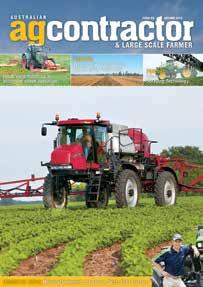

& LARGE SCALE FARMER

NEWS Rock around the clock

FEATURE

What’s new in seeders and planters

EQUIPMENT

Pöttinger Tegosem, the tank for flexible application

NEWS Rock around the clock

FEATURE

What’s new in seeders and planters

EQUIPMENT

Pöttinger Tegosem, the tank for flexible application

Accurate and easy seed drill calibration at the touch of your finger - right next to your drill.

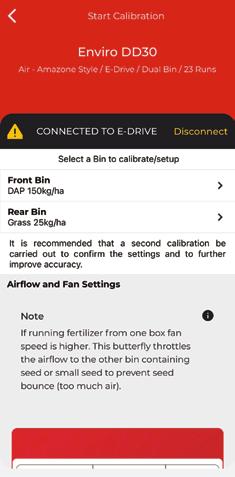

No more fumbling through manuals or using the tractor’s in-cab controller. Download our free Duncan Seed Drill app from the Google Play or App Store now for easy and accurate calibration.

The app contains step-by-step guides for making calibration and mechanical adjustments to the drill.

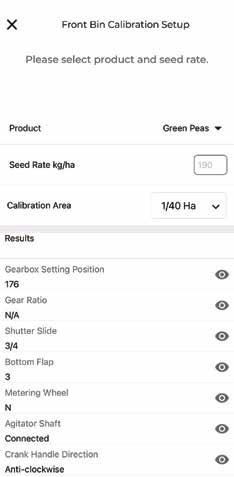

Calibrating a new or existing mechanical drive drill with seed or fert will display the required

Connect wirelessly to a Duncan E-Drive Drill to set up the sowing rates and run the calibrations

AML, Ashcroft House

Tancreds Road, R D 2, PO Box 37151, Halswell, Christchurch 8245

Ph: +64 3 329 6555

Fax: +64 3 329 6550

www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Manual.

EDITOR

Scott Wilson

Mob: +64 21 725 061

Email: scott@agrimedia.co.nz

ADVERTISING SALES

Pulse – Media Sales

Justin Bowler

Ph: 0429 699 553

Email: justin.bowler@mmg.com.au

CIRCULATION

DDI: +64 3 329 6555

Email: admin@agrimedia.co.nz

PRODUCTION, LAYOUT & DESIGN

Mark Winstanley

Email: art@agrimedia.co.nz

Contributors: Delwyn Dickey , Gerhard Uys.

Printed by PrintGraphics Pty Ltd

AC © AUSTRALIAN AG CONTRACTOR AND LARGE

SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

CONTRIBUTIONS - Editorial and photographic contributions are welcomed and should be sent directly to AML. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

02 FROM THE EDITOR:

03 Farmer’s labour of love a focal point for Case IH Farmall’s centenary celebrations

04 Rumin8 officially opens demonstration plant as it progresses towards commercialisation

05 Rocking around the Christmas Tree Farm

06 Fordham Agricultural launches new entity

08 Machinery equipment distributor celebrates 30-year milestone

10 Rock around the clock ASSOCIATIONS

12 Fertilizer Australia’s emissions white paper TECHNOLOGY

14 CropScan 4000VT On Combine NIR Grain Analyser

PROFILES

16 Eaglehawk Angus stud

22 Gillian Fennell: The sequin loving bush badass from Outbackistan

26 Across the ditch: Youthful passion turns into busy contracting business FEATURES

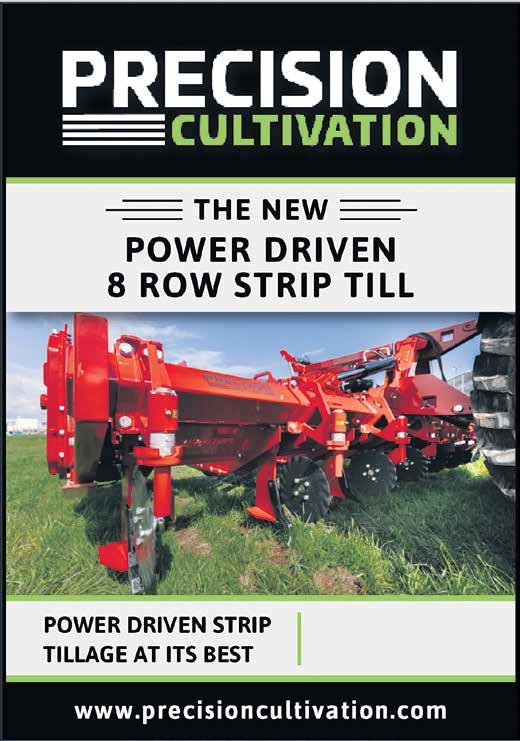

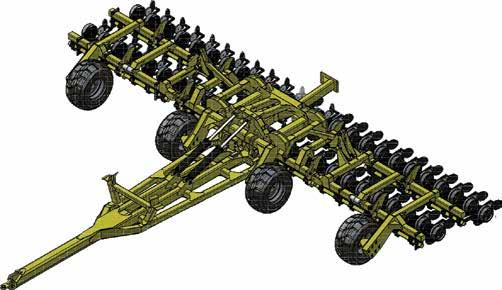

32 What’s new in cultivation and tillage

42 What’s new in seeders and planters

EQUIPMENT

54 Kubota’s new RTV-X1130 ready to tackle anything

55 Redekop’s new Seed Control Unit for X9 proven in heavy crop conditions

56 New turbo compact tractor gives next level performance

57 Robust seeder bar designed for durability

58 Toowoomba based agricultural machinery dealer and importer B&B Machinery is your forage harvester corn front specialist selling and servicing Kemper products in Australia

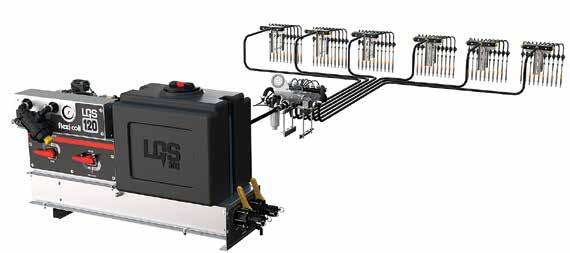

60 One for all from Pöttinger: Tegosem, the tank for flexible application

IT’S JUST THE NEWS THE AUSTRALIAN FARMING SECTOR NEEDS AS THE FIRST QUARTER OF 2024 STARTS TO SLIDE BY…PROVIDED THINGS PAN OUT AS EXPECTED

duction, I tripped across a report from ager for RaboResearch Australia and New Zealand, who indicated there are a number of early indications that 2024 should be a

outlook with a cautionary note, reminding

dently into 2024”, indicated there would still be some hangover challenges from the previous year – namely agri commodity

ty surrounding geopolitics in some chal

as 2024 starts to unfold in front of us.

in), farm input prices (fertilisers and chem ical plant protection products) are fore cast to come in below last season’s levels, and shipping costs are below the levels

her husband was nowhere to be seen. She was quite upset because they had a lot to do, so she called him on his mobile phone to ask where he was.

remember the jewellers we went into about

AS 2023 DREW TO A CLOSE, SO TOO DID THE CENTENARY CELEBRATIONS FOR THE CASE IH FARMALL TRACTOR, AND WHAT A YEAR IT WAS.

One of the focal points for the centenary has been a historic 1940s restored Farmall that has been on the field day circuit promoting the unique milestone and providing an insight into the proud history of this important tractor model.

The fully restored 1949 Farmall was purchased by Case IH during 2023 to help showcase the celebrations, and was displayed at the AgQuip, Henty and Yorke Peninsula field days throughout the year.

The tractor was bought from Kerang in Victoria, restored by passionate collector Cedric Sheaf who passed away early this year at the age of 91, and whose family wanted to ensure his tractor collection went to new owners who would appreciate them as much as their father and grandfather.

“Dad was so passionate when it came to restoring the tractors he collected, he was very meticulous and took a lot of pride in doing it right. When he died, the tractors were left to various family members, but without the room to store them properly, we then looked to passing them onto collectors as dedicated as dad was, who would real-

ly appreciate them and the history around them,” said Barbara Lawson, one of Cedric’s daughters.

Scott Jericho, Case IH Tractor Product Specialist, said it was important to the company to invest in its own vintage Farmall tractor to promote the centenary at a variety of events

THE TRACTOR PURCHASED BY CASE IH ON SHOW AT AGQUIP 2023.

CEDRIC SHEAF ON THE FARMALL SUPER A IN A LOCAL PARADE IN KERANG.

through 2023, and when he saw the 1949 Farmall Super A advertised by Cedric’s family, he knew it was the right one.

“The fact the tractor was fully restored was

AUSTRALIAN CLIMATE TECHNOLOGY COMPANY

RUMIN8 HAS OFFICIALLY OPENED ITS MANUFACTURING DEMONSTRATION PLANT, A SIGNIFICANT MILESTONE ON ITS PATHWAY TOWARDS COMMERCIALISATION OF THE COMPANY’S AFFORDABLE FEED AND WATER SUPPLEMENTS THAT REDUCE METHANE EMISSIONS FROM LIVESTOCK.

