AAPEX 2025

The Venetian Expo & Caesars Forum Las Vegas 4 – 6 November 2025 www.aapexshow.com

SEMA Show 2025

Las Vegas Convention Center 4 – 7 November 2025 www.semashow.com

Automechanika Shanghai

National Exhibition and Convention Center (Shanghai)

26 – 29 November 2025 www.automechanika.messefrankfurt.com

Automechanika Dubai

Dubai World Trade Centre 9 – 11 December 2025 www.automechanika.messefrankfurt.com

PRI Show 2025

Indianapolis, Indiana, USA 11 – 13 December 2025 www.performanceracing.com/tradeshow

Australian Auto Aftermarket Expo 2026

Melbourne Convention & Exhibition Centre 14 – 16 May 2026 www.autoaftermarketexpo.com.au

Collision Repair Expo 2026

Melbourne Convention & Exhibition Centre 14 – 16 May 2026 www.collisionrepair.com.au

Anthony’s Car & Head Centre

5 John Street BEGA NSW 2550

Ph: 02 6492 2442

E: ethan@anthonyscarandhead.com.au

Axle Co Mechanical

15 Howards Road BEVERLEY SA 5009

Ph: 0402 567 531

E: info@axlecomechanical.com.au

Bradleys Prestige

Factory 3 206 Governor Road BRAESIDE VIC 3195

Ph: 0412 225 894

E: nickjohnston08101993@icloud.com

Central Automatic Transmission Service

1A/3 Anderson Street BANKSMEADOW NSW 2019

Ph: 02 9662 1458 E: gr.centralauto@gmail.com

Emporium Australia Pty Ltd

Unit1, 7 St Jude Court BROWNS PLAINS QLD 4118 Ph: 07 3809 2711 E: sales@ssmech.com.au

Gallagher

2/74 Gheringhap Street GEELONG VIC 3220

Ph: 02 9021 7700 E: Dean.OHalloran@ajg.com.au

Global Clamps Pty Ltd

90 Latitude Boluevard THOMASTOWN VIC 3074

Ph: 03 9888 0175 E: p.davey@globalclamps.com.au

Gunning Service Centre

75 Yass Street GUNNING NSW 2581

Ph: 02 4845 1355 E: gunser@bigpond.com

Harry’s Tyres & More

7821 Goulburn Valley Highway KIALLA VIC 3631 Ph: 03 5832 6268 E: harrystyrecentre@gmail.com

IAA Australia

1/57 Burnside Road YATALA QLD 4207 Ph: 0483 039 282 E: elizabeth.owen@iaai.com

Inchcape Australia

Level 3, 58 Norwest Boulevard NORWEST NSW 2153 Ph: 0433 433 899 E: kate.gillis@inchcape.com.au

JBI Tyres

2/31 Munibung Road CARDIFF NSW 2285

Ph: 02 4044 5000 E: kam@brotyres.com.au

Mars Automotive College

5/200 Turner Street PORT MELBOURNE VIC 3207

Ph: 03 9645 2259 E: info@mars.edu.au

Midas Indooroopilly

Unit 9, 34 Coonan Street INDOOROOPILLY QLD 4068

Ph: 0403 162 834 E: 2025winston@gmail.com

Natrad Wagga Wagga

37 Pearson Street WAGGA WAGGA NSW 2650

Ph: 02 6925 4277 E: office@natradwagga.com.au

Pedders Suspension & Brakes Tamworth

25 Barnes Street TAMINDA NSW 2340

Ph: 02 6766 2774 E: tamworth@pedders.com.au

Repco Authorised Service Campbellfield (RR Automotive Campbellfield)

18 Sarah Street CAMPBELLFIELD VIC 3061

Ph: 03 9357 8389

E: rrautomotivecampbellfield@gmail.com

Repco Authorised Service Mickleham (RR Automotive Mickleham)

38 Distribution Drive MICKLEHAM VIC 3064

Ph: 03 93578389

E: rrautomotivemickleham@gmail.com

RoadMap Automotive Consulting

9/125 Main Drive MACLEOD VIC 3085

Ph: 0478 758 638 E: andy@roadmapconsulting. com.au

SPS Advanced Technology

29-31 Collins Street ALEXANDRIA NSW 2015

Ph: 0456 224 555 E: Info@spsadvancedtech.com.au

Sydney Diesel Centre Pty Ltd

126 Cumberland Highway SMITHFIELD NSW 2164

Ph: 02 9681 7700

E: garyc@sydneydieselcentre.com.au

Waverider Nominees Pty Ltd T/As

Walkers Diesel Services

142 Wongan Road Wongan Hills WA 6603

Ph: 0457 218 564 E: office@walkersdiesel.com

Westbury Automotive Pty Ltd

11 Fice Acre Row WESTBURY TAS 7303

Ph: 03 6393 1562 E: westburyautomotive@gmail.com

As we reflect on the past financial year, I am proud to share the story of another strong and impactful period for the Australian Automotive Aftermarket Association

At its heart, the AAAA is about more than regulations, events, and reports. It is about the collective strength of our members and the responsibility we carry to advocate, support, and lead. Reviewing our performance, I have seen that responsibility fulfilled with passion and purpose across every area of our work.

Our advocacy program remains the cornerstone of what we do. Some challenges come suddenly – requiring a strong and immediate response –while others demand persistence and strategy. We strongly opposed NSW’s flawed EV repair licensing proposal, which threatened to undermine consumer choice and workshop viability. Our pressure led to the Minister pausing implementation of the regulation and instructing his department to undertake further consultation with industry.

We secured the inclusion of automotive repairers on the federal immigration priority skills list, lobbied for a review of the Motor Vehicle Information Sharing Scheme, pressed for an update of Vehicle Standards Bulletin 14, advocated against unfair US tariffs on Australian automotive parts, responded to the National Vehicle Emissions Standards consultation, pressed for action on the QLD roadworthy scheme, and led the push for mandatory data sharing in New Zealand.

On behalf of our members, I appeared before state and federal parliamentary hearings to provide expert testimony on the EV transition – ensuring the independent aftermarket has a seat at the table as governments shape the future of mobility. From an event perspective, Autocare 2025 was our flagship achievement – and it really delivered for our industry. Autocare is the premier automotive training event in Australia, offering independent workshop owners and technicians the technical and business skills they need to thrive. This year’s event welcomed 2,700 attendees and 100

exhibitors, featured expert-led training sessions, an expansive trade show, and the launch of the new ADAS Industry Code of Conduct. Alongside Autocare, we also staged the second National Light Vehicle Modifications Summit, which has established itself as the leading forum for regulators and industry to come together to shape a balanced regulatory environment for modifiers, suppliers, and enthusiasts alike.

The Auto Innovation Centre also reached new heights. A 40 percent increase in revenue and productivity gains ensured it delivered a net operating profit, meeting its five-year expansion target ahead of schedule. The AIC grew its engineering, testing, and scan data services significantly and is proving to be an indispensable asset for Australian automotive businesses.

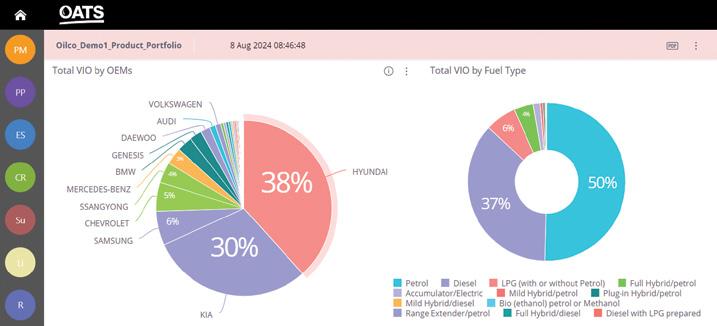

Staying connected with members has remained a priority. Networking events across the country gave us a chance to listen, learn, and bring people together. Our staff represented the Association at dozens of external forums, ensuring your voice was heard and your interests protected. We also enhanced our member services. A highlight was the launch of our Interactive Digital Dashboard – providing near real-time data to support business decisions – alongside improvements to our car parc data tool. These initiatives build on our popular quarterly reports to provide a richer picture of the aftermarket landscape.

Our AAAA Women initiative continued to grow, with its steering committee and regular events encouraging greater participation of women across our sector.

On the communications front, we achieved record levels of engagement. More media releases than ever before translated into broader coverage across the board. Our multi-channel communications strategy ensured that members remained informed and connected, while our

Australian Automotive Aftermarket Magazine continued to thrive as the trusted voice of our industry.

Internally, we have undertaken considerable efforts to streamline our systems and lower operating costs, all aimed at improving efficiency and allowing us to better serve our members. I am struck by the breadth of what we have achieved together – from advocacy wins and major events to new services and stronger member engagement. None of this would have been possible without the dedication of the AAAA and AIC teams, and the guidance of our Board. I want to thank them all sincerely for their passion and leadership.

