Optimise energy use and create adaptable spaces with intelligent lighting controls

Cut costs not performance

Eliminate unnecessary energy waste, helping budgets go further without compromising lighting quality

made simple

Optimise energy use in real-time, helping you meet carbon reduction targets and regulatory requirements

Scalable systems integrate with existing infrastructure, ensuring compliance and longterm savings with minimal disruption

Synapsys Lighting Control Systems help buildings to unlock smarter, more efficient lighting solutions - reducing waste, cutting costs, and enhancing comfort.

Email | enquiries@synapsys-solutions.com

Web | synapsys-solutions.com

Business Development Director James Scrivens james@abbeypublishing.co.uk

Production Sarah Daviner sarah@abbeypublishing.co.uk

Accounts Manager Katie Brehm accounts@abbeypublishing.co.uk

BFM is published digitally 10 times a year by Abbey Publishing Ltd. To receive a copy free of charge, contact our offices.

Tel: 01933 316931

Email: bfm@abbeypublishing.co.uk www.bfmmagazine.co.uk www.abbeypublishing.co.uk

www.twitter.com/ BFM_Magazine

Subscriptions are available via www.bfmmagazine.co.uk/subscribe

Platinum Facilities has expanded Platinum Mobile, a dedicated mobile engineering division that enhances the company’s ability to deliver services in-house and extend coverage across the UK.

Traditionally focused on London’s large corporate properties, Platinum has built its reputation on selfdelivered technical services for fixed-site contracts. As market priorities shift towards rapid compliance reporting and greater self-delivery, the company is investing heavily in mobile engineering capability to extend the benefits of its in-house expertise to smaller offices and regional sites that do not require a full-time on-site engineer.

Platinum has recruited a 25-strong mobile team to meet evolving client requirements and reduce reliance on subcontractors. The expanded division will support Platinum’s existing client base. Engineers are directly employed and will cover disciplines including combustion, air conditioning, chillers, water treatment (including cooling towers and closed systems analysis), mechanical systems, and electrical engineering, with Platinum holding Gas Safe, REFCOM and LCA accreditations to support safe, compliant and highquality service delivery.

Platinum Mobile will operate across London, the Home Counties, the South East,

the South Coast and parts of Dorset, with expansion into the Midlands and North planned for late 2025. Recent investment includes a new vehicle fleet, a standalone CAFM system for scheduling and reporting, the recruitment of 10 additional engineers in phase one, and the creation of a dedicated water treatment division. By increasing the proportion of services delivered directly by its own engineers, Platinum is reducing its reliance on subcontractors and increasing flexibility for clients.

“Our vision is to continue evolving as a truly selfdelivered specialist facilities service provider,” Glen Cardinal, CEO of Platinum Facilities, said. “Too often in our industry, providers act

as intermediaries, relying heavily on large supply chains. This can make it harder to maintain full control over quality, responsiveness, competence and cost. By building our mobile engineering capability, we can reduce that reliance, focus entirely on our own clients, and deliver a service that is more agile, consistent and value driven.

“This approach also supports our commitments to the United Nations Sustainable Development Goals by creating quality employment opportunities within the communities we serve.

Platinum Mobile is a significant step towards our ambition of becoming a national provider of self-delivered engineering services,” he added.

Summer is your prime opportunity to prepare your estate for the seasons ahead.

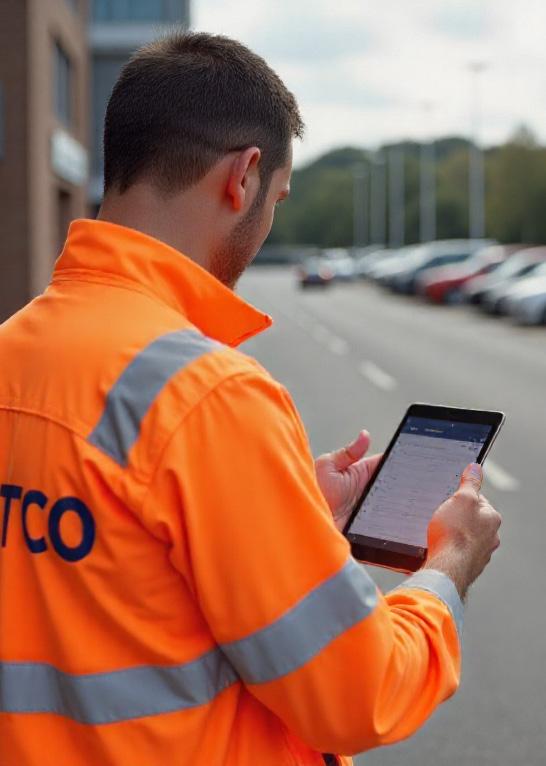

At OUTCO, we help clients take full advantage of the longer daylight hours and drier conditions to address surfacing issues, manage vegetation growth, and schedule critical inspections.

With expert planning, professional insight and technology-led solutions, OUTCO keeps your outdoor spaces compliant, safe, and always one step ahead.

0800 0432 911 enquiries@outco.co.uk

In the past, it’s been easier to define this – delivering tangible cost reduction through more efficient and effective working methods and volume delivery. However, as the market matures, opportunities for this reduce, so the objective for outsourcing needs much more careful consideration and articulation within business cases and decision points about whether to outsource or maintain this delivery model.

Paradoxically, however, as FM contracts go through multiple generations, often the profile of the procurement and contract management becomes less critical and strategic oversight around this decision point reduces.

This can leave contracts and management stakeholders in a difficult spot. Clients are looking for high performing contract delivery with a reduced cost, and suppliers are looking for margins that protect their business. Further, given the reducing levels of strategic input to contract management, there can be a lowering of organisational empathy between the parties.

The sector needs to think of these arrangements in a different way. Gone are the days of ‘success’ being defined by cost savings – there really isn’t much more of this to realise.