Located in Perth, Western Australia, and officially opened by Western Australia Agriculture Minister Jackie Jarvis, the demonstration plant has been constructed to provide

DAVID MESSINA (RUMIN8 CO-FOUNDER AND CEO) AND HON. JACKIE JARVIS MLC (MINISTER FOR AGRICULTURE AND FOOD; FORESTRY; SMALL BUSINESS).

very appealing because we wanted to be able to use it immediately, and Cedric had done such a beautiful job with it. It’s such a great example of a classic Farmall and it’s attracted a lot of attention and comments throughout the year,” Scott said.

Cedric Sheaf, and wife Inez, were farmers near Kerang before retiring into the town in the late 1990s.

Barbara said he had a Farmall tractor on the farm for many years, so once retired, he started to collect old Farmalls, all in reasonably

PRELUDE

proof of concept – technical, manufacturing and cost of production – to produce the various formulations of Rumin8’s inaugural product.

“The demonstration plant will help Rumin8 overcome one of the biggest hurdles to commercialisation,” said Rumin8 CEO David Messina.

“We know our product works in terms of reducing methane emission from livestock while retaining or improving productivity. Now we need to refine the production of our formulations in a pharmaceutical manufacturing setting rather than a laboratory setting to demonstrate a range of outputs such as cost, product integrity, QA, etc.

“We have every confidence we can success-

poor condition. For Cedric, it became a labour of love restoring the tractors to their former glory.

The 1949 Farmall Super A purchased by Case IH was bought by Cedric from Trentham Cliffs, Mildura, in June 2001, where it had been sitting in a paddock for 13 years.

His collection ended up totalling six Farmalls, which were kept in a shed in the couple’s backyard, Cedric enjoying showing them off at vintage tractor events and driving them in local parades. The Farmall Super

fully achieve those goals using this demonstration plant.”

The demonstration plant is a precursor to large scale production, including pilot plants and full-scale commercial operations.

Once operating at maximum design capacity, the demonstration plant is expected to produce thousands of doses a day, providing additives to support large-scale trials of Rumin8’s product.

“In addition to our own staff, we have established partnerships with local laboratories (University of Western Australia and Murdoch University) to supplement on-site operations for the testing and validation of product made at the demonstration facility,” David said.

A won a number of ‘Best Restored Tractor’ awards at vintage machinery club days.

“Dad would have been so thrilled to know one of his Farmalls was actually purchased by Case IH to help celebrate the Farmall’s centenary year. When my sister and I knew one of dad’s tractors was going to the company, we were really emotional. It meant such a lot and would have meant a lot to him,” Barbara said.

The Farmall Super A is currently on display to the public at Case IH dealership Larwoods Ag at Kadina, South Australia.

IN AUSTRALIA, THE 1ST OF DECEMBER MARKED A MOMENTOUS TIME OF YEAR.

SCHOOL WAS NEARLY OUT, THE HEAT HAD SET IN AND IT WAS OFFICIALLY TIME TO DUST OFF THE CHRISTMAS DECORATIONS AND PUT UP THE TREE.

But this annual ritual often sparks a long-standing debate. When it comes to Christmas trees, do you opt for real or fake?

For Yeowarra’s Tim McMahon, there’s only one answer.

“One hundred percent, nothing beats the real deal,” exclaims Tim.

Though, he might be slightly biased. Owner of Yeowarra Tree Farm, about an hour out of Geelong, Victoria, Tim works tirelessly to ensure the fresh scent of pine fills homes for the holiday season.

Specialising in wholesale Christmas Trees, the farm’s pruned trees are amongst the best in the country.

Each year Tim and his team harvest thousands of trees which are provided to wholesalers across Australia and their business is continuing to grow.

Tim says purchasing a real Christmas tree is growing in popularity, thanks to advances in farming technology.

“There is a misconception that real trees are hard to maintain and messy, however over the years with genetic selection, the trees have a higher density foliage and higher retention of needles.

“Whereas fake trees are made from artificial material which is non-recyclable and eventually end up in landfill.

“Plus, you can’t beat the smell of a real tree. You just don’t get that with the fake ones.”

That scent is overwhelming on the Yeowarra property. The land was originally purchased by Tim’s grandfather in the mid1970s. The intention was to train horses and run cattle.

When Tim’s parents took over the business in the 1980s, the farm’s very first row of Christmas trees was planted. As the trees grew, so too did a new passion.

"It all started as an experiment. They just sort of went for it,” explains Tim, “and they never looked back.

“I had a fantastic childhood, really idyllic. We all chipped in on the farm; even as a kid I loved the work!”

Today sustainability is a significant focus at Yeowarra Tree Farm. Ninety-nine percent of the trees harvested at the farm are sent to

wholesalers which results in minimal waste.

“We are also finishing our Carbon Neutral Certification for our trees which shows that our products are removing the same amount of carbon dioxide from the atmosphere that the production creates.

“This process will provide feedback on how to make our operations more sustainable.

“It also provides our customers with peace of mind that they are purchasing a product that is not harming the planet. We’re proving that you can have a real tree in your home every year, forever, with zero impact to the planet. That really excites us.

“That’s something you don’t get with plastic Christmas.”

Tim studied engineering when he finished school. He now lives somewhat of a double life, commuting to Melbourne part-time to work as an engineering consultant. The rest of the week and weekends are spent tending to the farm.

“I love the balance it provides, and I’m so lucky I’m able to spend time in both industries. It allows me to combine my two passions and establish efficiencies and innovation on the farm.

“October marks the start of our sprint season,” explains Tim, “That’s when we start preparing for harvest and we have a larger workforce join us.

“Harvest usually starts around November 20. Then it’s all systems go.”

With sustainability goals driving his business, Tim does not shy away from innovating and utilising new technology to aid in the operational activities on his farm.

“Working with a software developer

TIM MCMAHON

ONLY RECENTLY ESTABLISHED, FORDHAM AGRICULTURAL MACHINERY IS ALREADY WORKING HARD TO ESTABLISH ITS PRESENCE IN THE AUSTRALIAN MARKET.

Managing Director, Guy Fordham, has had considerable experience in the farming and agriculture sector, and he aims to bring that knowledge to his new company.

“Our vision is to deliver products and services that will add value to your farming business,” he says. “Our mission is to supply and support innovative agricultural machinery and technology to create opportunities for you to increase efficiencies and gain beneficial outcomes.”

Guy has spent his entire career in agriculture after being raised on a family farm in England. After leaving the farm and progressing into retail distribution, he took the oppor-

tunity to meet new people and experience many sides of the agriculture industry.

“I started with a merchant, gaining knowledge and understanding with grain, seed, chemical and fertilisers, then into retail sales of machinery for major brands, including managing a branch for CLAAS.”

He moved to Australia in early 2003 and held the role of National Sales Manager for CLAAS, working closely with dealers to support and develop distribution before moving back into retail, where he says he enjoys working with farmers and contractors directly.

This allowed him to build relationships and earn trust with both suppliers and customers to create improved outcomes for all parties.

“My plan for this year is to develop my own business whilst continuing the work that has already started with Novag T-ForcePlus seed drills and provide the necessary support,” he says.

company, I helped create our own workforce and operations management software.

“It helps us manage tasks and provides valuable data to help make informed decisions about our operations on the farm.”

Being away from the farm for half of the week, Tim says the bespoke software provides him with visibility to how his workforce is tracking, providing updates on daily, weekly and monthly tasks.

“It also encourages my team by setting daily goals and they can see how well they have performed the next day. It creates a healthy level of competition.”

Tim hopes his program can be adapted to

help other farmers streamline their operations.

“Right now, there are so few programs that help with workforce management in agriculture.

“My intention is to have this program refined enough to be expanded in the next couple of years so other farmers can enjoy the benefits of a more data-driven operation.”

According to Tim, technology and innovation need to be at the forefront of Australian agriculture.

“The future of technology in agriculture is looking bright. On our farm, we are looking to

“I will introduce a new range of equipment encompassing low disturbance soil looseners, strip-till and equipment from Grange Machinery in the UK whilst continuing to explore opportunities with both brands.

“I’m passionate about what farmers and contractors do and will do my best to develop and evolve my business to meet the demands that we are challenged with.

“I will rise to the challenge and remain optimistic about the future. I look forward to working with you, sharing information, and supplying and supporting innovative machinery.”

For more information, go to www.fordhamag.com.au.

mechanise as much as we can, and I think this movement will gather more momentum over the next 10 years.”

To best optimise on-farm practices, Tim needs the most reliable and durable machines on the market. That’s why his family have been choosing Kubota for years.

“We have some old tractors that were purchased second-hand more than 20 years ago. They are still used on the farm to this day.”

Tim currently uses the B3150 for spraying and the M7 tractors for loading trees onto trucks and other daily tasks.

“The last thing I want to worry about is our machinery not working during our harvest season. That would be devastating for the business and bring on major delays to our shipments. Kubota has never failed us.

“Our dealer, Rhys Evans, is very helpful. Always happy to help and accommodate us. It's wonderful working with them.”

According to Tim, another benefit to the Kubota range is its user-friendly experience.

