From NASA Astronauts to green members of parliament from Germany, it appears anyone and everyone is interested in the Resources Centre of Excellence (RCOE)

Well on its way to taking our region to the world, the RCOE is showcasing innovation and collaboration across traditional and emerging sectors, forging a path as a global leader on how to connect resources across our region and the world.

20,000+

In the past year alone, more than 18,000 people from 500 different companies walked through the doors of the RCOE. Hosting workshops, conferences and offering a simulated underground mining environment for training purposes, the RCOE is one of Australia’s most unique epicentres.

It is where government, project and grant funding are working together It is where industry, business and economic development collaborate to evoke change, opportunities and sustain economic growth across the Greater Whitsunday region

RCOE chief executive officer Steven Boxall said what started as an empty industrial shed is now bursting at the seams with users from all over Australia and visitors coming from all over the world

“Most days you’ll see a range of activities underway from training, innovation trials, collaboration across industry and education. In addition, the RCOE has been able to support dozens of other NFP, member groups, community groups and Indigenous groups via meeting and collaboration spaces, with an estimated profit of more than $200,000 in just the past year ”

Since opening its doors in 2020, the RCOE has a total of 15 FTE’s working under its roof, from an interesting range of companies and organisations including the Mackay Manufacturing Hub, Resource Industry Network, Strata Worldwide, Weld Australia, Trade and Investment Queensland, Gilmour Space, Trading Tracks, CQUniversity, BMA and Anglo American

Entering its forth year of operations, the board of RCOE are now working on the next five-year strategic plan having executed the initial strategic roadmap with great success.

As the RCOE moves into the next phase, along the way the centre is supporting METS innovators through a program called Innovator in Residence which provides free access to RCOE Facilities allowing for faster R&D and a path to market.

It is initiatives like this program that help build on RCOE’s growing capabilities across a wide range of traditional and emerging sectors. Due to the unique nature of the RCOE and the ability for innovators to work alongside industry to solve challenging problems, we now have people visiting from all over Australia, keen to break into the Greater Whitsunday innovation eco-system

