What’s new in tractors

90hp+… FEATURE

EQUIPMENT Biggest Quadtrac yet roars into town

EQUIPMENT

Claas Disco 9700 handles slopes, odd-shaped paddocks

What’s new in tractors

90hp+… FEATURE

EQUIPMENT Biggest Quadtrac yet roars into town

Claas Disco 9700 handles slopes, odd-shaped paddocks

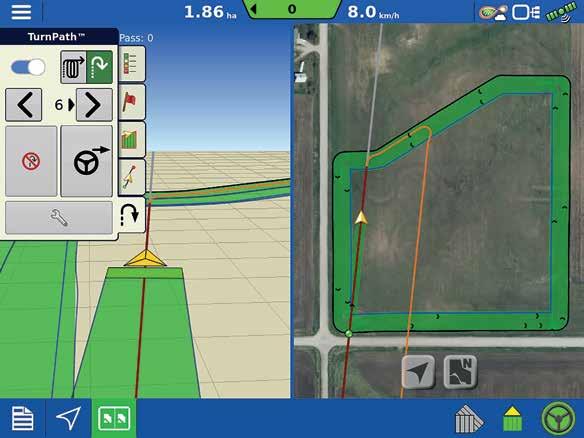

Get fully automatic, ‘hands-free’ turning with the new TurnPath™ unlock on Ag Leader SteerCommand® Z2 automated and SteadySteer® assisted steering systems. TurnPath provides precise and repeatable turns from straight or curved guidance lines, even skipped passes. Combined with all the other benefits of a SteerCommand or SteadySteer steering system, including rapid convergence, sub-inch accuracy and terrain compensation, TurnPath puts you on the path to effortless driving. Contact your Ag Leader dealer and find out how TurnPath and SteerCommand can make farming easier.

Ag (Waikato, BOP & East)

Machinery (Nth & Mid Canterbury)

Agriculture (Southland & Sth Otago)

JUNE/JULY 2024

02 From The Editor: Let it be?

INDUSTRY NEWS

3 Waikato woman’s farming career a labour of love

6 New Landpower complex a vote of confidence in NZ agriculture

7 Fendt gets behind young Kiwi for sprint challenge

8 Be prepared this harvest season with Ag Work NZ

10 CEAT agricultural tyres gaining ground in NZ

12 Farmer governance vital to Fertmark’s success

13 Deutz-Fahr guaranteed resale reduces risk in uncertain times

14 Public-private effort to cut farming’s greenhouse gases gains momentum

16 Next generation Fendt 700s getting rave reviews

18 Applause for spray contractor’s health and safety systems

20 Dairy farmers join efforts to protect Wairarapa ecosystems

21 Flagship Power Farming branch showcases JCB construction gear

22 Alternative proteins cast a shadow on NZ agriculture

23 John Deere gives nod to Vapormatic parts

24 Waringa jumps the ditch to offer Kiwis top machinery options

25 Cochranes takes the podium in CNH dealer of year awards

TECHNOLOGY

27 Robots and AI making inroads in ag

28 Battery swapping the route to electric tractors?

29 More capacity for Krone-Lemken autonomous tractor

30 CNH developing farm and fleet data management tool

31 Kiwi-Aussie joint venture develops robotic sprayer for horticulture

32 Another big step toward easy data management for Kiwi farmers

PROFILES

34 Family’s side hustle becomes full-service contracting business

40 Leap of faith gets drone contractor flying

44 Contractor helps Waikato farmers make the most of effluent

50 Across The Ditch: Gillian fennell: The sequin loving bush badass from Outbackistan

FEATURES

54 Special Feature: National Fieldays at Mystery Creek

70 What’s new in tractors 90hp+

EQUIPMENT

86 Claas Disco 9700 handles slopes, odd-shaped paddocks

88 Kubota compact diggers get bouquets from flower grower

90 Deere lubricants deliver peace of mind

92 Biggest Quadtrac yet roars into town

93 T175 the best of farming family’s long line of Valtras

94 New Holland T7245s and BigBaler deliver the goods in hill country

96 Contractor in his comfort zone buying five Deutz-Fahrs at once 95 08 62 30 16

KIA ORA. TWO RECENT ARTICLES IN THE PRESS CAUGHT MY ATTENTION BECAUSE OF THEIR CLASHING MESSAGES.

The first reported on the new government’s moves to repeal some of the previous government’s environmental legislation that applies to agriculture. This includes intensive winter grazing regulations and stock exclusion from watercourses.

The second was on the rising levels of nitrates in groundwater on farms and rural Canterbury towns. There are suspected links between high nitrate levels and both bowel cancer and birth defects. Some families in Selwyn and Waimakariri are drinking bottled water to avoid their well water with high nitrate readings.

The reaction from farmers to the relaxing of environmental restrictions is naturally positive. Comments are along the lines of: ‘end the war on farmers’ and ‘let farmers be farmers’.

But this overlooks the fact that the 2017 Labour-NZ First government came to power in part because it promised to clean up our waterways. Things can’t go back to the way they were.

Farmers’ spokespeople say they want more ‘practical’ ways to deal with environmental regulations. Let’s hope this does not simply mean a lax approach that allows problems to get worse.

A way forward is signalled by Spreadmark accreditor Peter Wood in his article in this issue. Spreadmark is the programme that confirms the accuracy of fertiliser spreaders, which has both economic and environmental benefits. Peter says Spreadmark is successful because farmers have a lot of input and governance on the programme.

There are already efforts to get farmers involved in better environmental management, through catchment boards, for example.

If government and regional councils

can provide the support, perhaps this approach can come up with practical, progressive practices.

Farmers and contractors have access to lots of new technology that can help them farm smarter, cheaper and more accurately. National Fieldays is a great place to check out the latest machines and other gizmos on offer. So check out the Fieldays Preview feature in this issue as well.

On that note, here are your Dad jokes for the month, courtesy of Logan Lisle on YouTube. Nga mihi.

Question: What do you call a magician who has lost his magic? Answer: Ian.

***

I got one of those annoying cold calls from a salesman at a funeral home. He tried to sell me a coffin. I told him that is the last thing I need.

***

It is a 15 minute walk from my house to the pub, but a 45 minute walk from the pub to my house. The difference is staggering.

***

I took my cat’s medicine last night. Don’t ask meow.

***

My geography teacher asked me if I could name a country with no ‘R’ in its name. I told him, “No way.”

***

A man told his friend, “My obese parrot died last night.”

“I am sorry to hear that,” his friend said. “It’s sad but I have to admit it is a big weight off my shoulders,” he replied.

*** I lost my wife’s audio book yesterday. Now I am never going to hear the end of it.

*** I made a chicken salad yesterday. It turns out they prefer grain.

PO Box 36753

Merivale, Christchurch 8146 ph 03 329 6555

www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Agrichemical Manual.

© RURAL CONTRACTOR AND LARGE SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

CONTRIBUTIONS - Editorial and photographic contributions are welcomed and should be sent directly to AgriMedia Ltd. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

EDITOR

Paul Titus

87 Stanbury Avenue, Christchurch ph (03) 381 6912 mob 021 655 092

email titus@agrimedia.co.nz

ADVERTISING MANAGER

Michael Lightbourne mob 021 403 853

email michael@agrimedia.co.nz

CIRCULATION

email admin@agrimedia.co.nz

PRODUCTION, LAYOUT & DESIGN

Hannah Kincaid

email art@agrimedia.co.nz

CONTRIBUTORS

Joanna Ibell, David Hill, Kathy Davis, Peter Wood, Alastair Hayfield, Heather Chalmers, Rohan Howatson.

Printed by Blueprint Ltd

PAUL TITUS, EDITOREVERY FAMILY WORKS OUT THEIR DIVISION OF LABOUR – WHO DOES WHAT TO KEEP THE HOUSEHOLD RUNNING. FOR BERNADETTE AND PHIL WINTER AND THEIR SEVEN CHILDREN, THIS INCLUDES HIS AND HER FARMS.

The pathway that got them there started when Bernadette was a child and saw a cow being milked at Mystery Creek.

Bernadette’s parents had a market garden in nearby Karapiro. She knew she wanted to work outside and liked animals, and the cow being milked fascinated her.

Her Mum knew a dairy farmer and Bernadette worked for him free after school. Then she went doorknocking and found herself a paid job milking 300 cows. She joined the Farm Cadets and started an apprenticeship in 1990, which included going to polytech.

Bernadette was laser focused on farming, so she attended every class and got top marks. She was nominated for the top cadet award, which was judged on farm and classwork. A male student received the award, however.

ALTHOUGH BERNADETTE WINTER KNEW FROM A YOUNG AGE THAT SHE WANTED TO BE A FARMER, SHE FELT SHE HAD TO WORK TWICE AS HARD AS BLOKES TO BE RECOGNISED IN THE PROFESSION.