“We have a lot of people working at the farm at different times of the year due to the nature of the business.

“The main reason we chose Kubota is the simplicity of its machines. They are easier to use and teach than some other machinery.”

As the Kubota M7’s tractors roll up and down the rows of pines, preparing them for sale, Tim has one holiday wish.

“As a society, we need to take practical steps towards improving sustainability and reducing our reliance on plastic.

“The best way to do that at Christmas is by choosing to buy a real-Aussie-grown tree.”

ONE OF AUSTRALIA’S MAJOR AGRICULTURAL AND CONSTRUCTION EQUIPMENT DISTRIBUTORS HAS RECENTLY CELEBRATED 30 STRONG YEARS AND IS GEARING UP FOR MORE TO COME.

McIntosh Distribution has been the name behind the rise of a number of popular brands across the industry, including Morris tillage and seeding rigs, Miller sprayers, Weedseeker and Bilberry spot spraying systems, the Harrington Seed Destructor and LiuGong construction equipment.

Cam McIntosh commenced the business and was the early architect of Morris’ growth in the seeding sector. Today it commands a significant market share and is continuing to deliver for Australian growers, the latest being a new 24-metre version of its revered Quantum air drill in time for next season.

It’s a similar story with Miller, which has just launched its Intelligence range of 7000 Series sprayers that break new ground in spraying application and machine data control, offering significant operational and servicing efficiencies for growers.

The spot spraying systems include WeedSeeker 2, which offers some unique advantages to growers for summer spraying, as well as the first commercially-available green-on-green spot spraying technology developed by Bilberry.

Meanwhile, LiuGong equipment, which celebrates its 20th year in Australia in 2024, continues to strike a chord with operators across the country, so much so that, to keep up with demand, McIntosh Distribution had

THE MCINTOSH DISTRIBUTION TEAM PICTURED DURING ITS 30TH CELEBRATORY CONFERENCE IN PERTH.

to hire several bulk carriers to maintain supply.

McIntosh Distribution General Manager Digby Moullin said the company wasn’t about to slow down either.

“We have more product releases in the pipeline as we are always looking at ways to support our dealer network and end customers,” Digby said.

Two key areas that have underpinned the success of McIntosh Distribution and its associated brands have been its core focus on product support through to dealers and grower customers and the local research and development of products to suit Australian conditions.

“We have a dedicated team working on product improvements to suit local requirements, of which many have then been incorporated by the manufacturers into the original designs to improve their performance in the global market,” Digby said.

The product support team based around

CAM MCINTOSH, WHO COMMENCED THE MCINTOSH DISTRIBUTION BUSINESS, PICTURED CONGRATULATING JOHN DUNCAN FOR 25 PLUS YEARS OF SERVICE DURING THE COMPANY’S 30TH CELEBRATIONS.

the country has grown to more than a dozen and is expected to continue to grow.

“We believe it is extremely important to ensure there are key representatives in each State who can assist with ongoing product improvements, as well as being on-hand and facilitating training for dealers and growers.”

The team is also backed by facilities, including parts warehouses in Perth, Adelaide, Sydney and at Tamworth in Northern New South Wales.

Production, parts and administration areas in Perth have continued to expand and further dedicated facilities are planned for this site and through eastern Australia.

The recent 30th celebrations in Perth brought together the 100-strong McIntosh Distribution team from around the country to acknowledge its journey so far and chart the exciting pathway ahead, while it also recognised the contributions of several members who have played key roles throughout its history.

“We have staff here that started with Cam McIntosh 28 years ago, so it was great to be able to acknowledge their tenure in front of the team,” Digby said.

In concert with the business growth, dealer groups for the equipment brands have continued to evolve and Digby said McIntosh Distribution looked forward to strengthening these networks and welcoming more dealers aboard to support grower customers.

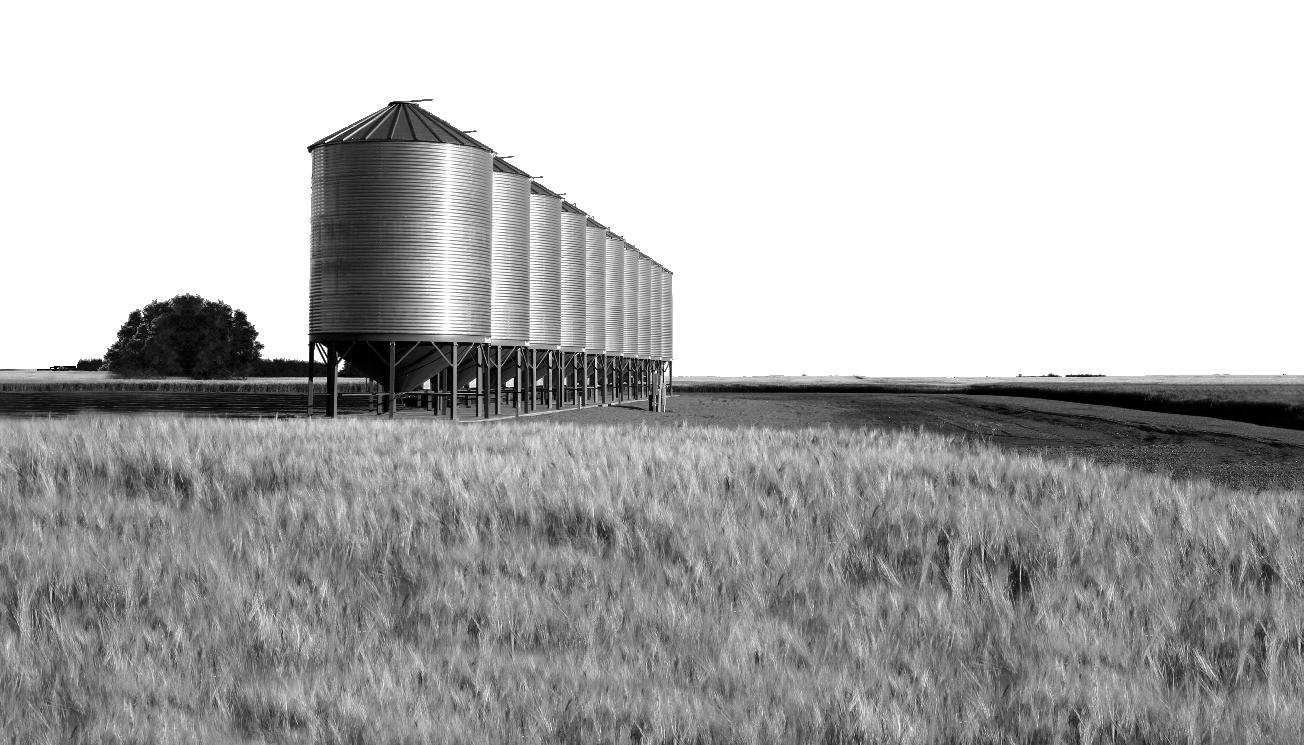

A LARGE-SCALE CROPPING OPERATION IN NORTHERN NSW HAS AMBITIOUS PLANS TO BECOME ONE OF THE FIRST AUSTRALIAN FARMS TO EMPLOY FULLY AUTONOMOUS CROPPING OPERATIONS WITH THE PURCHASE OF A REVOLUTIONARY AGBOT TRACTOR.

Developed by AgXeed, a Dutch technology start-up, AgBot tractors allow a range of monotonous tasks, including tramline renovation, spot spraying, and spreading, to be performed without an onboard operator.

Beefwood Farms, a 12,500-ha aggregation between Goondiwindi and Moree, has taken delivery of its first tractor.

If all goes to plan, the business intends to acquire more tractors.

Beefwood Farms is owned by Gerrit and Pam Kurstjens, together with their daughter, Marieke.

Gerrit had effectively retired after a successful career as an agricultural contractor, transport operator and farm machinery manufacturer in the Netherlands when his passion for gliding brought him to Australia more than 20 years ago.

Soaring high over the black soil plains of northern NSW, he was impressed by the region’s potential and decided to embark on a second career in broadacre farming.

Gerrit and Pam purchased Beefwood in 2006 and began converting the then 2500 ha livestock operation into a continuous cropping, controlled traffic min-till cropping system.

An enthusiastic adopter of technology, particularly those that minimise chemical usage, Gerrit and his team have been utilising optical sprayers for more than 15 years.

“Optical spraying has reduced our chemi-

cal usage by 95%, we’re getting better weed control and we’re putting less chemical in our farming system,” farm manager, Glenn Coughran, says.

“The downside is that each sprayer is spending more time in the field, which is why we started looking at autonomous tractors about 10 years ago.

“Gerrit knew some people in Europe who were making self-guided mowing equipment for use on golf courses and for highway maintenance.

“He had to twist their arm to come to Australia to fit this technology to a 350 hp tractor but they agreed to have a go.

“The engineer came over and installed the operating system on our Fendt 936 Vario.

“It took about two weeks to get it going but it worked.”

A John Deere 8345R was converted three years later.

Over the following years, the two tractors clocked up more than 4000 driverless hours spraying more than 40,000 ha and renovating about 25,000 km of tramlines.

Despite this success, Beefwood Farms was

forced to abandon the project after the technology was sold to a farm machinery manufacturer in 2019.

