulic and quickpush.

• Working depth of up to 400 mm and working width options from 3 – 6m in rigid or hydraulic folding.

• 5m Combi Tiller MKII in stock POA

A NEW JOINT VENTURE HAS BEEN SET UP TO TURN THE FORMER PAPER MILL IN THE SOUTHLAND TOWN OF MATAURA INTO A PLANT TO PRODUCE BIO-STIMULANTS FROM SEAWEED AND AQUACULTURE BY-PRODUCTS.

New Zealand Seaweeds already produce the liquid soil additive KoFert and bee health supplement Kobee from seaweed. Now it is joining forces with a Southland group that produces hydrolysed extracts from by-products of the aquaculture industry.

They have formed AgriHub Solutions to convert the old paper mill into a factory and distribution hub for their bio-stimulants.

AgriHub Solutions sales and technical manager Hamish McCallum says the company’s range will include both seaweed and fish biostimulants as well as blends of the two.

“Seaweed and fish bio-stimulants are complementary products that can optimise the ratio of fungi and bacteria in soil. New Zealand’s soil health has suffered due to the high use of synthetic fertiliser over the past 50 years.

“Our bio-stimulants encourage the growth of fungi and bacteria in the soil. The benefits are better animal health and a reduction in the amount of nitrogen needed to produce pasture. Farmers using our products grow

pasture and winter crops such as kale using a quarter of the traditional amount of nitrogen.

“They can use less or no insecticides because the bio-stimulants are applied as a foliar spray and they have oils that suffocate insect eggs and aphids. They also combine with sugars in the plant to form compounds that are unpalatable to insects.”

Hamish says an analysis of KoFert shows it has the best suite of amino acids that he has seen. It also contains trace elements and minerals that are readily absorbed by plants.

One of AgriHub’s goals is to educate dairy farmers about the benefits of using bio-stimulants in conjunction with the existing nutrients in their effluent systems. This can provide a more efficient delivery system of these nutrients.

“Applying a bio-stimulant with fertiliser gives farmers a tool to keep well under nitrogen caps without breaking the bank. And at a cost of about $60/ha at the recommended application rate, it is an affordable option,” Hamish says.

Kath Coopey is the original developer of the seaweed bio-stimulant now sold as KoFert. Kath was working for New Zealand Manuka, which had a sideline producing agar from native seaweed.

She says the agar was made by processing kelp gathered from beaches, mainly along the coast of Wairarapa. When the company looked to diversify, she decided to see what

FERMENTATION TANKS TO MAKE BIO-STIMULANTS ARRIVE AT THE FORMER PAPER MILL IN MATAURA.

AGRIHUB SOLUTIONS WILL PRODUCE KOFERT SEAWEED BIO-STIMULANT AND ANOTHER BIO-STIMULANT FROM BY-PRODUCTS OF THE AQUACULTURE INDUSTRY.

AGRIHUB SAYS KOFERT SEAWEEDBASED SOIL ADDITIVE DELIVERS PLANTS ALL THE MAJOR ELEMENTS THEY REQUIRE AS WELL AS TRACE MINERALS AND GROWTH STIMULATORS SUCH AS GIBBERELLINS.

could be made from the other seaweeds that were present.

“Seaweed is eaten by many people around the world and its use as a fertiliser is also well known. We use a natural process to extract the amino acids, so they are readily available to the plant.

“The whole process is sustainable and permitted by the Ministry of Fisheries. Because we use a variety of seaweeds, our bio-stimulant provides everything plants need.”

Kath says it includes all of the major elements – nitrogen, potassium, calcium and phosphorous – as well as trace minerals like copper, zinc and manganese. It also has gibberellins and other plant growth stimulators.

“Nothing is in huge concentrations and it is not a chemical, so the soil and the plants are not getting huge dollops of things they can’t handle.

“Some seaweed stimulants sold in New Zealand are made from imported seaweeds that have been processed in a way that takes the goodness out of them. Ours is made entirely from New Zealand seaweed. Even though it is sold in a liquid that can be diluted and applied through a sprayer, it is a living thing that can form lumps so it has to be filtered,” she says.

NZ Seaweed is a subsidiary of Pastoral Improvements, which develops and markets pasture seeds throughout the country and to international customers

Along with producing and distributing seaweed and fish bio-stimulants, AgriHub solutions will distribute the full range of Pastoral Improvements’ seeds and seed mixes.

Hamish says AgriHub is working on some exciting opportunities with complimentary products to their unique bio-stimulants so… watch this space.

SCAN

THE WORLD OF FERTILISER IS A LOT MORE COMPLEX TODAY THAN IT WAS BACK IN 1992 WHEN FARMERS FORMED THE FERTILISER QUALITY COUNCIL (FQC). SO HOW DO FARMERS AND CONTRACTORS ENSURE THAT THE COMPLEX RANGE OF NUTRIENTS AVAILABLE TODAY ARE THE REAL DEAL?

FQC’s certification programme, Fertmark, was originally established by farmers to ensure fertiliser nutrients were independently verified as true to label, performance claims were true and chemical contaminants were managed.

