INDUSTRY NEWS

04 With knowledge, threatening changes can become opportunities

06 Planning in the face of uncertainty

09 Unique industry forum continues to gain traction

10 Study finds link between evolution and herbicide resistance

13 Customised crop recording (and compliance) on the go

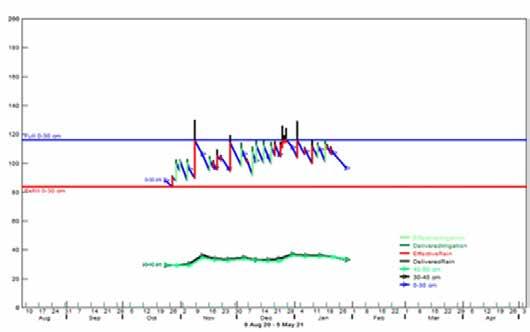

14 Keep a weather eye on one-of-a-kind model

17 Crop scientist welcomes extension work with growers

18 Major update for crop modelling in OverseerFM

20 Annual rye learns to love Queensland heat

21 World-first quality control system comes into effect next harvest

SEEDS

22 Just right - Goldilocks zone beckons for lower seed loss at harvest

24 Can we lift plantain seed yields?

25 Improving yield, returns for linseed SUSTAINABILITY

26 New test for biological soil health

31 Livestock adds value to arable, field day told

34 On guard – your best biosecurity defence is constant vigilance CEREALS

37 Spoiled for choice – grain breeder brings raft of new options to the market

39 Digging into the nitty-gritty of cereal economics

42 Long-running trials give growers confidence in cultivar performance

44 Whopper proves to be consistent performer despite challenges

AgriMedia Ltd, Ashcroft House PO Box 37151, Halswell, Christchurch 8245 ph 03 329 6555 www.agrimedia.co.nz www.novachem.co.nz

PUBLISHED BY: Publishers of Rural Contractor & Large Scale Farmer, AgriBusiness, AgriVet, NZ Cropping Yearbook, Australian AG Contractor & Large Scale Farmer, NZ Novachem Agrichemical Manual.

MAIZE

46 Closing the knowledge gap on narrow row spacing

48 Resilience & recovery underway in Gisborne

50 Maize delivers benefits to South Island farmers

CONTRIBUTORS

53 More focussed and flexible foliar disease control

54 New Duncan triple disc drill turns heads

56 Marking 10 years’ commitment to the future

57 Get back growing sooner

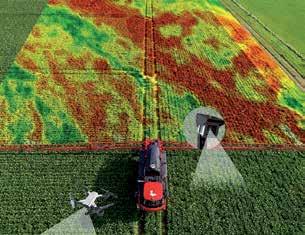

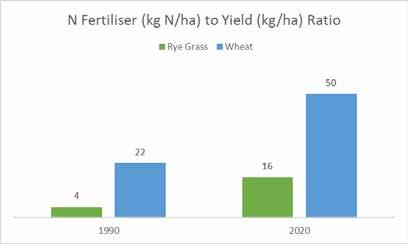

59 Sensor science supports more efficient nutrient use with no yield sacrifice

62 Clean, high yielding brassica crops a step closer this season

65 Sustainable nutrient management, to the next level

67 Keep on top of aphids before they’re on top of your crops

68 Adding value to Southland oats

71 Brace for the windy season

72 Glyphosate decisions based on politics

74 Stacking DMIs providing early season disease control in wheat

76 Want a drying floor without building a new shed? No problem

79 Wet year highlights the importance of drainage

80 ‘Listen, learn, deliver’ key to supporting farmers & growers

82 Prosaro & VIMOY iblon will help you deliver crop yield

85 Popular arable herbicide kills two birds with one stone

86 New control for rust in ryegrass seed crops excels

88 Banish grass weeds without having to add adjuvants

91 COMPANY LISTINGS

103 FIELD CONTACTS

112 SEED CERTIFICATION

EDITOR

Kathy Davis PO Box 37151, Halswell, Christchurch 8245 ph 03 577 5640

PRODUCTION & DESIGN

Hannah Kincaid email art@agrimedia.co.nz

ADVERTISING MANAGER

Paula Forde mob 027 229 0362

email paula@agrimedia.co.nz

CIRCULATION

email admin@agrimedia.co.nz

As 2023 is a referendum year for FAR, I would like to start by recognising the foresight of the original team of growers who were instrumental in campaigning and gaining industry support for the establishment of the levy funded, independent research organisation that is FAR.

WORDS: STEVEN BIERMA, CHAIR, FOUNDATION FOR ARABLE RESEARCHThey recognised that the New Zealand arable industry couldn’t rely on duplicating overseas research results; our unique climate meant imported approaches often provided quite different outcomes.

The initial goal of this group was to develop an applied research programme that would increase New Zealand arable crop yields, and with them, growers’ profitability.

The resulting research programme, which has included CPT trials, grass seed plant growth regulator research, fertiliser timing for a range of crops, 20 tonnes by 2020 and long term cultivation and establishment trials, has contributed to the development of a New Zealand specific approach to arable cropping and agronomy.

And nearly 30 years later, the FAR team has grown to include an outstanding range of plant and environmental research, technical, extension, financial and management skills.

This increase in skills reflects the changing world in which farmers now operate.

Rules and regulations, driven by consumer demand, have more impact on the way we farm than ever before.

In my opinion, the only way to meet those demands is through demonstrating proven good management practice (GMP), based on knowledge, scientific proof and data collected on-farm.

Since the end of World War II, food production has increased exponentially; artificial fertilisers, herbicides, fungicides and pesticides have played a big role in that.

Over time, a number of chemicals were found to be not that friendly and use was ceased. The availability and efficacy of pesticides, fungicides and herbicides is constantly changing due to regulation and resistance.

Current FAR work includes a big investment in identifying other solutions, with biopesticides, biological fertilisers, technical solutions and farm systems all being investigated.

2023 has also seen the launch of Cultivate Ventures, an investment fund, initiated by FAR, to support and encourage innovative New Zealand companies in the development

of technologies that will benefit arable growers.

I thank the growers, who share FAR’s vision, and have co-invested in this first round. Northington Partners, who are managing the fund, are keen to get this project on the way.

Growers Leading Change (GLC) is about to complete its third and final year.

Grower involvement and feedback has been high and FAR hopes to extend and expand on what we have learned from the first three years of MPI and grower investment.

Growers Leading Change has allowed growers to identify key issues and opportunities in their region and work with facilitators to receive targeted support and information.

Crop and region specific research, like exciting new technologies in maize, also create future opportunities.

As noted earlier, FAR is a levy organisation, and 2023 is a referendum year when we ask you, our growers, to confirm to the Minister for Primary Industries that we are delivering valuable research.

Voting papers will be out in July, and I would like to urge all the arable growers of New Zealand to vote and return the referendum papers, hard copies or digital.

Delivering a complete suite of crop protection solutions for today’s arable growers.

Samuel Whitelock – Plant Science Graduate, Lincoln University.

Our portfolio of powerful, proven products has helped farmers from one end of the country to the other create and maintain thriving businesses, and has earned us a reputation as New Zealand’s arable protection specialists.

Our suite of innovative crop protection solutions provide local farmers with everything they need to win the war on weeds, pests and diseases. Visit corteva.co.nz to view our range of online arable resources.

If there is one thing that last year has taught us it is that we are living in turbulent times and that trying to predict and plan ahead, with even a smidgen of certainty, is going to be very challenging.

WORDS: ALISON STEWART, CEO, FOUNDATION FOR ARABLE RESEARCHCovid related restrictions have lingered longer than many people anticipated and, while not impacting the arable sector to the same extent as those that rely more heavily on migrant labour, they have still brought many logistics and supply change challenges.

Add in the flow-on effects of Russia’s invasion of Ukraine and it’s not surprising that we’re seeing price increases along with food and fuel shortages around the world.

New Zealand is somewhat protected at present, but we can expect significantly higher farm production costs over the next 12-18 months.