“We were really disappointed – we’d put a lot of time and money into making this work and we were nearly there,” Glenn says.

“We’d got this to being about 95% perfect when we received an email saying the company had been sold and that technical support would no longer be available.

“One of their technicians came out, stripped the gear out, gave us a cheque and that was the end of it.

“We didn’t have the capabilities to do this ourselves so we had to give up.

“It was like losing a couple of our best staff.”

Undeterred, Gerrit contacted some of his former colleagues in the Netherlands who were developing their own autonomous tractor.

After visiting several start-up companies in Europe and the USA, he placed one of the first orders following the commercial release of the AgBot platform last year.

The tracked AgBot 5.115T2 model is powered by a 4.1 L four-cylinder Stage 5 Deutz

diesel engine that produces a maximum output of 155 horsepower and 610 newton-metres of torque.

The engine drives a generator that, in turn, powers the electrically driven tracks, PTO and 700-volt external electric supply.

This hybrid system delivers maximum torque and efficiency at all speeds, without the need for ballast.

“There’s a reason why diesel-electric technology has been used in locomotives for more than 50 years – and that’s because it’s a proven and extremely efficient drivetrain,” Gerrit says.

The eight-tonne unit is equipped with front and rear linkages, high capacity hydraulics, RTK steering guidance and four separate collision avoidance systems.

Two on-board cameras that are connected to the internet via Starlink allow remote monitoring of field operations.

“AgBot really ticks my boxes,” Gerrit says.

“It’s fully autonomous, it’s able to operate 24 hours a day, it’s on a three-metre track width, it’s reasonably economical to run and it’s low maintenance.

“This is a real tractor, it’s just a smaller size.”

The AgBot was immediately put to work renovating tramlines using a six-metre TPOS FlaTrac renovator.

The AgBot has also been successfully paired with a 24 m Croplands Weed-It optical spraying unit.

“So far, we are very happy with the AgBot and we have been pleasantly surprised about

how easy it is to set up and operate,” Gerrit says.

“It is a bit daunting that we’ve got the only unit in Australia but the back-up from AgXeed and Landpower has been great.

“Setting it up for different uses, such as our 48 m Hayes Weed-It optical sprayer, is going to take a bit of work, but it’s something that has to be done.

“We plan to run this unit for as many hours as possible, even doing work that is not necessary, to uncover any problems before we put more units in the field.

“This is just the start and we can’t wait to see what comes next.

“It is expensive but we estimate we’ll halve our hourly operating cost by eliminating the need for a driver and doubling the operating life of the tractor,” Gerrit says.

“We also expect that maintenance and fuel consumption will be much less, as our previous experience with autonomous tractors showed that humans tend to push the machine harder.”

These attributes make AgBot ideal for tedious jobs, such as tramline renovation or round-the-clock spraying.

“Tramline renovation is probably the most boring job on the farm,” Glenn Coughran says.

“We have about 8000 km of tramlines across the six properties and we try to renovate about one third each year, usually following chickpeas when there is less crop residue.

“This year we had three operators renovating tramlines all summer and some of them weren’t too happy about it.

“Being able to do this automatically is not about reducing labour – it’s about being able to use your resources better.

“We’re 55 km from town and we only have four to six full-time employees, so it’s important to get everyone doing what’s more important.”

The ultimate plan is to run a fleet of AgBots performing everything from 24/7 ‘green on green’ optical spraying and spreading fertiliser to shuttling 60-tonne grain bins during harvest.

“AgBot is going to take our spraying program to the next level,” Glenn says.

“Provided conditions are right, we will be able to spray 24 hours a day plus we will be able to cost-effectively apply a second or even a third spray if we have to.

“In time, we plan to retire two of our three self-propelled sprayers and let the AgBots take over.

“We’ll probably end up employing a manager for the day-to-day operations of the AgBots, with other staff going out to refuel and fill the machines each day.”

AgXeed has already caught the eye of several corporate investors, including the German farm machinery manufacturers, CLAAS and AMAZONE, with the former recently appointed international distributor.

AgBot is distributed in Australia and New Zealand by Landpower.

FERTILIZER AUSTRALIA RECENTLY COMMISSIONED A WHITE PAPER TO SUPPORT POLICYMAKERS’ DECISION-MAKING ON POTENTIAL WAYS TO REDUCE GREENHOUSE GAS EMISSIONS FROM NITROGEN FERTILISER WHILE PROTECTING AUSTRALIA’S SOIL HEALTH AND AGRICULTURAL INDUSTRY.

The white paper, Nitrogen Fertiliser Use and Greenhouse Gases – An Australian Assessment, was independently written by Dr Robert Norton, Dr Cameron Gourley and Professor Peter Grace.

Fertilizer Australia Executive Manager Stephen Annells said the white paper provides recommendations that can help the government develop a nuanced and well-considered response to reducing emissions from nitrogen fertilisers while maintaining Australia’s position as a prosperous country that feeds and clothes the world.

“Our recommendations incorporate technological advancements and practice change. None are stand-alone, and combining these recommendations is important to achieving our emissions reduction goal.” Stephen said.

The comprehensive document builds a picture of the challenges and opportunities for government and industry in its quest to reduce greenhouse gas emissions.

Subjects addressed include the importance of nitrogen to food security and public health, understanding and estimating nitrous oxide emissions, efficient and effective use of nitrogen fertilisers on Australian farms and

reducing emissions by improving farming practices.

The authors also explore ways to improve nitrogen use efficiency and reduce emissions through technical advancements like slow-release technologies, greater adoption of precision agriculture tools and incentivising low carbon footprint manufacturing.

Among the document’s key recommendations are:

- Consider policies encouraging the widespread use of nitrification inhibitors and slow-release technologies to improve nitrogen use efficiency and reduce nitrous oxide emissions. Scientific advancement will continue to play a crucial role in reducing nitrogen loss through technologies, but it must be cost-effective for farmers to purchase. They are unlikely to pay more for these products when there is no favourable market or yield outcome from their use. The recommendation suggests it would be more efficient and cost-effective for the government to pay a limited number of fertiliser manufacturers an agreed price per tonne to cover the abatement cost.

- Encourage greater adoption of objective tools like nitrogen budgets and soil and plant testing, which follow Fertcare® stewardship

principles, to guide fertiliser use. Encouraging farmers to determine specific crop nutrient demand from existing soil nutrient availability allows them to determine what type and how much fertiliser product is needed to achieve good soil health and yield. Minimising surplus nitrogen will significantly reduce the potential for offsite nutrient impacts such as nitrous oxide emissions.

- Encourage greater adoption of precision agriculture tools that deliver spatially and temporally targeted inputs where and when most needed. Optimising nitrogen application to minimise nitrogen surplus at a sub-paddock scale (i.e., different application rates within a paddock) will help optimise farmers’ financial return on nutrient inputs and reduce the potential for offsite impacts. Variable-rate fertiliser application technologies have been available for some time, though adoption is generally low. However, the ability to gather and interpret agronomic and economic data and spatially apply varying rates of inputs, such as fertiliser, is challenging for many growers. Others with specialist skills are often needed to implement precision agriculture pragmatically. Policies that make precision agriculture knowledge and skills more widely available and demonstrate the benefits to growers should be considered.

- Incentivise the Australian manufacture of nitrogen fertilisers with a low carbon footprint and nitrogen inhibitors. The production of ‘green’ ammonia, as a feedstock to nitrogen fertiliser manufacture, is an evolving technology. Using renewable energy sources in manufacturing can reduce nitrogen fertilisers’ Scope 3 carbon cost. Nitrogen inhibitors and their ingredients are largely imported, which may lead to supply chain insecurity. Policy settings that support the local manufacture of inhibitors to secure the supply of existing and emerging inhibitors

under development in Australia should be considered.

- Encourage industry bodies, research organisations and state and federal governments to share data on fertiliser use, farm management practices and nitrous oxide emissions. The research effort in developing nitrogen best management practices will need to continue as farming systems evolve and new technologies are available. The various commodity research and development corporations and the fertiliser industry hold high-quality data on fertiliser use and management practices. The ongoing high-quality research undertaken across industries provides more complete estimates of nitrous oxide emissions, which will affect the Australia Greenhouse Gas inventory. There is an opportunity for more active data sharing among these groups on nitrogen use and nitrous oxide emissions. This will better quantify nitrogen budgets and nitrogen use efficiencies across applications and scales.

Commenting on the white paper, Professor Richard Eckard, who is a professor of sustainable agriculture at the University of Melbourne and Director of the Primary Industries Climate Challenges Centre, said the document provides a practical overview of the nitrogen cycle, the implications for food security, and the principal loss pathways including greenhouse gases and nitrogen use efficiency.

“I would encourage governments and other people interested in this topic to read this

white paper and consider the recommendations as we move toward lowering GHG emissions,” Richard said.

Read the executive summary and the full White Paper: https://fertilizer.org.au/ news-events-and-publications/fertilizer-australia-white-paper.

AT AGRITECHNICA IN HANNOVER, GERMANY LAST NOVEMBER, CROPSCANAG RELEASED THE CROPSCAN 4000VT ON COMBINE NIR GRAIN ANALYSER.

