EQUIPMENT

Massey Ferguson introduces the new fleet flagship MF 9S

PROFILE

& LARGE SCALE FARMER

Sam Monk - an amaizing life

FEATURE

What’s new in sprayers and sprayer technology

AUSTRALIAN ISSUE 140 JANUARY/FEBRUARY 2024

FEATURE What’s new in precision agriculture

NOW’S THE TIME TO INTEGRATE YOUR WEED CONTROL 2024 EARLY ORDER Scan to place and order for the best price of the year. Hamish NSW +61 482 709 728 Ned VIC +61 409 969 227

AML, Ashcroft House

Tancreds Road, R D 2, PO Box 37151, Halswell, Christchurch 8245

Ph: +64 3 329 6555 Fax: +64 3 329 6550 www.agrimedia.co.nz

Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping, Australian AG Contractor & Large Scale Farmer, NZ Novachem Manual.

EDITOR

Scott Wilson

Mob: +64 21 725 061

Email: scott@agrimedia.co.nz

ADVERTISING SALES

Pulse – Media Sales

Justin Bowler

Ph: 0429 699 553

Email: justin.bowler@mmg.com.au

CIRCULATION

DDI: +64 3 329 6555

Email: admin@agrimedia.co.nz

PRODUCTION, LAYOUT & DESIGN

Mark Winstanley

Email: art@agrimedia.co.nz

IN THIS ISSUE....

INDUSTRY NEWS

Printed by PrintGraphics Pty Ltd

AC

© AUSTRALIAN AG CONTRACTOR AND LARGE

SCALE FARMER - No part of this publication may be reproduced in any form without the prior written permission of the publisher. Opinions expressed in this publication are not necessarily that of the publisher and suggest independent advice be sought before acting on information or suggestions contained herein.

CONTRIBUTIONS - Editorial and photographic contributions are welcomed and should be sent directly to AML. Editing of submissions is at the sole discretion of the editor and will accept no responsibility for unsolicited material.

03 Major announcement for Hardi Australia and manufacturing in South Australia

04 John Deere named Inclusive Employer for third year in a row

06 Flexi-Coil customers’ chance to pack their bags for Canadian adventure

07 Penske and Deutz partnership comes to a close

08 Connection and education at the centre of renewed ag innovation event

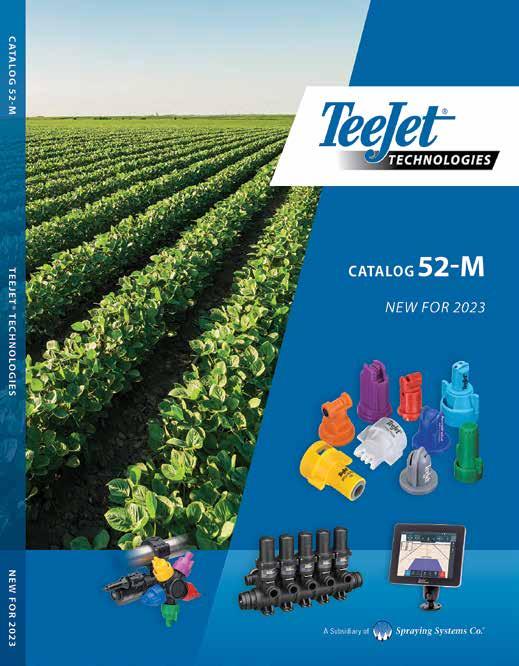

09 New TeeJet catalogue now available

10 WA mixed farming business values reliability in machinery as part of demanding year-round operation

TECHNOLOGY

12 Success with Fleabane Control

PROFILES

14 Fernlee Station, regenerating the land and people

18 Sam Monk - an amaizing life

24 Across the ditch: ‘Plenty of hedges to trim in Taranaki’

FEATURES

28 What’s new in sprayers and spraying technology

36 What’s new in precision agriculture

EQUIPMENT

43 Combi-Rt from Combilift, the no compromise poultry forklift

44 South Australia’s Seed Terminator changes the face of farming on the global stage at Agritechnica

45 Robust seeder bar designed for durability

46 Massey Ferguson introduces the MF 9S – the new straightforward and dependable fleet flagship 02

PUBLISHERS

THE EDITOR: People helping people JANUARY/FEBRUARY 2024

FROM

01 28

PEOPLE HELPING PEOPLE

AGRICULTURE AND FARMING THROUGHOUT AUSTRALIA PRIMARILY HAS ONE AIM.

Whether it’s a small farm, a single-operator contractor, a major supplier or a multi-faceted corporate, the idea behind the operation is to turn a profit and make money.

Some are good at it and can see an opportunity where they can jump in, create a business and build a strong business foundation, while others find it a constant battle and grind away every day, with a mindset built on tenacity, stubbornness and a never-say-die attitude.

Some, however have a much wider vision and view their day-to-day business as a bit-part in a much larger machine.

I’ve been really privileged in the weeks leading up to this issue to be trading messages with Susannah Simpson from Fernlee Station in Northern New South Wales.

This unassuming and rather humble woman successfully runs a pretty impressive cattle operation, something she had built up after taking over when the place wasn’t exactly top-shelf.

In the face of drought and, more recently, being wary of the bushfires that have ravaged the region, Susannah has continued

to battle through conditions she admits are tough… but it’s her ‘sideline’ that really impresses.

As part of Fernlee’s offering, a self-sufficient campsite allows visitors to take in the unique beauty this part of the country has on tap, but the reasons behind it run much deeper than that.

Susannah believes strongly in paying it forward to those she sees as Australian heroes – the first responders and the veterans who have served Australia and its citizens. For those people, camping at Fernlee is free, where they can take the time to cope with the trauma or stresses that have been caused by what they’ve had to deal with, both domestically and when serving overseas.

“It is an honour to be able to give a free holiday to who we see as our Australian heroes,” she messaged me as we were preparing this issue.

The full profile on Susannah, Fernlee Station and the story behind it starts on page 14. I hope you enjoy reading it as much as we’ve been honoured to put it together.

INDUSTRY NEWS 02

SCOTT WILSON

MAJOR ANNOUNCEMENT FOR HARDI AUSTRALIA AND MANUFACTURING IN SOUTH AUSTRALIA

THE HARDI BRAND IS SYNONYMOUS WITH AGRICULTURE IN AUSTRALIA. ORIGINALLY FROM DENMARK, THE HARDI BRAND HAS BEEN IN AUSTRALIA FOR OVER 50 YEARS. HARDI AUSTRALIA WAS ESTABLISHED AS A MANUFACTURING SITE IN 1997 IN SOUTH AUSTRALIA AND IN 2002 HARDI ACQUIRED DISTRIBUTION BUSINESSES IN QUEENSLAND, VICTORIA, NEW SOUTH WALES AND WESTERN AUSTRALIA TO CONSOLIDATE HARDI IN SOUTH AUSTRALIA. TODAY, ALL OPERATIONS ARE BASED AT A 10-HECTARE SITE IN CAVAN IN ADELAIDE’S NORTHERN SUBURBS. VISITORS TO OUR FACTORY OFTEN COMMENT THAT THEY HAD NO IDEA THIS TYPE OF MANUFACTURING WAS STILL DONE IN AUSTRALIA.

Since 2007, Hardi has been owned by Exel Industries, the largest specialised manufacturer of crop protection sprayers in the world. A recent decision by Exel to adopt a proposal put by Hardi Australia will see a dramatic change to Hardi’s future manufacturing activities in South Australia.

Up to this point, manufacturing has been limited mainly to Hardi’s market leading range of trailed sprayers and assembly of French manufactured self-propelled sprayer drive trains. At a meeting in Paris in July, Exel Industries agreed that over the next five years, Hardi Australia will move toward ground up design, development and manufacture of a specialist range of broadacre self-propelled sprayers at its Cavan site in Adelaide. This step allows Hardi Australia to develop a Centre of Excellence

here in Adelaide for the design and manufacture of cutting edge broadacre self-propelled crop protection sprayers, specifically for the Australian market.

Ultimately, this move will mean more people employed by Hardi Australia as it continues to grow. Engineers, electronic specialists, innovation and importantly, assembly and manufacturing personnel will swell Hardi’s current team of one hundred and thirty people.

Another key element of the plan is that from 2024, Hardi will become Australian distributor for Exel-owned brand Apache, manufactured by ET Works in the USA. This move will provide Hardi with a competitively priced, mechanical drive sprayer with approximately 4,500 litre capacity. Apache sprayers are renowned for their simplicity and reliability and have been sold in

Australia for a number of years. Hardi is committed to global food security through the safe and sustainable application of agricultural compounds. We are especially proud of our contributions here in South Australia, where we’ve achieved remarkable milestones. Hardi’s GeoSelect ® selective spraying technology is receiving global acclaim as the next step to conventional camera sprayers. GeoSelect ® was entirely developed in Adelaide and is now in the process of being commercialised globally. All Australians have a right to be proud that such cutting edge technology has been developed here in our state.

GeoSelect was further highlighted in the documentary series ‘The AgTech Revolution,’ where our groundbreaking technology for precision farming, GeoSelect, took center stage. Developed by our innovation team in Australia and manufactured locally, this technology has already made waves through the ACM network and discussions are underway for broader TV network coverage.

Our flagship creation, the Rubicon, stands as the nation’s largest self-propelled sprayer. When originally released, Rubicon earned the prestigious New Release Award at the Yorke Peninsula Field Days in 2017. Last year marked the launch of the Saritor Mallee 7000, a locally inspired update to our self-propelled sprayer range. Distin-

guished by the revolutionary HIVE (Hardi Integrated Vehicle Experience) console system, it offers seamless and intuitive operation.

At Hardi Australia, we’re proud of our roots and local impact. We embody the spirit of ‘global made local.’ Our team diligently assembles and manufactures the majority of our products on-site, supporting local jobs and contributing to the region’s economy.

Hardi Australia is deeply ingrained in the local agricultural and economic fabric. Our commitment to local production not only fosters valuable manufacturing jobs but also ensures that more of the funds invested by farmers in equipment remain within the country.

