FEW stories capture the spirit of Australian enterprise quite like that of Greenham Australia. From its humble origins, beginning as an immigrant butcher shop in Melbourne during the early 1800s, the business has grown over the decades to become a major player in the Australian beef industry. Throughout its evolution, Greenham has remained true to its core values while continually embracing innovation to meet the demands of the modern, global market.

A key element of Greenham’s enduring growth and success is its Tongala facility, which, after 30 years of operation, underwent a significant redevelopment. Reopening in 2023 as a state-ofthe-art facility, it is now capable of processing up to 1,050 cattle per day. This upgrade reflects Greenham’s commitment to delivering world-class beef while upholding its environmental and ethical responsibilities.

The company’s success is built on a rich heritage and is carried forward by continuous innovation, all while staying committed to its environmental and social responsibilities

To be the BEST, not the biggest, is Greenham’s mission, a principle that drives its steadfast focus on quality, integrity and customer satisfaction. Working closely with local farmers, the business prides itself on establishing longterm partnerships that ensure a consistent supply to both domestic and export markets. From 100 per cent grass-fed to premium wagyu, Greenham’s beef is renowned worldwide for its exceptional quality.

The Tongala facility has also played a vital role in the local community. Its recent expansion created 230 full-time jobs,

reinforcing the meat-processor's position as a major employer and economic driver in the region.

Sustainability is also embedded into every aspect of Greenham’s operations. The Tongala site features 1,000 solar panels, cogeneration systems to maximise energy efficiency, and advanced water recycling practices, all of which minimise environmental impact while supporting long-term resource conservation.

The company’s success is built on a rich heritage and is carried forward by continuous innovation, all while staying committed to its environmental and social responsibilities. In a dynamic global market, where Australian beef is highly regarded, Greenham exemplifies what can be achieved when tradition meets progress, and Australian ingenuity go hand in hand.

Greenham is a sixth generation, Australian family-owned business in high-quality, responsibly raised beef from some of Australia’s most renowned beef-producing regions. We believe that how and where your beef is bred, fed and raised directly affects how it tastes. With this in mind, we work with the best cattle producers across southern Australia and Tasmania who are committed to responsible beef productions.

IN today’s fiercely competitive global marketplace, where success is built on innovation, efficiency and vision, it’s more important than ever to champion the strength of local industry. One name that continues to stand out in Australian manufacturing is Pental, a name that has become synonymous with household trust, quality and local pride.

For generations, Pental has operated from its manufacturing plant and distribution centre in Shepparton, producing some of Australia’s most iconic household brands such as White King, Softly, Jiffy, Sunlight, Janola and more. These aren’t just cleaning and homecare products, they’re part of a long-standing commitment to Australian-made excellence.

Each product that rolls off the Shepparton production line represents more than just a brand. It symbolises local jobs, economic resilience, and a proud manufacturing legacy. In a competitively charged world where many companies move offshore, Pental’s continued investment in Australian operations sends a powerful message about the value of local production.

Following its acquisition by Dulux Group, Pental has entered an exciting new chapter. With millions of dollars invested in facility upgrades, the company is enhancing its manufacturing capabilities and reinforcing its leadership in innovation, sustainability and efficiency. This isn’t just about modernisation, it’s about future-

More than a success story, Pental is proof that when a homegrown enterprise invests in local talent, infrastructure and innovation, it not only strengthens communities and the economy, it champions the very best of Australian industry to the world.

proofing an iconic Australian company for generations to come.

At the heart of Pental’s success is its people. By harnessing local knowledge and expertise, and providing ongoing opportunities for skill development, Pental operates 24/7, driven by a local workforce dedicated to manufacturing

products fit for the world stage.

CHAMPIONING THE STRENGTH... of local industry, producing some of Australia’s most iconic household brands, Pental’s Shepparton manufacturing plant and distribution centre not only bolsters the local economy by providing jobs, but also invests in local talent, infrastructure and innovation - proudly promoting the very best of Australian industry to the world.