Later Spreadmark was used to promote and oversee accurate nutrient placement.

Quality assurance specialist Peter Wood, who audits Fertmark and Spreadmark through the company QCNZ, is a staunch advocate.

“You would be a fool not to use Fertmark certified products and apply them with a Spreadmark certified contractor,” Peter says.

While Fertmark’s mandate has not changed, the menu for fertiliser nutrients has. This change has been driven by the need for more efficient products that farmers can use to produce more with less.

Peter says with the price of fertiliser now it is essential that we are getting what we pay for.

The options marketed to farmers today

AN IMPORTANT ROLE OF FERTMARK IS STILL TO CERTIFY THE ACCURACY OF SPREADERS THROUGH ITS SPREADMARK PROGRAMME.

include products with different physical and chemical properties. Innovations range from nutrient inhibitors to prevent nitrogen from leaching, to stimulants that enhance the efficiency of the plant’s nutrient uptake, to a diversification in the physicality of the products.

Where once the granule dominated the market place, now liquids (both slurries and fluidised fertilisers), prills, precision blends and polymer coatings are becoming commonplace in the dairy, cropping and horticultural industries. They can help improve environmental impact, animal and human health, and productivity.

FQC chairman Anders Crofoot says the challenge is to ensure farmers are not buying lemons.

“Fertmark is extending its coverage to include bio stimulants and soil conditioners to protect farmers and growers from misrepresentation. The extension of the Fertmark code is essential to give farmers confidence in the products they are buying,” Anders says.

To make Fertmark fit for purpose, FQC has formed a Fertiliser Agronomic Group that will review agronomic and scientific trials. It will determine how Fertmark could be applied to a wider range of products beyond fertiliser, such as soil conditioners and plant bio stimulants.

Fertmark’s fertiliser certification programme is also being extended to work with other agricultural quality assurance programmes. This should increase confidence in the ‘control’ that Fertmark provides.

The range of products and how they are defined in legislation has evolved and so too must Fertmark.

“Without Fertmark farmers and growers will be vulnerable to snake oil salesmen and unsubstantiated claims,” Anders says.

FQC EXECUTIVE OFFICER TYLER LANGFORD.

The Fertiliser Quality Council believes its new director Tyler Langford will be a strong advocate for farmers.

FQC chairman Anders Crofoot says Tyler has experience making legislation workable for farmers

“She has a strong background in farming and refining legislation and has hit the ground running. She is able to negotiate the finer detail of legislation up the pipeline, which is just the strength we need," Anders says.

For the past five years Tyler worked for the Federated Farmers’ Dairy Council.

"For every piece of compliance farmers are made to fill out, that is another committee meeting or school event they can’t support. I am looking forward to maximising the opportunities within FQC’s Fertmark and Spreadmark quality assurance programmes,” Tyler says.

Advocating for farmers to ensure that rural communities not only survive but thrive is very personal to Tyler.

"I have the blessing of dairy farming in the Golden Bay with my husband Wayne and three teenage boys. I am hugely passionate about the strength and resilience of our rural community. I actively spend time in conservation groups, catchment groups, rugby clubs and serving as the chair of our local recreation park board.”

Tyler says she is now getting familiar with the work that FQC does and opportunities on the horizon. This includes updating the Spreadmark code.

CARRFIELDS HAS ADDED THE GRANGE RANGE OF SOILLOOSENING EQUIPMENT TO ITS PORTFOLIO OF CROP AND PASTURE ESTABLISHMENT TOOLS.

British farmer and engineer Rhun Jones established Grange Machinery specifically to produce conditioning tools to manage sub-surface soil damage. His company has quickly grown to become one of the UK's leading machinery manufacturers, wellknown for its innovation.

Sub-surface soil damage, by its very nature, is difficult to see and its effects are often poorly understood or only identified when it is too late. Usually, this is later in the season when cropped soil or grassland is lying very wet.

Also, as larger equipment and heavier tractors have been progressively employed over the past 30 years, sub-surface damage from soil compaction has been hidden from view.

The type of tyres used on farm machinery, operating pressures, the timing of field operations, weather, and of course soil type, all have a significant effect on subsurface soil damage.

With the use of some basic technology and a bit of physical exercise it is not hard to identify and then rectify or prevent compaction.

When compaction or drainage issues are suspected, it is important to identify whether you have micro or macro drainage issues. The first step is to pick up a very simple and often neglected tool – the spade. Dig some holes and look at your soil composition.

The Carrfields team can help

with visual soil assessment and can use a slightly more sophisticated tool, a penetrometer, to help identify any compaction layers.

When it comes to micro-drainage, soil structure is the key. Look for a nice crumb structure throughout the profile.

Macro-drainage combines two elements: 1) Letting water infiltrate into the lower soil profile, and 2) Moving water away from the lower soil profile.

If the upper soil profile is well structured but infiltration to the lower profile is hindered by a compacted layer, then ponding will occur. Subsoiling may alleviate the problem, but first, the spade (or penetrometer) must be used to identify if there is a compacted layer and, if so, at what depth.