Summing up, the AAAA is in perhaps its strongest position ever to push forward and effectively fulfil our mission of promoting and protecting our incredible industry – and at the core of this are you, our members.

Stuart Charity Chief Executive Officer

Capricorn recently released its sixth State of the Nation report, explains Group CEO, Brad Gannon

The State of the Nation report shares how our Members are feeling about the automotive industry and this year we are thrilled to have insights from three different research surveys, including feedback from apprentices.

Brad Gannon Group CEO

Society Ltd

Once again, Capricorn’s State of the Nation report shows that our number one industry-wide challenge is attracting and retaining good people. The skills shortage affects everything from productivity to customer wait times, to the health and wellbeing of business owners.

In good news, we continue to see that despite economic and labour pressures, 77 percent of Capricorn’s Australian Members have plans to either expand or to improve profitability in 2025 –perfectly demonstrating the faith and resilience of our community. Capricorn is there to provide help and support to this, every step of the way.

Feedback from apprentices also shows a strong passion for, and high level of confidence in, the automotive industry; and many are aspiring to be business owners – a great sign for the future of the industry.

You can find out much more information in the full report, available on the Capricorn website. I encourage you to have a read and reach out to continue the conversation. Together I am confident we can make a difference to our challenges and celebrate the contributions of the automotive community. Thank you to everyone who took the time to participate in Capricorn’s research and share your experiences.

Late last month, Capricorn started announcing our first ever Rising Stars Region Winners, celebrating some of the outstanding apprentices in the Industry. This year, we received more than 350 nominations and are thrilled to be able to celebrate winners in each of the Capricorn zones, before announcing an Overall Winner towards the end of the year.

Thank you to everyone who took the time to recognise their apprentices. Please join us in celebrating and congratulating the worthy winners as they are shared on Capricorn’s website and social media channels. For more on Capricorn Society membership, visit www.capricorn.coop

The Association warns against a ‘one-sizefits-all’ approach

The Australian Automotive Aftermarket Association (AAAA) has called on governments to deliver smarter, locally relevant standards reform, warning that simply “lifting and applying” international vehicle regulations could damage safety, limit choice, and stifle innovation in Australia.

In its submission to the Treasury’s consultation on Reforms to Improve Use and Recognition of Standards in Regulation, AAAA backs greater harmonisation between states and with trusted international benchmarks, but only where those standards suit Australia’s unique conditions.

AAAA Chief Executive Officer, Stuart Charity, said the industry’s successful campaign against the proposed adoption of UNECE’s Global Technical Regulation GTR 09 for Frontal Protection Systems proved the risks of uncritical adoption.

“At one point, it was proposed that GTR 09 be adopted in Australia without adaptation or consultation,” Stuart said.

“The intention was to improve safety, but in reality, it would have ignored high-speed animal strikes, rural road conditions, and the need for essential safety equipment on vehicles in remote areas.

“AAAA made the case that this overseas standard simply did not fit our conditions. The Minister ultimately agreed, and its adoption was stopped. That was the right decision, and a clear example of why early industry input matters.

“Australia has world-class capability in designing and manufacturing automotive components, from bull bars to advanced safety systems.

“Our modifications are not about cosmetic changes, they are essential adaptations to make vehicles safe, compliant, and fit for purpose in Australian conditions. Any reform to standards must recognise and protect this capability.”

AAAA Director of Advocacy and Government Relations, Lesley Yates, said the bigger, ongoing challenge is the lack of national consistency in how standards are applied across states and territories.

“Our industry faces a patchwork of conflicting rules that increase costs, create confusion, and slow down innovation,” Lesley said.

“The bull bar and Frontal Protection System example is just one case. We need a truly national approach that works for our conditions, eliminates unjustified differences between states, and ensures businesses can operate confidently across borders.

“But harmonisation must be done carefully, it’s not about making things easier for regulators; it’s about making them work for Australians.”

The AAAA’s submission also recommends that governments embed early and ongoing industry consultation into all standards reform processes.

“Our members bring decades of real-world technical expertise,” Lesley said.

“That expertise must be in the room from day one, not as a post-decision feedback loop to avoid costly and unnecessary mistakes.”

The AAAA says the Treasury review is a welcome opportunity to fix long-standing inconsistencies in the automotive standards framework, but only if reforms are grounded in local needs and informed by those with hands-on experience.

For more from AAAA, visit www.aaaa.com.au

The modern vehicle is no longer just a finely tuned machine of gears, pistons and panels — it is now a highly intelligent platform powered by lines of code, real-time data, and over-the-air updates. Welcome to the era of the Software-Defined Vehicle (SDV).

If that term sounds like Silicon Valley jargon, think again. SDVs are already on Australian roads, quietly reshaping the way vehicles are built, repaired, and experienced.

For the aftermarket, this isn’t tomorrow’s challenge. It is today’s business reality.

What is a Software-Defined Vehicle?

A software-defined vehicle is one in which key functions — from safety systems and powertrain performance to infotainment and even climate control — are governed by software rather than traditional hardware.

In an SDV:

• Features can be activated or deactivated through software updates.

• Diagnostics and performance data can be transmitted remotely.

• Repairs and upgrades can be delivered digitally, sometimes without a single spanner being turned.

This is possible because computing power is being centralised.

Where vehicles once carried more than 100 electronic control units (ECUs), many new designs consolidate those functions into just a handful of high-performance processors.

That allows manufacturers to roll out new features and updates long after the vehicle has left the showroom.

A real-world example

Take Autonomous Emergency Braking (AEB): in a conventional vehicle, AEB behaviour is “locked in” at the factory.

In an SDV, manufacturers can recalibrate braking

algorithms remotely — in response to road data, customer feedback, or even regulatory changes. Or consider consumer features: heated seats, adaptive lighting, or performance boosts can be unlocked with a click. Sometimes those upgrades are free; often they are tied to a subscription model.

Why it matters for the aftermarket

1. Servicing and repairs are becoming software jobs

Mechanical know-how will always matter, but the new frontier is digital.

Faults may be caused by firmware conflicts, corrupted updates, or lapsed licences rather than worn parts. Calibration and coding are now a core part of the repair task.

2. Access to data is make or break

If independent workshops can’t access the secure gateways, data channels, or software platforms inside these vehicles, repairs grind to a halt.

This is why Right to Repair laws and the Motor Vehicle Information Sharing (MVIS) Scheme are critical. Without genuine access, the aftermarket is effectively locked out.

3. Training and equipment need to evolve Technicians will increasingly need IT literacy alongside mechanical skills: understanding CAN networks, cybersecurity protocols, and passthrough programming.

Workshops will need to budget for updated tools, reliable internet connectivity, and ongoing training.

4. Customer expectations are changing Drivers are already used to app-based experiences in their cars.

They will expect their local workshop to understand subscription services, connectivity issues, and software faults as confidently as they handle brakes and tyres.

The risk of standing still

History is a guide here. Businesses that failed to adapt to fuel injection, ABS, or hybrid systems were quickly overtaken.

SDVs represent the next leap — and the pace is accelerating.

Car companies are designing future fleets around software ecosystems rather than mechanical upgrades.

That means more digital locks, more remote diagnostics, and a greater need for industry advocacy on data transparency. What can the aftermarket do now?

• Stay informed: tap into industry briefings, technical training, and trusted resources on SDV architecture.

Lesley Yates, AAAA Director of Government Relations and Advocacy info@aaaa.com.au

• Invest strategically: budget for pass-through tools (J2534 or equivalent), updated diagnostic software, and secure gateways.

• Support advocacy: engage with Right to Repair and MVIS — these frameworks will determine whether independents can compete fairly.

• Adapt the business model: think beyond the workshop floor. Remote diagnostics, subscription add-ons, and partnerships with software specialists could become core revenue streams.

Final word

Software-defined vehicles present undeniable challenges, but also remarkable opportunities. They can unlock new service revenues, enable remote diagnostics, and transform how we engage with customers.

What matters is readiness. In this new landscape, the most valuable tools won’t just be on the tool wall. They’ll be in the scan tool, the software licence, and above all, in access to the vehicle’s data.

The future of our industry is arriving on four wheels — and billions of lines of code.

The question is not whether SDVs are coming – it is how ready we are to meet them.