More than a success story, Pental is proof that when a homegrown enterprise invests in local talent, infrastructure and innovation, it not only strengthens communities and the economy, it champions the very best of Australian industry to the world.

and proud to be manufacturing products in Shepparton

Trusted by families for generations

These Pental brands are manufactured and packed by our team at our Shepparton facility

PROUDLY owned and operated by locals Nick McLean and Madi Sewell, GEM Electric Motors plays a critical role in keeping the region’s industries running smoothly. Specialising in the sales and service of electric motors, pumps, automation products and gearboxes, GEM provides a ‘service that’s a cut above’.

With over 16 years of hands-on industry experience, Nick brings a wealth of technical knowledge and innovation to the workshop floor. As President of the Australasian Chapter of EASA (Electro-Mechanical Authority), he also connects the business to global best practices, research, and emerging technologies, particularly in areas such as motor efficiency and environmental standards.

GEM’s strength lies not just in technical expertise but in its connection to the local community and industries. From rewinding electric motors to servicing pumps and gearboxes, GEM supports everything from municipal wastewater systems to the dairy farms and agriculture that form the backbone of the local economy.

“We’re the trade that other trades rely on to get the job done right in the region,” said Nick. “Electricians

and end users often rely on us for the motors and gearboxes that keep factories, farms, and processing facilities running.”

When asked what it means to be a locally owned and operated business, Nick said:

“As a locally owned and operated business, our biggest advantage is truly understanding our clients’ equipment and needs, not just reading specs from a desk. We’re on the ground, close to the work, and in tune with what services our customers require. It is understanding their equipment, what it does and the process it is a part of. I think being locally owned keeps our finger on the pulse of what local industries want and require.”

After recently moving into a larger, fully equipped facility, GEM is entering an exciting new phase of growth and is looking to expand its team. The business is currently hiring a junior apprentice or a qualified

Electrical Machine Repair Technician to help meet growing demand and continue delivering vital services.

“There’s a big skill shortage in our industry, and we’re focused on training the next generation and keeping those skills alive.” As a tight-knit, community-focused business, GEM offers more than just a job. New team members are welcomed into a supportive environment with opportunities for training, mentorship and longterm career growth. Madi, who leads administration and finance, is passionate about engaging with local schools to offer work experience and expose students to trade careers.

“It’s a niche industry, but it’s rewarding and full of opportunity,” she said.

GEM Electric Motors is looking for skilled Electrical Machine Repair Technicians. If you're interested, head to their website to learn more: https://www. gemelectricmotors.com.au

THIRTY years ago, Australia was facing significant water issues, primarily driven by its already dry climate, increasing demand, and the severe impacts unfolding during the Millennium Drought. In the mid1990s, population growth, agricultural expansion and industrial development were placing significant pressures on existing water supplies.

Rubicon Water's origins trace back to the early 90s, during a time when the Victorian Government set out to create independent rural water authorities to make rural water supply commercially self-sufficient.

In 1994, the Rural Water Corporation (RWC) was disbanded as the government regionalised water operations into independent authorities to manage each supply region identified under the RWC, paving the way for innovation and better water management practices. Amid this change emerged five engineers who saw an opportunity

to revolutionise and digitise gravityfed channel networks. In 1995, Bruce Rodgerson, Trevor Tennant, Gino Ciavarella, Tony Oakes and David Aughton founded Rubicon Water in Shepparton. Their mission was to transform inefficient, manually operated irrigation systems into automated networks.

In 1998, Rubicon formed a pivotal partnership with the University of Melbourne, a collaboration that continues today, combining engineering and academic expertise to tackle water challenges. The result was Total Channel Control (TCC): an integrated solution combining automated gates, flow meters, software, and communications to enable near on-demand water delivery.

This innovation, radical at the time, is now improving water distribution efficiencies to over 90 per cent, paving the way for more sustainable water management both locally

and internationally – with Australia accounting for less than one per cent of the global irrigated landscape. Rubicon's technology continues to attract global attention. Recently, the company hosted delegates from Italy and Chile, where projects are underway — including one of Europe's most innovative irrigation modernisation projects in Italy's Pontine Marshes, where Rubicon Water's technology is primed to solve an ancient Roman water management problem that has plagued the region well before Leonardo da Vinci mapped the area in the 16th century.

