Northampton Saints RFC Maintenance Case Study

Project Overview:

Abacus Lighting is proud to support Northampton Saints Rugby Club with essential lighting maintenance at their home ground, the Cinch Stadium at Franklin’s Gardens. This project focused on ensuring the continued reliability and performance of both the pitch floodlighting system and the stadium roof-mounted luminaires.

The work was particularly time-sensitive and required close coordination with the club, as it took place during team training sessions in preparation for a major European Cup final. The lighting infrastructure at the stadium includes four GL620 40m base-hinged masts, each equipped with CH3 metal halide floodlights, and additional CH1 metal halide units fixed to the stadium roof structure.

Protect Your Investment With Abacus’s Scheduled Maintenance Plans:

Neglecting routine maintenance can have serious implications for the warranty of an LED lighting solution. Most manufacturers stipulate in their warranty terms that proper installation and ongoing maintenance are required conditions for coverage. If a failure occurs due to issues that would have been identified during a scheduled maintenance checksuch as dirt build-up causing overheating, loose connections, or water ingress - warranty claims may be denied.

This could result in costly repairs or replacements that would otherwise have been covered. Therefore, maintaining a documented schedule of inspections and servicing not only extends the life and efficiency of the lighting system but also protects the investment by ensuring continued warranty support.

Maintenance of GL620 High Masts:

The Abacus team began by lowering each of the GL620 masts, using our signature base-hinged mechanism, which allows safe and efficient ground-level access to the floodlights.

Key maintenance activities included:

• Replacing failed lamps in the CH3 floodlight units

• Testing all electrical connections

• Mechanical inspections of each fitting and support structure

• Full mast condition assessment to ensure safe re-raising

• Completing any necessary repairs before each mast was returned to its upright position

After maintenance, the stadium floodlights were left on for an extended period to ensure all CH3 units were operating at full performance.

Abacus Lighting LED Upgrades:

This case study features data sheets for the Challenger 1 and Challenger 3 LED upgrades using advanced LED technology. These upgrades reduce energy costs, provide instant lighting, and require minimal maintenance. They also have a longer lifespan than traditional metal halide lights. Contact Abacus for more information on our LED upgrades.

The Northampton Saints RFC Case Study Video!

Northampton Saints RFC Maintenance Case Study

Stadium Roof-Mounted Lighting Maintenance:

To service the CH1 metal halide units on the stadium roof, the team utilised a Mobile Elevating Work Platform (MEWP) to safely access each luminaire.

Every CH1 unit underwent a thorough electrical and mechanical inspection, including:

• Accessing the Stadium lights via a (Mobile Elevating Work Platform) MEWP

• Checking terminal and lamp compartments individually

• Testing and fault-finding

• Performing on-the-spot repairs to restore performance

Challenges and Coordination:

One of the key challenges of this project was working at height with heavy lighting equipment, while ensuring minimal disruption to team activities. The Abacus Maintenance Team worked closely with Northampton Saints’ ground staff to coordinate timings so that critical maintenance could proceed without interfering with the team’s training on the pitch.

Project Conclusion:

All four GL620 masts and stadium roof lights were fully inspected, serviced, and restored to optimal working condition. This proactive maintenance ensured the Saints’ floodlighting was reliable and performanceready for evening matches and high-profile events.

Abacus Lighting’s commitment to safe, efficient, and high-quality lighting maintenance, especially in operational environments, makes us the trusted choice for sports facilities around the world.

Whether for routine servicing or urgent repairs, our team brings the technical expertise and coordination required to keep lighting infrastructure running brilliantly.