This is critical. Don’t be tempted to run the subsoiler too deep. In some heavy soils, this may make the problem worse by causing upward compaction if the ground is too wet.

The idea of upward compaction may sound strange because this type of damage appears to be at odds with the effect of weight from tractors or heavy machinery. Subsoiling will only be effective if the deep sub-surface is porous (e.g., with gravel or sand) and the soil above it is dry enough to crack or fissure to allow root growth and water movement.

If your upper soil profile is well structured and there is no compaction layer, but your subsoil is not porous (e.g., if it is clay), then subsoiling will only ‘increase the size of the sponge’.

In this case, subsoiling might improve short-term the amount of water the soil will absorb, but it will still become waterlogged after high rainfall. In this case, you can move excess soil moisture away with macro-drainage, either sub-surface (mole drains, tile/pipe) or surface drainage.

Timing is crucial. Subsoiling and mole ploughing differ in their optimal timing.

Subsoiling should be done when the upper surface layers are dry enough to create cracks radiating out from the point and wing of the subsoiler leg.

THE FIRST STEP TO DEAL WITH DRAINAGE PROBLEMS IS TO GET OUT THE SPADE (OR PENETROMETER) TO CHECK SOIL COMPOSITION AND ANY COMPACTION LAYERS.

On the other hand, mole ploughing should ideally be done in damp subsoil clay that then gets baked to a long-term mole channel in the following dry conditions.

Late spring will normally provide the best conditions for mole ploughing whereas there is more time flexibility with subsoiling.

Of course, the efficacy of subsoil macro-drainage relies on micro-drainage (good soil structure) to work. Both must go hand-in-hand.

If our future weather patterns are going to be more variable, then managing our soils to retain

SOME GRANGE SUBSOILERS ARE DESIGNED TO BE USED IN COMBINATION WITH A DRILL WHILE OTHERS ARE DESIGNED TO BE USED ON THEIR OWN OR WITH AN AIR OR DISC SEEDER.

NORWOOD AND ARGO TRACTORS

ARE PLEASED TO ANNOUNCE THEY HAVE SIGNED AN AGREEMENT, GIVING NORWOOD THE EXCLUSIVE DISTRIBUTION RIGHTS FOR THE NEW ZEALAND MARKET.

The new agreement comes into effect in June. It will see Norwood take over all import and wholesale activities for Argo Tractors.

Norwood CEO Aaron Smith says his company is excited to enter a partnership with Argo Tractors.

“They have a strong track record, manufacturing 22,000 tractors globally every year, and they have technology and sustainability front of mind,” Aaron says.

Initial the agreement is only for Argo’s Landini tractors. Its McCormick range will be placed ‘on hold’ while the new partnership is established.

Argo Tractors general manager for Oceania Kim Findlay says they are delighted to collaborate with Norwood to develop a new chapter for Landini in New Zealand.

“Argo Tractors has undergone extensive development. We have increased the amount of high-tech and high range machines and attracted global recognition,” Kim says.

“Norwood will provide an exceptional supply chain channel with their experience, expertise and country-wide structure. This will ensure the Landini brand and its customers are in great hands for years to come.”

Landini has a 140-year legacy in machinery. They manufacture a range of products, from agricultural to speciality tractors for all food producing segments, whether on the farm, the orchard, or the vineyard.

Norwood says the new Landini tractors it will bring to Aotearoa include the Landini Rex 4-120 GT RoboShift Dynamic, which won the Specialty Tractor of the Year award at

moisture more effectively in dry conditions and remove it in wet conditions will have a major impact on the resilience of our farming systems.

GRANGE RANGE

Grange Machinery is made by and for farmers. The company takes its name from the Jones family’s farm at Sproatley Grange in East Yorkshire.

It offers a range of soil-loosening tools that can be used on their

Agritechnica 2024. It will also offer the new high horsepower Landini Series 7 and Series 8 ranges.

Aaron says Norwood’s goal is to provide current Landini and McCormick owners more support through the existing Argo dealer network, and to seek out extra market opportunities

“It is important to us that all Argo customers feel supported. They will have support and access to aftersales service for their tractors with the additional depth of extra dealerships and the largest agricultural parts warehouse in the country,” Aaron says.

Over the past decade Landini has had significant growth and Norwood is looking to replicate that success here. It will give affected dealers all the support they can through the transition.

Kim also extends his thanks to Agtek, which has represented the brand as import-

own or in combination with other tillage or seeding machines.

The most effective way to use them is to identify and address the problem when the soil is dry and friable. This often aligns when seeding or preparing a seedbed, and therefore it can be combined with a drill or cultivator as a one-pass system. Grange machines are designed to loosen soil only at the depth specified whilst minimising surface disturbance. This makes

THE LANDINI REX 4-120 GT ROBOSHIFT DYNAMIC WON THE SPECIALITY TRACTOR OF THE YEAR AWARD AT AGRITECHNICA 2024.

er, distributor and dealer in the Bay of Plenty for more than 12 years.

Agtek managing director Gayne Carroll says he has worked with the Landini brand in New Zealand for nearly 30 years, first when the brand was introduced by Motor Holdings, then at Power Farming, and finally at Agtek.

