TRAINING PATHWAYS

THE PRO’S CHOICE FOR GARAGE EQUIPMENT & TRAINING

@WORKSHOPPRO

THE PRO’S CHOICE FOR GARAGE EQUIPMENT & TRAINING

@WORKSHOPPRO

IMI PROFESSIONAL DEVELOPMENT PROGRAMME 4-5

THE PROFESSIONAL SERVICE ADVISOR 6-7

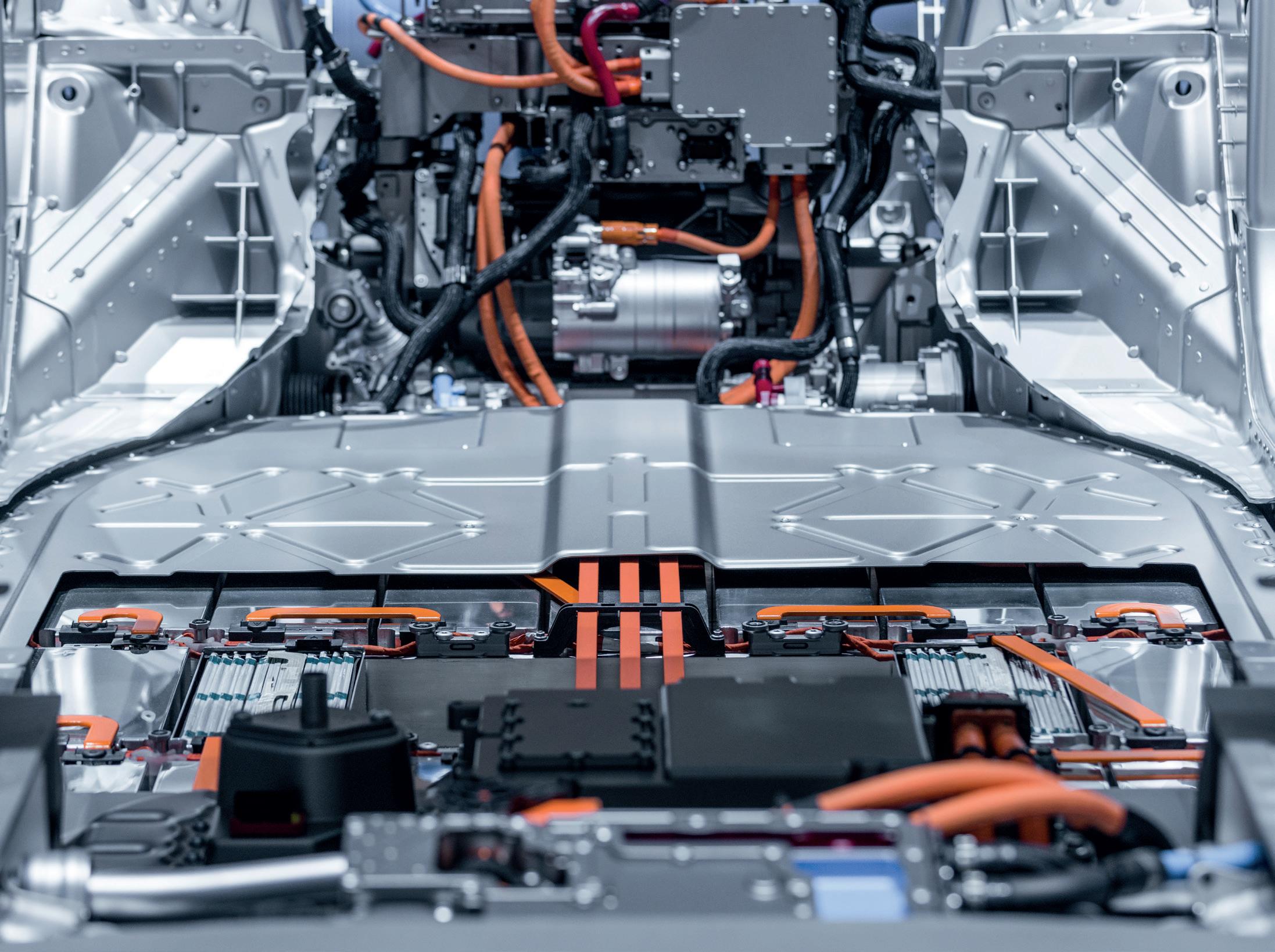

THE PROFESSIONAL EV TECHNICIAN 8-9

THE EXPERT DIAGNOSTIC TECHNICIAN 10-11

THE EXPERT CV DIAGNOSTIC TECHNICIAN 12-13

WORKSHOP PRO ACADEMY 14-15

• Present key financial terms and business goals

Measure business performance

• Explain Key Performance Indicators (KPI’s)