Demands on water are increasing worldwide, driven by population growth, climate change, and the need to produce more food with

fewer resources. Irrigated agriculture consumes approximately 70 per cent of the world's freshwater, yet more than half of this water fails to reach its intended destination due to lack of measurement and control.

With 2050 predicted to bring significant challenges for water availability and global food supply, Rubicon Water is contributing to the global effort through smarter, more sustainable large-scale water management. With proven technology now operating in over 20 countries, Rubicon is helping make more water available by reducing losses, improving efficiency, and supporting irrigators to do more with less.

Celebrating 30 years of global impact — with roots right here in Shepparton.

AMONGST the industrial landscape of Old Dookie Road, Future Recycling operates with a vision that goes beyond the clang and clatter of the recycling process.

This long-standing local business understands that its roots are firmly planted in the community and, as such, has cultivated a deep commitment to its well-being. More than just a place where discarded metal is given new life, Future Recycling actively champions local groups and sporting clubs, becoming

an integral supporter of the town's vibrant spirit.

"We believe our success is intrinsically linked to the strength of the wider community," said Shepparton Branch Manager Daniel Thewma. "Being truly embedded here allows us to understand and contribute to the causes that matter most to our neighbours. Of course, their choice to recycle with us is vital, enabling us to continue investing back into the local fabric."

Future Recycling's commitment

to the region is multifaceted, encompassing not only significant donations and sponsorships but also a conscious effort to bolster the local economy by utilising other local businesses to support operations and by employing local people.

In 2024, Future Recycling demonstrated its strong community commitment by donating $18,000 to a wide array of local groups, from sporting clubs like football, netball, soccer, and golf to the crucial Neffy's We Listen Suicide Loss Support Group. This ongoing support was further exemplified last month with a $3,000 contribution to the Shepparton United Football Netball Club.

"The response to our local club sponsorships has been overwhelmingly positive," said Daniel, noting the significance of community feedback. "Knowing that our support directly benefits the children and families in the Goulburn Valley region reinforces the importance of our community involvement."

Dubbed "The best scrap yard in Shepp," the business is always looking for new ways to improve its service and the communities it operates in. You can find Future Recycling's Shepparton depot and dedicated weighbridge at 121-135 Old Dookie Road or visit www.futurerecycling. com.au to learn more.

Your next adventure awaits with Australia’s most popular brand of RV’s for over 50 years, Jayco.

Underpinning every Jayco is the unwavering commitment to provide all Australians with the opportunity for a safe and accessible option to discover

Over the years, Jayco has built a strong reputation for offering unrivalled quality RVs and competitive pricing. It’s this combination that has set Jayco apart and has underpinned its growth to become the leading player in the Australian RV market.

We take pride in the strength, security and quality of every Jayco RV built. All caravans and motorhomes undergo rigorous examination at our Quality Assurance Centre to ensure they meet our stringent requirements and each vehicle attests to the skill and attention to detail of our team. It’s no wonder one in every two new RVs sold in Australia is a Jayco.

our great country. Designed and manufactured at Jayco’s state-of-the art facility in Dandenong South, Victoria, supported by a network of over 150 dealers and service agents, backed by expert partners and suppliers and best in class engineering, safety and construction specialists so you can travel with confidence knowing you are backed by the best. Find your Freedom today.

As one of the nations most recognised brands for quality and value for money RV’s, we are proud to be endorsed with the official Australian made logo. Passing on the benefits to you as an Australian made manufacturer means you get quality construction from locally skilled specialists, premium componentry sourced from reputable suppliers and an RV built by the largest RV manufacturer in the Southern Hemisphere. Employing more than 1200 employees and supporting a further 900+ local jobs, Jayco proudly remains a

locally owned family business. Today, Jayco is one of the nation’s most iconic brands and Australia’s most recognised company for quality and affordable recreational vehicles.