The CropScan 4000VT is the first fully integrated version of the CropScan analysers. The system is ISOBUS compatible with the latest Case IH and New Holland brand of combines. The CropScan 4000VT runs a Virtual Terminal within the CNHi Pro 700 and Intelliview IV combine monitors.

Based on 10 years of development through the CropScan 3000H and 3300H 0n combine analysers, the CropScan 4000VT includes a remote sample head that is fitted to the clean grain elevator of the combine, a fiber optic cable, communications cable and a waterproof and dustproof NIR spectrometer that is mounted on the wall of the combine outside the cabin. The NIR spectrometer includes an ECU (Electronic Control Unit) that runs the CropScan software and reads the combine’s CANBUS messages. The CAN messages for Yield, GPS, Crop Type, Grower-Farm-Field, Rotor Engage and

more are read by the CropScan ECU to control operation and data collection.

The CropScan is fully integrated into the CNHi Pro 700 and Intelliview IV monitors using a purpose designed VT screen for the CropScan 4000VT. Once the ignition is turned ON, the CropScan 4000VT screen is available on the Pro 700 and Intelliview IV monitors. The operator simply selects the Crop Type and Grower-Farm-Field menus.

Once the rotor is engaged by the operator, the CropScan begins to analyse the grain as it is collected in the remote sample Head. The protein, moisture, oil, starch and fibre (depending on the crop type selected) are calculated and combined with the Yield and GPS data from the CANBUS messages and then sent to the VT screen. Results are displayed on the VT screen every 3-4 seconds.

The field data is stored in the CropScan ECU and then sent

to the CropScanAg Cloud server, where farmers can access grain logistics, field maps and advanced analytics and performance maps using the N-GAUGE Apps on their mobile phone or tablet.

The CropScan 4000VT sample head has been designed to increase the sample cycle rate from small to large seeds including high moisture corn/maize and beans. The new design flow through cell allows the grains to flow faster through the chamber thus increasing the scan speed. The faster the flow, the higher the field map spatial density for protein, moisture, oil, starch, fiber and yield data. The CropScan 4000VT maps the data approximately every 4-6 meters. The new NIR spectrometer has been ruggedized with a new enclosure

for outside mounting and new operating platform running on a Linux OS to the in-cab app for Apple and Android OS.

The CropScan 4000VT has been bundled to include the N-GAUGE Harvest Manager app and SIM card subscription for five years streamlining all the data connectivity. Together the CropScan and N-GAUGE offers CASE IH and New Holland combine owners with a complete solution for measuring the quality (protein, oil and starch) and the quantity (yield and tank weight) in a seamless and fully integrated system.

For more information on the CropScan 4000VT and N-GAUGE apps, visit the CropScanAg web site www.cropscanag.com or contact CropScanAg at sales@ cropscanag.com.

Brandt field grain belts give you the edge you need, delivering high-volume performance with a powerful combination of speed, gentleness, and versatility.

The optimised intake and transition increases grain-flow efficiency to achieve peak performance in varying conditions, moving up to 12,000 bu/hr.

The double-lip intake seal keeps your crop on the belt where it belongs, increasing product retention while loading.

Brandt’s EZTRAK tensioning and tracking system keeps your belt aligned and properly tensioned.

Ian Vivers, who with wife Sally founded the Angus stud in the 1990s, says there are now three generations of the Vivers family on the farm, with their children and their spouses having joined them on their journey.

The farm has a long history.

Ian is a sixth generation farmer, with generations seven and eight already on the farm. A Vivers in one form or the other had continuous ownership of the farm since 1832, Ian says.

The farm was always a sheep and beef operation, with corn grown in the 1950s. Ian says his father John bred Hereford cattle, with Ian and Sally taking over in the 1990s.

As a result of succession in the early 1990s, Sally and Ian started with 1300 acres,

FROM LEFT: IAN’S SON HARRY, NEPHEW WILL, IAN, DAUGHTER ANNIE AND GRAND DAUGHTER THEA. IAN SAYS HE KEEPS THE FARM TOGETHER AND THE FAMILY ON THE FARM.

100 cows and 1000 ewes, and “some debt,” he says.

Today the Vivers family run their Angus stud across three farms.

The main farm, Eaglehawk, is west of Glen Innes, at an altitude between 950 meters and 1150 meters, on what is called the tablelands on the Great Dividing Range, Ian says.

EAGLEHAWK MARKETS APPROXIMATELY 250 BULLS EACH YEAR WITH A COMBINATION OF AN ON-FARM AUCTION SALE AND PRIVATE TREATY SALES.

The farm is approximately 4500 acres. It receives about 32 inches (800 millimeters) of rain annually, with moderate temperatures up to 37 degrees and lows that can dip to -8 degrees .

ALWAYS IN GOOD ORDER, AND BRINGS YOU A THICK EASY GOING CALF TO YARDS AT WEANING TIME.

“We rely mainly on temperate grasses, perennials, like phalaris, fescue, rye, clovers, and some chicory. We’re fortunate that we’re at the right altitude and rainfall to be able to grow such feed. We also do some fodder cropping,” Ian says.

The other farms have different climates. Two hours away, east of Armidale near Ebor, a second farm, Maiden Creek, was purchased in 2018. The farm is at about the same altitude as the Glen Innes land, but its weather patterns are influenced by climate coming from the east, it has higher rainfall and different soil types.

The third farm, Rivendell, is only a 20-minute drive West of the main farm. But it is 300m lower in altitude and has a longer growing season, he says.

It is 3200 acres, of which 2000 acres are developed for fodder cropping.

The main stud is run from the Eaglehawk farm and is also where sale bulls are finished. This farm is also the base for embryo collection.

Maiden Creek, east of Armidale, is an autumn calving cow calf operation and is used as a recipient farm, Ian says.

“It’s our lowest cost of production farm. It runs cows at low input.

“The third farm is a cropping farm and allows us to put young cattle on oat crops and a mix of winter and summer active pastures. It’s got a longer growing season and is better at wintering”.

Ian’s son, Harry, is the farm manager on the Armidale farm, Maiden Creek.

Daughter Annie’s husband, Jeremy, is the operations manager of both Eaglehawk and Rivendell, with Annie not only involved in the day-to-day business, but also leading the artificial breeding business and doing the administration of the farm and cattle records.

Daughter, Maggie, married a farmer, Ed Cordingley, and they farm on his family’s sheep and beef operation.

But she is a graphic designer and manages all Eaglehawk’s catalogue work.

“Sally and myself, we kind of fill in the gaps and we’re there to

be where we need to be to make things work.”

In 1994, Ian and Sally set up an artificial breeding contract business called Power Breeders to help make ends meet.

Through consultancy work attached to that business, Ian met a group of investors who needed help extricating themselves out of a bad investment position in Angus cattle.

He and Sally partnered with the

FROM LEFT: DAUGHTERS MAGGIE AND ANNIE AND SALLY.

group, Pacific Syndicated Beef.

As per the business goals, the syndicate exercised the 10-year exit plan leaving Ian and Sally independent owners of Eaglehawk Angus in 2006.

Ian says during those 10 years they reinvested their profits and income back into their own cows

IAN SAYS WHEN THE FAMILY DECIDED TO USE GENETICS FROM THE USA THEY DECIDED THEY NEEDED TO SEE THE HERDS THEY BUY GENETICS FROM WARTS AND ALL. NOW THEY VISIT THE US EVERY TWO YEARS AND DRIVE THOUSANDS OF KILOMETRES BETWEEN FARMS TO CAST AN EYE ON THE HERDS.

and building the Eaglehawk brand name.

Consequently the Eaglehawk Angus brand was able to continue and grow.

They now run around 700 registered cows and 500 commercial cows as well as followers.

In total, around 3000 head are on the three farms at any one time.

Eaglehawk markets approximately 250 bulls each year with a combination of an on-farm auction sale and private treaty sales.

Cows are blanket inseminated each year, with an average take rate of around 60%.

Their best bulls are kept back and go into their sire battery every year.

These bulls “pick up the 40%” of the cows that did not take to insemination, he says.

“The commercial cows and the bottom end of the stud herd have embryos put in. There’s an about 78% take rate on those.”

On Maiden Creek, there are 200 autumn calving stud cows and 500 dedicated recipient cows.

With embryos collected all year, programming and five lots of 100 cows in an embryo program, Ian says Novembers on the farms are manic.

Luckily for Ian, his youngest daughter, Annie, began working as an embryologist right after finishing high school, and continued the work through university, and now continues the work on the farm.

Ian is already an old hand and

unproven bulls into Australia,” Ian says.

“We then made a business decision that if we’re going to use American genetics, we’d need to do our due diligence in the US. It more than paid for itself,” he says.

has been working in the embryo field since 1994.

Ian says the stud took a number of years to find the right genetics that fit their long-term goals.

“Australia didn’t have what we were looking for. In the initial stages we trusted the catalogues. We were using imported sires from the US, but at that stage the Americans sold a lot of

The US Angus herd is 10 times bigger than the Australian herd and Ian says they wanted to take a different genetic approach to what Australian breeders were taking.

Now the Vivers family undertake a 11,000km trip through the US every second year and not only buy bulls that stay in the US but look at the herds “warts and all” before investing in genetics.

In the early 2000s, the Vivers

also established their own beef product, and Ian says this had an influence on what animals they chose for genetics.

