We are a leading provider of custom solutions for the handling of bulk materials for processing businesses across various industries. Dynamic Air has over five decades of expertise in designing and manufacturing pneumatic conveying systems and equipment for handling dry bulk solids.

At Dynamic Air, we set the standard for excellence in bulk solids handling. With a relentless focus on quality, reliability, and customer satisfaction, we deliver reliable, high-quality pneumatic conveying systems, equipment, and custom solutions that exceed expectations. BULKBUSTERTM

We never take a cookie-cutter approach just to cut costs up front; we know that the right solution will save you money in the many years to come. Our tailored solutions involve thoughtful planning, meticulous engineering and precise manufacturing that optimize efficiency and productivity.

Sales Director: James Scrivens

Production: Sarah Daviner

Accounts Manager: Avery Hudson

Office Manager: Katie Brehm

BULK SOLIDS TODAY is published 6 times a year by Abbey Publishing Ltd

ADVERTISING & EDITORIAL

Please contact us at: Tel: 01933 316931

Email: editorial@bulksolidstoday.co.uk advertising@bulksolidstoday.co.uk Web: www.bulksolidstoday.co.uk Twitter: www.twitter.com/ BulkSolidsToday

CIRCULATION

To receive a copy free of charge, please send your details to subs@bulksolidstoday.co.uk

No part of this publication may be reproduced by any means without prior permission from the publishers. The publishers do not accept any responsibility for, or necessarily agree with, any views expressed in articles, letters or supplied advertisements.

ISSN: 1365/7119

Following the completion of their Liverpool depot decarbonisation programme in 2024, Sunbelt Rentals UK and Europe has decarbonised their Plant & Tools, Powered Access and Traffic Management depots in Milton Keynes into fully electric sites, aligned with their sustainability strategy, Our Planet which is aimed at leading positive change across the rental industry to deliver a better future.

Their decarbonisation programme integrates features to create a resilient, lowcarbon operational model that delivers both environmental and workplace benefits. Features include:

• 250 kWp of solar PV, 370 kWh of battery storage

• 194 kW air-source heating

and cooling systems

• EV charging infrastructure

• The design and installation will provide significant green electricity to charge their increased range of battery-powered assets.

Mark Keily, Head of Health, Safety and Sustainability at Sunbelt Rentals UK & Ireland, said:

“Decarbonising our depots is a powerful statement of intent for our business.

By implementing this transition throughout our own facilities and practices, we are not only taking a proactive stance in reducing our carbon footprint, but we are also demonstrating to our customers, teammates and the local communities that our focus on sustainability is not a distant

goal or aspiration for the future. Instead, it is a reality for us.”

Chris Jones, Head of Property at Sunbelt Rentals, added:

“By fully electrifying our Milton Keynes depots, we’re creating healthier workplaces for our teammates and cutting operational costs while strengthening our overall energy resilience. That means we’re better equipped to serve our customers with reliable, sustainable solutions every day. It’s a model we can replicate nationwide, ensuring we stay ahead of UK decarbonisation policy and continue leading the rental sector on sustainability, ultimately giving our customers confidence that by working with us, they’re working with a partner who is committed to delivering a greener, more resilient future.”

UKWA NATIONAL CONFERENCE 2026

Next year’s UKWA National Conference, held on 4 March 2026 at the East Midlands Conference Centre in Nottingham and sponsored by Kallikor, will celebrate Warehousing: The Backbone of British Logistics.

UKWA CEO Clare Bottle comments, “UKWA’s National Conference provides a valuable opportunity to learn about the latest developments impacting the warehousing industry, share best practice and network with colleagues on a range of crucial topics.

Bringing together industry leaders, expert panellists and over 20 specialist suppliers showcasing an impressive range of products and services, this is the ultimate conference for warehouse professionals!”

A keynote session from sponsor Kallikor will examine the potential benefits of AI for warehouse operators, explaining that this powerful technology is not just for

major blue-chip companies, but can be a serious game-changer for SMEs too.

Naturally, the relentless rise of cybercrime and the importance of cyber security in protecting your business will be high on the agenda, with a panel session led by Helen Barge, Digital Risk & Resilience Leader at Barnett Waddingham.

Other panel discussions and break-out sessions will include:

• Automation, with Obinna Njoku, Warehouse Transformation Lead at Pepsico

• Property, with Danny Kennedy, Senior Property Strategy & Development Manager at Ocado

• Skills & Training, with Joann Robertson, Head of Supply Chain Transformation at Babcock International and CILT Board Member

Distinguished keynote speakers will include, Walter Boettcher, Head of Research & Economics

at Colliers, giving the opening address and setting the economic and geo-political scene for the conference and Andrew Malcolm, Owner & CEO of Malcolm Group, while Tony Mannix, Strategic Advisor – Retail Logistics at GXO will no doubt delight and inform delegates with an afterdinner presentation.

EARLY BIRD OFFER: Buy 3 tickets for price of 2! (Full members only)

Delegate tickets include:

•Full day of engaging sessions on the issues that affect your business

•All day refreshments, including lunch

•Conference Networking Dinner, with special guest Tony Mannix

•Overnight accommodation, including breakfast

Early bird tickets are available for a limited period only. Apply now at www.ukwa.org.uk

Global air charter specialist Chapman Freeborn, part of the Avia Solutions Group, the world’s largest ACMI provider, has completed the successful transport of two oversized truckloading skids for Tropicana Airlines Ltd, based in Accra, Ghana. The units, which were almost 9 meters in length, were flown from Zhangjiagang, China to Port Harcourt, Nigeria, via Liège, Belgium, in late August and early September, with Chapman Freeborn’s China and UK teams coordinating the deliveries. Each transportation was completed within approximately 72 hours and in a cost-efficient manner while meeting the client’s requirements for highly secure, carefully packaged delivery.

The CCMs measured 870 x 210 x 225 cm and weighed approximately 5 tons each. The delivery was divided into

two batches, both flown by a nose-loading Boeing 747-400F from Zhangjiagang to Liège Airport (LGG). The first shipment, collected in Zhangjiagang and departing via CGO, was completed within 72 hours up to its arrival in Liège, after which Chapman Freeborn’s UK team managed the onward transfer and air freight to Port Harcourt, Nigeria. The second shipment, which did not face the same strict deadline, departed on 7 September and was delivered on a longer timeline.

Along with the overall challenge of handling large cargo, an additional issue was the fact that the cargo initially arrived unpacked. Therefore, the Chapman Freeborn China team organised expert professional packaging to ensure secure air transport.

The tight turnaround for

delivery was another challenge for the Chapman Freeborn team to overcome. Due to the client’s strict time constraints, the shipments had to be executed swiftly. Both were successfully completed within approximately 72 hours from collection to departure. Achieving this required precise coordination between Chapman Freeborn’s teams, with its China division handling collection, packing and freight from China to the Liège, and its UK team managing the second leg from Liège to Port Harcourt. End-to-end monitoring with video and photographic updates ensured the client was kept up to speed on the cargo’s progress. According to Jason de Beer, Cargo Charter Broker at Chapman Freeborn, the successful transportation of these units not only met client expectations but also delivered additional

benefits. “We were able to meet the Tropicana Airlines’ needs in terms of secure packaging of the cargo and the tight deadlines they were working to. Furthermore, by splitting the cargo into two separate stages we avoided using a single charter, resulting in significant savings for the client.

Overall, this successful delivery demonstrated our ability to work effectively as a coordinated global team, and proved that we have the capability to handle oversized, high-priority shipments while meeting and even exceeding the client’s needs,” says Jason.

Chapman Freeborn is a provider of air cargo charter services to major corporations, governments, NGOs, relief agencies, and high net-worth individuals. It boasts over 50 years’ experience and offers extensive global coverage thanks to its well-developed network of partners. The company is part of Avia Solutions Group, the world’s largest ACMI (Aircraft, Crew, Maintenance, and Insurance)

provider, operating a fleet of 187 aircraft worldwide and the parent company of over 250 subsidiaries. The group offers a wide range of aviation solutions, including MRO (Maintenance, Repair, and Overhaul), pilot and crew training, ground handling, and other related aviation services. Supported by 14,000 highly skilled aviation professionals, the group operates across 6 continents.

For more information, please visit www. chapmanfreeborn. aero

Unlike other valves that seal with friction, Posi-flate’s unique butterfly valve uses an inflatable seat to seal with air pressure. Thus it requires less torque and a smaller actuator, resulting in lower cost. Plus, the seat automatically compensates for wear, providing longer life. Some users have reported over six million cycles and the valves are still going strong.