“When I started out, we weren’t recognised that well. The guy who won it had never been to class, and he said he had failed everything. I felt I had to work twice as hard to be recognised.”

Her next job was managing a herd of 140 cows in Rotorangi on her own. “That was hard because there was no one else to help get all the jobs done.”

Nevertheless, she completed her Farm Busi-

ness Management certificate during that year.

The next management job was 300 cows which was actually easier, because there was another worker on the farm.

Most of the time it was just business as usual, but there was the odd encounter that reminded her some men had to update their attitudes. One example was when the neighbour got his ute stuck and came over for help. He kept asking for the manager and struggled to grasp the concept that he was talking to her.

“He asked how I did everything on the farm. I said that for the heavy stuff I used a tractor just like everyone else. I didn’t see any man lifting 200 litres of bloat oil.”

Another incident was an electrician who kept trying to look past Bernadette to find the manager. You know, the man who really ran the farm.

Bernadette met Phil through Young Farmers. He was then share-milking 160 cows.

They got together and share-milked on a farm in Matamata, before purchasing a farm in Waotu (near Putāruru, South Waikato) in partnership with Phil’s parents. They also share-milked the neighbour’s farm to get ahead.

“We had kids so it was a mission. You have to be organised.”

The best division of labour for them was for Bernadette to be a stay-at-home mum.

“Not that I ever was, with kids needing to be all over the place. But it meant Phil came home to a semi-tidy house and a good meal.”

Bernadette would help on the farm when required, but mostly the farm work was covered by staff.

Nowadays, the kids are aged between 23 and 12 and the Winters have a home farm of 260 ha milking 680 crossbreed cows in Waotu.

In 2018 they bought Bernadette’s farm which is 45 ha, and only 6 km from home.

“The reason we got it was the heifers always came back a bit small. I kept saying we need a run-off.”

This block had been a milking platform with beautiful dairy pasture but needed work.

“I have done lots of fencing. I’m a pretty good fencer I reckon,” Bernadette says.

Phil raises 150 calves until weaning, when half of them go to Bernadette’s farm. About 150 rising two-year-olds are also grazing there.

“I have been rearing 100 kg bigger on average than what we got from the grazier, and one heifer was 200 kg heavier.”

In June the two-year-olds walk back to the main farm, and Bernadette gets the rest of the calves. “Winter is a holiday as there is only one mob of 150 calves.”

They have had fewer empties amongst the two-year-olds as they are bigger (averaging 425 kg) and more able to compete with the older cows.

Phil helps Bernadette with the drenching, but she does everything else, including pasture management, fencing, shifting, feeding, chain-sawing, and trough maintenance.

The joy of having the dry stock is Bernadette is free to arrange her days to fit in with family requirements. She could be on the farm all day, or alternatively shift them early in the morning and then head off to school sports day.

She feeds out with her favourite machine – a Deutz Fahr 6130 with a front-end loader. She uses forks, bucket and soft-hands as well as a mower and a bale feeder.

“We have a big four-wheeler, which is our day-to-day workhorse, but I love the Deutz. The big attractions are the radio and air-conditioning and it is just so comfortable.

“I have done some race work with it, put rock around troughs, and moved trees, but mostly I use it for feeding out.”

Overall, today there is less fuss or surprise about the fact that some farmers are women.

“I do what I do and don’t worry about anyone else. Physically, yes it may take me longer to put in a fencepost than Phil, and some jobs take some creative thinking in the absence of brute force, but I usually work it out.

“Women are far more represented and recognised in farming, including truck driving and contracting, now which is great.

“And why not? If you love it, and you can do it, then gender should not be an issue.”

Bernadette believes farming in general would be better if more people understood what was involved.

“Farming is an apprenticeship like any job. It takes three to four years to know enough to run a farm. People take it for granted.”

That is why it is relaxing being around other farmers who understand about grass growth and its significance, and appreciate all the myriad details and systems that have to be juggled to run a farm.

“The biggest part of farming is being observant. You have got to notice a sick animal, see the grass growth and figure out when you’re going to run short or have a surplus.”

All in all, it has been a good life decision.

“I don’t have issues getting out in the rain. I still love getting out every morning, patting my friendlies and watching the grass grow.

“I love being a woman in farming. I don’t want to do anything else.”

BERNADETTE WINTER DOES ALL OF THE WORK ON THE FAMILY DAIRY FARM’S SUPPORT BLOCK INCLUDING FEEDING OUT, FENCING, CHAINSAWING, AND TROUGH MAINTENANCE.

• 160-380 horsepower

• 4.2m-6.2m working widths

• Capable of reaching greater working depths

• 120-180 horsepower

• 3.2-4.7m working widths

• Excellent results on hard and dry soils

• 400 horsepower

• 5m-7m working widths

• Increased performance reliability and longevity.

ON A SUNNY AUTUMN DAY IN APRIL, LANDPOWER HELD THE PUBLIC OPENING OF ITS NEW STATE-OF-THE-ART AGRICULTURAL RETAIL HUB AND PARTS WAREHOUSE IN CHRISTCHURCH.

Landpower founder and director Herby Whyte told the guests at the opening that investing in the new building represents a vote of confidence in the future of the agricultural industry. It comes as the company heads into its 50th year in business in 2025.

“I have always had a long-term view and this building is our base for the future. It will allow us to bring more staff into the region for training and career progression, and it shows our commitment to Canterbury agriculture,” Herby said.

On hand to mark the occasion were Claas Group chairperson Cathrina Claas-Mühlhäuser and associate agriculture minister Nicola Grigg, who officially opened the complex.

It is located on West Coast Road in Yaldhurst. It brings together under one roof three former Landpower sites around Christchurch – its retail dealership in Templeton, its New Zealand national support office and parts distribution centre, and its training facility.

The complex also has an area for equipment demonstrations, where farmers and contractors can view and try out equipment first-hand.

LEADERS OF CLAAS AND LANDPOWER PLANTED A TREE TO MARK THE OPENING OF THE NEW RETAIL CENTRE AND NATIONAL PARTS WAREHOUSE IN CHRISTCHURCH.

In his address, Landpower

CEO Richard said the new complex creates efficiencies and will allow Landpower to deliver better products, customer experiences and services to farmers and contractors.

The advanced training facility will allow Landpower to teach more courses for the mechanics and technicians at its 16 New Zealand Claas Harvest Centres and one partner dealer.

These branches provide service and repairs to all of Landpower’s major brands, which include Claas, JCB, Amazone and Grimme.

During the opening, Landpower national parts manager Gavin Wellwood and warehouse manager Dave Cookson showed guests the new parts warehouse, which covers 3725 sqm of floor space. It holds 33,000 line items and has access to additional items from Landpower’s parts warehouse in Melbourne.

The dollar value of the parts in the new warehouse is $43 million. Another $26 million worth of parts is held in the NZ Claas Harvest Centres and the warehouse in Melbourne holds another $65 million worth.

Gavin said the parts team studied parts warehouses at a number of different types of businesses in New Zealand and Australia when designing the new facility. To increase efficiency, 76 percent of the most commonly ordered parts are concentrated in one area of the warehouse.

Landpower technical service manager Mike Parris introduced

A NEW TRAINING FACILITY WITH TWO TRAINING BAYS WILL ALLOW LANDPOWER TO INCREASE THE NUMBER OF COURSES IT RUNS FOR SERVICE TECHNICIANS.

the guests to the new training facility. It has two training bays and two classrooms and the capacity to double the number of training courses held each year.

Speakers during the opening pointed to the fact that both Claas and Landpower are family-owned businesses.

Cathrina said Landpower has been the sole distributor of Claas machinery in New Zealand since 1987 and in Australia since 1996.

It is one of Claas’s main distribution partners worldwide and the relationship between the two businesses is based on trust.

“As family-owned businesses, we have less room for mistakes. We use our own private capital and we cannot just go to the mar-

HERBY WHYTE AND CATHRINA CLAAS. LANDPOWER HAS DISTRIBUTED CLAAS MACHINERY IN AOTEAROA SINCE 1987 AND IN AUSTRALIA SINCE 1996.

ket to get more.”

Cathrina said like Claas, Landpower has an entrepreneurial spirit. Both companies know that they have to take risks to succeed in business.

“We are not the biggest fish in the pond but we work hard to understand our customers’ business models. We listen to them so that we can be technological leaders.”

FENDT IS SPONSORING NEW ZEALAND RACE CAR DRIVER CLAY OSBORNE IN AUSTRALIA’S PORSCHE MICHELIN SPRINT CHALLENGE, WHICH BEGAN IN APRIL AND EXTENDS THROUGH OCTOBER.