“Over that period, and continuing today, there was a large industry push to look at marbling genetics and high performance growth genetics,” he says.

“There’s nothing like running cows through to the point of having a knife in your hand to work out which cattle are the best eating quality, and overall best performers from start to finish.

“We found that cattle that had the highest marbling and growth EBVs took the most resources and were not necessarily the best eating quality,” he says.

As a result, Ian shifted focus to a “maternal on-farm performance animal that’s always in good order, and brings you a thick easy going calf to yards at weaning time. Not only that, they were producing a superior product at a lower cost of production.

“We’ve achieved that by visiting herds and considering more than just breed values. EBV’s are secondary to the main goal of building a cow herd that can handle all conditions,” he says.

The cow of the future, says Ian, is one that has a big rumen that can process lower quality feeds and still extract the protein and the energy they need to create meat, milk and get in calf.

“I think there’s a hype over growth performance in feedlots. They’ve created an animal which

ANNIE GETS STUCK IN!

thrives on a high protein and high energy, small quantity diet which has to be fed by hand.

“When we started our beef product, a long fed Angus was fed for 150 days. Animals are now fed 250 days to extract the most marbling. If farmers are being attacked as environmental vandals, which is completely untrue, we should be reducing days on feed. We are working with two feedlots and have managed to get our cattle down to 180 days feeding, and falling,” he says.

Also, not all farms in Australia can afford to run animals that require high energy and protein as, for example, many areas of Queensland, coastal areas and semi arid areas of western NSW, Queensland and the Northern Territory have poorer quality feed.

“Anything we do to breed an animal that doesn’t require much maintenance, especially not cash out maintenance such as hay etc, does the industry a favour,” he says.

Cattle at Eaglehawk are grazed in mobs of 80 to 100 cows, in eight paddock cells of 400 acres each (approx. 50 acres per pad

dock) and rotated when visual assessment shows they need to move on.

“If we run into a drought we do some forage cropping and put corn silage away, we sacrifice paddocks for that. But that is plan B. Cows only visit each paddock once in winter.”

While marbling seems to have a big influence in the industry, Ian says there should not be too narrow a focus on ultrasound scanning for marbling.

Eaglehawk cattle are bred with very secondary focus on mar

AS A RESULT OF SUCCESSION IN THE EARLY 1990S SALLY AND IAN STARTED WITH 1300 ACRES, 100 COWS AND 1000 EWES, AND “SOME DEBT”, BUT THEY NOW RUN AROUND 700 REGISTERED COWS AND 500 COMMERCIAL COWS AS WELL AS FOLLOWERS. IN TOTAL AROUND 3000 HEAD ARE ON THE THREE FARMS AT ANY ONE TIME.

bling and have average scan results for IMF and yet they have taken blue ribbons at major paddock to plate competitions for meat quality.

However, when Ian ran an on-farm trial to test the difference in marbling scores on animals tested at 400 and 600 days, they found that an animal scoring

high on day 400 might not score as good on day 600.

“And yet it is okay to lodge figures at the society at either 400 or 600 days of age.”

Ian questions the accuracy of the final figures as a result of this anomaly.

“We do our scanning when it suits us from a management

TO HEDGE AGAINST CLIMATE UNCERTAINTY IAN SAYS THEIR STUD COWS NEED TO BE INSURED IN SOME WAY, ESPECIALLY DURING DROUGHT TIMES. “PUTTING HAY IN THE SHED AND SILAGE IN PITS IS AN INSURANCE POLICY. BECAUSE SELLING THEM IS NOT AN OPTION FOR US.”

point of view, instead of trying to scan when we will get the best scores,” he says.

“A heap of things can change in two hundred days, like, for example, hormones. Some animals grow earlier and/or have higher testosterone.”

In the same vein, cattle running in country with fourteen inch rainfall at 45 degrees will perform differently than cattle of the same age run under a centre pivot in an area that’s 26 degrees, he says.

The only sure fire way is to breed the cattle and get feed-

back from the feedlots after processing, he says.

Ian says climate is their biggest challenge on the farm.

“We have very poor intel from the climate experts. There are so many different apps and websites and they all contradict each other. It’s almost impossible to plan more than a few weeks ahead,” he says. “In 2023 the Bureau of Meteorology forecast another El Nino event predicting another major drought. So soon after the 2018/2019 drought it

caused a panic sell off of cattle and a market crash. The El Nino and drought didn’t eventuate, but it was too late. It was a disaster that didn’t need to happen and no one was held accountable,” Ian said.

To hedge against climate uncertainty Ian says their stud cows need to be insured in some way, especially during drought times.

“Putting hay in the shed and silage in pits is an insurance policy. Because selling them is not an option for us.”

The 2018 drought was especially tough as the Vivers had just bought a new farm, and made the conscious decision to keep all their breeding stock.

“We trimmed up all the edges. Because we run a registered stud operation we couldn’t sell the house. That’s our bricks and mortar, that’s our business. We chose to feed at great expense. It ended up being the right decision. We still had all our assets after the drought and they went up in value, much more than the cost of feeding.”

Ian says young farmers who do not have land in their family will find it almost impossible to buy land, as prices are high and banks won’t loan to anyone who doesn’t have a history.

With that in mind succession planning is critical.

“Succession has become an industry that’s created a whole

heap of pizzas. You only get a little slice of a farm. The succession industry wants to split it all up. We’ve made a conscious family decision to keep our farm as one unit. That’s how we can win.”

Keeping the farms in one piece makes long term financial sense, because a property as a whole has more value than a divided one and allows more leverage at the bank and more scale to create income, he says.

Ian says the role women play is critical in a family, as women “keep everything on track”.

Communication is also key in families, he says.

“The family has to be able to communicate on all levels and across all ages and sex.”

To that end the Vivers family all sit down with a coach once a quarter to work on their goals.

Besides quarterly meetings with a coach, the family also sits down every Monday for an operations meeting and, when necessary, addresses family and work challenges and works through them.

Ian says by continuing to grow and by continuing to keep everyone communicating and staying together with a common goal, he envisions the family staying on the farm for another 100 years.

ANNIE IS INVOLVED IN THE DAY-TO-DAY, BUT ALSO LEADS THE ARTIFICIAL BREEDING BUSINESS.

The Discordon is the combinded tool for stubble cultivation, decompacting and consolidation in a single pass. The Voyager Plough offers high performance and precise ploughing in all soil types with exclusive hardened mouldbourd technology for superior strength and durability.

The Tine Seeder is suited to a variety of soils and stubble conditions whilst still ensuring precise and accurate seeding. The AirCart is available in tow-behind and tow-between models in capacities up to 22,000L.

The Highline rock picker tine is designed to follow the reel. This aids in raising rocks whilst allowing dirt to fall through. The tines are also extremely durable as they are hard surfaced on both the top and bottom leading edges.

The Haulmaster Chaser Bin has exclusive features and technology aimed at maximising unloading efficiency and increasing productivity whilst being extremely simple to operate.

Spread a wide range of materials including fertiliser, lime, and gypsum and take your spreading program to the next level! With exclusive design features and technology for precise application of product whilst being extremely durable and simple to operate.

The TruFlex headers are designed to be lightweight but sturdy. Hydraulically controlled depth wheels allow for optimum ground hugging for harvesting in almost any terrain.

IT’S AN OUTLANDISH INTRODUCTION TO A CATTLE FARMER WHO, FOR THE MOST PART, SEEMS PRETTY DOWN TO EARTH.

The larger-than-life name tag is part of Gillian Fennell’s online persona as she and husband Mark share their life with followers, raising cattle on Lambina Station, a million-acre rangeland property in the Pedirka Desert, 450km south of Alice Springs in northern South Australia.

And Lambina is very outback. The closest shop is in the town of Marla, a 70km drive away.

Freight for the surrounding areas is delivered there once a week, meaning a long drive to collect or do the grocery shopping over rough roads. The mail and school work for their youngest child, Eleanor (8), is delivered by plane from Alice Springs to the letterbox on their airstrip at the back of the house, on a Wednesday.

“We hear them come in – they’ll drop stuff off and take off again,” says Gillian.

Eleanor will eventually head off to boarding school in Port

Pirie as her two older brothers have, only seeing their parents in the holidays. Gillian and Mark also went to boarding school as youngsters in Queensland and it was here they first met.

Sharing their life on the land online, with humour, images and short videos adds a layer of fun and creativity to their lives. The more thoughtful blog posts, and industry commentary helps followers see the realities of production behind the humour.

Gillian initially got into social media to see what other farmers were doing on their land.

“I found it a fascinating way to learn about other people and other agricultural systems in other countries. They all seem to have challenges, including with

their governments and policy. I’d like to think they’re learning about agriculture from me as well.”

And it wasn’t just farmers who began following her, watching what was going on in stock cameras set up around the station, the cattle and wildlife that regularly visited, unwanted trespassers and camels, appreciating her sometimes sweary sense of humour.

Social media also became her way to bridge the divide between farmers and their urban counterparts.

A lot of farmers are too focused on their own issues, Gillian believes, while it’s in their own best interest to reach out - especially to those in towns and cities.

