Excellence Precinct Isaac Resources

By investing in education, innovation, and collaborative partnerships, we can create a mining sector that not only meets today's demands but also anticipates and adapts to the challenges of tomorrow, securing prosperity and opportunities for future generations in the Isaac region.

The Resources Centre of Excellence (RCOE) plays a pivotal role in this endeavor by serving as a hub for cutting-edge research and development, connecting industry leaders with emerging technologies and best practices, and supports advancements in strategic minerals and tailings reprocessing, further contributing to the sustainable evolution of the mining industry in the region."

The Isaac region is one of Australia’s largest resource regions. We are...

58,673sq km

Spanning from the coalfields. That is...

the size of ACT

We punch well above our weight.

25 times $11.92 billion

The Isaac local government area is a significant contributor to the state and national economies mining is the LARGEST industry employer generating 13,080 jobs in the mining sector,

equating to 60.9% of total employment in Isaac.

is our contribution to QLD’s gross regional product based on a population of full-time equivalent of 33,420.

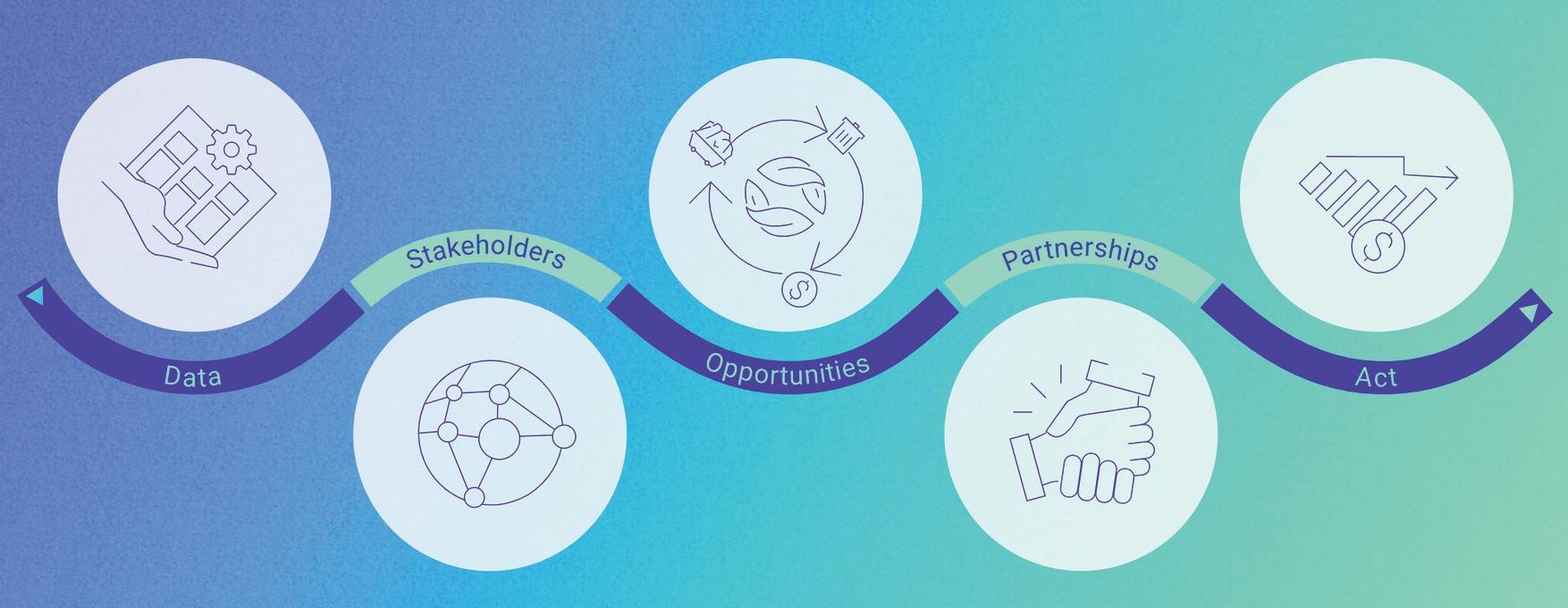

The RCOE was established to sit between

The RCOE was positioned to elevate our region on the global stage by highlighting innovation and collaboration across both traditional and emerging sectors. Over the past 5 years in operation, more than 20,000 individuals from over 500 companies have visited per year, including Queensland Ministers, Prime Minister, and the Federal Treasurer. The centre also hosted various events including 400 attendees at the Developing Northern Australia Conference in a simulated underground mining environment 2 years ago.

The RCOE stands out as a model of successful collaboration, merging government, funding initiatives, and industry efforts to drive economic growth in the Greater Whitsunday region. CEO Steven Boxall emphasises that strong relationships are crucial to success, with partnerships established with key organisations such as local councils, BMA/BHP, Anglo American and Queensland Resources Council (QRC).

Since launching in 2020, the RCOE has under its roof 20 staff from various sectors, including government funded initiative Mackay Manufacturing Hub and Trade and Investment Queensland along with other various smaller groups and businesses that drive innovation, mining, and support services. Boxall notes that the centre is now celebrating its 5 year in operation, hosting an array of activities such as training, innovation trials, and collaborations, while also supporting numerous non-profits and community groups.