$942,270 Direct investment into regional economic activities

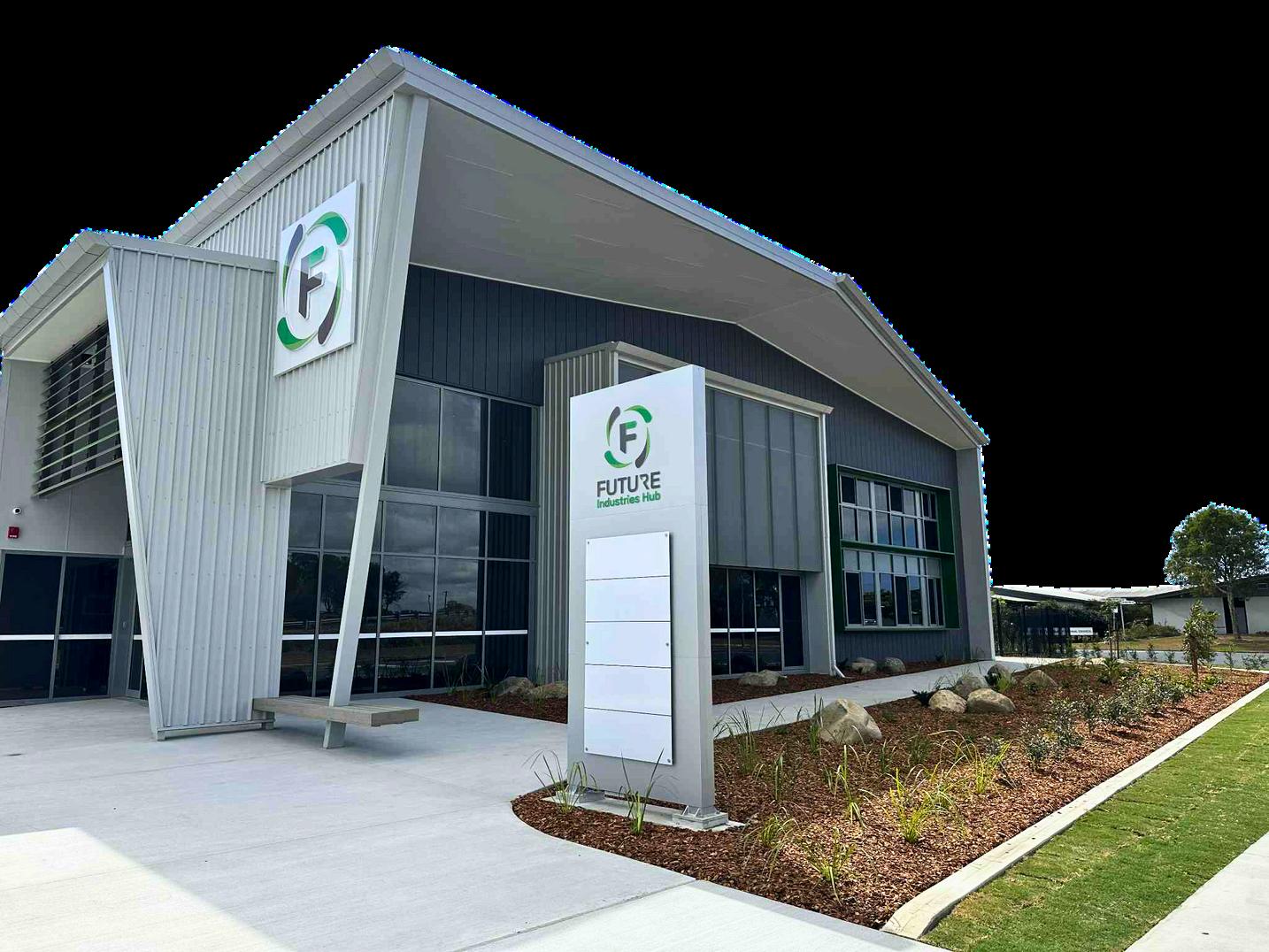

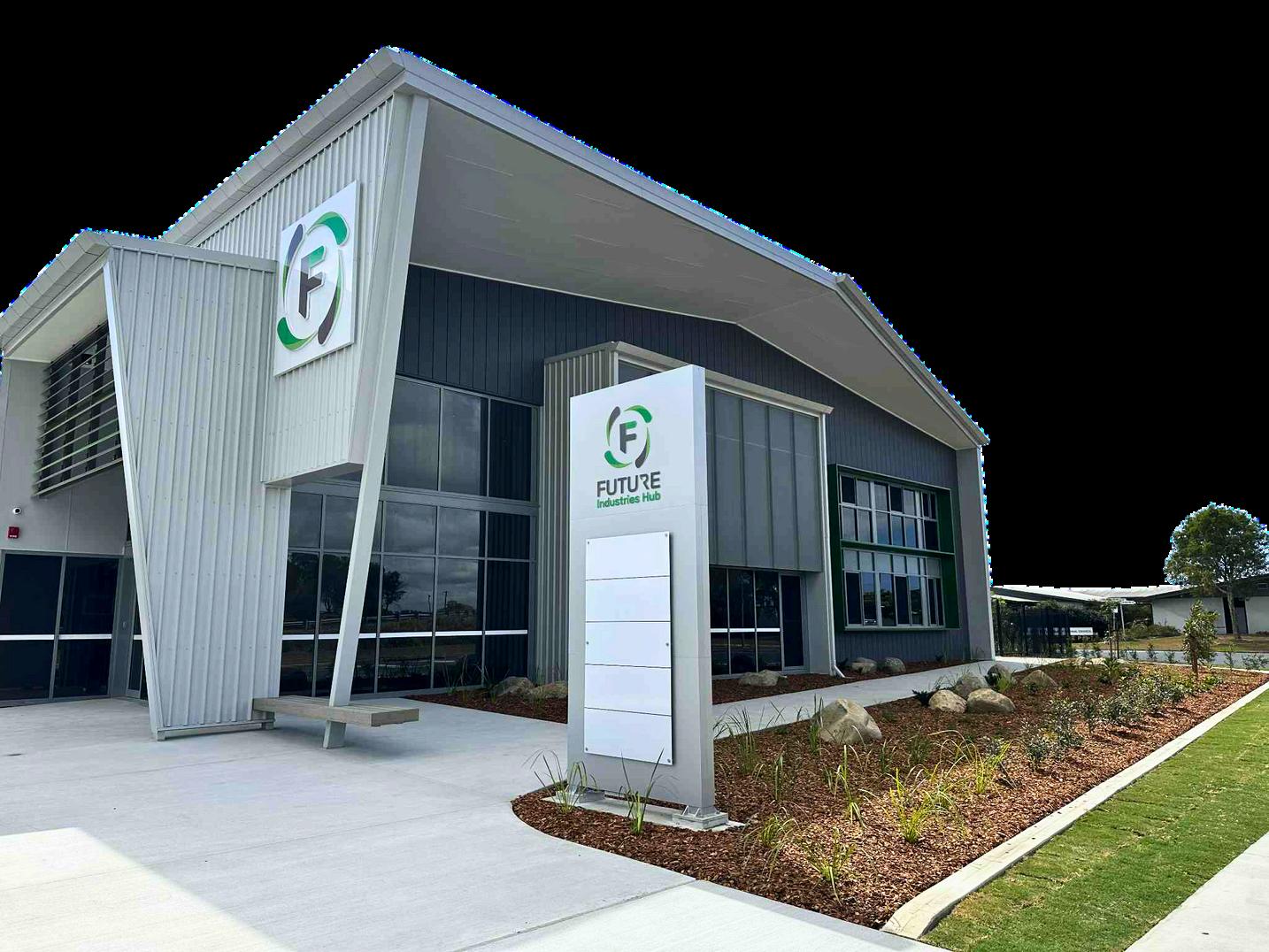

The RCOE is now moving into its second and third stages of development with Stage 2 featuring Future Industries Hub and the Isaac Resources Excellence Precinct in Moranbah

Along with Stage 2 and 3, the RCOE is also on the transition to a cleaner, greener future and building the skills needed for industry and business alike to look to diversification and decarbonisation as a key component to all future business plans and strategies.

$12,421,250 Indirect investment into regional economy

$2,000,000

Total value of signature decarbonisation projects

Connecting the brightest minds in research, technology, education and METS to shape the resources sector of the future.

The Resources Centre of Excellence Stage 2 Hub is a collaborative space to solve industry problems With technical, digital and immersive capabilities provided, there will be opportunities for manufacturing businesses to seize opportunities to supply high value goods and services into global supply chains and export markets.

Whether you are looking for an opportunity to accelerate your business or you have a need to expand and diversify, the Future Industries Hub offers invaluable industry connections. Placing your operations in close proximity to the pilot processing plant and RCOE will allow you to tap into other facilities and form relationships with industry leaders, researchers and METS organisations with a global reach.

A $12 million facility funded by QLD State Government and Mackay Regional Council.

20+ users in project pipeline for critical mineral pilot processing plant.

Workshops, events and training attracting visitation from investors, industry and all levels of government.

Critical mineral testing of 50kg of material per hour

This highlights tailings reprocessing as key to reducing waste, enhancing resource use, and supporting sustainable development goals

Environmental Remediation

Frame tailings reprocessing projects as environmental remediation efforts that recover valuable minerals while reducing environmental risks

Economic Benefits

Position tailings reprocessing projects as vital to regional economic development by creating jobs, supporting local businesses, and fostering innovation

The Future Industries Hub pilot processing plant will be a commercial common-user facility, helping to transition and support the emerging new economy minerals sector, generating jobs for the future and our regional economy.

The pilot plant will support the development of new and improved methods for processing minerals, enabling the pilot-scale demonstration of new technologies and assisting companies to increase mining yields and decrease associated costs.

Use advanced technologies to improve tailings reprocessing efficiency, reduce costs, and minimise environmental impact

Our team at the Future Industries Hub collaborate with key partners and stakeholders to deliver signature projects including the Bowen Basin Circular Consortium and Decarbonisation Accelerated.