The company is located at a 50-acre state of the art facility at 1 Jayco Drive, Dandenong South, Victoria, with a purpose-built 60,000sqm undercover manufacturing complex. This is where all Jayco RVs are made. It continues to operate as a locally owned family business employing more than 1,000 Australians.

FOR Redland Premium Fruits, the purchase of fruit packaging facilities formerly owned by Geoffrey Thompson Holdings in Mooroopna in 2023 was the "final piece of the puzzle."

One hundred per cent Australian-owned, this vertically integrated operation, now anchored by the significant Mooroopna assets, had finally assembled all the components of its ambitious vision.

"It's been great to be able to bring Redland to life as such, to be able to take full control of the level of investment that we've put into modern agriculture," said Head of Marketing Jordan Bain.

"We consider ourselves to be one of the most advanced, modern, permanent tree and vine crop producers in Australia, and if not, hopefully, globally," he said. "We really try to push the boundaries at a farm level to ultimately produce beautiful fruit."

Redland employs 201 people in the Mooroopna pack shed. At peak season, the facility produces

It’s been great to be able to bring Redland to life as such, to be able to take full control of the level of investment that we’ve put into modern agriculture

approximately 1,500 tonnes of citrus and 500 tonnes of apples each week.

From their burgeoning orchards stretching across Queensland, New South Wales, and Western Australia to the established apple and pear production of the Goulburn Valley, and now, crucially, these advanced packing facilities, Redland is in control of its destiny from the seed to the shelf. This control is vital as they cultivate a range of sought-after apple varieties, including the exciting new Sassy apple.

"It's probably the first genuine IP variety will come off the tree in Australia," Bain explained, highlighting its

early maturity and unique ability to colour in warmer climates, making it well-suited to Australian conditions.

Redland is also focused on established favourites and exploring opportunities with varieties like Dazzle, which Bain noted has potential for the discerning Chinese export market due to its sweetness and high colour. This focus on diverse apple offerings underscores Redland's commitment to meeting both domestic and international consumer demands.

This varietal strategy reflects Redland's commitment to catering to evolving consumer preferences around the world. Equally important is the company's investment in the local community. "We are invested in their community—through people, jobs, sponsorship, and food charity," Bain said.

FOR more than 160 years, J. Furphy & Sons has stood as a symbol of Shepparton’s engineering excellence. From its roots in tank and vessel manufacturing to its thriving galvanising operations, the business has consistently adapted to meet the evolving needs of industry.

As Australian continues to ramp up investment in renewable energy and largescale infrastructure to meet netzero targets, Furphy’s role has never been more critical. With operations in Shepparton, Albury, and Geelong, the company’s fabrication and galvanising capabilities are supporting the long-term durability of solar farms, transmission lines, and essential steelworks.

“The demand is growing, and we’re ready,” said Managing Director, Adam Furphy. “We see

We see galvanising and fabrication not just as services, but as essential components in building a sustainable future

galvanising and fabrication not just as services, but as essential components in building a sustainable future.”

From protecting steel against corrosion to strengthening Australia’s renewable infrastructure, J. Furphy & Sons continues to prove that regional manufacturers can lead the way – locally rooted, nationally relevant, and future-focussed.

With deep local roots, we’ve evolved from an agricultural implement maker into a leading, sustainable manufacturer of Australian-made street and park furniture and public open space structures.

Manufacturing remains at the heart of Furphy Foundry’s identity, with capabilities spanning steel and timber fabrication, cast aluminium, surface coatings, and product assembly and packaging.

Our in-house growth is bolstered by a strong local supply network, which provides critical components and parts across many of our locally-manufactured products. We credit our progress to the dedicated internal and external teams that deliver results every day. Proudly Australian Made and owned for more than 150 years.

WITH the heritage of an Australian manufacturing icon, Furphy Foundry has grown into a trusted name in public infrastructure. Their products ranging from street and park furniture to shelters, restrooms, BBQs and pedestrian bridges are all designed to enhance the usability and appeal of open spaces throughout Australia, serving communities large and small.

