TRAINING PATHWAYS

IMI PROFESSIONAL DEVELOPMENT PROGRAMME

THE PROFESSIONAL SERVICE ADVISOR

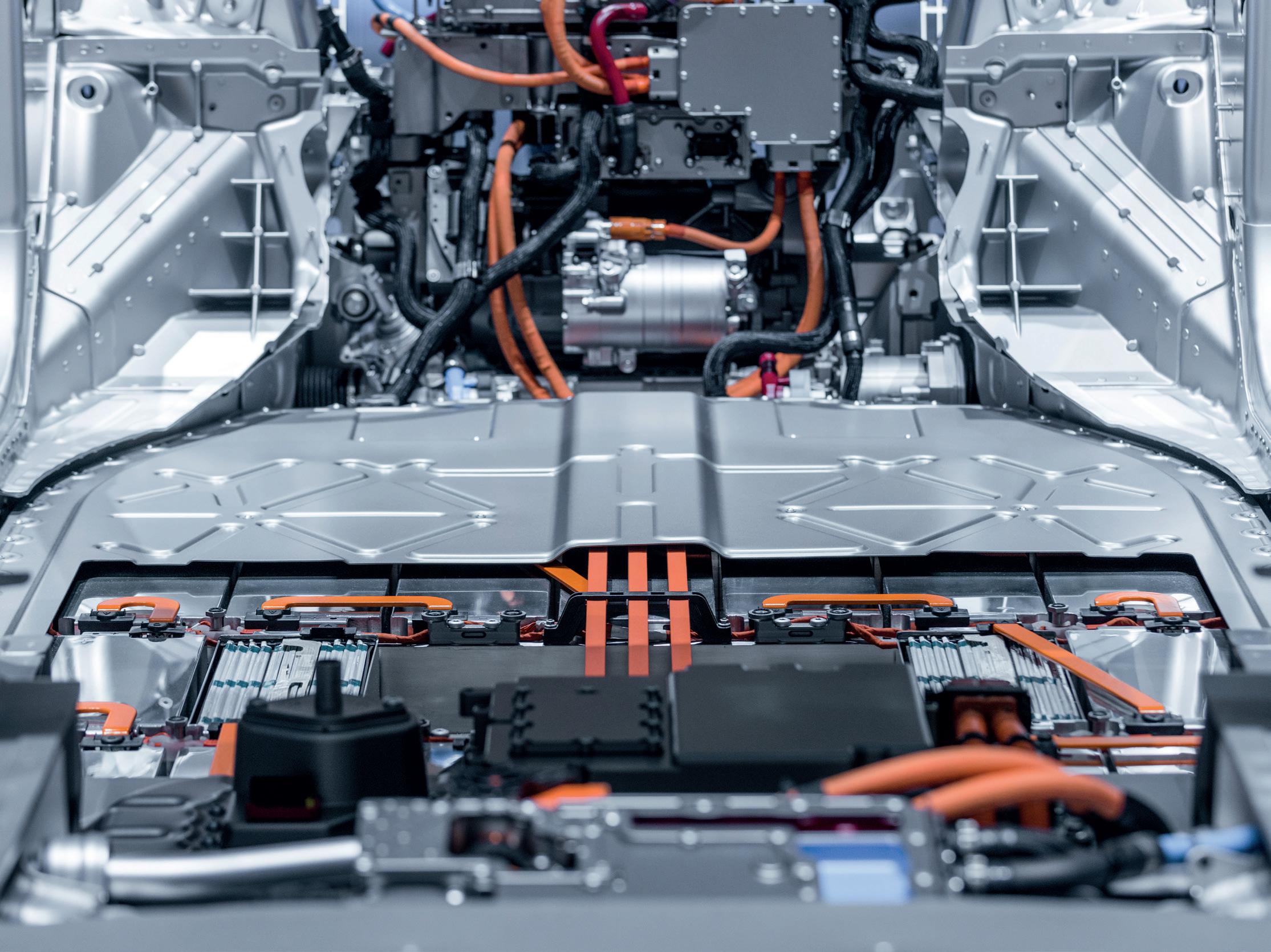

THE PROFESSIONAL EV TECHNICIAN

PROFESSIONAL EV TECHNICIAN PATHWAY

THE EXPERT DIAGNOSTIC TECHNICIAN PATHWAY

THE EXPERT DIAGNOSTIC TECHNICIAN

THE EXPERT CV DIAGNOSTIC TECHNICIAN PATHWAY

THE EXPERT CV DIAGNOSTIC TECHNICIAN

WORKSHOP PRO ACADEMY

• IMI Professional Register Certification

• 1 Year IMI Member Level Membership*

• Present key financial terms and business goals

• Measure business performance

• Explain Key Performance Indicators (KPI’s)