Clay comes from a family that is heavily involved with farm machinery, and in particular with the Fendt brand, through their Waikato-based sales and leasing business, Power and Earth.

Fendt Australia-NZ marketing director Fergal Meehan says Fendt is thrilled to support Clay as he continues his efforts to climb the racing ranks.

“Fendt is a proud German brand that is synonymous with power, precision and advanced technology. Our aim is to deliver the best possible performance for our customers.

“We are proud to be associated with Clay while he’s behind the wheel of a Porsche, another prestigious German brand that is also renowned for outstanding power and performance in their field,” Fergal says.

Clay’s career in motorsport racing began when he was five years old and displayed

a natural ability for kart racing. Since then, he has amassed an impressive collection of championships and titles including winning four NZ Karting Championships and the impressive 2019 World Karting Championship in Italy.

He developed his prowess further in Formula Ford and he recently competed in the Toyota Racing New Zealand 86 Series and the

IS SPONSORING CLAY OSBORNE IN THE 2024 PORSCHE MICHELIN SPRINT CHALLENGE AUSTRALIA.

Porsche Open Class. His impressive results now see him competing in the 2024 Porsche Michelin Sprint Challenge in 2024. When not driving at high speeds around

Besson and Highline, plus Broughan

Elmer’s chaser

FENDTFOR MANY CONTRACTORS, THE LOGIC OF BRINGING SKILLED OVERSEAS

WORKERS IN FOR THE BUSY SEASON IS A NO-BRAINER.

HAVING ACCESS TO SKILLED WORKERS IS AN ISSUE MANY AGRICULTURAL BUSINESSES FACE AND RECRUITMENT COMPANY AG WORK NZ IS TACKLING IT HEAD ON.

Providing experienced seasonal workers who can be on-farm at precisely the part of the year when they are really needed is Ag Work NZ’s mission. As a farmer owned and operated business they understand the need to hire workers who are skilled and ready to be part of a team.

Many farmers and contractors look to recruit themselves from overseas, but ensuring that person is suitable and skilled is the tough part. Recruiting from around the world, often through social media, can be testing for many employers.

Many don’t have the time and resources to thoroughly check candidates. Rather than hope for the best, farmers and contractors can work with a specialist recruitment company to make the process easy.

Cambridge-based Ag Work NZ takes a direct contact approach to recruiting. They connect New Zealand farmers and contractors with young people in the UK, Ireland and Europe, who are looking for their ultimate working holiday.

Ag Work NZ’s UK manager Abi Swaffield says the company works with ag contractors, dairy farmers and horticulture busi-

nesses looking for reliable and experienced seasonal employees.

“We offer hassle-free hiring and support to people looking to work in New Zealand. With full flight and visa support, we can guide them through the whole process as seamlessly as possible,” Abi says.

“We have an established office in the UK, so we can contact Northern Hemisphere workers swiftly. We work with trusted sources to find the right people and the reviews we have received from employers are a testament to the success of our approach.”

Ag Work NZ recruits young people in the 18-25 age group from their connections in Europe and the UK. They partner with agricultural colleges and universities and work closely with young farmers groups. They have a large social media presence, which allows candidates to get a taste of what is on offer.

racetracks, Clay has spent many hours in the tractor cab for the family’s machinery leasing business.

“I have grown up around farm machinery. I am humbled and very grateful for the support I have received in my racing career so far. I am very thankful for the team at Fendt for their support in pursuing my ambitions.

I have spent many hours in Fendt tractors

Abi says Ag Work NZ spends about 15 hours with each candidate, interviewing and checking their references. Their matchmaking approach ensures both employers and employees make the right connection for success.

All recruits come into New Zealand through Auckland, where they are met by Ag Work NZ operations manager Paula Syben. Paula helps deliver pastoral care to employees and acts as Ag Work NZ’s employer liaison officer to guide employers through the process.

Based in Cambridge, Paula meets incoming employees at the airport and gets them organised for life in New Zealand. This includes helping with paperwork, opening a bank account, getting an IRD number and SIM card.

“We can organise the onward travel of candidates around New Zealand. We work with North Island and South Island employers and are able to accommodate most needs,” Paula says.

over the years and I am very proud to be representing them on and off the racetrack,” says Clay.

The Porsche Michelin Sprint Challenge Australia was launched in 2008 by a group of passionate enthusiasts. Under the stewardship of Porsche Cars Australia, it has evolved into one of Australia’s premier racing series. This year there are six sessions – in Victo-

“Once a candidate has settled into their life in New Zealand, we are in the background to help with anything and we check in with our employers and candidates regularly.”

Many young people who will work for a contractor arrive in September or October and stay until the end of the season. Workers on dairy farms tend to arrive in the busy June-July period and stay 9-12 months, depending on the role.

Ag Work NZ operates using the Working Holiday Visa option. This allows British and Irish young people to a have year-long working holiday and, in the case of UK residents, it can be extended to as long as three years.

It is not too early to talk with the Ag Work team today about your staffing needs and how they can help find the experienced operators you need.

For further information call Ag Work on 0274 777 267 or email hello@agworknz.com.

ria, South Australia, Queensland, Tasmania and NSW. The series gives budding racers a platform to showcase their talent in the iconic 991.2 GT3 Cup cars. The series embodies a culture of competitiveness and camaraderie. You can keep up-to-date with Clay’s progress in the Australian Porsche Michelin Sprint Challenge through his Instagram page – Clay Osborne.

WE’RE GROWING.

We’ve extended our tractor line-up with all-new models handpicked for the conditions here in New Zealand. We’ve expanded our dealer network to offer you more purchase opportunities and aftersales care. And we’re only just beginning. Ask us how we can help you achieve your farming goals and let’s grow together. FIND

CEAT AGRICULTURAL TYRES ARE MAKING INROADS IN THE NEW ZEALAND MARKET THANKS TO THEIR HIGH PERFORMANCE, QUALITY, SUPPORT AND AFFORDABILITY.

Based in India, CEAT manufactures a growing range of agricultural tyres as well as off-road (OTR) tyres for sectors such as earthmoving, forestry and mining.

For Kiwi farmers and contractors, the CEAT range includes high-spec 60 Series very high flexion (VF) and increased flexion (IF) radial tyres through to specialised row crop and implement tyres.

YHI NZ Ltd is the proud distributor of CEAT agricultural and OTR tyres in New Zealand, and YHI NZ commercial tyres product manager Mark (Skippy) Mackaness says the brand is growing in popularity because of its quality.

“CEAT has been producing tyres for many years. In 2017 they began manufacturing radial agricultural tyres at their dedicated plant in Mumbai with the goal of being a global leader for this product.

“We have been supplying CEAT agricultural tyres into the New Zealand market since 2019. CEAT’s growth has been very exciting. A fair few contractors

now use CEAT tyres on their equipment and the feedback we are getting from them is fantastic,” Mark says.

Along with selling tyres through retail channels globally, CEAT Specialty now supplies original equipment (OE) tyres to such heavy agricultural equipment manufacturers as AGCO, CNH Industrial, John Deere and JCB.

The CEAT company was formed in 1924. It was originally an Italian business but it was acquired by the Indian corporation RPG Group in 1982.

Mark says the success of the company is due to its focus on excellence. He visited the CEAT factory last year and he says the dedication to quality and efficiency was impressive.

“In fact, in 2023 CEAT became the world’s first tyre company to win a Grand Deming Award, which is one of the world’s most prestigious quality awards.

“The Japanese Union of Scientists and Engineers presents the Deming Award to businesses that achieve excellence in apply-

ing the principles of Total Quality Management.”

CEAT’s commitment to research, development and continuous improvement shows through in its product development to suit different terrains and applications.

For example, given the greater number of high speed tractors now at work around the world, CEAT has modified the design and construction to build a range to meet the specifications for 65 kph road travel for longer trips between properties.

They are adding cut-resistant compounds to their full range of tractor and OTR tyres so they are more durable in rocky, harsher terrain.

In short, CEAT agricultural tyres are built to deliver traction, safe road travel, less soil compaction

Established in 1995, YHI (New Zealand) Ltd is a subsidiary of YHI International Ltd. It has Singaporean and New Zealand ownership.

YHI NZ is a diversified business that began supplying alloy wheels and then added a growing number of tyre brands including Toyo, Pirelli, Nitto, Nankang, Accelera, Farroad and Longmarch. CEAT agricultural and industrial tyres are the latest addition to the line-up.

For 25 years YHI has also supplied energy products. Its comprehensive range in this area covers solar panels, batteries, electric vehicle charging systems as well as electrical components for the marine sector and vehicles of all sizes.

