Are you copper confident?

Compatibility testing has come a long way. Older test methods involved simply bathing a copper strip in hot oil and then visually inspecting the result. They were then later adapted to also measure dissolved copper in the oil. These tests have been supplemented by tests that immerse an electrified copper coil and measure its changing electrical resistance. Tests have now advanced to assess lubricants in both their liquid and vapor phases.

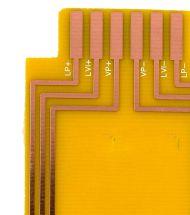

The future of copper compatibility testing may lie in the latest suite of enhanced, multi-phase tests, which o er greater sensitivity and insight into failure modes. By using standardized printed circuit boards (PCBs) instead of thin copper wire, e iciency, repeatability and real-world relevance can be improved. A test oil temperature of 150°C is used to accelerate test duration without undue severity.

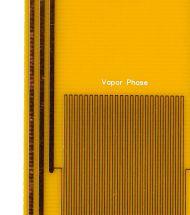

Designed by Afton Chemical, using di erent PCB layouts, tests are run until failure, for up to 1,000 hours. The multi-phase copper leaching test measures rising electrical resistance in three circuits until corrosion causes electrical interruption. The multi-phase conductive deposit test continues until each of three circuits shorts out due to the formation of a conductive layer (dendrite). Both methodologies clearly di erentiate performance in the liquid phase, the vapor phase, and the interface between the two, with good repeatability.

Afton’s findings show that the best-performing fluids have minimal impact on copper circuitry, while typical gear oils can be catastrophic – especially in the vapor phase or at the interface. Visual inspection echoes the electrical results, with corrosion

varying from mild discolouration to delamination or complete dissolution. Measuring the dissolved copper in the oil at the end of the test provides additional validation. Multi-phase PCB testing can take this approach even further, using stacked circuit boards held precise distances apart with a 3D-printed spacer. Spacing determined through collaboration with OEMs to be real-world relevant, creates a demanding multi-phase test for assessing copper compatibility. Test performance has implications for eAxle lubricants: classic formulations that protect gears from wear often contain chemistries that can be aggressive toward copper, especially in the vapor phase. Striking the right balance of characteristics is essential. Opportunities for oil to contact bare copper should, in theory, be fairly limited in electric powertrains. Most copper in EV powertrains is insulated with polymer coatings or other sealants. However, should that insulation become compromised through aging or quality issues, fluid compatibility with copper becomes of critical

importance. Moreover, in some areas – such as the three-phase end terminal connecting eMotor with power source or inverter –the copper pins are uncoated, exposing them to potential vapor phase corrosion. Assessing vapor phase corrosion also helps assess risk for electronic controls, sensors, and mechatronics, even in neighboring compartments.

Afton’s in-house test development team is further investigating fluid compatibility with various coatings on magnet wire such as polyesteramideimide, polyimide, etc., aiming to minimize the chances of insulation damage. This test methodology provides an indicative level of fluid performance with commonly used coatings or can be adapted to specific OEM materials if desired.

Understanding copper corrosion failure modes is fundamental to EV reliability and longevity; OEMs and lubricant experts working in collaboration to gain insights from the latest test methodologies will form a solid foundation for true copper confidence. www.a onchemical.com

It is time to embrace more innovative copper compatibility testing that is tailored to the materials and operating conditions found in electric powertrainsElectrifi ed copper-oil compatibility testing delivers live feedback of liquid phase, vapor phase and the interface Direct-cooled eMotors are gaining increasing interest due to improved effi ciency