Shepparton continues to be the home ground for Furphy Foundry, operating a facility that brings together metal and timber fabrication, cast aluminium production, protective coatings, and product packaging — all managed under one roof. This allows for both quality control and responsiveness across their diverse project range.

Over the past year, the company has made significant strides in sustainability, launching new solar-powered products aimed at reducing environmental impact while encouraging more Australians to enjoy public outdoor spaces. These developments are part of a broader transition toward low-emissions manufacturing, with Furphy Foundry now offering carbonneutral certified products in its portfolio.

While innovation drives their product roadmap, people remain at the heart of the business. Furphy Foundry continues to invest in regional employment, drawing talent from across the Goulburn Valley and building on a legacy that dates back generations.

SERVING COMMUNITIES BIG AND SMALL... Furphy Foundry is a legendary name in Australian manufacturing, renowned for designing and producing high-quality street and park furniture. Based right here in Shepparton, Furphy Foundry has made significant strides over the past year, launching innovative, sustainable products while advancing its broader transition toward low-emissions manufacturing.

THE Bega Group is home to many trusted and iconic food and beverage brands. Whether it’s VEGEMITE on toast, a Big M on the go or a Zooper Dooper on a hot day – you've probably grown up enjoying the iconic products we proudly manufacture every day.

Bega's growth story of becoming a successful ASX 200 listed company with an annual turnover in excess of $3B and approximately 4,000 employees, is made possible by its dedicated workforce who live and breathe Bega's values every day.

The Tatura site is an icon in the

region, well known worldwide for its quality dairy products. As the country’s largest producer of cream cheese, it also produces infant formula, nutritional lactoferrin, various milk powders, and our famous single-serve butter.

As Bega prepares for the upcoming seasonal peak, the company invites you to come and be a part of its success story as the manufacturer continue to build The Great Australian Food Company through creating Great Food for a Better Future!

“At the Bega Group, diversity and

Recruitment for Casual Dairy Production Operators will commence in June, with start dates between July and August 2025. Bega is seeking applicants who:

• Are willing to work 8 or 12 hour shifts across days and nights and have the flexibility to support a 24/7 factory operation (i.e. weekends, public holidays etc.)

• Have a safety always mindset!

• Maintain a positive attitude, attention to detail and a willingness to learn

• Hold a current forklift license and/or Heavy Rigid Truck licence

inclusion is a business priority, we want everyone to be themselves regardless of their background, religion, sexual orientation, age or gender so we can truly reflect the customers and communities that we serve,” said a Bega spokesperson.

The Bega Group is home to many trusted and iconic food and beverage brands. Whether it’s VEGEMITE on toast, a Big M on the go or a Zooper Dooper on a hot day - you’ve probably grown up enjoying the iconic products we proudly manufacture every day. Our growth story of becoming a successful ASX 200 listed company with an annual turnover in excess of $3 billion and approximately 3,800 employees, is made possible by our dedicated workforce who live and breathe our values every day.

Our Tatura site is an icon in the region, well known worldwide for its quality dairy products. As the country’s largest producer of cream cheese, it also produces infant formula, nutritional lactoferrin, various milk powders, and our famous single-serve butter.

As we prepare for the upcoming seasonal peak, we invite you to come and be a part of our success story as we continue to build The Great Australian Food Company through creating Great Food for a Better Future!

Recruitment for Casual Dairy Production Operators will commence in June, with start dates between July and August 2025. We are seeking applicants that:

• Are willing to work 8 or 12 hour shifts across days and nights and have the flexibility to support a 24/7 factory operation (i.e. weekends, public holidays etc.)

• Have a safety always mindset!

• Maintain a positive attitude, attention to detail and a willingness to learn

• Hold a current forklift license and/or Heavy Rigid Truck license * Eligibility criteria apply and subject to terms and conditions.

“No matter how you identify, we encourage talented people from all backgrounds, abilities, and identities to apply to work at the Bega Group.”