YHI’S MARK MACKANESS (RIGHT) AND DARYL SHUTTLEWORTH NEXT TO A CEAT 800/75R42 TYRE AT THE COMPANY’S MUMBAI FACTORY.

and a long working life.

Mark says CEAT’s 38-inch Farmax rear tractor tyre is the most popular in New Zealand, although the whole range has been well received.

“CEAT tyres are relatively new to the New Zealand market. They are less expensive than many competitor brands, but this does not mean the quality is any lower.

“One way I know that CEAT is a great product for New Zealand is the feedback we get at CEAT exhibits at field days around the country. Farmers and contractors openly give us positive feedback about key points such as road-ability and wear resistance.

“Our customers are nothing but positive about the tyres’ grip, ride and comfort. So, when you are ready to replace you existing tractor or implement tyres, ask your regular tyre supplier about getting a truly hard-working, affordable option from CEAT,” he says.

YHI has 13 warehouses around New Zealand to help support local communities and supply CEAT ag tyres via all major tyre dealers.

THE CEAT AGRICULTURAL RANGE INCLUDES HIGH FLEXION AND INCREASED FLEXION RADIAL TYRES AS WELL AS ROW CROP AND IMPLEMENT TYRES.

Power through every job with over 300HP of grunt, four-stage V-Shift transmission technology, and a tailor-made hydraulic system. The Landini Series 8 can handle all your farming applications and offers real productivity and efficiency benefits.

Ask us about the Landini Series 8 and let’s grow together.

IN THE EVER-EVOLVING LANDSCAPE OF MODERN AGRICULTURE, SUCCESS IS NOT MERELY MEASURED BY FINANCIAL GAINS BUT ALSO BY THE ADOPTION OF PRACTICES THAT BENEFIT BOTH THE ENVIRONMENT AND THE STAKEHOLDERS INVOLVED.

In the pursuit of sustainable and efficient agriculture, Spreadmark is a beacon of innovation and responsibility.

Spreadmark is a fertiliser placement quality assurance system. It has a dual focus – on maximising agronomic benefits for farmers and minimising environmental harm.

This balanced approach reflects a commitment to optimising yields while safeguarding the environment. It sets a new standard for fertiliser applications in today’s agriculture.

For many, including myself, the role of providing proof of accurate fertiliser spreading is more than mere compliance. It is a multifaceted approach that intertwines environmental sustainability, regulatory adherence, resource efficiency, and the overall image and viability of farming.

It aligns with economic goals but also underscores a commitment to ecological stewardship. It makes accurate fertiliser spreading a cornerstone of modern and responsible farming practices.

The true measure of success is the seamless integration of Spreadmark and Fertmark into farm Quality Assurance (QA) programmes. Synlait’s Lead with Pride programme is a prime example of how farmers can leverage these programmes to earn a significant premium and create a mutually beneficial ecosystem.

Paying a premium to those committed to sustainable practices creates a ripple effect, encouraging wider adoption.

Spreadmark is successful because of its distinctive strength – the robust control and governance wielded by farmers and growers. This unique approach has cemented Spreadmark’s position as a leading programme and it has given tangible benefits to the stakeholders who drive its governance.

Farmer control has been important to the programme’s success and has delivered significant advantages to agricultural processors and the producers who supply them.

At the heart of Spreadmark’s effectiveness is its farmer-driven governance model.

This marks a paradigm shift and puts those directly involved in production at the forefront of decision-making.

This instils a sense of ownership and ensures that the standards set by Spreadmark are practical, realistic and reflective of on-the-ground realities.

By elevating farmers and growers to positions of influence and fostering collaboration across the industry, Spreadmark has established a benchmark for accreditation schemes. It has also become a driving force in promoting sustainable agriculture. Refining these accreditation programmes

POWER FARMING HAS INTRODUCED A FIRST-OFITS-KIND GUARANTEED

BUY-BACK SCHEME FOR NEW DEUTZ-FAHR TRACTORS. THIS ALL-NEW ‘UPFRONT’ APPROACH

GUARANTEES CUSTOMERS THE RESALE VALUE OF ANY NEW TRACTOR IN THE FULL DEUTZ-FAHR RANGE.

Only available on new tractors that are financed through Power Farming, the Deutz-Fahr guaranteed resale value is based on the tractor’s hours and the term of the finance contract.

Unlike a typical finance, hire or lease programme, at the end of the finance term the customer has the option to retain the tractor, trade it back at the guaranteed resale value, or simply return the tractor to Power Farming. (See Figure 1.)

Power Farming Deutz-Fahr general manager Alistair Horrocks says the buy back guarantee provides farmers and contractors certainty around the total cost of ownership of one of their biggest capital investments.

“At Power Farming we have huge belief in Deutz-Fahr, so much so that we are standing behind the future resale value of the brand,” he says.

Founded in Morrinsville 75 years ago, Power Farming Group is the world’s largest independent distributor for Deutz-Fahr, with 21 dealers in New Zealand, more than 300 in Australia and more than 120 in the United States.

Since launching at the beginning of April, feedback from customers has been very positive, Alistair says.

“Confidence breeds confidence. With today’s market conditions, demonstrating commitment into the future is vital. Under this scheme the buyer knows exactly what their tractor will be worth at the end of the finance term.

“This assurance gives peace of mind and provides a means to accurately quantify the true cost of ownership for their new tractor.”

There is a range of available terms for the finance agreement that underpins the buy back guarantee, which can extend up to five years.

Alistair says after buyers decide which term they prefer, they agree on the finance details with their Power Farming dealer and the number of hours they can use the tractor each year.

“Different deposit, terms and hours options are available. We can even take into account seasonal payments to align with a business’s cash-flow.

“Service contracts can also align with the intended hours and term of the contract. This allows a customer to account for

POWER FARMING SAYS ITS DEUTZ-FAHR BUY BACK GUARANTEE PROVIDES NEW TRACTOR BUYERS PEACE OF MIND AND A MEANS TO ACCURATELY QUANTIFY THEIR MACHINE’S TRUE COST OF OWNERSHIP.

a true hourly cost of ownership and treat the investment as a fixed cost.”

The bottom line with the buy back guarantee is that when you get behind the wheel of your new Deutz-Fahr you know that Power Farming stands behind it and they are assuming a big share of the risk associated with the purchase of any new machine.

Alistair says Power Farming

has represented the Deutz-Fahr brand for 14 years in New Zealand, and the volume of tractors in use throughout the country is a testament to the brand’s success.

Power Farming is offering the buy back guarantee across the full Deutz-Fahr range. It is available through all of Power Farming’s New Zealand dealerships.

to ensure they remain inclusive and representative of the ever-evolving landscape of responsible farming is a step towards a more sustainable and efficient agricultural sector.

As we navigate the complexities of modern farming, Spreadmark’s strengths in governance illuminates its triumph in empowering a more resilient, sustainable and reputable future.

Peter Wood is Spreadmark and Fertmark accreditor with Hamilton-based QCONZ, which provides auditing for animal welfare, environmental, and food safety assurance programmes.

A JOINT VENTURE BETWEEN THE NEW ZEALAND GOVERNMENT AND THE PRIVATE SECTOR THAT AIMS TO HELP FARMERS MEET THEIR CLIMATE CHANGE OBLIGATIONS IS GAINING MORE SUPPORT FROM LEADING KIWI AGRIBUSINESSES.

AgriZeroNZ is a limited liability company that invests in innovative technology that can reduce methane and other greenhouse gas emissions. It was established in early 2023. The Crown made a commitment to match the private companies’ contribution to the fund dollar-for-dollar up to $50 million per year.

The founding businesses that helped set up AgriZeroNZ in partnership with the Crown were ANZCO, Fonterra, Rabobank, Ravensdown, Silver Fern Farms and Synlait. Agriculture Minister Todd McClay says the A2 Milk Company, ANZ Bank, and ASB Bank are now on-board as new shareholders.

With the additional investment from these companies, the investment in AgriZeroNZ will reach $183 million over its first four years. Half of this funding will come from the government.

Todd says this shows the commitment of New Zealand businesses to help farmers find ways to reduce emissions.

“With the backing of both government and private sector, New Zealand will be a global leader in developing tools, technologies, and practices to drive down agricultural emissions while maintaining the productivity and profitability of our food and fibre sector.

“Meeting our climate change obligations and encouraging a booming agricultural sector are not mutually exclusive. Collaborations

HOOFPRINT BIOME CO-FOUNDERS KATHRYN POLKOFF (LEFT) AND SCOTT COLLINS.

such as AgriZeroNZ will ensure that New Zealand’s economy and climate are well served,” Todd says.

AgriZeroNZ executive director Wayne McNee says the fund is looking all over the world for emission reducing technology that will work on New Zealand farms.