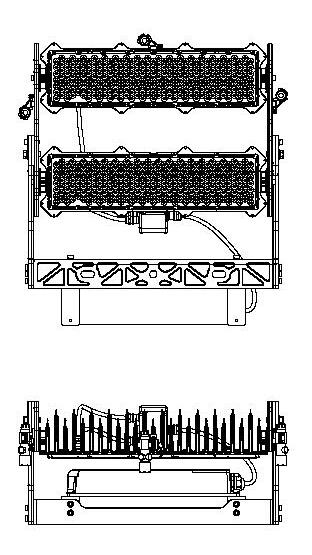

Specifications & Key Features:

Housing:

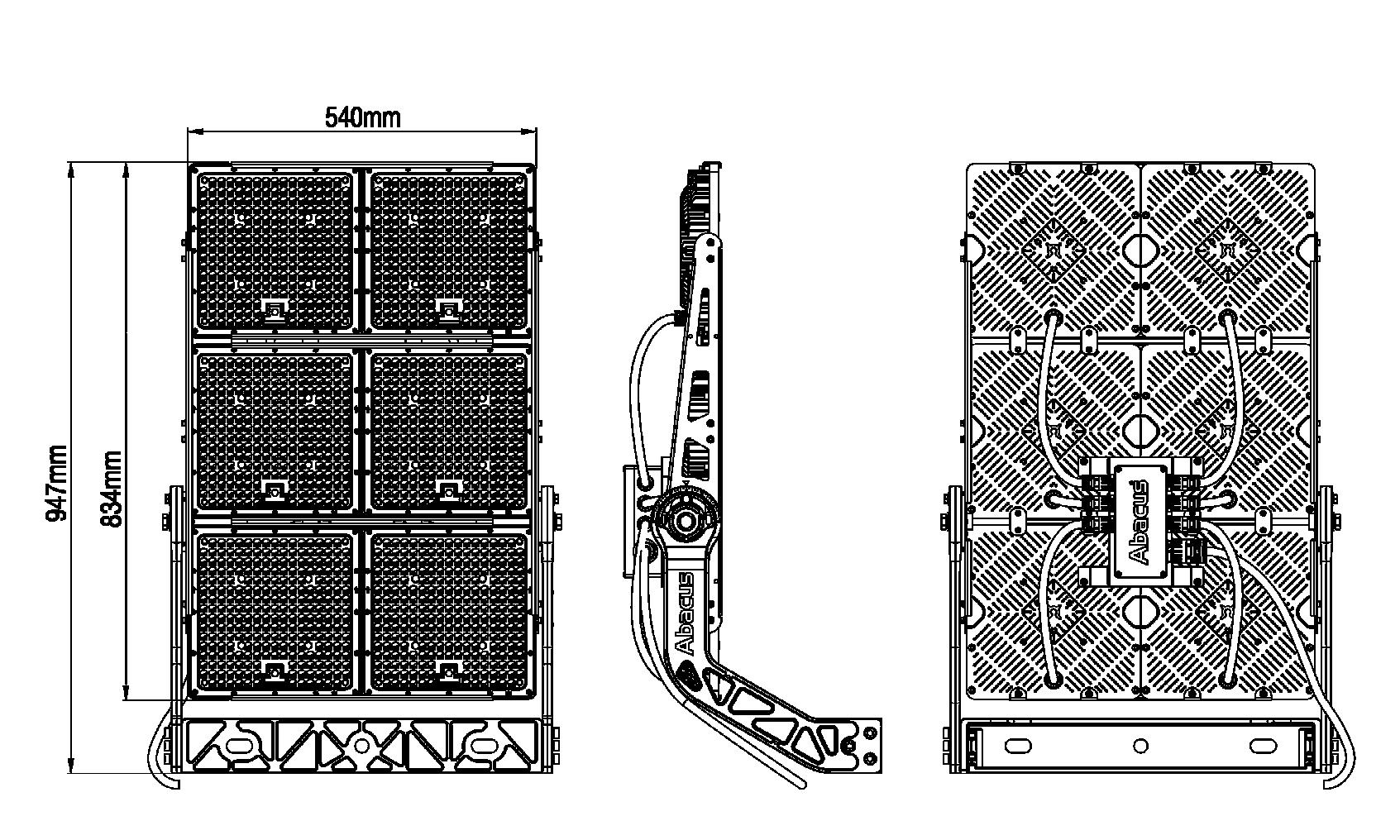

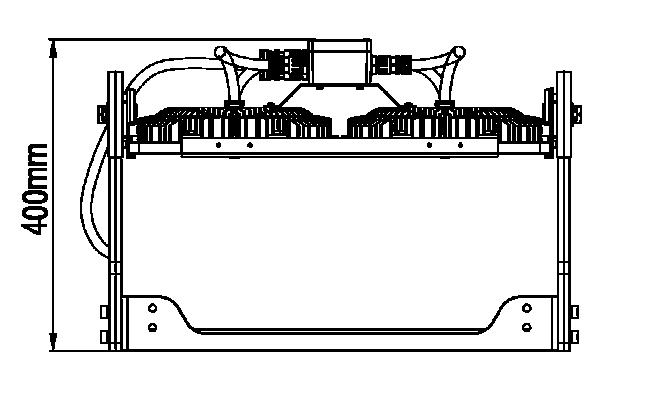

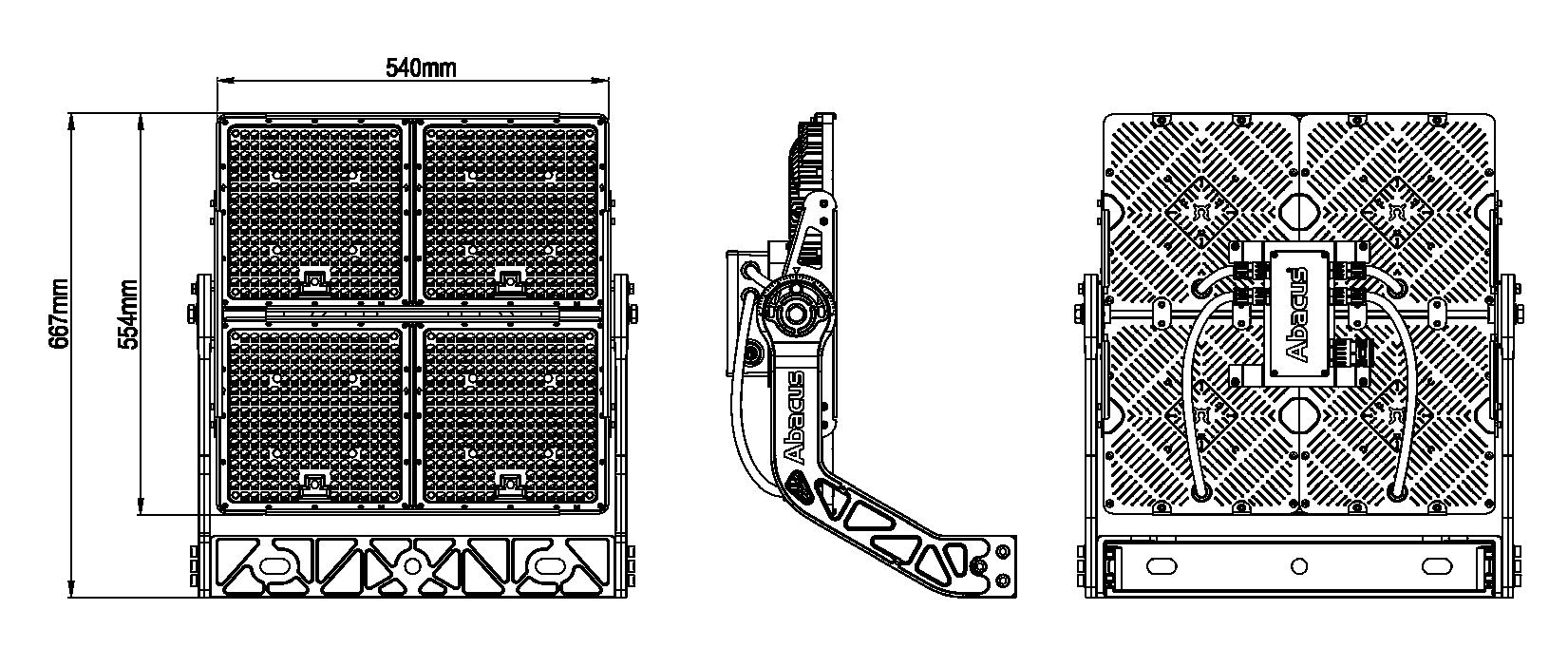

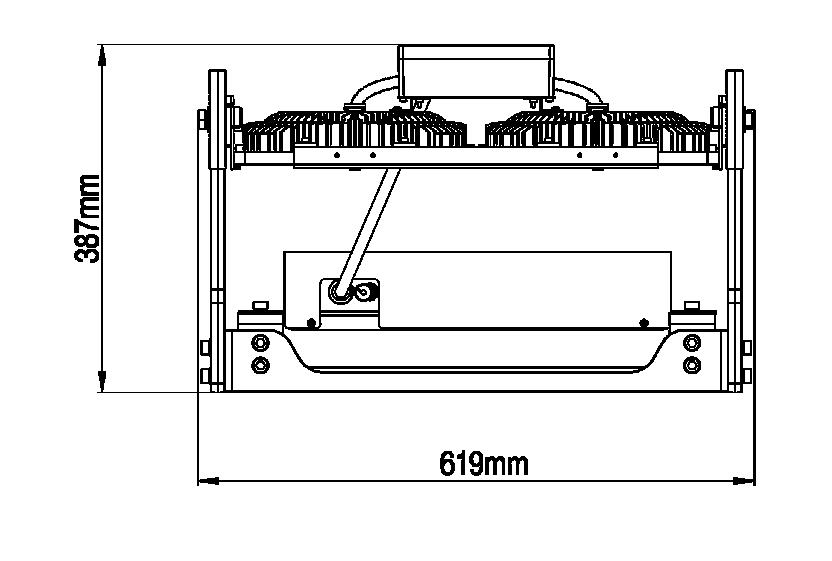

Challenger 1 LED AL6100 - AL6300 Series

Die-cast/profiled aluminium and steel are used to produce an elegant and unobtrusive low profile design.

Certifications:

UKCA, CE, CB, SAA

Finish:

Powder coated Black/Red

Driver:

• 400 to 1500W 3ch. DALI2/DMX driver

• Integral or remote operation

• IP66 rated

Warranty & Lifetime:

5 years standard warranty

60,000 hours L80B10 25°C

Wind Area (0° elevation):

6 module: 0.149m2

4 module: 0.130m2

2 module: 0.107m2

Product Applications:

Rail Depots

Sea Ports

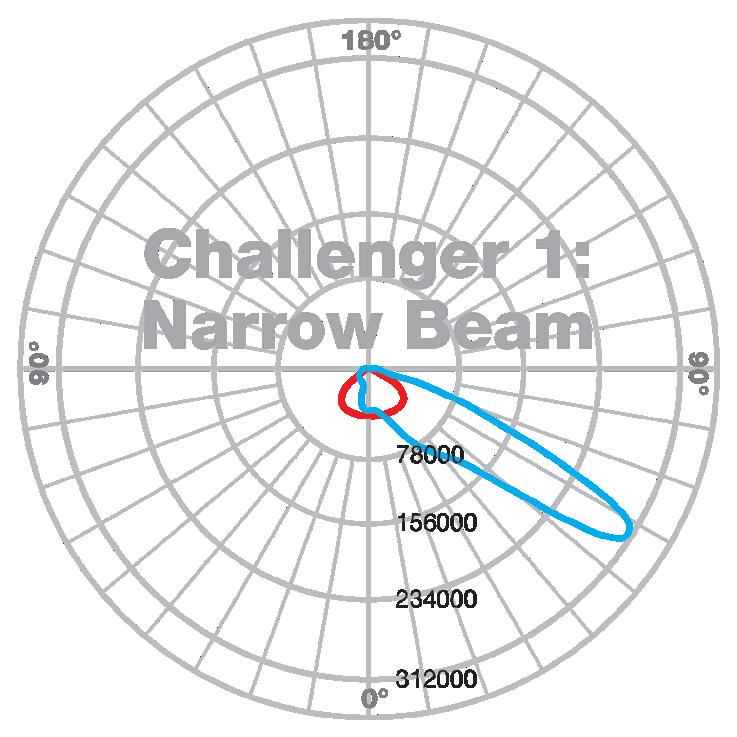

Challenger 1 Product Overview:

The Challenger 1 LED by Abacus Lighting is a cutting-edge floodlight that combines exceptional performance with a sleek, modern design and low cost of ownership. Featuring a flat glass, double asymmetric design, it provides precise and efficient illumination while minimising light spill. Available in 2, 4, and 6 module variants ranging from 400W to 1500W, the Challenger 1 LED is a versatile solution suitable for a wide range of applications. Whether used for sports facilities, industrial sites, large open spaces, or area lighting, it delivers powerful and reliable illumination tailored to specific project needs.