• Break down costs, Gross Profit (GP), and Net Profit (NP)

• Control costs effectively

Review part purchasing and return strategies

• Improve labour and parts efficiency

• Calculate labour and recovery rates

• Clarify profit margin vs. mark-up and risks

• Map the customer journey

Review core business processes

• Highlight the importance of diary management and parts ordering

• Cover technical data and GDPR essentials

• Explain risks of customer-supplied parts and trade MOT’s

• Introduce methods to maximise workshop loading

• Legal and regulatory requirements

• Analyse staff skills and training needs Plan for future skill growth

• Emphasise clear work instructions for teams

• Compare staff development vs. external hiring

• Outline the career path from apprentice to MOT tester

• Adopt Search Engine Optimisation (SEO) Build a positive company image

• Refresh the online customer experience

• Promote business goals and developments

• Show effective use of social media Prepare for new and emerging technologies

Introduction to vehicle layouts and core systems (engines, transmission, steering, suspension, braking, electrics, hybrid/electric)

Understand maintenance requirements and service intervals

• Explore common system issues and causes

• Present effective diagnostic questioning techniques

• Map the customer journey

• Ensure excellent service

Explore effective communication skills

• Highlight the importance of diary management and parts ordering

• Present product upselling strategies

• Show methods for handling conflict and difficult conversations

Present workshop processes that maximise potential

• Identify skill strengths and gaps

• Plan for future skill requirements to support growth

• Emphasise clear communication

Explain key aspects of workshop compliance

• Explore the fundamentals of Advanced Driver Assistance Systems (ADAS)

• Present safe working practices around electric and hybrid vehicles

• Highlight dangers and precautions to prevent injury

IMI Level 2 Award

IMI Level 3 Award

IMI Level 4 Award

NTDA Licensing

Techsafe Registration*

EV2.2:

• Work safely on electric and hybrid vehicles

• Use technical information to complete tasks

• Carry out repairs on high-energy electrical systems

• Record information and provide clear recommendations

EV3:

• Safe practices with electric and hybrid vehicles

Use technical information to complete tasks

• Carry out repairs on high-energy electrical systems

• Record information and provide suitable recommendations

• Present the basics of vehicle electrics

• Introduce computer-based test equipment Assess the serviceability of vehicle systems

• Inspect and test high-voltage EV systems

• Carry out EV inspection, best practice and service routines

Present the types of electric and hybrid vehicles

• Identify hazards in high-energy electrical systems

• Safe practices around EVs, including charging procedures

• Explain EV-specific tyre requirements Apply tyre repair standard BSAU159g

• Demonstrate best practice for jacking EVs

• Introduce safe working practices for fleet checking

• Provide the knowledge of dangers when repairing live high-voltage components

• Provide skills and awareness to carry out repairs safely Emphasise the importance of compliance and correct safety precautions

Identify hazards in EV high-voltage systems

• Outline HSE responsibilities in line with regulations

• Diagnose diagnostic trouble codes (DTC’s)

• Investigate low-voltage faults effectively Interpret wiring diagrams with accuracy

IMI Level 2 Award

IMI Level 3 Award

Autotech Training Workshop Pro Accreditation Face to Face

• Explore the different types of electricity

Show how electricity behaves in various circuits

• Demonstrate how to follow basic wiring diagrams

• Test electrical circuits using a multimeter

• Explain series circuits and parallel circuits

Clarify voltage (V), amperage (a), resistance (R), and power (P)

Safe practices for live circuit testing

EV2.2:

• Work safely on electric and hybrid vehicles

• Use technical information to complete tasks

• Carry out repairs on high-energy electrical systems

• Record information and provide clear recommendations

EV3:

• Safe practices with electric and hybrid vehicles

• Use technical information to complete tasks

• Carry out repairs on high-energy electrical systems

• Record information and provide suitable recommendations

Apply diagnostic processes across various vehicle systems

• Explain crystallisation and its effects

• Show regeneration processes and common issues

• Identify blocked filters and their causes.