To learn more about career opportunities, visit: begagroup.com. au/careers/recruitment/

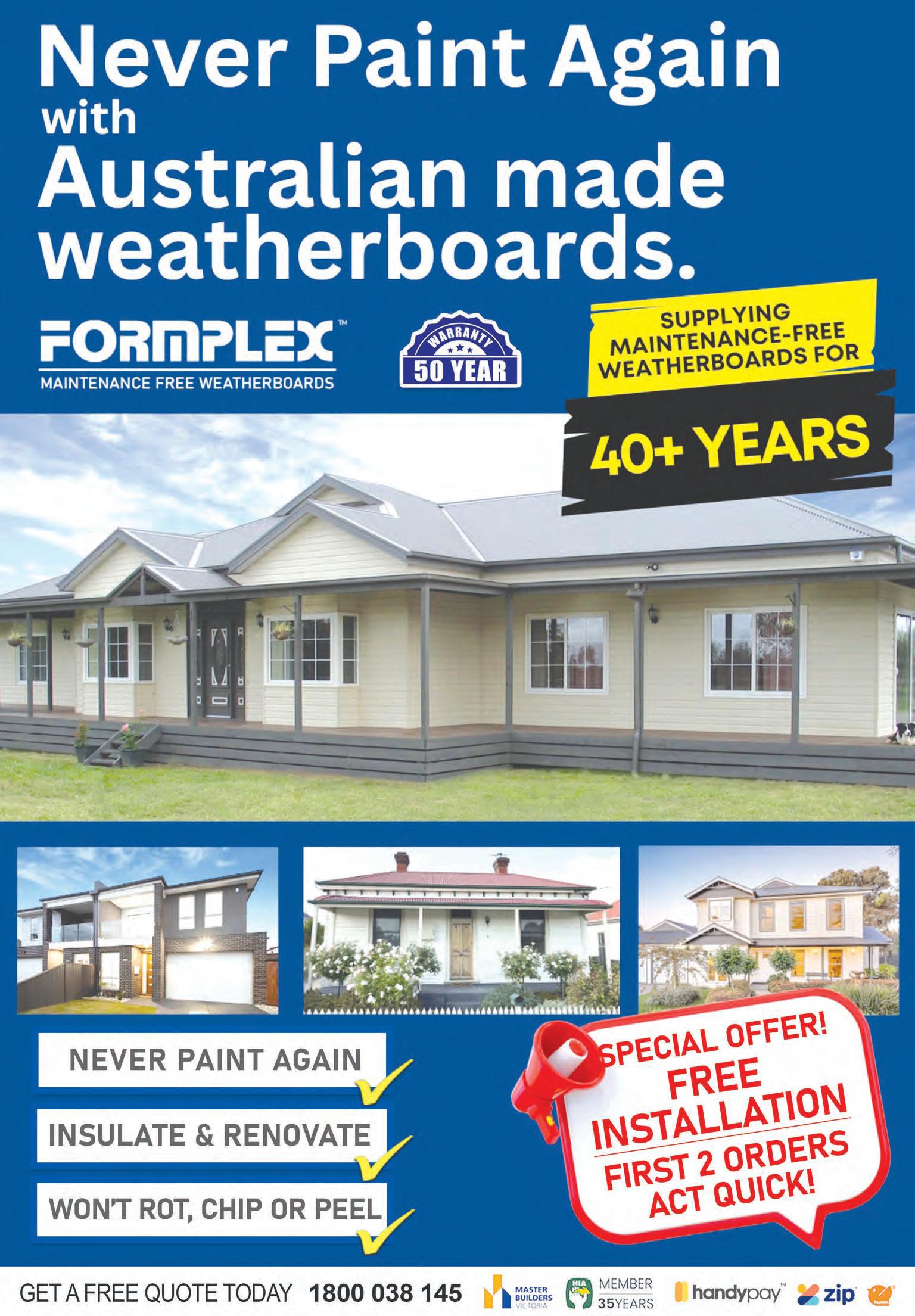

DESIGNED with the Australian home in mind, Formplex cladding combines the aesthetic appeal of freshly painted timber with the strength and resilience of modern UPVC materials. Unlike timber, Formplex weatherboards won’t rot, chip, peel or fade. They maintain their good looks year after year without the need for constant repainting, sanding, or patching.