Gayne says in the horticultural sector the brand has a reputation for no nonsense operation and productivity.

“We would like to say a sincere thank you to the independent, locally-owned dealers who have supported the brand over the years,” he says.

them well suited for use in combination with min-till and no-till systems.

The Grange Close Coupled Toolbar (CCT) and Low Disturbance Toolbar (LDT) are ideally suited to complement a min-till or no-till drill. More traditional subsoiling options are the Grange Low Disturbance Loosener (LDL) and Grassland Loosener (GLL) which are designed to operate as independent tools to renovate soil that has been damaged, for

example, by winter pugging from livestock.

The LDL and GLL can be fitted with a pneumatic or spinning disc seed applicator, and with a smooth or toothed packer roller. Both machines are the ideal tools for restoring grassland or establishing a cover crop in stubble.

So if you think compaction is an issue on your farm, it is time to get out the spade. Then, if the conditions are right, reach for your Grange subsoiler.

MARK DILLON, HIS TWO-FURROW KVERNELAND PLOUGH AND HIS MASSEY FERGUSON 362 ARE ALL GETTING READY TO TRAVEL TO ESTONIA.

CEAT TYRES IS ONE OF THE SPONSORS OF MARK DILLON’S APPEARANCE AT THE WORLD PLOUGHING CHAMPIONSHIPS IN AUGUST.

AS THE BEATLES SANG – ‘I GET BY WITH A LITTLE HELP FROM MY FRIENDS’. THOSE LYRICS WOULD STRIKE A CHORD WITH SOUTHLAND CONTRACTOR MARK DILLON, WHO IS PREPARING TO GO TO ESTONIA TO REPRESENT NEW ZEALAND IN THE 69TH WORLD PLOUGHING CHAMPIONSHIP.

The opportunity Mark has to take part in the event is, of course, the result of his own hard work and dedication, but he is also grateful for the support he has received from both friends and sponsors.

Along with help from his local club, the Waimea Plain Ploughing Association, he will have a new set of tyres for his tractor from CEAT Tyres and financial sponsorships from AGCO, JJs, Ardia Crop Protection and Diesel Performance Solutions.

Mark won the conventional title in the 2023

New Zealand National Ploughing Championships, which entitles him to take part in the World Champs. They take place 16-17 August near the city of Tartu, Estonia. Veteran Bob Mehrtens will represent New Zealand in the reversible plough category.

Because Mark is a large farmer and contractor on top of being a consistent top finisher in New Zealand national ploughing competitions, he is always a busy guy. The first half of 2024 has been even busier than normal, however.

To give himself the best chance of winning the world title, he is shipping not only his twofurrow Kverneland conventional plough to Estonia but also his ploughing tractor, a 1993 Massey Ferguson 362.

“We have had the tractor to the panel beaters. They took all the windows out, cut out all the rust and gave her a new paint job. A mate and I took apart the engine, gave everything a complete clean and put in a new starter motor and alternator.

“She is as good the day she came out of the factory and she has all new CEAT radial tyres which are 40 mm wider than what we usually run,” Mark says.

Mark is no stranger to high level ploughing competitions. He has been ploughing competitively for 23 years and for the past 10 years he has finished in the top three in the NZ nationals.

This is the second time he has taken part in the World Ploughing Championships. He competed in the 2014 Championships in France.

“We are competing in the New Zealand National Championships in Waikato in midApril and then the tractor and plough go straight to Tauranga to get on a ship for Estonia. My wife Sonia and I will arrive in Estonia in July and I will buy ground to practice on.

“The soils are mix of river loam and silt loam, and the proposed ploughing depth is 18-22 cm. That is fairly deep so we will want to get used to ploughing at that depth.”

From truck to motorbike sprayers, we can build & supply all your spray unit needs, big or small. Stainless steel tanks.

We are dealers of BA Pumps, Croplands & TopCon.

TABULA AND TOPCON POSITIONING SYSTEMS ARE COLLABORATING TO INTEGRATE THEIR TECHNOLOGY, WHICH WILL CREATE A COMBINED APPLICATION FOR GROUND-BASED FERTILISER AND SPRAY WORK.

Both Tabula and Topcon bring proven technology to the table and sat they are committed to driving great outcomes for agricultural businesses.

Tabula’s job management, health and safety, compliance and reporting systems will be able to work with Topcon’s accurate placement and auto steering technology for spraying and spreading equipment.

By integrating their products, the two companies say farmers and contractors can get the right tool for the right job.

Tabula CEO John Enlow says his company is very pleased to be able to work more closely with Topcon.

“We are always looking for ways to provide additional support to farmers and contractors.

This collaboration is a natural next step and fit for our businesses.

“Our strategy of building relationships with highly regarded partners, such as with Topcon, demonstrates our commitment to the farming sector,” John says.

Topcon director of sales ANZ Phillip Hubbard says the relationship brings together complementary technology.

“It is great to come together to provide something that we know will really make a difference to farmers and contractors. Together our companies have an offering that suits all operators from small to large.

“We know that both New Zealand and Australian ground application customers are very inter-

ested in Topcon’s field-proven auto steering and product control capabilities.