“We are moving fast to reflect the mandate for urgent action from our shareholders, and we are taking calculated risks to significantly accelerate efforts made by Kiwi farmers,” Wayne says.

AgriZeroNZ’s goal is to ensure all farmers in Aotearoa have access to affordable, effective solutions to reduce emissions. The aim is to cut agricultural emissions 30 percent by 2030 and drive towards near zero by 2040.

“Farmers will need at least two or three proven tools and technologies in widespread use by 2030 to meet this goal so that’s what we’re working to deliver,” Wayne says.

The most recent investment AgriZeroNZ has made is in Hoofprint Biome, a US startup that is developing probiotics and natural enzymes that reduce methane while improving cow health.

Other investments AgriZeroNZ has made are in two Kiwi companies, BioLumic and Ruminant BioTech.

BioLumic is a biotech company that uses ultraviolet (UV) light to develop more productive crops. It aims to develop low-emissions farm pasture by focusing its technology on ryegrass. Ryegrass with a higher fat content could reduce methane emissions from animals that consume it.

Ruminant BioTech is developing a slow-release, biodegradable methane-inhibiting veterinary medicine for ruminant livestock. A bolus of the material sits in the animal’s stomach for up to six months while active

ingredients are released over time. Initial trials show it can reduce emissions by up to 70 percent over that time.

Wayne says AgriZeroNZ has invested NZ$4.1 million into Hoofprint Biome to support development of its probiotic into animal trial proof-of-concept stage.

“Hoofprint Biome is developing novel technology with potential to be a real breakthrough to help meet our country’s climate goals. We’re really pleased to be backing Hoofprint as the lead investor, and secure this opportunity for New Zealand farmers so they can be at the forefront of its future success.”

Hoofprint Biome is a spinoff company from North Carolina State University, founded by Dr Kathryn Polkoff and Dr Scott Collins. The pair discovered enzymes that naturally reduce rumen methane emissions

The patent-pending enzymes are delivered to the animal along with probiotics. When it is fed as a supplement in small doses, the Hoofprint probiotic should reduce enteric methane emissions by over 80 percent but at the same time increase milk and meat yield by over 5 percent.

Kathryn says the investment from AgriZeroNZ offers a unique opportunity for Hoofprint to partner with New Zealand farmers, who have been leaders in sustainable agriculture, so they can tackle the climate crisis together.

AgriZeroNZ has also invested $2.5 million to support New Zealand research on a methane vaccine and methane inhibitor and $4 million to support construction of a new greenhouse gas measurement facility.

SINCE THE BEGINNING OF 2024, FENDT DEALERSHIPS IN THE NORTH ISLAND HAVE BEEN DEMONSTRATING THE NEW SEVENTH GENERATION FENDT 700 VARIO TRACTORS. THEIR RECEPTION HAS BEEN OUTSTANDING.

The salesmen who have demonstrated Fendt 700 Vario Gen 7 tractors are highly impressed with their power, fuel efficiency and handling. And they say feedback from farmers and contractors has been equally enthusiastic.

For now Fendt has replaced the Fendt 800 Series with the Fendt 700 Gen 7s. The five new 700 models all have a large frame and they span the power range from 203-303 hp.

One of the notable features of the new 700 range is the new 7.5-litre AGCO Power Core engine that delivers high power at low revs especially designed for the Fendt 700 Gen 7.

Another highlight is the VarioDrive transmission. VarioDrive is well-proven in the larger Fendt 900 Vario and 1000 Vario series and it is now available in the 700 Series.

VarioDrive gives variable allwheel drive through Fendt Torque Distribution. The front and rear axles are driven independently,

WITH THEIR VARIODRIVE TRANSMISSION, THE LATEST FENDT 700 TRACTORS DELIVER MAXIMUM TRACTION, LESS DAMAGE TO THE SOIL AND TIGHTER TURNING CIRCLES.

and the transmission automatically distributes power between them to give maximum traction in every situation.

The unique and exclusive VarioDrive transmission gives infinitely variable speeds from 20 m/hour to 60 km/hour. It also creates a pull in effect, which gives the tractor a very small turning circle.

The combination of the new AGCO Power engine and VarioDrive delivers outstanding fuel efficiency, the ability to handle a range of jobs, and a quiet, comfortable driving experience.

John Metcalfe is a sales rep at Waikato Tractors in Hamilton and something of a Fendt specialist. He has been selling Fendt tractors since they were introduced in Aotearoa in the late 1990s.

John says Fendt have always been leaders, not followers, when it comes to tractor technology, and every new generation of Fendts has offered something special. The new 700 Series is no exception. They take performance to another level.

“They are definitely a game changer. Anyone who knows anything about machinery loves the Gen 7 Fendt as soon as they get in it. It is so comfortable and quiet because of the engine

WITH ITS HIGH TORQUE-LOW REV ENGINE, FENDT 700 VARIO GEN7 TRACTORS DO AN EXCELLENT JOB IN CULTIVATION AND DEEP RIPPING JOBS.

and the transmission.

“The big thing you notice is that you get 20 percent more torque at low revs. You can do a job at 12 kph and you are only on 11001200 revs. You need to see it on the screen to believe it because it is so quiet.”

John says the power range that the Fendt 700 Series covers is very popular in Waikato as larger implements have become more common. For example, the new 724 Gen 7 is a direct replacement for the 824 Gen 6.

“The new 700s are so versatile. They have a turning circle as tight as a four-cylinder tractor. They are perfect for a larger dairy farmer who does a lot of their own work.

“They can pull a slurry tanker, do groundwork, run a baler or use a front-end loader. Plus the owner-operator has a machine that is an absolute pleasure to drive.”

James Hannon is dealer principal at AGCO dealership TFM Tractors in Masterton. At the beginning of the year, TFM took on two Fendt 728 Gen 7 tractors, one for demonstrations and one for sale.

A contractor has already bought

the one that was for sale and feedback from customers who have tried the demo model has been “unreal”.

“Fendt is a premium product. Other tractors have to come with a whole lot of spec to meet the quality of a standard Fendt. The new 728 delivers as much power as the 828 Gen 6, but it is smaller so it is more manoeuvrable. Its turning circle is just 10m in diameter,” James says.

“It is super quiet and the ride comfort is amazing. With pneumatic cab suspension and Fendt Stability Control it feels really good on the road. When you are going 50 kph on the road, you would think you are in a car.

“The AGCO Power engine is low rev-high torque. It delivers peak torque at 1300 rpm so it is extremely fuel efficient. The fuel savings are definitely noticeable, whether you are doing PTO work, road work or heavy draft work.”

James says Fendt’s VarioDrive transmission is a big part of the new 700 Series’ performance. It delivers power where it is needed to maintain traction.

“You don’t notice when it is sending power to the front or rear tyres. It is like four-wheel drive on

a car. It also helps pull the front tyres around when turning, which helps make tight turns.

“The power boost is also quite intelligent. It only boosts when the additional power is needed. It is always trying to achieve fuel economy.”

Versatility is another selling point. TFM Tractors has demonstrated the new Fendt 728 on farms with a variety of implements – power harrows, discs, big square balers, heavy direct drills and ploughs.

“The contractor who bought the other new 728 primarily uses it for cultivation and planting but it is so manoeuvrable that it will be more universal than a big lugging tractor. It will happily sit on a combi baler all day,” James says.

Logan Berg is a salesperson at TRC Tractors in Feilding, and he says the response from on-farm demonstrations with the Gen 7 700 Series has been “very positive”.

“The new 728 is the ultimate balance between high horsepower and manoeuvrability. It can handle heavy cultivation but is still a great size for a set of mow-

FEEDBACK ON NEW GENERATION FENDT 700S HAS BEEN

VERY POSITIVE BECAUSE THEY PUT OUT THE POWER OF A LARGER TRACTOR BUT ARE STILL NIMBLE ENOUGH TO HANDLE JOBS THAT A SMALLER TRACTOR WOULD NORMALLY DO.

ers or filling in on a smaller implement for a day if you are short of a smaller machine.

“The size of its frame paired with the Vairodrive transmission ensures it pulls extremely well. At one demonstration we ran a 6m set of speed discs. We covered 12 ha in two and a half hours and burnt 55 litres of diesel. That is just over 20 litres/hour, which is phenomenal.

“When we have demonstrated the Fendt 728, we have compared it directly with contractors’ current tractors in different applications. The Fendt has been much more efficient and it has exceeded all expectations.”

Logan says the low rev concept of the AGCO Power engine deliv-

ers fuel savings and makes the new tractor very quiet and comfortable to drive.

“We have put it on a ripper working at a depth of 500-600 mm and the new AGCO Power motor delivered the torque smoothly and just powered on with no surging.”

