Why Gambling on the Weather is the Riskiest Bet of All for Outdoor FMs

Why Gambling on the Weather is the Riskiest Bet of All for Outdoor FMs

Optimise energy use and create adaptable spaces with intelligent lighting controls

Cut costs not performance

Eliminate unnecessary energy waste, helping budgets go further without compromising lighting quality

made simple

Optimise energy use in real-time, helping you meet carbon reduction targets and regulatory requirements

Scalable systems integrate with existing infrastructure, ensuring compliance and longterm savings with minimal disruption

Synapsys Lighting Control Systems help buildings to unlock smarter, more efficient lighting solutions - reducing waste, cutting costs, and enhancing comfort.

Email | enquiries@synapsys-solutions.com

Web | synapsys-solutions.com

Business Development Director James Scrivens james@abbeypublishing.co.uk

Production Sarah Daviner sarah@abbeypublishing.co.uk

Accounts Manager Katie Brehm accounts@abbeypublishing.co.uk

BFM is published digitally 10 times a year by Abbey Publishing Ltd. To receive a copy free of charge, contact our offices.

Tel: 01933 316931

Email: bfm@abbeypublishing.co.uk www.bfmmagazine.co.uk www.abbeypublishing.co.uk

www.twitter.com/ BFM_Magazine

Subscriptions are available via www.bfmmagazine.co.uk/subscribe

Evoca Group has introduced a new product class - Gaggia G-Line - which brings together all the company’s bean-to-cup, table top and superautomatic coffee machines under a single brand.

Gaggia is a brand name like no other. Not only does it inspire confidence amongst seasoned coffee operators, but also it has a certain cachet with the general public. Who wouldn’t relish the prospect of enjoying a delicious drink from a machine brand that has become synonyous with Italian coffee?

All Evoca coffee machines that incorporate the latest bean to cup technology are now members of the Gaggia family. Gaggia G-Line machines will stand out from the competition thanks to their elevated performance, which is exemplified by the superior extraction process that’s made possible by the use of patented brewing technology, guaranteeing peerless in-cup quality.

The Gaggia G-Line range includes both fresh and powdered milk machines.

is up to 100 cups.

Compact? The G100 is just 31 cm wide and yet it comes equipped with a 7-inch touchscreen that has an intuitive display, which guides users through the drink selection process so they can select their favourite beverage with speed and clarity. This means you can choose to locate the machine ‘front of house’, allowing customers to serve themselves; giving you greater flexibility when it comes to staffing decisions.

Introducing the new Gaggia G100. There are 2 versions to choose from, depending on your particular requirements. The G100 Powdered Milk model - which was formerly known as Kometa, and the G100

Fresh Milk, which replaces La Brillante. Both are equipped with precision grinders, with a self-adjusting system that ensures consistent quality across the comprehensive menu of beverages on offer. Both versions deliver the outstanding in-cup quality that’s synonymous with the Gaggia Milano range, in a compact and versatile format, making it ideal for hotels, restaurants and offices – in fact all locations where the daily output of coffee

Maintaining the G100 is best described as ‘effortless’. It has an automatic milk cleaning system and the removal of the coffee waste bucket is simple, because you don’t have to take out the drip tray to get to it. What’s more, its brewing group is also simple to remove. As you’d expect from a state-of-the-art machine, the G100 is compatible with Evoca Digital Services and it supports telemetry and remote reboot capabilities, for seamless monitoring and updates.

Finally, in an era defined by rising energy costs, the G100 boasts an A-Class rating.

To find out more about the G100 and the entire Gaggia G-Line range, contact your Evoca UK Account Manager or e-mail rebecca.bailey@ evocagroup.com. Whilst they say, ‘seeing is believing’, wait until you taste what this great new machine can do...

With over 20 years’ experience, OUTCO keeps your sites safe, compliant and accessible through fully managed winter services including gritting, snow clearance and salt supply.

Our award-winning technology activates visits using sitespecific forecasts, with every job evidenced through GPStracked reports for complete transparency.

Trusted nationwide with a 99.8% service success rate, OUTCO helps your operations keep moving whatever the weather.

0800 0432 911 enquiries@outco.co.uk

London-based consultancy aims to end spreadsheet-based lease tracking with introduction of customisable solution for multi-branch organisations looking to take control of their property portfolios.

SHB Real Estate has unveiled TERA, a new lease management platform designed to help organisations manage complex property portfolios with a simplified approach. The platform is aimed at multi-branch companies and charities that often struggle with the limitations of traditional spreadsheetbased lease tracking but do not want the complexity of other available solutions.

TERA is the fifth technology product built by SHB since 2018 and builds on the company’s track record of developing tools that solve real-world challenges for its 900-plus clients, which include multinational brands, start-ups, charities and corporates. The

firm has been named finalists in several awards this year for, including PropertyWeek’s 2025 Tech and Innovation Awards.

The system replaces reactive, manual lease administration with proactive, strategic portfolio-level lease management. By providing real-time insights, automated alerts and comprehensive reporting, TERA helps clients avoid missed deadlines, consolidate underperforming space, cut unnecessary costs and make better-informed decisions about their properties.

Josh Pattison, Director of Technology at SHB Real Estate, said: “Many existing lease management systems complicate the process for property teams. TERA is designed for organisations that have outgrown basic tracking methods but do not have the resources to build and maintain their own internal systems. The cloud-based platform allows secure, consistent access for

teams in multiple locations and is fully compliant with data protection standards.”

Key features include:

Real-time dashboard with complete portfolio visibility

Automated alerts for key dates and deadlines with strategic reporting of options

Scalable design for portfolios from 10 to 500 properties or more API integration to connect with existing systems

Comprehensive audit trails and customised permissions

Collaborative reporting across multiple sites and territories

The launch comes as rising property costs and increasingly complex regulations make professional-grade lease management more important than ever for operational and financial success.

For further information please visit https://shbre. co.uk/our-technology/teralease-management

Like most businesses, you want yours to be the best it can be. Whether this is the through the products and services you provide, the prices you offer or the locations in which you are based.

