Fluid protection for electrified bearings

With a focus on bespoke in-house testing, Afton Chemical is exploring the benefits of lubricant additives as a coste ective solution, while developing bearing tests with greater relevance and value to the EV industry.

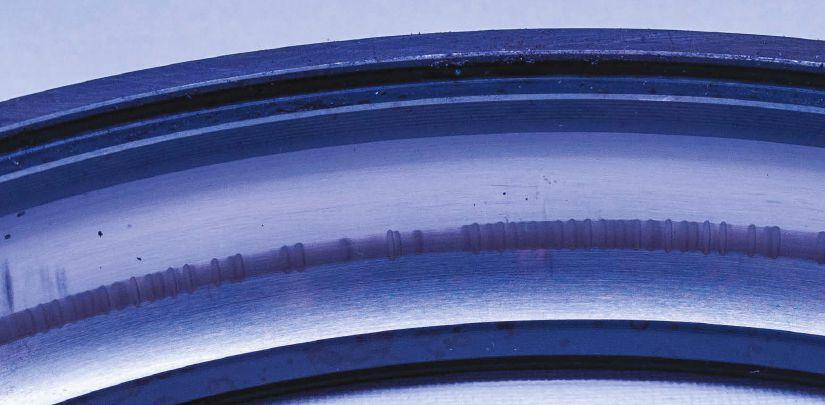

Bearing failure modes in electric drive systems are increasingly under scrutiny. Specific types of damage are being observed in bearings, causing discernible vibration and noise. An in-depth understanding of the mechanisms that lead to this type of failure is essential for developing mitigating solutions.

When an eMotor inverter constructs an AC waveform, multiple stray voltages are also generated within the motor. These chaotic voltages build up and discharge as an electrical arc. When electricity discharges across bearing components, surface damage occurs in the form of a tiny pit. Over millions of cycles arcing can cause frosting or fluting, which results in bearing noise and vibration that is apparent to the driver. If distressed bearings are allowed to deteriorate further, complete eMotor failure can result.

Potential hardware solutions include using bearings with greater conductivity to help control stray voltages, but these can lack durability. An alternative option is using non-conductive ceramic bearings; these add considerable expense. Attention has turned therefore to how lubricants and additives can positively influence electrified bearing performance and durability.

Intuitively, fluids with the right balance of electrical properties could help to dissipate stray voltages and protect bearings from arc damage. Establishing this in practice requires a mechanical rig that can accurately

reproduce stray voltage spikes in a repeatable manner.

Afton Chemical’s R&D facility specializes in bespoke mechanical rig design and development and can apply relevant testing conditions to evaluate additive performance characteristics in specific applications. Interestingly, the profile of stray voltages and currents is unique to each OEM’s electric drive unit. Being able to assess this aspect of a particular eMotor, then recreate the specific conditions that lead to electrified bearing failure, requires considerable R&D investment but is invaluable for developing electric drives with long-term reliability.

Existing industry bearing tests, such as FE8, do not represent the actual conditions electrified bearings experience. Bespoke testing on a purpose-built rig allows replication of real-world failure modes, enabling a holistic approach to lubricant formulation. Each adjustment in additive chemistry to improve one area of performance risks detrimental e ects on another, making fluid development an iterative and lengthy process. The deeper insights gained from in-house testing can enhance the e iciency and speed with which new lubricant additive packages are developed. This also avoids the need for expensive, time-consuming,

whole-vehicle testing, which makes it challenging to test variables independently.

The result of Afton’s close OEM partnerships is a bespoke rig and test method that can accurately assess electrified bearing performance quickly and repeatedly. This has huge potential as a valuable industry test, with new bearing durability tests being considered in parallel. With this greater system understanding, engineers and chemists can work together in order to establish the best possible fluid solutions for current and future electric drive designs.

a onchemical.com

Despite variation in hardware design, OEMs face many common EV lubrication challenges – one being how best to protect eMotor bearings operating in an electrified environmentBearing electrical fl uting damage from a custom-built test rig