Yes, high grain prices will help to balance the farm budget in the short term, but the revenue highs will be relatively short lived, while input costs are unlikely to come down.

Increased compliance costs are also looming with greenhouse gas emissions levies for agriculture coming into force in 2025, and following one of the most difficult harvests in decades, the risk of more regular extreme weather events is also on growers’ minds.

Obviously arable growers have more options available to modify farm management practices in the face of fluctuating input costs and market demands than monoculture systems, but it will still be challenging.

So how can you manage your farm business through such uncertainty?

How will you decide which crops to include in your rotation for the next five years? How will you identify which contracts offer fair and realistic prices for grain and seed you grow?

Unfortunately, there is no specific industry wide guidance that levy bodies or industry consultants can give because the market is changing so quickly and the trends are somewhat unpredictable. Basically, it comes down to understanding the true cost of production for

each crop and livestock unit within the farm and having a farm operational plan that allows for maximum flexibility.

This may seem like teaching growers how to suck eggs, but we know, from the farm profitability workshops that FAR has held over the last few years, that many growers do not accurately account for all of the direct and indirect costs for each crop and often overestimate forecast gross margins.

This, combined with price uncertainty, could result in growers signing forward contracts at prices that will deliver limited if any returns.

Armed with this knowledge, growers will be able to identify fair contract prices, with acceptable margins of error for price fluctuations. This could be even more effective if growers worked together to negotiate contract prices, terms and conditions with the various seed, feed and grain companies.

Many other industry sectors have grower contracts with differential pricing tiers linked to specified market conditions.

Armed with this knowledge, growers will be able to identify fair contract prices, with acceptable margins of error for price fluctuations.

Many farm finance packages address accounting, but they do not necessarily provide detail on the profitability of individual crops/livestock units. This is where platforms such as ProductionWise® fit in.

ProductionWise is freely available to all arable levy payers and captures very specific details on crop inputs and outputs, thus providing a more accurate assessment of gross margins. On a simpler scale, FAR has also produced a simple crop production cost template (in the form of an Excel spreadsheet) that growers can use if they want a quick assessment of production costs.

This also allows growers to do some sensitivity analyses by playing around with different input costs and potential contract prices so that they can see what their gross margins will look like under different scenarios.

This is not about growers trying to screw every dollar they can out of the processor/distributor, rather, it is about fair financial recompense for the quality and quantity of product being sold, and enabling growers to maintain profitability and continue to service the needs of the processors/ distributors.

Surely a win-win for all parties. Arable growers are known for their technical competence and ability to manage complex farm systems, but do not always have the same abilities when it comes to finance and budgeting.

With the introduction of emissions pricing in 2025, it will become even more important to understand exactly where your farm income (and greenhouse gas emissions) come from. For example, if your system includes livestock finishing or winter grazing, you need to be able to work out the extra cost associated with the livestock’s methane emissions versus the revenue generated from the animals to make sure that having livestock on the farm makes financial sense.

Likewise, given the many new growing opportunities around plant proteins, plant based milk, specialty grains etc, which are likely to come along over the next 10 years, it is important that you are able to calculate the true cost of each component of your farm business and from there, the real value of new crops. We don’t need more low value commodity crops!

More than 140 delegates took advantage of the opportunity to get together last month for another successful Women in Seed forum hosted by the New Zealand Grain and Seed Trade Association.

Association vice president Charlotte Connoley says the event serves as an important annual networking opportunity for females within the seed industry and was also about challenging attendees around the issues of the day with the aim of resulting in personal and professional growth for those present.

A networking breakfast opened the event promoting much greater collaboration between industry professionals for the betterment of the industry before delegates heard from an outstanding line up of speakers from within the seed trade, business sector and health and wellbeing.

Covering a variety of perspectives, presenters included Foundation for Arable Research CEO Alison Stewart; special agricultural trade envoy Mel

Poulton; athlete Gemma McCaw and Gabrielle O’Brien, chief executive of Rural Women NZ.

In the afternoon session, speakers included Maury Leyland Penno, cofounder of Leaft Foods; Julia Jones, head of analytics at NZX; ANZ rural economist Susan Kilsby and psychologist Dr Lucy Hone.

“The success of the forum just continues to grow,” Charlotte says.

“It is challenging times for the primary sector at the moment as a result of the earlier weather events and ongoing legislative pressures.

“Now more than ever it is crucial our delegates are given opportunities to expand their technical and industry knowledge to support growers and farmers with the challenges ahead.

“Providing tools for better mental re-

silience as we heard here today from one of our keynote speakers Dr Lucy Hone is also critical for our own health and wellbeing but also so we can provide support to the farming community.”

With attendee numbers surpassing the organisation’s annual conference it is clear there is demand for an opportunity such as this forum for females in the industry, Charlotte says.

“We were absolutely delighted with the turnout and support from our many industry members ranging from administrators, plant breeders, plant researchers, agronomists, and traders to lab and technical experts.”

The Foundation for Arable Research conducts research, development and extension on grain and seed crops for New Zealand arable farmers under three compulsory Levy Orders (Arable crops, Maize grain and silage, Cereal silage). The current Levy Orders expire in July 2024 and growers will be asked in July/August 2023 to vote in a referendum to renew these Levy Orders.

Voting papers together with an information sheet will be sent out to all levy payers on 21 July 2023 with the option to cast a postal or online vote. Only those growers who have harvested arable crops, maize or cereal silage in the period between 1 July 2022 and 30 June 2023 are entitled to vote.

Voting closes at 12 noon on Wednesday 23 August 2023, we ask (if possible) to use the online voting option.

FAR has provided valuable research to New Zealand arable growers over the last 27 years. We need your support to continue this work so please take the time to vote.

A study of one of the worst weed-control problems facing farmers worldwide – herbicide resistance – has helped a global team of scientists determine the genes behind an evolutionary plant trait.

The trait is NTSR, or non-target site herbicide resistance.

Associate professor Christopher Saski, of Clemson University in South Carolina, USA is collaborating with researchers from Rothamsted Research in the United Kingdom, the University of Copenhagen in Denmark, and Bayer Crop Science for a study to understand the origins of this trait.

The researchers believe this knowledge ultimately may help usher in new herbicides and improved crop management.

“Herbicides are designed to a specific target in plants,” says Christopher, an associate professor of systems genetics in Clemson’s Plant and Environmental Sciences Department.

“Historically, the type of resistance farmers have dealt with is called ‘targetsite’. This is where the plant incurs a mutation in the herbicide’s target, resulting in the herbicide no longer being effective so that it no longer kills the weed,” he says.

Target-site resistance typ-

ically is linked to a specific herbicide or group of herbicides and is easy to identify and manage.

The more complicated problem is ‘non-target site resistance’, also known as ‘metabolic resistance’.

NTSR involves more changes in the plant than just the target site.

“Non-target site herbicide resistance occurs when the plant is able to detoxify the herbicide or when the herbicide does not reach its intended target,” Christopher says.

“This form of resistance is much more difficult to identify and manage. This is a really bad situation because it causes the loss of multiple options for weed control.”

The study focuses on blackgrass, a grassy weed that is native to Europe and Asia and has been introduced to many other regions of the world, including North America.

Blackgrass is considered the most noxious weed of small grains in Europe.

It is difficult to control because it is resistant to many

herbicides and completes its lifecycle within the cereal crop growing season.

It is also a prolific seed producer, with each plant capable of producing thousands of seeds, allowing uncontrolled infestations to grow rapidly.

Efforts have been made to control blackgrass with chemistry but that has led to widespread multiple-resistance to herbicides, especially post-emergence herbicides.

Pre-emergence herbicides are more effective, but NTSR is beginning to threaten these actives too, reducing the available options for controlling this weed.

Rothamsted Research researchers have spent years developing the genetic study populations used, two that have independently evolved NTSR and one that was susceptible to herbicide.

To develop a foundation from which to study heritable traits in blackgrass, the researchers created a roadmap to show where the genes are located on chromosomes.