So, why not provide the best experience? You could:

01 02 03

Enhance the environment, set the tone, boost the mood and create a more upbeat atmosphere

Boost customer engagement by using music to create an entertaining environment

Stand out from your competitors

Boost employee engagement, collaboration and motivation

Foster customer loyalty and retention through improving their shopping experience

Attract new customers

Set the spending mood by creating an upbeat and positive atmosphere

Create a feel-good factor through the use of music

Support the future of music

Define and reinforce your brand

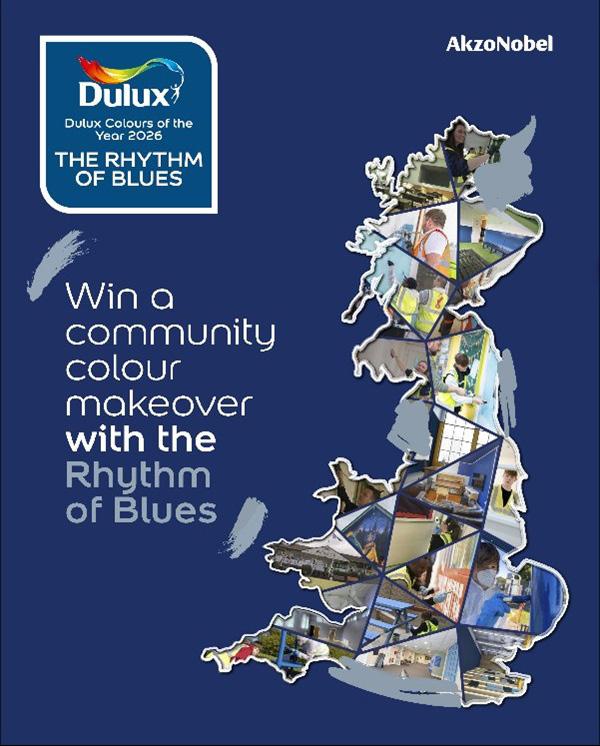

Dulux, the UK’s leading paint brand, has unveiled its Let’s Colour – Colour of the Year Community Initiative, a nationwide campaign inviting the public to nominate local community spaces to win a transformation like no other. As part of the prize, selected spaces will receive a Colour of the Year consultation with Marianne Shillingford, Creative Director at Dulux UK&I, along with the paint needed for your project. To top it off, the community space will be transformed by social enterprise Volunteer It Yourself (‘VIY’), in partnership with Dulux.

Nominators can submit their local community space under one of three categories inspired by this year’s hero palette for Dulux’s Colours of the Year 2026, Rhythm of the Blues – find the right pace for your space:

• Slow Swing Project (spaces to connect, think big and find calm stillness): Healthcare centres, charitable enterprises, or libraries.

• Free Groove Project (spaces to explore, play, and go wild): Sports halls, football clubs, or outdoor areas.

• Mellow Flow Project (spaces to cosy up, connect, and feel welcome): Community centres or multipurpose venues.

The Let’s Colour initiative continues

Dulux’s mission to bring communities together through paint by working closely with partner organisations. VIY has been working with Dulux for over five years and, since July 2020, this partnership has supported communities across the UK, with over 120,000 lives positively impacted through transforming over 200+ community spaces using donated Dulux Trade paint.

These projects have successfully supported and developed over 3,000 young people aged 14-24 through taking part. They have also helped train over 2,360 young people in painting and decorating, including over 2,000 City & Guilds accreditations earned, with over half of these in painting and decorating. The winning community spaces will form three of VIY’s community projects.

Becky Orton, Marketing Manager at Dulux, commented: “Colour has the power to uplift, connect and transform. With Rhythm of Blues, we’re celebrating the different paces of life and giving communities the chance to reflect that in their spaces. This

Let’s Colour initiative is about more than paint – it’s about pride, possibility and creating places that feel truly in tune with the people who use them. Together with partners like VIY, we are working to safeguard the future of our evolving industry to ensure it remains vibrant, skilled, and sustainable by building a resilient, talented workforce.”

Marianne Shillingford, Creative Director at Dulux, commented: “We know how vital community spaces are, but renovations can be costly and time consuming, so we’re excited to be able to step in and help transform a well-loved space in need of new life. Now, we’re calling on the public to help shape the future of their communities – one brushstroke at a time”.

Nominations are now open until Friday 14th November 2025. Submit your local project and tell us why it deserves a Colour of the Year makeover. Winners will receive a full paint transformation using Dulux’s 2026 hero colours and palettes, plus support from the Let’s Colour team, the VIY team and volunteers, and partners.

Nominate your community project today at: www.dulux. co.uk/letscolour2026

Heat pump technology for air renewal represents a significant step forward in improving energy efficiency and indoor comfort. Today, Clivet, integrating full inverter technology and environmentally friendly refrigerant, outlines a new frontier in air renewal in a wide range of applications, from restaurants to offices, from public buildings to large hotels.

Clivet launches the new generation of ZEPHIR4 air renewal and purification units, continuing the innovation introduced with the first model, launched in 2004. The new series, with air flow rates from 2,300 to 19,000 m³/h, integrates full inverter technology and eco-friendly refrigerant R-32 to achieve even higher operating efficiencies throughout the year.

The ZEPHIR4 system recovers energy from the exhaust air and transfers it to the fresh air, amplifying it through the refrigeration circuit. In this way, it is possible not only to completely neutralize the thermal load of the outside air at any time of the year, but also to contribute to satisfying the internal loads of the building. It stands out for its high thermal and mechanical performance, classified as T2/ TB2 according to UNI EN 1886. It guarantees comfortable air intake conditions even with outdoor temperatures as low as -20°C with the standard unit and offers an extended operating range in cooling mode.

“The main benefit of ZEPHIR4 is its versatility: it is the ideal solution for both the renovation of existing buildings and new constructions,” says Damiano Rossi, Product Manager at Clivet.

Thanks to its ‘independence’

from other air conditioning systems, its capacity, and its low consumption, ZEPHIR4 allows significant savings in both first investment and daily management. Its advantages can be enjoyed by all players in the supply chain, from the designer to the investor, from the installer/maintainer to the end user.

The integrated iFD electronic filtration technology and continuous monitoring of indoor air quality allow only the necessary air to be introduced into the environment, with significant energy savings (up to 45%) for ventilation compared to traditional solutions, while ensuring comfort for people.

Its characteristics make it an ideal system for all applications where hygienic air exchange is necessary to ensure air quality for occupants, such as restaurants, offices, public buildings, schools, gyms, and large hotels.

ZEPHIR4 stands out for these advantages:

• full inverter with highefficiency energy recovery and low ventilation absorption

• high-performance mechanical and thermal structure (class T2 /TB2)

• efficient operation down to -20°C in heating mode and with extended envelope in cooling mode

• latest generation iFD electronic filters for maximum efficiency and savings

• precise temperature and humidity control in heating and cooling modes

• free modulating post-heating

• additional capacity to contribute to room conditioning

• complete absence of contamination between exhaust air and intake air

• intelligent management of free cooling and ambient air quality

• easy design with all components mounted on board the machine

• compatibility with VRF centralisers and Clivet supervision

• systems (CLIVET EYE, INTELLIAIR).