If you would like to offer your thoughts on this subject, please email advocacy@aaaa.com.au

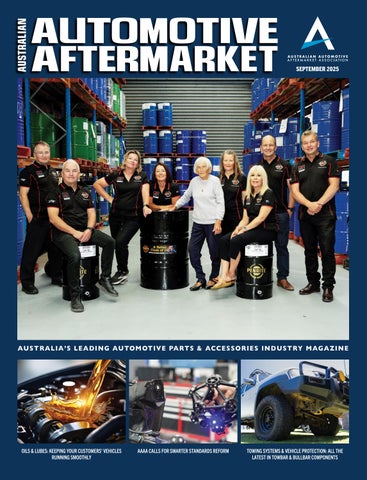

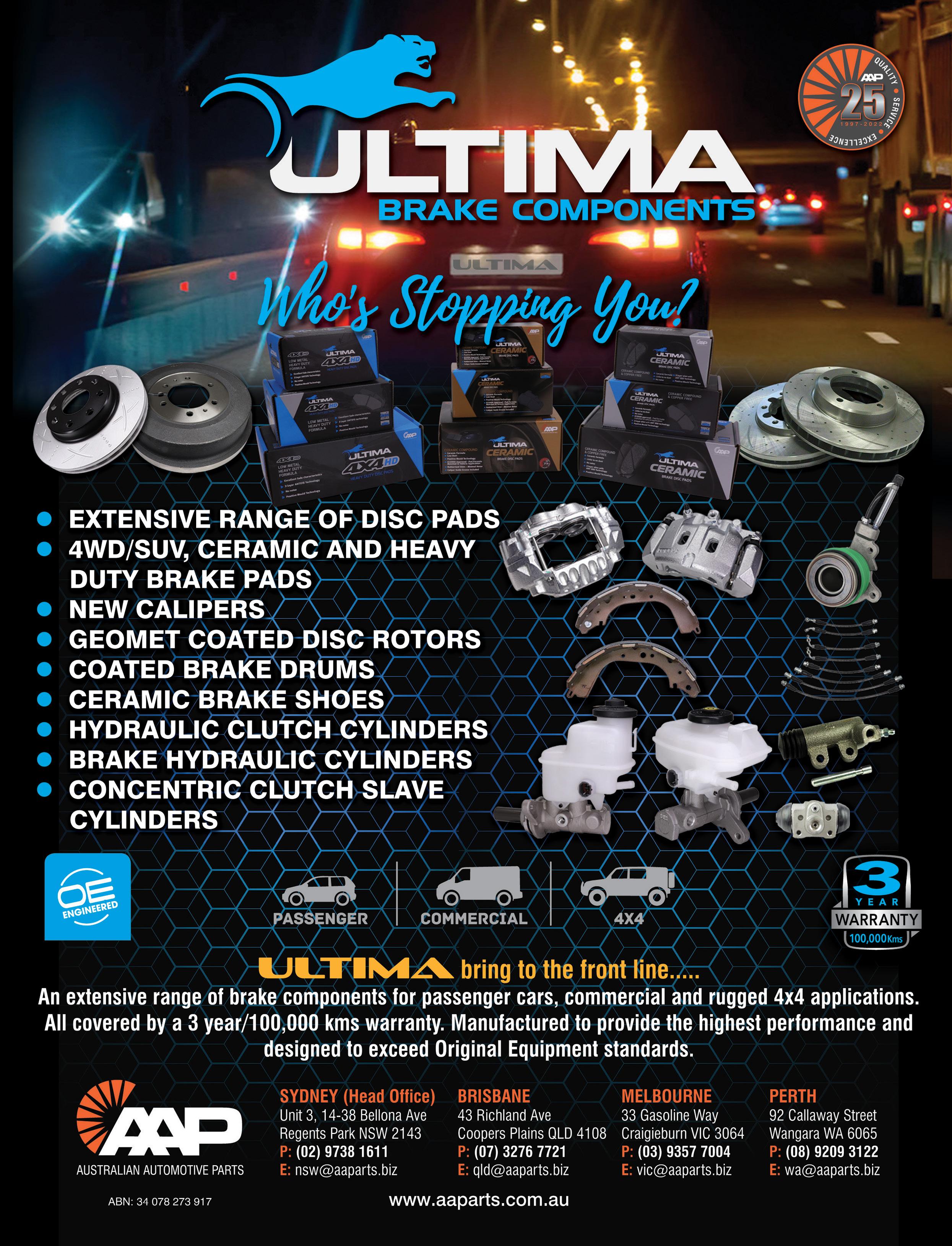

Penrite Oil has acquired Brandlines and Australian Automotive Parts (AAP)

Penrite, an iconic Australian family-owned business, has officially announced its acquisitions of Brandlines and Australian Automotive Parts (AAP).

Brandlines is a well-established player in the Australian aftermarket automotive sector and this strategic move marks an exciting chapter for both companies as they join forces to leverage their strengths and expand their market presence in non-ICE reliant segments.

Founded in 1984 by Sil Luksich, Brandlines originated as the Australian representative for Gabriel Shock Absorbers, a trusted manufacturer from the USA.

Over the years, Sil’s vision was embraced by his sons, Mark and Maurice Luksich, who have played a pivotal role in building the company into a respected brand within Australia and beyond.

The company significantly expanded its product offerings, including filtrations and also renowned brands such as Autolite Spark Plugs, and Ezilift Gas Lift Supports enhancing its reputation in the automotive sector.

This partnership is aligned with Penrite’s strategic plans to diversify and grow its business in a rapidly evolving market that increasingly prioritises sustainability and non-ICE technologies.

By acquiring Brandlines, Penrite says it is not just investing in a company but is also cementing its commitment to innovation within the automotive industry.

The acquisition, effective from July 1 2025, enables Penrite to work closely with the Luksich family and the dedicated team at Brandlines. Together, they will develop a comprehensive plan aimed at bolstering Brandlines’ operational capabilities, customer service, and market outreach both within Australia and internationally. Penrite says this partnership promises to be

symbiotic, enhancing the strengths of each brand while ensuring that customer service and relationships with factory and trade partners remain a priority.

Mark and Maurice Luksich expressed their enthusiasm regarding the partnership, highlighting the shared vision for innovation and growth.

“We are thrilled to team up with Penrite and look forward to the opportunities that lie ahead. Our commitment to delivering quality products and exceptional service will only be enhanced by this collaboration,” the pair said in a statement.

For Penrite, this acquisition represents a significant stride into a progressive future.

At the time, it was the first major acquisition the company had undertaken in several years, marking a decisive step toward expanding its footprint in non-ICE segments.

As the automotive landscape shifts and evolves, Penrite says the partnership is focused on tapping into new growth opportunities and addressing the changing needs of consumers.

“This partnership with Brandlines is a natural fit for Penrite’s vision of innovation and growth in the evolving automotive landscape,” Penrite Chief Executive Officer, Toby Dymond, said.

“By combining our resources, expertise, and shared commitment to quality, we are positioning both companies to lead in emerging non-ICE markets while continuing to deliver exceptional value to our customers and partners.”

Brandlines will continue to operate independently while benefiting from the resources and support that Penrite offers.

By acquiring Australian Automotive Parts (AAP), a leading distributor of automotive hard parts across Australia and New Zealand, Penrite Oil expands its market reach and product capabilities.

The deal enhances Penrite’s diversification strategy by broadening its product portfolio and enabling the company to deliver a more comprehensive range of high-quality solutions to customers nationwide.

Founded in 1926, Penrite says it has built a longstanding reputation for innovation, reliability, and dedication to Australian manufacturing.

“We are proud to welcome AAP into the Penrite family,” Toby said.

“This acquisition is not only about growth — it is about delivering even more value to our customers.

“By combining Penrite’s world-class lubricants with AAP’s extensive hard parts range, we’re creating a stronger, more agile business that’s equipped to meet the evolving needs of the automotive sector.”

AAP, a respected brand with more than 30 years in the industry, specialises in the wholesale and import of key aftermarket brands including Ultima, Selby, Platinum, EFS, Oetiker and more.

The company services suspension, drive train, steering, braking, and engine parts segments with a reputation for reliable supply, deep product knowledge, quality parts and strong customer relationships.

AAP will continue to operate under its current name, ensuring uninterrupted service for its loyal customer base.

AAP has four distribution centres in Brisbane, Sydney, Perth and Melbourne that will continue to operate.

This acquisition supports Penrite’s broader strategy to expand beyond lubricants and solidify its role as a full-service provider in the automotive aftermarket.

The company reaffirmed its ongoing commitment to Australian ownership, local manufacturing, local employment, innovation, and maintaining its high standards of quality and customer service.

“We’re excited to join forces with John and his team at AAP. This move has been part of our longterm strategy to enter the hard parts space,” Toby said.

“It allows us to provide not only the best lubricants but also an extensive range of automotive components — all backed by Penrite’s commitment to customer service, premium quality, availability, and Australian-owned excellence.”

AAP Chief Executive Officer, John Bourne, echoed this sentiment.

“Joining forces with Penrite is a natural fit for AAP. We’ve always shared similar values — a commitment to quality, strong customer service, and supporting the automotive aftermarket industry across Australia,” John said.