They used genetic analysis techniques to compare the two study populations that uniquely evolved NTSR, to determine genes involved in the trait.

A fundamental question the researchers asked was, ‘Do traits that evolve independently have the same genetic basis?’

Their answer is, ‘possibly’.

“While we were keen to highlight the genes involved, we also wanted to compare how similar this trait was in different populations,” says David Comont, research scientist at

Rothamsted Research.

“Understanding how variable this trait is from one population to another can help us understand how best to diagnose and manage this resistance, whilst also shedding light on the evolutionary processes involved.”

The researchers found some overlapping genes involved, as well as some unique ones.

“This suggests this resistance involves a shared ‘core’ set of genes, within a uniquely evolved profile or ‘fingerprint’ from one population to the next,” Christopher Saski says.

Since the beginning of time, plants have changed their genetic makeup in response to stresses such as heat and drought, as well as herbicides.

Weed resistance to herbicides is increasing worldwide and threatening global food security. Christopher says this study can help plan for the future.

“These findings have wide significance for understanding the potential for rapid plant adaptation under novel and changing environments.

“Knowledge of the genes (and how they are regulated) that confer NTSR can be used in the design of new monitoring and mitigation strategies as well as novel herbicides, to help combat herbicide-resistant weeds.”

Other researchers involved in the study include Lichun Cai from Clemson, Dana MacGregor and Claudia Lowe from Rothamsted Research; Roland Beffa and Bodo Peters from Bayer Crop Science and Paul Neve from the University of Copenhagen.

When ProductionWise started, few growers could have imagined how much compliance they would have to manage in today’s systems.

Launched by FAR in 2012, the unique webbased farm management system was designed first and foremost to improve on-farm decision making, financial recording and industry benchmarking.

Eleven years later, it’s still doing this.

It’s also become a chemical inventory, complete with mandatory H&S documentation; a crop rotation planner; a risk-mitigator for herbicide and pesticide resistance; and a seamless channel for shared operations with third party service providers like contractors and advisors.

Beyond these functions, however, it has become an invaluable compliance tool - cheap (free to FAR levy payers); fully customised for New Zealand arable producers; auditor-approved and capable of capturing pretty much every piece of information required to meet increasingly stringent rules and regulations.

FAR’s ProductionWise manager Melanie Bates says there was no way of knowing for sure during early days of system development that recording even ostensibly small details would one day be useful, like what personal protective equipment was worn for a particular spray job, prevailing weather and wind direction, start and finish time, or operator details.

But the ability to do so was retained nonetheless, just in case…

Fast forward to 2023, and it’s no surprise that an increasing number of the 1200-

plus users currently registered with ProductionWise are turning to it for compliance first, financials second.

That said, the financials still matter, now as much as ever, if not more.

Which makes the recent release of the updated ProductionWise app all the more useful, Melanie says.

“Being able to capture key on-farm operations and tasks on a phone or tablet, while you’re in the field, reduces admin time, improves data accuracy and makes it easier to keep track of what’s been done, when, by whom, and how much it cost.”

Devon Long, general manager, Regrow (NZ and Australia) says the new app is a complete rebuild, and should solve the operating issues that were frustrating many users for some time.

“The original ProductionWise app was built over five years ago. Since then, smartphone technology has changed and evolved significantly, resulting in the app’s underlying technical infrastructure no longer being supported by major smartphone operating systems like iOS and Android.

“That lack of support led to issues with speed and functionality of the original app. The newly built app will meet the needs of current users and is also a good foundation for any improvements over the next couple of years.”

Included in changes to ProductionWise is an extra input box to capture the price of chemicals applied to

Updated app lays the foundation for future improvements.

crops, which is an essential part of calculating accurate gross margins per crop, Melanie says.

“As well as the system default, which is FAR’s basic price, we’ve now got an option that remembers the price that you’ve entered previously, either via my diary or the chemical shed function.”

Individual user benchmarking under tools has also been further developed to include graphs colour coded to show water, fertiliser and spray inputs per crop, she says.

“It’s much easier sometimes to look at a visual than at rows of numbers! You can use this to see at a glance not only what’s gone into that particular crop but also how those inputs compare to FAR regional benchmarks.”

More importantly, the user's own benchmarking reporting function summarises and compares all your farm’s gross margins for any time frame, so you can compare all your wheat crops, for example, or compare different crop types within your own system.

When the Seed Certification Information System (SCIS) comes online this sea-

son, ProductionWise users will be able to export their map straight into it, which will help growers transition to the new programme.

“There’s also a relatively new calendar function, which automatically captures paddock operations so you can easily look back on last year and see what you did at any particular time. You can use this to add a new ‘activity’ directly from it.”

Looking ahead, Melanie says FAR is always looking at ways to support potential improvements for ProductionWise, including something that plenty of users are very interested in.

“We know they want a livestock recording system built into ProductionWise, because they’ve been asking for it. Many arable farmers have livestock as part of their business, and in those situations, they have to use a livestock recording system as part of their reporting obligations. It would make things much easier for them if they could do it all through ProductionWise.”

For more details visit productionwise.co.nz or phone the FAR office, 03 345 5783.

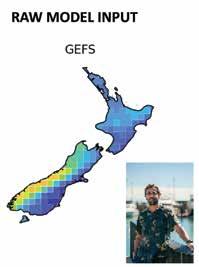

Updated daily, super easy to check on-line and free of charge, a unique sub-seasonal prediction model released by NIWA late last year gives arable farmers the chance to further fine-tune crop management.

NIWA35 is the fruition of two years’ collaboration between institute forecasters and modellers, and the Ministry for Primary Industries.

Every day, it looks five weeks into the future and assesses the outlook for drought or rain during that time across New Zealand, and in different regions (shiny.niwa.co.nz/drought-forecast).

Billed as a drought forecasting tool, NIWA35 works for excessive rainfall too, picking out the potential for extreme rainfall from Cyclone Gabrielle over 10 days in advance.

Those behind it say it’s one of a kind, globally as well as in NZ, and they want people from all walks of the agri economy to take advantage of it.

The model provides rolling 35-day forecasts of dryness, drought and rainfall, at much higher resolution than has ever been available, giving farmers, growers, advisors, contractors and other primary professionals a ‘reasonable’ estimation of wettest and driest case scenarios over the coming five weeks.

Auckland-based data scientist Neelesh Rampal has worked with NIWA colleagues, meteorologists Ben Noll and Tristan Meyers, to develop the model.

Tristan says in an arable scenario, given the high proportion of operating expenses often associated with paying for, pumping and applying water, one way NIWA35 could be used is in making key decisions about when to turn irrigators on or off.

“It’s another tool to help support climatic resilience on-farm. Having

To water, or not to water? New model can help decide, NIWA says.

a heads-up on when to think about starting or stopping irrigating can save thousands of dollars, money which in turn can then be re-directed to help strengthen the climatic resiliency of your operation in other ways.”

The model uses recent advances in both atmospheric modelling and artificial intelligence, coupled with the processing power of the latest generation supercomputers, to push forecasting

out further, with both higher certainty and resolution.

Data collection to create NIWA35 is extensive, and researchers are leveraging off a United States model established by the National Oceanic and Atmospheric Administration (NOAA).

Raw data is pulled down onto NIWA’s high-performance computer from NOAA every day. It is at a 50 km resolution and a 31-member ensemble, which means that data is drawn from 31 different instances of the model.

This supplies 31 different scenarios for the forecast. When these scenarios agree, forecast confidence is generally higher, and when they diverge you’ve got lower confidence.

Importantly, NIWA35 is able to scale the ‘coarse’, global 50 km input grid down to a 5 km radius over New Zealand. This resolves the country’s com-

Neelesh Rampal shows how NIWA35 uses artificial intelligence to create high resolution forecasting at 5km (right), from a low resolution input forecast at 50km.