ZEPHIR4 Air renewal and purification unit with air flow rates from 2,300 to 19,000 m³/h, for large spaces such as offices, schools, gyms, restaurants, hotels.

Active energy recovery with heat pump technology and R-32 eco- friendly refrigerant. Precise temperature and humidity control all year round and comfortable air intake even at -20 °C outside.

High-efficiency electronic filtration and CO 2 monitoring for excellent air quality. Perfect for both new and existing systems.

Steve Juson, Managing Director,

Cadaema Consulting Services recently project managed the re-imagining and re-opening of the café at Pontefract Castle. This involved a desktop commercial modelling exercise for the Museums team of the Arts, Culture & Leisure directorate at Wakefield Council as well as the operational, hands-on project management ahead of the opening of a new café.

Built in the late 11th Century by Ilbert de Lacy, a friend of William the Conqueror, and known as the Key to the North since the 13th Century, Pontefact Castle has been the centre of some of English history’s most important events and is a popular tourist attraction.

Cadaema’s brief was to achieve three objectives:

• Create a café that enhanced the visitor experience at the Castle and cement its place as a tourist destination

• Provide a boost to the local economy through employment and the use locally sourced products and suppliers

• Deliver a commercial strategy that blended a price point relevant to the local community whilst not providing a drain on the Council’s finances

“It didn’t need to provide huge profits,” says Cadaema director, David Parrett, “but it couldn’t cost the Council too much either. We needed to determine what that would mean for the pricing strategy, the staffing structure and

opening times, and present our findings so the Council team could get approval to commit to the investment needed to re-open the café.”

Cadaema developed a solution specific to the challenges and history of a café at Pontefract Castle. This included a focused menu that allowed the café to open on time and be really clear about what it was trying to achieve and what it would offer the local community, and then to project manage its re-imagining and opening.

“The timeline was tight, with just three and a half weeks to develop and submit the commercial model to hit our proposed opening date of 1st August to take advantage of as much of the lucrative summer holiday market as possible,” Parrett continues. “As well as developing the commercial, menu and staffing structure models, we committed to being on-site before, during and after the opening date to

make sure that everything was ready on time and set up.”

On behalf of the Council, Cadaema established a supply chain of providers showcasing local organisations selecting Recent Beans to supply coffee and Artisan Bakes for cakes and tray-bakes. It registered the cafe with the Council’s licensing department, created a bespoke set of relevant procedures and policies, supported with recruitment of the café team and delivered a full range of training for the new team, including barista training. A stock-take process for the team to manage costs was put in place, along with testing and inspection of the machines that had been left on site to bring them back to operational life. The counter, displays and flow were defined and the till and cash collection system were set up.

“We also wrote a social media campaign, working with the Council’s team, to advertise the re-opening,” Parrett notes.

“We ran a supplier engagement day for Councillors to attend Recent Beans roastery in Wakefield to make their own coffee as part of a PR exercise, and ran a social media-based competition to name the new café – it’s going to be called The Keep and there’s going to be an official opening with Cllr Appleyard in a few weeks’ time.”

The key to all this was, says Parrett, collaboration, collaboration and more collaboration: “Only by being in touch with the Council team twice a week initially, and then being on-site every day for the last week could we stay on top of everything that needed doing…some by us, some by them. d. We worked especially hard with the Council to respond

positively to the feedback on social media, which ultimately created even more interest.”

Cadaema provided structured project management and process so all the prerequisites that were needed were done for other tasks to take place. Through its partner, Cantium Catering Consultancy, Cadaema offered a huge amount of specific guidance around policies, legislation and hands-on set up. The result was that the café opened on time and initial financial feedback is that it is making a small surplus.

Julie Russell, Service Director – Arts, Culture and Leisure at Wakefield Council comments, “What’s impressed us most about Cadaema’s involvement has been their immediate empathy with

our objectives. They’ve understood the importance of the café for the local community, and demonstrated a willingness and ability to drive the implementation of the agreed operating model by being on-site throughout the mobilisation process.”

“We are so grateful for the way that Cadaema owned the project and turned it into reality in such a short space of time,” adds Councillor Hannah Appleyard, Wakefield Council’s Cabinet Member for Arts, Culture and Leisure.

“It was a truly collaborative exercise between us, Cantium and the Council team, and a testament to the hard work that all concerned committed,” concludes Parrett. “We’re delighted that the outcome has been so successful.”

Industry-leading lift company continues to grow future talent with hands-on engineering training and nationwide opportunities.

Stannah, a leading British lift company, has welcomed a new cohort of apprentices into the business, continuing its long-standing commitment to developing skilled talent and supporting the future of the UK lift industry.

Since 2017, Stannah has seen 84 apprenticeships completed across a variety of disciplines. This year, 79 apprentices are currently on programme across the business, with 16 new lift engineer recruits having joined across 11 branches nationwide.

At the heart of this success is Stannah’s renowned Lift Engineering Apprenticeship Programme. As one of the only lift businesses in the UK to offer comprehensive hydraulic lift training, and the only one with a dedicated handson learning training centre for lift engineers, Stannah provides an unrivalled start to a career in lift engineering.

Apprentices benefit from extensive hands-on experience, working alongside expert engineers, many with more than a decade of service. They also have the privilege of training with Will Roberts, Stannah’s longest-serving employee, who this year celebrated 50 years with the business.

Stannah’s lift apprentice programme has achieved an impressive 87% End Point Assessment pass rate, demonstrating the quality of its training and the commitment of its learners. While lift engineering is

at the core of Stannah’s apprenticeship offering, the company also provides opportunities across a range of disciplines, from business administration and IT to marketing and customer service management. Each programme is designed to combine practical experience with professional development, helping apprentices build lasting careers within a family-run business that has been supporting engineering excellence for more than 150 years.

Tim Collins, Training Manager at Stannah, said, “Lift apprenticeships are central to our business and to the future of our industry. Our lift engineering apprentices gain real-world experience as well as technical training in the training centre, giving them a comprehensive start to their career. With access to specialist facilities and mentorship from some of the most experienced engineers

in the country, they’re learning the skills that keep the UK moving safely and efficiently.”

James Buttigieg, Chief People Officer, added, “We’re proud to be one of the few lift companies offering such a comprehensive and supportive apprenticeship route. Everything we do is designed to give our apprentices the strongest possible foundation for their careers whether it is in lift engineering or administration. It’s incredibly rewarding to see them grow in confidence and ability, and to know they’re part of our future.”