“This partnership opens new doors for our customers, suppliers, and employees. We’re excited for the future and confident this move will take AAP to new heights.”

For more information, visit www.penriteoil.com.au

The Australian Automotive Aftermarket Association (AAAA) has welcomed the announcement by the NSW Minister for Fair Trading, The Honourable Anoulack Chanthivong, that proposed reforms introducing a new electric vehicle (EV) mechanic repair class will be deferred to allow for further consultation with industry. This outcome means that from 1 September 2025, workshops will continue to safely service and repair EVs and consumers will retain the freedom to choose who services and repairs their EVs.

It is an important win for both industry and motorists, ensuring safety and choice are maintained while the policy is properly reviewed.

AAAA Chief Executive Officer, Stuart Charity, said the Minister’s decision “demonstrates a genuine commitment to evidence-based policy, a willingness to engage, and a practical understanding of how the automotive industry operates.”

“We want to thank Minister Chanthivong for his leadership and his openness to hearing from the people who do this work every day,” Stuart said.

“When governments consult with industry, they get better outcomes, and this decision shows the Minister is prepared to take the time to get this right.

“Workshops put together teams of skilled people, each contributing according to their training and responsibilities.

“The original proposal from NSW Fair Trading reflected a fundamental misunderstanding of modern workshop operations, wrongly assuming that one technician services an entire vehicle.

“The proposal would have required every team member to complete extensive EV certification, even if the work is unrelated to the high-voltage system. That’s not safety, that’s bureaucracy for its own sake.”

The proposed EV licence class formed part of the draft Motor Dealers and Repairers Regulation 2025, which was due to commence on 1 September 2025.

While other reforms in the Regulation have proceeded, the EV licensing changes will now be subject to a separate consultation process led by NSW Fair Trading.

“We want to acknowledge and thank our independent workshops right across the state, who have been actively engaged throughout this process. Their input and persistence have delivered real results,” Stuart said.

“AAAA and our members stand ready to work

The tariff is threatening Australia’s automotive component industry

The Australian Automotive Aftermarket Association (AAAA) is calling on the Federal Government to prioritise trade discussions with the United States to secure relief from the 25 percent tariff currently applied to Australian automotive component exports under the US Section 232 provisions.

The tariff, originally introduced in 2018 and reintroduced in May 2025, was designed to protect America’s domestic car manufacturing base.

However, for Australian exporters who specialise in aftermarket parts that are not sold to US car manufacturers, it remains a significant barrier to competitiveness in our most important market.

AAAA Chief Executive Officer Stuart Charity said the tariff is a critical issue for the survival of Australia’s remaining automotive component manufacturing sector.

“Our industry has worked hard to remain globally

competitive despite the end of local vehicle manufacturing,” Stuart said.

“We now produce world-class, niche components that are in demand overseas, but a 25 percent cost imposed on our largest export market is a heavy burden to overcome.

“The tariff has nothing to do with the quality or safety of Australian products, which are widely recognised as meeting or exceeding global standards.

“This is about ensuring that our exporters can compete on a level playing field. The US market is vital to the future of our industry, and removing this tariff would be a game changer for jobs, innovation, and investment in Australia.”

The AAAA is urging the Federal Government to: 1. Re-engage with their US trade counterparts to seek an exemption or reduction for Australian automotive components under the Section 232 provisions.

closely with NSW Fair Trading to design a framework that genuinely improves safety while remaining practical for workshops of all sizes.

“We share the Government’s goals of keeping workers safe, protecting consumers, and ensuring our industry is ready for the EV future.

“The Minister’s decision gives us the opportunity to design smart, targeted training that focuses on real risks, recognises existing skills, and avoids unnecessary hurdles.”

AAAA will continue to engage constructively with Government to ensure that the growing EV fleet can be serviced safely, efficiently, and affordably and that policy decisions are informed by the dayto-day realities of automotive service and repair. For more from AAAA, visit www.aaaa.com.au

2. Highlight the high quality and strategic value of Australian-made components in bilateral trade discussions.

3. Treat tariff relief as a key priority for supporting advanced manufacturing and export growth.

“The Government has talked about not just protecting, but growing domestic manufacturing. Here is a clear, immediate test of that commitment,” Stuart said.

“This is not about pointing fingers, it is about working constructively with our friends to find a solution that supports both countries’ automotive industries.

“For some of our exporters, this issue could make or break their ability to maintain an Australian manufacturing base.”

For more from the AAAA, visit www.aaaa.com.au

Fifth Quadrant has released the latest Australian Responsible AI (RAI) Index

The latest Australian Responsible AI (RAI) Index 2025 has officially launched.

Now in its fourth iteration, the 2025 Index provides in-depth analysis and valuable insights into how Australian organisations are adopting and implementing Responsible AI (RAI) practices.

The index categorises organisations into four maturity levels – Emerging, Developing, Implementing, and Leading – based on their adoption of key RAI practices such as fairness, accountability, transparency, explainability, and safety.

Download the 2025 Index to discover practical insights and opportunities to strengthen your organisation’s responsible AI approach.

This year’s Index provides Australia’s most comprehensive benchmark of responsible AI maturity.

Key insights include:

• 30 percent of organisations report productivity gains from responsible AI

• Leaders achieve up to three times greater operational and innovation benefits

• A persistent confidence–implementation gap, with many overestimating their maturity

This year also marks the launch of Australia’s first national Responsible AI Self-Assessment Tool.

As part of the 2025 Index, the Responsible AI SelfAssessment Tool, developed by Fifth Quadrant and sponsored by the National AI Centre (NAIC), helps Australian organisations evaluate their maturity in responsible AI practices.

The tool enables your organisation to:

• Measure your current AI maturity

• Benchmark performance against industry peers

• Receive tailored guidance aligned with the Voluntary AI Safety Standard (VAISS)

To download the Australian Responsible AI Index 2025, try the Responsible AI Self-Assessment Tool, or access the 2024 Responsible AI Index findings, visit, www.fifthquadrant.com.au/responsible-ai-index

Organisers state attendees were pleased with the integration of automotive mobility solutions with lifestyle and the Malaysian market’s connection to global opportunities at the event

Automechanika Kuala Lumpur 2025 concluded successfully recently, receiving positive feedback from exhibitors and visitors who valued the connections made during the three-day event.

The expanded exhibition spanned the entire automotive value chain, from manufacturing to the aftermarket, and saw 311 exhibitors interact with 15,098 visitors across six halls of the Kuala Lumpur Convention Centre.

Organisers state the space fostered positive interactions including business exchanges, educational opportunities, and entertainment experiences.

These were marked by the introduction of cuttingedge technologies and innovations in automation, connectivity, digitalisation, new energy, and more, driving growth and infusing dynamism into the entire automotive market in the region.

Key figures from Automechanika Kuala Lumpur 2025 include:

• Exhibitors: 311 from 21 countries and regions

• Visitors: 15,098 from 61 countries and regions (International: 21 percent; Local: 79 percent)

• Scale: 12,538 sqm (halls one to six)

• 29 fringe events and activities (eight by organisers, 21 by industry associations and organisations)

“I am pleased to see that our decision to expand the show to six halls was effective,” Messe Frankfurt (HK) Ltd General Manager, Fiona Chiew, said.

“The increased space allowed more exhibitors and attendees to engage in activities covering the entire automotive value chain and provided greater opportunities for networking, collaboration, and recreation.

“The array of new concepts, technologies and solutions showcased over the three days signified the ongoing momentum and innovative spirit of the ASEAN automotive industry.

“Similarly, Automechanika Kuala Lumpur is poised to match this positive trajectory, and I look forward to an even stronger event in 2026.”

Participants praised how the event remained at the forefront of these industry trends and showcased key technologies driving the future of the sector.

For example, the Automotive Mobility Solutions Zone displayed the latest innovations in digitalisation and electrification, transforming supply chain operations, logistics efficiency, and

consumer satisfaction, with a particular focus on energy transition, new energy vehicle (NEV) adoption, cybersecurity, digital solutions and more. Attendees emphasised that the event effectively highlighted the growing importance of environmental awareness and new lifestyle trends, both in manufacturing processes and consumer choices.

Reflected through the new Outdoor, Camping, Campervan and Caravan, Motorsport, JDM and Classic Cars zone, this successfully celebrated automotive subcultures while spotlighting and responding to emerging lifestyle trends.

The exhibition also hosted leading brands within the Passenger, Commercial Vehicles and Fleets, and Automotive Repair and Maintenance / Body and Paint / Care and Detailing / Oils, Lubricants and Fuels / Accessories and Customising zones, who presented groundbreaking technologies in these sectors.

Elsewhere, fringe programme events returned to a warm reception, and were said to be productive meeting places for industry players to converge, share ideas, and discuss solutions to some of the unique regional challenges.