What must define success is a thorough thought process

that clearly understands why the services have been outsourced in the first place, and that this be clearly articulated to client and supplier teams alike. Processes then need putting in place to track how effectively the contract can achieve these objectives.

Regrettably, there is a growing gap between the impact FM services can have on an organisation’s ability to operate and the strategic input to contract and, dare I say it, partnership management which prevents this from being regularly delivered.

For FM contracts to be successful in the future, this conundrum needs solving.

Thomann-Hanry® have revolutionised the way building façade cleaning and restoration is achieved, through our patented conservation grade cleaning system ‘Façade Gommage®’.

The system reduces time, money, and the inconvenience of needing unsightly scaffolding. Works are normally completed in half the time of conventional methods and without the use of high pressures, harsh solvents, or damaging aggregates.

Thomann-Hanry® will serve as your principal façade contractor; we seamlessly manage all areas of façade restoration with minimal disruption — from surveys, permit application, restoration of stone masonry and render, intricate internal and external painting, window and roofing works, and our highly specialised techniques to delicately strip away layers of grime to unveil the original splendour.

The Independent Inspector has completed 83 audits across the CHSA’s Accreditation Schemes during the first half of 2025. Compliance with the Standards and Technical Regulations of the Accreditation Scheme continues to be high.

The CHSA operates Accreditation Schemes for manufacturers of soft tissue, plastic refuse sacks, cotton mops and cleaning chemicals. It also operates an Accreditation Scheme for distributors.

During the 83 Audits conducted in the six months to 30 June 2025, the Inspector reviewed a total of 20,780 product lines in the Accreditation Scheme for distributors. Across the Schemes for soft tissue, plastic sacks and cotton mops, 926 product labels were checked, and 687 individual products were tested.

The labels are checked to ensure they indicate the manufacturer to enable tracing and accurately represent the contents of the packaging so buyers can be certain’ what’s on the box is what’s in the box’.

Depending on the Accreditation Scheme, the product checks involve confirming the sheet count, width, duty, weight and performance of the product. The Inspector also assesses members’ quality assurance procedures. Members of the Accreditation Schemes for manufacturers of soft tissue, plastic sacks and cotton mops achieved up to 86.2% compliance with product standards, reflecting a strong performance across all categories. For distributors the Inspector confirms that where

product falls within the scope of an Accreditation Scheme, it is either from a CHSA Accredited Manufacturer or conforms to the specification of the relevant scheme. 79% of relevant products were found to be from Accredited Manufacturers.

In addition to the product and label checks, the Inspector now also seeks evidence of a SMETA Audit (Sedex Members Ethical Trade Audit) from manufacturing members or their suppliers who have completed the process in advance of the end of year deadline for having this process in place.

Nicky Biggart, Chair of the CHSA’s Accreditation Schemes, explained: “Our Accreditation Schemes offer buyers of cleaning and hygiene products the guarantee that ‘what’s on the box is what’s in the box’. They also underpin quality and efficacy.

“The inspection process is fundamental to this guarantee. It provides buyers with evidence they need to trust the CHSA Accreditation Scheme Mark.”

In the small number of instances where product was found not to meet the relevant Scheme Standard or Technical Regulations, the Inspector raised a ‘product of concern’. Working closely with the manufacturer or distributor involved, the Inspector has supported those members to address the issue within a specified time frame. Every CHSA member is required to sign the CHSA’s rigorous Code of Practice, which includes the Competition & Markets Authority’s Green Claims Code.

The combination of the Code of Practice and Accreditation Scheme membership means every member: Trades ethically and sustainably; Provides supporting information for claims made; Provides quality, fit for purpose products; and Makes sure what’s on the box is what’s in the box.

@CHSACleaning www.CHSA.co.uk

As organisations across the UK face mounting pressure to reduce emissions and control costs, many are discovering that the smartest infrastructure investment is not physical - it’s analytical.

According to TEAM Energy, the key to unlocking meaningful energy savings lies in understanding how your estate actually uses energy, and where it’s being wasted.

In a recent article, TEAM considers the role of the commercial energy audit, positioning it not as a compliance exercise, but as a strategic tool for transformation. With energy prices volatile and net zero targets looming, the timing could not be more relevant.

From data to direction

The blog highlights how audits, which can range from desktop reviews to investment-

grade assessments, arm organisations with the insight needed to make confident, cost-effective decisions. Whether it is identifying inefficient HVAC systems, uncovering hidden baseloads, or benchmarking performance across sites. An energy audit is designed to turn raw data into actionable intelligence. And it is not just about the big-ticket items. Even simple upgrades, like switching to LED lighting, can deliver significant returns. To illustrate this, TEAM has launched a free online tool: the LED Lighting Energy Savings Calculator. This enables organisations to estimate their potential savings in energy, cost, and carbon by

inputting just a few details about their current lighting setup.

A smarter path to net zero

What sets TEAM’s approach apart is its focus on clarity and customisation. Every audit is tailored to the organisation’s estate, operations, and sustainability goals. The result is a roadmap that not only supports compliance and funding applications but also builds a compelling case for change - one that stakeholders can get behind.

As the energy landscape evolves, so too must the way organisations manage it. Insight, not infrastructure, is the foundation of a smarter, more sustainable future.

To explore how a commercial energy audit could benefit your organisation, and to try the LED calculator, read the full blog at teamenergy.com.

Steve Juson, Managing Director,

MILWAUKEE® delivers the brand new M18 FUEL™* High Performance 4-mode 16mm SDS-Plus Hammer. A completely versatile and compact design, with 4-mode operation- rotary hammer, hammer only, rotation only and variolock for maximum versatility and light material removal. Drilling up to 58 holes ⌀10 x 50 mm on a M18™ HIGH OUTPUT™ 3.0 Ah battery per charge. The light and safe solution for end users in the later stages of construction and renovation. Never compromising on important ergonomics and performance.