Stannah’s approach reflects the founding values first set out by Joseph Stannah over 150 years ago, a belief in craftsmanship, learning and responsibility to the next generation. Those principles remain firmly at the centre of the business today as Stannah continues to nurture future engineers, innovators and leaders.

https://www.stannahlifts.co.uk/

Building & Facilities Management editorial content covers all the major FM areas of interest within the workplace and the built environment.

This includes industry developments, company news, case studies and application stories, product news as well as articles from leading authorities within the marketplace.

To find out more information about BFM Magazine or to subscribe, please visit www.bfmmagazine.co.uk

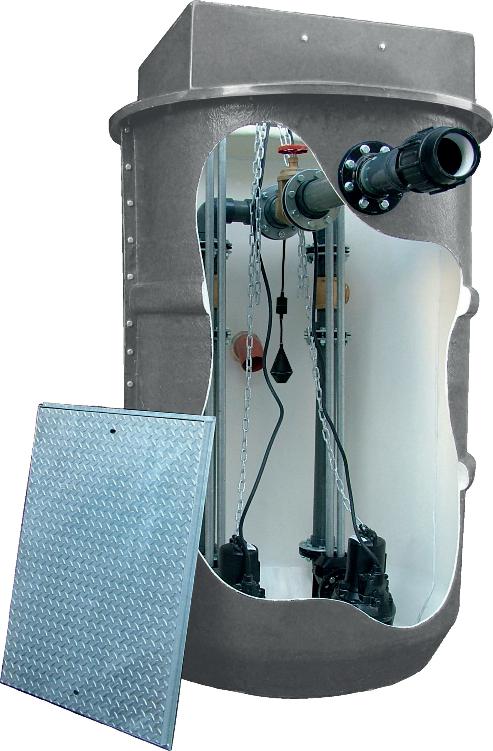

For Facilities Managers working down in a tank or in the depths of a plant room, it can sometimes feel like being stuck in a black hole when faced with a broken waste water or sewage pump with a missing identification plate.

Perhaps the internet can’t help, but luckily, all is not as dark as it might seem. This is where calling on the expertise of a Pump Technology Ltd specialist can probably save the day.

Pump Technology Ltd’s team of engineers have been working with the company for many years so their pool of knowledge is second to none. Because of their extensive expertise that ensures their equipment is sold into the right application providing reliable service and long product life, as well as enhancing the product’s reputation, all the leading pump manufactures have authorised Pump Technology Ltd for the supply of their equipment,

Over the years the company has gained an enviable reputation for helping clients to quickly specify equipment that is “right first time”. Often a simple call will result in a constructive conversation, leaving the caller confident in the solution provided! This is probably why many leading facility management companies

have partnered up with Pump Technology Ltd and now use them as their sole source for everything pumping.

The technical team, lead by Will McPhee Technical Manager, offer exceptional customer service and competitive pricing on goods immediately available from possibly the largest stock of drainage, waste water and sewage pumps in the country.

The team pride themselves in being able to offer “like-forlike” replacement or identify models without markings. Where the broken pump is a superseded model they will specify an equivalent, not only matching its hydraulic performance, but also its fit. They can also help with site upgrades and new installations.

In the course of this activity, the company’s engineers constantly check the internet to ensure that customers always receive the best price.

This specialist, personal skill and service far outshines any web shop, which is why Pump Technology Ltd are finding that so many leading facility management companies are now partnering with them.

To find out more about Pump Technology Ltd facility management partnerships contact:

Andy Spence, Joint Managing Director at Britannia Fire, explains how composite fire extinguishers are changing the face of fire suppression

“Launched 15 years ago, Britannia Fire’s innovative P50 composite fire extinguishers have revolutionised the market. With demand growing, we have ceased our metal fire extinguisher production and re-focussed our entire business on composite models.

Composite fire extinguishers are made from a unique combination of durable plastic and aramid fibres. As a result, they are strong, lightweight and don’t corrode. Crucially, composite models don’t need an annual service, just a simple visual check by a responsible member of staff and a refurbishment after 10 years. Today, we have a raft of customers undergoing their first refurbishments, with sales continuing to outstrip supply.

So why are facilities managers making the switch? They are principally driven by three types of savings: costsavings due to vastly reduced servicing needs and number

of units required; timesavings thanks to simpler checks and maintenance; and finally significant carbon-savings to help meet sustainability targets.

Historically, the fire extinguisher market has been dominated by metal products manufactured cheaply in China. The problem with metal is that the casing can rust and seals can degrade, causing leaks or faults. For safety reasons, annual servicing is recommended, coming at a significant cost and inconvenience to the customer. Composite designs don’t corrode, so have totally changed servicing timescales. P50s just need an annual visual check carried out by a competent member of staff. They have a life-span of 20 years, and only need a full service and refurbishment once

during this time, after 10 years.

Anglian Water has been using P50s for the last decade. Many of its extinguishers are located in isolated plants and hard to reach sites, which made annual servicing difficult before they made the switch, as Michelle Ketley explained at the time:

“It was a logistical nightmare for us to bring them in, get them serviced and then get them back out to remote sites, whilst all the time leaving us vulnerable to fire whilst they were away from site. It has been a massive cost and time saving for Anglian Water.”

As well as saving on servicing costs, P50s have the added benefit that they are multi-purpose. Both the water mist and fluorinefree foam versions are suitable for Class A and electrical fires up to 1000V, with the P50 ECO foam additionally suitable for

Class B and Class F fires. This means that one or the other is suitable in most locations, and that CO2 extinguishers for suppressing electrical or class B fires, are often no longer required. Many of our new customers can reduce the number of extinguishers they need by half, saving costs.

The University of Brighton has a community of 2500 staff and 20,000 students, many of whom live on site, so fire safety is a top priority. Fire Safety Manager, Nick Greenwood, comments:

“The P50 is suitable for a multitude of fires, including electrical fires, meaning we only needed one at every fire point rather than two. The cost savings were huge. We cut the number of fire extinguishers needed by

half and have not had to fork out for expensive third-party servicing over the last 10 years, saving over £200,000.”

London’s Heathrow Airport is another customer that has benefitted from replacing its multiple sets of two extinguishers with single P50 Foam multi-purpose units. This, along with reduced servicing costs, has saved the airport more than £1m.

A sustainable solution

Finally, over and above the cost, time and convenience factors, composite fire extinguishers are also much kinder to the environment. They have a 20 year life-span, are easy to recycle, and require less energy to produce. Our P50 production process emits 22% less carbon than metal

alternatives and is partially powered by solar energy.