At the Automotive Mobility Solutions Conference, 28 speakers from Amazon Web Services, Auto Data Technology, EV Connection, Proton, Stellantis, Volvo, and more engaged over 517 attendees. Simultaneously, 20 trainers addressed more than 230 visitors at the Collision Repair Training Workshop, where participants learned about the latest equipment, tools, technologies, and techniques for servicing ICE, hybrid and NEV vehicle types in today’s green and connected landscape.

The collaborative and inclusive spirit was also highlighted by attendees as they praised the immersive activities at autoFEST@KL.

The next edition of Automechanika Kuala Lumpur will take place from 14 to 16 May 2026.

For more information, visit www.automechanika-kl.com, or email autoasia@hongkong.messefrankfurt.com

The AAAA says, ‘now the real test begins’

For the first time in history, four Chinese vehicle brands have broken into Australia’s top 10 new car sales, according to the August 2025 figures.

Australian Automotive Aftermarket Association (AAAA) Chief Executive Officer, Stuart Charity, said this milestone reflects the growing diversity of Australia’s car parc and the increasingly global nature of our market.

“Chinese manufacturers are clearly no longer niche players – they are competing head-to-head with established brands in Australia,” Stuart said.

“This is a positive development that gives consumers more choice, but the real test is how these manufacturers support their vehicles once they’re in the hands of Australian drivers.

“That means more than just selling cars. It means ensuring strong after-sales service, timely recall support, and the provision of critical technical resources for independent workshops.”

Stuart highlighted the role of Technical Service

Bulletins (TSBs) – formal communications issued by car makers that explain how to diagnose and repair known problems in specific models.

“TSBs are not optional. They are essential for both dealer and independent technicians to keep vehicles safe and reliable. We need to see Chinese brands commit to releasing these bulletins promptly and fully,” Stuart said.

Stuart also emphasised the legal obligations under Australia’s Motor Vehicle Service and Repair Information Sharing Scheme (MVIS) – the ‘Right to Repair’ law.

“By law, all car makers selling in Australia must make dealer-level service and repair information available not only to their authorised dealers, but also to independent repairers, parts suppliers and dismantlers.

“This ensures a level playing field and protects consumer choice. We expect Chinese manufacturers to comply fully with these obligations.”

The network was awarded for outstanding customer satisfaction

JAX Tyres & Auto was recently crowned as winner of Canstar Blue’s Most Satisfied Customers – Car Tyre Retailers Award 2025.

Dominating the category with an impressive set of results, JAX Tyres & Auto says this Award has further confirmed its position as “the customer experience leader in the automotive industry.”

Canstar Blue is one of Australia’s best-known and respected comparison websites and has been helping Australians make better-informed decisions on purchasing over 300 different goods and services since 2010.

JAX Tyres & Auto achieved the highest scores across a range of performance areas, including store layout and presentation, product range, quality of products on offer, value for money and customer service – outperforming all other national retailers in the tyre category.

“Being recognised by Canstar Blue as the number one tyre retailer for customer satisfaction is an incredible achievement and a proud moment for our entire network,” JAX Tyres & Auto Chief Executive Officer and Managing Director, Steve Grossrieder, said.

“This award reflects our consumer promise of ‘Peace of Mind Driving,’ delivered through transparency, trust and professionalism.

“The trust our customers place in us every day is

never taken for granted, with our customer centric culture truly embedded in our DNA.”

This recognition follows a string of recent accolades for the business, having been awarded CX Team of the Year at the 2025 CX Awards, Inside Retail - Retailer of the Year Award 2023, CX Transformation of the Year 2022 and 2020 and, CX Leader of the Year 2020.

The network says these sit alongside multiple other awards across the franchising and automotive industry, all helping to further cement JAX Tyres & Auto’s commitment to placing customers at the centre of its operations.

“We don’t view customer experience as a one-off initiative at JAX Tyres & Auto, it’s embedded in how we operate every day and, being recognised at a national level validates the hard work our team brings to every interaction, every day,” JAX Tyres & Auto Chief Franchising Operations Officer, April Harwood, said.

“Congratulations to JAX Tyres & Auto for receiving the 2025 Canstar Blue Most Satisfied Customer Award for Car Tyre Retailers,” Canstar Blue spokesperson, Eden Radford, said.

“When choosing a car tyre service centre, customers are after a service they can rely on and trust.

“This is why earning a Canstar Blue Most Satisfied

With vehicle ownership in Australia averaging more than 10 years, Stuart said long-term support is just as important as short-term sales success.

“Breaking into the top 10 is an impressive achievement, but maintaining trust in this market requires cooperation and coordination with the entire aftermarket – not just dealers,” Stuart said.

“Australian consumers deserve nothing less.”

For more from the AAAA, visit www.aaaa.com.au

Customers Award is a remarkable achievement, with the winner determined by the opinions and ratings of customers themselves.

“This year’s results prove JAX Tyres & Auto’s accolade is certainly well deserved, with a top rating of five stars for overall satisfaction as well as customer service, product range, and store layout and presentation.

“This achievement is certainly worth celebrating, and a fantastic endorsement from JAX Tyres & Auto’s own customers.”

With 94 locations nationwide and growing, JAX Tyres & Auto says it continues to be recognised as a leader in the premium automotive retail space, with best practice customer experience across Australia.

For more information, visit www.jax.com.au

Bosch eXtras is a loyalty program tailored to the automotive aftermarket Supercheap Auto Trade has officially joined the Bosch eXtras program as a supporting supplier, allowing Bosch eXtras members the opportunity to earn rewards on eligible Bosch purchases made through their Supercheap Auto Trade Account.

Bosch eXtras is a loyalty program tailored to the automotive aftermarket, where members can earn points on Bosch products and redeem them for a range of attractive rewards.

Tiered incentives are also available, such as exclusive signage and branded merchandise, with a welcome bonus of $50 worth of points on sign-up (eligibility requirements apply).

In addition to rewards, members also gain access to the Bosch Module Workshop Program – a free portal created to support independent workshops with up-to-date product knowledge and technical information.

Through the portal, workshops can access:

• Technical tips for technicians and apprentices

• Automotive product, system and diagnostic info

• Specialised training events and exclusive webinars

• Curated industry news from the Bosch Mobility Aftermarket team

• Exclusive product promotions

• The Bosch Spare Parts e-Catalogue –searchable by rego

Now, Supercheap Auto Trade Account Holders can tap into all of this while continuing to shop the Bosch range in store, online or via the dedicated trade hotline, backed by fast 30-minute Click and Collect on stocked products.

The company says it is another reason to make sure your workshop is set up with a Supercheap Auto Trade Account, combining everyday value, quality parts and now, Bosch rewards.

It says if you are not a Supercheap Auto Trade Account Holder yet, you can register to unlock exclusive trade pricing for your workshop (eligibility criteria applies).

For more information and to register, visit trade.supercheapauto.com.au

New Automotive Academy launched

Several of Queensland’s major industry associations have partnered with an independent school to launch a new Automotive Academy in response to key workforce challenges.

The Heavy Vehicle Industry Association (HIVA), the Australian Automotive Aftermarket Association (AAAA), and the Motor Trades Association of Queensland (MTAQ) announced the launch of the specialist academy with The Industry School on August 12.

This initiative, said to be the first of its kind in Queensland, aims to ignite interest amongst young people, build practical skills, and inspire pathways in the rapidly evolving automotive sector.

“HVIA is delighted to extend its existing relationship with The Industry School and looks forward to the opening of The Automotive Academy,” HVIA Chief Executive Officer, Todd Hacking, said.

“The heavy vehicle industry needs an additional, sustainable, energetic pipeline of apprentices and targeting school-based learners is an exciting opportunity for the industry.”

This Academy aims to address key skills gaps and drive workforce growth.

“MTAQ has identified that addressing skills and labour shortages is the number one issue facing the industry today,” MTAQ Chief Executive Officer, Rod Camm, said.

“Creating pathways for students into automotive careers that The Industry School has developed

is a critical feature of the automotive industry’s workforce development strategy.”

Designed for senior secondary students (Years 10-12), the specialist automotive program blends classroom learning at The Industry School with immersive hands-on training with strategic partner TAFE Queensland, and what is described as “unmatched work experience and employment opportunities designed especially for a career in the automotive industry.”

Starting in January 2026, students will earn a Certificate II in Automotive and engage in industryimmersive experiences spanning light vehicle, heavy vehicle, and the automotive aftermarket.

Lee Smith, Chief Executive Officer of The Industry School, said an integrative approach to industry education fosters technical talent, character, and employability.

“Our students spend up to 28 weeks per year in industry, balancing academic and vocational education, work experience, and an apprenticeship, driven by real-world exposure,” Lee said.

“It all starts by partnering with industry associations like the HVIA, AAAA, and MTAQ.”