Our range of cutting-edge agricultural machinery, encompassing sprayers, nozzle technologies, and innovative farming solutions, has consistently driven productivity and efficiency across the region. With an unwavering focus on technological advancement and sustainable farming practices, we are dedicated to positively shaping the agricultural landscape.

As we embark on a new strategic plan for Hardi, including relaunching the iconic Rubicon and introducing a new sprayer in 2024, we are committed to contributing to the growth of Australian manufacturing and employment opportunities in South Australia.

03

JOHN DEERE NAMED INCLUSIVE EMPLOYER FOR THIRD YEAR IN A ROW

DIVERSITY COUNCIL AUSTRALIA (DCA) HAS AWARDED JOHN DEERE AUSTRALIA AND NEW ZEALAND INCLUSIVE EMPLOYER STATUS FOR 2023-24, IN RECOGNITION OF THE COMPANY’S COMMITMENT TO DIVERSITY AND INCLUSION.

DCA announced the 82 employers to earn a place on the list, with John Deere being one of only six employers to receive the title three times, having been recognised in 2021-22 and 2022-23.

To make the list, participants must prove their commitment to diversity and inclusion by having employees complete an in-depth survey to map the state of inclusion in their workplace and produce results that exceed national benchmarks on a series of key measures.

John Deere Australia and New Zealand Managing Director, Luke Chandler, said achieving Inclusive Employer Status for the third year in a row was a proud moment.

“Each year, this assessment has provided us with valuable insight on where to focus our efforts to ensure we offer an inclusive workplace for everyone,” he said.

“An inclusive workplace is not the result of the actions of one, but the actions of many.”

As Head of People and Culture at John Deere Australia and New Zealand, Camilla Kelly has led the company’s Diversity, Equity and Inclusion (DEI) journey.

MEMBERS OF THE JOHN DEERE AUSTRALIA AFTERMARKET TEAM CELEBRATING WORLD INCLUSION DAY RECENTLY, (L-R) KURT PETERSEN, RAVI NAYAK, ANJANA NIPUNA, DAMITH GUNARATNE.

“DEI is multi-layered, requiring time, dedication, and a holistic approach to fully understand its complexities,” Camilla said.

“It can challenge deeply held beliefs and raise difficult questions. It’s not about checkboxes or quotas, but rather it’s interwoven in everything we do and everything we want to be.

“We have taken the time and energy to expand knowledge across the company – not just talk.

“Our policies, talent selection criteria and workplace practices have been updated, including introducing industry-leading gender-neutral parental leave.

“We’ve also worked on developing leadership capabilities and implementing DEI frameworks that empower everyone to lead initiatives that move the needle on DEI.”

John Deere’s Australia Aftermarket team recently led such an initiative, holding an event at the Brisbane office to celebrate

JOHN DEERE AUSTRALIA AND NEW ZEALAND HAS BEEN AWARDED INCLUSIVE EMPLOYER STATUS FOR THE THIRD YEAR IN A ROW.

World Inclusion Day. Staff were encouraged to share their personal stories, food from their cultural backgrounds, and discuss perspectives on what inclusion means to them.

“Inclusion is all about creating a work environment where everyone feels respected,”

Aftermarket Marketing & Communications Specialist, Laura Pozniak-Elphick, said.

“You should feel like you can bring your true self to work every day, and John Deere really embraces that.

“While your colleagues always try to be their most professional selves, it’s important to remember they are individuals with families and lives outside work. Someone could be smiling on the outside but struggling on the inside, so we just need to be mindful of each other and be as kind and inclusive as possible.

“If your corporate values are rooted in diversity and inclusion, that extends to your ability to recruit the best people, which ultimately elevates your whole business. I think there’s also a halo effect where if a company is a good corporate citizen, they’re more likely to be offering their products and services in the best possible way.”

With innovation as one of John Deere’s key values, Camilla said diversity and inclusion was paramount to the company’s success.

“As a smart industrial company, we need both diverse talent and an inclusive culture to develop this competitive advantage,” she said.

INDUSTRY NEWS

04

TINE SEEDER BARS & AIR CARTS

AVAILABLE NOW LIMITED STOCK FOR 2024 SEEDING!

Equalizer Precision Seeding Equipment has been tested and proven in Australia’s tough sowing conditions.

Limited stock for the 2024 seeding season are now available. Configure your seeding equipment to suit your specific needs!

PRECISION

options to suit your soil needs

equalizer tine seeder

9m, 12m, 15m, 18m & 24m seeding widths

Single or double chute seed boot

4 knife point options

Narrow or wide press wheel alternatives

Quick seed depth adjustment clip

maximise your seeding capacity

equalizer air cart

8,000L, 12,000L, 16000L & 22,000L capacities 2 & 3 bin configurations

Tow-behind or tow-between

Digi-Star Scale System

Liquid distribution option

08 6154 5999 WARINGA.COM.AU

UNTIL IT’S TOO LATE! VISIT WARINGA.COM.AU TO LOCATE YOUR NEAREST DEALER LIMITED STOCK AVAILABLE FOR 2024

SEEDING EQUIPEMENT DON’T WAIT

FLEXI-COIL CUSTOMERS’ CHANCE TO PACK THEIR BAGS FOR CANADIAN ADVENTURE

THE FLEXI-COIL RANGE OF SEEDING EQUIPMENT IS INTERNATIONALLY-RENOWNED AND NOW A UNIQUE PROMOTION IS GIVING FLEXI-COIL CUSTOMERS THE CHANCE TO SEE JUST WHERE THIS WORLD-CLASS REPUTATION ORIGINATES.

David Gibson, Brand Leader for CNH Industrial Seeding and Tillage, Australia/New Zealand, said the Flexi-Coil range was well-known for its innovative design features and high manufacturing standards, and CNHI was keen to recognise Australian customers for their support.

Under the promotion, Australian farmers who place an order before December 15 for a FlexiCoil 5500 precision hoe drill, 6000 Series disc drill or any air cart in the range – with delivery before the end of May 2024 –book themselves a seat to Canada in July.

The trip includes a tour of the Flexi-Coil manufacturing facility in Saskatoon, attendance at the famous Calgary Stampede and a visit to a large Canadian field day, Ag In Motion, just outside Saskatoon.

“We know we’re looking at potentially more challenging times ahead for farmers, so we’re offering customers this opportunity to head away for a while after they finish seeding next year to see where and how their seeding equipment is made, and get a first-hand look at how farmers in another part of the world operate their businesses,” David said.

“The visit to one of the world’s biggest rodeo events in Calgary is just the icing on the cake and a really unique way to reward our Flexi-Coil customers for their loyalty to the brand.”

A recent dealer training event in South Australia, which also included 185th birthday celebrations for CNH Industrial brand Horwood Bagshaw, had focused on the attributes of Flexi-Coil seeding equipment with good

EQUIPMENT TO CONSIDER ORDERING NOW – AND RESERVE A SPOT FOR A TRIP TO THE CALGARY STAMPEDE.

stock levels currently available.

“These are best-in-class seeding products and this customer opportunity reflects the belief CNH Industrial has in their ability to deliver the highest level of

performance for farmers, and ultimately improved productivity down the line,” David said.

For more information on this opportunity, contact your local dealer.

DAVID GIBSON IS URGING CUSTOMERS IN THE MARKET FOR SOME NEW FLEXI-COIL SEEDING

DAVID GIBSON IS URGING CUSTOMERS IN THE MARKET FOR SOME NEW FLEXI-COIL SEEDING

Visit our website for this customer story & others. (08) 8357 4437 Multiple liquids in one pass - SAVE FUEL & TIME - Measured & controlled delivery - TARGET INPUTS - Boost germination, protect crops, improve soil - INCREASE YIELD Engineered to deliver target rates - RELIABLE OPERATION - Easy retrofit onto any liquid cart, drill or planter - LIQUID READY. Visit www.liquidsystems.com.au Liquid Systems (SA) is an Australian company that has been manufacturing liquid delivery systems since 2002. INDUSTRY NEWS 06

Lee Lonergan, NSW “It’s critical for the liquid application to be very accurate to make the numbers work. With this system, each seed gets just the right amount, so there’s no wastage and it’s applied right at the seed source.”

PENSKE AND DEUTZ PARTNERSHIP COMES TO A CLOSE

AFTER MANY SUCCESSFUL YEARS OF WORKING TOGETHER, PENSKE AUSTRALIA & NEW ZEALAND AND DEUTZ AUSTRALIA & NEW ZEALAND ARE BRINGING THEIR PARTNERSHIP TO A CLOSE.

Representing the Deutz engine portfolio across the industrial, mining, power generation and agricultural sectors, Penske’s team will continue to supply Deutz engines until mid-January.

Customers will be taken through a comprehensive handover process to ensure a smooth transition.

“We have proudly represented the Deutz engine portfolio across a range of industries and to a range of customers over several years,” said Matthew Smith, Executive General Manager of Off-Highway, Penske Australia & New Zealand.

“We intend to focus our people on higher power nodes and future technologies. We thank Deutz for a successful partnership and wish the team all the best.”

Deutz Australia CEO Craig Chamberlin said a full handover program would be imple-

mented to deliver seamless customer support.

“Through this transition period and beyond, existing and new Deutz customers will receive thorough support through the Deutz representative network across Aus-

MATTHEW SMITH, EXECUTIVE GENERAL MANAGER - OFF-HIGHWAY, PENSKE AUSTRALIA AND NEW ZEALAND.

tralia and New Zealand,” said Craig.

“On behalf of the Deutz team, I’d like to thank Penske for their partnership over many successful years, and we wish them all the best. We look forward to a smooth and efficient transition for all our customers.”

07

STOCK AVAILABLE FOR IMMEDIATE DELIVERY! Like to know more? visit www.jcbcea.com.au or Ph: 1300 522 232 BOOK A DEMO WITH YOUR LOCAL JCB CEA DEALERSHIP TODAY! OFFERING OUTSTANDING FLEXIBILITY IN CONTROL AND THE ULTIMATE IN OPERATOR COMFORT.