Having peak torque at 1300 rpm rather than the traditional 18002000 rpm reduces fuel consumption, wear on the engine, and noise in the cab.

The Vairodrive transmission is very impressive because of the way it adjusts power to the front and rear axles on the go. Because it directs more power to the front when turning it pulls the front around and gives it a similar turn-

MORE THAN JUST A ROLLER BREDAL K SERIES

5.4m Tip Roller

$45,995+gst Ready to deliver now

• Versatile roller; options to cultivate, level, seed and consolidate. Can include levelling boards and/or spring tines.

• 3 section, contour following, central pivoting wing sections. 4.5–10.2m working widths.

• Maximum 2.45m travelling width.

• Equipped with HE-VA’s unique SAT pressure system. Uniform soil consolidation across the entire working width.

ing circle to the small frame Fendt 700s.

“Gen 6 Fendt 700 tractors have a two-speed transmission, one for the road and one for the field.

The VarioDrive transmission in the Fendt 700 Gen 7 range has just one range to go from 0 to 55 kph. So there is no chance for the driver to accidently work in the wrong range.

“Our aim is to get operators in seats. Once someone drives the new 700, they can see how it performs and how it could improve the efficiency of a business. It is as nimble as a smaller frame machine but has the power and pull of a large frame machine making it the ultimate all-rounder.”

• Five ring choices to match with soil type. All with 5 yr warranty.

• Tip Roller has become the roller of choice for NZ’s testing conditions.

• Heavy-duty construction for even the most rugged paddock.

• Versatile Lime & Fertiliser spreader

• Two large spreading discs distribute Bredal’s signature 4 x overlap

• K45 – K165 models, trailed. Option to truck mount

• 3500 – 19,000 L capacity

• Working widths: Lime 12m. Fertiliser 12 – 36m

NORTHLAND VEGETATION CONTROL DOES SPRAY CONTRACTING THROUGHOUT NORTHLAND – FROM THE BRYNDERWYN HILLS TO CAPE REINGA.

WHAT HAPPENS WHEN A LINESMAN AND A NURSE CHANGE PROFESSIONS AND BECOME RURAL SPRAY CONTRACTORS? IN CHANCE AND ROCHELLE CAMPBELL’S CASE, THEY CREATE AN AWARD-WINNING CULTURE OF HEALTH AND SAFETY.

Chance and Rochelle bought the spray contracting business Northland Vegetation Control in 2018.

In 2023, they entered the Northland Business Excellence Awards. While they didn’t set out to win the workplace safety category, they are very proud to have done so.

They took out the ACC Workplace Injury Prevention Award over companies in forestry, manufacturing, fitness and accommodation.

Rochelle says the awards presented a good chance to showcase the agricultural industry in a positive way.

“Everyone who enters the awards has to fill out a safety and health section as part the application process. We weren’t specifically targeting that.

“We entered because we thought it would be good for us to look at all aspects of the business from the outside in, and see where we could improve. Actually winning the award on the night was a big surprise.”

Since they bought it, Rochelle and Chance have diversified the business to take on tree planting and maintenance contracts as well as weed control. They now field a full time

team of 10 people, including themselves, with up to eight further casual staff planting trees in the winter months.

The spraying they do is largely in Northland – from the Brynderwyn Hills to Cape Reinga. Chance’s brother Trale manages the tree planting work, which they do as far afield as Levin, Gisborne and Hawke’s Bay.

Northland Vegetation Control joined the Nufarm Accredited Contractors scheme last year.

Nufarm is an integral part of the business, both in terms of product and support.

“It has been really good forming a relationship with one supplier. It has made everything flow better in our yard. They back their products 100 percent and we are really impressed with the support and guidance we get from Joe Heng. He is a mine of knowledge.”

Nufarm supports Rural Contractors NZ which the Campbells also belong to. They say working with the organisation that represents contractors has benefitted them personally and professionally.

“We didn’t get to the Rural Contractors NZ conferences for a start, because of Covid. But when we did, it was really cool to meet and chat with other contractors from around the country, and learn from them.

“It is great to see the effort Nufarm puts into supporting rural contractors. Sometimes as spray contractors, you are not really seen as a professional. You are just someone who sprays weeds.

“When you see Nufarm putting resources

into the industry, it makes you feel more valued.”

Chance and Rochelle have three children, and health and safety has been a priority for from the get-go. This is not only because of their experience in their previous careers, but also for the good of their team and the business as a whole.

The Business Excellence Award judges described their processes and procedures as ‘exemplary’. They highlighted one-on-one training covering risks with chemicals, transport, planting equipment, machinery and working in remote environments.

Rochelle says health and safety is a collaborative effort that tries to address all aspects of their team’s well-being. This includes social and family life.

“When they come into this industry, our people know they are going to be dealing with chemicals. They know that they are going to

HAVING GOOD HEALTH AND SAFETY PRACTICES AND TRAINING IS A WAY THAT CHANCE AND ROCHELLE CAMPBELL LOOK AFTER THEIR TEAM AND THEIR FAMILIES.

PERFECT PARTNER PASTURE’S

WAIRARAPA DAIRY FARMERS

RACHEL AND HAMISH HAMMOND ARE AMONG THOUSANDS OF FARMERS THROUGHOUT NEW ZEALAND VOLUNTEERING IN LOCAL ENVIRONMENTAL INITIATIVES.

The couple work with fellow community members to help protect and enhance the P āpāwai stream and neighbouring bush block. The Pāpāwai Care group is led by John Argue and a small committee and has been planting every year and managing established plantings.

Rachel says the group started many years ago and Hamish’s grandfather, Malcolm Hammond, was involved in some of the first plantings.

“We get a great sense of satisfaction from volunteering and it is a great way to connect with other locals,” Rachel says.

On their dairy farm, Hamish and Rachel use mixed pasture species, including the leafy herb plantain. DairyNZ-led research suggests Ecotain plantain can reduce nitrogen loss from pasture to help improve water quality while maintaining milk production.

The couple are also efficient with their water usage. “In dry summers we irrigate but our water application is closely monitored with soil moisture probes to ensure water isn’t wasted and the plants are optimising the water applied,” Rachel says.

Water is recycled to wash the yard and the cows are milked once a day, which has halved daily water use at the dairy shed.

“We know we need a good environment to farm well and we want our kids to have a great backyard,” Rachel says.

Hamish is active in the Wairarapa Water Users Society advocating for equitable and scientifically based decision-making around regulations and compliance. The society advocates best practice irrigation and runs training and field days.

On the farm, the Hammonds have planted alongside the stream and their boundaries to provide shade and shelter for animals.

“We are committed to best practice in

be driving on rough terrain.

“We talk about those risks when we interview them, and make sure they have the training they need to work safely.”

Physical well-being is monitored through regular blood testing to measure chemical exposure.

“We are also aware that when they go on spraying or planting jobs, they might be with-

everything we do, including breeding the best cows and being efficient with feed and fertiliser use. We want a really sustainable farming business that is resilient to change,” Hamish says.

Both Hamish and Rachel have Master’s degrees from Massey University – his is in agribusiness and farm management, and hers is in animal science. They decided dairy farming would be the best use of their skills.

“Farming is a great lifestyle. Running your own business means you are in charge of your destiny and the work is mentally and physically rewarding.”

Hamish says after spending a lot of time in front of computers at university, he appreciates the break from the glare of screens.

The farm is right next to Greytown and Rachel says the family loves the rural/urban mix. They are keen to inspire young people

out Internet for up to a week at a time. So we have a portable Starlink to help them stay connected to family and friends.”

Likewise a pool table and darts board are part of the fit out at head office, and there is almost always a Friday night social catch-up for everyone.

Rochelle says entering the Northland Business Awards was an opportunity well worth

WAIRARAPA DAIRY FARMERS HAMISH AND RACHEL HAMMOND WITH THEIR TWO YOUNG SONS, GEORGE (2) AND LOU (5 MONTHS). RACHEL SAYS THEY NEED A GOOD ENVIRONMENT TO FARM WELL AND TO CREATE A FUTURE FOR THEIR CHILDREN.

from towns, cities and rural communities into dairy farming.

The couple host high school students for work experience on the farm and give talks at career days. “We want to show what a great lifestyle it is to live and work on a farm and get people involved in the dairy sector,” Hamish says.

Rachel says a farm is a great place to bring up a family, with their children spending time outdoors and with animals every day.

seizing. “As a contractor, you are so busy that you never have time to work on the business, as opposed to working in it. Going through the application process has been great for us. We have started working with a business advisor, and we have learned so much.”

Would she encourage other contractors to enter similar competitions? “Yes, 100 percent!”