• Break down costs, Gross Profit (GP), and Net Profit (NP)

• Control costs effectively

• Review part purchasing and return strategies

• Improve labour and parts efficiency

• Calculate labour and recovery rates

• Clarify profit margin vs. mark-up and risks

• Map the customer journey

• Review core business processes

• Highlight the importance of diary management and parts ordering

• Cover technical data and GDPR essentials

• Explain risks of customer-supplied parts and trade MOT’s

• Introduce methods to maximise workshop loading

• Legal and regulatory requirements

• Analyse staff skills and training needs

• Plan for future skill growth

• Emphasise clear work instructions for teams

• Compare staff development vs external hiring

• Outline the career path from apprentice to MOT tester

• Adopt Search Engine Optimisation (SEO)

• Build a positive company image

• Refresh the online customer experience

• Promote business goals and developments

• Show effective use of social media

• Prepare for new and emerging technologies

• IMI Level 1

• Autotech Training

• Workshop Pro Accreditation

• Introduction to vehicle layouts and core systems (engines, transmission, steering, suspension, braking, electrics, hybrid/electric)

• Understand maintenance requirements and service intervals

• Explore common system issues and causes

• Present effective diagnostic questioning techniques

• Map the customer journey

• Ensure excellent service

• Explore effective communication skills

• Highlight the importance of diary management and parts ordering

• Present product upselling strategies

• Show methods for handling conflict and difficult conversations

MODULE 3

• Present workshop processes that maximise potential

• Identify skill strengths and gaps

• Plan for future skill requirements to support growth

• Emphasise clear communication

• Explain key aspects of workshop compliance

MODULE 4

• Explore the fundamentals of Advanced Driver Assistance Systems (ADAS)

• Present safe working practices around electric and hybrid vehicles

• Highlight dangers and precautions to prevent injury

• IMI Level 2 Award

• IMI Level 3 Award

• IMI Level 4 Award

• NTDA Licensing

• Techsafe Registration* Face to Face Online Exam Practical Assessment

9 Days

1

E V2 2:

• Work safely on electric and hybrid vehicles

• Use technical information to complete tasks

• Carry out repairs on high-energy electrical systems

• Record information and provide clear recommendations EV3:

• Safe practices with electric and hybrid vehicles

• Use technical information to complete tasks

• Carry out repairs on high-energy electrical systems

• Record information and provide suitable recommendations

• Present the basics of vehicle electrics

• Introduce computer-based test equipment

• Assess the serviceability of vehicle systems

• Inspect and test high-voltage EV systems

• Carry out EV inspection, best practice and service routines

• Present the types of electric and hybrid vehicles

• Identify hazards in high-energy electrical systems

• Safe practices around EVs, including charging procedures

• Explain EV-specific tyre requirements

• Apply tyre repair standard BSAU159g

• Demonstrate best practice for jacking EVs

• Introduce safe working practices for fleet checking

4

• Provide the knowledge of dangers when repairing live high-voltage components

• Provide skills and awareness to carry out repairs safely

• Emphasise the importance of compliance and correct safety precautions

• Identify hazards in EV high-voltage systems

• Outline HSE responsibilities in line with regulations

• Diagnose diagnostic trouble codes (DTC’s)

• Investigate low-voltage faults effectively

• Interpret wiring diagrams with accuracy

• IMI Level 2 Award

• IMI Level 3 Award

• Autotech Training

•

1

• Explore the different types of electricity

• Show how electricity behaves in various circuits

• Demonstrate how to follow basic wiring diagrams

• Test electrical circuits using a multimeter

• Explain series circuits and parallel circuits

• Clarify voltage (V), amperage (a), resistance (R), and power (P)

• Safe practices for live circuit testing

2

IMI LEVEL 3 AWARD IN ELECTRIC/ HYBRID VEHICLE MAINTENANCE, SYSTEM REPAIR & REPLACEMENT

E V2.2:

• Work safely on electric and hybrid vehicles

• Use technical information to complete tasks

• Carry out repairs on high-energy electrical systems

• Record information and provide clear recommendations

E V3:

• Safe practices with electric and hybrid vehicles

• Use technical information to complete tasks

• Carry out repairs on high-energy electrical systems

• Record information and provide suitable recommendations

3

• Apply diagnostic processes across various vehicle systems

• Explain crystallisation and its effects

• Show regeneration processes and common issues

• Identify blocked filters and their causes.