• Demonstrate sensor operation and testing

• Introduce diagnostic equipment and data reading

• Provide an overview of service procedures and regeneration

• Demonstrate accurate testing of NOx, heat, and pressure sensors, plus communication lines

• Perform pressure testing and compare live data effectively

Build a strong diagnostic mindset

• Present strategies for overcoming self-doubt

• Follow a structured diagnostic process

• Gather evidence to support conclusions

Apply the input, process, and output method

• Use a flow diagram approach for clarity

• Apply process of elimination techniques

• Explore the back-to-front diagnostic technique

Apply the end-split technique for complex issues

• Emphasise the principle of “no substitution for substitution”

• Identify and test components

• Fault finding through use of equipment and guided diagnosis

• Demonstrate live testing to support fault diagnosis

• Introduction to fuel injectors

• Introduction to ECU’s and common faults

IMI Level 2 Award

IMI Level 3 Award

NTDA License

Autotech Training Workshop Pro Accreditation

• Explore the different types of electricity

Show how electricity behaves in various circuits

• Demonstrate how to follow basic wiring diagrams

• Test electrical circuits using a multimeter

• Explain series circuits and parallel circuits

Clarify voltage (V), amperage (a), resistance (R), and power (P)

Safe practices for live circuit testing

• Apply diagnostic processes across various vehicle systems

• Explain crystallisation and its effects

• Show regeneration processes and common issues

• Identify blocked filters and their causes.

• Demonstrate sensor operation and testing

• Introduce diagnostic equipment and data reading

• Provide an overview of service procedures and regeneration

• Demonstrate accurate testing of NOx, heat, and pressure sensors, plus communication lines

• Perform pressure testing and compare live data effectively

• Build a strong diagnostic mindset

• Present strategies for overcoming self-doubt

• Follow a structured diagnostic process

• Gather evidence to support conclusions

• Apply the input, process, and output method

• Use a flow diagram approach for clarity

• Apply process of elimination techniques

• Explore the back-to-front diagnostic technique

• Apply the end-split technique for complex issues

• Emphasise the principle of “no substitution for substitution”

• Identify and test components

• Fault finding through use of equipment and guided diagnosis

• Demonstrate live testing to support fault diagnosis

• Introduction to fuel injectors

• Introduction to ECU’s and common faults

HEV2 – Prepare Heavy Electric/Hybrid Vehicles for Repair

Explain system components and their operation

• Identify hazards when working with heavy EV/HEV systems

• Reduce risks for self and others

• Show how to make high-energy systems safe before repairs

• How to reinstate systems after repairs

Apply safe practices to isolate and reinstate high-voltage systems

HEV3 – Heavy Electric/Hybrid Vehicle System Repair and Replacement

• Remove and replace high-energy electrical components

• Demonstrate safe working practices on heavy EV/HEV systems

• Use technical information to guide repairs

• Apply correct tools and equipment

Record findings clearly and make suitable recommendations

• Carry out daily vehicle and equipment checks

• Apply pre-breakdown planning methods

• Approach breakdowns safely and effectively

• Follow essential health and safety precautions

• Apply correct motorway and non-motorway procedures

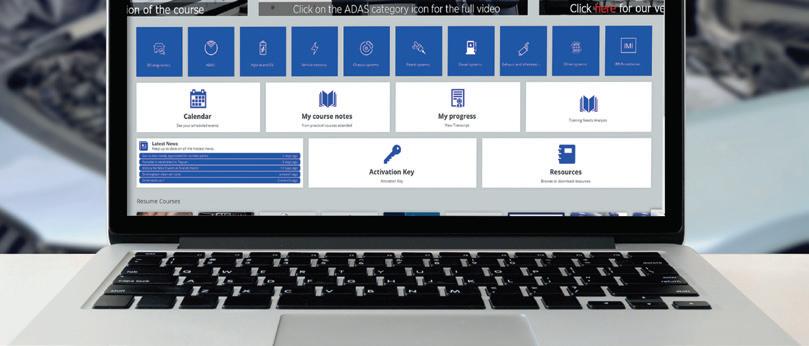

• E-LEARNING PORTAL

• EXPERT LED COURSES

• TRAINING NEEDS ANALYSIS

• RANGE OF SKILL LEVEL COURSES

• INTERACTIVE ENGINE SIMULATION BITESIZE MODULES 300+

For enquiries, email sales@workshop-pro.co.uk or visit www.workshop-pro.co.uk/training/