“We need urban people to understand farming life better so they feel more connected to people living on the land and the countries’ food systems,” she says. “There’s a lot of negativities around farming and people often don’t make the connection we are real people. We may not have the exact same struggles or issues but we all want what’s best for our families, access to a decent education and health care – these are universal things.

“Someone has to extend their hand and I think agriculture has to do it first. We need to connect on a human level or nothing will ever change.

“We’re such a small number of people, and a small number of the vote base. No political party has to pay attention to us and our needs. We have all these people in the cities, who have no idea about farming, saying we need to protect the environment. We need these people in cities to also say we need to look after the

farmers too - to protect our production systems, to protect our food sources.”

Gillian has also been critical of conservatism within the agriculture industry’s leadership. Failing to engage as the industry faces new pressures including from climate change is doing their membership a disservice she believes, as it locks the industry out of senior level discussions around planning, strategies and policies.

“You lock yourself out of the room when, if you’re genuinely serving your members and your industry, you should really be staying in there until they turn the lights off and kick you out.”

With these big picture views on agriculture it’s perhaps no surprise that Gillian is an industry representative on the board of Livestock SA, as well as being on a couple of committees of Cattle Australia (Cattle Council of Australia).

This sees her periodically off the station at meetings and conferences, meeting new people and hearing their stories.

Her followers often get to follow along on these trips.

While Gillian loves the outback, she admits it can be a bit drab and as she’s a bit of a magpie, something sparkly is usually part of her ensemble when she heads off the station. It’s also why she called her recent start-up media/ communication business Glitterati Media.

Gillian admits station life was tougher than she expected when

BOARDING SCHOOL IS AN EXPECTED PART OF LIFE IN THE OUTBACK FOR STEPHEN AND ELEANOR.

she and Mark first settled in to help run the property 21 years ago after Mark’s parents decided they wanted a change to farming life in Queensland.

While Mark’s family had always farmed, Gillian had grown up in Richmond, a small town in northwest Queensland whose main claim to fame was Minmi - Australia’s best preserved 100-million-year-old dinosaur skeleton, and the marine reptile museum Kronosaurus Korner.

Travelling around with her dad when he was working as a station mechanic, and watching her grandfather shearing wasn’t enough to prepare her.

Nor was the contracting job she did with Mark when they first got married and she left her “cushy” office job to maintain and repair windmills on the Barkly Tablelands in the heat of summer when most of the work was done. This saw them both living rough and sleeping for weeks at a time in swags.

Climbing to the top of 40-foot structures with a great big spinning wheel on the front to do maintenance can be dangerous she says, and they had a lot of close calls. And coming across venomous brown snakes while

UREA IN FEED SUPPLEMENTS HELPS CATTLE TO BREAK DOWN NUTRITIOUS MULGA TREES.

climbing down wells to the pumping infrastructure at the base was also memorable. While windmills may be an iconic image of outback Australia, they are fast disappearing from the landscape.

A windmill will only pump when the wind is blowing, but there’s also no real way to stop it when it is blowing. Once the tanks and everything else are full, the water pumps out onto the ground. This is one of the reasons people have been moving to motor pumps which are easier to run and maintain.

On the station Gillian and Mark are transferring their last two windmills over to solar pumps which have a shuttle switch and will stop pumping automatically once the tanks are full.

“The sun shines pretty much every day, but we can go weeks without enough wind to pump water for the cattle.”

Completely off grid, power on the station has been a work in progress since they moved in. For a long time, they ran a generator. But this went off at 10pm and didn’t start up again until 6am. This meant no water during the night with the fridge and freezer also turning off with food going off quicker, especially in summer.

Gillian and Mark are used to the heat now and don’t think it’s anything extraordinary. But with no air conditioning in the early days, Gillian was really suffering when carrying her first baby through summer with temperatures hitting 45 degrees Celsius. To get some sleep, she ended up with a mesh gazebo set up on the front lawn with a bed in it. The sprinkler would water the grass and

when the power went off, she’d sleep in the gazebo overnight with a cool breeze coming off the wet grass.

When Alan was born, bottle-feeding meant boiling water with the gas stove and torch light.

For Stephen, born five years later, there was at least 24-hour lighting.

By the time Eleanor came along in another five years, Mark had designed and built a solar power

COMPLETELY OFF-GRID, A SOLAR POWERED MICROGRID SUPPLIES ALL ENERGY NEEDS.

system providing 24-hour power and water, and as a winter baby she even had a heater.

These days, the house has evaporative air conditioning. Not as power hungry as refrigerated air-conditioning but, if it isn’t humid, it’s enough, she says.

The solar system 15 years ago had panels covering the top of a 20ft container which was full of acid batteries needing to be topped up with water every week.

Mark’s recent upgrade sees a 17kW solar array with a 24kW three phase output microgrid supplying power to the buildings on the station. The panels are smaller and more efficient, with six lithium-ion batteries that look like bar fridges.

“That’s enough storage for our three dwellings and the work shed, and enough battery stor-

age to run all that for about two days if we get cloud cover.”

The output can be expanded to 25kW in the future if needed, with each of the buildings able to have additional solar panels added.

Falling component prices saw the upgrade come in at $60khalf the price of the original system.

Because they’re so isolated, contractors are pretty thin on the ground, and they need to be self-sufficient and do things themselves.

This has seen them build up all the equipment they need – loader, grader, backhoe, crane, and a couple of trucks, even if most of it is over 30 years old.

Mark’s repair and maintenance skills have also come in handy in recent years and enabled him to discover a love of flying. He is now happiest when in the air at the controls of the two-seater ultra-light gyrocopter they bought.

Marketed as a recreational flying machine and made in Germany, the AutoGyro comes in a box ready for home assembly. Much cheaper than a helicopter, the AutoGyro can cover hundreds of kilometres and can see Mark gone for six hours, says Gillian. Able to do their own servicing, the aircraft is also cheap to run. Their manoeuvrability at low speeds makes them ideal for life on a cattle station, although they aren’t meant to be used for commercial purposes like mustering and there are rules around how high they can be flown.

“He’s passionate about it and

takes it very seriously. If we could afford it, he’d love to have a helicopter,” says Gillian, whose airsickness sees her stay firmly on the ground.

Aircraft ownership, particularly fixed-wing, is popular among landowners in the area including for mustering while others use contract helicopter pilots.

Motorbikes were used a lot more for mustering in the past, but labour shortages and a lack of experienced riders with the skills to muster out in the bush - without stressing the animals too much, means smaller numbers are being used.

“A lot of blokes just like to chase shit but that’s not helpful to anyone,” she says.

The stony plains on the property also make riding at speed, for the inexperienced, difficult and dangerous.

Pedirka Desert covers around half the land and has undulating red sand hills covered in trees and native grasses. The Mulga wattle tree is common, and with an unusually long tap root, is able to withstand long periods of drought. It’s also very palatable to sheep and cattle, giving them both food and shade, with urea part of a feed supplement for the cattle which helps them to digest the woody matter.

Loamy clay soil makes up the rest of the property and, while it is stony, it grows good feed with enough rain.

AN AUTOGYRO SEES MARK ABLE TO COVER BIG ON-FARM DISTANCES.

Not surprisingly in this part of the country rainfall is never high - 80 inches annually in the extreme west falling to just 5 inches in the east, with drought fairly common.

This sees the couple running 5000 Charbray cattle - a cross between French Charolais cattle and American Brahman cattle. These hardy animals are well suited to the heat and desert conditions. Their light colouring helps keep their bodies cooler and they are also resistant to humidity, parasites and diseases. The challenging conditions mean they only breed from their own cattle which have naturalised here, as outside animals often don’t survive.

Because of the large distances on the rangeland and limited fencing infrastructure, over time Gillian and Mark have learnt to use the cows natural herding instincts so they move to new forage largely on their own.

By putting in more water points and then turning them on and off, the cattle shift themselves. This also helps to maintain biodiversity and the health of the country, by reducing overgrazing, says Gillian.

“They’ll graze out to a maybe 10km circumference from a water point, maybe 25 if they’re young cattle or steers.”

They also don’t control joins, having bulls in with the cows all the time. They have found the cows cycle naturally on feed availability and rain fall, and become fertile when conditions are such they will be able to raise a calf.

They do, however, make sure the bull size is matched to the heifer size, with only young bulls going in with maiden heifers so they aren’t being covered by big giant one tonne bulls, she says. Maintaining production through droughts sees them change weaning practices - taking calves off earlier, along with culling unproductive cows and other unproductive animals out of the herd, ensuring enough food is left for the productive animals.

They also try and breed traits that reduce the need for intervention for animal welfare with the focus on polled cattle, small birthweight bulls, big frame breeders with wide hips so calving is easier.

Having to handle the cattle through the yards alone, a lot of breeding effort goes into a quiet temperament (research has shown calmer cattle are also more heat tolerant than excitable ones).

This sees a difficult temperament as one of the four T’s they cull animals on.

The others are teeth which need to be in good order for obvious reasons, toes too long making it harder for animals to travel, and “bottle” teats that are large and difficult for calves to latch onto.

“We want them to live, breed and survive with as little human interference as possible,” says Gillian.

Because the cows are producing calves as conditions allow, animals are sent to market sporadically. But being a small operation, they are still able to maintain a good cash flow and remain financially stable.