Our entire P50 range is also free from harmful PFAS chemicals, which are typically found in traditional foam extinguishers. These ‘forever chemicals’ don’t break down in the environment and can be toxic. Europe has already announced a ban on firefighting foams containing PFAS and the UK is expected to follow suit in the coming months.

We’re proud to have disrupted the market with a product that delivers farreaching benefits. We’ve proved it’s possible to provide affordable, convenient, high-quality fire safety, while minimising impact on the environment.”

www.britannia-fire.co.uk

Industry-leading lift company continues to grow future talent with hands-on engineering training and nationwide opportunities.

Stannah, a leading British lift company, has welcomed a new cohort of apprentices into the business, continuing its long-standing commitment to developing skilled talent and supporting the future of the UK lift industry.

Since 2017, Stannah has seen 84 apprenticeships completed across a variety of disciplines. This year, 79 apprentices are currently on programme across the business, with 16 new lift engineer recruits having joined across 11 branches nationwide.

At the heart of this success is Stannah’s renowned Lift Engineering Apprenticeship Programme. As one of the only lift businesses in the UK to offer comprehensive hydraulic lift training, and the only one with a dedicated handson learning training centre for lift engineers, Stannah provides an unrivalled start to a career in lift engineering.

Apprentices benefit from extensive hands-on experience, working alongside expert engineers, many with more than a decade of service. They also have the privilege of training with Will Roberts, Stannah’s longest-serving employee, who this year celebrated 50 years with the business.

Stannah’s lift apprentice programme has achieved an impressive 87% End Point Assessment pass rate, demonstrating the quality of its training and the commitment of its learners. While lift engineering is

at the core of Stannah’s apprenticeship offering, the company also provides opportunities across a range of disciplines, from business administration and IT to marketing and customer service management. Each programme is designed to combine practical experience with professional development, helping apprentices build lasting careers within a family-run business that has been supporting engineering excellence for more than 150 years.

Tim Collins, Training Manager at Stannah, said, “Lift apprenticeships are central to our business and to the future of our industry. Our lift engineering apprentices gain real-world experience as well as technical training in the training centre, giving them a comprehensive start to their career. With access to specialist facilities and mentorship from some of the most experienced engineers

in the country, they’re learning the skills that keep the UK moving safely and efficiently.”

James Buttigieg, Chief People Officer, added, “We’re proud to be one of the few lift companies offering such a comprehensive and supportive apprenticeship route. Everything we do is designed to give our apprentices the strongest possible foundation for their careers whether it is in lift engineering or administration. It’s incredibly rewarding to see them grow in confidence and ability, and to know they’re part of our future.”

Stannah’s approach reflects the founding values first set out by Joseph Stannah over 150 years ago, a belief in craftsmanship, learning and responsibility to the next generation. Those principles remain firmly at the centre of the business today as Stannah continues to nurture future engineers, innovators and leaders.

https://www.stannahlifts.co.uk/

Analogue telephone lines have copper conductors. These are being updated with fibre connections to provide broadband connections to commercial and domestic users.

BT Openreach has an objective for all buildings to be on fibre connections by the end of 2025 when support of existing analogue lines will be no more!

Many lift alarm systems use analogue telephone lines and need a dial tone and dual-tone multi frequency (DTMF) signalling to work.

Your lift alarm communication systems will need to work over fibre connections. However, fibre cannot carry a voltage and routers so you will also need a backup power supply to maintain the lift alarm in the case of power failure. See BS EN 81-28:2022

Telephone lines are the responsibility of the building owner. Who need to be prepared.

1. Talk to your communication provider to understand the changes to your line and when it will happen.

2. Check with your lift maintenance company for advice on equipment that can be fitted. Check you are complying with BS EN 81-28:2022

1. Test the emergency call system: Check test calls use the same method as the actual lift alarm calls.

2. Battery Back-up: - Make sure both the autodialler and GSM gateway have a monitored backup.

Or you may simply contact our friendly team Who have the correct solution for you. Supplied Installed and Tested.

JLG pioneers world’s first ‘Quick Fold Lift’ for working at height indoors, bringing ground-breaking levels of safety, convenience and performance to soft facilities maintenance.

JLG Industries, Inc., an Oshkosh Corporation company [NYSE:OSK] and a leading global manufacturer of mobile elevating work platforms and telehandlers, is set to transform the world of working at height for generations to come with the global launch today of LiftPod: a first-to-market elevation device that pioneers the Quick Fold Lift – a brand new category within low-level access.

LiftPod is not simply an evolution of the ladder or podium. It’s different to anything that has gone before, offering a safer, smarter, more efficient alternative that is fast and discreet for use in public and indoor spaces.

A new essential for owners and facility managers of hotels, retail areas, offices, hospitals, public buildings and more, LiftPod is the culmination of many years of research by the experts at JLG and the award-winning specialist design consultancy DCA.

JLG developed LiftPod for the modern business environment, as a response to the increased focus on employee health and wellbeing, and a growing awareness of the risks many indoor workers face when operating at height.

The resulting device promises to be transformative, bringing tangible benefits for operators and business

owners in six key ways:

• Safety: first and foremost, a powerful new device designed to help manage and reduce the risk of falls, strains and injury when working at height, and to promote staff wellbeing, via an ingenious ergonomic design backed by science and robust research;

• Performance: uniquely foldable and featuring a patented self-powered lifting mechanism, LiftPod is intuitive to use but powerful and effective for working at height with minimum fuss and disruption. Built on 55 years of trusted expertise and the highest standards of engineering quality from JLG;

• Convenience: designed for comfort and real-world usability, based on listening to and understanding what people need in their day to day roles. Versatile, adjustable, helping all individuals carry out everyday tasks at height with confidence. Designed to be rolled in and out of spaces with minimum effort for ‘first time fixes’;

• Sustainability: patented, durable technology that is sustainable and compliant with the environmental standards and regulations of modern businesses. Accessible 24 hours a day with no charging or power requirements, and designed with no scheduled maintenance, apart from pre-operating checks and other requirements as explained in the operating and safety manual;

• Style: quietly elegant with good design at the core, LiftPod’s aesthetic fits into a wide variety of modern spaces. Sleek, sturdy and compact, easy to store, lightweight and manoeuvrable, it allows users in soft facilities maintenance to operate in busy customerfacing environments with minimal disruption;

• Savings: supporting the bottom line through enhanced performance and productivity, minimal downtime and operational disruption, and the potential to help reduce staff absences.

A revolutionary new design

LiftPod’s design is simple yet revolutionary and draws on JLG’s world-renowned expertise in creating solutions for accessing work at height. It is available in 1.2 and 1.5 versions, with a 1.8 model set to launch in 2026.

