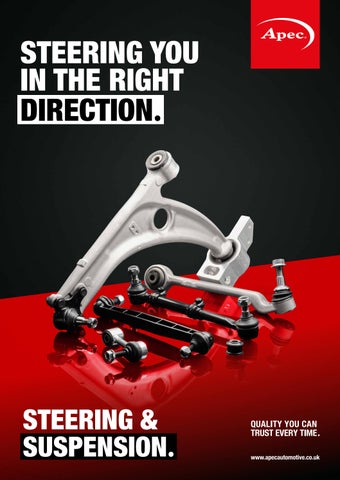

STEERING YOU IN THE RIGHT DIRECTION.

Our range of steering and suspension products are an extension of what we do best. Quality, dependability, and performance come together for a selection of OE-matching parts designed to carry your car to new heights of handling –another reason to choose Apec.

All production is carried out at our industry-leading, computer-controlled manufacturing facility. We guarantee that all our products are designed, tested and manufactured to Apec standards, giving peace of mind for these safety critical products.

.

In addition to cataphoresis coating and testing, Apec Steering and Suspension parts are evaluated using the following methods:

• 1,000,000 Life Cycle Testing

• Fatigue and Wear Testing

• Rotational Torque Testing

• Grease and Lubrication Testing

• 3 Axis and 4 Axis Testing

• Push & Pull-Out Testing

• Dynamic Testing

All Apec Steering and Suspension parts are tested against peak performance parameters and exposed parts are cataphoresis coated and tested to extreme temperatures to assess durability in the harshest road and weather conditions.

Processes involved in manufacturing include:

• Steel Forging

• CNC Machining

• Sheet Metal Stamping

• Cataphoresis Coating

• Robotic Welding

ANTI-CORROSION GUARANTEE.

With an added 900 hours of salt spray testing, we instil each finished part with a 10 year anti-corrosion guarantee.

At Apec we are constantly striving to improve the product & service available to our valued customers, that work never stops.