Built for durability, the Challenger 1 LED is IP66 rated, ensuring protection against dust and water ingress, making it a robust choice for even the harshest environments. With Abacus-designed medium and narrow beam optics, it provides excellent coverage and efficiency, enhancing visibility and safety.

The floodlight offers integral or remote driver options, allowing for flexible installation. Finished in a durable powder coating, it not only performs exceptionally but also maintains a professional modern aesthetic. Whether lighting up sports venues, industrial complexes or large public spaces, the Challenger 1 LED sets the standard for highperformance floodlighting.

Challenger 1 LED AL6100 - AL6300 Series

Specifications & Key Features

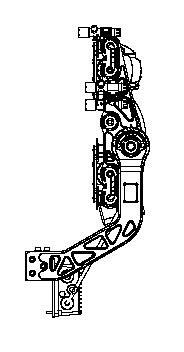

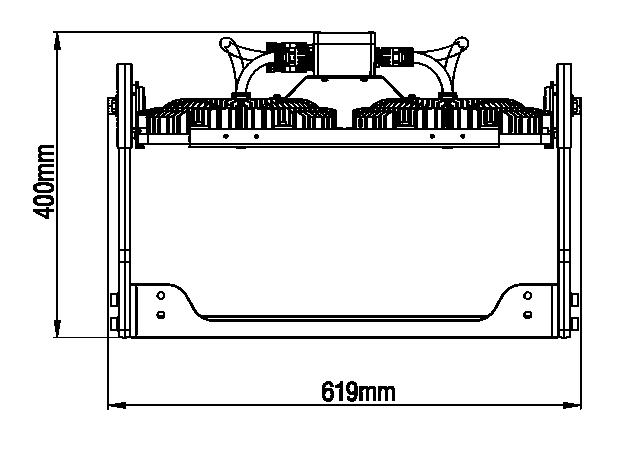

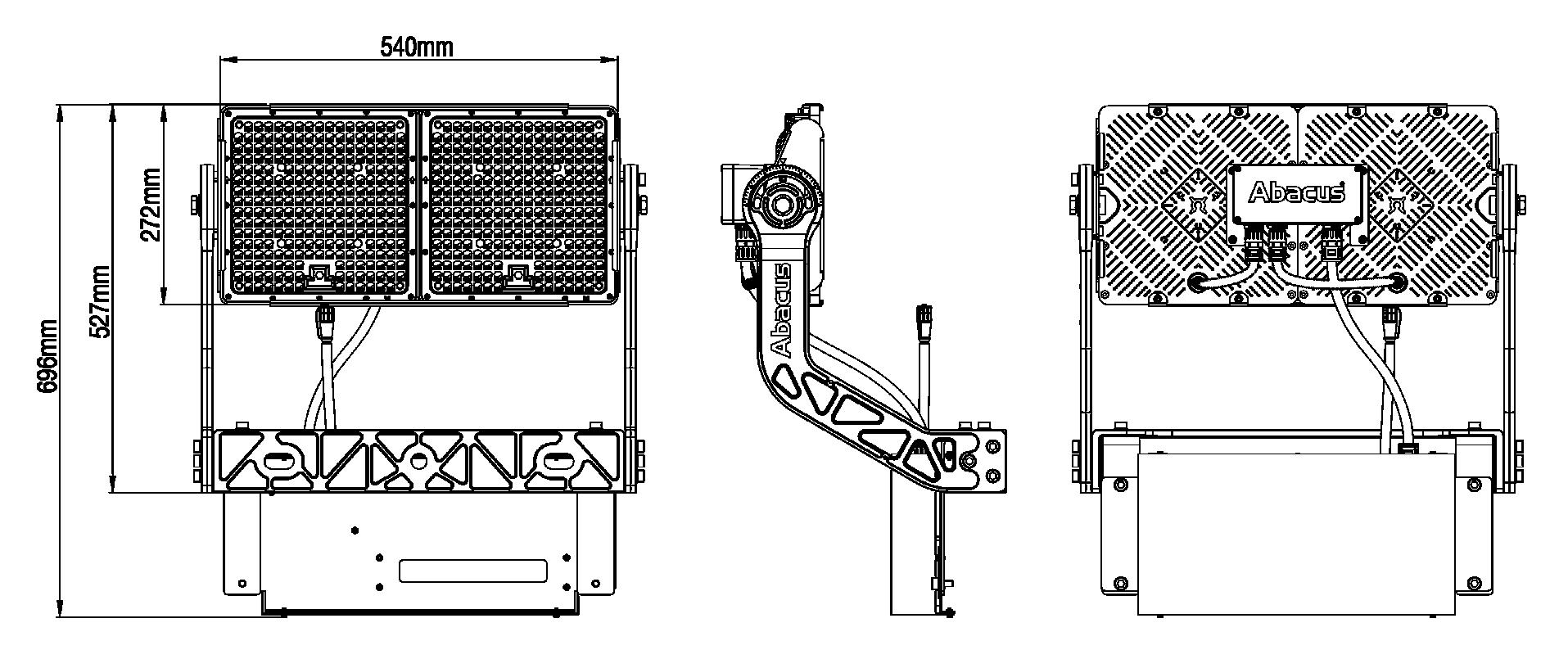

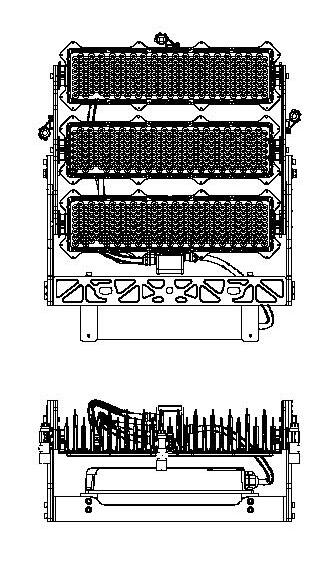

Challenger 3 LED AL7100 Series

• Advanced design reduces light pollution and improves spectator viewing

• Precise optical control designed specifically for sport

• Robust for all environments with an IP66 and IK10 rating

• Lens and lumen packages available in a versatile design for multiple applications

• Dali and DMX options

• Full cut off low spill design for control of light

Product Applications

• Sport

• Open Areas

The Challenger 3 LED by Abacus Lighting is a high-performance floodlight designed for sports fields, arenas, and large outdoor spaces. Engineered with advanced optics and LED technology, it delivers exceptional illumination while minimising light