• LiftPod 1.2: maximum platform height 1.2m, maximum working height 3.2m, closed height 1.6m (on castors), weight 180kg

• LiftPod 1.5: maximum

platform height 1.5m, maximum working height 3.5m, closed height 1.9m (on castors), weight 205kg

All models feature a patented, self-powered lifting mechanism and fully adjustable platform that carries up to 150kg and is accessible for a wide range of personnel. With a footprint of less than 1m square when in use, LiftPod takes up a minimal amount of space, helping reduce potential trip hazards and allowing for maintenance work to be carried out safely and discretely when public buildings and spaces are in use. An additional tool tray adds to its utility.

Central to LiftPod’s design is its unique folding system and lightweight construction, which allows for quick and easy manoeuvring, from storage to required task location and back again.

Improving health & safety, reducing risk

For the user, LiftPod is designed to help reduce the risk of injury and strain. They engaged expert Dr Frank Emrich, a digital ergonomics and occupational biomechanics specialist, to deploy the very latest assessment methods to quantify the impact of a wide range of factors contributing to spinal stress when performing day to day tasks in the facilities management field. As a result, LiftPod helps to address potential issues during transport, setup and elevated tasks to minimise trunk flexion and disc compression, avoiding manual lifting and awkward postures and helping to reduce repetitive mechanical strain.

LiftPod has been designed and built in the UK by JLG Industries, the world-leading manufacturer of access equipment. Commenting on the launch, Richard Puglia, JLG Sales and Business Development

Director EMEAI said:

‘JLG has broad global experience and expertise in engineering and manufacturing products for working at height. We are also a customerfocused business, listening attentively to understand the challenges faced by the people who use our products, to understand what they need to do their jobs safely, efficiently and with confidence. LiftPod was born from that process.

‘This is a device that is so ground-breaking that it needed its own newly named category – the Quick Fold Lift. It is setting a new standard for commercial application, offering an alternative to traditional aluminium equipment, with a modern, sophisticated solution, helping to address trip and fall hazards, uncomfortable climbs and unsafe processes.

‘After spending decades supporting operators in industrial and outdoor environments to work safely and effectively at height, we are extremely proud to bring a customised product to indoor spaces such as commercial shops, offices, hospitals and hotels where people are a priority. We believe that the positive changes LiftPod will help bring to staff wellbeing, safety and efficiency within these sectors will be transformative for many businesses.’

LiftPod will be unveiled at Preventica Bordeaux (Stand C02), 14th – 16th October, Bordeaux, France, an annual event showcasing the latest innovations in health, safety and quality of life at work.

The launch of LiftPod will also be supported by a Europe-wide marketing campaign, inviting businesses to ‘Re-think UP’, with activity taking place across digital, advertising and PR channels.

https://www.jlg.com/liftpod

LinkedIn: JLG Industries

By Brendan Aherne, Chief Operating Officer, OUTCO

When facilities managers are asked to trim budgets, outdoor winter maintenance can often come under scrutiny. If the previous winter has been mild then it can seem like an easy saving on paper. However, gambling on the weather is a risk that almost always backfires.

The cost of “doing just enough” can be staggering. A slip on ice can go far beyond a single claim and payout. Wider impacts can include lost productivity, reputational damage and higher insurance premiums. Individual FMs can be personally implicated – should investigations by insurers and courts determine reasonable precautions haven’t been taken. Ultimately, betting against the British winter is like rolling the dice at a casino: the house always wins - and facilities managers often have the most to lose.

To see how expensive this gamble can be, let’s provide a practical example. NB - this is fictionalised version based on a several real case studies in the retail sector. Let’s imagine a hypothetical shopping centre in the south of England called “Cold Bay Park” that attracts around 16,000 visitors a day. In 2024 its managing agent was tasked with finding operational savings. Among the services targeted for possible cost savings was the annual winter maintenance contract. Worth around £18,000 a year, it provided

proactive gritting, round-theclock weather monitoring and auditable compliance records. Keen to make the numbers look healthier, management cut the contract and opt for a reactive approach: gritting would only be called in if forecast conditions demanded it. It seems like a sensible punt. But as seasoned gamblers know, luck has a way of running out.

Early in December, a sudden arctic blast shifts the mild, wet weather to bring icy conditions across much of the country. Even so, the weather in the south was forecast to be above freezing, so the team at Cold Bay Park decide that a gritting service wouldn’t be needed. However, the team doesn’t consider road surface temperature forecasts for their area. These indicate that at ground level things might get far colder. As a result, overnight the already wet car parks and

access roads freeze over. Within hours of opening three customers slip badly enough to need hospital treatment. The car park is hurriedly closed. The supermarket at the park sees a 20% drop in footfall as shoppers find safer alternatives. The £18,000 gamble on a mild winter has already been lost.

Scrambling to recover, the FM calls in a contractor to grit the site. With no pre-agreed service level agreement, the response time is twelve hours. By the time gritters arrive, the damage is done: cancelled deliveries, furious tenants, and social media lights up with images of the “treacherous” conditions. The local press writes of stranded shoppers and unsafe conditions.

In the following weeks, an injury claim makes the consequences even clearer. Without service records of the decision-making process

there’s no evidence that “reasonable steps” had been taken. A personal injury claim is eventually settled at a cost of around £45,000. Later, Cold Bay Park’s insurers hike annual premiums by tens of thousands for the next three years.

In our example, you can already see the financial hit of this gamble but there’s also reputational fallout. A video of a shopper slipping in the icy car park goes viral under the hashtag #ColdBaySlip. Tenant satisfaction scores fell by nearly a third and two retailers opt not to renew their leases, citing poor site management. December footfall drops twelve per cent. By the time the snow has melted the short-term saving snowballs into a long-term liability. The £18,000 “saving” is dwarfed by £45,000 in claims, £180,000 in lease penalties and compensation, thousands more in insurance premium hikes and £1.4 million in lost sales.

The Cold Bay Park story may be fictionalised, but the risks it illustrates are real. Across the UK, slips, trips and falls are among the most common winter accidents, costing employers hundreds of millions each year. Hidden impacts like reputational damage, operational disruption, legal exposure and lost trust, can be equally costly. For facilities managers, perception is often as important as performance. A safe, well-maintained site inspires confidence that an icy car park can erase – especially when a lurid video can go viral. In an age where corporate and brand reputation matters, the stakes are especially high.

Gritting is not simply about safety; it is about continuity. Frozen access roads delay deliveries, strand vehicles and force businesses to close at the very time of year when demand peaks. In sectors like healthcare, logistics and education, the cost of those delays can be

a catastrophic gamble.