The Bowen Basin Circular Consortium is the next stage of the Pit to Port Circular Economy project which involved a material flow analysis of the region’s waste streams to identify circular intervention opportunities. The BBCC will bring together industry players with government support to implement circularity practices across the Greater Whitsunday region Guided by the material flow analysis, stakeholder mapping and input from key stakeholders, the BBCC will target opportunities for a circular economy that will help solve industry challenges, while supporting the Bowen Basin’s capacity to maximise its environmental, social and economic value.

Decarbonisation Accelerated, led by Greater Whitsunday Alliance (GW3) and Resources Centre of Excellence, aims to support, educate, and motivate businesses and industries to start their decarbonisation journey The purpose of the Decarbonisation Accelerated project is two-fold:

Securing the traditional sectors of the Greater Whitsunday region through decarbonisation strategies; and Empowering new opportunities in emerging and decarbonised industries.

Everyone stands to play a part in decarbonisation, and businesses across all industries will soon need to demonstrate the steps they are taking to decarbonise if they are to remain competitive in supply chains

The Future Industries Hub will incorporate industrial tourism experiences that complement the underground mine simulator at the Resources Centre of Excellence, where tours will be conducted.

The critical mineral pilot processing plant has been designed to include a full window viewing pane to allow visitors to see the flexilab in action This viewing area will connect to the critical mineral education zone

Co-existing with the Bio Futures Digital Education space, the critical mineral education zone will feature interactive digital displays and information about mineral processing and critical minerals. Educational videos and hands-on activities will showcase the job opportunities within the critical mineral industry, along with the variety of products that are created from battery minerals and the circular opportunities of coal tailing reprocessing This space would be suitable for the general public, industry and school groups to visit

Virtual reality pods will deliver an interactive experience for viewers The story of mining including its transition into future industries will be showcased through educational videos that allow viewers to choose their interactions with the content.

Advocacy

$10million funded by Queensland and Federal Government

$5million towards infrastructure

$5million towards activation

$5.7million funded by the Queensland State Government for the Flexi-Lab

$5.7million funded by Mackay Regional Council

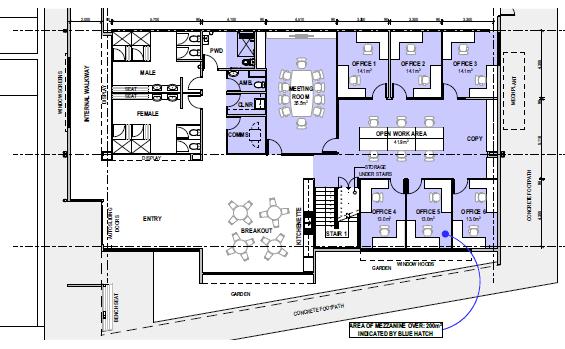

The Future Industries Hub has been purpose-designed to connect a vibrant community of innovators working side-by-side to help generate ideas, collaborations and experiences.

The foyer of the Future Industries Hub will feature a Bio Futures Digital Education space. With interactive touchscreens and displays, this state-of-the-art facility will introduce the topic of Bio Futures to visitors, also touching on other future industries such as critical minerals and circular economy After watching the informative videos and engaging with the educational content, visitors can move through to the viewing window overlooking the critical mineral pilot plant to see mineral processing in action.

Biotechnology companies or projects require a quality premises with facilities like microbiology suites and cold rooms The laboratory and bio incubator within the Bio Futures Centre will allow for research, innovation, product development and industry learnings. This facility will complement the existing QUT Mackay Renewable Biocommodities Pilot Plant which has limited surplus space.

nd collaborate

The Resources Centre of Excellence has a partnership with the ARM (Advanced Robotics and Manufacturing) Hub which has resulted in a dedicated ARM Hub facility located at the Future Industries Hub At present, the ARM Hub operates out of Brisbane and has a significant need to connect with regional industry players such as the various METS businesses in the Bowen Basin.

The innovation pod would include cobot (collaborative robot) stations, 3D printers and AR headsets and supporting software to be used in workshops and for training, prototypes and demos.