THE POWERSTATE™ BRUSHLESS MOTOR DELIVERS 1.7 J OF IMPACT ENERGY, 1400 RPM, AND 5080 BPM, ENHANCING PORTABLE PRODUCTIVITY. REDLINK PLUS™

with the HEPA filter that is widely regarded to as the ultimate filter trapping all sizes of particles with an efficiency rating of 99.75%.

Intelligence ensures maximum hammer performance and protects it from overload, overheating, and overdischarge. At only 263 mm long and 2.6 kg, this hammer has the power to complete the toughest concrete applications, for its size.

For enhanced safety, this hammer includes an AVS Antivibration system for maximum comfort and AUTOSTOP™ enhanced kickback control to reduce over-rotation. For maximum versatility, the LED lighting provides increased visibility, and the integrated hang hook for functional storage and convenience. The dedicated dust extractor kit allows for maximum power and productivity. Designed to collet dust effectively

MILWAUKEE® is committed to improving productivity by providing performance-driven and trade-focused solutions so users can perform an entire day’s work on one battery system. The M18 FUEL™ high performance 4-mode16mm SDS-Plus hammer is fully compatible with the entire M18™ line, now offering more than 315 solutions.

MILWAUKEE® remains unwavering in their commitment to delivering disruptive innovation by working alongside trade professionals to identify challenges and provide solutions that are unparalleled in enhancing job site safety and productivity.

*M18 FUEL™ is engineered for the most demanding tradesmen in the world. Delivering

unrivalled performance, all M18 FUEL™ products feature three MILWAUKEE®exclusive innovations—The POWERSTATE™ Brushless Motor, REDLITHIUM™ Battery Pack and REDLINK PLUS™ Intelligence Hardware and Software—that deliver unmatched power, run time, and durability on the job site. Simply put, M18 FUEL™ tools are the most powerful 18V cordless tools in their class.

Specifications

M18 FUEL™ High Performance 4-mode 16mm SDS-Plus Hammer

• M18 FHAC16-302X

• Battery Type: Lithium-ion

• Battery System: M18 FUEL™

• Blow Energy [EPTA]: 1.7 J

• Max. Drilling Concrete: 16 mm

• Max. Percussion Rate: 5080 bpm

• No Load Speed: 0 -1400 rpm

• Optimised Drilling Capacity in Concrete: 5 – 12 mm

• Vibration Chiselling: 10.9 m/s²

• Vibration Drilling into Concrete: 13.6 m/s²

• Weight with Battery Pack (EPTA): 2.6 kg (M18 HB3)

Kit Includes: (1) M18

FUEL™ High Performance 4-mode 16mm SDS-Plus Hammer, (2) M18 HB3 Battery Packs, (1) M12-18 FC Charger, (1) HD Box

M18 FUEL™ High Performance 4-mode 16mm SDS-Plus Hammer with Dedicated Dust Extractor

• M18 FHACDDE-0C

• Battery Type: Lithium-ion

• Battery System: M18 FUEL™

• Blow Energy [EPTA]: 1.7 J

• Collection Container Capacity: 0.31 L

• Filter Type: HEPA 13

• Max. Drilling Concrete: 16 mm

• Max. Percussion Rate: 5080 bpm

• No Load Speed: 0 -1400 rpm

• Optimised Drilling Capacity in Concrete: 5.5 – 13 mm

• Vibration Chiselling: 10.9 m/s²

• Vibration Drilling into Concrete: 13.6 m/s²

• Weight with Battery Pack (EPTA): 3.1 kg (M18 HB3) Kit Includes: (1) M18 FUEL™ High Performance 4-mode 16mm SDS-Plus

Hammer, (1) M18 FUEL™ Dedicated Dust Extractor for M18 FUEL™ High Performance 4-mode 16mm SDS-Plus Hammer (1) HD Box

Perfect Match:

SDS-Plus MX4 Set 2–5 pc (4932498298)

SDS-Plus MX4 Set 1–5 pc (4932498297)

SDS-Plus MX4 Set 3–10 pc (4932492115)

To find out more about the new M18 FUEL™ High Performance 4-mode 16mm SDS-Plus Hammer, see video footage of it in action or find your nearest store, please visit www.milwaukeetool.eu

Visit Milwaukee Tool UK’s Instagram and LinkedIn for further information.

Wildflower Turf Ltd has continued to develop its Enhance Wildflower Biodiversity range, a collection of innovative products designed to boost existing wildflower areas and grasslands.

This range tackles the challenge of enhancing existing wildflower areas and grasslands. We spoke with James Hewetson-Brown, MD and Owner of Wildflower Turf Ltd, to get the inside scoop:

Q: James, what was the inspiration behind developing the Enhance Range?

A: While our previous offerings focused on creating new wildflower spaces, we recognised the need for solutions to improve and preserve biodiversity in existing ones. As you know, oversowing can have varying results. It often takes years to see any impact and it’s very difficult to establish new species without them being outcompeted by existing plant and grass species. The Enhance range provides a practical and costeffective alternative to this.

Q: So, what exactly is

the Enhance Wildflower Biodiversity range?

A: The products themselves come in the form of a preseeded growing medium. That makes it sound simple, but it’s a collection of innovative products that blend cuttingedge science with ecological care. For many years now we have been growing and harvesting our own wildflower seed at the farm just outside Basingstoke. Having control enables us to produce a seed crop that is correctly handled as soon as it is harvested, ensuring it is as viable as possible. We are also hugely fortunate to have a lab onsite. These facilities have enabled us to scientifically develop a substrate that provides the optimal environment to incubate the seed, giving it the best start in life. The combination of the premium seed and specially formulated substrate enables us to significantly improve germination rates and the speed of wildflower establishment.

Q: You mention it significantly improves germination rates and establishment time.

Can you tell us more?