Less friction

Low torque

Low maintenance

Lower actuator costs

Longer valve life

More reliable

Eriez®, a global leader in separation technologies, has introduced a new program to help food, pharmaceutical, and packaging customers upgrade their legacy Xtreme® Metal Detectors using the PrecisionGuard™ X8-C Upgrade Kit. This initiative enables users to modernize existing systems quickly and affordably, providing enhanced sensitivity, smart connectivity, and intuitive operation without the need for a complete system replacement.

The X8-C Upgrade Kit is a direct “drop-in” retrofit for installed Xtreme Metal Detectors, featuring the same shell dimensions and footprint to facilitate fast, seamless set-up. By replacing only the electronics and user interface, operators can continue using their existing sensing head, conveyor, and reject device while gaining advanced performance, data integration, and user control.

“Our goal is to streamline the transition to our next-generation PrecisionGuard platform at a pace that suits each customer,” said Emmett Keim, Global Product Manager for Inspection Systems. “The X8-C Upgrade Kit offers a straightforward, cost-effective path to bring legacy systems up to date with the latest PrecisionGuard technology, enhancing performance today and preparing companies for future full-system upgrades.”

The X8-C Upgrade Kit extends metal detector lifespan by seven to 10 years and introduces a range of high-performance enhancements, including:

• Large capacitive touchscreen interface with intuitive controls

• State-of-the-art high-speed processor for

earlier, more accurate detection

• 304 stainless steel construction rated for IP69 washdown conditions (optional 316 SS available)

• Built-in web user interface technology (replaces SMART Link) with optional Wi-Fi bridge

• 12-month warranty from installation (not to exceed 24 months from ship date)

Each kit includes complimentary Quality Retail Compliance software for customizable data logging and audit-ready record keeping. Special pricing is available for two-year verification services and spare parts.

To learn more, request a quote, watch a demonstration video, and access downloadable brochures, visit eriez.com/X8C.

Established in 1942, Eriez is a global leader in separation technologies. Our commitment to innovation has positioned us as a driving market force in several key technology areas, including magnetic separation, flotation, metal detection, and material handling equipment. The company’s 1,000+ employees are dedicated to providing trusted technical solutions to the mining, food, recycling, packaging, aggregate, and other processing industries. Headquartered in Erie, Pennsylvania, USA, Eriez designs, manufactures, and markets on six continents through 12 wholly owned international subsidiaries and an extensive sales representative network.

For more information, visit eriez.com.

For us it’s no problem.

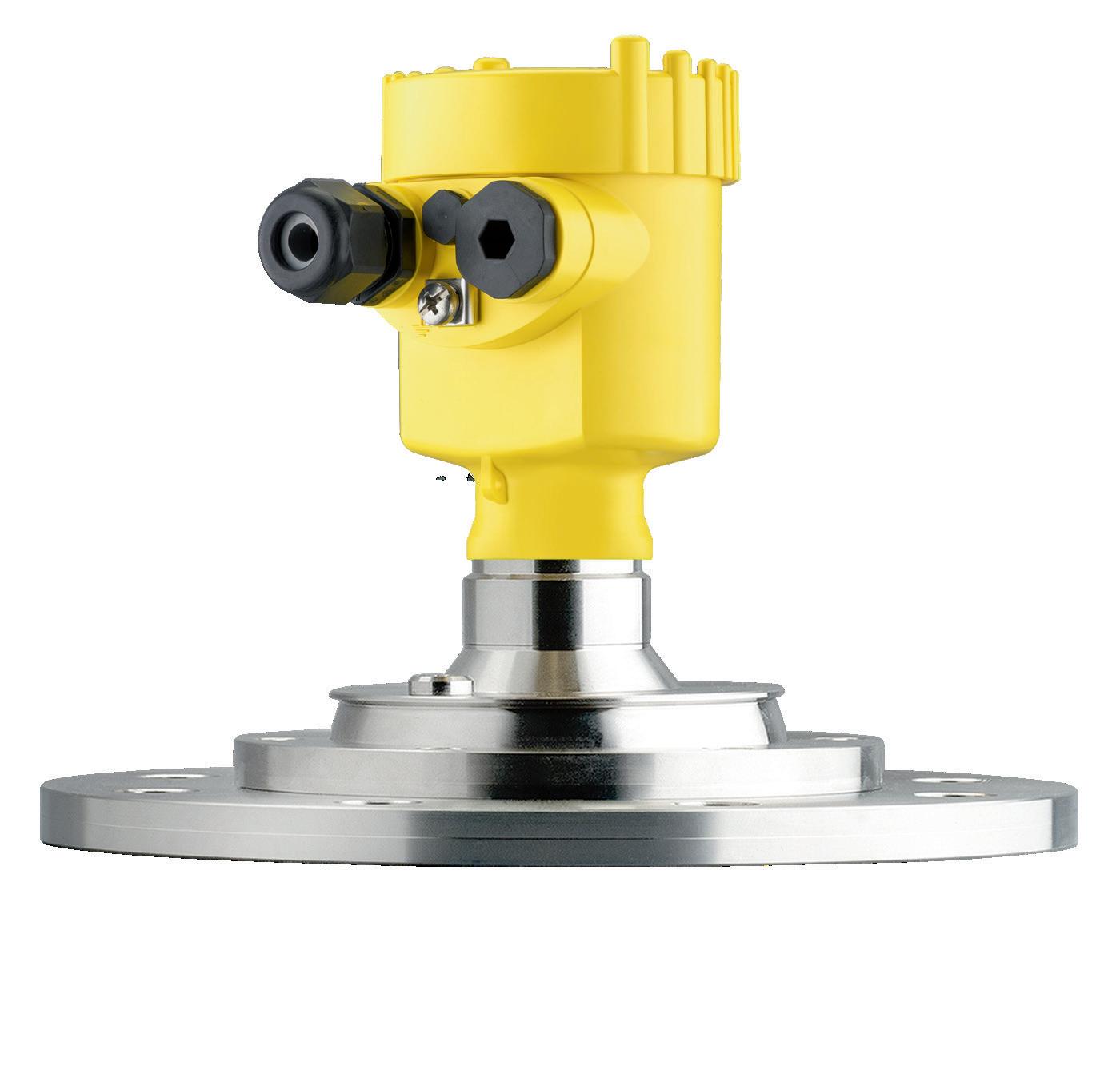

VEGAPULS 6X

The perfect radar level transmitter for measurement of bulk solids in all environments.