The Mackay ARM Hub facility would also provide one full time employee who can provide one-on-one business tech adoption assessments and plans, along with advanced manufacturing onsite assessments and reviews. This would be supported by an ongoing workshop program providing advanced manufacturing training.

The ARM Hub Robotics & Manufacturing Innovation Pod will collaborate with the RCOE to host relevant events throughout the year focused on education and awareness for school groups and community organisations.

The opportunities for creative thinkers are endless when it comes to product development and manufacturing. Below are some examples of small-scale innovative activities happening around the globe in spaces just like the Future Industries Hub.

Flexible industrial workspace for businesses looking to create, manufacture and incubate their ideas. Move in and make the space your own, with no red tape.

400m2 space

The European Space Agency has created a smallscale mining on mars terrain simulator to conduct research and test prototype sensors for future space missions.

Scan the QR code to enquire on working with the Future Industries Hub

An Austrian firm OMV has built a chemical recycling demo plant, which converts plastic waste into synthetic feedstock, under moderate pressure and normal refinery operating temperatures The innovative facility targets plastic waste that cannot be mechanically recycled and would otherwise be sent to waste incineration.

Tesla has built a pilot battery cell manufacturing line in Fremont, California, to make its own battery cells for electric vehicles. Tesla sources cobalt, nickel and lithium to create its batteries.

The following table details the valuable materials produced by the Flexi-Lab and the downstream processes required to turn them into final products.

Product Produced by Flexi-Lab

Aluminosilicates

Downstream Process Required Explanation of Downstream Process Use Cases Markets

Calcination orAlkaliActivation

Residual Carbon

Carbothermic Reduction and Refining

The clays are thermally or chemicallytreated to transform them into a reactive, cement-like material

As a supplementary cementitious material (SCM) to replace Portland cement in concrete, and for use in other clay-based products

Construction and Building materials

Pyrolysis and Activation

The silica is reacted with a carbon source at high temperatures to produce metallurgical-grade silicon, which is then further refined to high purity for solar and electronics applications

The carbon is heated in an inert atmosphere to create a char, which is then "activated"to create a porous structure for filtration The project will use innovative methods like MicrowaveAssisted Pyrolysis (MAP) or Concentrated SolarThermal (CST) Pyrolysis.

A primary feedstock for high-purity polysilicon for solar PV and computer chips

Solar, electronics, and ceramics

As activated carbon for water and air purification

Water and air treatment, and industrial filtration

Recovered Coal Flotation and Upgrading

The Flexi-Lab's flotation cells recover a commerciallyviable coal product This can be used directly or further upgraded to meet the strict quality standards for steelmaking

Can be upgraded to prime coking coal for steelmaking, and for use in cement production

The steelmaking and cement industries

Product Produced by Flexi-Lab

Rare Earth Elements (REEs)

Titanium-bearing Minerals

Downstream Process Required

Hydrometallurgical Processes

Chlorination or Hydrometallurgical Processes

Sulphide Minerals Oxidation

Explanation of Downstream Process Use Cases Markets

This process involves leaching the REEs from the concentrate using an acid, followed by solvent extraction and precipitation to separate and purify the individual elements

These minerals are treated with chlorine gas at high temperatures or leached with acid to produce a high-purity product

Sulphide minerals like pyrite (FeS 2) are oxidised to produce sulphuric acid

Critical for magnets in electric vehicles, wind turbines, and other high-tech applications

Electric vehicles, wind turbines, defense, and electronics

Phosphorus Leaching and Separation

Phosphate-bearing minerals are dissolved using acidic reagents, and the phosphorus is then separated and purified through precipitation or solvent extraction

Used in white pigments, UV-blocking agents, and highstrength alloys

Markets: Pigments, aerospace, paints, and manufacturing

As a feedstock for sulphuric acid, a widely used industrial chemical in mining, fertilisers, and chemical processing

An essential component for fertilisers and animal feed supplements

Markets: Fertilisers, mining, and chemical industries

Markets: Agriculture, animal feed, and chemical industries