A: Absolutely. These products are designed for rapid establishment. They boast an impressive germination rate of up to 93%. In terms of establishment times, the species included fully establish within 3-18 months, which when compared to 3-5 years for traditional seeding is a significant improvement. That 3-18 month range is quite broad because the time of year that you install the product impacts the speed of establishment. For example, installing in the Autumn will see speedy germination however, it will stay dormant over Winter, before bursting back into life in the Spring and Summer.

Q: That’s impressive. Are there any chemicals within the substrate that enable you to achieve such rapid results?

A: That’s the brilliant part, the whole range is completely chemical and peat free! It’s made of 100% natural ingredients as well as native seeds. The product’s purpose is to enhance biodiversity, so it was important to us to ensure ecological integrity both above and below the surface.

Q: Sounds great! So, there are five products within the range, is that right?

That’s right. There’s Bees, Butterflies, Birds, and Grass Control, which uses Yellow Rattle to rebalance biodiversity by suppressing dominant grass species. We also offer a Bespoke option which allows anyone to select specific species that they would like to add into an existing habitat. This is perfect for attracting specific wildlife or supporting site specific requirements to achieve BNG.

Q: It sounds like you and the team have put a lot of

Building & Facilities Management editorial content covers all the major FM areas of interest within the workplace and the built environment.

This includes industry developments, company news, case studies and application stories, product news as well as articles from leading authorities within the marketplace.

To find out more information about BFM Magazine or to subscribe, please visit www.bfmmagazine.co.uk

West Fraser is celebrating four decades of producing SterlingOSB board products; now the SterlingOSB Zero portfolio.

The Inverness plant employs 140 workers and was the first facility in Europe to manufacture OSB, a panel product used in a wide range of applications, including construction materials, furniture, packaging, and art installations.

To mark the anniversary of the site, the team hosted a family day event; the staff were also celebrating the recent Safety Star achievement which recognises commitment to employee safety.

The factory was established in 1985, following the closure of several paper mills and the near collapse of the UK forest

products industry during the 1970s and early 1980s.

In a move to support the struggling industry, and with support from the Highlands and Islands Development Agency (HIDA) and the Forestry Commission, a consortium of local and institutional investors launched a new company, Highland Forest Products in November 1983, with the Inverness site opening two years later.

Four decades of development later, the site has evolved into today’s West Fraser facility which, when combined with the Genk site in Belgium, forms the largest OSB production operation in Europe. The Inverness plant is also the first OSB plant in Europe to receive the Forestry Stewardship Council (FSC)

accreditation, recognising its commitment to sustainability and environmental stewardship.

Steve McTaggart, HSEQ Manager from West Fraser at Inverness, said: “West Fraser Inverness is proud to have been part of the community for 40 years and we look forward to many more.”

The West Fraser facility has benefited from sustained investment over the past 40 years, including a £95m expansion back in 2018 to install a new manufacturing line and increase production capacity, which was officially opened by then-First Minister Nicola Sturgeon.

For more information on West Fraser, visit https:// uk.westfraser.com/.

Providing a platform to collectively improve the delivery of estates, facilities and patient services through peer knowledge sharing, expert insights and the presentation of the latest technologies and service solutions.

• Entry to the Exhibition is FREE OF CHARGE and includes access to a full programme of Keynotes and seminars.

• Upgrade to a Conference Delegate Pass to unlock exclusive access to an additional multi-stream programme, plus on-site extras.

Discover the 2025 programme online now

21-22 October 2025

Lighting is playing an everincreasingly important role in the circular economy. Luminaires are no longer seen as part of the disposable society, thanks to a recognition that they can be upgraded and refurbished to extend their lifetime. Responsible manufacturers are integrating this approach into the design of luminaires from the outset, providing greater convenience to sustainability. David Goddard, Head of UK Projects from LEDVANCE explores this principle.

For many years the lighting industry faced the challenge of reducing electronic waste. The barrier to achieving this was the limited lifespan that traditional light sources, and even early generation LEDs, offered. To address this, responsible manufacturers have adopted manufacturing practices that enable luminaires to be part of the circular economy.

At its heart, the circular economy is a model of production and consumption that involves reusing, repairing, refurbishing existing products for as long as possible. The lifecycle of products is subsequently extended and is a move away from the linear economic model society had become reliant on. The unsustainable linear model is one which involves large quantities of cheap, and therefore rapidly disposable, products. These are never recycled or upgraded and ultimately end up being sent to landfill on an all too frequent basis.

One example of the circular economy in practice is LEDVANCE’s EVERLOOP approach. This principle enables the replacement of individual light sources and drivers in a convenient way, rather than having to replace luminaires in their entirety. The purpose

behind EVERLOOP is that it is integrated into the LED from the offset, allowing for the straightforward upgrade with new drivers and new LED light sources at any time. This means the luminaires have an almost unlimited lifespan.

The ease of replacement is key to the success of this sustainability practice. Having the ability to change the driver and light source embedded into the luminaire offers a convenient choice for many across the industry. This includes installers, planners, and facilities managers, among others wanting to secure sustainable efficiency of industrial and office applications, as well as public buildings.

The EVERLOOP approach is one way that LEDVANCE is contributing to the EU’s plan to reduce electronic waste. As well as meeting legislative requirements and targets, it also represents how lighting manufacturers are demonstrating efforts and measures that go above and beyond to address sustainability matters.

There are many reasons why focusing on the reduction of electronic waste is crucial. Firstly, the re-use of existing products slows down the use of natural resources and raw materials. This means a reduction in landscape and habitat disruption as materials do not need to be mined.

A circular economy further protects the natural environment by lowering the amount of waste that is sent to landfill, or disposed of through burning. Figures from the World Resources Institute show that each year, 300 million tonnes of plastic waste is produced globally. This is in addition to 54 million tonnes of electronic waste. Designing products that can be

used for much longer will reduce waste levels, and therefore pressure on the environment.

Adding to this, creating more efficient and sustainable products from the beginning of its lifecycle helps to lower energy and resource consumption. This is because, according to research published by the European Parliament, it is estimated that more than 80% of a product’s environmental impact is determined during the design phase.