The Automotive Academy will strengthen a critical pipeline of educated, skilled technicians in South East Queensland, countering workforce shortages, industry perceptions, and technology advancements.

The AAAA said The Automotive Academy is a fantastic initiative with an innovative approach to secondary school trade pathways.

“It is no secret the automotive industry is in the midst of a skills shortage,” AAAA Chief Executive Officer, Stuart Charity, said.

“As it stands, we need a further 13,500 apprentices just to meet our current needs and with 3,300 new workshops opening in the past five years, the demand is certain to grow well into the future.

“New strategies and partnerships are necessary if we are to meet the challenges before us, and we are extremely proud to be supporting The Automotive Academy, helping to kickstart careers for the next generation of technicians as we move towards a more sustainable automotive workforce.”

The first students for The Automotive Academy will start in Term 1 of the 2026 school year. Initial enrolments will launch through The Industry School’s Ipswich campus, with plans to expand across additional campuses in South East Queensland.

For more information, visit www.theindustryschool.com.au

Australia’s automotive aftermarket continues to face a serious and persistent skills shortage

Data from the Mining and Automotive Skills Alliance has revealed that women currently represent just 20 percent of the automotive workforce, and only 2.6 percent within automotive and engineering trade roles.

This underrepresentation is exacerbating the talent gap – particularly as Australian Automotive Aftermarket Association (AAAA) research estimates the industry is short of almost 40,000 technicians, comprising 27,000 qualified technicians and 13,500 apprentices.

With these shortfalls, every workshop in the nation is impacted.

Meanwhile, nearly 35 percent of key occupations within the automotive industry are flagged as being in shortage, according to the Job Services Australia Skills Priority List – highlighting that the skills crunch is both significant and systemic.

The importance of expanding female workforce participation is reinforced by a landmark report from Impact Economics and Policy for Chief Executive Women, which found that increasing women’s participation could generate up to one

million full-time equivalent workers nationally, underscoring the macroeconomic benefit of engaging more women across all sectors, including automotive.

“Women are a largely untapped resource within our industry,” AAAA Chief Executive Officer, Stuart Charity, said.

“We know that increasing female participation isn’t just a matter of equity – it is a practical and urgent response to near-term labour shortages.

“Even a modest rise in the number of women enrolling in automotive trades could make a substantial difference.

“We aren’t pointing fingers – this is about partnership, opportunity, and readiness for change.

“AAAA is committed to supporting initiatives that bridge gender gaps – through promotion, training access, career visibility, and creating inclusive, flexible work environments.

“Addressing skills shortages goes hand in hand with harnessing female talent.”

Key industry actions AAAA supports include championing recognition and funding for female automotive apprenticeships and vocational training, collaborating with initiatives like AAAA Women to raise awareness, mentorship and leadership pathways, and working with policymakers and training providers to ensure working conditions, curriculum, and recruitment actively encourage women into trade-based roles.

“Our goal is clear: to strengthen our workforce, build a sustainable future, and reflect the communities Australia serves,” Stuart said.

“Expanding women’s participation in our trade pipelines is not just fair – it is vital.”

For more from the AAAA, visit www.aaaa.com.au

The Institute of Automotive Mechanical Engineers (IAME) says training must evolve

In an industry defined by rapid innovation, one thing remains timeless: the need for skilled, adaptable, and passionate automotive professionals.

The Institute of Automotive Mechanical Engineers (IAME), says it is “not just keeping pace — it is setting the standard.”

Explaining that it believes ‘training must evolve,’ IAME says Australia’s workshops are changing with smarter technology, more complex vehicles, and rising customer expectations – all demanding a new kind of technician.

IAME says it delivers training that is hands-on and workshop-based, led by seasoned professionals, and focused on real-word readiness – stating that this isn’t textbook theory, it is practical learning that “stays for life.”

Further, IAME says it believe in being inclusive, safe, and fair, stating that every learner deserves a seat at the workbench.

Whether you are a First Nations apprentice, a woman entering the trades, or someone seeking a fresh start, IAME says it welcomes you, noting that “diversity isn’t a checkbox, it is the engine of progress.”

IAME offers nationally recognised qualifications in Light Vehicle Mechanical Technology; Heavy Commercial Vehicle Mechanical Technology; Automotive Electrical Technology; Body Repair Technology; Automotive Refinishing Technology; and Automotive Sales.

These qualifications are offered with flexible start dates, personalised support, and wellbeing services, with IAME seeking to remove barriers so learners and employers can focus on results.

When it comes to Recognition of Prior Learning (RPL), IAME says your experience matters and its RPL pathway helps seasoned professionals

gain formal qualifications based on real-world expertise with fair, consistent and industry-aligned assessments.

IAME invites you to stay ahead of seasonal demand with its Certificate II in Automotive Air Conditioning Technology, encouraging you to gain the skills, knowledge, and licence to keep customers cool and businesses thriving.

IAME says, “we don’t just train mechanics — we shape futures. Whether you’re starting out or stepping up, we’re here to help.”

For more information, call 02 9782 1100 or visit www.iame.com.au/training-education

Swansons Gaskets is “still” a family-owned and operated business

Australian Transmission Components (ATC) says it is proud to announce the acquisition of Swansons Gaskets.

After completing the transition in late August 2025, ATC has been ready to service customers from early September.

Swansons Gaskets has a history going back three generations and has been a leading manufacturer for Automotive, Marine, Farm Machinery and General Restoration vehicles since 1942.

ATC says acquiring the business was a strategic move and helps to maintain the supply of gasket and sealing material it requires for its range of Manual Gearbox / Transfer Case and Differential Overhaul Kits, which it supplies to its Wholesale, Gearbox / Differential, and 4WD Specialist customers.

“We are a family-owned business and have recently celebrated 40 years in business; and we are excited to add this iconic business to our stable,” ATC Managing Director, John Wilcox, said.

“We will integrate the machinery / equipment and gasket material into our Wagga Wagga HQ for a seamless supply into our kitting program and ongoing supply to the existing Swansons customer base.

“ATC has historically led the way with our diverse range of product, focusing on technical fixes and upgraded components for common reoccurring issues, in addition to our extensive range of overhaul kits for Manual Gearbox and Differentials across many popular makes and models.

“The acquisition will also allow us to diversify into other industry sectors and broaden our scope moving forward – this will expose us to a whole new customer base with additional business in areas we would have normally never ventured into,” ATC National Sales Manager, Norm McDonough, said.

For more information, visit www.austtrans.com

The July 2025 AADA Insights Report highlights a used car market in transition

Listings climbed 2.9 percent while used vehicle sales slipped 2.8 percent, leaving more cars on the market for longer.

These shifts point directly to where owners will need support, guiding aftermarket workshops on where to focus investment.

ownership, stretched servicing

More Australians are keeping cars for longer. In practice, that often means stretching service intervals or delaying non-critical repairs.

The work doesn’t disappear, it simply builds up, and when it surfaces, owners need someone they can trust to get their vehicle back in shape.

Workshops that position themselves around safety, preventative checks, and transparent pricing are more likely to attract these cautious owners.

Framing maintenance as a way to protect resale value is also powerful: even owners holding on for longer want to ensure their vehicle is attractive when the time comes to sell.

The fuel transition: hybrids first, EVs to follow

Used hybrid listings surged 12.8 percent in July, while sales fell 8.8 percent. Alongside this, used EV listings rose 4.9 percent, while sales dropped 20.3 percent.

Supply is improving, and consumers are curious, but buyers are still taking time to commit.

The message here is simple. Both technologies are part of the same transition, and the strategy is to build capability in stages.

Investment in hybrid servicing sets the foundation for future work on EVs (as the wave of 2023–24 fleet and novated lease EVs cycle into the used market from 2026 onwards).

For many workshops, that’s when it will make sense to expand investment. Until then, they can take small, cost-effective steps to signal readiness without overcommitting.

Shops that want to capture this opportunity need to be equipped to handle it; for example, with heavy-duty hoists, diesel particulate filter cleaning systems, and 4WD diagnostic capabilities.

New owners, new opportunities

The data on average selling times reveals another opportunity. Popular used vehicles like the Toyota Hilux, Toyota Corolla and Hyundai i30 sell within about 40 days.

That means a steady flow of Australians are becoming new owners each month, often with vehicles of uncertain service history.

This is a moment of vulnerability, and a chance for workshops to stand out.

Offering a tailored “new owner package” that combines a thorough inspection, safety check, and logbook update at a fair price helps establish trust early.

Getting that first interaction right can turn a oneoff visit into years of repeat business.

July saw nearly 90,000 used SUVs and more than 35,000 used utes sold, even as the wider used vehicle market softened.

These vehicles bring higher servicing needs: driveline complexity, diesel emissions technology, heavier suspension wear, and accessory-related maintenance.