Everything is possible. With VEGA

• Highest operational reliability, immune to noise, dust and abrasion

• Non-contact operation - safe, reliable and maintenance-free

• Easy measuring beam alignment with swivel bracket and aiming app

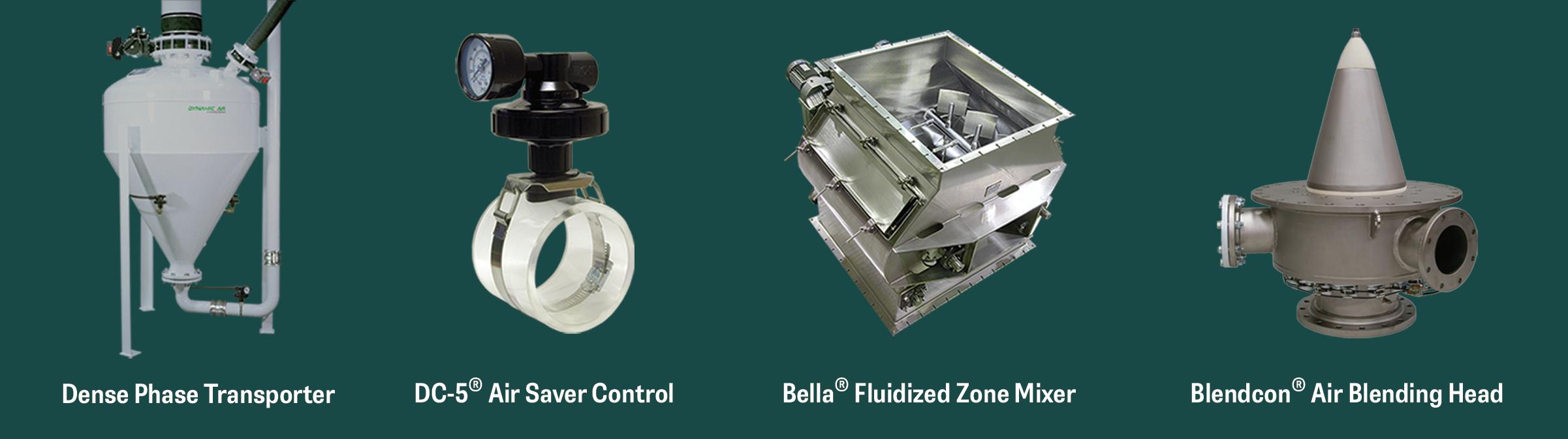

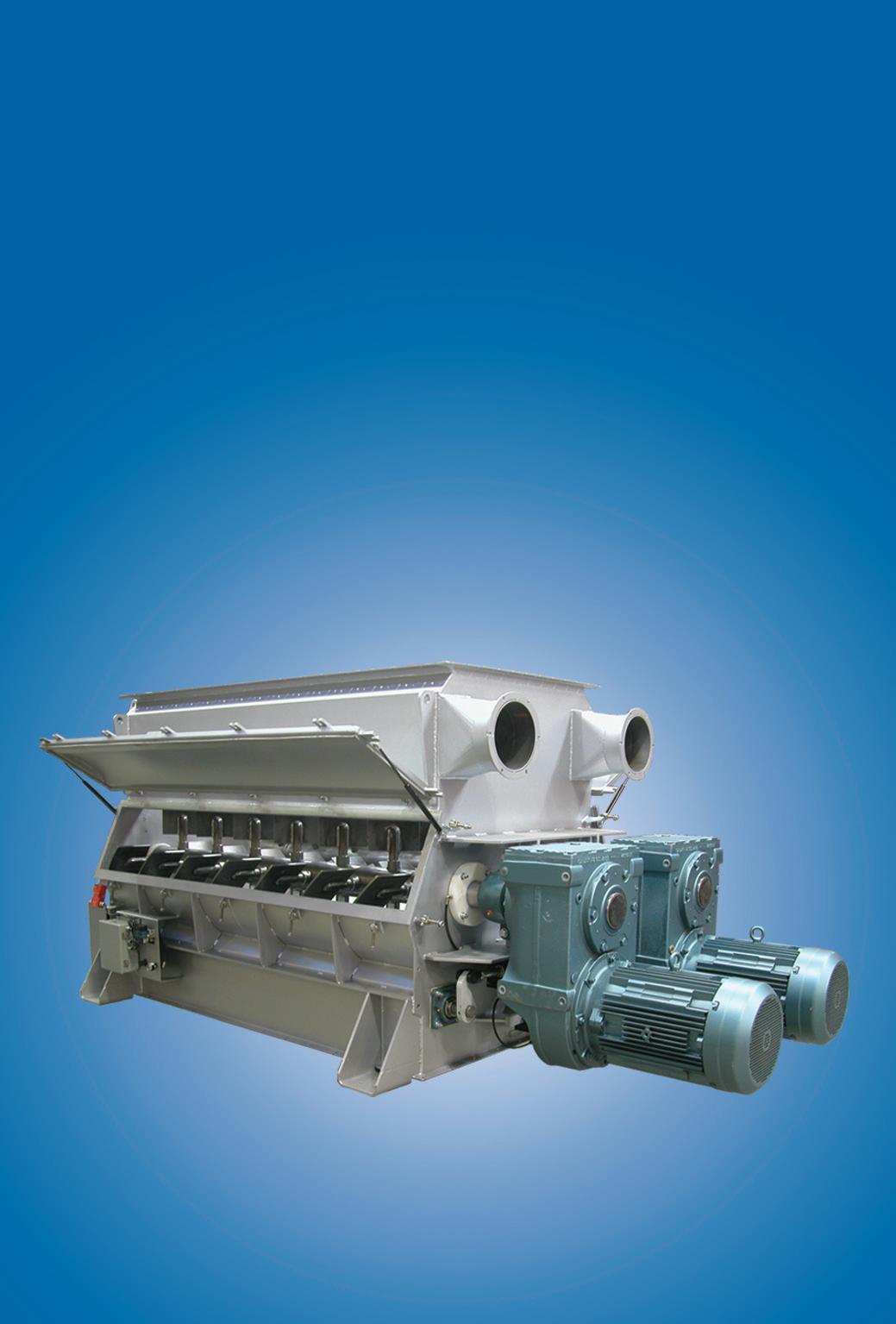

Dynamic Air dense phase pneumatic conveying systems have been proven in over 15,000 installations worldwide. They handle a wide range of materials and bulk densities at rates from a few hundred pounds to 400 tons per hour, over distances exceeding 5,000 feet. The HDP 4000 Full-Line Concept dense phase pneumatic conveying system has many advantages over more traditional dense phase concepts with regard to abrasion, particle degradation and energy consumption. The system utilizes the DC-5 Air Saver technology to achieve an optimum pressure balance while counteracting forces of friction to enable low conveying velocities. The Full-Line Concept system conveys materials at low velocity and high density while utilizing very low air consumption. The enclosed system is clean and can

be fully automated to convey to packaging or process bins. Very few moving parts are utilized, as the prime mover is standard plant compressed air at 100 PSIG. Dynamic Air Full Line Concept systems have proven to be very low in maintenance and are very flexible with regard to space and various custom plant situations. https://www.dynamicair.com/system/hdp4000-full-line-concept-dense-phase-pressure-system

Dynamic Air Ltd

Milton Keynes, United Kingdom

+44 (0)1908 622344

e-mail: sales@dynamicair.co.uk www.dynamicair.com

If you would like to subscribe to receive a regular copy of the digital edition of Bulk Solids Today magazine, you can subscribe on our websitewww.bulksolidstoday.co.uk

If you are interested in advertising within Bulk Solids Today magazine or supplying editorial content, please feel free to get in touch using the details on our website or below.

Bulk Solids Today is sent to our digital readership of over 9,000 Chief Engineers, Operations Managers and Technical Managers from within sectors including Chemicals, Food & Drink, Mining, Quarrying, Transport/ Distribution, Recycling & Waste Management and more.

www.bulksolidstoday.co.uk bst@abbeypublishing.co.uk

Tuf-Lok ring grip pipe and tube couplings are rugged, heavy duty, self-aligning and self-grounded couplings with a high end pull. They can be used for almost any application where pipe or tube ends need to be connected. The Tuf-Lok self-aligning couplings install quickly and easily with little effort.

Features

• Self-aligning

• Self-grounding

• High pressure rated

• Full vacuum rated

• Stainless or mild steel

• Usable on thin or thick wall pipe or tube

• Low cost

• Reusable

• Absorbs vibration

• Externally leakproof

i.safe MOBILE introduces the Mobile Operator Panel, a technological breakthrough that fundamentally transforms industrial automation in hazardous environments. The system embeds contextual process automation directly into the hands of field operators, ending decades of disconnection between centralised control rooms and field-level reality. Where operators previously worked with static procedures whilst critical decisions lagged behind real-time conditions, the Mobile Operator Panel delivers smart orchestration at the right moment decisions matter most. This is artificial intelligence reimagined for Ex-zones, where human expertise meets sovereign AI processing. The Mobile Operator Panel transforms how industries achieve safety, efficiency, and operational excellence in environments where both are non-negotiable.

BEYOND TRADITIONAL HUMAN-MACHINE INTERFACES

Traditional human-machine interfaces display information and accept commands. The Mobile Operator Panel does something fundamentally different. It understands the operator’s location, active permits, surrounding equipment, and current conditions. The system then coordinates workflows dynamically. The result transforms passive information displays into active decision surfaces that amplify human expertise rather than simply relay data. This represents the shift from Industry 4.0 connectivity to Industry X.0 collaboration. Machines no longer simply connect to networks. They understand operational situations and respond in a way that takes into account both technical constraints and human judgement. The Mobile Operator Panel creates truly adaptive operations where automation serves human decision-making rather than replaces it.

“For too long, industrial automation has forced field teams to adapt to rigid systems designed for control rooms,” explains Martin Haaf, CEO at i.safe MOBILE. “The Mobile Operator Panel inverts this logic entirely. We deliver intelligence directly to the field. Operators gain situational awareness and structured decision support at the moment they need it most, not minutes or hours later. This is human expertise amplified by smart automation, and it changes everything about how work is

done in Ex-zones.”

Legacy systems cause bottlenecks due to centralised decision-making hierarchies. They force operators to wait for approvals, confirmations and releases that are delayed to the conditions on site. The Mobile Operator Panel eliminates these friction losses. It provides information that responds to current plant conditions, approval status and operating parameters directly on the spot. This achieves unprecedented operational transparency while the system complies with the strict safety standards required in ATEX and IECEx-certified environments.

PURPOSE-BUILT

The Mobile Operator Panel consists of the following fully ATEX and IECEx certified components, which have been specially developed for potentially explosive atmospheres in Zone 1/21 and Zone 2/22: Firstly, the Android tablet (IS940.x) or the Windows tablet (IS945.x), which offer intrinsically safe mobile platforms with on-device AI inference capabilities. These devices bring contextual process automation through interfaces built from the ground up for potentially explosive atmospheres. The other component is the IS-CS1A.1 Connectivity System, which provides secure synchronisation, powering and integration infrastructure that connects field operations seamlessly to enterprise systems without compromising safety certification.