To put this into context, data shows that around 45% of global greenhouse gas comes from product use and manufacturing. By implementing circular economy strategies that reduce this need to keep producing more and more, will significantly lower greenhouse gas emissions. This has the ability to reduce and potentially reverse some of the negative implications of climate change.

The circular economy also secures benefits that go beyond the individual products themselves. A reduction in the number of new products also lowers the associated packaging that needs to be disposed of. By upgrading the products that are in situ, there is less packaging for the replacement products – only what is needed to transport and store them safely. This in turn lowers the amount of waste, that in too many cases is still non-recyclable, that will be sent to landfill.

The role of lighting in the circular economy is clear to see, especially when there is an easy solution to challenging the outdated and detrimental linear model. The move to refurbishing and upgrading luminaires is becoming increasingly commonplace, and LEDVANCE is proud to be part of this movement.

or

Recolight isn't just about recycling, we help the lighting industry take real steps toward a sustainable future. With a Reuse Hub and Circular Lighting Live Conference, to workshops, webinars, and Life Cycle Assessments. Supporting businesses in taking practical actions to embrace the Circular Economy. What’s more, we can provide carbon footprint data for every waste collection. Make your lighting more sustainable. Make it circular.

Leading cleaning manufacturer and distributor Robert Scott has announced the launch of two new additions to its fastgrowing robotics range.

The MT1 Robotic Sweeper and the SH1 Upright Scrubber Dryer are the latest pioneering products to join Robert Scott’s suite of advanced robotics tools.

The company, which is currently celebrating its 100year anniversary, has been at the forefront of robotic solutions since introducing the autonomous MS60 scrubber dryer to the UK in 2023.

The MT1 Robotic Sweeper is the world’s first AI-powered sweeping robot designed for large-scale environments, delivering results that rival ride-on sweepers.

The MT1 is equipped with AI cameras that can recognise and identify a variety of types of waste in real time, continually learning and evolving through deep learning and database updates. A key feature is the MT1’s Visual Simultaneous Localisation and Mapping (vSLAM) which further enhances the machine’s ability to navigate through changing/ dynamic environments. An ultra-wide scanning field of view means it can effortlessly cover large areas, accurately detecting and efficiently cleaning up waste during routine patrols.

The MT1’s dual disc brushes easily handle larger debris like leaves and bottles, while also efficiently sweeping up fine dust and dirt. High-flow negative pressure ventilation and an efficient filter to trap particles in the debris box helps to prevent secondary pollution. Expanding the product line further is the newly launched SH1 Upright Scrubber Dryer. It’s designed with instant scruband-dry capability, delivering spotless surfaces in a single pass to save time and effort.

The SH1 features a userfriendly 4.2inch touchscreen that serves as a central control and information hub for the cleaning robot. It offers intuitive navigation and displays realtime information like battery levels, water levels, and cleaning mode selection. The screen also provides on-screen training with instructional videos and guides for tasks like battery care, brush selection, and maintenance.

It has multiple cleaning modes, and is equipped with innovative accessories to excel at cleaning vertical surfaces such as glass display cases, tiled walls, and mirrors, as well as floors. It also connects via WiFi to enable reporting.

The SH1 features a market first: a wastewater tank with an air-solid-liquid separation system. By separating gases, liquids, and solid particles, it facilitates a smooth disposal process for both wet and dry refuse and eliminates the risk of drain blockages. Compared to a conventional mop, it saves 80% on water

and cleaning agent usage and reduces cleaning time by 70%.

Alistair Scott, sales director at Robert Scott, said: “Expanding our offering in automated cleaning technologies with the MT1 and SH1 marks a significant milestone in Robert Scott’s rich history of supporting the cleaning sector with worldleading, innovative products.

“As automation, AI and the Internet of Things continue to evolve at a rapid pace, and the cleaning sector seeks smarter solutions to economic challenges, it’s clear that robotics will play a key role in the future of commercial cleaning. Our growing robotics division, backed by 100 years of cleaning know-how, positions us strongly to lead the way in intelligent cleaning tools.”

The MT1 and SH1 are available in the UK through Robert Scott. For more information and to book a demo, visit: www.robertscottrobotics.co.uk

How Rubbermaid Commercial products are refreshing their range with upgrades to key products

With businesses facing increasing pressure to address their environmental impact and promote sustainable practices, as well as meeting the higher demands from customers for superior levels of hygiene, all while balancing tighter budgets, it’s essential that they are investing in effective equipment.

To support businesses in delivering across this criteria, Rubbermaid Commercial Prodcuts (RCP) has announced the release of upgraded models of existing, core products. After extensive research and field visits, the Executive Housekeeping Cart has been updated to address the critical needs of users, and the business has launched the new HYGEN™ r-40 Microfibre Cloth, an upgraded version of their existing microfibre offering.

The next generation of housekeeping carts

With housekeepers twice as likely to experience a workplace injury involving pushing and pulling tasks relative to other occupations and 43% of housekeeping accidents directly related to pushing or pulling loaded carts1, supporting your team with equipment designed to take the strain is essential. Investing in ergonomic and efficient cleaning tools enhances the speed and quality of cleaning while contributing to higher job satisfaction, fewer injuries and lower turnover rates amongst staff2. The newest model of the Executive Housekeeping cart is designed with these priorities in mind, directly addressing maneuverability and ergonomic concerns.

Key ergonomic improvements of the cart include:

• Five caster wheels –allowing users to easily switch

the cart between fix and swivel.

• A new ergonomic handle – encourages an even grip to better control movement.

• Impact-absorbing bumpers – protect both the cart and the surroundings.

When assessing housekeeping practices, driving efficiency and improving productivity are always key concerns, along with budgets. Poor cart organisation and lack of storage space can increase the number of trips to the supply room during shifts, having a knock-on effect on overall efficiency.