Crop residue cultivation and incorporation is an important factor in conservation tillage. It incorporates all the crop residue evenly into the soil with an intensive mixing. With 600mm discs, Qualidisc has excellent penetration and soil movement for both shallow and deep cultivations.

The Kverneland Kultistrip only prepares the soil where the crop is going to grow. Depending on the intended width of the row, up to 70% of the soil surface is not worked. This not only protects the soil against erosion and drying but also reduces the tillage costs.

A special feature of this machine is the separate adjustment of the break-up share and fertiliser injector. This means that you can change the working depth whilst keeping the fertiliser placement the same, or vice versa.

plex topography far more effectively.

“It’s challenging to make decisions from something coarse, and 50 km is not representative of the wide diversity of our terrain in New Zealand,” says Neelesh Rampal.

Climate change is exacerbating extreme weather events and NIWA’s longterm climate projections point towards an increasing risk of prolonged dry spells across much of NZ in the decades

ahead, particularly in northern and eastern regions.

The implications of such projections are significant – both for individual farmers and the country at large.

Treasury figures show drought has cost NZ more than $5 billion in lost agricultural production over the past 15 years.

Tristan Meyers says one of the beauties of the NIWA35 model is on-

Drought has cost NZ more than $5 billion in lost agricultural production over the past 15 years.

going development.

“It’s not just sitting there as a static, unchanging tool. We’re working on it continuously.

“For example, a key research area we as forecasters are exploring with it, given that this is an AI-type system, is whether training the model on recent heavy rainfall events to learn from will then make a difference in our predictive abilities.”

Regardless of the outcome with this particular area of research, the accuracy and reliability of the model will continue to improve in the future, he says.

Meantime, NIWA35 is already helping people in all sorts of occupations plan ahead.

“I keep finding out people are using it in new and different ways. They like to have a heads up as to when it is likely to be wet, or likely to be dry, and they’re enjoying having a sneak preview of the month coming up vs the standard 5-6 day forecast outlook.”

Sean Weith.

Sean Weith.

A passion for science, and crop protection in particular, means FAR is a natural fit for new researcher Sean Weith.

Sean joined FAR at the start of the year, focusing on herbage and vegetable seed research in collaboration with Richard Chynoweth.

His appointment coincides with Phil Rolston’s departure into the role of technical advisor at SIRC.

Sean says he has always had a passion for studying plant pathogens and how to control and manage them in different agricultural crops.

His primary experience in arable comes from his 10-year involvement with Bayer Crop Science in Canterbury.

He worked as a casual field trial assistant for the first eight years while pursuing his master’s and PhD degrees and then as a full-time field agronomist for the last two years after completing his PhD.

Since joining FAR, he has been involved in a project considering white clover desiccation options, as well as the control of downy mildew in cocksfoot.

Some crossover with cereals is also possible, particularly around general agronomy and disease control.

Sean’s expertise in data collection and research reporting will help increase FAR’s research output, so results can be shared more quickly with growers.

He says it is great to be

involved in extension work, where he is able to interact directly with growers.

FAR partially funded Sean’s master’s degree at Lincoln University, where he focused on investigating tan spot in wheat, marking his first involvement with the organisation.

Tan spot, caused by the fungus Pyrenophora triticirepentis , is a destructive and economically significant foliar disease of wheat which has been increasingly occurring in New Zealand.

As part of his master’s project, Sean undertook a survey of wheat growing areas around the country, collecting samples of the fungus from each site and using molecular biology approaches to characterise the genetic diversity among different populations.

He then went on to complete a PhD two years ago.

For his PhD, Sean studied the complex interactions between the legume white clover with different strains of nitrogen-fixing bacteria known as Rhizobium.

His work investigated the plant genetics in the cloverRhizobium interaction and explored how this information could be utilised to produce new white clover cultivars with enhanced interactions with Rhizobium.

New Zealand’s most comprehensive farm nutrient management tool OverseerFM has improved the software’s crop modelling capabilities.

The extensive crop changes incorporate new information available from New Zealand cropping specialists at Plant & Food Research.

The update includes the addition of new crops, adjustments to enable a better representation of what is happening in a farm system and software updates to make it easier for growers to enter farm information.

Alastair Taylor, business development manager for OverseerFM, says the upgrade removed the ‘seasonal’ variations of crops to describe and estimate the impact of how crops are farmed more appropriately.

“Previously, one of the issues was that the growth of a crop was fixed in the model. The growth time was set at a national average value.

“If you grew a crop for only three months when the national value was six months, the model would go through a six-month process, which would limit the accuracy of the model.

“Under the new model, crops now have a farm-specific growth curve and are more representative of what is actually happening in the farm system.

“Users can now also specify product loss occurring in the field. For instance, a broccoli crop might have five to ten per cent of spoiled heads left in the paddock.

“These have grown and taken up nutrients. The model can now allow for field loss of damaged crops, which will be incorporated into the results.”

The update has also added four new crops, chickpea grain, pak choi, rape green manure and turnip green manure,

and now allows for further additional crops to be more easily added.

An issue around the modelling of fodder beet has been resolved and modelling has been reviewed for crops of broad beans, green beans, cauliflower (winter/ spring), cabbage (winter/spring), spinach, oats and rye, broccoli (summer), turnips (leafy), cabbage (summer), and radish.

Overseer and independent scientists have been assessing the tool’s reliability in a range of areas including deeper-rooting plants, the effects of different climate data sets, multi-layer soil and sensitivity and uncertainty.

Analysis of the impact of deeper-rooting plants on N-uptake below 600 mm found that N-uptake will generally occur only when there is insufficient nitrogen available above 600 mm. OverseerFM was updated to incorporate N-uptake by deeper rooting plants with a software release in late December 2022.

“The model sensitivity and uncertainty work really emphasised the importance of a farm’s geophysical characteristics – where it is, what climate it is farmed in – things which our farmers consider each and every day,” Alastair says.

“Overall, the uncertainties for the OverseerFM estimates were in the range of other environmental models and the results were comparable for dairy, beef and sheep and cropping farms.”

The work to update the crop model began in 2020 with Overseer Ltd working with Plant & Food Research.

The first outcomes of that pro-

INDUSTRY NEWS

Fodder beet is one of several crops covered by the latest update.

gramme, updating crop parameters for some existing crops and significantly extending the number of crops that could be modelled, were added to OverseerFM in late 2021.

“We knew there were some ‘quick gains’ to be made in adding new crops and some cropping changes,” he says.

“We then went on to do the longerterm work, with support from the Ministry for Primary Industries. The work took into account the findings of an independent science review of the OverseerFM model, released in August 2021.

“It has taken some time, as it was complex work and difficult to incorporate into the model. However, as a result we now have something better for farmers and growers.

“Farmers may notice their numbers change but the main difference will be that the way crops are modelled should be more representative of what is actually happening in the farming system.”

The updates also mean it is now much easier to collect data for incorporating new crops into the model.

The update of the crop co-efficients table enables easier of crop coefficients by botanical relatedness and/or similar crop end use.

The ‘end N uptake crop’ function and the end use and/or planting time crop variations (seasonal variations) have both been removed, and the data entry required for crop selection updated.

The changes do not include any update to how pasture or pasture crops are modelled.

Overseer Limited is working hard to improve the understanding of OverseerFM and the way it should be used, says Alistair.

“One way to think about OverseerFM results is to view them more like a weather forecast than a measure you might obtain from a rain gauge or thermometer. Weather forecasts provide valuable insights and are continually improving, but nobody expects them to be 100% spot on 100% of the time.

“We will continue to develop OverseerFM to improve its utility, reliability, and usability. This will include providing insights and information that enables farmers to follow and communicate their progress so their hard work and investment can be recognised and rewarded.”

Further information can be found at www.overseer.org.nz.

With the cost of fertiliser at a premium you need precision application. With hopper sizes up to 10000 L and working widths up to an impressive 54 m, we have a spreader to suit every farming operation.

AMAZONE is world-renowned for building of the most robust, technically advanced sprayers available. With tank volumes up to 11200 L and working widths up to a remarkable 40 m, we have a sprayer to suit every farming operation.