• Demonstrate sensor operation and testing

• Introduce diagnostic equipment and data reading

• Provide an overview of service procedures and regeneration

• Demonstrate accurate testing of NOx, heat, and pressure sensors, plus communication lines

• Perform pressure testing and compare live data effectively

4

• Build a strong diagnostic mindset

• Present strategies for overcoming self-doubt

• Follow a structured diagnostic process

• Gather evidence to support conclusions

• Apply the input, process, and output method

• Use a flow diagram approach for clarity

• Apply process of elimination techniques

• Explore the back-to-front diagnostic technique

• Apply the end-split technique for complex issues

• Emphasise the principle of “no substitution for substitution”

5

• Identify and test components

• Fault finding through use of equipment and guided diagnosis

• Demonstrate live testing to support fault diagnosis

• Introduction to fuel injectors

• Introduction to ECU’s and common faults

• IMI Level 2 Award

• IMI Level 3 Award

• NTDA License

• Autotech Training

• Workshop Pro Accreditation

to Face

• Explore the different types of electricity

• Show how electricity behaves in various circuits

• Demonstrate how to follow basic wiring diagrams

• Test electrical circuits using a multimeter

• Explain series circuits and parallel circuits

• Clarify voltage (V), amperage (a), resistance (R), and power (P)

• Safe practices for live circuit testing

• Apply diagnostic processes across various vehicle systems

• Explain crystallisation and its effects

• Show regeneration processes and common issues

• Identify blocked filters and their causes.

• Demonstrate sensor operation and testing

• Introduce diagnostic equipment and data reading

• Provide an overview of service procedures and regeneration

• Demonstrate accurate testing of NOx, heat, and pressure sensors, plus communication lines

• Perform pressure testing and compare live data effectively

• Build a strong diagnostic mindset

• Present strategies for overcoming self-doubt

• Follow a structured diagnostic process

• Gather evidence to support conclusions

• Apply the input, process, and output method

• Use a flow diagram approach for clarity

• Apply process of elimination techniques

• Explore the back-to-front diagnostic technique

• Apply the end-split technique for complex issues

• Emphasise the principle of “no substitution for substitution”