“Our collaboration will deliver real benefits for landowners and contractors and we are excited to initially launch this in New Zealand and Australia,” Phillip says.

RURAL CONTRACTORS WILL GATHER IN MASTERTON IN JUNE FOR THEIR CONFERENCE AND ONCE AGAIN IT WILL BE FREE FOR THEM TO ATTEND.

RCNZ CEO Andrew Olsen says the RCNZ Board has confirmed that the organisation will again provide free registration to members. RCNZ members and life members are entitled to free registration for up to four people.

The Wairarapa conference from 18-20 June will also again feature a revised programme similar to that introduced at last year’s conference in Invercargill.

“We’re excited about the changed content and being able to again offer the conference free to full members. The Board and I took a good look at the feedback from the Invercargill event which

accommodated more offsite workshops and activities to balance sponsored and business components.

“We are looking forward to welcoming first-time conference attendees and welcoming back our conference faithful. My message to members and industry is don’t miss this opportunity to join us, catch up with old mates, learn some stuff and make new connections.”

The event will take place at Copthorne Solway Park Hotel, kicking off at lunchtime on Tuesday June 18.

“Minister Todd McClay has been booked to open the conference. Todd has attended our last two conferences. Now he is Agriculture and Trade Minister so it will be great to have his insights.”

On the first day of the conference there will be off-site work-

TABULA JOB MANAGEMENT AND REPORTING SYSTEMS WILL SOON BE ABLE TO INTEGRATE WITH TOPCON AUTO STEERING AND CONTROL TECHNOLOGY FOR SPRAYERS AND SPREADERS.

CAN THE WAIRARAPA MATCH BLUFF OYSTERS AND HOKONUI MOONSHINE? SOUTHLAND CONTRACTOR BRIAN HUGHES WAS AMONG THOSE SAMPLING THE BEST OF HIS REGION AT LAST YEAR’S CONFERENCE IN INVERCARGILL.

shops for both the agrichemical and cultivation sections of RCNZ as well as a Good Yarn mental health workshop.

The format will be similar on Wednesday June 19 before the industry’s awards dinner.

A final morning on Thursday

June 20 will include speakers on health and safety, ACC, immigration and employment issues, before a lunchtime wrap-up.

All the details and registration forms are available on the RCNZ website – ruralcontractors.org. nz.

The pilot project will recycle 10,000 SenseHub cow collars (previously known as Allflex collars) that have reached the end of their battery life. It will provide a template for recycling all types of e-waste off farms as digital, data-driven farming becomes common place.

Cow collars are increasingly used by Kiwi farmers to manage their animals’ wellbeing, track their productivity and control their movements. About 17 per

collars is a natural progression for us as an industry leader.

“It is core to our business and we want to help our customers meet their sustainability goals so that we are all making a difference.”

Agrecovery chief executive Tony Wilson says farmers use an increasing amount of electronic componentry on-farm. This ranges from collars to cell phones, EID readers, sensors in their yards and milking sheds, batter

THE REALITIES OF RODENT CONTROL AREN’T PRETTY OR TIDY, AND THAT IS WHY GENERATION SOFT BAIT WASN’T JUST TESTED ON LAB RATS. IT WAS TESTED ON WILD RATS.

UPL NZ Upper North Island regional manager Pieter Van Der Westhuizen says this means the bait is going to deliver where it counts – in rural sheds and around buildings.

“The testing process was very rigorous and you can definitely see that with Generation’s performance in real life situations.”

Pieter says Generation soft bait contains vegetable oil and crushed grain that gets rats’ attention faster and the soft bait’s paper ensures the tempting aroma disperses widely.

“That draws in even the shyest feeders. Scientists took into consideration all aspects of wild rat behaviour including the feeding ‘pecking order’. Rats are neophobic – they mistrust anything new – so, the bait’s attrac-

tiveness is vital.

“Because the effects of Generation Soft Bait are delayed a bit, once the dominant rats have fed, other rats gain in confidence and follow their lead.”

Pieter says he owns dogs, cats, aviaries and chickens, and he has hand-on-heart confidence in using Generation Soft Bait.

“Generation Soft Bait contains Bittrex a bittering agent which reduces the risk of consumption by non-target animals, like cats and dogs. Quite reasonably, that’s something that worries people about using rat bait.”

Generation Soft Bait is also very easy to deploy by skewering the plasticine-like bait on the metal rod, or wire, within the Generation bait station. “It’s quick, clean, and really easy to use.”

The smallest non-dispersible bait on the market, Generation Soft Bait kills effectively and in a single feed.

The bait’s active is the most advanced anticoagulant on the market, difethialone 25

separate recycling. The componentry is then sent to where it can be recycled and used in new products.

Agrecovery will collect the collars at a North Island and a South Island site, and MSD Animal Health will collect collars from their customers as they come up for renewal. By taking part in the scheme farmers can demonstrate they can meet environmental initiatives such as Fonterra’s Co-operative Difference scheme. This pays farmers a premium to achieve targets around milk quality, sustainability, animal welfare, and health and safety.