th

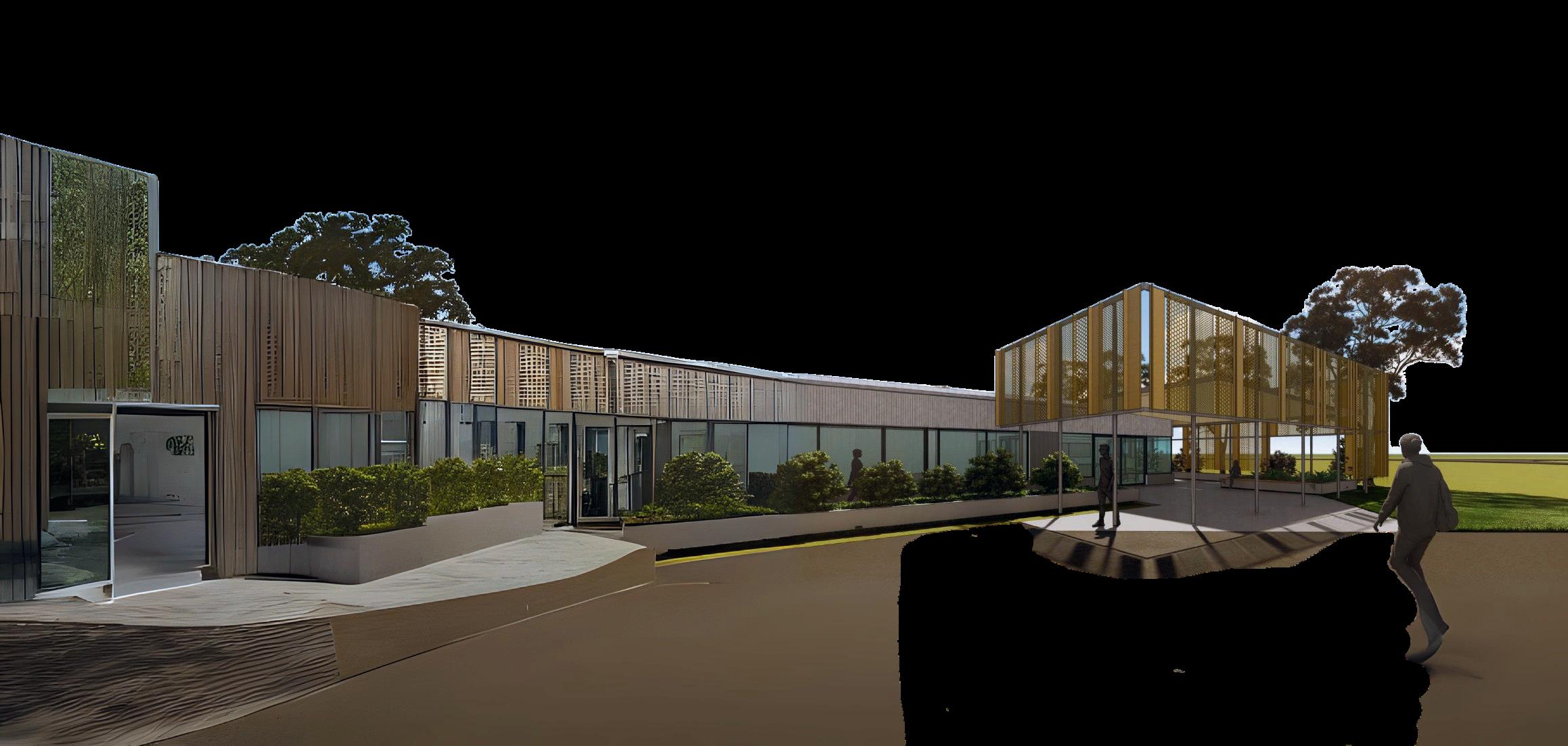

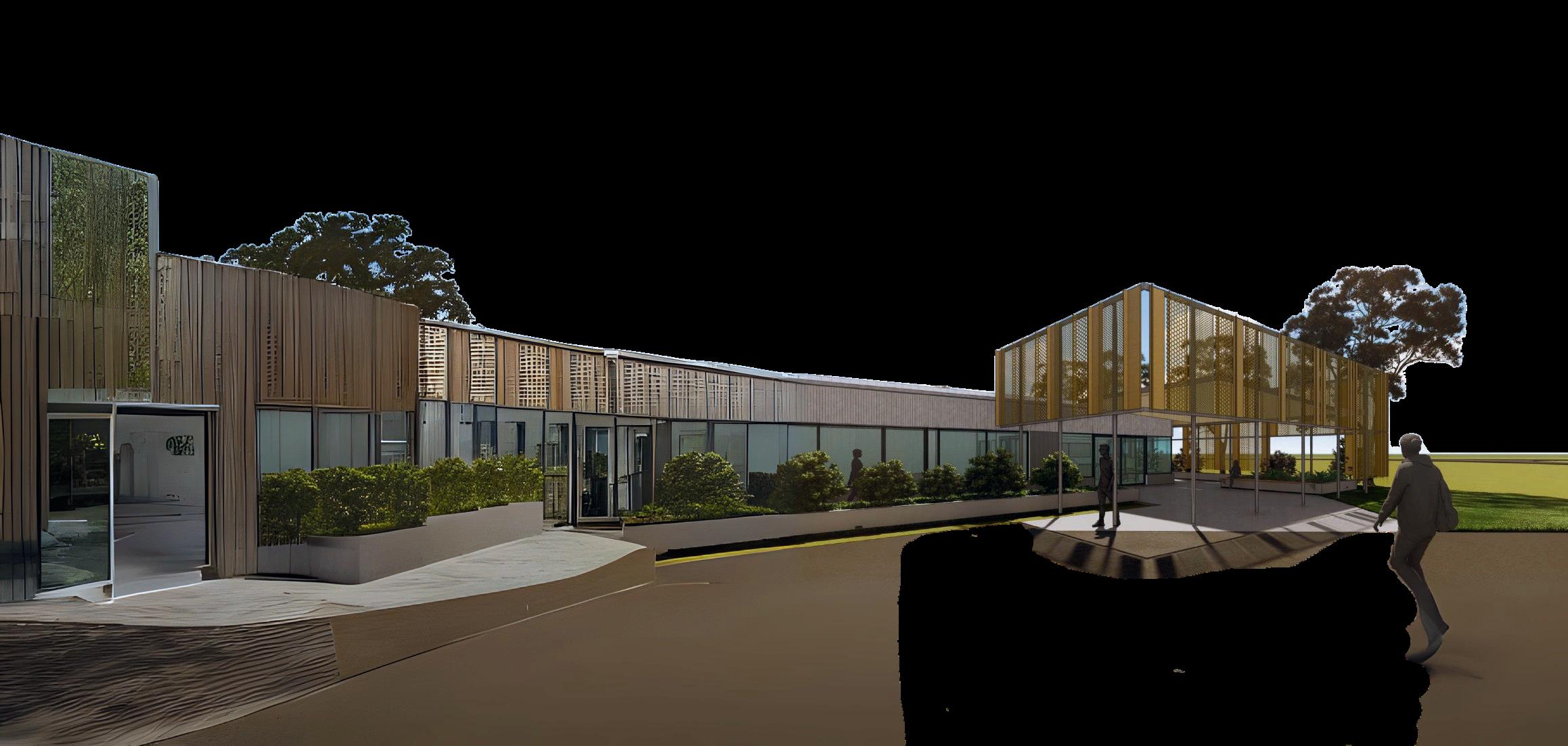

Over the next five years, the Resources Centre of Excellence (RCOE) will roll out its strategic initiative, "The Carbon Advantage," which seeks to position the MIW region as a global frontrunner in carbon harnessing, management, and innovation. This initiative will build on the foundational strengths of the traditional resources sector, while incorporating cutting-edge technologies and circular economy principles to create a diversified and resilient industrial future. The outlook is promising with the Future Industries Hub and Flexi-Lab slated to open in January 2026, focusing on advancing strategic minerals and tailings reprocessing. Additionally, the Isaac Resources Excellence Precinct in Moranbah aims to establish a world-leading model for a modern, integrated resources economy, providing substantial economic and social benefits to the region.