Why persist with high-maintenance weatherboards that require ongoing time and money to preserve? Formplex offers a costeffective and easy renovation solution. Whether upgrading an older home or future-proofing a

new one, this cladding system provides not only immediate visual impact but also long-term protection and energy efficiency.

Formplex weatherboards also help insulate the home, keeping it cooler in summer and warmer in winter, an important feature for reducing energy bills and increasing year-round comfort.

With a range of styles and colours to choose from, Formplex can dramatically transform any home’s exterior, delivering the crisp, clean appearance of freshly painted weatherboards,

without ever needing a brush.

Renovate smart. Renovate once. Renovate with Formplex.

A proudly Australian made product, Formplex is pleased to make a very special offer. By calling now to book a free quote, you could be eligible for a FREE INSTALLATION on the first two orders. That’s right, just pay for the boards and installation is free!

Call 1800 038 145, for this cracker of a deal, not to be missed!

Strong, diverse and innovative A nation wellplaced to weather the storm

AUSTRALIA is well-placed to thrive in a world that’s becoming more complex and connected. With rich natural resources, a welleducated population and a diverse, multicultural society, the country has strong foundations. Despite global uncertainty, highlighted by political shifts like the rise of the Trump administration, Australia remains steady.

Its economy is resilient, with strong ties to the Asia-Pacific region. Australia continues to punch above its weight, regularly ranking high for innovation, economic freedom, and investor confidence. The tech sector, worth $167 billion in 2023, is now the third-largest part of the national economy. Australia also has

a proud history of invention, such as Wi-Fi, the black box flight recorder, and Google Maps, which shows its strength in creative thinking and problem-solving.

Australia is also stepping up in key areas that will shape the future: climate change, cyber security, and sustainability. The shift to renewable energy is picking up speed, with major solar and wind projects putting Australia on track to become a clean energy exporter. At the same time, the cyber security sector is growing fast and is expected to double in value by 2028, an important move as digital threats increase.

Still, there are challenges. There are not enough skilled workers in fast-growing industries, and more investment is needed in infrastructure and digital skills. To keep moving forward, Australia must plan carefully and act boldly. Progress will depend not only on innovation but also on strong partnerships between government, business, and local communities.

A NAME interchangeable with freedom and adventure for those wanting to explore the vast Australian landscape, Jayco Australia is celebrating 50 years of caravan manufacturing in Australia. From caravans and camper trailers to motorhomes, Jayco has been the trusted companion of countless road trippers who, above all, value the company’s renowned reputation for quality, reliability, and local ingenuity, making it the go-to choice for unforgettable Australian journeys.

Founded by Gerry Ryan in 1975, Jayco began as a small operation in Victoria and has since grown into a world-class manufacturing plant in Dandenong. Over the years, Jayco has transformed into an industry leader, producing thousands of caravans annually and employing hundreds of Australians.

With advancements like Tough Frame construction, JTECH suspension, and off-grid capabilities, Jayco caravans are built in Australia to handle Australia’s rugged terrain while ensuring comfort and reliability. These innovations have allowed Jayco to cater to a wide range of customers, balancing durability with affordability.

For over 30 years, Prestige Jayco Bendigo has been proud to play a role in Jayco’s success. As a long-standing dealership, the business shares Jayco’s commitment to quality and customer satisfaction. Their team provides expert advice and personalised service, helping Australians find the perfect caravan for their adventures.

With access to Jayco’s full product range and the

support of Australia’s largest service and warranty network, customers can enjoy peace of mind on every journey. Whether it’s a weekend getaway or the adventure of a lifetime, Prestige Jayco Bendigo is here to make it happen.

Jayco’s reputation goes beyond engineering excellence, it’s built on trust and community. With

Australia’s most extensive dealer network and repair agents, Jayco continues to be a household name.

As Jayco celebrates 50 years, Prestige Jayco Bendigo remains proud to connect Australians with the joy of discovery and the freedom of the open road. Call into Prestige Jayco Bendigo today and see the range of Jayco 50th Anniversary models on display.