CRAIG CHAMBERLIN, CEO, DEUTZ AUSTRALIA.

CONNECTION AND EDUCATION AT THE CENTRE OF RENEWED AG INNOVATION EVENT

REGISTRATIONS NOW OPEN FOR AGSMART CONNECT IN TAMWORTH IN MARCH, 2024.

There’s a new name and a sharpened focus, but an event that has showcased agricultural technology for the past two years is returning with the same promise of highlighting to the industry the enormous potential and opportunity in the agricultural innovation sector.

Organised by ACM Rural Events, AgSmart Connect is back in Tamworth from March 6 to 7 next year, where it was first staged in 2022, with exhibitor registrations and sponsorship opportunities now open.

Lupe Prada, Commercial Manager ACM Rural Events, said the change from AgSmart Expo to AgSmart Connect was a reflection of the renewed emphasis on not only presenting new technology updates and developments, but also giving attendees the ideas and knowledge to put them into practice in their own agricultural businesses.

“Three years on, we’re more than an expo now, so we wanted to make the information and education seminars the heart of the event. This event is about education and bringing people together. Connecting them through agri-innovation, AgSmart Connect will be a forum for agri-innovation providers to engage with farmers, investors and the agri-curious from across the industry,” Lupe said.

“We want to show ag technology innovation is accessible to anyone who wants to grow the profitability and viability of their business. This is about demonstrating there’s no reason to be intimidated by the amazing

level of innovation out there, it’s about giving attendees the tools and information they need to employ it practically in their operations.”

AgSmart Connect will be held at the Tamworth Regional Entertainment and Conference Centre (TRECC), with seminar rooms for speakers at the centre of the event space and the exhibitor stands wrapping around these speaker areas. A new feature next year is the addition of an outdoor networking space with food trucks, and a business lounge for exhibitors.

“As well as being an educational and seminar-led event, it’s also a platform for suppliers of agricultural and agro-industrial prod-

ucts, services and technology nationally to connect and explore new opportunities and perspectives that could benefit and grow their own businesses,” Lupe said.

Registrations for AgSmart Connect are now open, with the incentive of a special early bird offer that gives exhibitors the opportunity to lock in their stand at the 2022 price. This is open until December 15 2023.

“In 2024, we’re raising the bar on this event because we see the enormous potential and opportunities around it. We know that a big part of its success is our exhibitors who commit time, resources and energy to participating, so we want to give something back to them with this early bird deal that reflects 2022 pricing, a saving of 10%,” Lupe said.

Potential exhibitors can visit www.agsmartconnect.com.au, email agsmartconnect@ austcommunitymedia.com.au, or phone 02 6768 5800 to learn more.

For businesses interested in coming on board as a sponsor, there are also attractive packages available, and a dedicated sponsors page can be found on the same link.

“With connection at its core, AgSmart Connect is Australia’s most accessible agri-innovation event, connecting attendees to like-minded exhibitors, who are there to offer expert guidance and knowledge around technology innovations. By providing a platform for education and connection, our aim is to inspire growth in agri-innovation as a means of helping secure the future of agriculture in Australia,” Lupe said.

Potential exhibitors and sponsors can also contact Lupe at lupe.prada@austcommunitymedia.com.au or on +61 472 679 196, or ACM Rural Events sales executive Ananya Singhal at ananya.singhal@austcommunitymedia.com.au or on +61 435 034 091.

INDUSTRY NEWS 08

NEW TEEJET CATALOGUE NOW AVAILABLE

TEEJET HAS RENEWED ITS COMMITMENT TO KEEPING GROWERS AND CONTRACTORS INFORMED OF THE LATEST DEVELOPMENTS IN SPRAY APPLICATION WITH THE RELEASE OF ITS 2023/24 CATALOGUE.

TeeJet Australasia Technical Specialist, Jake Lanyon, said the 200+ page catalogue 52-M, and TeeJet’s new look website (www. teejet.com) are loaded with content-rich information, making them a valuable resource for anyone involved in spray application.

Renowned for over 50 years as the ‘spraying bible’, the TeeJet catalogue is specifically designed for end users in the spraying industry such as primary producers and contractors.

“There is a complete nozzle selection guide combined with a comprehensive number of charts and tables as well as

handy technical information including formulas and conversion factors, sprayer calibration, droplet size and spray drift,” Jake said.

The TeeJet Catalogue 52M is available to download at www. teejet.com and printed versions will soon be available from all TeeJet distributors in Australia and New Zealand.

TeeJet Technologies manufactures a comprehensive line of products including agricultural spray nozzles for various herbicide/fungicide applications, boom components, valves/ manifolds, strainers, and spray guns, as well as guidance systems, sprayer control systems,

continues to invest in research and development to advance precision application and control technology.

09

ISOBUS job computers, assisted steering systems and other precision farming products. In addition, TeeJet Technologies

Cultivation Machinery www.mandamaustralia.com.au www.joskin.com.au

WA MIXED FARMING BUSINESS VALUES

RELIABILITY IN MACHINERY AS PART OF DEMANDING YEAR-ROUND OPERATION

WEST AUSTRALIAN CONTRACTING

BUSINESS WILLYUNG FARMS HAS WRAPPED UP ITS HAY CUTTING FOR THE SEASON, BUT ITS BALERS WILL HAVE ONLY A SHORT HIATUS BEFORE GOING TO WORK DURING THE UPCOMING HARVEST, AND BEFORE THAT THERE’S THE MATTER OF A FEW THOUSAND AVOCADO TREES TO TEND TO.

Sandy and Narelle Lyon run what can only be described as a highly diversified business, Willyung Farms, a 600ha operation about 15km north of Albany.

As well as hay contracting, the business comprises a 1000-head capacity feedlot, has 3000 avocado trees and supplies straw to multiple free-range piggeries and chook farms in the area.

Sandy, a second-generation farmer whose parents arrived from the UK in the early 1970s and settled on the Albany property, said the hay contracting side of the business had just wrapped up for the season, about a month earlier than usual due to the seasonal conditions.

“We normally start late September and finish about December, but it just stopped raining which shortened the season. We had very good conditions for baling though so we got through it pretty quickly,” he said.

The contracting business has a crew of up to six during the season and runs two current-model Case IH LB 436 HD balers pulled by a pair of Case IH Optum 300hp tractors. The balers and tractors, bought through

Farmers Centre, are in their third season. The Lyons also employ the machines at home to bale silage.

“We’ve used Case IH balers for 25 years and they’ve been great. When we went from a standard baler to high density, we really noticed the quality and increased weight of the bales and the improved capacity of the balers. Going up to the larger balers, we needed a higher horsepower tractor, and the Optum 300s have been really successful – we’ve had a great run with them,” Sandy said.

The balers and tractors will now swing into action for this year’s harvest, which is underway in parts of Western Australia. Willyung Farms also have contracts to supply straw to many of the free-range piggeries in

the region, and more recently to a number of broiler farms.

“Straw is used more and more because since limits were introduced on logging, sawdust has become limited. We buy it out the back of a header and then bale it, stack it, cart it, so that keeps us busy during harvest season,” Sandy said. “Harvest has just started down our way and that’s about a month ahead of usual, too.”

He said with the hours clocked up by the balers, they needed robust and reliable machinery that could go the distance.

“They’ve really stood up to the demands of our business, they’re easy to maintain and consistently produce high quality bales under a variety of conditions,” Sandy said.

Back on the farm, the Lyons have just started harvesting avocadoes from their trees, although Sandy said it was a lighter crop this year with only average prices currently. The avocadoes go to an agent in Melbourne and they’re distributed around Australia from there.

Rounding out the operation is the feedlot, with the business, which has a contract with Coles, backgrounding at least 1000 head at any one time, and the feedlot having a 1000head capacity.

“There’s a lot going on, some days you’d say too much,” Sandy laughs.

For more information on the Case IH baler range, contact your local Case IH dealer.

INDUSTRY NEWS 10

THE LYON FAMILY’S CASE IH BALER AND OPTUM TRACTOR AT WORK ON THEIR MIXED FARMING BUSINESS NEAR ALBANY WA.

Photo credit: Narelle and Zoe Lyon.

Voyager Plough

The Discordon is the combinded tool for stubble cultivation, decompacting and consolidation in a single pass. The Voyager Plough offers high performance and precise ploughing in all soil types with exclusive hardened mouldbourd technology for superior strength and durability.

Min-Till Tine Seeder

The Tine Seeder is suited to a variety of soils and stubble conditions whilst still ensuring precise and accurate seeding. The AirCart is available in tow-behind and tow-between models in capacities up to 22,000L.

The Highline rock picker tine is designed to follow the reel. This aids in raising rocks whilst allowing dirt to fall through. The tines are also extremely durable as they are hard surfaced on both the top and bottom leading edges.

The Haulmaster Chaser Bin has exclusive features and technology aimed at maximising unloading efficiency and increasing productivity whilst being extremely simple to operate.

Spread a wide range of materials including fertiliser, lime, and gypsum and take your spreading program to the next level! With exclusive design features and technology for precise application of product whilst being extremely durable and simple to operate.

The TruFlex headers are designed to be lightweight but sturdy. Hydraulically controlled depth wheels allow for optimum ground hugging for harvesting in almost any terrain.

AVAILABLE NOW AT Product Range Get everything you need FOR 2024 SEASON! CONTACT US TO SECURE YOUR STOCK 08 6154 5999 | WARINGA.COM.AU AS Spreader Chaser Bin

Picker TruFlex Razor

Air

Rock

Discordon

Carts

SUCCESS WITH FLEABANE CONTROL

WE ALL KNOW FLEABANE IS A HARD WEED TO CONTROL. SO WHEN AGRONOMISTS ACHIEVE GOOD CONTROL OF THE, IT’S WORTH MAKING A BIT OF NOISE ABOUT.