pollution, ensuring optimal viewing conditions for players and spectators. Its modular design not only allows for straightforward installation but also simplifies maintenance, making it a preferred choice for high mast lighting solutions and stadiums worldwide.

Built to withstand the harshest environments, the Challenger 3 LED boasts an IP66 and IK10 rating. With precise optical control tailored specifically for sports applications, it offers full cut-off and low spill lighting, reducing glare and unwanted light spill. The floodlight’s versatile lens and lumen packages cater to various requirements, while DALI and DMX options provide advanced control capabilities. Whether illuminating a football pitch, a racetrack, or a multi-use sports facility, the Challenger 3 LED delivers powerful, efficient, and reliable lighting for any large-scale setting.

Product Overview

Challenger 3 LED AL7100 Series

Challenger 1 LED - Product Code Selector

Lumen output up to 162,865 up to

up to

LED Chips numbers 224 pcs 120 pcs 288pcs

Light Efficiency Up to 159lm/W

Beam Angle+ 17°, 25°, 50°

Colour Temperature 4000 - 6000K (5700 standard)

Colour Rendering Index (CRI) ≥70 (≥90 optional)

Colour Heat sink: RAL 9017, Bracket: RAL 9017 & Abacus red

IP Rating IP66

IK Rating IK10

Operating Temperature Range -40° - +50° (module)

Optional accessories Front glass, shields, aiming device

Input Voltage

AC 200-440V @50/60hz (Single or 3 phase L1/L2/PE)

Input Voltage - US Option AC 208-480V @50/60hz (Single or 3 phase L1/L2/PE)

*Non-standard options may be subject to MOQs or longer lead times.