An introduced weed that already costs Australian grain growers more than $90 million a year is becoming an even bigger threat according to University of Queensland-led research.

Professor Bhagirath Chauhan from the Queensland Alliance for Agriculture and Food Innovation (QAAFI) has found for the first time that annual ryegrass is now germinating in summer in northern grain growing regions.

“This adaption is a potential disaster that could cost many millions of dollars across all cropping systems,” he says.

“Annual ryegrass has mainly been a winter weed in the southern and western regions of Australia, but recently we have seen it in Queensland.

“Not only is it germinating outside of the original winter window, but it is doing so in temperatures as high as 40 degrees and then growing to produce seeds in summer.”

Professor Chauhan says annual

ryegrass can spread quickly, often carried accidentally by vehicles or, in one case, by a hay bale which fell from a truck.

“Annual ryegrass can quickly spread from the roadside into a paddock and then grow alongside a crop,” he said.

“One ryegrass plant can produce more than 40,000 seeds, which can grow into 40 or 50 plants per square metre.

“Weeds like ryegrass compete for nutrients, water, sunlight and space and can harbour insect pests that will attack a food crop.”

Adding to the problem is the weed’s resistance to most herbicides.

“Farmers rely on glyphosate to control weeds in fallow areas and ryegrass has developed resistance even to that, which means it will produce seeds that

go into the soil’s seed bank and germinate over many seasons,” Professor Chauhan says.

“The plants will keep growing and costing farmers money every year which is why it is now Australia’s number one

▶ Easily grazed by stock due to the majority of the bulb sitting higher above ground

▶ Suitable for all stock types but especially suited to sheep and young stock

▶ Latest fodder beet genetics available

▶ Consistently high yielding in all on-farm trials to date

▶ Large top growth

▶ Suitable for sheep, cattle and deer for grazing in-situ

▶ Reliable even germination

▶ Large top growth with excellent green leaf retention late into season

▶ Very good bolting tolerance

▶ Suitable for sheep, cattle and deer for grazing in-situ or lifted and fed out later

▶ All seed is pelletised with world leading technology and coated with insecticide and/or fungicide-only options

▶ Available in handy 50,000 seed boxes

▶ Contact your local Cropmark representative for more information

New Zealand’s high quality seed is respected at home and abroad because of a highly capable industry applying rigorous certification standards and processes.

WORDS: NEW ZEALAND PLANT BREEDING AND RESEARCH ASSOCIATION

This has resulted in our industry enjoying significant premiums for its certified seed compared to uncertified seed in our domestic and international markets.

To keep pace with technology advances and to meet new regulatory requirements, a new online seed certification system has been designed.

Owned by the NZ Seeds Authority, a body representing farmers, seed companies and seed processors, the platform is thought to be the first in the world to utilise digital mapping technology to verify the area and location of certified seed crops.

This feature reinforces the global status NZ has as being a trusted producer of seed that is true to type.

The new Seed Certification Information System (SCIS) is being developed with significant non-financial contribution from AsureQuality and significant oversight by the Ministry for Primary Industries.

MPI oversight is to ensure SCIS is a tool that will provide the verification required by the ministry to enable it to issue credible OECD seed certification assurances to our export partners.

Crops planted this season for harvesting in 2024 will be the first ones to be entered in the new system.

The most significant change users of the new system will notice is the complete removal of paper-based application forms – all this administration will be completed online.

Growers will also find that the system has lots of smart tools to help them check the eligibility of their crop applications for certification and manage the information needed when they deliver their harvested crops into processing stores.

problematic weed in grain cropping systems.”

Professor Chauhan said more research is needed.

“We need to study why this plant is growing outside of its normal window

The new SCIS has been funded out of contributions directly from all value chain stakeholders as well as investment from the SFF Futures.

Certification assures the customer that the purchased seed retains varietal identity, genetic purity, and high-quality standards.

Seed crops, ranging from arable crops, brassicas, and herbage grasses to legumes are checked throughout the growing cycle by growers, merchants and AsureQuality field inspectors to ensure good quality control, consistency and genetic purity.

Once harvested the seed is sampled

Ryegrass is New Zealand’s top certified seed crop.

and analysed by government-accredited laboratories to assess germination and purity.

According to interim statistics issued by AsureQuality the total area of certified seed in NZ is around 44,000 hectares.

An analysis of the different varietal groups shows herbage and amenity grasses represent around 70 per cent of the total certification area. The second leading group was legumes with around 16 per cent of the hectarage, followed by brassicas at 8 per cent and arable crops with 5 per cent of the area.

The top certified seed crops are ryegrass, clover, and cocksfoot.

and why it’s happening in Queensland and northern New South Wales,” he said.

“We need to learn from the experience of the southern and western grain regions to ensure we don’t get to the

point where it’s really difficult to manage.”

The research was published in Weed Technology and enabled through Grains Research and Development Corporation investment.

In a hot dry summer, what’s the next best thing to a dewy night for cutting perennial ryegrass seed crops?

It might just be a light sprinkle of irrigation.

Depending on seed moisture content, a few millimetres, maybe as little as 5 mm, to dampen the canopy shortly before cutting could be enough to increase your yield of saleable seed by up to 200 kg/ha, with no subsequent quality issues.

It will take more trials to substantiate this. But indications from the first years of research show it is worth further investigation among other strategies to reduce ryegrass seed loss at harvest.

With memories of the 2022 nightmare wet harvest still far too vivid for some growers, FAR’s Richard Chynoweth is quick to point out this particular technique would only help when crops are already well ripened by nature, when the seed head being just that little bit too dry increases risk of shattering.

In 2023 harvest conditions, Base perennial ryegrass dampened with the equivalent of 8 mm irrigation one hour prior to cutting yielded more machinedressed seed than seed simply windrowed as normal.

This yield advantage oc-

curred at 39% (+311 kg/ha) and 45% (+219 kg/ha) seed moisture content, suggesting some seed loss occurred at cutting in the hot dry conditions experienced at the time.

No difference in yield was shown for irrigation applied at between 24% and 33%. A lack of irrigation response at 33% suggested the crop was damp enough from overnight rain, while no response at the lower SMC suggested the easier to lose seed had shed due to environmental conditions prior to windrowing.

Richard and fellow researcher Owen Gibson are repeating the trial again this season as part of an on-going Seed Industry Research Council (SIRC) project.

“We know a dewy night will give you less seed loss at cutting than if conditions are dry, reducing losses by ~100 kg/ha. That’s consistent between New Zealand and Oregon. But often of course when the nor’west is blowing we don’t get a dew,” he says.

“It’s too early to say for sure if we can simulate the same effect with irrigation when conditions are hot and

dry, but there could be 200 kg per ha in it, so we’re planning to continue collecting data.”

They’re hoping to compare windrowed ryegrass seed with disc mown for the irrigation experiment, but this has yet to be confirmed for the 2023/24 trials.

Compared with 20 years ago, when it was not unusual to record as much as 1000 kg/ha of saleable seed lost at harvest, and 500 kg/ha was common, growers’ losses today appear much reduced.

“We’re a lot better at judging the cutting window now. When FAR last did harvest loss assessments in the mid

2000s, many losses were due to seed falling out before cutting.”

“The big difference now is that growers appear much more aware of the potential losses, weather forecasting is better and generally we cut before the seed is lost,” Richard says.

That said, there’s still room for gain, especially given both the wide range of heading dates now grown for commercial harvest, and the corresponding risk posed by increasingly unpredictable weather patterns.

In 2023, with the Base perennial ryegrass crop used for the SIRC trial, seed moisture was lost at 1.5% SMC per day from early January, and seed yield was maximised when cutting occurred at or above approximately 39% SMC.

Dressing losses were highest when the crop was windrowed at or above 45% SMC, indicating seed fill was incomplete at cutting.

But those results were for just one late heading date cultivar (+22 days), in one particular set of largely

warm, dry harvest conditions.