The edge AI architecture powers this revolution.

Sovereign AI processing through high-performance inference engines, including QNN, ONNX Runtime, and TensorFlow Lite, delivers real-time decision support without cloud dependency. This matters critically in hazardous environments. Operations cannot rely on connectivity that may fail precisely when conditions become most challenging. The Mobile Operator Panel processes information locally, maintains data ownership, and continues to function even when external networks become unavailable.

The Mobile Operator Panel delivers quantifiable operational improvements across safety, efficiency, and decision quality. Intelligent automation processes sensor data, video feeds, and operational information through AI-driven analysis. The system provides actionable guidance precisely when conditions shift. It eliminates decision latency and enables adaptive responses that exceed static procedures. Operators receive information tailored to immediate circumstances rather than generic instructions designed for average conditions.

Enhanced safety emerges through predictive technology. Continuous monitoring detects anomalies, compliance deviations, and equipment degradation patterns that human observation might miss. The system triggers immediate alerts and activates preventive workflows before incidents occur. This shifts safety management from reactive response to proactive prevention. Seamless multi-system integration creates a unified operational surface. Native connectivity across legacy control systems through RDP and VNC, process automation via OPC-UA and MQTT, business systems using HTTPS, JSON, and XML, and AI overlays eliminates information silos without requiring infrastructure replacement.

Human-in-the-loop governance ensures transparent AI logic so that operators retain decisive oversight. Every automated action remains explainable, accountable, and subject to human validation. The system recommends, humans decide. Edge-native resilience eliminates cloud dependencies. Local AI processing ensures consistent performance in remote or connectivity-constrained Ex-zones whilst the architecture maintains complete data sovereignty. Operations continue without interruption regardless of external network conditions.

The Mobile Operator Panel addresses specific operational friction points that constrain efficiency and safety across hazardous environments:

Structured maintenance and inspection workflows boost uptime and safety by guiding every step. From preparation to execution. Smart, contextual automation turns these procedures into live guidance for operators. By adapting steps to real conditions and

delivering instant insights on mobile panels, it ensures consistency, safety, and efficiency, everywhere and every time.

SIMOPS are overlapping industrial tasks that can create serious hazards if not well coordinated. Risks are reduced through early hazard identification, a dedicated coordinator, and clear communication. Mobile operator panels give real-time oversight and instant team connectivity for safer operations.

Permit-to-Work (PTW) management streamlines hazardous work authorisation to enhance safety and compliance. Automating PTW with contextual process automation accelerates permit approvals, enforces safety checks dynamically, and adapts requirements based on current conditions. Integrated with mobile panels, it boosts communication, reduces errors, and provides instant visibility across teams. This makes high-risk work safer, faster, and more efficient.

A shift handover transfers key operational and safety information between teams to ensure continuity. Mobile operator panels standardise this process, enabling real-time digital input, secure records, and AI-supported clarity for safer operations.

“We witness the emergence of Contextual Process Automation as a new category in industrial technology,” notes Jan Rieks Zonderman, Product Manager Automation at i.safe MOBILE. “This convergence of intrinsically safe hardware, sovereign AI processing, and human-centric design creates interfaces that respond dynamically to field realities. For industries that operate in Ex-zones, this shift from centralised control to contextual orchestration fundamentally reimagines how work happens. The question is no longer whether to automate. The question now is where intelligence is located and how it serves human expertise.”

i.safe MOBILE will introduce the Mobile Operator Panel at ADIPEC in Abu Dhabi from 3-6 November 2025 in hall 15, booth 15118. The launch will highlight how context-aware automation enhances system resilience and enables solutions for holistic global progress.

At this year’s PPMA Show, Holmach Ltd, the UK and Eire’s leader in thermal processing technology solutions, highlighted the key trends shaping modern manufacturing, including protein innovation, food safety and sustainable automation.

The company’s stand became a focal point for producers looking to strengthen product quality, improve flexibility and futureproof operations across both food and non-food sectors.

Protein rich foods continued to dominate discussion, with producers exploring a widening range of applications from whey protein ice creams developed for medical nutrition to baby foods, plant based snacks and nut butters designed for health conscious consumers.

“Protein is shaping a new era of food innovation,” said Chris Holland, Managing Director of Holmach Ltd. “Manufacturers are rethinking how to balance texture, flavour and functionality while keeping processes efficient and sustainable.”

Holmach’s partners showcased solutions supporting this shift. Making its UK debut, Kreyenborg’s pioneering infrared technology offers a 100% electric, chemical free method to pasteurise, sterilise, roast, toast and dry bulk products such as grain, nuts, seeds and extruded proteins. Its ability to heat ingredients from the core ensures complete microbial reduction while preserving natural flavour, colour and nutrition. This provides a timely and transformative response to recent recalls of nut-based products.

A show highlight saw Chris Holland appear on camera with TV’s Spencer Kelly, former host of the BBC’s Click, for a feature on sustainable innovation and the future of food processing. During the interview, Chris Holland demonstrated Kreyenborg’s infrared technology alongside Roboqbo’s versatile universal processing vessels, showing how both systems support safer, more sustainable and creative production.

Alongside this, Roboqbo’s high shear capabilities enable producers to create smooth, stable protein rich foods without the grainy textures often associated with traditional processing methods, giving manufacturers a reliable route to achieve consistent, high-quality results.

The growing demand for faster, more flexible product development was another key theme at the show. As manufacturers look to shorten development cycles and bring ideas to market more efficiently, Holmach’s pilot scale solutions drew strong interest. Roboqbo’s 15 litre vessel enables teams to test and refine recipes with precise control over texture, timing and temperature, while Lagarde’s pilot steam and air retorts allow producers to validate processes and

packaging formats before scaling up. Kreyenborg also offers lab scale infrared systems for testing and refining heat treatment parameters prior to full production, providing a joined up approach to innovation across multiple processing stages. Together, these solutions provide a powerful platform for innovation with reduced risk and waste.

Ongoing labour shortages and growing product diversity also made automation a major talking point. Holmach’s partners Mengibar and Posimat demonstrated how smart automation can transform line efficiency, from Mengibar’s precision filling and closing systems, which deliver fast, toolless changeovers across multiple closure types, to Posimat’s automated bottle unscramblers that handle a variety of formats on the same line. Mengibar’s swirl fill technology also attracted attention for its ability to add decorative visual appeal directly into the product. Up to twelve unique swirl patterns can be stored and randomly applied, giving each bottle a hand filled appearance. The technique is widely used in personal care products such as shampoo and body wash, and increasingly in cosmetics to enhance the perception of quality and premium value. Together, these technologies enable manufacturers to maintain high output and consistency with fewer skilled operators.

“Flexibility is now as important as speed,” added Lewis Peasgood, Commercial Director of Holmach Ltd. “Manufacturers want systems that adapt to their product mix, not hold them back.”

A strong theme of customer loyalty ran through the event, with many visitors returning to Holmach to expand existing installations, a clear endorsement of long-term reliability and service support.

“Seeing customers come back to build on what we have already achieved together is the best endorsement of all,” said Chris Holland. “Our technologies do not just solve immediate challenges; they give manufacturers confidence to grow.”

The UK food and drink industry is uniting to tackle a workforce crisis. Facing a critical labour shortage and skills gap, businesses, trade bodies and government are rallying behind the Mmmake Your Mark initiative led by IGD. The 2025 campaign aims to directly address the workforce challenges by highlighting the wide range of rewarding career paths available, from farm to fork.

New research commissioned by IGD reveals a significant disconnect between young people’s career aspirations and their awareness of diverse opportunities within the UK’s dynamic food and drink industry. The comprehensive survey, involving over 1,000 young people aged 16-25 and 1,000 parents, underscores a pressing need to reframe the industry’s image and highlight its breadth of modern career paths.

The new findings challenge long-held perceptions, indicating that while young people are passionate about creative and purpose-driven careers, they often overlook the food and drink sector as a viable pathway to explore this. This “Guidance Gap” is further compounded by parental influence, which often steers young individuals towards more “traditional” career fields.

Reshaping Youth Career Perceptions

The research shows that over a third (38%) of young people aged 16-25 cite their parents or guardians as the single biggest influence on their career considerations. This influence often translates into pressure, with 57% of young people admitting they have felt pressure from parents or teachers to pursue ‘traditional’ or ‘safe’ careers such as law, medicine, or finance, even if not aligned with their interests.