• Identify and test components

• Fault finding through use of equipment and guided diagnosis

• Demonstrate live testing to support fault diagnosis

• Introduction to fuel injectors

• Introduction to ECU’s and common faults

HE V2 – Prepare Heavy Electric/Hybrid Vehicles for Repair

• Explain system components and their operation

• Identify hazards when working with heavy EV/HEV systems

• Reduce risks for self and others

• Show how to make high-energy systems safe before repairs

• How to reinstate systems after repairs

• Apply safe practices to isolate and reinstate high-voltage systems

HE V3 – Heavy Electric/Hybrid Vehicle System Repair and Replacement

• Remove and replace high-energy electrical components

• Demonstrate safe working practices on heavy EV/ HEV systems

• Use technical information to guide repairs

• Apply correct tools and equipment

• Record findings clearly and make suitable recommendations

• Carry out daily vehicle and equipment checks

• Apply pre-breakdown planning methods

• Approach breakdowns safely and effectively

• Follow essential health and safety precautions

• Apply correct motorway and non-motorway procedures

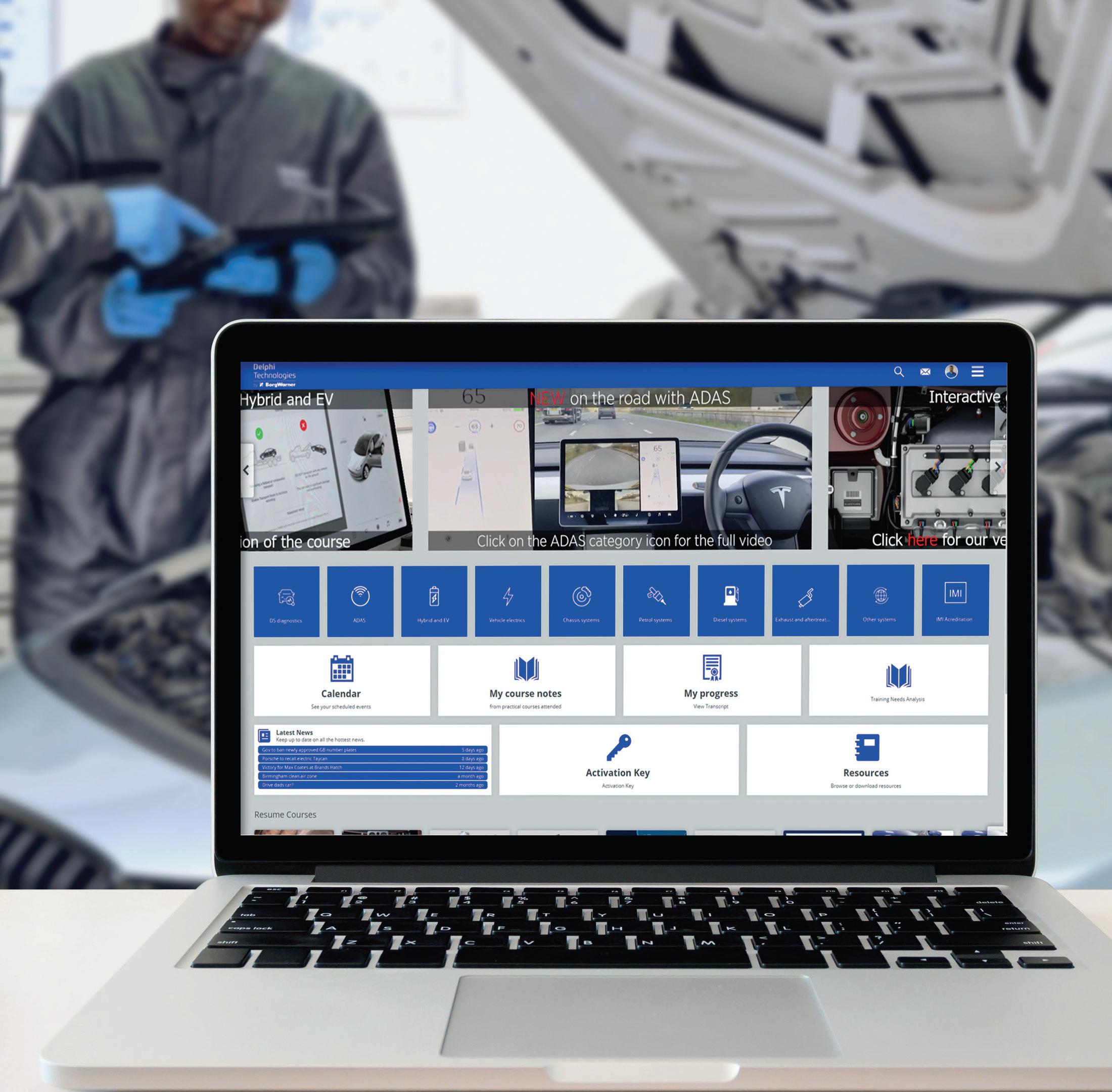

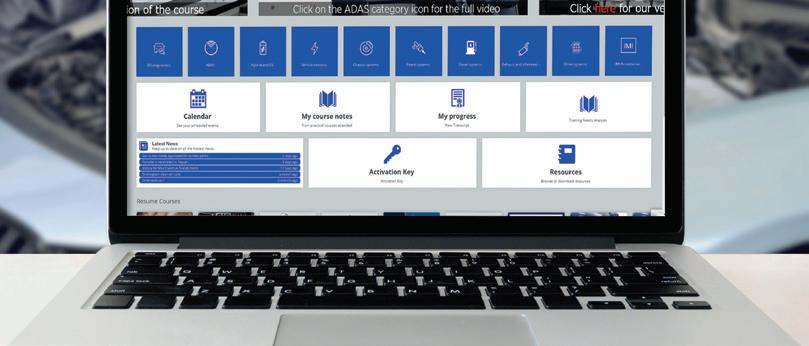

• E-LEARNING PORTAL

• EXPERT LED COURSES

• TRAINING NEEDS ANALYSIS

• RANGE OF SKILL LEVEL COURSES

• INTERACTIVE ENGINE SIMULATION BITESIZE MODULES 300+