Angus and Hereford cattle are very popular beef breeds in SA, says Gillian. With buyers less familiar with Charbray cattle and unsure how they will go in feedlots, the animals don’t do so well going through the yards.

Along with wanting to avoid agent and yard fees they sell their stock privately.

This has seen them recently buy a farm block 900kms south in the Flinders Ranges where they can stockpile large numbers of cattle to sell, and where prospective buyers can come and see them.

Purchasing a B-double Mack truck to get them there means they are now self-reliant with transport.

At 10 - 11 hours drive away, it is also within livestock transport guidelines before the animals would need to be unloaded and spelled.

It’s been a valuable addition to the business, says Gillian, as they also grow lucerne there. When they deliver cattle, they can then bring hay back to the station.

While Gillian’s industry involvement and activity on social media doesn’t generate revenue, it has seen her guest writing columns for agricultural media, making appearances at events and participating in conference panels.

Along with her boutique social media company she is also involved with Australian agricultural platform Farm Table.

Gillian and Mark can be found on Twitter/X @stationmum101, Instagram & Threads - @stationlife101, and Linkedin - Gillian Fennell.

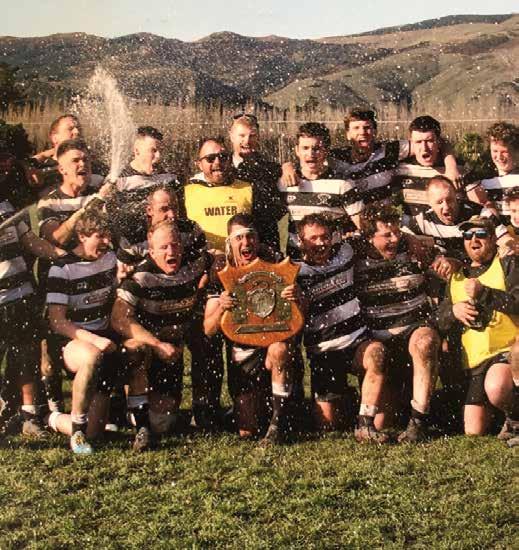

JACK OWEN BOUGHT HIS FIRST BALER WHEN HE WAS JUST 16 AND STILL AT SCHOOL.

He grew up on a lifestyle block in Ladbrooks, on the outskirts of Christchurch. His mother’s family were farmers, and Jack always wanted his own block.

That first baler was an old conventional baler. Contracting with it seemed a good way to finance his aspirations. Also Jack just likes machinery and being out on the land.

Summertime baling also paid for his B Comm (Agriculture) degree at Lincoln University, which he finished in 2019.

“The contracting got busier and busier, so when I finished Lincoln, I went full-time.”

He still makes conventional bales, and has added round baling, wrapping and drilling to his repertoire.

THE BUSINESS IS FULLY EQUIPPED TO MAKE CONVENTIONAL HAY BALES AND ROUND HAY AND SILAGE BALES.

“Individually wrapped bales are big around here. There is a lot of silage trading to meet the needs of the dairy industry.”

Because he is so close to Christchurch there are also lots of lifestyle blocks in his district, and he has many as clients. He is also increasing his farming clientele, both dairy and arable.

He says farming is varied around the Ellesmere area.

“I had a couple of guys who were mentors and taught me and got me going. One was a local farmer, David Hight, and another was mobile mechanic Grant McCarthy.

“Both of those guys know machinery and they were there at the drop of a hat if I needed help to keep things going,” Jack says.

across ditch the PROFILED IN NZ’S RURAL CONTRACTOR & LARGE SCALE FARMER FEBRUARY/MARCH 2024, WE VISIT OWEN AG, IN CANTERBURY, NEW ZEALAND.

This was the start of Owen Ag. Jack started making conventional bales over summer beginning 2013.

FROM HIS BASE AT LADBROOKS JACK OWEN LOOKS AFTER DAIRY AND ARABLE FARMERS AS WELL AS LIFESTYLE BLOCKS IN THE ELLESMERE AREA.

Some soils are heavy and hang onto moisture through summer and there is also lighter country.

“Even the drylands hang on well in summer. This means we have a long baling season. We start in September and continue into May.”

Another source of income is buying standing grass and selling it, mostly as silage round bales. “A lot goes to the West Coast. I have some good clients who buy off me every year.”

Jack leases 20 ha and makes balage to sell plus he grazes a few head of cattle. He says the farming that he does and the contracting work well together. He would like to expand the farming side in future.

Most contractors struggle to find staff. So far Jack has had no problems. “I have one full time guy and two part-time guys. Hayden James is full-time and Ryan Gallagher and Ben Thornley are part-time. They are all really

good operators. They think outside the box and fix problems.”

When Jack started the business his grandad, Barclay Hall, was a big help.

“Grandad was helping me out and driving a rake well into his 80s. My father also helped me a lot in those early days.

“My dad, Andrew, was a rural banker but he would swap the desk for the tractor seat. My mum Anne still helps out a lot and does

a lot of running around.”

He says it is easier getting staff as he has upgraded his gear.

“Now everyone wants to come and drive a tractor. A big part of it is knowing everyone in the area.

People support you.”

Keeping small and focusing on a couple of services has kept the stress levels lower than they would be if he had more staff.

“I am not trying to find 20 guys. It’s a sweet spot not being too

big, and there are not so many overheads. On a wet day it is much easier to keep Hayden and myself amused, rather than find work for lots of drivers.”

The stressors that remain are those that all contractors face, including price hikes for plastic and diesel, health and safety, and road travel.

Jack says the roads are the biggest challenge to their safety because the Selwyn district’s

Goldacres Series 2 sprayers are Australian designed, engineered & manufactured sprayers for your farming enterprise.

JACK OWEN IS CAPTAIN OF WAIHORA RUGBY CLUB’S SENIOR B TEAM, WHICH WON THE ELLESMERE COMPETITION LAST YEAR.

Having a less stressful winter job gives Jack Owen time to spend with family and play sport. He is an open-side flanker and captain of the Senior B team at Waihora Rugby Club.

“We actually won the Ellesmere competition last year, and the Under 85 team I play for won the National Club Cup up in Auckland.”

The rugby team is both a great way to just be human and hang out with friends while training. Because his team mates are farmers, it can also bring in more work.

“The team has been good at supporting me and one day I will sponsor them.”

CLIENTS FOR CONVENTIONAL BALES INCLUDE LIFESTYLE BLOCK OWNERS, HORSE STABLES, AND EVEN A FEW FARMS.

A DUNCAN ECOSEEDER IS A RECENT ADDITION TO THE BUSINESS.

population is growing quickly. “You’ve got to be on the ball with health and safety. We use industry guidelines for contractors.”

Jack’s tractors are all blue and it is a family tradition. “I grew up with New Holland. Grandad had them.”

He still has his first tractor, a 2003 New Holland TS90 with a 16x16 powershift transmission. “I have had the TS90 since I was 16. It is a bloody awesome tractor and bullet-proof. It is a little tractor but it has done everything.”

Now it’s on 9000 hours and semi-retired towing the conventional baler or raking. Theoretically it is worth nothing now as a trade in, but it remains useful.

The second tractor is a 2008 TS100A with a Quicke loader. Jack likes its short wheel base and zippy turning circle because he spends so much time in small paddocks.

“It is well spec-ed, the cab is a lot bigger than the TS90’s, and it is well laid out. It is a well-proven model.”

The newest recruit is a T6070 which Jack got to run his McHale Fusion combi baler. It boosts to 160 hp.

A fourth tractor is an old Ford 4610 that Jack bought off a Lincoln University researcher. It does some raking and is a handy spare tractor to have. “It’s been a great tractor.”

Mowing is done with a 3m Krone EasyCut disc mower. Jack says it follows contours nicely. It has a modular bar and is centre-swung.

Last year Jack replaced a module and was away again within hours. He then repaired the broken section to have on hand as a spare.

For some jobs, he gets a subcontractor, Max Templeton Contracting, in to do some mower conditioning.

Max has a Kverneland mower/ conditioner. He does the lucerne mowing because the conditioner does a good job of kinking the stems which helps it dry off faster.

Jack says Max has been another mentor, who has helped him out.

Owen Ag also has a four-rotor Lely Lotus tedder, a single-rotor Kuhn rake, and a V rake.

He bought the single-rotor rake to work in front of the conventional baler. “It makes a lovely fluffy row, especially in some of the

heavy crops we do.”

The V rake is bulletproof. It does the raking in front of the round balers and it has fully hydraulic steering.

The latest conventional baler is a New Holland BC5060. Jack likes the density of the bales it makes as well as its hydraulic pick-up and its camera, which allows him to see what is happening at the back.

“It also has a moisture meter. It gives a real time reading of the bale moisture. If a client thinks you should be baling but it is not quite fit you can show them the number on the screen.”

In good conditions the NH BC5060 can pump out 500 bales an hour. It was the first piece of equipment Jack bought new.

He bales conventionals for lifestyle blocks and horse stables. A few farmers also want conventionals. They are predominantly after grass hay, but he also makes some pea and barley straw. He does the straw mainly for clients but he also does some for himself to sell.

This season Jack added a McHale Fusion 3 Plus to his fleet. He wanted a baler/wrapper because they are more efficient and it means one less driver and tractor.