In July, more than 200,000 used vehicles changed hands. Each of those sales represents a consumer deciding who they trust to keep their car safe and reliable.

Workshops that are building hybrid capability today, preparing for the EV wave tomorrow, equipping for larger vehicles, and capturing new owners at the right moment, will be the ones that turn uncertainty into lasting growth.

This column was prepared for AAA Magazine by Fifth Quadrant, the AAAA’s partners in the AAAA Aftermarket Dashboard which is delivered to AAAA members each quarter. For more information about its services, visit www.fifthquadrant.com.au or contact Ben Selwyn on ben@fifthquadrant.com.au

In 2025, the event will utilise all 15 halls of NECC for the first time

Preparations are underway for what is set to be one of the largest global automotive industry gatherings of the year.

From 26 to 29 November 2025, Automechanika Shanghai expects to welcome a record 7,000 exhibitors, filling every corner of the National Exhibition and Convention Center (Shanghai), which spans 383,000 sqm.

Organisers state this marks the first time in the show’s history to reach such a scale.

The trade fair offers opportunities for marketing, trade, information exchange and education to continue evolving alongside market trends, which, for this year, reflect those innovations and transformations driving sustainability within the sector.

“Automechanika Shanghai has grown to become one of the most influential platforms in the automotive industry for exploring collaboration on a global scale and showcasing innovative technological advancement,” Messe Frankfurt (HK) Ltd General Manager, Fiona Chiew, said.

“Last year, we welcomed attendees from over 180 countries and regions, achieving record-breaking levels of exhibitor and visitor participation.

“We take great pride in this coming together of nations and minds. Moving into this next edition, we will keep looking to foster deeper integration and development of the global industry by aligning our offerings with market updates and fast-paced automotive trends.”

Automechanika Shanghai 2025 is wellpositioned to showcase products, services, and technologies driving advancements, catering to the entire automotive ecosystem, from R&D and manufacturing to sales and after-sales services.

With a rising need for safe, intelligent and efficient mobility, the fair expands and enhances several elements for companies eager to exhibit in highpotential market segments.

For instance, over half of all exhibitors are set to present products related to the development of new energy vehicles, including advancements in traditional components, diagnostics and repair, body and paint, accessories and customising.

Following a positive introduction to the show, the New Energy and Connectivity sector will expand by 50 percent to cover 39,000 sqm of exhibition space.

The area will feature battery, motor and electric control systems, as well as charging, swapping, and energy storage technologies alongside hydrogen fuel cells, connected and assisted driving systems, intelligent chassis, and thermal management.

Here, Innovation4Mobility offers a window to the future through a range of product displays, forums, and start-up activations. This complete showcase offers a comprehensive guide to emerging trends by the variety of resources from various sectors.

The start-up zone, as an example, will see collaborations between research institutes, universities, start-ups and financial establishments, all presenting developing technologies poised for commercialisation through scenario-based presentations.

Digital technologies are also creating space for new business models in the automotive value chain. The Digital Services / Solutions zone embraces the integration of applications that improve efficiency and reduce costs in the aftermarket.

Companies here can also address cross-border e-commerce, as well as smart logistics and warehousing. The zone will introduce automatic identification technologies, digital solutions, and supply chain management solutions.

Likewise, the Tyres and Wheels sector sees an increase of 50 percent in terms of exhibition space. The sector has steadily grown over the years, but the extra weight, rapid acceleration, noise reduction and battery requirements of electric vehicles have allowed companies to explore more product innovation.

More than 60 percent of all exhibitors will also cater to commercial vehicles, underscoring the evolving landscape of logistics, transportation and mobility. This is particularly relevant for expanding business channels in emerging markets like those along the Belt and Road.

Other sectors include Parts and Components featuring chassis, automotive electronics, and

remanufacturing; Electrics and Electronics; Accessories; Customising; and Diagnostics and Repair / Body and Paint.

The International Automotive Industry Conference 2025 Presented by Automechanika Shanghai will offer perspectives on how current trends are influencing supply chains, market dynamics, and relevant policies and regulations.

This year’s edition shall also emphasise the need to build up industry professionals and a Gen Z workforce during the International Automotive Industry Talent Development Conference 2025. This will be accompanied by a talent development programme for participants to get to grips with the skillsets needed for wider market changes.

Additionally, the Automechanika Shanghai Technology Seminar Series debuts with global experts discussing electric drive systems, thermal management, autonomous driving, intelligent chassis, new materials, and tyre technology.

Participants can further take advantage of other approachable networking activities to stay ahead in the ever-evolving industry landscape, including the Global Collective, while local trade authorities will lead discussions and a series of themed networking receptions will connect like-minded professionals and Press Connect will provide participants with the opportunity to engage with journalists. Match Up will also continue to offer customised one-to-one business matching for attendees to form strategic partnerships.

For more information, please visit www.automechanika-shanghai.com or email auto@hongkong.messefrankfurt.com

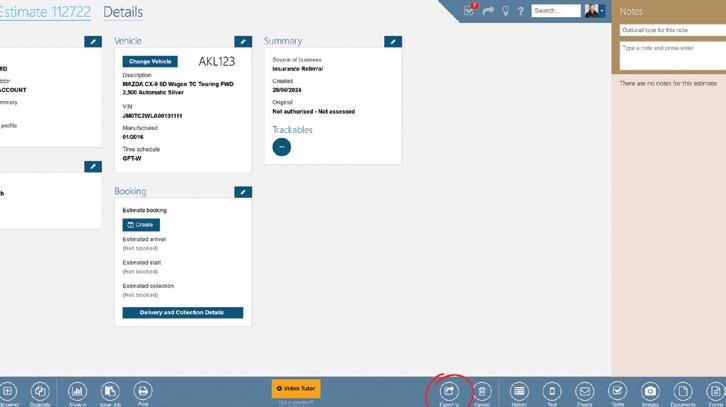

In this article, AASRA’s Executive Director reviews what Right to Repair is, and why it matters

AASRA’s core function is to support the day-today operation of the Motor Vehicle Information Sharing (MVIS) Scheme and to facilitate the vetting process in accordance with the Scheme Rules for individuals seeking to access security or safety-related repair information.

“As I move around the industry, whether it is delivering formal presentations, or participating in panel discussions, I am still amazed at the number of independent repairers who are still unclear about the Right to Repair legislation, even though the Motor Vehicle Information Sharing scheme has been in place for the past three years,” AASRA Executive Officer, Joe McFadries, said.

“So, I thought, perhaps it’s time for a refresher on ‘what it’s all about.’

“Well, following a decade-long campaign by the AAAA, advocating for the rights of independent repairers, the Right to Repair legislation was enacted in July 2022.

“While there are many elements to this groundbreaking legislation, essentially all repairers now have access to the information needed to service and repair vehicles, including software updates

such as that required to connect a new spare part with a car, and diagnostic information and security codes for vehicles’ computerised systems.

“AASRA was appointed Scheme Advisor to oversee the day-to-day operation of the scheme, and three years down the track service and repair procedures for the vast majority of vehicles on our roads can be accessed through the AASRA website.

“Of course, you still need to pay for the manufacturers’ information, however the information is available at a fair market rate.

“This all sounds straightforward, but as with many things, the devil is in the detail, especially if you are an all makes, all model repair business.

“Each manufacturer has its own system and processes to access the information, which can be initially daunting until you become familiar with the brands that you access most frequently.

“So, why is the Right to Repair legislation so important? Well, it allows independent repairers to compete with dealer networks on a level playing field.

“The information is accessed directly from the manufacturer’s own database and is therefore live, genuine and complete every time.

“This ensures that you return the vehicle to the owner knowing that you have completed the repair to the best of your ability and in line with the manufacturer’s requitements.”

For more information, contact AASRA on 1300 222 772, or visit www.aasra.com.au

The Capricorn Rising Stars Award celebrate the next generation of automotive talent across Australia and NZ

Tasmania’s Cole Cleaves and Queensland’s Cody Chapman have been named as the Victoria/ Tasmania and Queensland 2025 Capricorn Rising Stars Region Winners.

Described by his mentor as a “once-in-a-lifetime apprentice,” Cole’s passion for diagnostics, commitment to quality, and a customer focused mindset have positioned him as an emerging leader in the trade.

Completing his apprenticeship at WD Auto Electrical and Air Conditioning, Cole exemplifies the importance of investing in the next generation of tradespeople, and his achievements highlight the critical role apprentices play in shaping Australia’s automotive future.

“It is clear from their nominations that Cole and Cody bring a level of professionalism, initiative and care that sets a benchmark for how apprentices can contribute,” Capricorn Chief Executive Officer Brad Gannon.

“Apprentices like Cole and Cody are the future of our industry, and we must continue to invest in and celebrate the vital role they play — especially in regional areas like Tasmania and Townsville, where skilled professionals are essential to local economies.”