POWER FARMING HAS OPENED A LARGE NEW BRANCH ON THE OUTSKIRTS OF AUCKLAND, WHICH GIVES A BIG PLATFORM FOR JCB CONSTRUCTION EQUIPMENT.

The new retail facility is at Paerata, near Pukekohe, and it was officially opened in March by Prime Minister Christopher Luxon.

Since the beginning of 2022 Power Farming Construction (a new division of the Power Farming Group) has been the distributor of JCB Construction Equipment in New Zealand.

The distribution agreement brings together two significant family-owned businesses.

Founded by Joseph Bamford in 1945, JCB is one of Britain’s most successful family-owned businesses, while the Maber family has run Power Farming since Laurie Maber established it in 1948.

Given the size of Auckland’s construction and civil engineering sectors, it has built the new branch to support distribution of the JCB Construction range in the region.

JCB Group executive director George Bamford attended the opening of the new branch along with JCB Pacific region director

THE NEW RETAIL AND FACILITY AT PAERATA WILL GIVE AUCKLAND’S LARGE CONSTRUCTION AND ENGINEERING SECTOR ACCESS TO JCB CONSTRUCTION

PM CHRISTOPHER LUXON (LEFT) AND JCB’S GEORGE BAMFORD (RIGHT) CUT THE RIBBON TO OPEN THE CENTRE, ACCOMPANIED BY POWER FARMING’S BRETT MABER.

Richard Myles. They are both very positive about what the partnership with Power Farming presents for their brand.

“It is great to see Power Farming investing in the JCB brand and expanding into the construction business. We are very optimistic

thought

didn’t

NEW ZEALAND NEEDS TO PREPARE FOR SIGNIFICANT CHANGES TO OUR KEY FOOD EXPORT MARKETS, FINDS A NEW REPORT LOOKING AT HOW THE RISE OF ALTERNATIVES TO ANIMAL PROTEINS COULD CHANGE THE FUTURE OF FARMING IN AOTEAROA.

Alternative proteins are likely to significantly affect the global market for proteins, as food technology improves and diets change in response to concerns about climate change, human health and animal welfare.

AgriBusiness Group director Jon Manhire says countries like the UK and China which depend on importing food from countries such as New Zealand will increasingly be able to produce more of their own alternatives to animal protein as technology advances.

The dairy sector in New Zealand is more threatened by the development of new proteins than our meat producers, found the research.

The Protein Future Scenarios research project was funded by the Our Land and Water. It investigated the potential impact on New Zealand of the global growth of new proteins that could compete with milk and meat.

Modelling by the research team projected the economic and environmental implications of three plausible future scenarios against a baseline scenario. The three future scenarios were based on different rates of technological advancement for alternative protein technologies, with associated growth in consumer demand.

Precision fermentation drove the worst economic scenario predicted by the research. Precision fermentation uses fermentation and yeasts to replicate dairy products. This could increase the global supply of dairy proteins and reduce prices for traditional New Zealand dairy products.

Technologies to reproduce dairy ingredients are more advanced than those for meat proteins. Whey derived from precision fermentation is already in commercial pro -

duction, and casein and milk fats can also be produced.

Demand for proteins is expected to increase globally due to population growth and changing diets. This won’t automatically drive increased production from New Zealand’s animal protein sector, because the increased demand could be met by alternative proteins, the research suggests.

Lincoln University’s Dr Christopher Rosin was part of the research team. Christopher says greater global demand for plant protein will have economic and environmental benefits for Aotearoa, but the economic benefits will be unevenly distributed.

“The modelling indicates that precision fermentation has negative economic impacts, mostly for our dairy sector. It does have positive environmental impacts, however. Cell-cultured protein is likely to have negative impacts on the New Zealand meat sector,” Christopher says.

“If widespread availability of cheap alternative proteins reduce profits for beef, sheep and dairy farmers, we are likely to see landuse change into arable, horticulture and carbon farming. This will have positive economic benefits for those sectors, but would reduce the size of our pastoral sector.”

The research models showed that alterna-

AS PROTEIN PRODUCTION FROM PRECISION FERMENTATION ADVANCES, IT COULD DISRUPT NEW ZEALAND’S DAIRY AND MEAT SECTORS.

tive proteins may have a relatively minimal impact on New Zealand agriculture when projected until the year 2035, but significantly greater impacts were identified when the modelling horizon was extended to 2050.

“Long-term modelling forecasts – like longterm weather forecasts – are less certain, but we are confident the research shows the likely trend in direction,” Jon says.

Research scenarios considered regional economic outlooks. For example, a 2050 scenario for Canterbury in which alternative proteins take off could decrease greenhouse gas emissions by over one-third, decrease nitrogen loss by almost 15 percent and increasing economic output 15 percent if some intensive dairy shifts to horticulture and arable.

Another key finding of the research was that global demand for new proteins could hit New Zealand’s meat and milk industry harder if we don’t mitigate our agricultural greenhouse gas emissions and meet high standards for animal welfare and water quality.

about a bright future for the Power Farming Group Construction team as we raise the brand profile in the New Zealand market,” Richard says.

Power Farming executive director Brett Maber says the purpose-built facility at Paerata is a multi-million dollar investment.

“We are very proud to establish this new branch alongside JCB Construction. It rein-

forces our commitment and confidence in the agricultural sector, and now for the first time also positions our brand for future growth in the construction sector too.”

Christopher Luxon acknowledged the importance of brands like Power Farming and JCB Construction to the New Zealand economy, and the respective roles they can play in contributing towards the government’s

future-focussed infrastructure plan.

“This is a great example of a fantastic New Zealand business investing in construction and also in agriculture, and it’s fantastic to see a family-owned business wanting to take the step of investment to actually make sure we can serve the agriculture industry and the construction and building industry in a much better way,” Christopher says.

JOHN DEERE HAS EXPANDED ITS OFFERING OF REPAIR AND REPLACEMENT PART OPTIONS BY ADDING VAPORMATIC PRODUCTS TO ITS RANGE OF ALTERNATIVE PARTS IN NEW ZEALAND AND AUSTRALIA.

UK-based Vapormatic is a subsidiary of John Deere. It has served the agricultural industry for more than 70 years and exports more than 30,000 tractor and agricultural machinery parts and accessories to 90 countries.

Vapormatic supplies parts for all European-built tractors as well as large row crop tractors out of the US. The range includes wear parts such as alternators, starter motors and filters for American-built tractors.

The addition bolsters John Deere’s Alternative Parts offering, which also includes products from A&I and Sunbelt that are made to fit John Deere equipment.

John Deere Australia-NZ director of customer support Emma Ford says alternative parts are an economical choice for John Deere machines, regardless of age.

“These parts have been manufactured to fit John Deere equipment. They are lower priced

than genuine John Deere parts, but still give customers peace of mind they are backed by a 12-month warranty,” Emma says.

“Adding Vapormatic to the range helps provide even more repair solutions for customers no matter their budget. We know customers have a choice when it comes to

VAPORMATIC HAS BEEN OFFICIALLY ADDED TO JOHN DEERE’S AFFORDABLE RANGE OF ALTERNATIVE PARTS.

John Deere equipment, so that’s why we offer choices when it comes to parts.

ONE OF AUSTRALIA’S FASTEST GROWING EQUIPMENT DISTRIBUTORS HAS ARRIVED IN NEW ZEALAND AND IS GEARING UP TO SUPPORT FARMERS AND CONTRACTORS ACROSS THE COUNTRY WITH SOME OF THE WORLD’S LEADING BRANDS.

Waringa Distribution has been operating for around a decade and in that time it has recorded exceptional growth. It has developed an astute understanding of agricultural markets and how to deliver machines and support to producers and dealers.

Part of a diversified farming group, Waringa Distribution thoroughly appraises and tests machinery before introducing it to the market.

Waringa Distribution general manager Sam Abbott is originally from New Zealand. He says he and his team listen to different markets and they are passionate about the equipment ranges they support.

“We work closely with farmers and contractors, and we focus on producing food as productively and cost-efficiently as possible,” Sam says.

Waringa Distribution has been looking to further grow and expand into New Zealand, but this had been hampered by disruptions to the global supply chain in recent years.

Now, however, it has appointed local industry identity Chris Tricker to lead its operations here and has established freight, assembly, warehousing and parts distribution locations in both the North and South islands.

Chris entered the industry as an agricultural engineer and has extensive experience in machinery sales, farm contracting and farming in the UK. He has been in New Zealand since 2007.

Before moving to Marlborough Chris was involved in sales and operations management, consulting and contracting, including with Claas Harvest Centre in the Waikato.

Waringa Distribution is already the exclusive New Zealand distributor for Agri-Spread fertiliser and muck spreaders, Gregoire Bes-

son tillage and soil structuring equipment, Highline rock handling and hay bale processing equipment, and Broughan Engineering trailers.