With a gap of 20 days or more in flowering between early and late heading tillers within the same crop, striking the Goldilocks zone between cutting late-maturing seed heads too soon, and early-maturing seed heads too late, is a balancing act.

Shattering at low SMC before or at cutting remains the main cause of seed being left on the ground, and losses can be deceptive because they don’t always show at the time of cutting but fall out of the row during dry down.

Richard and Owen will again investigate optimum harvest timing for perennial ryegrass seed in the coming season.

Also scheduled for a repeat is testing the use of a crop desiccant to improve harvested seed yields.

Year one work in 2022/23

followed on from the really wet harvest in 2021/22, Richard says.

Applying a desiccant to reduce SMC prior to harvest could reduce the time from cutting to threshing, and/or reduce ryegrass re-growth following cutting.

Historical research from the United Kingdom however showed applying a preharvest desiccant resulted in a high level of abnormal seed and low germination rates.

“Re-growth after cutting was quite a bad problem for anything with a heading date

of +14 days or more in the 2022 harvest, and there was a lot of grower enquiry at the time about desiccation as a salvage tool, so we wanted to look into this particularly regarding any impact desiccant might have on seed quality.”

Glyphosate was thus applied to the Base perennial ryegrass used in last year’s trial three days before the targeted windrowing date.

This did stop plant regrowth after cutting, and seed yield results for this treatment looked similar to

those achieved with no desiccant, but germination results have yet to come back from the laboratory, Richard says.

Ryegrass seed is considered to have reached physiological maturity at approximately 37% SMC.

At physiological maturity the seed stops feeding, and as such cannot translocate chemicals into the developing seed. However, the seed may still be vulnerable to direct chemical uptake while it remains green.

For more detail contact FAR.

The all-new Continental Farm Tyre range has extra grip to help lower fuel costs and get the job done faster. There’s extra resistance, with N-Flex technology to absorb deformation and damage, for a longer lasting, more comfortable ride. All backed by 10 year manufacturer's warranty. It all adds up to a better season, every season.

As seed crops go, plantain is far from a heavy hitter.

Only 165 ha were grown for certification last season, placing it between phacelia and meadow fescue, and measuring less than 1% of the area sown for certified perennial ryegrass seed.

But phacelia, meadow fescue and even perennial ryegrass aren’t getting half the end-user publicity plantain continues to get.

And where there’s demand for seed, there’s also demand for finding ways to grow better, higher yielding seed crops.

So it’s no surprise that Seed Industry Research Council (SIRC) trials are once again in the ground this autumn to help fine-tune recommendations about the yield effects of nitrogen and fungicide in particular.

These are the latest steps in an on-going programme which began in 2018/19 to get growers closer to what Richard Chynoweth from FAR says is plantain’s commercial yield potential of 3000 kg/ha or more.

“It can produce really well. But right now we probably only achieve half of that potential at best, at 1500-1600 kg/ha, with average yields perhaps 1000-1200 kg/ha. There’s a very wide variation between crops, so it’s hard to know for sure.”

It’s not an easy crop to grow, he says.

“You can’t use much in the way of broadleaf herbicides, so there aren’t

Then there are pests to consider, like plantain moth and slugs, as well as disease.

“Plantain moth is a problem in seed production – it needs to be controlled around the time of seed head emergence and flowering – and slugs love it too. They’re not an issue once the plantain is established, but can cause massive problems for following crop.”

Phomopsis stalk disease, which results in stem collapse below the plantain seed head, is a major challenge, because affected stems commonly produce no saleable seed.

It’s also severe in second year crops, -

FARMERS GROW CROPS SUSTAINABLY

Capacity, capacity, capacity and extreme endurance with the Condor range of sprayers from 5,000-8,000 litres.

The most innovative sprayer in the world. Condor offers the most stable spraying with StabiloPlus, every drop hits the right spot and booms available up to 55 m.

Full circulation and no rest liquid with GreenFlowPlus. Optimal control and intuitive operation with EcoTronicPlus.

(topographic, soil type or pest maps) combined with boom mounted cameras to reduce chemical usage.

That’s the question behind a new trial and demonstration area that went into the ground in late April and early May, at the FAR Arable Research Site at Chertsey, and on commercial farmland.

FAR’s Ivan Lawrie, who is involved with new value chains, says that while there is farmer interest in growing more linseed, it has to be a viable crop.

“There’s not a lot of information on current commercial crop yields, but from what growers tell us, they can achieve over 3.5 tonnes/ ha. We want to see if we can improve that for higher returns.”

FAR is working with Bio Oils New Zealand which already contracts and manages linseed crops in Canterbury for oil extraction for export and domestic markets and is looking to identify cultivars with the right quality parameters.

Daryl Prebble, head of production and quality con-

trol for Bio Oils, says the best yield recorded by its growers so far has been 4.8 tonnes/ ha.

As well as measuring the yield difference between different sowing dates, FAR also wants to find out if some of the new linseed varieties from overseas present any advantages over the ones that are used now, Ivan says.

Up until this year all linseed has been planted in the spring because this suits growers’ rotations and the cultivars available, like Juliet, Bilton, Bilstar, and Hinau are best suited to spring sowing.

Autumn sowing linseed has the potential to make more rational use of land over winter, Ivan says, and both basic principles and overseas evidence suggest that the longer the crop is in the ground, the more biomass it accumulates and the higher its seed yield.

Four cultivars have been autumn-sown this year, comprising one commercial

standard (Bilton) and three winter breed imported lines. Their performance will also be compared to spring sowings of other suitable cultivars to understand if autumn sowings present an advantage.

Agronomic benefits of linseed for growers include providing an alternative break crop from grass-type crops, increased diversity in the rotation and the opportunity

Linseed grown in New Zealand has some of the highest alpha-linolenic acid (ALA) levels in the world.

to address soil health and hard to control weeds.

Ivan says there is a fledgling export market for high value NZ grown linseed oil for human consumption, thanks to its highly concentrated alpha-linolenic acid (ALA) levels.

NZ produces seed with some of the highest ALA levels in the world, Daryl says, and the crop is ideal for Canterbury.

“Canterbury is the best region in NZ for growing linseed due to the soils, climate, day to night temperature variations and growers’ management skills.

“Linseed is well suited to any Canterbury soil type with most lighter soils now being irrigated. Each region requires slightly different management depending on the location and season.”

The crop is ideal for Canterbury.

comes an annual crop.

Richard and fellow FAR researcher Owen Gibson have confirmed fungicide treatment to control phomopsis significantly increases plantain seed yield in both first and second year crops. They are now investigating different modes of action.

Growers are currently heavily reliant on prothioconazole (Group 3), so fungicide treatments for this year’s plantain trials now in the ground at the FAR Arable Research Site at Chertsey will be extended to bring in other groups.

They will also repeat trials on seed yield response to spring nitrogen, as pre-

vious research has been inconclusive, Richard says.

“We have one set of results which showed that spring nitrogen did positively influence seed yield, and one which showed that it didn’t, so we need to firm that up.”

For more detail contact FAR.

A quick way to assess the biological health of soil has been developed using molecular techniques to measure earthworm activity.

But this needs more work before it’s ready for use on New Zealand farms.

Roger Hill of Hill Laboratories imagines a day when farmers can not only test the fertility of their soil but, using the same samples, also get an assessment of their soil health based on the level of earthworm activity from traces of their DNA found in the soil.

“Currently earthworms are assessed by going out to a field and taking a spadesquare down to the depth of the spade, taking that soil, breaking it up and counting the earthworms. We realised that perhaps we could use our capability with DNA testing to develop a faster and more convenient earthworm test,” Roger says.

He also says that interest in the health of our soils, beyond the common measures of fertility, is growing both among farmers and consumers.

Earthworms are a key component of the soil biology and abundant populations are recognised as a sign of a healthy soil.

Current methods used to identify earthworm populations are labour-intensive.