The Isaac Resources Excellence Precinct (IREP) is designed to develop a skilled and diversified workforce, build deeper First Nations partnerships, and ensure the Isaac region continues to energise the world while fostering sustainable, thriving communities. This project acknowledges the global shifts in resources, energy, and climate, positioning the Isaac region as a leader in innovation, resilience, and opportunity.

The IREP project will:

Grow and diversify the industry by advancing innovation across resources and renewables. Strengthen ESG credentials while protecting the environment and driving sustainable practices. Foster coexistence and sustainable communities, ensuring long-term regional prosperity. Ensure strong and genuine First Nations partnerships, embedding Indigenous knowledge and opportunity. Build a safe and resilient future workforce through education, reskilling, and technology access. Improve regulatory efficiency to accelerate growth and adaptation in the sector.

The Isaac Resources Excellence Precinct has transitioned from concept to action. Backed by $42 million in secured funding, the Resources Centre of Excellence (RCOE) is now progressing to the implementation phase. This milestone marks the beginning of a fully funded, state-of-the-art hub, a central part of the region’s masterplan to build long-term capability, diversity, and innovation in the resources sector.

The Resources Centre of Excellence (RCOE) was established to sit between industry, research, and government, accelerating innovation, training, and solutions for Queensland and the Greater Whitsunday region. In just five years, RCOE has delivered outstanding results, and IREP is the next bold step forward. Strategically located at the corner of Moranbah Access Road and Railway Station Road, in the heart of the Bowen Basin, the hub is a beacon for the future.

Funding Partners:

$39.7M Queensland Government (Resources Community Infrastructure Fund).

$2M Australian Government Project Leadership: Isaac Regional Council, in partnership with RCOE.

At the heart of the Isaac Resources Excellence Precinct is a commitment to strengthening our communities and fostering genuine partnerships with Traditional Owners. By creating a hub that drives innovation, skills development, and sustainable industry practices, IREP will generate lasting opportunities for local people and First Nations communities across the Bowen Basin. From education and training pathways to research in mine rehabilitation and renewables, the precinct will act as a bridge connecting industry with community, ensuring that Indigenous knowledge, perspectives, and participation remain integral to shaping a more resilient and prosperous regional future.

The Isaac Resources Excellence Precinct will include: Research and development facilities for critical minerals, mine rehabilitation, and renewable energy technologies.

A dual-sector learning centre, delivering universitystyle education and reskilling programs.

A mining heritage centre, celebrating industry history while shaping the future.

Multi-functional collaboration spaces, connecting industry, community, and research. This hub will create jobs, develop skills, and open pathways for workers and families to stay in the Isaac for generations.

Construction is underway, with completion expected by 2027. Once operational, the precinct will be managed by the RCOE ensuring its long-term sustainability and alignment with industry and community needs.

Building on the region's mining legacy, this initiative creates new economic opportunities from rehabilitated mine sites:

Water Re-use and Storage: Utilising former mine voids for large-scale water storage and re-use for agriculture, new industries, and community resilience, addressing the region's vulnerability to climate impacts like droughts. This represents responsible water management (ESG).

Agriculture and Aquaculture: Developing intensive agriculture and aquaculture operations on rehabilitated land, leveraging available water and infrastructure, with potential for even greater returns than traditional grazing. This includes exploring how transformed land, particularly non-prime agricultural land, can generate new, high-value agricultural products, such as bioenergy crops for Sustainable Aviation Fuel (SAF). This transforms environmental liabilities into community assets (ESG).

Carbon Sequestration through Land Management including algae produced in the region: Implementing innovative land management practices that enhance carbon sequestration in soils and vegetation, generating new income streams through carbon farming. These projects can generate Australian Carbon Credit Units (ACCUs) through increased carbon sequestration, providing a new revenue stream for landholders and project developers, and contributing to positive environmental outcomes (ESG).

Current Status:

Scoping study funded

Potential Partners:

Local agricultural bodies, major resource companies and bio energy tech companies

Renewable Energy Hubs: Repurposing mine sites for large-scale renewable energy generation (solar, wind) and long-duration energy storage (LDES), including pumped hydro storage (PHS), leveraging existing cleared land and transmission infrastructure. Queensland's abandoned coal mines alone could host up to 52 GW of solar power. This strategic placement on non-prime agricultural land helps address community concerns regarding land use for renewables, promoting consistency in regional planning and policy alignment across local government areas for major projects. This demonstrates a commitment to clean energy transition (ESG).

Eco-Industrial Tourism & Heritage: Exploring opportunities for developing unique tourism experiences on rehabilitated mine sites, such as eco-industrial tourism or heritage tourism, which can attract visitors and create new economic avenues while showcasing the region's transformation.

Leveraging the region's rich geological endowments and existing mining expertise, this initiative focuses on extracting and processing essential materials for the global energy transition:

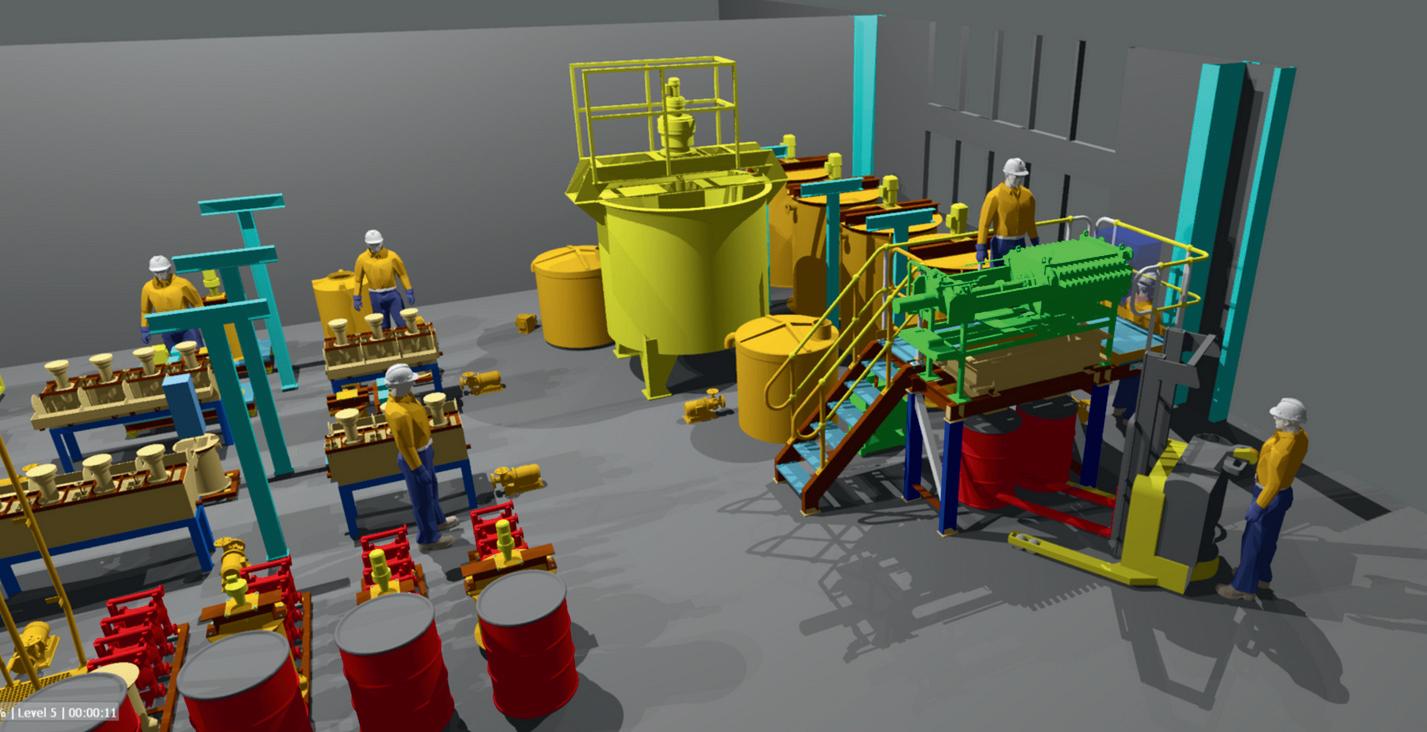

ategic Minerals Extraction: The Flexi-Lab located at the FIH is specifically designed as a pilot processing plant for strategic minerals such as cobalt, nickel, zinc, vanadium, molybdenum, silica, alumina, rare earth elements, lithium, copper, rhenium, and scandium. This facility plays a crucial role as an "essential de-risking engine" for bridging the gap between mature technologies and industrial commercialisation, focusing on "minerals not normally produced" and unlocking a global market that reached $400 billion in 2022.

IREP’s potential could see Flexi-Lab 2.0 become a commercial spin-off, using the technology and processes proven in the RCOE Flexi-Lab. Its business in IREP would be to secure contracts to re-process legacy tailings dams across the Bowen Basin, extracting and selling not just the residual high-grade coal but also valuable co-products like aluminosilicates for cement production (SCMs).

Tailings Reprocessing: The Flexi-Lab 2.0 will also enable the reprocessing of metallurgical coal tailings, unlocking significant value from existing waste streams by recovering valuable minerals and other co-products such as aluminosilicates (for supplementary cementitious materials and clay products), quartz (for construction and glass), residual carbon (for coking coal upgrade), sulphide minerals (for sulphuric acid), rare earth elements, heavy metals, titanium-bearing minerals, phosphorus, sulphur, and other oxides. This contributes to responsible resource management and improved environmental outcomes (ESG).

Current Status:

Potential Partners:

Major resource companies with legacy tailings facilities, critical mineral companies Critical Mineral National Productivity Initiative (CMNPI)

Tungsten Carbide Circularity: We are implementing projects to develop test cases for the adoption of circular practices for tungsten, a rare but strategic mineral. While recycling rates are already high (95% of tungsten carbide is captured for recycling), a key opportunity exists for cleaner recycling and the life extension of tungsten products through refurbishment, exemplified by the work of DGH Engineering in the region.

Industrial Waste-to-Value: The IREP's focus on diverse industrial waste streams (including Off-The-Road (OTR) tyres, Diesel Particulate Filters (DPFs), bulk bags, scrap metal, timber pallets, food & organic matter) supports waste-to-energy and resource recovery, turning liabilities into assets through innovative processing and demonstrating circular economy principles (ESG).

The IREP will incorporate industrial tourism experiences that complement a potential underground mine simulator, FlexiLab 2.0 and viewing, VR pods.

Flexi-Lab Viewing Window: The critical mineral pilot processing plant has been designed to include a full window viewing pane to allow visitors to see the Flex-ilab in action. This viewing area will connect to the critical mineral education zone.

Critical Mineral Education Zone: Co-existing with the Bio Futures Digital Education space, the critical mineral education zone will feature interactive digital displays and information about mineral processing and critical minerals. Educational videos and hands-on activities will showcase the job opportunities within the critical mineral industry, along with the variety of products that are created from battery minerals and the circular opportunities of coal tailing reprocessing. This space would be suitable for the general public, industry and school groups to visit.

Current Status:

Scoping study partly funded

Potential Partners:

Local and regional tourism bodies, universities, adult education institutions

Virtual Reality Pods: Virtual reality pods will deliver an interactive experience for viewers. The story of mining including its transition into future industries will be showcased through educational videos that allow viewers to choose their interactions with the content.

This initiative capitalises on the region's agricultural strengths and commitment to resource efficiency, expanding to include diverse organic waste streams:

Agricultural Waste-to-Products: Leveraging the region's abundant agricultural biomass (e.g., sugarcane bagasse, trash, molasses, wastewater), the FIH can support biomanufacturing initiatives. Examples include converting sugarcane waste into high-value nutritional fibres (e.g., technologies like those planned by NuFiba for a commercial demonstration plant in Australia, or the Kfibre project by Health Food Symmetry in Ayr), opening new markets for agricultural byproducts and aligning with Queensland's goal for a $1 billion sustainable bioproducts sector. This also includes exploring opportunities for other fibre projects in the region, such as those related to Townsend Industries' alternative sugarcane processing facility in Mackay, which aims to produce diverse highvalue products from the full sugarcane plant. These initiatives enhance the social and environmental sustainability of the agricultural sector (ESG), and can contribute to "climate positive" and traceable product value chains.

Municipal Waste-to-Value (Biogas & Bioproducts): Implementing advanced technologies to convert municipal solid waste and other organic urban waste streams into valuable resources. This includes:

Biogas Production: Capturing methane from landfills and anaerobic digestion of organic waste to produce renewable energy (electricity and heat) or upgraded biomethane for gas networks and vehicle fuel. The captured CO2 from this process can also be used to produce algae for bio-stimulant production for plants and animals. This directly reduces landfill emissions (ESG).

Compost & Fertiliser Production: Transforming organic waste into high-quality compost and soil conditioners, supporting sustainable agriculture and land rehabilitation, and reducing landfill burden (ESG).

Other Bioproducts: Exploring the potential for extracting other valuable compounds or materials from municipal waste through biorefining processes.

Resource Recovery & Recycling: Implementing advanced processes to recover and recycle valuable materials from various waste streams (municipal, agricultural, industrial), contributing to a truly circular economy. This includes exploring opportunities to increase Australia's current circularity rate, which is half the global average, potentially unlocking over $700 billion in economic benefits for Queensland by 2040. This demonstrates strong environmental stewardship (ESG).

Current Status:

Phase 3 scoping underway

Potential Partners:

Major mining companies and local/national waste companies

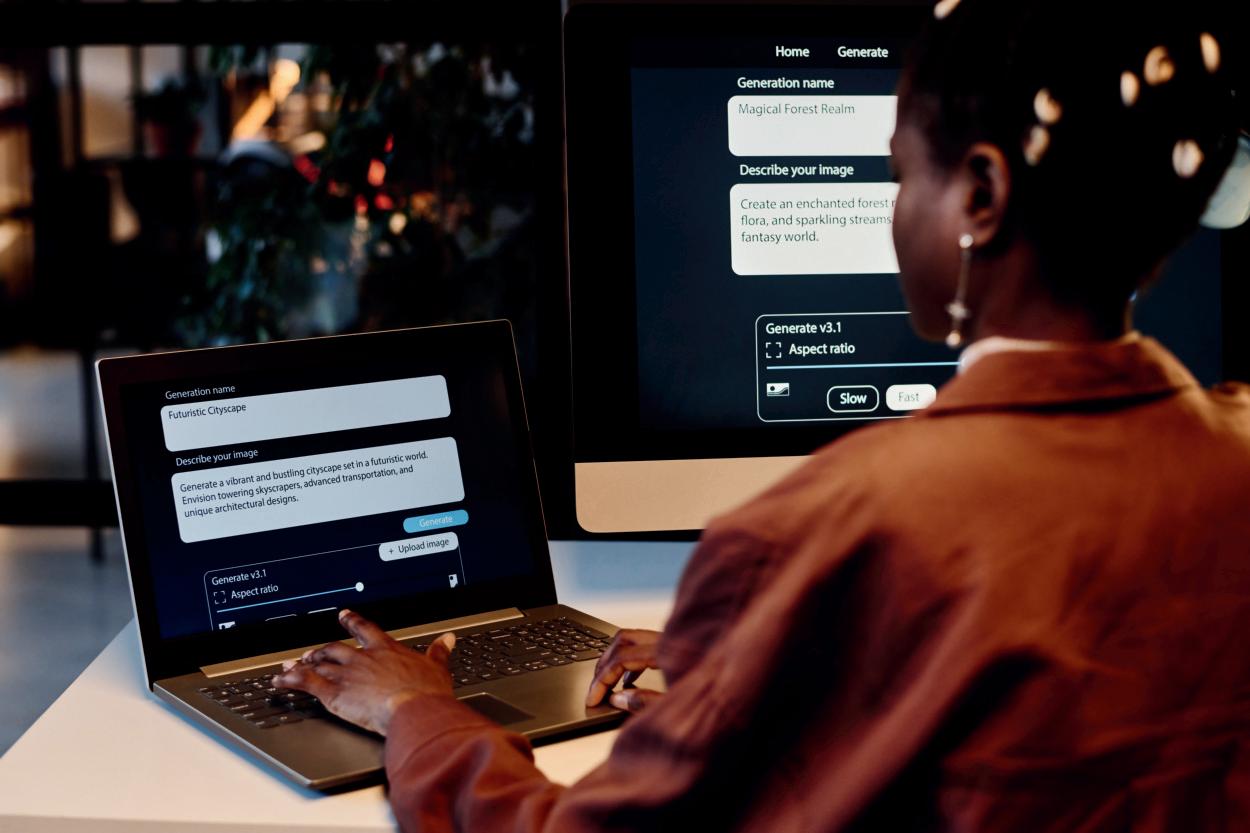

Digital & AI-Driven Solutions: Leveraging the Australian Centre for Industrial Intelligence (ACII) capabilities to develop and export cutting-edge digital and AI-driven solutions for optimising carbon-related industrial processes and regional supply chains (e.g., "pit-to-port" and "farm-to-market").

This includes:

Advanced Data Analytics & Machine Learning: For predictive maintenance, operational efficiency, and resource optimisation across mining, agriculture, and new energy systems.

Digital Twins: Creating virtual models of physical assets and processes to simulate, analyse, and optimise performance for carbon reduction and value creation.

Large Language Models (LLMs) & Generative AI: Utilising technologies like Gemini and Grok for complex data interpretation, generating insights for carbon markets, supporting decision-making in resource management, and enhancing workforce training and knowledge transfer.

Current Status:

Scoping study underway

Potential Partners:

Global cyber security firms

Earth Observation & Satellite Applications: Employing geospatial data for enhanced environmental monitoring, precision agriculture (e.g., crop yield optimisation, water management), and tracking carbon sequestration efforts.

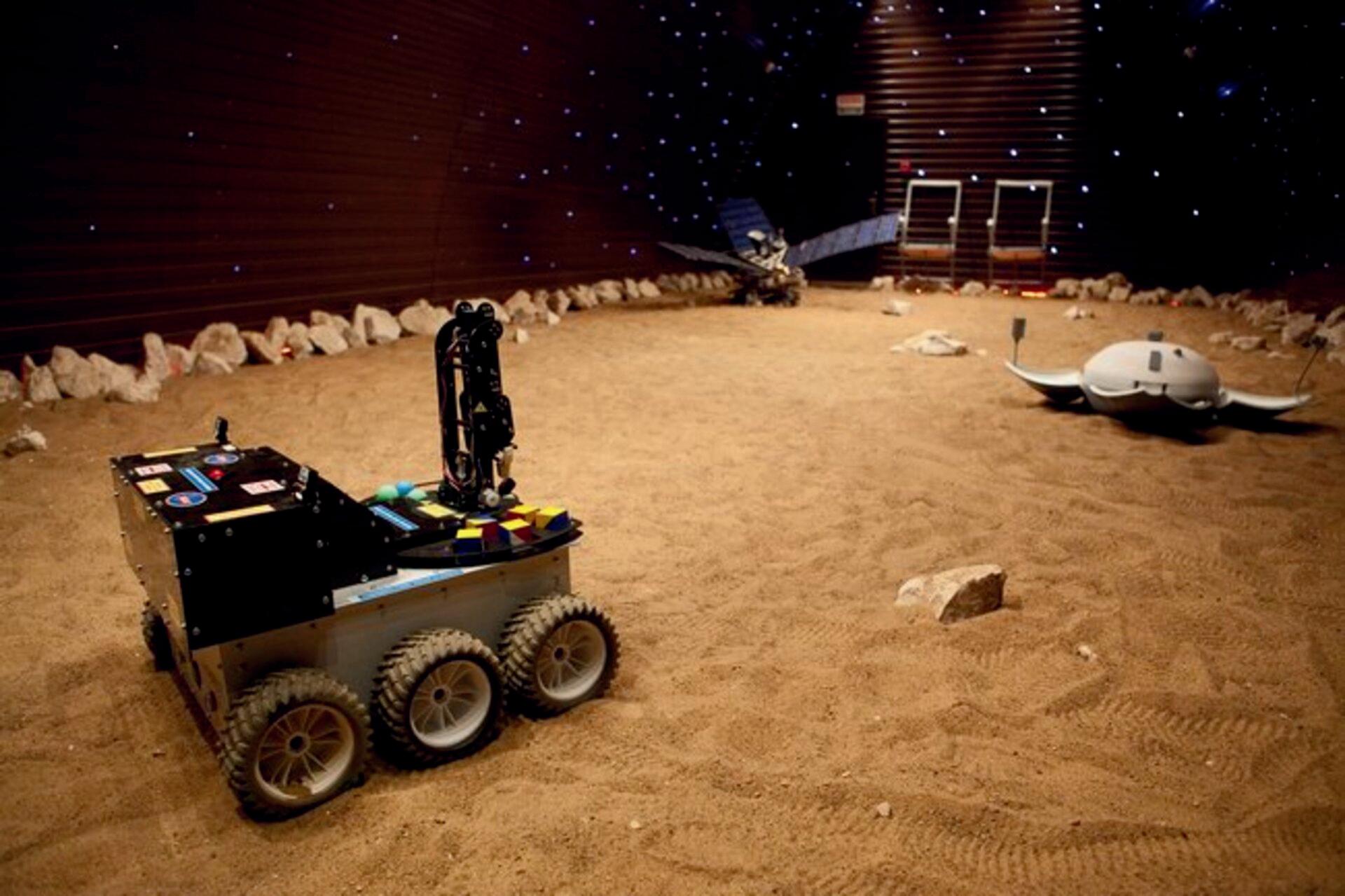

Automation & Robotics: Developing and deploying automated systems for efficiency and safety in new and evolving industries.

Digital Infrastructure Advocacy: Advocating for and investing in robust digital infrastructure, including high-speed cable, fibre, and satellite connectivity, to ensure the region has the foundational network capacity to support these advanced digital and AI applications.

This pillar focuses on transforming carbon emissions from a liability into valuable resources. Technologies and initiatives include:

Methane-to-Value Projects: Projects aim to capture and convert potent methane emissions from sources like coal mines into valuable resources such as electricity (e.g., for on-site power), chemical feedstocks (e.g., syngas for methanol or hydrogen), or vehicle fuels (e.g., displacing diesel in haul trucks). This directly addresses a significant environmental and economical challenge, especially with new regulatory changes mandating more precise methane estimation. These projects can generate Australian Carbon Credit Units (ACCUs) by avoiding methane emissions, creating a new revenue stream for miners and project developers, and demonstrating strong ESG performance.

Green Ammonia & Low-Carbon Fertiliser Production: This involves leveraging renewable energy (e.g., solar) to produce hydrogen via electrolysis, which is then used to make low-carbon ammonia fertiliser. This process displaces high-carbon, fossil fuel-based nitrogen fertilisers, reducing significant CO2-equivalent emissions. The GEGHA project in regional NSW is a leading Australian example of this integrated solar-to-hydrogento-ammonia model, demonstrating the potential for new domestic supply chains and competitive, stable pricing for agricultural inputs. While highly promising, the largescale production of green hydrogen and ammonia requires rigorous assessment of water usage and energy intensity to ensure overall sustainability and commercial viability.

Current Status:

Actively pursuing partners and funding opportunities

Potential Partners:

Major coal producers and technology providers in methane capture

Industrial Carbon Capture & Carbon Feedstocks: Exploring innovative methods to capture CO2 from industrial processes, and to produce high-value carbon feedstocks (e.g., solid carbon, hydrogen as a reducing agent) for various industrial applications, including their potential use in green steel manufacturing processes in Australia and internationally. This includes leveraging pathways such as Molten Oxide Electrolysis (MOE), Flash Ironmaking with Carbon Capture and Storage (CCS), and Electrified Biomethane-based Direct Reduced Iron (DRI) with CCS. These approaches offer credible and economically viable routes, aligning with Australia's abundant renewable electricity potential, natural gas resources, and biomass availability, and positioning the MIW region as a crucial supplier within global value chains.

Algae-Based Carbon Utilisation: Algae are highly efficient biological carbon capture agents. As an example, Genesis Algae Innovation in our region is pioneering a circular economy model that can utilise captured CO2 (e.g., from industrial exhaust) to accelerate algae growth, yielding high-value bioproducts like AlgaeFeed (a stockfeed supplement proven to reduce livestock methane emissions) and AlgaeFert (an organic biofertiliser). This process also yields a valuable solid carbon byproduct and can enable green hydrogen production.

Direct Air Capture (DAC) & Carbon Mineralisation:

Investigating and potentially piloting advanced technologies that capture CO2 directly from the atmosphere (DAC) or permanently store it through mineralisation processes, offering long-term carbon removal solutions.

As the precinct evolves, there is strong potential to integrate specialised services such as a Mine Safety Training Centre into the IREP ecosystem. A Mine Safety Training Centre plays a critical role in safeguarding workers and communities by providing expert emergency preparedness, response capability, and training for mining-related incidents. Its presence within the precinct would not only strengthen regional safety capacity but also create opportunities for collaboration in training, skills development, and applied research. By sharing tenancy and utilising IREP’s state-of-the-art facilities, a Mine Safety Training Centre could expand its capacity to deliver vital programs while contributing to the broader goal of building a safer, more resilient resources sector.

A new, dedicated regional base established by the Queensland Minerals and Energy Academy (QMEA) to support and expand its talent pipeline programs for the mining and energy sectors. The Queensland government is funding this expansion to create more regional hubs in places like Mackay, Rockhampton, and Townsville, which will connect more schools and students to industry-focused STEM education and career pathways in the resources sector.

The importance of place-based research cannot be overstated. Extending the Sustainable Minerals Institute’s (SMI) partnership with the Resources Centre of Excellence to the Isaac Resources Excellence Precinct in Moranbah creates a strong platform for regional innovation. UQ, through SMI, could serve as the specialist tertiary institute alongside the Country Universities Centre, offering expertise in mine closure, post-mining land use, automation, risk management, community health, agriculture, and engagement. With tailored short courses and a regional MBA, partnerships led by RCOE could deliver transformative outcomes.

Flexible industrial workspace for businesses looking to create, manufacture and incubate their ideas. Move in and make the space your own, with no red tape.

The innovation pod would include cobot (collaborative robot) stations, 3D printers and AR headsets and supporting software to be used in workshops and for training, prototypes and demos.

The facility would also provide one full time employee who can provide one-on-one business tech adoption assessments and plans, along with advanced manufacturing onsite assessments and reviews. This would be supported by an ongoing workshop program providing advanced manufacturing training. 400m2 space.

Up to 220sqm of office space will complete the Bio Futures Centre, creating a flexible environment where businesses, researchers, and innovators can work side by side. Designed to encourage collaboration, the space will provide opportunities for knowledge sharing, project partnerships, and the cross-pollination of ideas across the Bio Futures sector. With modern facilities and access to the broader IREP ecosystem, the office space will not only support day-to-day operations but also foster the growth of emerging enterprises, helping to drive innovation, sustainability, and longterm industry development.

solutions. This ensures they meet market standards and achieve optimal performance for various applications.

Energy Integration & Optimisation: The IREP will facilitate the integration of diverse energy sources (like methane-to-energy systems, renewables, and waste-to-energy solutions) with carbon capture and utilisation processes. This optimises energy flows, demonstrates end-to-end circular economy solutions, and creates resilient energy systems for industrial applications. This includes demonstrating demandside management (DSM), energy efficiency (EE), and various long-duration energy storage (LDES) types like pumped hydro storage (PHS).

Attracting Investment: By showcasing proven technologies and viable commercial pathways within dedicated precincts, the IREP will become magnets for national and international investment in a broad array of low-carbon, high-value industries. Their commitment to ESG leadership will be a key differentiator in attracting capital from investors increasingly prioritising sustainable portfolios.

to be licensed and scaled nationally and internationally, positioning the MIW region as a global benchmark for responsible resource development and industrial transition.

RCOE's Operational Advantage: As the Resources Centre of Excellence (RCOE) is the established operator of the RCOE facility and FIH, this provides IREP with unparalleled expertise in managing common user facilities, fostering industry-led research, and accelerating the commercialisation of solutions. This operational capability provides a significant advantage in rapidly activating and maximising the impact of these precincts for "The Carbon Advantage" initiative.

Queensland Resources & Innovation Expo is a premier platform for showcasing cutting-edge technologies, fostering industry collaboration, and driving sustainable advancements in the resources sector.

THE RESOURCES CENTRE OF EXCELLENCE (RCOE) WAS ESTABLISHED TO SIT BETWEEN INDUSTRY, RESEARCH AND GOVERNMENT TO FAST-TRACK INNOVATION, TRAINING AND INDUSTRY SOLUTIONS FOR THE GREATER WHITSUNDAY REGION AND QUEENSLAND. IN JUST FIVE YEARS THEY HAVE MADE REMARKABLE PROGRESS, AND THERE IS PLENTY MORE TO COME.

“The concept of the RCOE was actually thought up a long time ago, way before the facility opened in Mackay,” said RCOE CEO Steven Boxall.

“The whole idea was around having a genuine stake in the ground to showcase the great work that was happening in the resources sector in our region, but also really trying to set our region up for the future whether that be through new resource innovation or capturing aligned future industries.

“We are a common user facility and are here to support a whole range of different initiativesinnovation, safety, training and collaboration. Providing a physical location where people can connect and network and come together to problem-solve and innovate.

“But, most importantly, it’s about providing a facility that sits external to government, industry and education, yet is able to weave all of them together to get the right outcomes for our region.”

Steven said what also sets RCOE apart is that its doors are open to anyone, from startups all the way up to large corporations.

“We work with everyone. Someone might come to us because they have a good idea and they need somewhere to test or trial it, whether that be physically testing the product or testing their thinking by connecting with industry. Then we go right from that level all the way up to working with Tier 1 resource companies.”

Those collaborations include running major projects such as the pilot program RCOE recently launched with BHP Mitsubishi Alliance (BMA).

The “Pit to Port” project is a material flow analysis of all processes of mining – from pit to port - to quantify and understand what waste there is, where it’s located and how much there is, and what opportunities there are for integrating circular principles along the whole value chain. In addition it provides a foundation for the concept to be extended to a regional context.

Another project is

Decarbonisation Accelerated which is aimed at supporting businesses and industry on their decarbonisation journeys as well as empowering new opportunities in emerging and decarbonised industries.

In total, the RCOE is involved in - either leading or contributing to - 25 different significant projects which cover everything from work skills of the future to the circular economy.

“Most days you’ll see a range of activities underway here at RCOE, from training and innovation trials to collaboration across industry and education. There is such great diversity to how people can be involved.

“We have a lot of RTOs and training organisations that will come and use our underground mining simulator facility to deliver training, but equally there are a lot of companies that

have based themselves at the RCOE, using our facilities as their first office or their first step into the region.”

The RCOE also hosts workshops, conferences and has its own fully equipped VR laboratory where VR technology meets cuttingedge safety education for an unparalleled learning experience.

“We have gone from being an empty building in the industrial estate here in Paget to now 25,000 people coming and using our facility each year as well as connecting with over 500 different companies.

“I think that’s probably what I’m most proud of, that we’ve been able to take what was a really great idea, create a strategic plan and then we’ve actually been able to activate that plan to the point of where we are today.”

THERE ARE THREE STAGES TO THE STRATEGIC PLAN. STAGE 1 HAS BEEN SUCCESSFULLY COMPLETED AND NOW THEY ARE POWERING AHEAD WITH STAGE 2 WHICH IS BEING BUILT ALONGSIDE THE RCOE FACILITY IN MACKAY.

“Stage 2, our Future Industries Hub, is nearing completion and will be operational by the end of this year.

“The Hub will be a collaborative space to solve industry problems. With technical, digital and immersive capabilities, there will be opportunities for manufacturing businesses to seize opportunities to

supply high value goods and services into global supply chains and export markets.

“It will be home to our Future Industries FlexiLab Pilot Processing Plant, a critical mineral pilot processing plant which will be the first of its kind in Australia. The FlexiLab will be a commercial common-user facility, helping to transition and support the emerging new economy minerals sector, generating jobs for the future and our regional economy.

“The pilot plant will also support the development of new and improved methods for processing minerals, enabling the pilot-scale demonstration of new technologies and assisting companies to increase mining yields and decrease associated costs.”

The RCOE has also turned the first soil on Stage 3, which is the Isaac Resources Excellence Precinct at Moranbah.

“That project is really exciting, it’s a $42 million fully funded project that will weave together everything that we have done across Stage 1 and 2, and we envision it as being able to bring to life opportunities for aligned future industries and help secure the futures of our Bowen Basin mining towns.”

It’s quite remarkable what RCOE has achieved in such a short time, though Steven said it hasn’t been without its challenges.

“Without a doubt it has been challenging. We started with virtually next to nothing though we were fortunate to have good support

from Mackay Regional Council, the Queensland State Government and organisations like BMA which gave us our first kick along.

“But since then we have made sure that we are financially sustainable and we can stand on our own two feet and as we have grown we have reinvested our success to further evolve the organisation.”

That evolution has seen the team at RCOE grow to seven, with Steven being the only employee in the beginning, to the most recent addition, Jason Sharam who is the new Resource Innovation & Partnerships Manager.

“Jason will pick up the platform that we’ve built, the connections that we’ve made and he is tasked with charging forward to genuinely help solve industry problems, weaving people together across industry, education, university research and government.”

Steven said another challenge was getting the word out when they were starting out, a challenge that they still are overcoming today.

“A lot of people still don’t know who we are, or they don’t really understand what it is we do and can offer.

“WHAT WE WANT THEM TO KNOW IS THAT THE RCOE IS ABOUT BRINGING PEOPLE TOGETHER, EMPOWERING NEW OPPORTUNITIES IN INNOVATION AND TECHNOLOGY, AND DELIVERING POSITIVE OUTCOMES FOR ALL OUR FUTURES.”

Tony is an accomplished senior executive and board director with more than 30 years of experience in the Australian resources sector, specialising in underground coal and metals. A former CEO and Managing Director of an ASX-listed mining services company, Tony oversaw the organisation’s substantial growth, leading major acquisitions, diversification strategies, and cultural transformation programs. Today, Tony serves as Chair of the Resources Centre of Excellence (RCOE), Chair of the Greater Whitsunday Alliance (GW3), and Advisory Board Member of a mining services engineering and maintenance business. With extensive experience in corporate governance, risk management, M&A, and stakeholder engagement, Tony brings a balanced perspective that combines strategic governance with deep operational insight. Recognised for integrity, collaboration, and building high-performing organisations, Tony contributes expertise in safety leadership, people and culture, and strategic growth to boards in complex and high-risk sectors.

Darryl is General Manager APAC at Infravision PTY LTD, an Innovation and Technology enabled, aerial Power Transmission line Stringing Company that delivers power transmission line construction and maintenance activities across the globe. Darryl has extensive experience in Operational risk management and continuous improvement in the Construction, Bulk materials handling and complex logistics operating environments. Darryl has a keen interest in renewable power generation and sustainable management of pressure vessels and equipment. Darryl has extensive experience in working across the globe in construction and operating steam and power plants.

Shane is a strategic mining executive with over 15 years of leadership experience in underground coal operations. He began his career at Aurecon while completing a Bachelor of Engineering (Electrical) at the University of Queensland, before joining Anglo American in 2010. He has held senior leadership roles across Anglo American’s underground portfolio, including General Manager and Site Senior Executive at Aquila and Grosvenor mines, where he led operational transformation and introduced remote longwall strategies. Previously, Shane served as Principal Technology & Automation, shaping the Longwall Mine of the Future strategy and driving the deployment of transformative technologies across multiple sites.

operating thermal coal mines producing 22% of QLD’s thermal coal

Recognised for his collaborative leadership style, strategic foresight, and ability to drive operational excellence, Shane is passionate about shaping the future of mining through innovation, resilience, and value creation. He brings a strong focus on safety, continuous improvement, and stakeholder alignment to his role as a Board Director at the Resource Centre of Excellence.

Linda has a career spanning more than 20 years in the mining industry and more than 10 years in heavy industrials. Linda has a diverse background in chemistry, processing and mining engineering and has worked in most aspects of the mining supply chain from Production (overburden and ore), Processing, Ports, Maintenance (MEM and Plant/Port/Shutdowns), Logistics and Technical Services. Linda holds a Bachelor of Science, a Masters of Mining Engineering and a number of other qualifications. Linda has a proven track record of business improvement and cultural transformation. Linda is passionate about developing people and is a strong advocate for mentoring and training.

Naomi is a Senior Associate and experienced commercial solicitor at McKays Solicitors. She acts for a diverse range of individual and business clients, including those involved in the mining and resources sector. Naomi’s legal experience, combined with practical commercial insight, allows her to deliver solutions that align business objectives with broader community outcomes. A proud Mackay local, Naomi is deeply committed to fostering the growth and sustainability of the region. She is actively engaged with a number of local not-for-profit organisations and charities. Naomi brings to the board a combination of legal expertise, commercial acumen, and a genuine passion for regional development.