There is also the issue of accountability. Insurers and courts now expect clear, auditable trails showing that every reasonable precaution was taken. Without adequate records, liability often falls on the decision makers in facilities management. Moreover, higher standards of what count as adequate and reasonable steps has left those playing a more amateur game increasingly exposed. The gritting industry has become highly professionalised, with the best providers like OUTCO able to deliver gritting schedules, GPSpowered breadcrumb trails of where and when salt has been laid, and records of the forecast data used to back decisions. When things go wrong, being seen to fall short of this higher bar can appear reckless.

Given all these risks, why does winter maintenance still fall victim to budget cuts? Part of the answer is a tendency to underestimate low-frequency, high-impact events. To avoid such traps requires a mindset shift to treat winter maintenance as an investment rather than a cost. This starts with a cleareyed risk audit, reviewing past incidents and quantifying exposure. Compare the annual cost of proactive gritting with the potential losses from even one serious incident. Build a business case that positions

winter services as insurance against multi-million-pound risk. And choose a provider who can deliver guaranteed response times, accurate forecasting and full audit trails.

At OUTCO, we see the benefits of this approach every winter. By combining live meteorological data with preagreed service schedules, our teams can treat surfaces before ice has a chance to form. Our digital reporting systems give clients the evidence they need to demonstrate compliance, protect against claims and reassure stakeholders. Most importantly, our proactive model removes luck from the equation. Facilities managers don’t need to gamble on the weather; they can be confident they are prepared.

The lesson from Cold Bay Retail Park is clear. The most expensive decision an FM can make is to cut corners on winter maintenance. What looks like a canny saving can easily snowball into huge liability. With winter fast approaching and budgets under pressure, facilities managers face a choice: make a small investment in proactive safety or keep rolling the dice.

For more information on how OUTCO can bring an innovative approach to your winter gritting, contact 0800 0432 911 email enquiries@outco. co.uk or visit www.outco.co.uk

The brand is known for its technology-led approach to onsite power generation, using submetering to inform customers how they can operate more sustainably

Power-Zero has launched updates to its Power-Zero Optimise Portal, a userfriendly interface that provides continuous updates and valuable insights to customers, providing them with access to comprehensive system data which can seamlessly assist ESG reporting requirements.

Power-Zero customers utilise the Power-Zero Optimise Portal for smart data insight that enables businesses to maximise energy efficiency and minimise consumption, making it a market-leading technology that can easily integrate into operations.

The new updates include:

• Generation forecasting and optimum generation periods: Companies can optimise generation shifts and change production to

specific hours or charge vehicles, for example.

• Live electrical carbon view: Customers can see how much carbon the site is using from electricity.

• Carbon avoided can be seen as a value over time

• Renewable Energy Guarantees of Origin (REGO): Customers will be able to see the REGOs on a live basis and monthly historical view as a gift from PowerZero to the customer.

• Historical data: Customers can track generation to hold their system to account and flag any discrepancies. They can highlight any hourly period since the system was installed. Customers will also get a historical overview of site carbon vs the grid.

• Alerts: Customers can see live data from the inverters and alerts are triggered if any issues arrive.

Earlier this month, Derbyshire-based Denby Pottery announced it has achieved 900 carbon-free hours between April and August this year, thanks to its partnership with Power-Zero and utilisation of the Optimise Portal. This milestone represents 37.9% of the total 2,376.3 daylight hours during the period, showcasing Denby’s commitment to sustainability and innovation.

Simon Mitchell, Commercial Director, Power-Zero, said: “We’re excited to be updating and evolving our Optimise Portal to help improve trust and transparency for our customers, as well as giving them access to historical data and generation forecasting.

“As two thirds of businesses now worry about rising energy costs, Power-Zero is well placed to help alleviate concerns by helping companies to deliver clean, renewable energy in a cost-effective manner by developing robust onsite solutions through a PPA.

Star Platforms, a leading powered access specialist, responded swiftly to an urgent hire request from a Loughborough University student, delivering a low-level access platform within 48 hours to support the installation of a final-year sculpture ahead of a key end-of-degree exhibition.

The request came in on a Friday afternoon after the university’s usual supplier was unable to fulfil the requirement. Understanding the time-sensitive nature of the project, Star Platforms arranged the rapid delivery of a Power Tower Nano SP push-around vertical (PAV)

access platform, ensuring it arrived at the School of Design & Creative Arts ready for use on Monday morning.

Compact and easy to manoeuvre, the Nano SP provides a maximum working height of 4.5 metres and a safe platform capacity of 200kg, offering a practical and safe solution for indoor tasks requiring low-level access. Its zero turning radius and self-propelled design make it ideal for navigating tight spaces like galleries and studios.

The equipment was used by student Rebecca

Matthews to safely adjust and position her large-scale artwork within the Fine Art Gallery, forming part of her final assessment and public exhibition. Working alongside Beacon Commercial Solutions, who installed a lifting eye to the structural beam, Rebecca was able to complete the installation with precision and confidence.

Artist, Rebecca Matthews, commented: “The platform completely changed my approach to how I installed the artwork. It gave me the freedom to make adjustments safely and independently, which was crucial given the scale and ceramic elements of the piece. It’s inspired me to explore a new way of working and constructing pieces. I’m grateful to Star Platforms for providing the platform; their support meant I could realise the installation exactly as I’d envisioned it.”

Steve Simmons, Joint Managing Director at Star Platforms, added: “This project is a great example of how our team goes above and beyond to meet customer needs, even at short notice. We were pleased to support a creative, educational project like this and to see our equipment in use in such an inspiring environment.”

Photographs captured during the project showcase both the technical setup and the final artistic touches, demonstrating how powered access plays a vital role in creative and educational settings as well as more traditional industries.

Robert Chandler, Principal Building Surveyor, Loughborough University, said: “The entire process was arranged with ease, delivery was prompt, and communication was clear and concise throughout. That level of service is rare

in the hire industry, where centralised desks can often make things more difficult.”

He continued: “Star Platforms provided a responsive, reliable service with a personal approach, which is something we really value at the University. We found the equipment so useful that we extended the hire to support the ongoing refurbishment of the School. I would have no hesitation in recommending them.”

With a flexible three-week hire in place, Star Platforms ensured the student had the

time and equipment needed to complete the installation with confidence. The project highlights Star Platforms’ responsiveness and serviceled approach, supporting everything from one-off specialist projects to ongoing requirements across a broad range of sectors, including: construction, facilities management, education, and the arts among others.