It is anticipating further interest from grain growers for its Geringhoff header fronts and Elmer chaser bins.

Chris says Waringa will add to its team and resources in New Zealand, which includes appointing dealers. It will be flying the flag and developing relationships at National Fieldays.

Agri-Spread spreaders are already well known in New Zealand. Chris says they are quality-built, durable and have high spec features and precision technology that can help limit environmental impact from fertiliser applications.

“Proof of placement with product applications will drive adoption of these technologies into the future,” Chris says.

“The level of technology with the AgriSpread spreaders is excellent. It offers full section control on a 36-metre spreader and that is almost unheard of.”

He says Gregoire Besson machines will be of particular interest to contractors and larger dairy enterprises that want to manage and incorporate trash when establishing maize

“With challenges around production costs it’s important we provide a wide range of parts to suit all budgets and repair scenarios.”

John Deere’s full range of parts include Genuine, Reman (or remanufactured) and Alternative.

“Genuine parts are built specifically for John Deere machines, meaning they are identical to the new parts fitted at the fac-

tory – in other words, the perfect fit,” Emma says.

“Reman parts have components replaced or remanufactured to deliver like-new performance at a lower cost than brand-new parts. They undergo extensive testing by our engineers to ensure they meet or exceed original performance specifications.

“As the name suggests, Alternative parts are an economical alternative choice which

WARINGA DISTRIBUTION GM SAM ABBOTT (LEFT) AND NZ SALES MANAGER CHRIS TRICKER EXPECT STRONG INTEREST IN AGRI-SPREAD FERTILISER AND MUCK SPREADERS AND GREGOIRE BESSON TILLAGE IMPLEMENTS.

and to undersow forage crops.

Gregoire Besson’s semi-mounted plough, disc harrow and one-pass finishing machines are ideal for these operations.

Chris says Highline rock pickers, rakes, bale feeders and tub mixers will also be a good fit for New Zealand farmers and contractors.

And Broughan Engineering trailers are ideal for famers who need to carry out a variety of tasks. Its farm trailers have removable sides and are ideal for moving a range of materials and picking up hay bales.

Geringhoff header fronts and Elmer’s chaser bins will capture attention from grain growers in the Canterbury region.

For further information on the Waringa Distribution equipment range or demonstrations, contact Chris Tricker on 027 577 0058 or visit waringa.co.nz.

still deliver the performance and reliability expected of John Deere parts.

“Expanding our Alternative Parts offering with the addition of Vapormatic is part of our commitment to offering our customers the right part at the right price.

“Customers who want to find out more about the range of parts designed for John Deere equipment, should contact their local dealership.”

COCHRANES OF CANTERBURY HAD A STRONG SHOWING IN BOTH THE NEW HOLLAND AND CASE IH AUSTRALIANEW ZEALAND 2024 DEALER OF THE YEAR AWARDS.

The award winners were announced in April. Cochranes won both the red and blue CNH Capital Dealer of the Year awards.

The Dealer of the Year awards are based on a range of criteria, including finance and business management, performance in sales and marketing, parts and servicing, precision technology and total market share.

CNH Australia-NZ business director Aaron Bett congratulates all the award winners. He noted the level of excellence achieved by the dealerships and their dedication to their customers.

“The winners should all be very proud of what they have achieved in the past 12 months. Their teams consistently go that extra mile and place a high priority on delivering the service, support and advice their customers rely on,” Aaron says.

“The standard across our network is very high, so to be successful in our Dealer of the Year Awards is an outstanding achievement,

COCHRANES OF CANTERBURY DEALER PRINCIPAL CHRIS WEST IS CONGRATULATED BY CNH CAPITAL ANZ MANAGING DIRECTOR MATT DOWLING AFTER RECEIVING THE CNH CAPITAL DEALER OF THE YEAR AWARD.

and recognition of the work that has gone in across all aspects of the winners’ operations.”

Australian companies took out the other Dealer of the Year awards.

NSW dealership network Intersales in New South Wales was the Case IH Dealer of the Year for dealers with three branches or more and South Australia’s Larwoods Ag Services won Case IH Dealer of the Year with one or two branches.

In the New Holland dealership awards, On-Trac Ag (NSW) was the large dealer network winner and Flinders Machinery (SA) was the small network winner.

Intersales CEO Amanda Blachut says the award they won was a testament to the hard work of their whole team. “The dedication the team put towards training, team collaboration and knocking down barriers between departments is to be admired,” she says.

The contractors’ solution for every effluent pumping or mixing problem out there. The FarmChief Mega Mix Lagoon Mixer/Pump is excellent for high-performance incorporation of severely crusted large ponds and lagoons, whilst doubling as a top-of-the-range pump for priming umbilical pumps or transferring directly to tankers. Features include dual hydraulic rams for depth control, hydraulic 300 o rotating jetter for breaking up surface crusts, a Hardox intake chopper plate and impeller drum for incorporating

and a fully galvanised frame for a hard-wearing long life. What peak performance looks like.

AUTONOMOUS VEHICLES AND ARTIFICIAL INTELLIGENCE ARE POISED TO SHAKE UP THE FARMING INDUSTRY, SAYS AN AMERICAN EXPERT IN THE FIELD.

Dr Scott Shearer is chair of the Department of Food, Agricultural and Biological Engineering at Ohio State University.

He notes that John Deere already sells a fully autonomous tractor, and the only question is how quickly robotic vehicles will replace human drivers. At the same time artificial intelligence (AI) and digital agriculture is now the new shape of precision agriculture.

“Previously it was start-ups talking about autonomy, but now it is almost all tractor manufacturers. It will be one of the things that will change the marketplace,” Scott says.

He spoke via video link at the Foundation for Arable Research’s maize conference at Hamilton in February. He says he attended the 2023 Agritechnica show in Germany, and nearly every manufacturer of agricultural equipment had a robotic or autonomous offering.

Examples include Australian company SwarmFarm which uses the tagline ‘My Dad used to drive a tractor’. Its autonomous sprayers can operate around the clock and they automatically shut down in adverse weather.

Running autonomous systems requires 5G connectivity which is not always available in rural areas. In the US, however, farmers can become their own mobile phone provider within a 2-3 km radius using their own antenna.

Autonomous vehicles present a possible way to counter the cost of farming machinery. To reduce costs and maximise coverage in the field during optimal conditions, agricultural machinery is getting bigger. As tractors become increasingly more high tech and expensive, a major question is how fully they can be used to justify the cost.

While it is now possible to plant seed at speeds of 10-16 kph there are challenges when working higher speeds.

Scott says another trend in the US is using drones to apply agrichemicals. In Ohio, there are about 25 companies that spray fungicides on maize and soybean crops with drones. One group claimed to have sprayed 10,000 ha with eight drones, while another used two drones to spray 2000 ha in a 30-day period.

FAR TECHNOLOGY MANAGER CHRIS SMITH SAYS AI’S ABILITY TO MANAGE AND INTERPRET LARGE VOLUMES OF DATA WILL GIVE FARMERS SOME GREAT OPPORTUNITIES.

Drones are getting bigger. For example, a Hylio AG-272 spray drone weighs 175 kg when fully loaded with batteries and 70 litres of product. It has a 12m application width and can spray up to 20ha/hour.

Scott says AI will help farmers interpret the huge amounts of data they generate when using precision agriculture. It is part of the trend toward what he calls digital agriculture.

“Digital agriculture covers everything from when the seed goes in the ground until there are end products on the consumer’s table. Everything is connected to the Internet.”

Digital agriculture uses artificial intelligence and machine learning to interpret huge amounts of data to support farmers’ decision-making and improve the efficiency of their work.

Scott gives the example of a spray applicator using a camera and processors to distinguish green on brown weeds and in some cases green on green.

“We will use this for a lot more than just spraying weeds. We will use it to manage fungicides, insecticides and nutrients.”

Central Ohio has become the US MidWest’s Silicon Valley, with tech giants Intel, Google, Meta and AWS moving in. When AI is fully implemented, electricity consumption in the Mid-West is expected to increase by 25 percent, he says.

FAR technology manager Chris Smith says the biggest challenge for growers adopting precision agriculture as an everyday tool on-farm has been the perceived cost versus the return on investment. Data transfer and sharing information between different systems by service providers are also barriers to adoption.

“Internationally, several countries are trialling new technologies that may provide

OHIO STATE UNIVERSITY PROFESSOR SCOTT SHEARER SAYS ALL MAJOR FARM MACHINERY MANUFACTURERS ARE DEVELOPING AUTONOMOUS VEHICLES WHILE AGRICHEMICAL APPLICATION WITH DRONES IS TAKING OFF IN THE US.