There have been many varied spray mixtures tried over the years, all with mixed success.

So far, most attention has been with multiple mixtures of herbicides to achieve acceptable results. But, more recently, agronomists have been using the spray mixtures with superior adjuvants to attempt to achieve an improved job.

In Chinchilla, South West Qld, weed control was achieved on Fleabane plants at the rosette stage, up to approximately 20cm diameter, just prior to stem elongation and flowering. The spray mix used was Glyphosate 450 at 1.2L/Ha; 2,4-D Amine 625 with Promax at 500ml/100L water as the spray adjuvant to improve penetration, and coverage.

A similar mix had been used in the past using a wetting agent plus sulfate of ammonia to overcome water hardness, however,

Promax the penetrant adjuvant is suited to use in hard water.

When the job was checked 2 weeks after it was sprayed the good control of the Fleabane evident. A real benefit is one less product for the farmer to have to worry about carrying and mixing.

“With good growing conditions during the last couple of seasons where in-crop post-emergent sprays could not be done due to wet conditions, farmers face the real prospect of Fleabane getting out of control.”

“We used to have weeds we couldn’t kill, but by choosing Promax as the adjuvant to use with the herbicide mix, for the first time we have had 100% kill” Greg Smith, wheat and chickpea farmer.

“Initially we chose Promax as it works well in our hard water, but we have found that it helps to control these hard to con-

Above: Effectivness of the spray mix including Promax was excellent on fleabane rosettes.

trol Fleabane. Greg used 2,4-D amine 625 at 2L/ha, some with Promax at 400ml and some with 500ml/100L.

“The Fleabane was 9-10 inches (22 – 25cm) high. When we checked the job out it was clear that the 500ml/100L rate of Promax had done a superior job killing the weeds, and doing it quicker,” he says.

According to Greg, people are taking notice of his results.

“The local agronomist has been out to have a look at our results, and I noticed that there was stock of Promax in the store. We under-stand they have some farmers doing test strips. We also have neighbours who are looking seriously at using spray mixes with Promax.”

12 TECHNOLOGY

For more information contact us today on 1300 669 556 grevilliaag .com.au PROMAX ® MAXIMUM POWER DIRECTIONS FOR USE NOT TO BE USED FOR ANY PURPOSE OR IN ANY MANNER CONTRARY TO THIS AUTHORIZED UNDER APPROPRIATE LEGISLATION. GENERAL INSTRUCTIONS PROMAX will maximise the performance of horticultural and agrochemical sprays by increasing droplet deposition, the target. PROMAX is designed to aid the formation of uniformly sized spray droplets to reduce water evaporation PROMAX mixed sprays are rain fast within minutes of application. PROMAX is non-phytotoxic at recommended commonly applied chemicals. can be used with herbicides, fungicides, insecticides and other foliar sprays. MIXING INSTRUCTIONS 1. Fill spray tank to three quarters of required water volume. 2. Add pesticide to spray tank whilst mixing continuously. 3. Add measured amount of PROMAX to the spray mix. 4. Top up with water to required volume whilst mixing. CAUTION DO NOT mix pesticides together before adding to spray tank and add individual products one at time. To avoid excess uptake of pesticide material damaging crop always test the rate applied by application to small with product. PROMAX is compatible with most commonly applied chemicals including herbicides, fungicides, insecticides and always check the pesticide label and in doubt test mix small quantity or talk with your local nursery or chemical PROTECTION OF WILDLIFE, FISH, CRUSTACEA AND ENVIRONMENT DO NOT contaminate streams, rivers or waterways with the chemical or used containers. KEEP OUT OF REACH OF CHILDREN Store in the closed, original container in a well-ventilated area, as cool as possible. Do not store for prolonged or preferably pressure rinse empty containers before disposal. Add rinsings to spray tank. Do not dispose of undiluted crush, puncture and bury empty containers in local authority landfill. not available, bury the containers below specifically marked and set up for this purpose, clear of waterways, vegetation and roots. Empty containers should Do not swallow. Avoid contact with skin or eyes. Wear rubber gloves, overalls and goggles or face shield. Wash use. FIRST AID If poisoning occurs, contact Doctor or Poisons Information Centre Ph: 13 1126 Australia wide or New Zealand PROMAX is supplied as high grade product and is suitable for the purpose which is expressly intended and with the directions for use. Because Grevillia Ag has no control over handling, storage or use of PROMAX, the implied representations or warranty (other than non excludable statutory warranties). This product is sold on the user assumes all risks of the handling and use of PROMAX as well as the results obtained from its use. P A E boomspray CDA Hand Gun Orchard Plantation Spraying R T SSpot Spraying 15 - 30 mL per 10 L waterHigh Volume - per Ag Pty Ph: 07 3205 1788 Fax: 07 3205 4327 admin@grevilliaag.com.au APVMA Approval No 58699/1/0904 58699/5/0904 58699/10/0904 58699/20/0904 58699/200/0904 SPRAY ADJUVANT ACTIVE CONSTITUENT: 700G/L CANOLA OIL ESTER FOR USE WITH: Herbicides, Insecticides, Fungicides and foliar fertilizers to improve coverage, rain fastness and uptake in plants and reduce spray drift. Proudly Australian In an Emergengy Dial 000 Police or Fire Brigade PROMAX200LTR Grevillia Ag Pty Ltd A.B.N. 36 083 323 817 PO Box 5510 Brendale Qld 4500 23 Duntroon Street, Brendale Qld 4500 Australia Ph: 07 3205 1788 Fax: 07 3205 4327 E-mail: admin@grevilliaag.com.au READ SAFETY DIRECTIONS BEFORE OPENING AND USING Promax Spray Adjuvant helps to unleash the power of your sprays Proven results on 9 Fleabane 9 Lantana 9 Blackberries Rainfast in 20 Minutes! Ag Contractor Sep-Oct 22.indd 1 14/12/2023 8:21:43 PM

Agrispare pty limited 104 Levels RoadCavan SA Ph.: (08) 8260 5419www.agrispares.com.au POLMAC S.r.l. Via Statale Sud, 13741037 Mirandola (MO) ITALY Tel.: +39.0535.20004Fax: +39.0535.26595info@polmac.it www.polmac.it DISTRIBUTED BY

fernlee station,

REGENERATING THE LAND AND PEOPLE

“IT USED TO BE A DESERT, A MAN-MADE DESERT,” SAYS SUSANNAH SIMPSON ABOUT FERNLEE STATION IN NORTHERN NEW SOUTH WALES.

But the 2000 acre (809 hectare) station is coming to life after Susannah took it over eight years ago and began implementing regenerative agriculture principles.

“There was dust and dirt everywhere, and very little ground cover. The water just ran off,” she says.

Since she has focused on retaining and growing ground cover, water absorption improved significantly with the farm recovering well.

Susannah runs a working cattle enterprise that is home to a predominantly Hereford line, with some speckled park hybrids in the mix.

“I’ve got breeders and a grazing enterprise,” she says.

The approximately 300 cows in the commercial line of beef cattle acclimated well to the farm.

Susannah’s family, and her cattle, came from Augathella in Queensland.

“My grandfather, Alfred Simp -

ZARLEAH, SUSANNAH AND RYLIE.

son, came back from Papua New Guinea as a soldier. He got a soldier settlement block at Augathella in Queensland.”

Both her grandfather and her father Max passed away when Susannah was young.

“We sold that country about 20 years ago and then I moved in towards this area.

“It was very rundown when I bought it. It was a man-made drought. I’ve been slowly improving it. It was extremely overgrazed,” she says.

Despite the previous overgraz-

THE FARM USED TO BE OVERGRAZED BUT REGENERATIVE AGRICULTURE PRINCIPLES MEANS IT IS RECOVERING WELL.

ing, cattle now play a massive role in regenerating the land.

“We’ve been enjoying watching the transformation of grazing and regenerative agricultural principles. Four years ago, we had the worst drought in modern history. It hung on very well.

PROFILE

14

Partly because of those principles that we had and tried to stick to. We’re in another drought now.”

On top of severe drought conditions, other local land holders have also had to fight large scale bushfires that have destroyed what was left of grazing in the Ashford and surrounding areas, Susannah says.

Cows now have calves at foot, but even though they are hanging on, Susannah admits conditions are tough.

Susannah does not let tough times get her down but rather focuses on what she can control.

She is a coordinator with Aussie Hay Runners and helps coordinate hay for farmers in need.

Susannah says the regenerative principles she applies are all about ground cover.

Cattle cell graze paddocks for about three weeks, and only return to a paddock again in six months, which gives the area plenty of time to recover.

The size and condition of a pad-

dock play a part in how long cattle stay on.

Paddocks on the station are between 100 to 300 acres each, she says.

“I spin them around. For instance, the 300 acres usually has a mob on it for a month or three weeks. I’m always watching and adjusting the system. I’m very much out in the paddock observing. Conditions are always changing,” she says.

“At the moment, with the drought, they’re on a very quick spin. It’s hard at the moment because it’s so severe,” Susannah says.

The station’s grazing is predominantly native grass species, with some improved pasture. Super and clover mixes are planted strategically in the grass country every year, she says.

“We have slowly been improving the growth.”

Because the property is “hilly”, not all areas can be tackled, but mobs are used where needed.

“It [the land] is still healing, but

we saw a massive result within 12 months of buying the place and implementing that strategy, with cell grazing and regenerative agricultural practices.”

Fernlee station should get about 29 inches (700mm) of rain every year.

“We haven’t had proper rain for about eight months now,” she says.

As a drought strategy, Susannah’s partner, Jeff, is working on the Boggabri mine on a fourday-on, four-days-off schedule, which brings in a regular income.

A few years ago Susannah

SUSANNAH RUNS A WHALER HORSE STUD. WHALER’S ARE GREAT STOCK HORSES.

also began diversifying the farm income by allowing campers onto the property.

The undulating hilly country and the Severn river that snakes through the station is a prime spot to camp, she says. Campers get well manicured lawns next to the river, fishing holes, a fire pit and places to hike.