In 2025, Cole also received the TasTAFE Trade Excellence Award for Automotive Final Year Apprentice of the Year.

Cole’s vision for the future is to become a leading diagnostic expert on Tasmania’s North-West coast by advancing his knowledge in electronic circuit repair and diagnostics.

“I look forward to increasing my knowledge base to be able to repair all faults associated with electrical components and keep all repairs in house,” Cole said.

Cody Chapman is a 21-year-old third-year diesel fitter apprentice with Morgan Transport Group in Townsville.

In his nomination, Cody’s manager praised his preparation, process and results as he is consistently ahead of his peers during training blocks – proof that his work ethic, leadership and appetite for learning aren’t just talk; they’re tested on the workshop floor.

Looking down the road, Cody sees himself running a workshop fulltime, doubling down on mentorship and passing on the finer points of the craft –especially the complex jobs that build confidence and capability.

“I look forward to sharing everything I’ve learned

The Motor Vehicle Insurance and Repair Industry Code of Conduct Administration Committee (CAC) has held its first face-to-face meeting since the conclusion of public consultation on the Code.

The meeting marked a significant milestone in the ongoing review process, as members came together to discuss the future direction of the Code.

CAC Chair George Manos described the meeting as a constructive and encouraging step forward.

“It is clear from the submissions received and the consultation process that the insurance and repair sectors have both shared and differing priorities when it comes to shaping the future of the Code,” George said.

“This meeting was a positive first step toward developing a more effective Code. CAC members engaged in open and collaborative discussions, demonstrating a strong commitment to improving outcomes for the industry.”

“The CAC has agreed to continue dialogue and negotiations, with the Insurance Council of Australia and Motor Trades Association of Australia continuing to consult with their members and the broader industry.”

As part of the meeting, George was reappointed as CAC Chair for another term, ensuring continuity and leadership as the Committee works through the next phase of the Code review.

with the next group of apprentices. I know firsthand how valuable it is when someone takes the time to explain more technical or difficult tasks while you’re learning,” Cody said.

2025 marks the first year Capricorn will be awarding Region Winners as well as an Overall Winner for the Rising Stars Award, rewarding more apprentices than ever before, with Cole and Cody joining four other Region Winners in the race for the national title, to be announced later this year.

Winning the Capricorn Rising Stars Award –established in 2018 and supported by longstanding industry partners Castrol, Repco, and The Workshop Whisperer – can be a career defining moment for both finalists and winners, while also boosting the reputation of the workshop that has supported, trained and recognised their talent.

Now in its eighth year, the program plays a vital role in developing the next generation of automotive talent, helping Capricorn Members attract and retain skilled workers, and supporting the industry as it navigates skills shortages, the transition to EVs and an increasingly competitive landscape.

For more information, please visit www.capricorn.coop/rising-stars

In addition, the CAC has released its 2024 Annual Report, which is now available on the Code website. For more information and to access the 2024 Annual Report, visit www.abrcode.com.au/resource-centre

Kangan Institute says this nation-first training is important in the drive towards net zero

Leading the charge towards net zero, a nation-first hydrogen vehicle training program is now underway in Victoria.

In a move to advance clean energy and workforce innovation, the pilot program was officially launched recently at Kangan Institute’s Automotive Centre of Excellence in Docklands by the Honourable Gayle Tierney MP, Minister for Skills and TAFE – marking a major milestone in Australia’s clean energy transition.

“We are investing in skills and training to build the pipeline of workers that Victoria needs,” Minister for Skills and TAFE, Gayle Tierney, said.

“This training course is the first of its kind in Australia. It’s great for jobs and great for the economy.”

TAFE teachers from around the country were onsite at Docklands eager to take part in the training as they prepare to play a key role in training technicians across Australia for the vehicles of the future.

Developed by Kangan Institute and Foton Mobility Distribution (FMD) the initiative upskills technicians to work safely and effectively with hydrogen fuel cell electric vehicles (FCEVs) – a fast-emerging technology in low-emissions transport.

The industry changing initiative is made possible thanks to the Victorian Government’s Skills Solutions Partnerships program.

“This program is a national first – bringing together educators and technicians from every corner of the country to build the skills needed for a zeroemissions future,” Kangan Institute Chief Executive Officer, Sally Curtain, said.

“It’s a powerful example of what’s possible when industry and education collaborate to solve realworld challenges.

“We’re proud to be leading the way in hydrogen vehicle training and helping shape the workforce of tomorrow.”

Kangan Institute will use the funding to roll out a comprehensive clean energy skills package, including:

• Specialist hydrogen FCEV training for automotive teachers and technicians

• New nationally AUSMASA developed FCEV training units

• A safety-focused, online micro-credential course developed by eWorks for businesses interested in using hydrogen vehicles in their fleets.

• Cutting-edge hydrogen safety technology installed at Kangan Institute’s Automotive Centre of Excellence

Adding to the momentum, FMD’s hydrogenpowered truck is now housed at ACE, giving students and teachers direct access to real-world hydrogen vehicle technology as part of their training experience.

“FMD are proud to be associated with this exceptional initiative,” Foton Mobility Distribution Chief Executive Officer, Neil Wang, said.

“When we set out three years ago to bring classleading zero emissions transport product to Australia, we always knew that there would be a need to not only back the product with exceptional after-sales support and service, but that we would need to foster knowledge-sharing around the technology,” Neil said.

Victoria and Tasmania’s finest automotive businesses and top apprentices were recently revealed

Twenty-two elite businesses, business leaders and apprentices were recently announced as leaders in their field at the 2025 Automotive Industry Awards.

Established in 2016, the premier awards celebrate the Victorian and Tasmanian automotive industry.

Victorian Automotive Chamber of Commerce (VACC) Chief Executive Officer, Peter Jones, said the awards demonstrate member and apprentice commitment to quality and customer service.

“It is a huge accolade to be named the best in Victoria and Tasmania. These winners go above and beyond and have proved themselves more than worthy of these titles,” Peter said.

Categories crowned at the 2025 Automotive Industry Awards include Best Small and Best

Large Business, Employer of the Year, Employee of the Year, and Apprentice of the Year.

Additionally, Outstanding First, Second and Third Year Apprentice, Outstanding Trainee, and the VACC and TACC Progressive Excellence Awards, were announced, recognising the next generation of the automotive industry.

An independent judge evaluated entries based on business management, workplace practices, customer service and environmental impacts.

To ensure only the finest of VACC and TACC’s 5,000 members would be crowned, finalists were also randomly audited to ensure transparency and equity.

Winners were announced at the 2025 Automotive Industry Awards (AIA), a formal evening that combined industry awards and apprentice

“This partnership with Kangan Institute has allowed us to share technical knowledge gained from millions of km’s of real-world experience.”

Kangan Institute’s Automotive Centre of Excellence is the largest purpose-built automotive training facility in the southern hemisphere.

With world-class diagnostic labs and a $1.4 million electric vehicle lab, it trains up to 5,000 students annually across more than 25 specialised areas – making it uniquely positioned to lead the next generation of clean energy training.

A trading brand of Bendigo Kangan Institute, Kangan Institute is in the running for the 2025 Victorian Large Training Provider of the Year, following its success as the 2022 Australian Large Training Provider of the Year.

Through campuses in Broadmeadows, Docklands, Cremorne and Essendon, Kangan Institute provides training services to students, industries, and businesses throughout metropolitan Melbourne and beyond.

For more information, visit www.kangan.edu.au

graduation festivities. Attendees heard from the master of ceremonies, Shane Jacobson, and a string of entertainers on Saturday, 28 June, at the Palladium at Crown, Melbourne.

For the complete list of winners, please visit www.automotiveindustryawards.com.au/2025-winners/

Australia’s automotive industry is facing a workforce turning point — and this time, the momentum is real

Since launching in mid-2025, the GearUp Auto Careers Initiative says it has been steadily gaining traction as a national platform designed to tackle the skills shortage by inspiring the next generation of automotive professionals.

What began with a bold debut in Adelaide has since rolled out across the country, with major activations at the Brisbane and Sydney Careers and Employment Expos.

Those behind the initiative say the results have been undeniable: tens of thousands of attendees, thousands taking on the challenge, and countless meaningful conversations with students, teachers, jobseekers and parents eager to learn more about automotive careers.

At each event, GearUp Auto Careers delivered a hands-on experience that brought trade careers to life, through a now-iconic Tesla Wheel Change Challenge, engaging live demos, and down-toearth conversations.

Attendees lined up to try the tools, feel the pace of real-world work, and talk to the people who do it every day.

Backed by industry, driven by collaboration

GearUp is not acting alone, with the initiative supported on the ground by a growing list of forward-thinking organisations and industry leaders, including: