The Resources Centre of Excellence (RCOE) in Mackay is a beacon of collaboration, driving innovation within the METS and resources sector. Built on robust partnerships across industry, government, and community, RCOE fosters an environment where progress thrives.

Expanding on this vision, the Future Industries Hub in Mackay is set to advance decarbonization, automation, and sustainable resource innovation. Concurrently, the Isaac Resources of Excellence Precinct in Moranbah will enhance regional capabilities With world-class simulation, technology testing, and training facilities, the RCOE solidifies Central Queensland's position as a global leader in mining technology, training, and research.

The Future Industries Hub is currently under construction and is expected to be operational in January 2026 A key component of this hub is the Flexi-Lab, a state-of-the-art minerals processing piloting facility designed to incubate new industries by focusing on critical minerals, reprocessing coal tailings, and other metals

The Flexi-Lab is supported by $5.7 million in funding from the Queensland

Government, reflecting a long-term commitment to diversifying the state's resources industry and fostering a genuine "pit to product" value chain This investment is a cornerstone action within the Queensland Resources Industry Development Plan and is further backed by the Mackay Regional Council.

What is the Flexi-Lab?

The Flexi-Lab is a cutting-edge minerals processing piloting facility located in Mackay, Queensland. It has been funded by the Queensland Government and Mackay Regional Council, developed through a partnership between the RCOE, Core Resources, the University of Queensland's Sustainable Minerals Institute (UQ SMI), and DGH Engineering.

True to its "Flexi-Lab" label, the pilot plant is designed to be highly versatile, capable of processing a wide range of materials by integrating various equipment items. This supports a broad spectrum of beneficiation processing options The facility will also provide invaluable opportunities for operator and metallurgist training, research and development, and the trialling of new process equipment and technologies. The initial design of the Flexi-Lab will accommodate tailings retreatment, with provisions for future expansion to handle vanadium and other hard rock applications, showcasing its adaptability to evolving industry needs

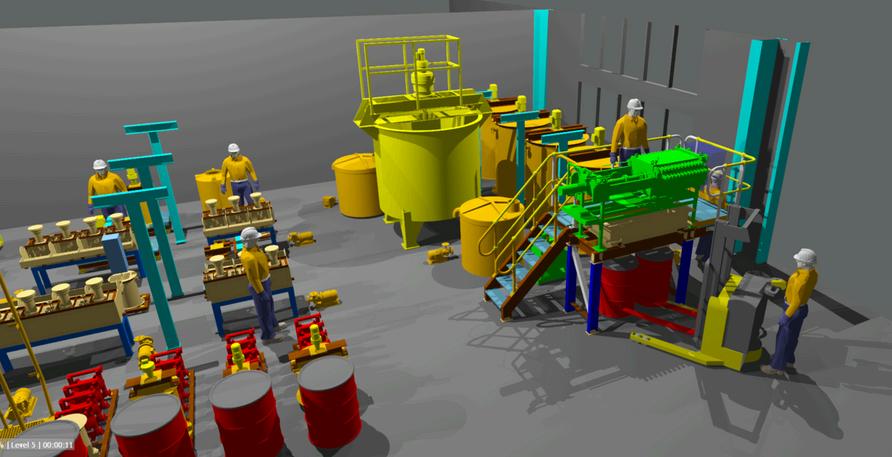

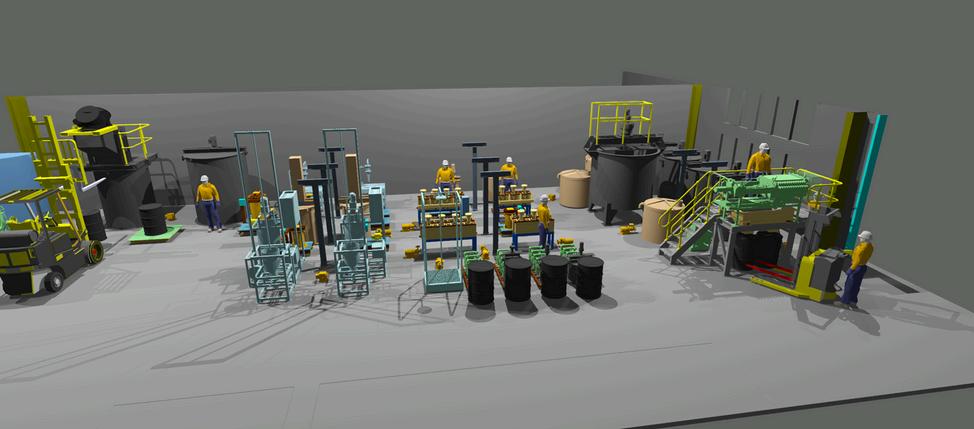

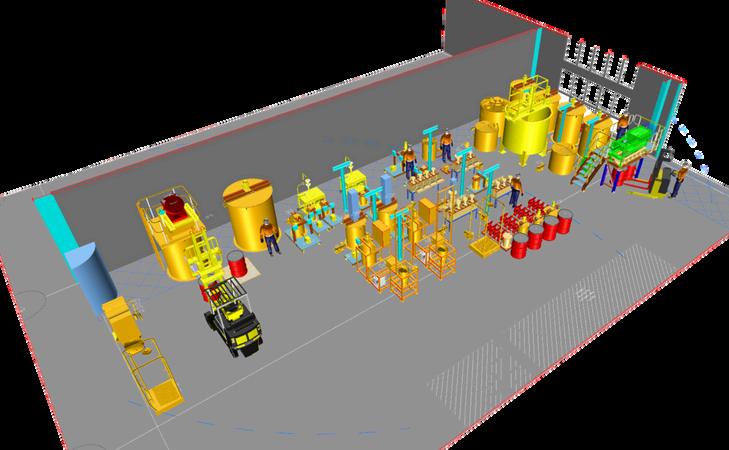

What does it look like?

The Flexi-Lab's design for the tailings beneficiation pilot plant incorporates major equipment items that can be reconfigured to suit the specific needs of the valuable commodity in question. This modularity ensures maximum flexibility for diverse processing requirements.

Key Equipment Items:

Tailings Reslurry Tank: For preparing feed material

Deslime Cyclones: Optional classification/deslime stage to remove fine particles.

Thickener and Associated Pumps: To provide surge capacity and density control.

Rougher and Scavenger Jameson

Flotation Cell Units: Particularly suited to fine particle flotation, including coal and base metal applications. These are self-contained units with feed pumps, offering flexibility in the flowsheet.

Variety of Mechanical Flotation Cells: Available in 40 L, 20 L, and 12 L sizes with feed conditioning tanks These are skid-mounted, allowing for relocation and reconfiguration

Pressure Filter for Product Dewatering: For dewatering the final products.

Reagent Mixing, Storage, and Distribution: Essential for chemical processes.

Water Storage and Distribution System: For efficient water management

Air Compressor: To supply compressed air for flotation and other processes.

Operational Capacity and Flexibility:

The flotation circuit is designed to process up to 77kg/hr of solids The pilot plant can be operated continuously, either on a day shift (at approximately 800textkg/day) or 24 hours per day (at approximately 1.8textt/day).

A core aspect of the Flexi-Lab's design is its emphasis on adaptability The mechanical flotation cells are skidmounted, meaning they are designed to be easily moved and reconfigured. This allows for rapid changes to the processing circuit to optimize for different feed materials or desired outcomes. Furthermore, the piping throughout the facility is of a flexible hose type. This flexible pipework is critical, as it enables individual units to be easily moved around the facility, connected in various sequences, or even bypassed entirely as required by the specific testwork or flowsheet configuration. This inherent flexibility minimizes downtime and maximizes the range of experiments and processes that can be conducted within the lab, enhancing its operational versatility and research capabilities.

What will it be used for?

The Flexi-Lab pilot plant can be configured for a variety of tailings materials that can be concentrated via froth flotation. It is capable of producing up to three products as moist filter cake: up to two concentrates (products) and one tailings (residue).

Coal Tailings: Given the high quality of coal in the Bowen Basin and the long history of mining, a large quantity of material is available for reprocessing. Many historic flowsheets did not utilize fine particle flotation, making older tailings amenable to flotation using Jameson cells. The ideal first project for the facility is the reprocessing of coal tailings to recover valuable coal through the flotation process.

Pyrite Tailings: With the future closure of the Mt Isa copper smelter, there is a potential deficit of acid production in Queensland. Pyrite tailings can be concentrated via froth flotation to produce a feed suitable for acid generation. There is also potential for the recovery of cobalt and/or gold if sufficient quantities are present

Base Metal Tailings: There is some opportunity to reprocess bulk samples of base metal tailings, particularly to feed downstream hydrometallurgical processes, as it is much more difficult to achieve a saleable concentrate grade directly from tailings

Other Potential Commodities: The plant can also process gold tailings (especially where gold is associated with sulphide minerals), rare earth oxide (REO) minerals, graphite-rich tailings, and phosphate slimes.

Beyond the primary tailings types, the Flexi-Lab's versatile design supports a broad range of applications, including:

Optimizing Existing Processes: Companies can use the Flexi-Lab to test modifications to their current beneficiation flowsheets on a pilot scale, identifying improvements in recovery rates, product quality, or operational efficiency before implementing changes at a full-scale plant. This de-risks capital investment and accelerates process optimization.

Developing New Flowsheets: For novel ore bodies or complex mineral assemblages, the Flexi-Lab provides a platform to develop and validate entirely new processing flowsheets

Researchers and companies can experiment with different equipment configurations, reagent schemes, and operating conditions to unlock value from challenging materials.

Critical Minerals Recovery: With increasing global demand for critical minerals, the Flexi-Lab is ideally positioned to pilot processes for extracting these valuable elements from various feedstocks, including primary ores, waste streams, and even unconventional sources This includes exploration of new flotation reagents and techniques specific to critical mineral separation

Waste Valorization and Circular Economy Initiatives: The facility can be used to develop and test processes for transforming mining waste (beyond just tailings) into valuable co-products. This aligns with circular economy principles by reducing environmental impact and creating new revenue streams, for example, producing construction materials from mine waste

Training and Skill Development: The operational pilot plant serves as an invaluable training ground for metallurgists, process engineers, and plant operators. It provides hands-on experience with industrial-scale equipment and real-world processing challenges, fostering a skilled workforce for the future of the resources sector.

and Development:

Academic institutions and R&D organizations can leverage the FlexiLab for applied research projects, testing new theories, technologies, and equipment performance under controlled, yet representative, conditions This bridges the gap between laboratory-scale studies and commercial application

Environmental Remediation and Tailings Management: The Flexi-Lab can be utilized to develop and test processes that not only recover value from tailings but also contribute to their safer and more sustainable management or remediation, potentially reducing the environmental footprint of mining operations

How does it operate?

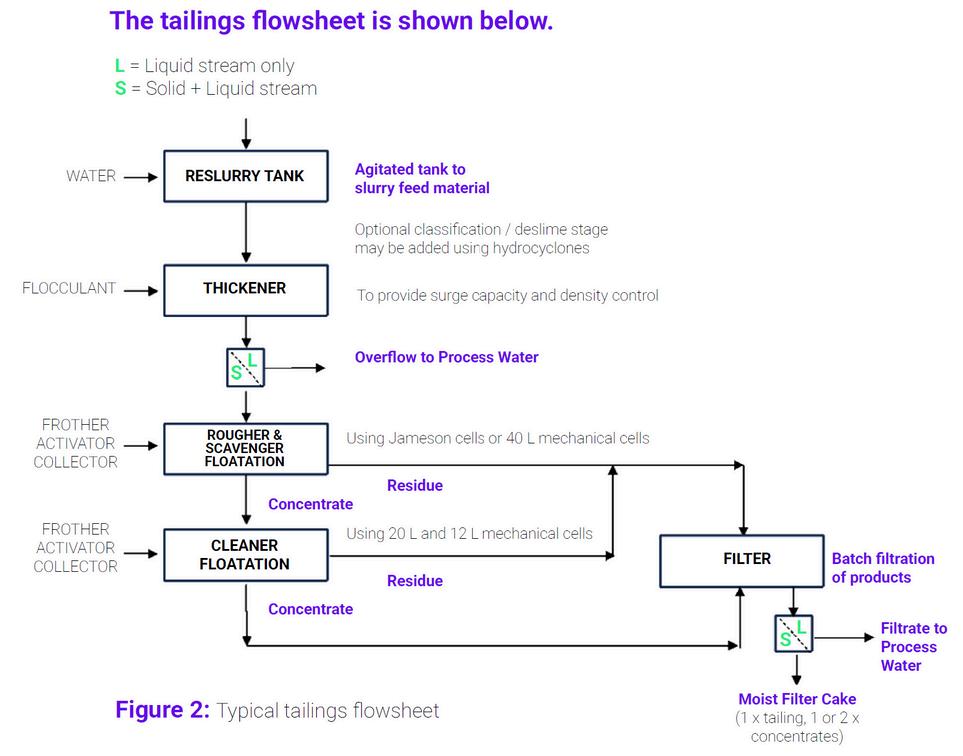

The typical tailings flowsheet for the Flexi-Lab is designed for efficient and flexible operation:

Reslurry:

The process begins by introducing the tailings into a feed tank where they are re-slurried. This involves mixing the solid tailings with water to achieve a specific target percentage of solids, creating a pumpable slurry that is ready for subsequent processing. This step ensures a consistent and homogenous feed for optimal downstream operations.

Following reslurrying, the feed slurry can be directed to an optional two-stage cyclone system This system is used for classification, which separates particles based on size, and desliming, which removes very fine, undesirable particles (slimes) Alternatively, if not required for the specific material or process, the slurry can be sent directly to the flotation feed conditioning tank. This flexibility allows for tailoring the preparation step to the characteristics of the feed material

The heart of the Flexi-Lab's beneficiation process is the flotation circuit. This circuit comprises two Jameson pilot rigs connected in series, complemented by mechanical cleaner and re-cleaner cells. This advanced setup allows for the selective separation of valuable minerals from the tailings based on their surface properties. The modular nature of the cells and flexible piping enable various configurations of the flotation banks, adapting to different circuit requirements and optimizing recovery for diverse mineral types

After the flotation process, the flotation tailings (the unwanted residue) and any waste from the deslime cyclones are sent to a thickener The thickener concentrates the solids, allowing for the recovery of process water which overflows and can be recycled. The thickened tailings, along with the valuable flotation products (concentrates), are then transferred to storage tanks. From these tanks, they proceed to a batch filtration process, where remaining water is removed to produce a moist filter cake, ready for further handling or disposal.

The Flexi-Lab offers flexible service arrangements to cater to diverse project needs, formalized through various commercial agreements:

Pilot Plant Service Agreement (Industry Partners): This agreement is for mining companies and resource developers seeking to conduct specific pilot-scale mineral processing trials. It defines the scope of work, target throughput, campaign duration, and required analytical support Key aspects include clear service fees (per-hour, per-day, or campaign-based), client ownership of all raw and processed data, and strict confidentiality clauses.

Equipment Testing & Validation Agreement (OEM/Manufacturer Partners): Designed for equipment manufacturers, this agreement focuses on testing, validating, and demonstrating the performance of specific OEM equipment or technology within the Flexi-Lab's circuit. It covers installation, test campaign design, and demonstrations. Fees include access and support, with clear delineation of IP ownership for both OEM technology and Flexi-Lab operational improvements.

Research Collaboration Agreement (R&D Partners): This framework is for universities and research institutions collaborating on R&D projects utilizing the Flexi-Lab's capabilities It outlines shared research objectives, joint experimental design, and pathways for joint publications and grant applications. The agreement provides a clear framework for Intellectual Property (IP) ownership, including provisions for joint IP and licensing rights.

Training Services Agreement (Training Partners): For Registered Training Organisations (RTOs) and other training providers, this agreement facilitates the delivery of practical, hands-on training programs using the Flexi-Lab. It covers curriculum development, scheduling, participant numbers, and the use of Flexi-Lab equipment for practical exercises. Fees are typically per-day or per-program, with clear agreements on curriculum and IP ownership.

Master Services Agreement (MSA) for Flexi-Lab Operations (Commercial Partners): This overarching agreement establishes general terms and conditions for commercial partners who may operate the Flexi-Lab on behalf of RCOE for third-party clients. It defines roles, responsibilities, revenue-sharing models, and the framework for specific projects outlined in subsequent Work Orders (WOs) or Statements of Work (SOWs) This allows for broader commercial collaborations and joint service delivery.

In all cases, projects can be conducted under confidentiality agreements, and intellectual property generated through testwork remains with the client unless otherwise agreed.

The Flexi-Lab's model is built on the principle of "full value realisation," offering a complete and derisked solution for the entire tailings stream. This approach is critical for stakeholders who must meet stringent environmental approvals and regulatory obligations for site closure. We provide a clear pathway for all materials, transforming a liability into a complete value chain.

Through detailed pilot-scale testing and analysis, we help qualify the commercial viability of high-value materials recovered from tailings This provides the business case for investment by demonstrating clear market pathways for each product:

High-grade coal: Beyond its traditional use in steelmaking, recovered coal fines can be reblended into a prime product or upgraded for use as fuel additives in the shipping industry, and can even be processed into products like activated carbon

Aluminosilicates and clays: These materials can be calcined to create Supplementary Cementitious Materials (SCMs), which replace a portion of Portland cement in concrete production, significantly reducing the carbon footprint of construction. They also have commercial applications in claybased products such as bricks, tiles, and specialty ceramics

Fine silica: When processed to a high purity, fine silica can be used in a range of high-value industrial applications, including the manufacturing of glass, ceramics, specialty chemicals, and as fillers in composites

Sulphide minerals: The recovery of pyrite and other sulphides provides a feedstock for the production of sulphuric acid, a high-demand commodity in the mining and chemical industries. This process can also allow for the recovery of associated trace elements like gold or cobalt.

Critical and rare earth minerals: REEs such as neodymium and lanthanum are vital for emerging technologies. They are used in highstrength permanent magnets for electric vehicles and wind turbines, as catalysts in petroleum refining, and in advanced electronics and lighting.

A key component of the Flexi-Lab's value proposition is the ability to find a second life for the remaining material, ensuring the entire stream is accounted for. This directly addresses regulatory and environmental obligations, transforming a waste disposal problem into a resource management solution:

Soil conditioners and land rehabilitation: The final residue can be processed into a beneficial soil amendment. Depending on its composition, it can be combined with organic matter to improve soil fertility, structure, and water retention, making it ideal for the rehabilitation of mine sites and agricultural lands.

Void fill and aggregates: The inert, non-acid generating nature of the final residue makes it suitable for use as backfill to stabilize underground mine voids or for surface construction It can also be valorized as a partial replacement for natural sand and aggregates in road construction and concrete mixes, reducing the need for virgin materials.

Simplified disposal: The Flexi-Lab's process effectively "detoxifies" the tailings by removing potentially acidgenerating sulphides and other contaminants The final material is a more stable and environmentally benign product, which simplifies tailings dam closure strategies, minimizes long-term environmental risk, and ensures compliance with post-closure regulatory frameworks

TThe Flexi-Lab provides a critical link between laboratory testwork and commercial deployment, enabling the validation and de-risking of various mineral processing strategies. Here are several real-world examples that illustrate the diverse applications and successes of pilot-scale facilities, similar to the Flexi-Lab's potential:

Core Resources (Coal Tailings Reprocessing): Core Resources successfully operated a coal tailings reprocessing pilot plant, demonstrating a novel flowsheet to create an ultra-low ash flotation product for the shipping industry, leading to a demonstration-scale plant.

EnviroGold Global (Sulphidic Tailings Valorization): Utilized a pilot facility to demonstrate their NVRO Process, efficiently recovering precious, strategic, and rare earth metals with low environmental impact

Hastings Technology Metals (Rare Earths Beneficiation): Completed pilot plant operations to validate their beneficiation and hydrometallurgical flowsheet, providing crucial data for the engineering design of their Yangibana Project.

CSIRO (Battery Materials Development): Conducting pilotscale projects for cathode and anode materials, developing sustainable processes to establish a local battery manufacturing industry.

The Flexi-Lab is strategically located within the Future Industries Hub, adjacent to the existing Resources Centre of Excellence building in Mackay. This prime location facilitates seamless collaboration and access to a broader ecosystem of mining technology, training, and research.

The Flexi-Lab provides a low-risk, technically robust environment to validate site-specific recovery strategies, improve yield performance, and de-risk future capital investment For Bowen Basin operators looking to unlock value from tailings, the Flexi-Lab is the critical link between opportunity and action