Novel Test Methods for Electric Transmission Fluid Development

Yungwan Kwak and Christopher Cleveland

Afton Chemical Corporation, Richmond, VA

May 19th, 2022

76th STLE Annual Meeting & Exhibition, Orlando, FL

Introduction

Performance Requirements of Electric Drivetrain Fluid (EDF)

New eMobility Tests

Various Cu corrosion types, connectors, magnets and magnet wires, plastic materials.

Summary

The Drive to Electric Drivetrain Fluid (EDF)

Speed of change is high Risk is therefore high OEMs interest in:

Cooling performance

Efficiency

Material Compatibility

Mechanical protection • Antiwear • Bearing

OEMs are investing ~ $300 billion in the coming years to develop and launch electric vehicles. As resources shift to electric vehicle development, investment in traditional powertrains is decreasing.

Some OEMs are even questioning if Hybrids are a sustainable strategy

Major Components in eDrives

Electric Motor Power Electronics Reduction

Converts electrical to mechanical energy

Converts DC (battery) to AC (motor / generator)

Gear set reducing high rpm of eMotor to suitable output. Single or 2-3 speed

Compact system bringing these components together.

Allows each wheel independent speed (for cornering etc)

Electric Drive Unit Requires Optimized ETF

Electrical Properties

Fresh electrical conductivity

Electrical conductivity after aging

Dielectric breakdown voltage

Cooling Performance

Material Compatibility

Copper and other yellow mtls.

Plastics/insulation materials

Elastomers/seals

Water contamination

Thermal conductivity

Specific heat capacity

Oxidation

Mechanical Protection

Extreme Pressure

Pitting

Wear (Gear & Bearing)

Protection under electrification

Efficiency

Friction

Viscometrics

Thermal property

eMobility Tests to be Discussed

Various Cu Corrosion Tests: Static and Electrified Condition

Conventional Cu Corrosion Tests: Vapor and Liquid Phase Test

Vapor phase test

Cu corrosion behaves differently in vapor and liquid phase

No correlation between the amount of Cu dissolved and visual rating

Severe Cu leaching can cause hardware issue

Visual ratings are misleading for Cu corrosion

Cu corrosion under electrification and material compatibility important

Liquid phase test

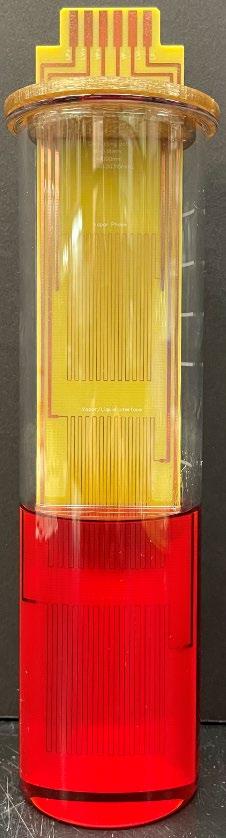

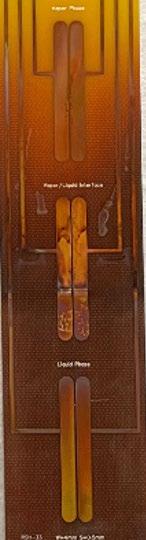

Copper Corrosion Test via Printed Circuit Board

Test condition

1 mV supply and 150 °C

Monitor resistance change over time

Liquid, interface, and vapor phase

Easy set up

Fluid A

Fluid B

Fluid C

Electrified Cu Corrosion Test via Printed Circuit Board

Test condition

10 V DC 0.5 mm electrode gap 150 °C

Monitors conductive layer

Evaluates 3 phases

Realtime evaluation

Easy set up

Low Voltage Connector Test

Assess conductive deposit on the connector pins under electrified condition

Liquid phase and vapor phase evaluation

12 DC voltage applied

Condition: 500 h, 1000 h, or longer at 150 °C

Conditions and parts selected with OEM and Tiers

Results of Low Voltage Connector Test

Good fluid @ 1000 hours

Bad fluid @ 500 hours

Bad fluid confirmed conductive deposit formation via resistance change

Clear differences between fluid chemistry/formulation

Degree of non-conductive deposit

Nature of S chemistry

V. P.

L. P.

Fresh

h

A B C D

Polyesterimide resin/varnish

20mm x 50 mm x 3 mm

Cured 1h at 150 °C

Aging tested in 150 °C

Color darkening

(lighter) A > C > D > B (darker)

Fluid chemistry important

Type of S more important

S content not critical Other various components

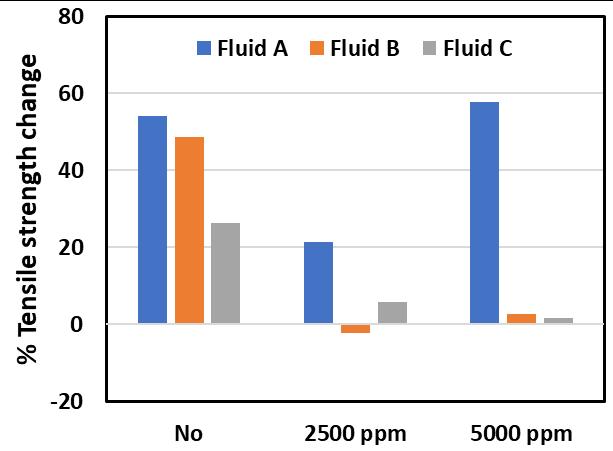

Plastic Material Compatibility Test

150 °C / 336 hour

Fresh A B C

Materials’ compatibility varies with fluid chemistry, material type, and water content

Permanent Magnet Test

Aged at 150 °C

Magnet strength decreased

20 – 28% No meaningful fluid contribution

Corrosion of surface (less) B < A < C (more)

Fluid chemistry affected corrosion not magnet strength

Magnet typically not direct contact in eMotor

Breakdown Voltage of Magnet Wire

Thermal rating of 200 °C magnet wire (twisted pair)

Aging conditions

150 °C in a pressure tube

Aging time and water content affect performance

Fluid chemistry and formulation important

Partial Discharge Property of Magnet Wires

PD or corona discharge occurs when sufficiently strong electric filed applied, generating localized hot, fluorescent, and audible discharge

Typically, PDIV is much lower than BDV

Dependent on type of insulation and thickness of insulation

Aging of magnet wire deteriorate PD performance

Takes long time to see differences without added water

Concept demonstrates that we can screen for compatibility

Discrimination between good and bad fluids

Fluid formulations can be adjusted to improve compatibility Diversity of designs means divergent needs

New requirements on top of all conventional requirements

The optimum solution will differ for each OEM

Working closely with expert partners is the best way to develop optimized ETF technology

Close collaborations with OEMs/Tiers

• Conditions and parts relevant to the OEM applications

Salute industry activity