The newest edition of the cart features:

• Increased top surface area storage, new deep tower storage, large lockable cabinet and additional modular shelves – maximising the carts capacity.

• Optional side load linen bag – increases capacity for clean linens without the need for a larger overall cart.

• Improved stick holders and vacuum holder spaces – allow for

easy access to cleaning equipment on the move.

RCP’s products are famed for their durability, and the housekeeping cart comes with a 3-year warranty for added peace of mind.

Bolder, brighter, better Today, cleanliness is profitability, and poor hygiene could result in costly consequences. From protecting the wellbeing of staff and reducing costly absenteeism to considering reputational damage and even the risk of facing fines, all against the backdrop of improved sustainability practices and challenging budgets, there’s much for businesses to consider.

The newly launched HYGEN™ r-40 Microfibre Cloths are the latest iteration of the business’ existing microfibre

cloths. The new model, in bold, bright colours, is designed to withstand 200 commercial washes – and 100 with bleach – while the colours remain steadfast, reducing the risk of cross-contamination. Made with 40% recycled material from recycled plastic, the cloths also support better sustainability practices by reducing the need for virgin plastics in production, while continuing to deliver a high level of clean removing 99.9% of tested pathogens, including fungi and bacteria, using only water.

RCP are committed to developing products that are built to last and that can stand up to the tough demands of any sector day in day out. Providing businesses with quality solutions allows them to buy better, waste less, reducing the hassle and cost of replacing flimsy solutions.

Find out more about the newest innovations here:

https://www.rubbermaid. eu/en/cleaning-mobility/ housekeeping-trolleys/ full-size-housekeepingcart/?sku=2202581

https://www.rubbermaid. eu/en/cleaning-mobility/ housekeeping-trolleys/ compact-housekeepingcart/?sku=2202585

https://www.rubbermaid. eu/en/cleaning-mobility/ housekeeping-trolleys/fullsize-housekeeping-cart-withhood-doors/?sku=2202587

https://www.rubbermaid. eu/en/cleaning-equipment/ reusable-microfibre-cloths/ hygen-r-40-recycled-microfibercloths/?sku=1820583

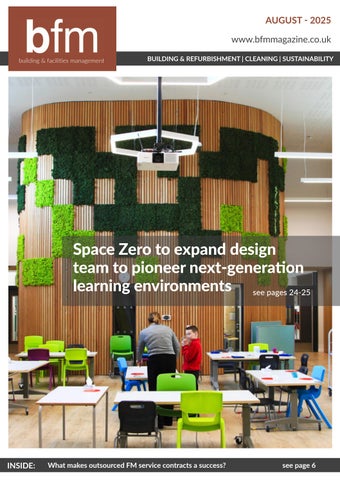

Strategic design consultancy to boost headcount by eight to support expanding project pipeline

Space Zero, a strategic design consultancy, is expanding its team of designers, strategists and procurement experts to lead the reimagining of future learning environments.

The Manchester-based firm, which has delivered more than 1,000 education projects in 26 countries, is recruiting eight new specialists to strengthen its design-led approach, combining biophilic, trauma-informed, and neurodiverse principles with cutting-edge digital tools.

This expansion comes as the company projects turnover of more than £10 million by March 2027, representing 35% growth over two years. It follows an increase of 12 new hires over the past 18 months, including senior appointments such as Kirstine Robinson (Associate Director, Strategy), Olga Collins (Head of Procurement), and

Chris Hayley (Head of Projects), and new talent in design, technology, procurement and administrative support.

Space Zero’s portfolio spans state schools, SEND facilities, independent schools, and higher education campuses, with landmark projects delivered internationally across the UAE, Saudi Arabia, China, Thailand, Malaysia, Europe, and the USA.

Founded by Wayne Taylor and Philip Gardner in 2009, the firm found success in interior design and Fixed Furniture and Equipment (FF&E), supporting the design gaps faced by construction companies and architects, especially within the education sector.

Space Zero is poised to help shape the next generation of learning environments under the Department for Education’s

new £15.4 billion Construction Framework 25 (CF25), starting in 2026. Building on its success delivering schools through the previous CF21 framework, Space Zero is preparing to support modernisation, optimisation and capacitybuilding efforts across the public education estate.

The consultancy is also broadening its reach into the UK’s independent schools’ market, leveraging its international experience to respond to the rising demand from private education providers seeking to modernise and differentiate their facilities.

Wayne Taylor, Founder and CEO of Space Zero, said: “Space Zero’s growth is underpinned by our international reputation for delivering on our promise: to reimagine learning environments in

ways that improve outcomes, unlock potential, enrich lives, and enhance wellbeing. Our mantra is that we don’t just design classrooms, we help shape futures.

“Growth, for us, isn’t just about numbers. We’re scaling with purpose, to reach more communities and deliver schools that genuinely change lives, backed by world-class, fully integrated solutions from strategy to fit-out, without compromising quality.

“As education faces outdated infrastructure, tighter budgets, inclusion demands and rising expectations, our message is clear: build better or fall behind.”

“Investing in our talented and brilliant people is central to maintaining our momentum and continuing to drive positive change across the education sector.”

“Our international team is made up of bold, curious, and collaborative specialists who never settle for ‘what is’ — they ask, ‘what if?’. We’re expanding because our design works, and because our people believe in our purpose.”

Space Zero’s growth strategy is being driven by its continuous £1m+ annual investment in research and innovation. Through purpose-driven, datainformed design, supported by robust BIM and ISO-accredited processes, the company drives innovation, and creativity whilst embracing digital tools, automation, AI-assisted workflows, digital twinning, and simulation to improve speed, accuracy, and sustainability.

“We’re moving beyond traditional design to become a full-spectrum education

change partner, reimagining how space, technology, and human experience come together to transform learning — not just for today, but for the next generation,” Wayne said. “By applying emerging technologies and future-focused thinking, from neurodiverse and trauma-informed environments to biophilic design, we deliver projects with proven cognitive, emotional, and social benefits far beyond aesthetics.”