Strikingly, despite this external pressure, 6 in 10 (61%) of young people expressed a genuine passion for creative and service-led industries, including careers in food, hospitality, and media. However, a stark one in five (19%) do not realise they can pursue these passions within a career in the food and drink industry.

The Hidden Depths of Food and Drink Careers

From AI and cybersecurity, to engineering and analytics, many roles in the food and drink industry go unnoticed. Nearly a fifth (19%) of young people surveyed admit to not being aware of the jobs available, highlighting the need to showcase the breadth of exciting, purpose-driven possibilities that are on offer to them within food and drink.

A staggering 72%[2] of young people do not consider it a place where they could discover their purpose and learn essential skills, even though 78% of respondents have a passion that could be met in the food and drinks space.

Sarah Bradbury, CEO, IGD, comments: “The food and drink industry is one of the UK’s most dynamic and largest private-sector employers, offering incredible careers which are professional, varied, high-tech, and well-paid. Through our cross-industry Mmmake Your Mark campaign, we want to bridge this knowledge gap and showcase to parents, career advisors and young people the rewarding careers available in our industry.

“Young people are often unaware of the incredible career paths and sense of purpose they can find in the food and drink industry. By joining the Mmmake Your Mark campaign, businesses can help put these careers front and centre, attracting the next generation of talent.”

Balwinder Dhoot, Director of Growth and Sustainability, The Food and Drink Federation said: “From data and sustainability experts, to product developers and food scientists, food and drink manufacturing provides half a million jobs in every corner of the UK, all contributing to a thriving food system. The next decade will be critical for our sector as we look towards achieving net zero, shaping healthier diets and unlocking a 14bn growth opportunity through AI, digital technology and automation. But this can only be achieved with the right people to drive this growth. That’s why raising awareness of the exciting career opportunities in the UK’s largest manufacturing sector is so important.”

John Yarham, Interim CEO of The Careers & Enterprise Company, said: “The food and drink industry is vital to the UK economy, yet it faces urgent skills and workforce challenges. Mmmake Your Mark is a leading example of how industry and education can come together to showcase the exciting, purposeful careers on offer and inspire the next generation to take their best next step.”

This lack of awareness around inspiring roles within food and drink has national implications. The UK food system employs 4.2m people, making up around 13% of all employment, or more than 1 in 8 jobs[3]; however, IGD foresight predicts that the workforce challenge is set to escalate if proactive action is not taken by the industry.

This is because in the next 10 years, the UK population will grow from 69.9m (2025) to 73.4m (2035)[4], meaning more food and drink will be needed. Some will be sourced from abroad but, realistically, UK food and drink capacity will have to increase to meet demand.

By guiding young talent away from essential industries based on outdated views or lack of awareness, the UK is at risk of exacerbating critical skills gaps and labour shortages in sectors vital to the economy.

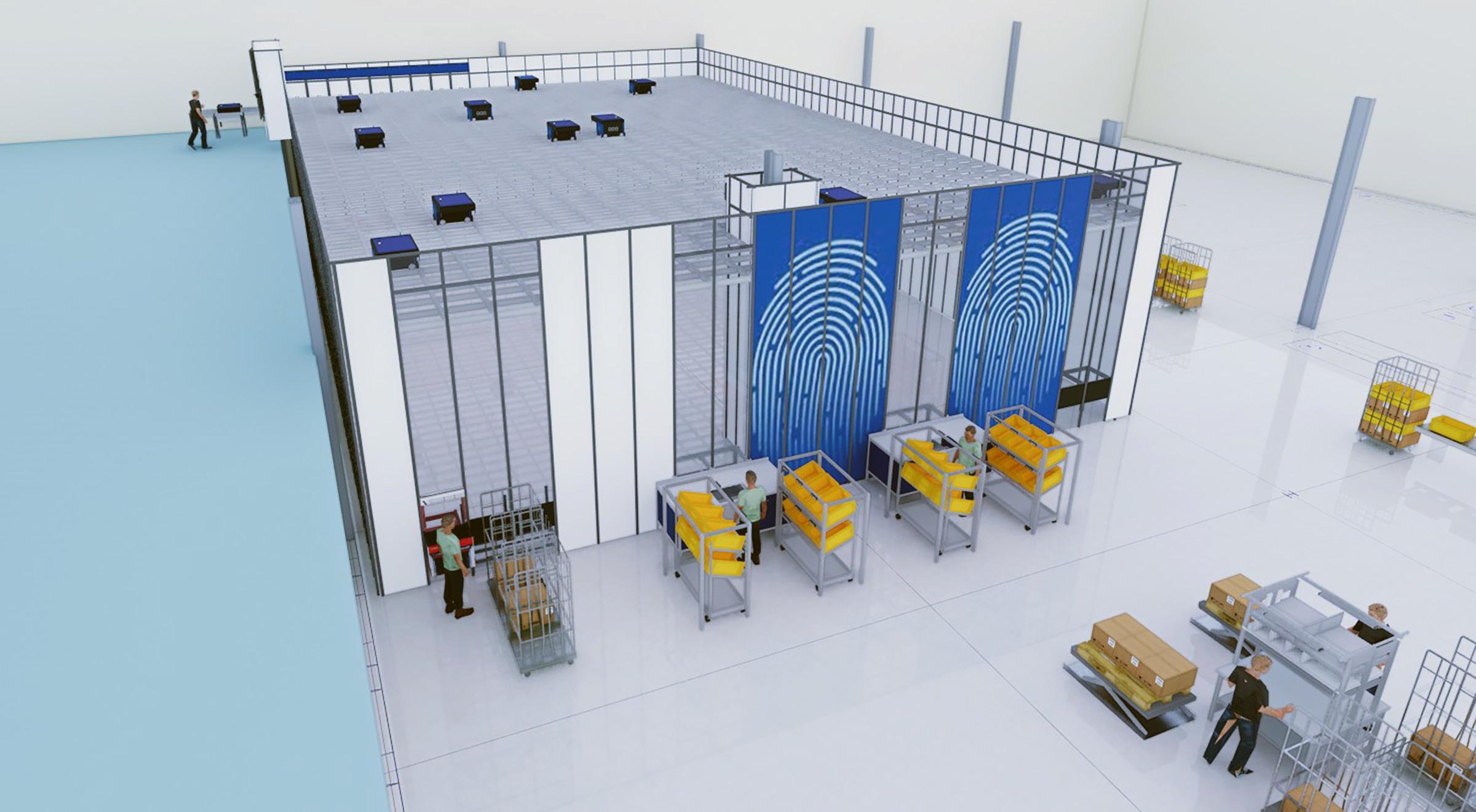

New central logistics centre for Maria Middelares hospital realises several operational efficiencies as well as reduces traffic risks and deliveries

Dematic, a leading global supplier of automated warehouse solutions, has been recently selected by Maria Middelares vzw, a non-profit medical organization, to implement the first AutoStore™ system for the Belgian healthcare industry. The system will supply two hospitals in Ghent and Deinze and two medical centres in Aalter and Gentbrugge. Maria Middelares counts more than 400 physicians and 2,500 employees at its facilities.

“This is an important step in the modernisation of our logistics processes,” notes Isabel Verniers, project manager who reports directly to the coCEO/COO of Maria Middelares. “Our goal is to increase our operational efficiency by roughly 30 percent with the implementation of the AutoStore™ system,” explains Verniers adding, “and the high-

density storage will allow us to store more stock in a smaller area and support our aim of supplying other hospitals in the future.”

The solution provides scalability, a plan to mitigate risk with back-up technology, a low total cost of ownership, and a reliable customer service package. According to Maria Middelares management, these were decisive factors in selecting the solution.

The centralisation of warehouse and pharmacy operations, with the AutoStore™ system integration playing a critical role, is intended to make the institutions run more efficiently by purchasing larger volumes, which reduces the number of deliveries to the hospitals and cuts down on traffic congestion around the hospitals.

The new logistics centre – located at a

brownfield site on the De Prijkels industrial premises in Nazareth, a municipality in East Flanders –combines the storage facilities and pharmacies of hospitals located in the cities of Ghent and Deinze as well as medical centres in Gentbrugge and Aalter.

The AutoStore system consists of a 4.5-meterhigh grid with space for up to six workstations and a capacity of more than 12,000 storage bins. Initially, 6,000 bins are planned for installment with three workstations and eleven robots. By adding storage bins and robots, the storage and order picking capacity can be scaled up quickly and easily in the future.

Because Dematic offers multiple solutions for automatic storage and order picking, it was able to design a solution that matches the requirements of the hospitals. “After we analysed the specific product attributes and order pattern, we knew that the AutoStore™ solution would be the best fit,” says Stijn Wouters, a senior sales manager at Dematic.