Pauline says by collaborating with Agrecovery MSD Animal Health will know which farm the collars have come from, and how many collars they have recycled. Dairy farmers can then use this information to meet their own sustainability goals.

A compulsory stewardship programme for animal health products comes into effect in September 2024 under the Waste Minimisation Act. Under the scheme Agrecovery is an accredited provider. There is not a compulsory scheme for e-waste yet, however. The Ministry for the Environment is expected to consult on regulations to support e-waste

ppm, which rodents can’t detect. There is no known genetic resistance among rodent populations in the lab or wild.

A feed of bait of 2-3 gm kills a rat while 0.30.4 gm kills a mouse. To put that in perspective, a rat’s average intake of food is around 20 gm/day while a mouse consumes around 3 gm/day.

Rats can produce litters up to 12 pups every two or three months, and Pieter says getting ahead of their astonishing ability to multiply is the best way to protect property, grain, and feed.

“Using Generation Soft Bait proactively is the best strategy. It will save money down the track.”

Pieter warns rodents cause more damage than we are aware of, including fires in vehicles and buildings due to chewed electrical wires. That is on top of damage to buildings and the loss and contamination of feedstuffs.

Among the most serious mammalian pests known to man, the rodents are destructive, dirty, and disease-carrying.

New Zealand has four species of introduced rodents – the Norway rat (Rattus norvegicus), the ship rat (Rattus rattus), the Polynesian rat (kiore), and the house mouse. The ship rat is the most common, and the smaller of the three rats.

Remember – all poisons should be handled in accordance with the label and best practice, and stored out of reach or children, cats, and dogs, and ideally in a locked cabinet. Bait stations must be used with Generation Soft Bait.

Generation Soft Bait and bait stations are available exclusively from PGG Wrightson.

GENERATION SOFT BAIT FROM UPL DELIVERS THE MOST ADVANCED ANTI-COAGULANT ON THE MARKET IN A PACKAGE THAT RODENTS CANNOT RESIST.

product stewardship in 2024-2025.

“Whilegovernment regulates these stewardship schemes, we also know it is the right thing to do and our consumers are demanding it. E-waste isn’t yet included in the product stewardship scheme, but we wanted to get ahead of the game with this pilot,” Pauline says.

MSD Animal Health supplies innovative, high quality veterinary products. In New Zealand and around the world it supports research and development for animal health products used by veterinarians, farmers and pet owners.

KVERNELAND QUALIDISC

COMPACT DISC HARROW

• Compact and sturdy

• Excellent penetration

• Simple adjustment

• Long lasting discs

• Perfect cutting angle

• Maintenance-free bearings

New stock arriving June, order now for Spring.

KVERNELAND TURBO T UNIVERSAL CULTIVATOR

• Operate at high forward speeds whilst maintaining a consistent working depth

• A great choice for a wide field of seasons and applications.

THE FRESHFILTER POSITIVE AIR PRESSURE SYSTEM IS IMPROVING WORKING CONDITIONS FOR SPRAY CONTRACTORS AND ANYONE WHO WORKS IN DUSTY OR HAZARDOUS ENVIRONMENTS.

Developed in the Netherlands, Freshfilter can be fitted to any vehicle with a closed cab.

Southland spray contractor David Kean has been trialling a Freshfilter system in one of his Land Cruiser spray units. He says it certainly has impressed him and he is definitely going to purchase it.

David speaks from experience. His father started the business Farmers Dipping Ltd back in 1966 and he joined the company in 1992. Now the third generation of the family is on board – for the past six years, his two sons have also worked in the business.

On top of running a successful business, David was on Rural Contractors NZ’s board of directors for more than 20 years, and he served four years as its president. “I enjoyed every minute of it and met some bloody good guys,” he says.

Christchurch-based company Landlogic distributes the Freshfilter range in New Zealand, and last year Landlogic South Island sales representative Graham Booth asked David to trial one of their cab filters. He happily agreed.

“You don’t turn down cutting-edge technology which is going to better the working environment for our drivers,” David says.

Farmers Dipping runs 12 spray trucks, including six Landcruiser units. They are custom built in Hasting by AgTech.

When they ordered a new Landcruiser sprayer last June, a Freshfilter M10 system was included. It is mounted on the roof and connects to one air intake, while all other vents are blocked off.

It is powered by either 12 or 24 volts from the vehicle and it pushes filtered air into the cab via the outlet behind the passenger’s seat.

David says the two main things he wanted to achieve from the Freshfilter were to eliminate any spray residues from entering the cab and to keep dust out. It has achieved both.

“There is no chemical smell in the cab and no dust. It is such a winner. The cab still looks as clean as the day it came out of the showroom. That is huge to me and great for the driver.”

Graham had been a spray truck operator in a family owned business (Booth Ag) in Otautau for over 20 years. He could immediately see the advantages Freshfilter offers, and he thought David would be a great one to trial it.

“I knew the feedback would be honest either good or bad. It is another tool to improve your staff’s work environment and factoring it into your setup is a real investment in your staff’s health and wellbeing.