To learn more visit https:// spacezero.co.uk/

National brickwork and scaffolding specialist Phoenix Brickwork, based in Pinxton, Derbyshire, has completed its work on the prestigious Secklow Gate residential development in Milton Keynes. The project, undertaken in partnership with longstanding client, Galliford Try, saw Phoenix Brickwork deliver both masonry and scaffolding services, marking the first time both divisions have worked together on a Galliford Try project.

Work took just under a year to complete, was valued at £4.5 million, and used 850,000 bricks across four buildings, which reached up to 11 storeys in height.

Christian Watson, Group Chairman at Phoenix Brickwork (UK) Ltd, said:

“We are extremely proud to have successfully delivered the masonry contract for the Secklow Gate scheme, helping to create 329 private rental sector apartments in the heart of Milton Keynes. This project adds to our strong portfolio of award-winning work with Galliford Try, and it has been fantastic to collaborate once again with their talented team.”

The development, located on Avebury Boulevard opposite the well-known Xscape building, features a central courtyard with commercial space spanning 12,700m2 and flexible parking solutions. Phoenix Brickwork played a crucial role in bringing the project to life, ensuring highquality masonry and scaffolding services throughout the build.

Sam McSpadden, Scaffold Managing Director, added: “It has been a privilege to

contribute both scaffolding and masonry expertise to such a significant project. Our team worked seamlessly alongside our brickwork division, showcasing the strength of our integrated approach. The continued trust from Galliford Try speaks volumes about the quality of our work.”

A standout feature of the Secklow Gate development is the intricate brickwork, which includes a striking ‘honeycomb’ style and ‘protruding headers’ that add architectural interest and character to the buildings.

With this successful completion, Phoenix Brickwork continues to reinforce its reputation as a leading provider of masonry, scaffolding, and multi-trade support for major construction projects across the UK.

Chelsea Physic Garden has recently installed a Condair ML high-pressure spray humidifier to maintain the perfect atmosphere for horticultural success in its restored Victorian glasshouses.

Founded in 1673 by the Worshipful Society of Apothecaries of London, Chelsea Physic Garden is one of the oldest botanical gardens in Britain, occupying four acres of land on the edge of the Thames. Today, it is home to more than 4,500 species of medicinal, edible and useful plants, and remains a vital centre for plant science and education.

John Constable, Glasshouses Manager & Gardener, commented, “Maintaining the right humidity is vital for the health of our tropical collection. Without it, we quickly see signs

of stress in the plants - yellowing, crisping and even death. The Condair humidification system has enhanced how we manage the environment in the glasshouses. It gives us peace of mind that the conditions are right, so we can focus more on the plants themselves. It has made a noticeable difference to both plant health and how we work day-to-day.”

The garden’s historic glasshouses are key to cultivating sensitive tropical and subtropical species, such as cocoa and vanilla as well as a wide range of other tender ferns, epiphytes, woody trees and climbers. These plants rely on consistently high humidity to replicate their natural rainforest environments.

Previously, humidity was

maintained by wetting down the heating pipes to create a steamy environment. The recent restoration of the glasshouses presented an opportunity to modernise features, including the introduction of an advanced humidity control system.

The Condair ML spray humidifier was installed by Parker Air Conditioning Ltd. A water treatment system both purifies and pressurises mains water, supplying it to a series of nozzles located around the greenhouse. These nozzles release a fine mist that is fully absorbed into the air, providing consistent, hygienic humidity without any wetting on surfaces or the floor.

The use of reverse osmosis water filtration and onboard UV-light sterilisation ensures the mist is hygienic and mineral-free. This not only maintains a healthy environment but also prevents any dust being released into the greenhouse from the supply water. In addition to precise humidity control, the system provides low-energy evaporative cooling, making it ideal for greenhouse environments.

The Condair Group is the world’s leading specialist in humidity control and evaporative cooling, with energy efficient, hygienic and innovative technologies for commercial, industrial and heritage applications. Condair is represented in the UK by Condair Ltd, which offers system design, manufacture, supply, installation, commissioning, maintenance and spares. You can find out more by visiting the company’s website at www.condair.co.uk.

Revitalise your wildflower meadow with vibrant colour and biodiversity thanks to our new Enhance range.

Easy and reliable: A proven technique to boost species diversity in your meadow, backed by scientific innovation.

Optimal incubation: Achieve an impressive success rate of up to 93% germination, far exceeding traditional seed methods.

Rapid establishment: Establish the additional species with the grassland area in just 3-18 months, compared to 3-5 years with oversowing.

BNG facilitator: Enhance habitat preservation with a focus on enriching existing environments and supporting UK native species.

Chemical-free: 100% natural ingredients. No peat, no plastics.

UK developed and grown: Product developed and cultivated in the UK. 100% native seeds with verified origins.

This product is best laid in Autumn and Spring.

Visit wildflowerturf.co.uk/enhance to find out more or call 01256 771 222

Star Power was appointed to deliver a complete temporary utility solution for several site welfare compounds located within an Area of Outstanding Natural Beauty in the Snowdonia region. The project required a reliable and environmentally considerate approach, with services including temporary power, water supply, and on-site support.

Due to the sensitive nature of the location and its remote positioning, the infrastructure had to be not only robust but also discreet and sustainable. From initial consultation through to full installation and maintenance, Star Power delivered a turnkey service designed to meet both practical requirements and strict environmental expectations.

Working within an AONB introduced a series of challenges, most notably the need to balance operational functionality with environmental protection. The welfare compounds had to be fully serviced despite their remote setting, meaning all systems had to be dependable and designed to operate autonomously.

Additionally, Star Power was required to meet high standards of health and safety, as well as stringent quality benchmarks set by key stakeholders. Minimising downtime, managing cost efficiency, and reducing environmental impact were also key project objectives.

To meet the project brief, Star Power delivered a bespoke utility solution that addressed both short-term operational needs and longterm sustainability goals.