“The system’s decisive factors were its compact size and its exceptional fit within the existing building’s dimensions. It was clear there was no better solution in terms of cost efficiency and reliability as well as AutoStore’s track record in leading to energy reduction savings,” says Wouters.

“NEARLY

The selection of Dematic was made following a thorough European tendering process, which saw

several AutoStore™ partners participating. Bids were evaluated based on predefined selection criteria.

“Dematic achieved a near-perfect score both in terms of its technical solution as well as total cost of ownership, project approach, and service and aftercare,” says Verniers.

Verniers also notes that reliability and continuity are particularly critical for the two Maria Middelares sites in Ghent and Deinze. With Dematic providing a local team of service technicians, it can easily meet the strict requirements for response times. Offers Verniers, “As a hospital, it is important that any sudden interruptions are quickly resolved since the products picked in the AutoStore™ can be vital to our patients. We cannot afford to deliver them a day later.”

Notes Farly Orie, managing director of the BeNeLux market for Dematic, “The project is more than just technological advancement; it is a fundamental step towards more efficient and reliable healthcare logistics, which directly contributes to the health and well-being of our society. It demonstrates that we can elevate healthcare to a higher level in our market through smart automation where our logistics innovation ultimately benefits both patients and healthcare professionals.”

For more information about Dematic, visit dematic.com or follow us on LinkedIn, Facebook, and Instagram.

Flawless packaging is a crucial component throughout the entire production and storage chain. It is essential for the safety and shelf life of food products. Until now, undetected microcracks, faulty seal seams, or inconsistent test results have put quality at risk, led to unwanted complaints, and, in the worst case, resulted in costly product recalls. Brugger Feinmechanik, based in Munich, Germany, offers a specialized range of heat-sealing machines and related equipment designed to address these challenges. These systems allow reliable seals to be created, documented, and subsequently evaluated under precisely controlled conditions. Additionally, permeation testers measure the barrier properties of films, ensuring that packaging continues to provide its protective function. Users – particularly in the food industry, as well as in laboratories and research institutions – benefit from solutions that enhance safety and document quality. Brugger’s equipment has also proven effective in many other industries over the decades. With Brugger’s testing and sealing systems, manufacturers can reliably meet stringent product and production requirements, verify packaging integrity,

and safeguard their processes for the long term.

“Even the smallest leaks in seal seams can significantly compromise shelf life and product safety. Without precise testing and measurement technology, such risks often go undetected,” says Maurice Dinkelbach, Managing Director and Owner of Brugger Feinmechanik GmbH in Munich.

Precise packaging tests ensure quality, shelf life, and product safety

Packaging is exposed to a wide range of stresses in everyday production. Throughout its entire life cycle – from transport and storage to presentation at the point of sale – it must maintain its sealing integrity to meet the quality standards required by manufacturers, retailers, and consumers. Even the smallest microcracks in films or poorly sealed seams can quickly lead to problems. Gases may escape or enter, the protective atmosphere can be compromised, and moisture can penetrate, significantly shortening the shelf life of food products or causing spoilage. For manufacturers, this can lead to increased complaints, reputational damage, and considerable financial losses due to poor packaging seals. Another issue is the lack of comparability of test results along the supply chain. Different testing methods

and equipment often produce inconsistent results among manufacturers, bottlers, and laboratories, complicating coordination and increasing uncertainty.

Brugger Feinmechanik addresses these challenges with a systematically organized range of compatible specialized devices that are widely used across the industry. This ensures transparency in testing, better comparability of results, and greater reliability. Users can trust the results, regardless of where in the production workflow they are obtained. In particular, the HSG-CC (heat sealing machine) and GTT (gas transmission tester) are central components for packaging sealing and quality assurance. They are robust, durable, and designed for practical use –often developed in close collaboration with customers or research institutions.

“We at Trüb Emulsions Chemie AG in Ramsen, Switzerland, have been operating in the chemical industry since 1978. Since 1988, Brugger’s heatsealing tester has delivered precise and reliable results, performing flawlessly to this day. At the time, we were testing new types of plastics for their weldability,” Mr. Nicolas Pfetsch, Head of R&D, explains. “Based on these experiences, we decided to acquire an additional unit. The decisive factors included long service life, ease of operation, measurement reliability, and Brugger’s excellent service. Based on our experience, we can fully recommend purchasing a Brugger device.” The Munich-based company deliberately focuses on a small number of highly specialized devices, which are continuously developed. Producing reliably sealed packaging that preserves protective atmospheres such as nitrogen or carbon dioxide (CO₂), meets sterilization requirements, and ensures shelf life is essential – particularly in the food and pharmaceutical industries.

Comprehensive food packaging sealing tests from a single source – ensuring maximum quality and product safety

Brugger’s testing and measurement systems follow a systematic process that evaluates packaging under realistic conditions. First, the mechanical durability of the films is simulated, for example using the KFT-C (flex durability tester) according to the Gelbo Flex Method (ASTM F-392), to detect crease resistance and potential micro damage that may occur during filling, transport, or storage. The next step is permeability testing with the GTT, which measures how much oxygen (as well as CO₂ or other gases) passes through a film – particularly when barrier layers may be damaged. This is especially critical for the food industry, as it directly impacts both shelf life and product safety. Following this, optimal sealing parameters are determined using the HSG-CC or the NDS (low-pressure heat sealer), with temperature, pressure, and time precisely tailored to the material combinations. Finally, the VNG-E (universal tensile tester) assesses the strength of the seal seams and provides values for adhesion, coefficients of friction,

and mechanical strength. Brugger thus provides a comprehensive system, covering everything from mechanical simulation to final seal seam testing. This ensures manufacturers receive clear, comparable results and allows for targeted optimization of their packaging operations.

From gas permeability to seal integrity –reliable seams ensure product integrity and shelf stability

Brugger Feinmechanik offers a broad product range, specifically developed to meet diverse requirements. In the field of leak testing, the GTT is a proven example. It operates according to the differential pressure method in compliance with ISO 15105-1 and measures the gas permeability of films in the range of 0.05 to 10⁶ cm³/(m²dbar) with a resolution of 0.01 cm³/(m²dbar). The sample temperature is regulated via Peltier elements from 15 to 45°C with a stability of ±0.2°C. The humidity and temperature of the test gas are continuously monitored, with optional humidification if needed. This 22-kilogram device only requires a simple rotary vane or diaphragm pump and is operated via a 10inch touch panel or PC software. The actual sealing process takes place before the seal test.

The second product line focuses on the secure bonding of materials. The HSG-CC enables optimal sealing processes while precisely adhering to the specified parameters. Sealing times from 0.1 to 300 seconds can be set with 0.1-second accuracy. The sealing temperature can be regulated up to 300°C separately for the upper and lower sealing jaws. Sealing force ranges from 40 to 1000 Newton. The devices are available as a benchtop version (24 kg) or as a floor-standing model with its own compressed air supply (76 kg). An optional hot tack testing device is available, along with corresponding documentation software or test equipment monitoring. Both product lines reflect Brugger’s high technical standards. The GTT captures material tightness with extremely fine resolution, while the HSG-CC simulates real production conditions and ensures the quality of the seams. Together, they enable manufacturers to accurately determine material properties and ensure long-term process reliability in packaging production.

“Our development is an ongoing process. We are currently working on an enhanced hot tack test, which in addition to the distance measurement method will soon also offer a force-measuring variant. This will allow us to make an even more accurate analysis of the quality of heat-sealed packaging,” says Maurice Dinkelbach. “In the future, this will provide further quality assurance, especially for products that are mechanically stressed immediately after the sealing process. Further steps in digitalization are already underway. Automated documentation and interfaces for databases will open up new avenues for quality assurance.”

Working on behalf of Holcim UK, the team from Careys has successfully completed works on a new cement manufacturing and distribution facility at the Port of Tilbury. A key part of the project saw over 3,500 concrete piles of various dimension used. Playing its part were PC400 and MultiBar Large hydraulic pile croppers supplied and supported by National Pile Croppers.

Holcim UK recently announced that it has reached a pivotal milestone in the construction of the company’s flagship Tilbury cement terminal with the successful completion of all civil engineering works. This marks a key point in the multi-million-pound project, as structural and mechanical installation begins on one of the most advanced facilities of its kind in the UK. Located at the Port of Tilbury on the river Thames, the state of the art terminal is central to Holcim UK’s long term strategy to redefine sustainable construction through innovation, circularity, and decarbonization.