Roger says that while much is known about how to test the chemical and physical properties of soil, assessing its biological properties is less well developed.

“From what I’ve read, less than 5%

of the organisms that live in the soil have been identified. But when you talk about soil biological health, one of the first things that comes to mind is earthworms, and people associate good earthworm activity with healthy soil,” he says.

This study involved three different species of common NZ pasture earthworms – Lumbricus rubellus (epigeic), Aporrectodea caliginosa (endogeic) and Aporrectodea longa (anecic) – being hand sorted from soil samples (20 × 20 × 20 cm) collected from farms in Canterbury, Waikato and King Country.

Hill Laboratories’ scientists Lisa Hsu and Sara Loeffen worked with AgResearch scientist Nicole Schon on the project, funded by Our Land and Water via its Rural Professionals Fund.

“There was published information about DNA for those three types of worms, but when we took the literature data and designed a test around those it wasn’t completely successful,” Roger says.

“So our scientist Dr Hsu got some earthworms from Dr Schon and sent samples away for the DNA to be characterised and we went right back to first principles to develop the tests.”

Next was to develop a reliable way to assess actual worm populations from

the DNA test results.

Spade-square samples were taken, the worms counted and then DNA levels in adjoining core samples measured.

The intention was to establish a correlation, and therefore derive a conversion formula that could then convert the DNA result into units that people are used to (i.e. numbers of earthworms per sq m).

Soil samples collected from five sites showed a good correlation between molecular and morphological assessment, good extraction efficiency and precision.

Further samples analysed during the validation stage of the project reduced the strength of correlation between the molecular and morphological assessment of earthworms. Investigation into the factors causing this are ongoing.

“Initially the first few samples looked promising, but then as we added more soils from different areas the correlation weakened significantly, to the point that as we finished the project we thought, ‘This isn’t good enough’,” says Roger.

Work is continuing beyond the initial trial to improve that correlation, selffunded by Hill Laboratories and with the support of AgResearch scientists.

“To work out why the correlation is not as good as we would have expected, we need to understand more about the stability of DNA residues in the soil and the behaviour of earthworms,” says Roger.

“In particular, we need to quantify the uncertainties associated with each of the two approaches (DNA sampling and physical counting).”

Factors now being studied include the stability of DNA in fresh soils, earthworm behaviour after heavy rain compared with when soil is dry, and the accuracy of taking spade-square samples in a paddock for assessing worm populations.

Several hundred samples will be taken to better understand those issues.

Roger says good progress was made in the Our Land and Water project, but not yet good enough for a reliable test that can be offered to farmers commercially, as was hoped.

“Because we do many thousands of samples a year for fertility testing, we would like to be able to do this test on the same soil sample as it has already been collected, dried and ground for the other tests. If it’s just a tick box to say, ‘I’d also

Roger Hill (Hill Laboratories) collecting worms from a spade-square sample.

Earthworms were collected and sorted manually into three separate species.

like an earthworm assessment’, from a commercial point of view, that’s very convenient for everybody.”

What the uptake of such a test would be among farmers is difficult to estimate, Roger says, although he expects those interested in the biological health of their soils are likely to be very interested.

“With something like phosphate availability, a soil test may show it’s very

low, and if you put phosphate on you can expect a significant improvement in production.

“This new test won’t be quite like that, it’s more to provide insight about earthworm activity in the soil.”

Roger believes that with our overseas clients showing increasing interest in whether their food is produced in a sustainable manner, there could also be

• This study has shown that earthworm eDNA in the soil can be measured successfully and, in many cases, correlate well with the earthworm counts by traditional visual assessment.

• The project identified suitable primers for the most common earthworms found within each earthworm ecological group in New Zealand.

The test was sensitive to changes in earthworm abundance at individual sites. Further data needs to be collected prior to the test becoming commercially available to ensure confidence in the test developed, and the ability to predict earthworm abundance and diversity. SUSTAINABILITY

marketing advantage for Aotearoa.

“To be able to say to our overseas customers that we are monitoring the soil’s biological health with regular testing for earthworm activity, I think it could be useful as a marketing ploy, especially in terms of selling our produce at the top end of the market.”

No-one’s better placed than Arxada to formulate a slug pellet to make the most of META. That pellet is AXCELA. AXCELA slug pellets are produced using a unique wet-extruded production process.

® AXCELA slug pellets are better because they have an immediate effect on a slugs ability to feed. Put simply, they kill more slugs, more quickly.

Väderstad Tempo gives your valuable crops the best possible start. Delivering unmatched precision, this high-speed planter gives exceptional performance in all conditions across no-till, min-till or conventional tillage operations.

Integration of livestock is a strength of the New Zealand arable farming system, but challenges lie ahead, a Mid Canterbury field day has been told.

The event, the first time the Foundation for Arable Research and Beef + Lamb NZ have combined resources to hold a joint field day, attracted about 150 farmers.

FAR senior environment researcher Abie Horrocks says NZ arable growers have some of the most diverse crop rotations in the world.

In comparison to arable soils overseas, the degree of livestock integration means arable soils are in better condition because rotations that include livestock can support inclusion of restorative crops, such as ryegrass, that build soil organic matter.

In addition to soil quality, nutrient cycling and cashflow, there are other reasons why arable growers have livestock.

These include weed control, natural tillering (managing height and bulk of grass seed crops), crop residue management and rotation fit.

In NZ, pastures hold 109 to 138 tonnes of carbon per hectare and cropping soils 90 t per ha (2018 Ministry for the Environment report).

This compares with 10 t per ha for some overseas cropping soils.

“This reflects the diverse rotations in the New Zealand arable system and frequent inclusion of restorative phases,” Horrocks says.

As new environmental and greenhouse gas emissions regulations come on-stream, regulators need to be wellinformed of the role livestock plays in an arable farming system.

“If soil quality declines, more fertiliser and irrigation may be required.

“Removing livestock from mixed rotations may have an unintended consequence of increasing pesticide use and if weeds become more problematic as a result it could introduce a risk to the production of weed and disease-free pure seed lines.

“Quality seed lines are the ultimate driver in an arable business,” she says.

Four Canterbury farmers outlined the importance of livestock to their arable farming operations.

Hamish Marr, who farms Longfield near Methven with family, says that animals, unlike crops, are not at risk of damage from hail, frost and wind storm.

Longfield winters 800 dairy cows as well as grazing 600 dairy heifers.

As the Marrs specialise in cocksfoot seed production, which is shut from grazing in June, compared with October for ryegrass, it was difficult to buy lambs and have them finished by then.

“Some years we made money, but a lot of years we didn’t.”

Instead, they changed their policy and now graze 4000 lambs for another farmer.

Longfield has 400 ha of arable crops, including cocksfoot, process peas, wheat, barley and red clover as well as 100 ha of pasture.

It has two separate cropping rota-

tions, one based around cocksfoot seed production and the other based on the pasture, with a five year rotation based around both.

“There is not a lot of chemical resistance in Mid Canterbury yet, but it is coming. Pasture and animal integration lengthens our rotation and the longer the cropping rotation, the greater exposure to different modes of management,” Hamish Marr says.

Westerfield farmer Darryl Oldham, who farms a 200 ha family property, says he initially grazed dairy cows in winter but for environmental reasons went back to lambs which provided a lot of flexibility around the timing of buying and selling.

FAR chairman Steven Bierema, who hosted the joint field day, says the winter grazing of livestock plays an important role on his Mitcham farm near Rakaia, which is fully cropped in summer.

The 500 hectare farm buys in 4000 lambs in March and April for finishing as well as winter grazing 400 dairy cows.

Steven farms in partnership with his son Pieter Taco Bierema. They grow ryegrass, clover, pak choi, garden peas, marrowfat peas, maize, barley and milling and feed wheat. Land is also leased to others for growing lilies and potatoes.

Finishing of lambs is closely linked with ryegrass, with the last of the lambs sold to the meat works in mid-October when the last paddock of ryegrass is closed for seed production.