For more information about Star Platforms and its services, please visit www.starplatforms.co.uk.

ABM, a leading provider of facility, engineering, and infrastructure solutions, is proud to announce that it has been awarded a Silver EcoVadis sustainability rating, with an impressive score of 74, placing the business in the top 15% of organisations globally assessed by EcoVadis, and within the top 8% of all submissions worldwide.

EcoVadis is the world’s largest and most trusted provider of business sustainability ratings, evaluating over 130,000 companies across more than 180 industries and 175 countries.

The assessment measures performance across four key areas: Environment, Labour and Human Rights, Ethics, and Sustainable Procurement.

ABM’s rating demonstrates significant achievements in sustainability, with standout results including ‘Leader in Environment’, achieving 88 out of 100 points and being ‘Advanced in Labour and Human Rights’, reflecting ABM’s commitment to its people and ethical practices.

The Silver recognition is an important milestone in ABM’s ongoing journey to embed sustainability and

responsible business practices across its operations.

Graham Moxon, Director, Sustainability UK & Ireland, says: “To be placed in the top 8% of companies worldwide is a real testament to the efforts of our teams and our partners who drive positive change every day.

“We’re particularly proud of our environmental performance, which reflects our commitment to helping clients and communities thrive while reducing our impact on the planet. This result firmly cements ABM’s position as a sustainability leader within its industry.”

Building & Facilities Management editorial content covers all the major FM areas of interest within the workplace and the built environment.

To find out more information about BFM Magazine or to subscribe, please visit www.bfmmagazine.co.uk

Specifying CFA members for your flooring projects means you’ll be gaining a wealth of experience from vetted contractors with the knowledge and products to fulfil your specification with a sustainability criteria.

CFA members are part of a supply chain that includes specialist contract flooring contractors, manufacturers and distributors, all of whom promote the highest standards and expertise.

Security expert Abloy UK is calling for greater awareness of compliant access control solutions amongst Health and Safety Managers, to ensure workers across critical infrastructure, commercial facilities and high-risk environments are protected and secure.

Many businesses are putting themselves at risk of financial loss and reputational damage due to lack of understanding of safety legislation and compliant access control. With this in mind, Abloy is highlighting the need for greater understanding of the role access control has within

health and safety strategies.

Fatalities and injuries in the workplace remain a serious concern, as according to the latest figures, 124 workers and 92 members of the public were killed in work related accidents over the last year. Additionally, more than 600,000 injuries were reported, leading to 33.7 million working days lost and £21.6 billion in costs to the UK economy.[1]

In some cases, these incidents involve unsafe access to hazardous or restricted areas, including plant rooms, electrical infrastructure, maintenance zones or escape routes that have been misused

or blocked. Whether intentional or accidental, unauthorised access to these locations creates significant safety risks for both workers and the public.

For example, in industrial and commercial environments, individuals entering confined spaces or machinery zones without the correct training or authorisation can be exposed to life threatening hazards. In public spaces, unsecured emergency exits or staff only areas can lead to safety breach, vandalism or misuse during evacuations.

David Rock, Market Development Manager, at Abloy UK, explains: “These

insights highlight the need for increased awareness around access control in life safety management. Every time we reduce the chances of someone being in the wrong place at the wrong time, we lower the risk of injury, improve compliance and protect organisations from disruption.”

It is recommended that life safety access control includes systems that can restrict access to hazardous areas and manage permissions in real time. For example, Abloy’s electromechanical eCLIQ solution offers complete control over which key cards can access certain areas.

This can be integrated into permit to work procedures, ensuring that only trained, competent individuals are able to access the correct areas.

Not only this, but eCLIQ offers traceability, tracking and audit trails, allowing for a complete overview of who accessed certain areas, including more remote locations, and when they did so. Having this capability offers a more organised approach to health and safety, allowing organisations to have complete insight into movement patterns and identify potential breaches before they escalate.

By creating a verifiable record of all access events, organisations can more easily investigate incidents, demonstrate compliance to regulators and provide evidence during audits. This also supports a culture of accountability, as employees and contractors are aware that their access history is recorded and monitored.

By using a solution like this, access rights can be granted and taken away easily, which is important if an individual’s training has expired and they are no longer allowed to have access to a certain area or machinery. It is also useful to have this feature if key cards

are lost or stolen, which aids the protection of both staff and public, deterring unlawful behaviour and removing threats in high-risk environments.

Compliant escape door systems (EDS) are essential for a successful health and safety plan as they allow for safe, compliant escape during emergencies. In normal use, an EDS maintains security to prevent unauthorised entry, but when triggered by a fire alarm or power failure, it releases instantly to provide a quick evacuation route.

This capability is important for safeguarding both employees and members of the public, as delayed or blocked exits can significantly increase the risk of injury or loss of life. Escape routes always need to be functional, even in the event of a technical fault or power outage.

When managing electrically controlled escape door systems, it is important to refer to NCP 109 Issue 4. It includes enhanced guidance on compliance to support a safe and secure approach to controlling escape doors. The issue mandates that access control systems on escape routes must comply with European Standards, specifically EN 179, EN 1125 and EN 13637.

Meeting legislative requirements, EN 1125 and EN 179, not only ensure legal adherence but also demonstrates a proactive commitment to occupant safety and emergency preparedness.

EN 13637 also needs to be considered, particularly when electrically controlled escape doors are present. As the standard is relatively new, it is important that Health and Safety Managers understand the need for greater control of escape doors and routes, without compromising

on safety or the ability to escape in an emergency.

Including EDS within a wider access control plan helps to maintain site security in everyday operation while guaranteeing unrestricted escape when needed. This means that safety is not compromised for the sake of security and vice versa.

By integrating solutions like eCLIQ and the Abloy EDS, organisations can create an intelligent, layered system that prevents unsafe access, enables rapid evacuation and meets the most stringent safety standards.

Industry support is available, the Abloy Academy offers training for those who want to become more proficient in the latest compliance legislation, safe locking strategies and integrating access control into wider safety management plans. Through training, individuals like Health and Safety and Facilities Managers can gain the knowledge needed to specify the correct systems and implement solutions that actively reduce risks while strengthening compliance.

David Rock concluded: “People tend to forget that health and safety isn’t just responding to incidents, it’s about preventing them in the first place. Too often, organisations only look at access control and escape provision after something goes wrong.

“By taking a proactive approach and implementing a preventative strategy, you can protect your people, meet compliance requirements and avoid the costly consequences of inaction.”

For further information on products and services available from Abloy UK visit www. abloy.com, email info@abloy. co.uk or call 01902 364 500.