The role of TBN in Engine Oil

What makes up an engine oil additive package?

The majority of the engine oil additive package is made of dispersants and detergents. Dispersants prevent sludge and enable soot handling, whilst detergents improve engine cleanliness by preventing deposits forming.

What is TBN (Total Base Number)?

TBN is an important part of the detergent in an engine oil. It is designed to react and neutralize acids in the engine. Acid can be caused by sulphur in diesel fuel or from oxidation of the oil. TBN works to prevent both by neutralizing acids as they form by creating a neutral salt. Without this neutralisation reaction, the acids would attack the metals in the engine. This reaction isn’t reversible, so the acid remains permanently neutralised.

How does sulphur in fuel affect the engine?

If there is less sulphur in fuel, then less sulphuric acid will be created in the engine. Today, the average sulphur level is 60% to 90% less than it was historically. This means your TBN needs today should also be proportionately lower. That’s because the sulphur level in diesel used to be a lot higher and >5,000ppm was the norm. Some markets are currently at 2,000ppm with further reductions planned, but most markets are now <500ppm.

Africa as an example

Fuel sulphur levels across the continent are reducing and this trend has been seen across many countries over the past 20+ years.

How are harsh conditions a factor for TBN?

Countries that still have a significant proportion of unpaved roads, or where road quality is poor, means mechanical problems - like sand and water in the engine oil - are more common and happen faster than in more developed countries. This means the engine oil is changed more frequently and possibly before the TBN is really used up.

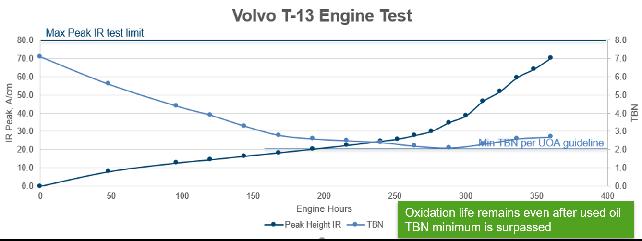

Its important to note that an antioxidant can often be more important than TBN to maintain oil quality over the oil’s lifetime, as these types of harsh conditions may promote oil oxidation.

Do Minimum Engine Oil Standards also play a role?

Many African countries have their own regulatory requirements to help ensure oil quality and to stop issues such as oil counterfeiting.

For example, in Nigeria’s 2006 SON (Standards Organisation of Nigeria) specification for API S and C claims, there was a TBN minimum of 6.5 for multi-grades and 5.0 for monogrades. However, the most recent SON specification does not contain a TBN requirement, as it was removed in the 2017 update. Elsewhere in Africa, Kenya has a TBN minimum of 10 for diesel engine oils, whereas in Tanzania, there is a TBN minimum of 7.

Regulations are not consistent, but they are beginning to change. People are beginning to recognise that TBN is not the only concern in engine oils.

What about Industry and OEM specs?

API and ILSAC have never mandated a TBN level in any of their specifications. However, ACEA and some OEMs do have TBN requirements in their specifications:

• Daimler Truck DTFR 15B110 spec has an 8 TBN minimum.

• Cummins’ 20078 spec has a 10 TBN minimum.

• Deutz’s DQC III-18 has a 9 TBN minimum.

• MTU’s category 2 spec has an 8 TBN minimum.

There is no one number all OEMs agree on, because different OEMs use different test methods and have different drain intervals, so they adjust their TBN needs accordingly.