“Freshfilter has done the testing overseas

SOUTHLAND’S DAVID KEAN SAYS THE FRESHFILTER PREVENTED BOTH DUST AND SPRAY RESIDUES FROM ENTERING THE CAB OF HIS LAND CRUISER SPRAY TRUCK.

and they work, but to put my name to it I needed proof for myself. In my mind, if the cab stays clean from dust and doesn’t smell, then it must stay clean from fumes and residues, and it does.”

When the Freshfilter system is on 100 percent it will produce a maximum pressure of 440 kilopascals (kPa). During trials they found this was overkill, so the unit on David’s Landcruiser is at 50 kPa.

Freshfilter provides three different models to cover all needs. David has the FF M10 mounted on a roof rack. It is only 205 mm high, so it is ideal for vehicle roofs. It is the most popular model for tractors, trucks and skid steers.

Another model is the FF Tube, which is the smallest option for when space is an issue such as in compact excavators. The third option is the FF Multibox which comes in various sizes for larger vehicles such as big excavators, wheel loaders and dumpers.

Graham says Freshfilter can go on any vehicle so long as it has space for the outside unit and the cab can be sealed off adequately.

MOUNTED ON THE ROOF OF THE VEHICLE, THE FRESHFILTER M10 KEEPS THE CAB PRESSURISED AND IT WARNS THE OPERATOR IF THERE IS A CHANGE IN THE AIR QUALITY OR IF PRESSURE DROPS.

He can see a broad range of applications in New Zealand across a wide variety of industries including chemical, fertiliser, civil, roading, demolition, quarries and many more.

“I am really excited to be able to offer this product. As an ex-employer, having a tool that benefits your employee’s health and wellbeing as much as this system does is a no-brainer. It is an investment in both your staff and business.”

Freshfilter keeps the cab pressurised, but it is not the same as air-conditioning. Graham says the operator does not have to change any other settings other than to put the airconditioning setting to recirculation.

A monitor on the dashboard gives updates on the condition of the air in the cab. It sounds an alarm if the pressure drops, for example if a window is open.

M10 units have layers of filters 120-mm thick. The filters are paper or carbon with different ratings depending on what you are trying to filter out.

Landlogic recommends that every six months operators change the pre-filters, which trap dust particles greater than 4 microns, and the main filters, which trap harmful particulates such as quartz dust and

asbestos. The carbon filters, which trap gaseous or liquid particles, should be changed every 13 weeks.

The unit can filter at 120 m3/hour and the monitor alerts the driver when the filter is full or blocked.

David intends to install Freshfilter units in all his new builds in the future.

“The driver feels at the end of the day as fresh as when he started. It is a game-changer, sitting in a fresh, beautiful-smelling vehicle.”

He also likes that it can be turned off when

not needed. “Some drivers like to drive home with the window open.”

Improving work conditions also makes it easy to keep drivers. “Honestly, when you have good gear and leading technology, we don’t even have to advertise for staff.”

He compares it to the upsurge in GPS. Initially some embraced it whilst some could not see why they needed it, but now most have auto-steer.

“We thought we didn’t need Freshfilter, but the guys are so much fresher at the end of the day.”

VALTRA UNLIMITED HAS UNVEILED THE NEW CONCEPT SMART TOP LINK TO IMPROVE THE ACCURACY OF FERTILISER APPLICATIONS.

Valtra NZ product marketing manager Mark Hamilton-Manns says Valtra is constantly innovating to bring tailored technology to farmers and contractors, and this is another unique product offering.

Smart Top Link improves the spreading accuracy of mounted fertiliser spreaders by automatically adjusting the top link’s length to ensure the spreader is correctly calibrated throughout application.

“Traditionally, to ensure the correct performance of a fertiliser spreader, the operator has to adjust the top link’s length to ensure the spreader is level. As a result of extensive field trials, the Valtra team found that the weight change in the spreader during the spreading cycle causes an angle change of around 3°,” Mark says.

“This may not sound much but it has the ability to significantly impact the accuracy and reliability of fertiliser placement.

“Today farmers, growers and environmental regulators are demanding accurate delivery

and calibration of fertiliser spreaders, and the Valtra Smart Top Link offers both agronomic and financial benefits.”

With the changing angles on the top link, the spreader is calibrated properly for only about 20 percent of the spreading cycle. Such poor consistency in spread pattern results in a loss of yield and over application in certain areas.

A study on a Danish farm found this to have a negative average effect of $35/ha. The Valtra Smart Top Link adjusts the top link in real time, to ensure the spreader remains level and fertiliser is applied accurately. This reduces the negative effect by an average of $26/ha.

Available as a Valtra Unlimited feature from the beginning of 2024, the system works via the SmartTouch display to keep a mounted fertiliser box spreader level during work.

Two radar sensors are supplied with Smart Top Link. The sensors are fitted to the front

SMART TOP LINK USES RADAR SENSORS TO MEASURE THE DISTANCE TO THE GROUND AND THEN ADJUST THE LENGTH OF THE TOP LINK ACCORDINGLY.

and rear of the fertiliser spreader to measure the distance to the ground. The data they provide is used to control the length of the top link.