The three year construction project has seen the successful completion of all excavation, foundations, buried utilities, and site roads. Every element of the build to date reflects Holcim UK’s and its contractors commitment to sustainability. Materials excavated from the site have been reused either in the construction process itself, or in Holcim manufacturing plants. Meanwhile, the civil works have used the firm’s own portfolio of lower carbon products, including ECOPact ready-mixed concrete, recycled aggregates, concrete paving, and reclaimed asphalt. In total, more than 25,000m3 of concrete from the original site have been reused, alongside 10,000t of recycled asphalt planings. In addition, nearly 20,000t of excavated material has been processed through Holcim’s waste management business.

Specialist in groundworks

Working on behalf of Holcim UK, Careys began groundworks in early February 2024 before moving onto

the main civils package. This included concrete works for the storage hall, VRM, silo array, conveyor systems and other structural foundations, installation of surface water and foul water drainage, utilities, fire main, and water and gas services and asphalt site roads. Before all of this work could be undertaken there was the small matter of installing over 3,500 concrete piles, and their subsequent cropping to size. The concrete piles were of various dimensions - 250mm,

300mm, 350mm – and were driven by Aarsleff. In addition, 400mm precast piles were manufactured by Aarsleff. The latter is highly unusual in the UK, although favoured in the US.

Rising to the challenge

As Careys’ pile cropper partner of choice, National Pile Croppers supplied the hydraulic pile croppers and support for the project over a number of months. Given the importance of the facility to Holcim UK, both Careys and National Pile Croppers were fully on-board when it came to being environmentally focused, with the concrete and rebar from the piles being re-used and recycled. As well as this, the time frames around the project were demanding, with little room for unscheduled down time. Safety, efficiency and productivity had to go hand in hand to ensure that Careys’ part was completed to time, to the exacting standards specified.

National Pile Croppers’ MultiBar Large is designed to aid in such projects as these, proving to be the workhorse of the cropping onsite. It is simply lowered over the concrete pile which is then reduced at 250mm intervals enabling broken pile sections to be removed. The key to productive and efficient use is to ensure that the last bite at the finish level is of at least 250mm to ensure a good cut is obtained. “The cropper is best used by an excavator of at least 6t, and depending on the variant chosen, weighs either 450kg , 550kg or 600kg. This all means that it’s small enough to be highly manoeuvrable but has the substance to deal with the toughest of precast piles with four or more reinforcement bars (rebar),” explains National Pile Croppers Roy Taylor.

four or more reinforcement bars. The new cropper is designed for flexible and efficient use, and weighing in at only 550kg, the cropper can be mounted on a 6t excavator. The cropper is designed to remove sections of concrete at approximately 250mm per crop, with the four powerful rams and blades penetrating past the rebar and into the centre of the pile to leave a minimum of trimming.

“The PC400 proved itself on this project. Careys reported high levels of productivity, and ease of use,” added Roy who concludes. “Being able to be used by a 6t excavator meant that cropping could be undertaken with existing equipment onsite. The cropping was undertaken in a timely and efficient manner, with the concrete and rebar being able to be recycled and reused in line with Holcim UK’s inspiring environmental goals.”

The Bella dryer/cooler offers thermal efficiencies to 80 percent or better because air flows around material while it is suspended in the weightless zone. The result is a more consistent material.

Further aiding efficiency and cropping refinement, the MultiBar Large further benefits from a new range of specifically in house manufactured chisels, designed with the purpose to not only penetrate the pile, but to leave a perfect finish with little or no tidying up. The new chisels effectively break up the concrete into pieces, and furthermore, the cropped unit can then easily be lifted off the pile enabling the removal and recycling of the cut away concrete in a safe manner.

New Pre-cast 400 Cropper

One highlight on the project was the use of National Pile Croppers’ newly designed cropper for piles from 300-400mm. As its name suggests, the PC400 is used for precast piles (PCC ) with

Warehouses, transport hubs and fulfilment centres will be under immense pressure to perform in 2026. But what are the key trends and influences driving change? Craig Davenport, Sales Director at Rushlift sets the scene.

Safety will remain the top priority for businesses operating material handling equipment in 2026. According to the British Safety Council around 1,300 people a year are involved in forklift related accidents. Several are fatal. Failure to maintain a safe working environment can have dire legal consequences for a business and its directors, so getting the best value from a truck in terms of safety is now widely seen as absolutely essential.

Ensuring that trucks are correctly specified for the task and equipped with critical safety equipment will be of primary concern. Sealed disc brakes, automatic parking brakes, speed limiters, anti-collision devices, flashing beacons, reversing alarms and ‘pedestrian awareness’ projected blue light systems are all now commonly fitted to vehicles as a matter of course. This trend is set to develop further in 2026 with the introduction of further advanced safety features from a number of OEMs.

Vehicle design and safety features go hand-inhand, but options vary significantly across makes. So, selecting well-engineered, intrinsically safe

warehouse and counterbalance trucks suited to each individual task is becoming more complex and increasingly important – making mixed fleets and access to multiple-brands a growing trend.

Comprehensive operator training programmes and thorough vehicle maintenance regimes will also play a significant role in reducing risk to people, goods and equipment in 2026. Many organisations will be seeking to go beyond mere legal compliance in order to build a strong culture of safety in the workplace.

Sustainability is now a major agent of change in the warehouse, and 2026 will see significant investments into rooftop solar initiatives for on-site power generation, smart HVAC heating and cooling systems, and critically, a continuation of a major shift to electric forklift trucks. Demand from consumers and regulators for greener business practices, along with increasing supply chain compliance measures to reduce carbon-emissions, have created a sea-change in the way energy and resources are used within the warehouse. As many organisations have realised, the adoption of green power has the potential to create a competitive edge for winning new business.

The long established 60-40 market split between IC and Electric counterbalance forklift trucks, once in

favour of diesel, is now seeing a dramatic shift – and it’s set to continue apace in 2026. Electric models are fast becoming the preferred choice as purchasers seek to improve their environmental performance in the wake of societal demands for sustainability and tightening EU regulations on carbon, nitrogen oxide and particle emissions.

Importantly, established and fast-developing battery technology supports the move. Electric counterbalance trucks are now fully capable of working outside, eight hours a day, in dirty and dusty environments such as builder’s yards and industrial sites. And heavy lifting is no longer the sole domain of IC engine vehicles, as electric models with capacities up to 8,000kg and above are now in wide use.

Electric trucks are cleaner, quieter and cheaper to maintain, however, there are choices to be made over battery type and charging options. Lithium-ion batteries are increasingly seen in fast-moving, multishift operations but it’s essential to have adequate time set aside for top-up charging throughout a shift. In many instances lead-acid remains the best option. Although IC engine forklifts may still be preferred for particular applications, hydrogen fuel options may soon be seen more widely in use, as buyers move away from carbon-based fuels such as diesel and LPG. A trend that may well gather pace in 2026.

Increasingly, organisations are uncertain about the future demands on the business and what changes may be required within the fulfilment operation. Will there be more promotional activity, resulting in sharper peaks? Or could there be longer, extended peak periods, with a greater number of returns? Could product profiles shift, SKUs radically expand, and how might new, spontaneous marketing initiatives impact operational processes?

There are many unknowns ahead for businesses in 2026. So, if companies are to minimise risk and respond quickly to change, greater operational agility will be required to provide the responsiveness that customers expect – and the resilience logistics practitioners are looking for.

Reliability, flexibility and performance will be core attributes required of the materials handling fleet in 2026. Rigid fleet ownership models will become less attractive, as businesses turn to flexible hire and leasing options – enabling them to scale up or down quickly without locking up capital. Suppliers of materials handling equipment capable of supporting responsiveness and agility through blending a ‘best for purpose’ mixed fleet, will play an important role for businesses in 2026.

People are at the heart of every successful business and this is particularly true in the warehousing and logistics sector. Motivated, well-trained and skilled individuals are more likely to be more productive and engaged, resulting in higher performance, safer

working conditions and higher levels of staff retention. It’s highly likely then that 2026 will see increased investment in operator training programmes that promote safety, staff well-being and continuous improvement. In particular, forklift truck training will take a high profile, as businesses seek to pursue higher levels of on-site safety.

‘THE CONNECTED FLEET’ FIT FOR A DIGITAL AGE

Warehouses and fulfilment centres will become more integrated, more intelligent and more connected. Digital transformation of the warehouse will continue apace in 2026, with increasing levels of automation, principally in the form of AMRs, AGVs, shuttles and sophisticated conveyor systems. However, businesses will need to ensure they have the expertise within the business to deliver a viable solution with a reasonable ROI.

As part of this mix, forklift fleets will become more integrated within the warehouse too. ‘The connected fleet’ is now a reality for a growing number of businesses, not just large fleet owners. Insights gained from analysing vehicle usage data will help drive overall performance and provide valuable guidance on optimising the size and shape of the fleet.

Telematics and intelligent fleet software, such as Rushlift’s on-line proprietary Fleet Management System, can gather data on vehicle usage and overall performance of the fleet, enabling management to make data-driven decisions in real-time, such as reallocating resources to where they’re needed quickly. In addition, remote access by off-site service engineers will increasingly help extend vehicle uptime – facilitating preventative maintenance, fast diagnostics and enhanced operational resilience.

With cost pressures rising for businesses going into 2026, there will be even louder calls for higher levels of performance and operational resilience within the warehouse. This will require coordinated action, and quite likely, expert help.

Specialist material handling service and support businesses, such as Rushlift, work closely with fleet owners over the entire length of the contract to maximise the overall performance of the fleet: from specifying and recommending the most appropriate trucks for the duties to be performed – and that means providing the best truck for the job, whatever the make – to providing full, regular servicing, fast breakdown call-out, and on-site meetings to review fleet performance. From analysing the usage of individual trucks Rushlift experts can make recommendations that may save significant costs, whilst improving operational performance and reliability – maximising asset value across the lifetime of the fleet.

For further information on improving warehouse performance, go to https://www.rushlift.co.uk

Danfoss Power Solutions today announced the launch of Hybrid Load Control, a displacement control designed for the company’s H1P and MP1P hydraulic pumps. Intended for dual-mode hydrostatic propel applications in mobile machinery, Hybrid Load Control combines the behaviors of two control types into one unit: load-independent behavior (also known as electric displacement control or EDC) and load-dependent behavior (also known as non-feedback proportional electric control or NFPE). The patented control eliminates performance compromises, increasing operator comfort and productivity.

Many hydrostatically propelled machines — telehandlers, wheel loaders, street sweepers, and forestry equipment, for example — perform multiple tasks or have different operational modes. These machines benefit from both load-independent and load-dependent pump controls. Load-independent control delivers consistent speed and responsiveness regardless of the load or the terrain. Load-dependent control adapts to actual load conditions to deliver smooth hydrostatic braking and optimize power delivery. Until now, machine designers had to select only one control type for the machine’s hydrostatic pump. Danfoss’ Hybrid Load Control eliminates that compromise, delivering the best driving behavior regardless of the task. It improves hydrostatic braking smoothness in load-dependent mode, and it provides precise speed and instant response in load-independent mode. This superior driving performance increases operator comfort and productivity.

Hybrid Load Control is an integrated hardware/ software solution offering machine designers the flexibility

to define and optimize the vehicle’s driving behavior. The control works with the Danfoss PC036 microcontroller as part of the PC-PRO software package. The PLUS+1® compliant package enables the designer to set key parameters that determine the behavior, resulting in simple configuration.

Compared to conventional methods of achieving this dual behavior, Danfoss’ Hybrid Load Control improves system robustness, simplifies machine architecture, and minimizes costs. The solution does not require additional sensors, thereby eliminating potential points of failure and additional costs. Reducing the number of components simplifies system design. In particular, the omission of sensors for complicated control strategies, such as swashplate angle or pressure sensors, eliminates the wire harness and calibration, thereby reducing startup time and service efforts.

Additionally, by optimizing hydrostatic braking, the system minimizes reliance on mechanical brakes. This reduction in mechanical brake usage decreases wear and further reduces total costs.

“Hybrid Load Control is a groundbreaking addition to our H1P and MP1P family of controls, combining the best of EDC and NFPE. You no longer have to choose between the two — it’s truly a ‘no compromises’ solution,” said Abhijit Patwa, Director, Medium Power Portfolio Management, Hydrostatics, Danfoss Power Solutions. “Hybrid Load Control offers unparalleled flexibility and performance that no other control or system on the market can match. We invite OEMs and distributors to learn more by visiting us at Agritechnica.”

MyToyota is purpose-built to transform how businesses manage their forklift fleets, serving as a versatile multiservice platform that adapts to evolving customer needs. The portal offers a comprehensive view of material handling fleets, delivering reliable insights into cost management, contracts, services, energy consumption, and safety protocols. This all-in-one tool empowersmanagers to make informed decisions and boost operational efficiency across their entire fleet.

“We recognise that the expectations for fleet management have evolved significantly,” says Cecilia Nilsson, Head of Digital

Business at Toyota Material Handling Europe, “My Toyota is our response to these changing demands. It’s more than a portal; it’s a strategic partner that empowers businesses to navigate the complexities of modern fleet management.”

One of MyToyota’s distinguishing features is its seamless integration with I_Site from Toyota Material Handling, Toyota’s proven fleet management tool, of which a next generation has been unveiled. This integration enables users to effortlessly transition between strategic insights and operational essentials. Whether in meetings or day-to-day operations, MyToyota ensures that fleet managers have the

actionable insight they need to make fact-based operational business decisions and make sense of their data through a deep-dive analysis.

As businesses continue to seek transparency, efficiency, and datadriven insights, MyToyota emerges as a beacon of innovation in the fleet management arena. The portal’s launch marks a significant step forward in Toyota Material Handling’s commitment to deliver solutions that meet the evolving needs of businesses across the UK.

For more information on MyToyota visit: Toyota I Site Fleet Management | Toyota Material Handling UK

With a range of more than 120 original attachments, the Bobcat brand can increase the productivity of its compact equipment with versatile, intuitive and highly specialized solutions. Going well beyond buckets, the new generation of Bobcat attachments redefines the use of compact equipment.

In the world of compact machinery, versatility is synonymous with profitability. Bobcat, recognized worldwide for the versatility of its compact loaders, has made its line of attachments a key pillar for multiplying the applications of its compact equipment, turning them into true ‘tool carriers’, whether in construction, landscaping, agriculture, demolition, or rental, along with many other applications.

With the widest range of original attachments on the market, the company not only guarantees an effective response for almost any application, but also boosts machinery sales thanks to their adaptability. The design department works closely with customers, developing and producing tools to meet the main demands shared by thousands of users.

Bobcat has achieved what many manufacturers strive for: turning a single machine into a multifunctional tool. From buckets and forks to advanced equipment such as forestry cutters, trenchers and laser graders, Bobcat attachments stand out for their ease of use, robustness, and performance. Added to this is a constant focus on quality, safety, hydraulic compatibility and automation.

One of the key developments has been the Attachment Control Device (ACD) system. This innovation turns each attachment into a plug-and-play device. When connected, the machine automatically recognizes the attachment and adjusts the controls and flow rates to

maximize performance. This system not only reduces human error and setup times, but also extends the life of the equipment.

Another industry-leading standard is the wellknown Bob-Tach quick-attach system, developed in the 1970s. Its simplicity and reliability have even led other brands to adopt it. Many customers emphasize that it is very intuitive, convenient, easy to use and foolproof for exchanging attachments without wasting time or effort on the part of the operator.

Katinka Kincses, Bobcat Product Manager for Attachments in the Europe, Middle East and Africa region, says: “At Bobcat, we constantly invest in the development of new attachments to ensure we meet the needs of all major and even specialized applications. Our commitment to innovation continues with the upcoming reintroduction of our line of post-hole diggers and trenchers. These next-generation models are designed to deliver increased performance, reducing effort in demanding tasks. Additionally, an optional LED guide improves accuracy by helping operators easily position the attachment at the desired angle.”

Rental companies are one of Bobcat’s main customers. For them, the ease of attaching and operating attachments without an operator is essential. Bobcat has responded to this demand with systems such as ACD and new features that improve the operator experience: engine-independent speed management, drift compensation and full control from a single joystick.

In addition, Bobcat has developed training tools and remote support, including QR codes on attachments, so users can easily access quick guides or tutorials without the need for direct technical assistance.

Although construction remains a key market for Bobcat, sectors such as landscaping, demolition and agriculture also demand an increasingly specialized range of attachments. Structured by both machine type and application, this allows Bobcat to effectively meet the needs of a wide variety of customers.

The Attachments division represents a key element in Bobcat’s expansion, fundamental for expanding applications across a wide variety of sectors and machines. Telehandlers are no longer limited to lifting and material handling, while excavators now perform much more than trenching, thanks to the wide range of possibilities offered by Bobcat attachments.

The wide range of attachments has become Bobcat’s differentiating factor compared to competing brands, allowing dealers to offer the right tool to fit customer needs to carry out any task that may arise, in all sectors: including construction, demolition, road maintenance, agriculture, forestry, precision grading, beach cleaning, landscaping and many others.

For more information about Bobcat products, attachments and services, visit www.bobcat.com