On arrival, lambs are given a vaccine and after a feed transition period grazed on former clover seed paddocks

Four Canterbury farmers outlined the importance of livestock to their arable farming operations. Hamish Marr, of Methven, speaks during a farmer panel session made up of, from left, Darryl Oldham, Pieter Taco Bierema and, far right, Erica Callaghan.

until the end of May. Left to regrow after being harvested in February, these produce 3000 kg of DM/ha.

This is then sown in milling wheat, utilising the extra nitrogen in the soil from nitrogen-fixing clover.

In winter, lambs are grazed on greenfeed oats, which are drilled after either peas or cereal crops.

Dairy cows are winter grazed on kale and some short rotation Italian ryegrass after peas.

“It sounds complicated, but it is not. The cropping and the lambs in winter really complement each other,” Steven Bierema says.

“We try to maximise it as much as possible with the farm in full production all year. There is always something growing, either for crop production or livestock.”

Arable farmers need sheep farmers to breed lambs for them to graze, while sheep farmers need an outlet for store lambs they are not able to finish themselves. “We need each other.

“Lambs only work for us if we can crop the whole farm in summer and fin-

ish lambs in winter and not have ewes ourselves, especially under irrigation.”

This year, the Bieremas’ lambs were predominantly sourced from South Otago.

Tom Fraser, formerly of AgResearch, suggested forming long-term supply and grazing relationships with sheep farmers.

“A lot of hill country farmers struggle to rear their ewe hogget replacements, so like to send them to grazing in autumn and bring them back in spring.”

Hamish Marr says that in grazing relationships, farmers have to be prepared to compromise.

“You can’t go in thinking you will win every time; there has to be mutual benefit for both.

“Those people are there. Ask the agents about people wanting hogget grazing or a permanent solution to getting rid of store stock.”

North Canterbury Vets Clinics veterinarian and Wormwise facilitator Sarah Williams says drench resistance is now common and about a third of New Zealand sheep farms have worms resistant to all three drench families.

“For arable farmers, the biggest risk

Steven Bierema and son Pieter Taco with lambs grazing a harvested clover seed crop. Winter finishing of lambs fits in well with their cropping operation.

is buying in animals with resistant worms.”

Farmers are advised to avoid unnecessary drenching and to develop an animal health plan with their vet.

No new drench families are coming and research and development spending in this area is declining, Sarah Williams says.

“Start developing systems that are not reliant on drenches.”

Even distribution is guaranteed with the Sulky X 40 ECONOV fertiliser spreader.

Hopper capacity ranges from 1900 to 3000 litres and working widths of between 18 to 44 metres make getting uniform coverage across the paddock a breeze.

Plus, with a seven-year paint warranty you know the ECONOV will go the distance.

There’s nothing like a real-world insect pest incursion to test theoretical computer models of how such an unwelcome visitor might spread across New Zealand.

In this instance, confirmed reports of fall armyworm (FAW) surviving the NZ winter last year largely matched the overwintering risk hotspots that had been flagged in modelling work done by the Better Border Biosecurity (B3) consortium.

In turn, says FAR biosecurity spokesperson Ivan Lawrie, actual on-farm FAW findings have now been fed back into the model to help refine it further.

It’s one example of col-

laboration between B3 and FAR, through the Seed and Grain Readiness and Response (SGRR) partnership, on multiple projects, including some PhD scholarships, which seek to model scenarios for dispersal of pests and diseases under a changing climate.

It would be nice to think such tools would not be needed.

But if 2022/23 showed anything, Ivan says, it’s that NZ arable cannot afford to drop its guard for a moment.

• 4000, 5000 or 6000 Litre capacity

• 24-36 metre options

• Househam TMC (Total Machine Control) with Fieldmaster GPS and autosteer

• Improved Air Ride suspension

• Option of Caterpillar or MTU Engine

• New category 4 cab with improved layout and lighting

Between new and unusual climatic patterns that are already altering the pest and disease status quo and our position as a trading nation, reliant on imported seed to maintain our multiplication and export markets, the risk of biosecurity incursions is not only with us permanently, but will be ever-changing, he says.

FAW’s spread from Kaitaia to the West Coast of the South Island, with 139 confirmed reports, was itself indicative of the mild weather conditions that prevailed throughout the 2022/23 season.

“There will be research undertaken this year to better understand its distribution, biology and control within NZ,” Ivan says.

• Specialised fertiliser spreader designed for professional users

• Perfect variable width & rate spreading

• Auto turn on and off at headland

• Isobus operated 12 section control

• Versatile Lime & Fertiliser spreader

• Two large spreading discs distribute Bredal’s signature 4 x overlap

• K45 – K165 models, trailed. Option to truck mount

• 3500 – 19,000 L capacity

• Working widths: Lime 12m. Fertiliser 12 – 36m

Crop scouting, trapping at key sites and awareness raising will continue, while research will be targeted at understanding potential green bridges, the pest’s overwintering capabilities, biological control, insecticide efficacy and management and the development of an online FAW alert tool using real-time climate data to provide growers with an indication of highrisk periods.

FAW is no longer classified as an unwanted organism now that the initial incursion response has finished and moved to long term management, so it is not mandatory to report finds.

But significant observations are important, so FAR is asking growers to record them and inform it.

Further, Ivan says, any information on new host plants will be welcomed as researchers begin to understand overwintering capabilities and green bridges.

FAW has been observed on ryegrass and clover in a harvested maize paddock, and volunteer maize should not be overlooked either.

Meantime blackgrass resurfaced on two properties in Canterbury in February, from a line of imported linseed seed from France.

Crops were subsequently destroyed on three proper-

ties deemed to be of highest risk, as was the remaining imported seed, and an ongoing surveillance plan is underway, Ivan says.

SGRR in partnership with the Government Industry Agreement (GIA) is facing the costs for this response, including compensation for growers affected.

Most recently, nine velvetleaf plants were found in a mid Canterbury paddock during routine surveillance before Easter. The paddock is associated with the 2015 velvetleaf incursion via imported fodder beet seed.

“To date, all plants have been removed and no others found. Surveillance remains active on that property.”

With FAW, blackgrass and velvet leaf, it has been a ‘particularly active’ year for SGRR, Ivan says.

And the single best thing growers can do to protect not only their crops and properties but the industry as a whole is to remain constantly vigilant for anything that looks suspicious, whether it’s a weed or an insect pest.

“There is no substitute for active monitoring of crops, and contacting us if they see something that is not quite right.”

For more information, contact Ivan Lawrie at FAR or visit www.mpi.govt.nz.

University of Queensland is working with the Queensland Department of Agriculture and Fisheries (DAF) to develop guidelines to help Australian grain growers decide when and how to treat fall armyworm (FAW) to save their crops and finances.

Dr Joe Eyre from UQ’s Queensland Alliance for Agriculture and Food Innovation (QAAFI) is working with DAF on the project, which has investment from the Grains Research and Development Corporation (GRDC) and will determine economic thresholds for the pest to give farmers certainty.

“The overseas recommendations for treating fall armyworm are vague, and we don’t know how they relate to the Australian environment,” Joe Eyre says.

“The current recommendations are to take action based on obvious damage from the caterpillars, which may not be the most economically efficient or ecologically friendly time to protect crops.”

The research project will establish the relationship between the timing of an infestation, its density and the crop’s response.

“Fall armyworm are easy to treat when small so we need to predict what the likely yield loss is going to be if the infestation is not treated, as opposed to spending money on treatments when it is too late or when FAW are unlikely to result in yield penalty.

“The development of these economic thresholds will be absolutely fundamental to the management of fall armyworm in broadacre crops.”

DAF’s Dr Melina Miles says field trials in maize and sorghum at UQ’s Gatton campus are providing important data.

“We haven’t had a severe defoliating pest before and most producers haven’t seen a shredded crop, so there’s a lot to learn.

“Australia’s grains industry is used to having economic thresholds on which to base decisions about crop management and farmers are crying out for guidance because fall armyworm is so damaging and new.”