Using the same data the system also displays the height above ground. The Smart Top Link can be used with most mounted fertiliser spreaders regardless of manufacturer.

The Smart Top Link is now available via Valtra Unlimited on new N and T Series tractor orders.

“To satisfy the needs of our customers an aftermarket version of the product will be released later in the year,” Mark says.

WESTERN AUSTRALIAN FARMERS STEPHEN AND ALBIE BOOKHAM HAVE UPGRADED THEIR 20-YEAROLD SELF-PROPELLED SPRAYER INTO A STATEOF-THE-ART PRECISION SPRAYER FOR A FRACTION OF THE COST OF A NEW MACHINE.

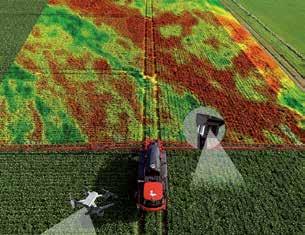

Their RoGator 1064 sprayer is one of the first self-propelled sprayers in Australia to be retrofitted with a RightSpot precision spraying system from Ag Leader.

RightSpot uses pulse width modulation (PWM) technology to ensure boom pressure remains constant regardless of operating speed. This ensures consistent droplet size, minimises spray drift and ensures the correct application of chemicals.

By comparison, boom pressure in a conventional flow-based sprayer is determined by ground speed. Any reduction in speed produces larger droplet sizes and potentially reduces the efficacy of the product being sprayed, while any increase in speed will produce smaller droplets that are more prone to spray drift.

Stephen and Albie run a largescale cropping operation near Wongan Hills, WA. Over the past six years, the brothers have doubled the size of their cropping program to about 4000 ha of canola, wheat, barley and export hay.

This expansion has put pressure on every machine in their fleet, none more so than their ageing sprayer.

“Last January, the spraying system on the RoGator threw in the towel,” Stephen says. “It was finished. Nothing worked, the board had completely crashed and the wiring had short-circuited. We had no choice but to buy a new sprayer or try to rebuild the old one.

“We’d just bought a new combine harvester, so we weren’t really in the market for a new sprayer. We were interested in getting a pulse width modulation system because we have lots of

STEPHEN BOOKHAM SAYS HE LIKES RIGHTSPOT’S AUTOSWATH SYSTEM, WHICH SHUTS DOWN NOZZLES AS THE BOOM PASSES OVER ALREADYCOVERED SECTIONS, BOUNDARIES OR HEADLANDS.

undulating country, irregularshaped paddocks and trees.

“With flow-based spraying systems, you have to maintain speed to maintain pressure, and that’s how accidents involving boom tips happen.”

A chance conversation with Doug Jeans, a precision ag specialist based in Perth, provided the way forward.

“Doug told us about RightSpot. It sounded exactly like what we wanted, so we got a quote,” Stephen says.

“We were quite surprised to find out we could get all the latest spraying technology for a fraction of the cost of a new or even a used sprayer.”

The system was installed in time for the 2023 sowing season and Stephen says they are happy with its performance.

“RightSpot is not just about being able to go faster but rather doing a better job at whatever speed you are travelling. We usually spray at about 27 kph but

we know we can slow down if we have to without affecting the spray pattern.

“We have checked the spray pattern using blotting paper and the coverage is perfect whether you are doing 3 to 30 kph.”

Stephen particularly likes the AutoSwath feature, which eliminates over- or under-application.

It automatically shuts down each nozzle as the boom passes over previously-applied sections, boundaries or headlands.

Likewise, automatic turn compensation adjusts the application rate of each nozzle to ensure a consistent rate is applied right across the boom during turns.

He also likes the high visibility of the InCommand 1200 universal display, which provides onscreen monitoring of operating speed, boom pressure, droplet

RIGHTSPOT USES PULSE WIDTH MODULATION TO ENSURE BOOM PRESSURE REMAINS CONSTANT REGARDLESS OF OPERATING SPEED.

size, nozzle status and any diagnostic alerts.

InCommand displays have DisplayCast wireless connectivity, which automatically syncs and shares guidance lines, application and yield maps, operating data and satellite imagery with other connected machines and remote devices.

Application and yield maps can be transferred to Ag Leader’s SMS software and then combined with other farm data to generate prescription maps or crop plans.

The Sulky brand you know and trust, now with a new look. Find simplicity in the simplest detail with the Sulky DX20.

A hopper capacity from 900 to 1500 litres, and working widths of between 9 and 18 metres, the double cone hopper with steeply slanted walls guarantees a very regular fertiliser flow, even on slopes and when the hopper is nearly empty

Plus, with a seven-year paint warranty you know the ECONOV will go the distance.

THE HEAD OF A JOINT VENTURE BETWEEN LINCOLN UNIVERSITY AND THE NZ ORGANIC MOVEMENT SAYS ELECTRICAL WEED MANAGEMENT HAS THE POTENTIAL TO BE A REAL ALTERNATIVE TO HERBICIDES.

Dr Charles (Merf) Merfield is head of the BHU Future Farming Centre. Merf says herbicides are on an ever downward spiral due to evolved resistance, lack of new chemistry, legislative headwinds and consumer resistance.