“We get really good Murray cod fishing. We also have a colony of platypus that people love seeing, and koalas. Some of our campers told me spotted quoll come up to the fire at night.”

The spotted quoll are extremely rare.

The campsite is for self-contained campers only with no ablution or shower facilities, and a ‘what you bring in you take out policy’. This is usual for camping in such remote areas, she says.

The site draws “campers and caravaners that love remote camping and self-sufficiency”.

“We had thought to develop things further, with toilets and showers but everybody really

15

JOHN SHEARER

AGROWDRILL CONVERT YOUR OLD DRILL TO A DISC SYSTEM Better manage your stubble with the RYAN-NT Double Discs. This ideal upgrade turns your old drill into a no-till disc planting rig that can save you up to 50% on fuel. Achieve minimal disturbance when you are planting into stubble or pasture. MANUFACTURERS OF SEEDING EQUIPMENT FOR OVER 50 YEARS RyanNT Get your old seeder into no-till action! Contact Paul Ryan today 0417 354 617 paul@ ryannt .com.au ryannt .com.au THE KIDS HELPING OUT WITH THE CATTLE.

DUNCAN

just wants to see nature. They don’t want to see structure.”

The campsite is a full-time job, on top of the cattle, Susannah says.

“It is bringing in a great surprising amount of income.”

A huge benefit of the campsite is that Susannah does not have to leave the farm and can be near her four kids, Zarleah (11), Jaxon (5), Zoey (3) and Rylie (1).

The campsite draws all kinds of adventurers.

“Since Covid, there’s a lot of families that are homeschooling their children. We get a lot of families that are on the road.

“We see a lot of grey nomads and lots of families during the Christmas holiday bringing their children to learn about nature, fishing and bushcraft.”

Besides honeymooners, there have been wedding proposals and even an elderly gentleman who brought his wife out for what would be her last trip, she says.

At Fernlee both the farm enterprise and camping is about more than just an income and is also all about giving back.

At the campsite the average citizen pays, “but anybody that is a veteran or first responder stays free. That’s how our family gives back to Australian heroes.”

Susannah has multiple reasons for giving back to veterans and first responders. Firstly her grandfather was a soldier. She has also seen search-andrescue teams perform searches in the remote areas where she farms, and felt for them, especially when they have to deal with a fatality.

“My respect grew for them, and I thought maybe they need to get away from it all and can camp with their families or by themselves on the river.”

The parents of Australian war hero Corporal Cameron Baird VC MG, who was killed in action in Afghanistan in 2013, were one of Susannah and Jeff’s first guests at the campsite and since then the campsite has become a getaway for many Australian heroes.

With the same concerns for heroes in mind, Susannah also uses horses for equine therapy with trauma victims.

It has been proven that horses are effective in helping people with trauma, anxiety and post traumatic stress disorder.

“I’ve helped people that have been in the police force or veterans that come back from Afghanistan. I’ve also helped women in domestic violence. I see huge results with any kind of trauma. It’s really positive what the horses can do,” Susannah says.

Susannah’s journey into horse therapy began when she introduced a police friend to her horses after suffering severe trauma.

“She got amazing results and, from that, I’ve now formulated what I do with the horses. I will

SUSANNAH RUNS A WORKING BEEF CATTLE ENTERPRISE WITH PREDOMINANTLY HEREFORDS, BUT SOME SPECKLED PARK HYBRIDS IN THE MIX. SHE AVERAGES ABOUT 300 COWS.

PROFILE 16

A GUEST WITH A MURRAY COD.

CAMPERS NEXT TO THE SEVERN RIVER.

THE SEVERN RIVER IS A PRIME SPOT FOR CAMPING, WITH LOTS OF FISHING HOLES AND A POPULATION OF PLATYPUS TO BOOT.

SUSANNAH IS A COORDINATOR FOR AUSSIE HAYRUNNERS. HAYBALES KEEP SOME OF THE FARM GOING.

read the person’s body language a lot more than their words.”

When dealing with adults and trauma Susannah relies on a gentle giant to help her.

“I’ve got a big Percheron cross Andulisian. She’s about 16 hands but she’s gentle.”

When helping younger people or children, Susannah relies on her daughter’s miniature horses and ponies.

Susannah says people suffering from trauma build trust with horses by simply leading them around and, for example, brushing them.

They often become very emotional and begin opening up, she says.

“A lot of people come here and have the thousand-mile stare;

BUSHFIRES HAVE IN SOME AREAS OF ASHFORD DESTROYED WHAT WAS LEFT OF THE DROUGHT STRICKEN GRAZING.

after staying here or working with the horses there’s a twinkle back in their eyes.”

Susannah says she reads people’s body language more than listening to what they say.

“Working with horses gives them confidence,” she says. “I have been involved with horses my entire life.”

To that end Susannah runs a

Whaler horse stud, with one stallion and about 19 mares.

She uses the horses wherever she can on the farm, such as mushing cattle, but says with a young family it can be hard to find time for riding.

Some of the yearlings are sold, but she often gives horses away to veterans or first responders that need a horse.

17

HARDI Australia www.hardi.com.au Email us: hau marketing@hardi com Call us: 1 300 042 734

AN AMAIZING LIFE sam monk -

SAM

MONK ENJOYS A CHALLENGE AND ISN’T AFRAID OF HARD WORK. HE ALSO LIKES TO LET OPPORTUNITIES TAKE HIM WHERE THEY WILL AND, IF THEY LOOK PROMISING, HE’S HAPPY TO GIVE THEM A GO.

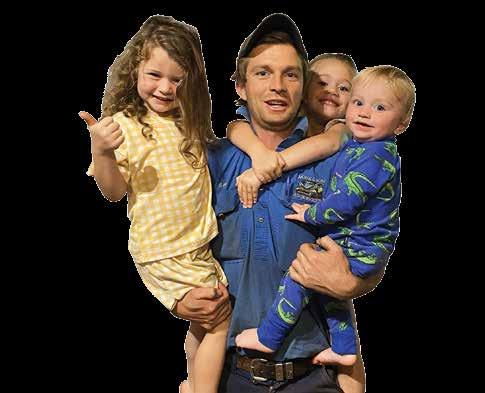

This open-mindedness now sees Sam with multiple business interests including dairy farming, running one of the biggest silage contracting operations in Victoria, to owning a share in a local pub – at just 28 years old.

And if that weren’t enough, he also has three young childrenMatilda (7), five-year-old Ellie, and Charlie (2) to wrangle into line at times.

While there’s no denying he’s been remarkably successful, Sam credits his parents for not only having his back as he set out on his own by acting as guarantors, but also instilling in him a strong work ethic.

“My drive for success is derived from my parents work ethic and commitment to their work,” he says.

Dairy farming has long been a part of the Monk family tradition,

AT 28 YEARS OLD, SAM HAS BUILT UP A RANGE OF BUSINESS INTERESTS, AS WELL AS PLAYING DAD TO MATILDA (7), FIVE-YEAROLD ELLIE, AND CHARLIE (2).

with Sam the third generation farming the original 200-acre dairy farm his grandparents owned in Cobden, 200 km west of Melbourne, in south western Victoria.

His father, Rod, had increased the original dairy farm to 515 acres, running it by himself, while his mother, Clare, became a very successful primary school principal at Warrnambool West Primary School.

“Dad is one of the hardest

MONK AG SERVICES IS NOW ONE OF THE LARGEST OPERATIONS OF ITS TYPE IN VICTORIA.

workers I know, while Mum has just recently been awarded Outstanding Primary Principal of the Year at the 2023 Victorian Education Excellence awards,” he says.

Sam loved the lifestyle growing up on the family dairy farm in this lush part of the country.

18

PROFILE

Along with a high annual rainfall, Cobden sits on the southern border of the Lakes and Craters Country - the fourth largest volcanic plain in the world. This has seen the area covered in rich volcanic ash from past eruptions, making it a highly productive agricultural area.

There are also dozens of lakes dotted across the area formed from extinct volcanos. Dams on some of these lakes see irrigation companies supplying water to surrounding agricultural operators.

While still at school, Sam appreciated not having to find part-time work elsewhere as there was always paid work for

him on the farm - milking for his father.

Things started happening quickly for Sam when he started thinking about a career.

Along with farming, Sam also enjoyed working with machinery so, when his parents insisted he have an apprenticeship lined up before he could leave school, he began a diesel mechanic apprenticeship with Swayne McCabe in Warrnambool.

But he also wanted to eventually become his own boss. So, at around the same time, he used the wages he had earned from milking to raise the finance he needed to buy a John Deere 467 silage special baler - with his

parents acting as guarantors. Hooked up to the farm tractor, Sam’s silage contracting operation also got under way.

The hands-on mechanical experience was of real interest and very useful. While his two brothers and sister headed off to do their own thing, Sam stayed on the farm with his parents, building his contracting business. Three years later he was contracting full time and working on the farm when work was a bit slow.

It didn’t take long to realise that there weren’t enough hours in the day to do everything by himself and in those early days he really appreciated having good

SAM HAS A RANGE OF MOWERS IN HIS FLEET, ABLE TO TACKLE A WIDE RANGE OF JOBS.

mates who would come and help out with driving.

But as the business expanded the workload got too much and Sam quickly realised he needed more staff.

An advertisement for a tractor driver on the Gumtree website, which connects jobseekers in the UK with jobs in Australia, saw Sam taking on a young Irish driver, Nigel Sheridan, from West Ireland, County West Meath. Nigel had been backpacking

i4M CLOUD SERVER IMPROVES FARMING EFFICIENCY AT REDUCED COSTS.

Precision Agronomics Australia, the developer of the industry leading i4M system, has launched the new Version 2 i4M Cloud Server to seamlessly transfer prescription maps to machinery operating in the field.

Improvements to the Version 2 Server include :

• Automatic detection of the rate control layer from the shape file

• Automatic checking of maps for errors, fixing common prescription map issues

• Users can link an Agronomist to an account, allowing direct transfer of prescription maps from Agronomist to Machinery

• A migration tool allowing users to sync older maps across to the Version 2 server

For existing i4M users, it only takes 3 simple steps to move map data across to the new cloud server.

i4M is designed by a team of local engineers and backed by a local support network to ensure you maximise your investment in Precision Agriculture Technology.

Contact us now on +61 8 9072 0542 or by email at admin@precisionag.com.au

19

JCB LOADERS, FITTED WITH BUCKRAKES, ARE USED ON THE SILAGE STACKS.

MONK AG SERVICES SPILLING OVER INTO NSW AND SOUTHERN AUSTRALIA AS IT CONTINUES TO GROW.

around Australia at the time with a friend, when he spotted the ad and applied. His friend then also came to work for Sam.

That was the start of also hiring international skilled workers or travellers, mostly from Ireland, England and New Zealand. Along with skilled locals, they have become an essential element of the business, says Sam.

Nigel still works for the company, having settled in the area and started a family.

He is now an integral component within the business, Sam says, essentially in charge of a Claas forage harvester and its crew throughout the year.

With the contracting business taking on a life of its own, there wasn’t a lot of spare time for dairy farming anymore, but Sam saw it as too good a business opportunity to move away from.

While there is dairy farming in every state, Victoria is the dairy industry capital for the country with nearly 65 percent of the milk produced annually coming off its farms.

There has been a reduction in milk production overall in the country over the last couple of decades, but the dairy industry remains strong in Victoria.

Sam is confident the numbers will continue to stack up long term, when compared to returns for dry stock farming. It’s also an industry he knows and understands well.

This confidence saw him invest in a 556-acre dairy farm when it came up for sale next door to his parent’s farm four years ago,

with Sam putting a manager in place to run it. Another farm joined the fold a couple of years later and then a third.

But it was the fourth farm to join the fold last year that was the most important and held a special place for Sam - his parent’s farm. The farm he had

JCB EQUIPMENT MAKES UP A LARGE PART OF SAM’S FLEET….AND IS POPULAR WITH HIS KIDS TOO.

grown up on and which he knew and loved every inch of, became his own – ensuring it stayed in the family.

Now managed as a single farm, the four properties cover 2700 acres and carry 1000 Holstein cows, along with another 1000 head of stock, including young

animals connected to the dairy operation.

There have been quite a few improvements recently including a new feed pad and barn com-

WHEAT, GRASS AND MAIZE ALL GO THROUGH THE COMPANY’S HARVESTERS.

AROUND 90 PERCENT OF THE COBDEN AREA’S MAIZE IS GROWN UNDER IRRIGATION.

20

PROFILE

More success with PÖT TINGER

More success with PÖT TINGER

Roots in Austria, at home throughout the world.

Roots in Austria, at home throughout the world.

Innovative agricultural technology for more than 150 years

Innovative agricultural technology for more than 150 years

Highest functionality and productivity

Highest functionality and productivity

Efficient and sustainable farming

Efficient and sustainable farming

Forage conserving solutions guarantee best forage quality

Forage conserving solutions guarantee best forage quality

For more information on our product line contact us at (03) 8353 2770, www.poettinger.com.au

For more information on our product line contact us at (03) 8353 2770, www.poettinger.com.au

plete with flood wash. A new calving barn has gone up, centre pivot irrigation been installed, along with concreted silage pads, extensive fencing, and water and track work throughout the property.

While they may have handed over the reins of the farm to their son, Rod and Clare are still very much part of Sam and his children’s life. Still living on the farm, they have their own plot of land with a house, with Rod still very hands-on in some operations on the farm, and now having more time to spend on his pet project - a small herd of Hereford and Angus beef animals.

While the scope of the contracting work has increased and now also covers everything from cultivation and tillage to effluent and compost spreading, to spraying, silage is still the mainstay of the business including on 2000 acres of leased cropping farmland.

“We’ll do anything that will go through a forage harvester,” says Sam.

That includes a lot of wheat, grass and maize silage.

The success of the silage operation is also connected to the dairy industry as the majority of grass and maize silage is used as feed on the farms he contracts on, while the wheat is generally sold.

While there may be a drought currently underway in other parts of the country, around the Cobden area it’s been one of their best springs, says Sam.

The reliable rainfall sees good pasture growth for grazing and also for dryland grass silage. Around 90 percent of the maize is grown under irrigation with water coming from the nearby lakes, along with some ground water irrigation.

Contracting covers all farm sizes with clients ranging from small family-run dairy farms to corporate entities.

Strip tilling has become more popular in recent years, often for moisture conservation in drier areas particularly on dryland soils. Although this is a high

rainfall area, Sam still uses strip till for pre-preparation with their corn planting program. Overall he finds there is around a 50/50 split between strip till and full cultivation with their work these days.

Contracting is looking good for the future, Sam says, although it has become a lot more intense even in the short time he has been in it.

“People expect a higher quality product now.”

This has seen him keeping up with satellite tech, including with NRI sensors for silage, and precision planting on the corn. He expects this type of tech and more automation to continue increasing into the future.

This attention to tech innovation may well have contributed to the success of Monk Ag Services spilling over into NSW and Southern Australia as it continues to grow.

Business opportunities connected to the contracting side of

things continue to emerge with earth works a new enterprise.

The very latest business foray may well be appreciated by his staff most of all.

Sam and his family have now ventured out into a completely new business area which may prove particularly enjoyable. They have taken on a half share - with their operations manager taking the other half - of the lease on the pub in town.

And while there are likely to be some good fringe benefits, once again Sam will be too busy to be very hands-on with the business, instead having managers running it.

From the hard-earned baler and the family tractor, Sam’s business Monk Ag Services has transformed into one of the biggest contracting businesses in the state with around 100 full-time staff with another 50 part-timers and casual staff, and an eye-watering array of machinery and equipment. The busi-

SAM HAS EXPANDED HIS FARMING-BASED BUSINESSES INTO A RANGE OF APPLICATIONS ACROSS THE AGRICULTURAL SPECTRUM.

ness continues to expand into both NSW and South Australia.

Sam is looking forward to what else the future may hold.

He acknowledges his family has helped in his journey so far, and encourages others looking at getting involved in farming or agricultural contracting at a young age not to be discouraged by their youth.

“Age doesn’t matter – if you’re prepared to have a go.”

Be open to new opportunities when they present themselves, but also be prepared to put in the hours needed to be successful, he says.

“I worked day or night and never said no to a job, so I worked long hours.”

CATERS

SMALL

LARGE

THE COMPANY’S CONTRACTING OPERATIONS

TO ALL SIZES OF CUSTOMER FROM

FARMS TO

OPERATIONS.

PROFILE 22

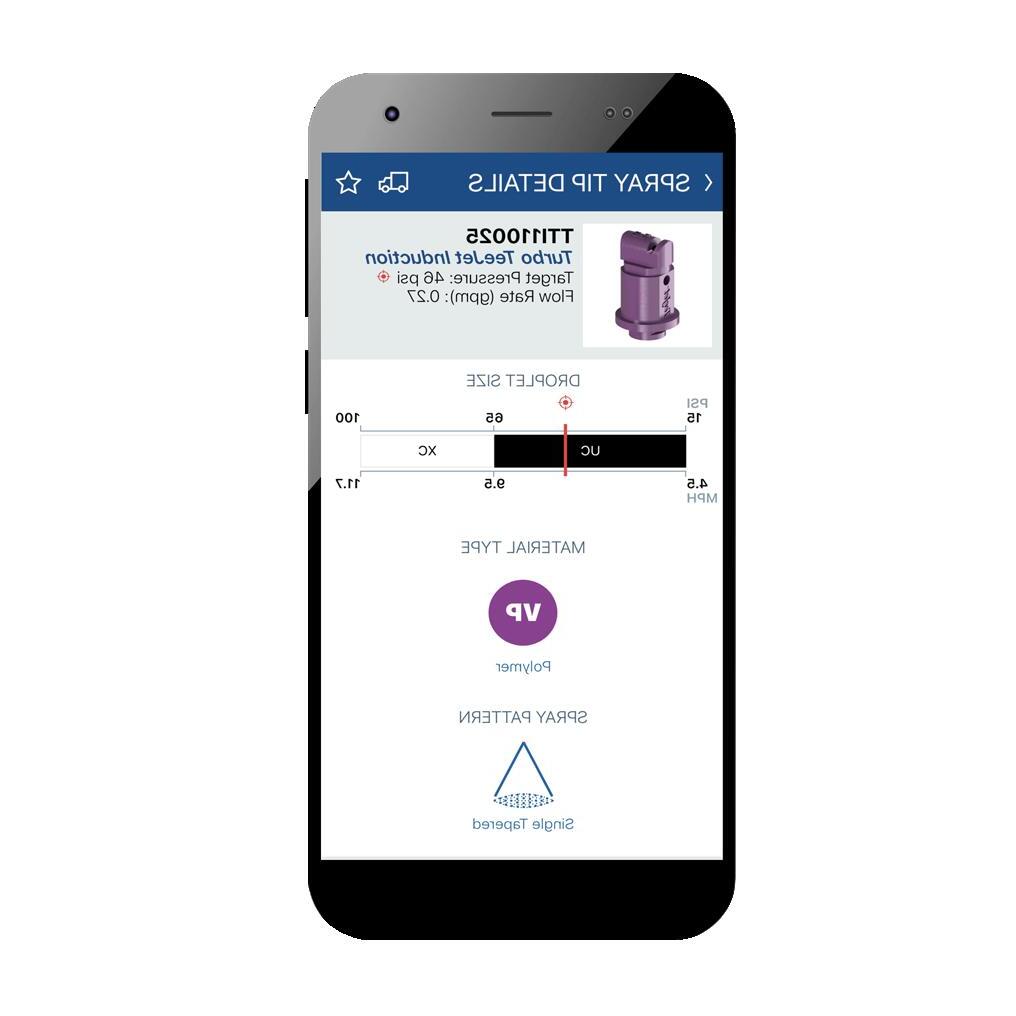

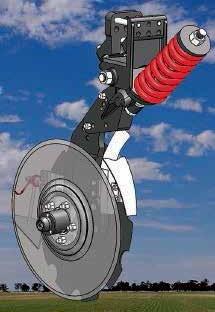

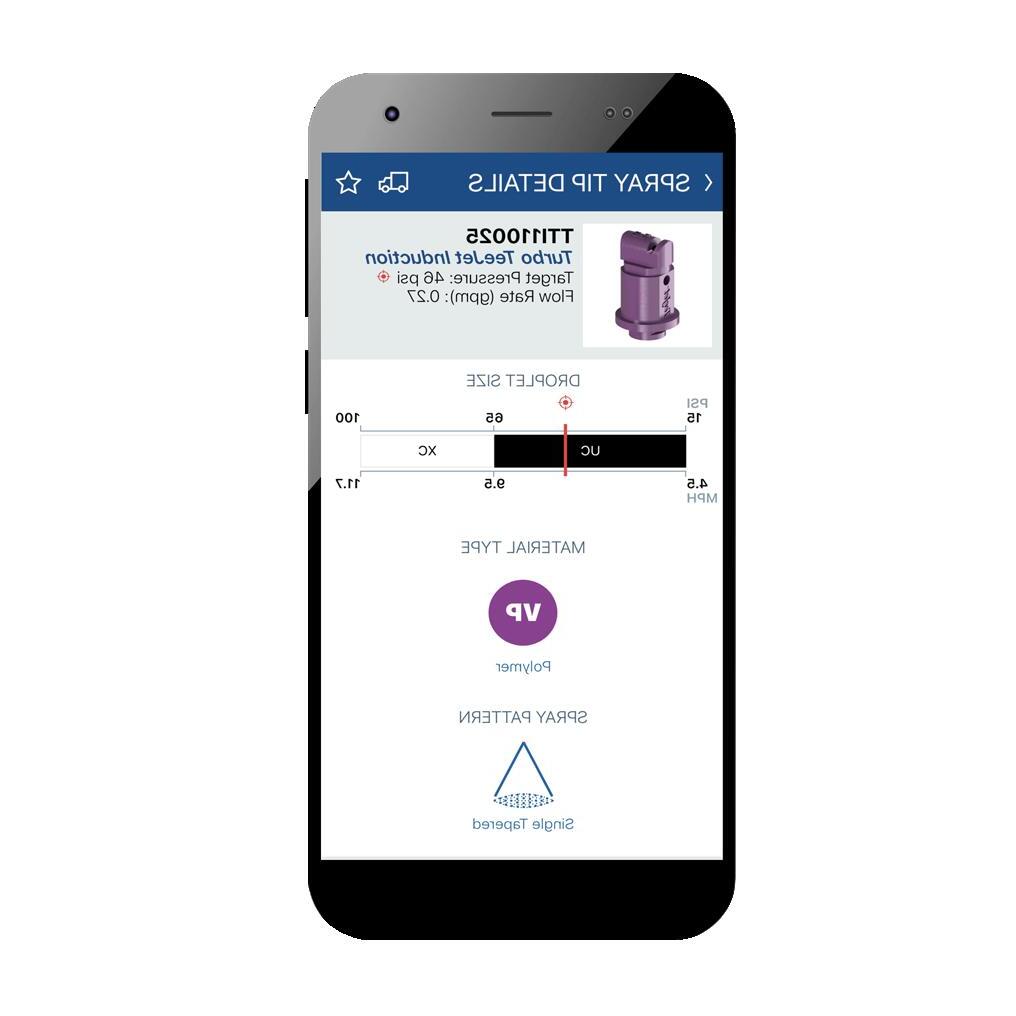

THE NEW & IMPROVED SPRAYSELECT MOBILE APP FROM TEEJET helps you to select the optimal spray tips for your specific application. Visit teejet.com/SpraySelect to download the FREE SpraySelect app today! NEW! THE ULTIMATE DRIFT CONTROL SPRAY TIP™

‘plenty of hedges

TO TRIM IN TARANAKI’

AFTER YEARS OF WORKING FOR OTHERS, SAM LUCKIN PURCHASED SOME HEDGE MULCHING MACHINERY FROM ANOTHER CONTRACTOR WHO WAS LOOKING TO STEP BACK FROM SOME SERVICES.

“My mother-in-law pointed out that I have spent a lot of time driving everyone else's gear, so I may as well drive my own. I definitely like how it has all workedout.”

Sam and his wife Sarah are based in central Taranaki, between Stratford and the village of Cardiff (to the west of Stratford). They offer hedge trimming and mulching services.

a dairy farm east of Stratford.

His parents still own a 350 cow dairy farm, where his brother is employed as the contract milker.

“It is just up the road, so I go up and cut some hedges when they want some done.”

Sarah was also raised on a local dairy farm, around the corner from where they are now based.

FROM THEIR BASE NEAR STRATFORD, LUCKIN HEDGE MULCHING TAKES CARE OF FARM HEDGES IN CENTRAL AND SOUTH TARANAKI.

tractor in south Taranaki. There he worked alongside several Irish workers.

After leaving school, Sam trained as a structural engineer and soon found he had a passion for anything “hot, heavy and sharp”.

He went to work for a local con-

“After the second year they convinced me to go back to Ireland with them, so I spent three months driving over there and saw how they did it. It made sense seeing it. The guys said it

He works mainly with dairy farmers, but also dry stock farmers and lifestyle block owners in central and south Taranaki.

across ditch the

PROFILED IN NZ’S RURAL CONTRACTOR & LARGE SCALE FARMER AUGUST-SEPTEMBER 2023, WE VISIT LUCKIN HEDGE MULCHING IN TARANAKI, NEW ZEALAND.

“There are a lot of dairy farms in the area and sheep and beef farms in the hills. We go wherever we are needed, if someone rings we go. Where there are hedges to be cut we go.”

Sam is firmly rooted in Taranaki, having been born and bred on

WITH SAM IN THE CAB AND SARAH CRACKING THE WHIP BEHIND THE SCENES, LUCKIN HEDGE MULCHING GETS THROUGH A BIG WORK LOAD.

24

PROFILE

SAM LUCKIN DRIVES ONE OF THE HEDGE MULCHING UNITS AND HE EMPLOYS A YOUNG DRIVER TO OPERATE THE OTHER.

was a lot in quieter Ireland compared to New Zealand.

“The ground is wetter because it rains a lot more and crows peck holes in the silage as soon as it has been baled, so there was a team coming along right behind to pick them up. It was definitely an eye opener.”

Sam returned to Taranaki, where he continued working for a local contractor. He then became a self-employed contractor for a number of years, providing con

A

tract labour for around half a dozen local contractors.

Then in May 2021 came the opportunity to buy the hedge trimming equipment off Hinton Contracting, a large Taranaki contractor, that was looking to downsize a bit.

“I was filling in for different contractors, driving diggers or trucks or doing tractor and trailer work. I was making silage for whoever needed a hand, until this opportunity came up.”

TRACTORS AND TRIMMERS

Sam runs three Massey-Ferguson tractors, which range in power from 140 hp to 160 hp. They run two McConnell hedge mulchers.

“It is quite good having a bit of size and weight in your tractors when you are on the hills,” Sam says of his tractors. “Having the mulchers on the side tends to throw them round a little bit.”

Two of the tractors run on

DynaVT constantly variable transmission, which makes them simple to operate, he says.

“They are pretty good. You don’t have to keep changing gears and I can have them going at 2 kph and then get them up to 11 kph when I am heading over to the next hedge.

“You don’t have to fully go through the gears. I can just keep cruising on.”

Fieldtorque in Stratford is Sam’s tractor dealer. It is owned by another branch of the Hinton family and has a good range of parts in store. The staff at Fieldtorque have been good to deal with, he says. Sam says the McConnell brand is well-established.

“McConnell mulchers tends to be what the other brands model on and they seem to handle what we are doing.”

He purchased two mulchers from Hinton Contracting and has since bought a new machine, which had 90 hours on the clock. This led to a change around with the machines.

“Everything on the new mulcher is real tight and smooth. It has a few extra features I wouldn’t have specified, but

25

For further information liugongaustralia.com.au HIGH PERFORMANCE EASY MAINTENANCE BEST VALUE

of tough TOUGH WORLD. TOUGH EQUIPMENT.

new world

WITH HIS ENGINEERING BACKGROUND SAM LUCKIN DOES SOME OF THE MAINTENANCE ON HIS MACHINES AND ALSO BUILDS SOME NIFTY TOOLS SUCH AS THIS LOG SPLITTER.

now I wouldn’t be without them.”

He bought his McConnell mulchers from Agriquip in New Plymouth, which is the local importer for the McConnell brand and has a good range of parts.

“You just cruise on up. They are a friendly bunch and they provide a good service and good parts. If you are ever having a problem, you can ring up for tech support and they talk you through it.”

Being a structural engineer by trade, Sam looks to do as much preventative maintenance as he can himself.

WHILE HEDGES MIGHT BE DISAPPEARING IN OTHER PARTS OF THE COUNTRY, THERE ARE STILL PLENTY OF THEM IN TARANAKI AND THERE IS PLENTY OF DEMAND FOR THE MULCHING BUSINESS.

“On the mechanical stuff, I am pretty good, but for the electrical stuff, they send someone out or they point us in the right direction.

“I do all my own servicing and transmission changes, but for something major or electrical or if something’s not quite working out, I can ring for reinforcements.”

One of the Massey Ferguson tractors has done 18,000 hours, so it is ready to become the backup tractor, Sam says.

“I’m on the lookout for a bargain. I will keep an eye out and see what is about. When something pops up I will jump on it.”

Being a new business, Sam has yet to develop a replacement policy, but he likes to keep an eye on TradeMe and AgTrader to see what is on offer.

So far there have not been too many logistical challenges when it comes to moving the tractors and mulchers around the Taranaki countryside, he says.