A rainwater harvesting system was designed and installed beneath the main temporary office complex. This included three interlinked 3,000-litre plastic tanks, connected to a filtered water pumping unit. The system was integrated into the existing plumbing infrastructure, enabling all toilet facilities within the cabins to be flushed using harvested rainwater. This significantly reduced the site’s reliance on mains water and contributed to the project’s environmental objectives.

For power provision, the site was initially supported by a 250kVA Stage V diesel generator, providing a stable and compliant energy source from the outset. Over 500 metres of armoured singlecore cable was installed through underground ducting to connect the generator to the main distribution panel within the welfare compound.

Several months into the project, the client requested a transition from temporary generation to mains power. The new supply point was located on the opposite side of the compound, requiring careful planning to avoid disruption. Star Power successfully managed the transition, reusing as much of the existing cabling infrastructure as possible to minimise both waste and additional costs. The upgrade

was delivered without impacting the site’s day-to-day operations.

The successful delivery of this project demonstrated Star Power’s ability to provide intelligent, environmentally responsible utility solutions, even in the most sensitive and logistically challenging environments. From water conservation to power continuity, the team ensured every element was delivered safely, efficiently, and in line with client expectations.

Benefits of the Solution

• Environmental Responsibility: The rainwater harvesting system supported the project’s sustainability goals, reducing reliance on external water sources.

• Operational Continuity: The transition from temporary to permanent power was delivered with no unplanned downtime, maintaining full site operations throughout.

• Cost and Waste Reduction: By reusing pre-installed materials during the mains upgrade, Star Power limited waste and controlled additional project costs.

• Compliance and Quality: All work met high standards of safety, quality, and professional conduct.

For more information about Star Power’s temporary power solutions, please contact Star Power or visit our website.

Specifying CFA members for your flooring projects means you’ll be gaining a wealth of experience from vetted contractors with the knowledge and products to fulfil your specification with a sustainability criteria.

CFA members are part of a supply chain that includes specialist contract flooring contractors, manufacturers and distributors, all of whom promote the highest standards and expertise.

Exclusive Ranges is pleased to share that the very first ER BESPOKE installation has been completed by ‘ABDA Design’.

Sitting pride-of-place in the development kitchen of one of the world’s biggest food manufacturing brands, this bespoke, stainless-steel island incorporates all of the elements required to adequately test, demonstrate and finish food products. This is made possible by integrating various elements such as a Menu System Multifunction/Multipan Induction Hob with two coils and cooking surfaces and GN2/1 Electric Oven. Completed with elements such as an integrated sink, double door cupboards, and a plush shopfitted counter with decorative fascia, this cooksuite is both visually impressive and practical.

Richard Steade, Managing

Director from ABDA Design, goes on to talk about the specific requirements that this blue-chip site had, and why ER Bespoke was the perfect fit:

“ABDA were appointed to design the new development kitchen in collaboration with lead interior designers, ‘We Are Incognito’. The space was designed as a stateof-the-art facility, equipped with high-end cooking equipment to support both functionality and innovation.

At the heart of the kitchen sits the ER BESPOKE demonstration station, a showcase feature designed to reflect the aesthetics of the surrounding interior and embody the brand’s ethos.

Created for use by both the inhouse development team and visiting guest chefs, the station needed to deliver exceptional

quality and performance whilst offering familiarity and ease of use for a broad range of industry professionals.

As a centrepiece for both in-person and live-streamed demonstrations, every element of the counter was carefully considered and immaculately finished.

We were extremely pleased with the final result: seamlessly finished welded joints, ergonomically integrated equipment, and a collaborative design process carried out with a high level of professionalism and clear communication with the Exclusive Ranges team.”

Trevor Burke, Managing Director of Exclusive Ranges, shares in Richard’s enthusiasm, saying:

“To see the first ER BESPOKE installation

completed, in a site as significant as this, a great milestone for Exclusive Ranges. For months, we’ve worked hard perfecting the ER BESPOKE offering so that customers can draw on the many benefits of a customised suite, without the ultra-premium price tag.”

Positioned to fill a clear gap between off-the-shelf ranges and ultra-premium suites, ER BESPOKE offers a range of venues an opportunity to specify a bespoke configuration - without premium cost barriers. Its comprehensive range of high-spec appliances includes induction hobs, SLIDE CONTROL power hobs, planchas, electric chargrills, pasta cookers, ovens, refrigeration, drop-in fryers, and more. Together, these appliances allow operators to benefit from a kitchen setup that fits their specific needs, layouts, and menus.

Manufactured to a high standard, each suite includes,

3mm stainless steel tops mounted on stainless steel plinths, double-skinned doors and panels for durability, front-access servicing for easier maintenance and integrated fabrication for seamless installation in modern kitchens, such as this.

Trevor finishes, by reflecting on their work with ABDA Design:

“We’d like to thank ABDA Design for their trust and confidence in ER Bespoke. Together, we’ve delivered a truly outstanding first ER Bespoke installation, and look forward to working closely together to complete further installations on the horizon.”

ABDA and Exclusive Ranges have been working closely together for many years but this is the first full project that they have collaborated on.

With over 25 years of expertise, Exclusive Ranges is a leading UK supplier of advanced kitchen equipment solutions, partnering with

brands like Menu System, Rosinox, Salvis, and Vianen. The company supports over 200 installed kitchens and 54 Michelin-starred restaurants across the country.

ABDA Design has been operating since November 1997, specialising in hospitality and F&B design. Their design team is formed of both interior and commercial kitchen designers meaning they are frequently involved in both front and back of house design. Having expertise in many sectors, including education, business & industry and retail & leisure working with clients such as IHG and Compass Group as well as boutique hotels and private members clubs.

For more information on the new ER BESPOKE range, or on Exclusive Ranges, please visit www.exclusiveranges.co.uk

For further information on ABDA Design, please visit www.abdadesign.co.uk