PRODUCTS & SERVICES

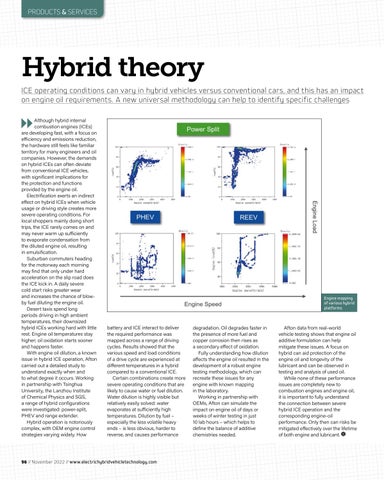

Hybrid theory ICE operating conditions can vary in hybrid vehicles versus conventional cars, and this has an impact on engine oil requirements. A new universal methodology can help to identify specific challenges Although hybrid internal combustion engines (ICEs) are developing fast, with a focus on efficiency and emissions reduction, the hardware still feels like familiar territory for many engineers and oil companies. However, the demands on hybrid ICEs can often deviate from conventional ICE vehicles, with significant implications for the protection and functions provided by the engine oil. Electrification exerts an indirect effect on hybrid ICEs when vehicle usage or driving style creates more severe operating conditions. For local shoppers mainly doing short trips, the ICE rarely comes on and may never warm up sufficiently to evaporate condensation from the diluted engine oil, resulting in emulsification. Suburban commuters heading for the motorway each morning may find that only under hard acceleration on the slip road does the ICE kick in. A daily severe cold start risks greater wear and increases the chance of blowby fuel diluting the engine oil. Desert taxis spend long periods driving in high ambient temperatures, their downsized hybrid ICEs working hard with little rest. Engine oil temperatures stay higher; oil oxidation starts sooner and happens faster. With engine oil dilution, a known issue in hybrid ICE operation, Afton carried out a detailed study to understand exactly when and to what degree it occurs. Working in partnership with Tsinghua University, the Lanzhou Institute of Chemical Physics and SGS, a range of hybrid configurations were investigated: power-split, PHEV and range extender. Hybrid operation is notoriously complex, with OEM engine control strategies varying widely. How

Engine mapping of various hybrid platforms

battery and ICE interact to deliver the required performance was mapped across a range of driving cycles. Results showed that the various speed and load conditions of a drive cycle are experienced at different temperatures in a hybrid compared to a conventional ICE. Certain combinations create more severe operating conditions that are likely to cause water or fuel dilution. Water dilution is highly visible but relatively easily solved: water evaporates at sufficiently high temperatures. Dilution by fuel – especially the less volatile heavy ends – is less obvious, harder to reverse, and causes performance

96 // November 2022 // www.electrichybridvehicletechnology.com

degradation. Oil degrades faster in the presence of more fuel and copper corrosion then rises as a secondary effect of oxidation. Fully understanding how dilution affects the engine oil resulted in the development of a robust engine testing methodology, which can recreate these issues for any engine with known mapping in the laboratory. Working in partnership with OEMs, Afton can simulate the impact on engine oil of days or weeks of winter testing in just 10 lab hours – which helps to define the balance of additive chemistries needed.

Afton data from real-world vehicle testing shows that engine oil additive formulation can help mitigate these issues. A focus on hybrid can aid protection of the engine oil and longevity of the lubricant and can be observed in testing and analysis of used oil. While none of these performance issues are completely new to combustion engines and engine oil, it is important to fully understand the connection between severe hybrid ICE operation and the corresponding engine-oil performance. Only then can risks be mitigated effectively over the lifetime of both engine and lubricant.