“The beauty of the hedge mulcher is that you just jump in the cab and away you go.”

Where possible he will try to line up two or three jobs in an area, before moving on to another area. And he will often pick up

work on the way.

“We try to be as efficient as we can, so we are not just driving around everywhere.”

Sam employs “a young fella” full-time, while Sarah takes care of the administration, the wages and invoices. She also “cracks the whip”.

“We didn’t know how much work we were going to pick up when we took over the business.

There are other contractors who do hedge trimming but they also do silage and other services, so they get in the gate like that and then offer a full service.

“For the first year I didn’t know

ANOTHER JOB THAT GOT DONE DURING A RAINY DAY IN TARANAKI IN SAM LUCKIN’S WORKSHOP WAS REPAIRING THE THUMB ON THIS DIGGER.

how many hours I was going to do and I ended up doing 1300 hours in the first six months. That was probably a bit too much, so in January we took on a young fella and he has worked out really good.”

Hedge trimming tends to be seasonal work. It dries up once calving starts in July, and then it

SARAH AND SAM LUCKIN BOTH GREW UP ON DAIRY FARMS IN TARANAKI, SO THEY HAVE STRONG ROOTS IN THE REGION.

TWO OF THE COMPANY’S MASSEY FERGUSON TRACTORS HAVE DYNAVT CONTINUOUSLY VARIABLE TRANSMISSIONS, WHICH MAKE THEM VERY GOOD FOR HEDGE TRIMMING.

26 PROFILE

picks up again in September. It then goes quiet again as farmers focus on cutting silage and then it picks up again over Christmas and runs until June.

To tide himself over, Sam still picks up work with contractors cutting silage and does other jobs when the hedge trimming work quietens down.

“I can take the mulcher off and hook a baler on my tractor and then go back to mulching after a couple of months.”

Coming from a farming back ground certainly has its advantages. He knows how to work around a farm’s other operations when he comes in to do the mulching, Sam says.

“It definitely makes it easier when you go on to a farm. For example, you know when you come on to the farm that they are going to be milking in the morning and the evening, so it is a good idea to do the races when it is not milking time.”

Sam says there is an art to trimming a hedge.

“Mulching is definitely the hardest thing I have ever done in a tractor. There is definitely an art to it.

“I am not sure how much you can do to improve it with technology. I suppose you could put GPS in, but it would be fairly expensive.”

With the rising costs of farming, hedge trimming can become a fringe item.

“The work can vary because farmers don’t have to do their hedges every year. Some farmers want it done every six months, while others might leave it for a couple of years or even five years.”

Fuel is a big cost and there are question marks for how much longer contractors will be able to burn diesel.

Sam doubts electric tractors and mulchers are the future, but he wonders whether hydrogen might be an option going forward.

“But how do you fill up your tractor with hydrogen? Do you pour hydrogen in or do you just pour the water straight in?

SAM LUCKIN HELPING OUT THE HAWERA WATER SKI CLUB BY MULCHING GRASS AT THEIR CAMPING GROUNDS IN PREPARATION FOR SUMMER.

SAM LUCKIN SAYS MUCHING HEDGES IS THE MOST DIFFICULT JOB HE HAS EVER DONE IN A TRACTOR AND HE DOES NOT SEE ANY TECHNOLOGY COMING DOWN THE TRACK THAT WILL MAKE IT ANY EASIER.

“I am just a small factor. Imagine some of these large contractors who have a large fleet having to switch over to an alternate energy source.”

For now Sam is just happy cutting hedges and maintaining good relationships with other local contractors – especially those who don’t cut hedges.

“You can spread yourself too thin and most contractors tell you the biggest headache is finding good staff and retaining them, or having good staff move on. So, by concentrating on one thing it makes it easier for us. We can make sure we are doing it well.”

Farm ownership is always an option.

“We tried to buy a farm in the middle of last year, but it didn’t pan out. We are always on the lookout for a bargain, so we will see what happens.

“I think I would always have some degree of contracting and Taranaki is definitely a place where there are plenty of hedges.”

While other parts of the country

have seen dairy conversions over the last few decades, which has led to trees and hedges being pulled out, Taranaki seems to be doing the opposite, Sam says.

“If anything farms are converting back to beef. There are a few getting out of dairying and going to dairy grazing or beef or leasing the land out.”

Sam says if he did buy a farm, it would be more practical to do dairy grazing and run beef cattle, rather than milk cows. That way, he can tie it in with mulching.

Whatever the future holds, agriculture certainly seems to be

in the blood for the young family. Sam and Sarah have two daughters and their eldest daughter already has a little tractor of her own, just like dad, which she won in a competition through Fieldtorque.

“It is hard work getting out of the house in the mornings because she always wants to come,” Sam says.

“I took her out with me in the cab on a drizzly Friday morning, when I just had a job for an hour, and ever since then I am not allowed out of the house without her.”

SAM LUCKIN TRIES TO GIVE BACK TO THE COMMUNITY

He takes his gear down to do a general tidy up at the Hawera Water Ski Club camping grounds after the winter.

“I spend about three to four hours mulching up the grass in the camping ground during the spring so it is ready for summer. We camp at the lake and I am on the committee. It is not just a water ski club, it is somewhere to go camping without cell phones.

“You just pop out there and there is bush everywhere and birds. It is quite neat out there.”

He also trims the hedges at the local Toko Rugby Club grounds, to the east of Stratford.

27

what’s new in.... SPRAYERS AND SPRAYING TECHNOLOGY

AS SPRAYING TECHNOLOGY GETS MORE SOPHISTICATED, IT GIVES FARMERS AND CONTRACTORS THE ABILITY TO APPLY CHEMICALS MORE ACCURATELY AND AT FASTER SPEEDS. HERE ARE THE LEADING PRODUCTS AVAILABLE IN AUSTRALIA FOR APPLYING CROP PROTECTION AND FOLIAR FERTILISERS.

MASSEY FERGUSON

MASSEY FERGUSON 500R SERIES SPRAYERS

Massey Ferguson® 500R Series sprayers bring fast, efficient, user-friendly application to farmers everywhere.

Backed by the AGCO family’s 60+ years of experience in the application space, the MF 500R Series is a robust, flexible machine which has been engineered to give you more control over your farm.

The Massey Ferguson 500R Series sprayer is user-friendly and easy to operate, offering a welcoming balance of technology paired with an intuitive layout so operators can easily take control of their spraying with confidence.

The tractor-style cab makes it easy to jump behind the wheel and get to work with a roomy, ergonomic layout, similar to the award-winning MF S Series tractors, providing maximum comfort for long days of spraying.

Near 360-degree visibility

makes it easy to keep an eye on the tyres and booms without craning or leaning while the cab is also designed to reduce vibration and noise experienced by the operator.

Flex is built right into the chassis of the MF 500R Series, enabling all four wheels of the machine to maintain ground contact even beyond full suspension travel.

More power to the ground comes via the standard smart

all-wheel drive, which ensures you always have the traction you need to deliver consistent coverage.

The smart all-wheel-drive system provides more powerto-ground transfer while maintaining product pump pressure at lower rpms, giving consistent coverage and greater fuel efficiency in a wider range of conditions.

The MF 500R Series sprayer arrives from the factory fitted with AgControl® and auto-steer

28

WHAT’S NEW...

with sub-meter accuracy. If at any point higher precision is required, it can be upgraded to RTK.

Easily accessed maintenance points, booms that require no lubrication and a ‘recirculate to tank’ feature with no end-cap cleanouts mean the MF 500R Series provides a stress-free ownership experience.

Owning a sprayer offers unmatched flexibility to apply product at the best possible time, maximizing yields and reducing wasted product.

With a user-friendly, easyto-operate design, and an attractive cost of ownership, operators

can confidently spray when and where they need to, no questions asked.

No more waiting on custom applicators. The MF 500R Series is the entry-level spraying solu-

tion that offers a new level of control over spraying.

The LiquidLogic ® system comes standard, delivering fast, efficient priming in under 50 seconds, with no wasted chemical.

Choose between a 740- or 860-gallon tank to better fit your operation. Each is equipped with a rotating rinse nozzle fed by a 92-gallon freshwater tank, a 10.5-gallon standalone handwash tank, adjustable agitation rate, and high- and low-level tank sensor.

The reload station of the MF 500R Series is easy to understand and operate. It features a 2-inch and 3-inch camlock fill point, optional 150-gallon/

www.bobcat.com.au | 1300 736 848 Distributed by

FENDT RELEASES ALL-NEW 900 SERIES ROGATOR SPRAYER

AGCO, a global leader in the design, manufacture and distribution of agricultural machinery and precision ag technology, has launched the new Fendt Rogator 900 Series applicator into Australia and New Zealand. The Fendt Rogator will offer more opportunity for owners to maximize the potential of their investment with capabilities such as adjustable clearance, a combo-chassis designed for multiple application systems as well as industry leading technology and first-class performance and operator comfort.

“We’re excited to introduce this machine to the Australian and New Zealand market,” explained Warwick McCormick, Director of Fendt for ANZ and Far East. “We’ve been working hard internally to put together an expert team focused on the Fendt Rogator, with dedicated staff based across the country to support our dealers, backed up by the global network of profession-

als at AGCO.” he said. “We have plans in place to ensure that service and parts will be readily available for Rogator customers as well as product and technical training to ensure we hit the ground running on the arrival of the first batch of machines.”

Fendt have confirmed that the new-look Rogator 900 Series will be exclusively distributed through the existing Fendt dealer network across Australia and New Zealand. “In the past the AGCO factory in Jackson, Minnesota built Rogator sprayers which have been distributed through a separate distribution network in Australia,” explained Fergal Meehan, Fendt Director of Marketing for ANZ, and the Far East. “In support of our long-term strategy for a full line of agricultural equipment designed to provide solutions for farmers across the world, the new Rogator will be distributed through existing Fendt dealers in Australian and New Zealand who are ideally placed to support the Rogator as it joins the Fendt family.